Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Thorough protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

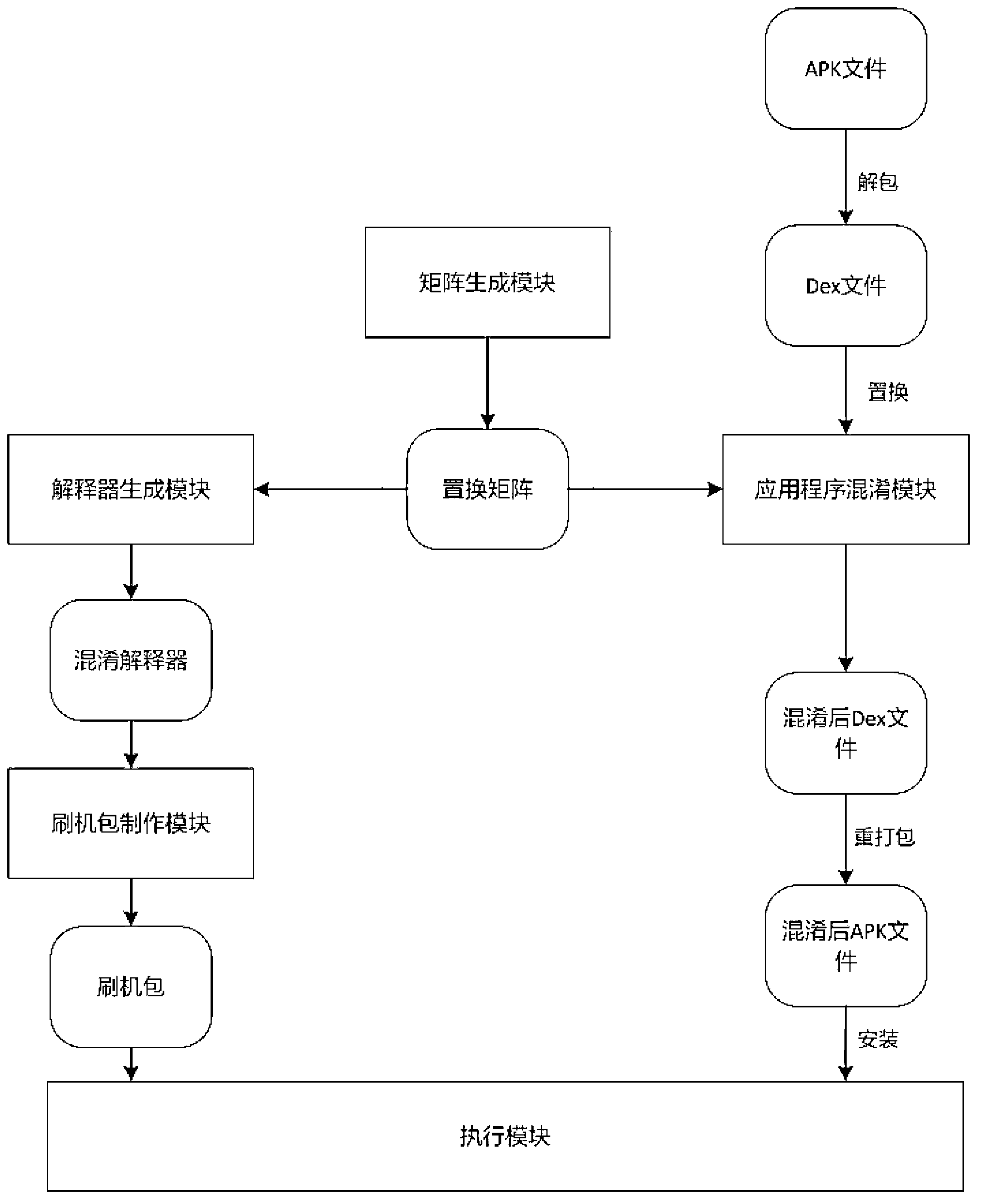

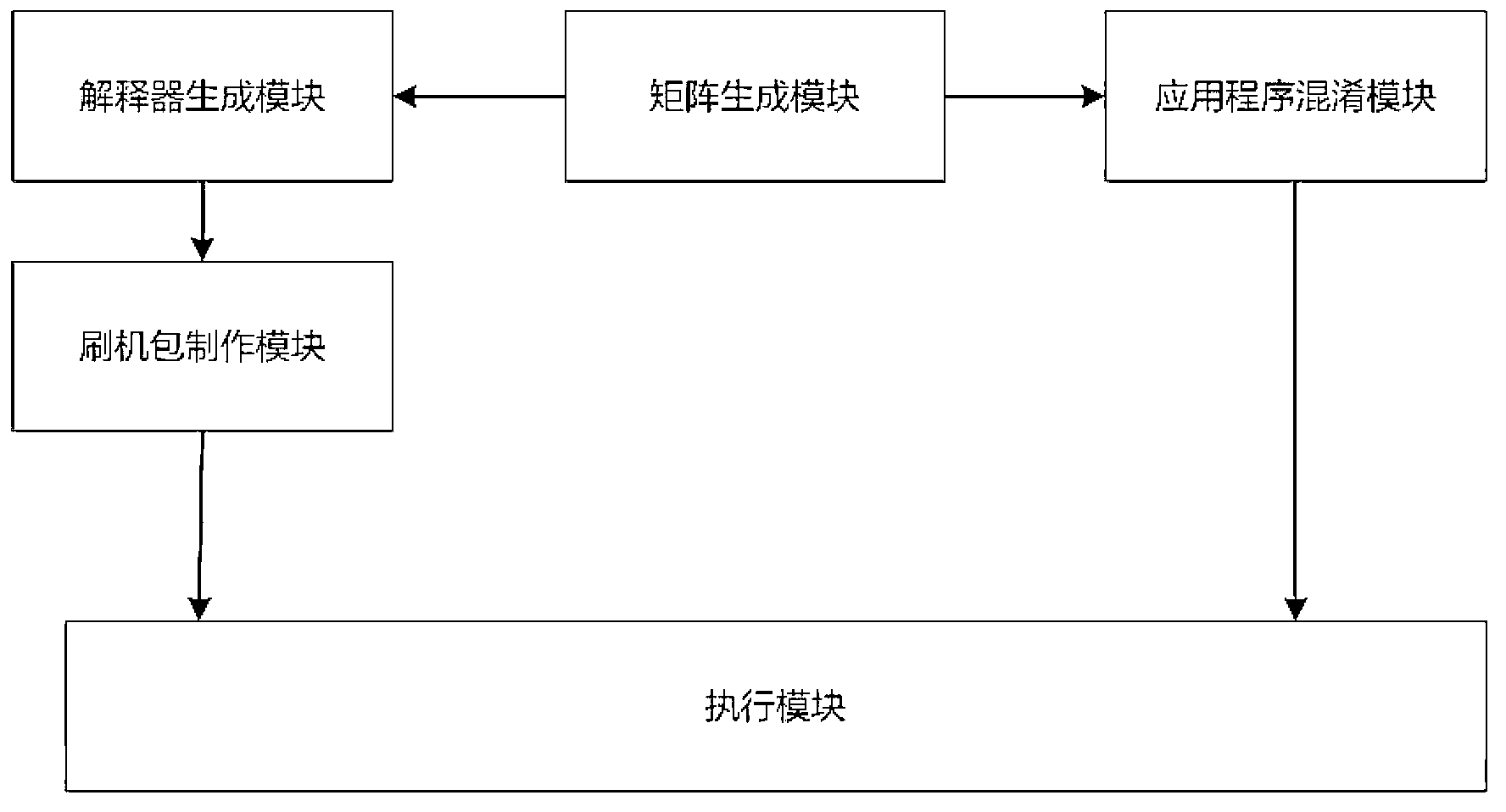

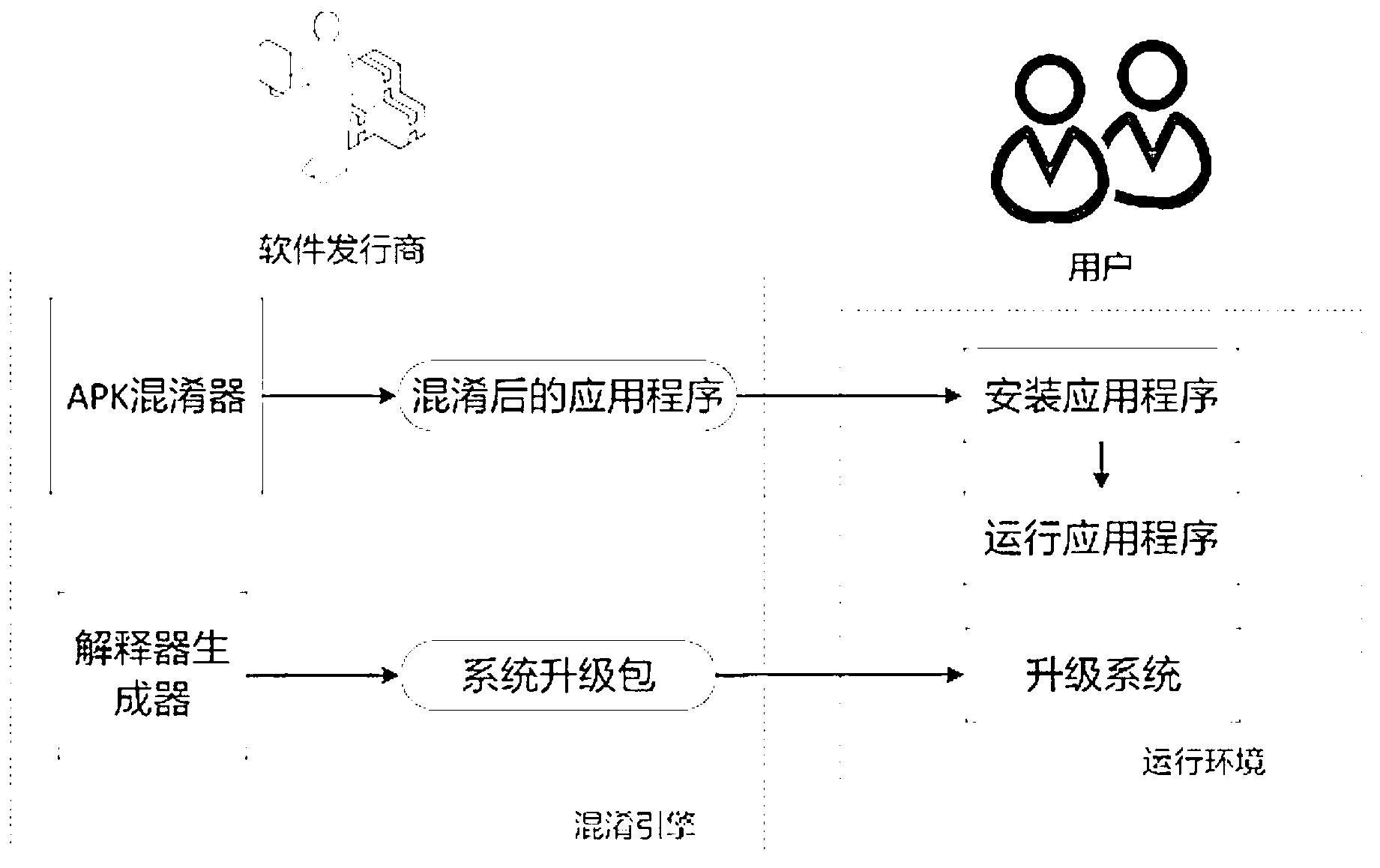

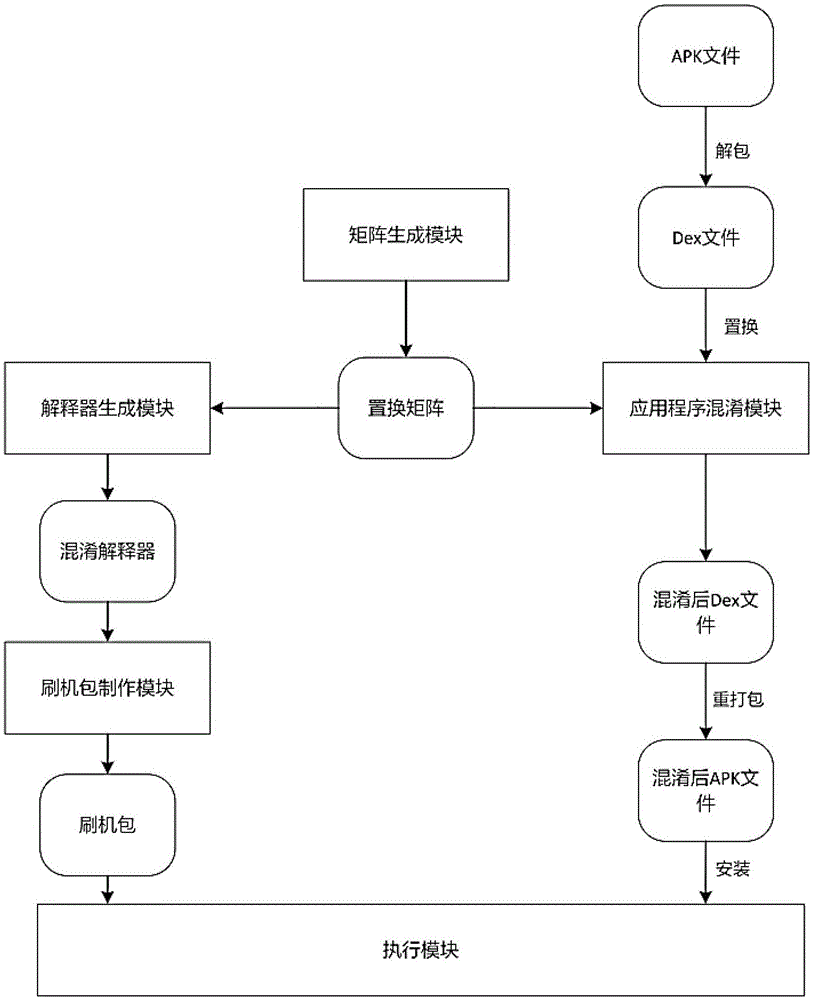

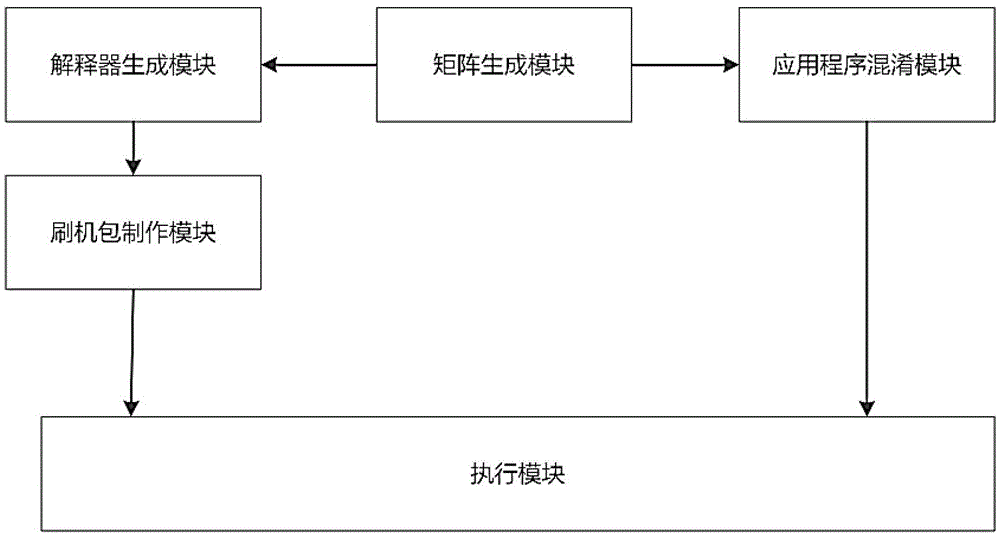

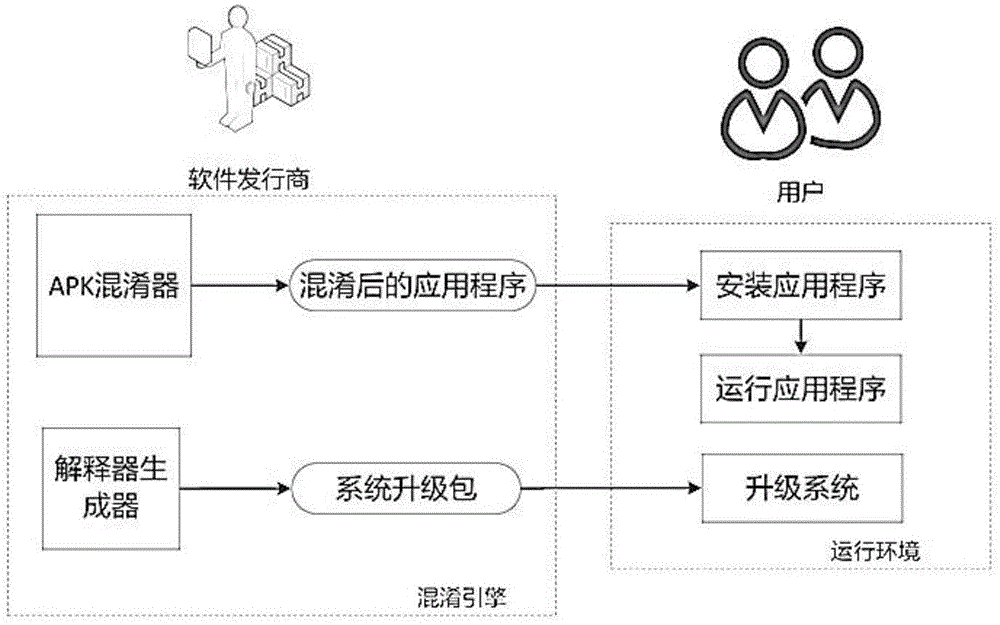

Android application program protective method and system based on order confusion

ActiveCN103324872AResistance to static reverse analysisFully transparent security execution processProgram/content distribution protectionConfusionApplication software

The invention discloses an Android application program protective method and system based on order confusion in the technical field of information safety. A permutation matrix needed when an application program is confused is generated, and binary codes of the Android application program are confused, so that the confused codes can not be reversed. A system mirror image document used for executing the confused application program is generated, a safe executing platform is set up, and the confused application program is executed. The Android application program protective system based on order confusion comprises a matrix generation module, an application program confusion module, an interpreter generating module, a system document generation module and an executing module. The Android application program protective method and system based on order confusion can effectively protect the Android application program from the attack of an attacker suck as reversing and tampering.

Owner:SHANGHAI JIAO TONG UNIV

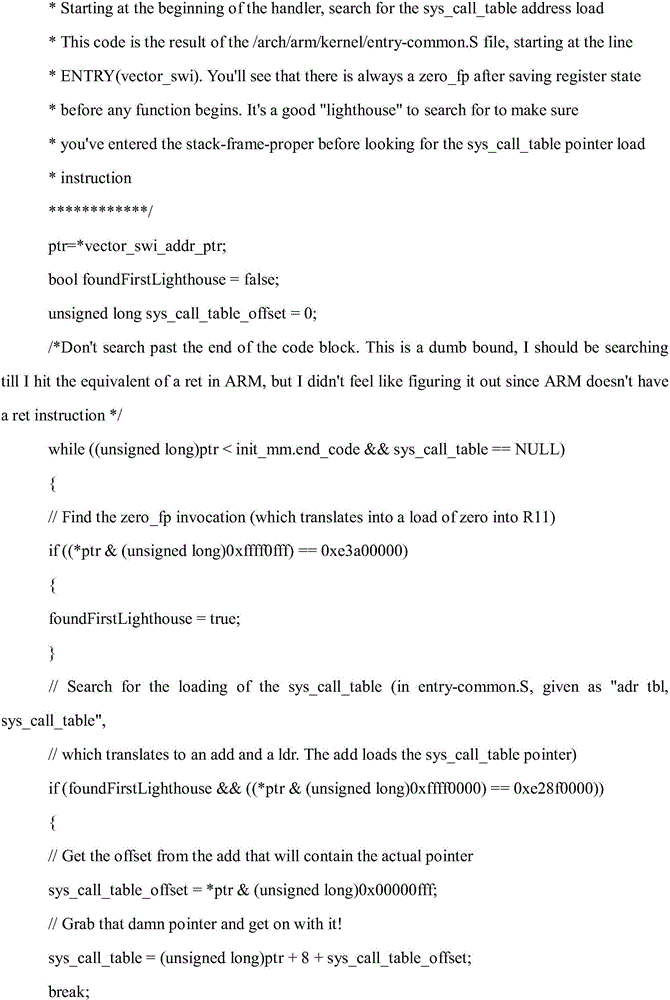

Monitoring method for App behaviors in Android system

InactiveCN105844157AImprove the protective effectTo achieve the purpose of security protectionPlatform integrity maintainanceRelevant informationAddress book

The invention discloses a monitoring method for App behaviors in an Android system. The method comprises the steps as follows: firstly, writing a kernel module, and performing cross compilation by writing of own Android kernel module; secondly, loading the module into the Android system, and intercepting specific functions (such as functions for reading related information of address books and the like) to obtain corresponding system call information including information about reading through which process and the like; thirdly, returning the corresponding recorded information to an application layer and forming corresponding monitoring log files to achieve system calling interception and monitoring of the whole Android system. According to the monitoring method, monitoring can be performed on system calling generated in both the application layer and a Native layer, and compared with existing monitoring methods for the application layer, the monitoring method has the advantages that protection can be more thorough, and the security protective property on mobile phones is higher; users are enabled to know behaviors of installed software thoroughly, thereby being capable of discovering malicious acts of the software timely.

Owner:北京鼎源科技有限公司

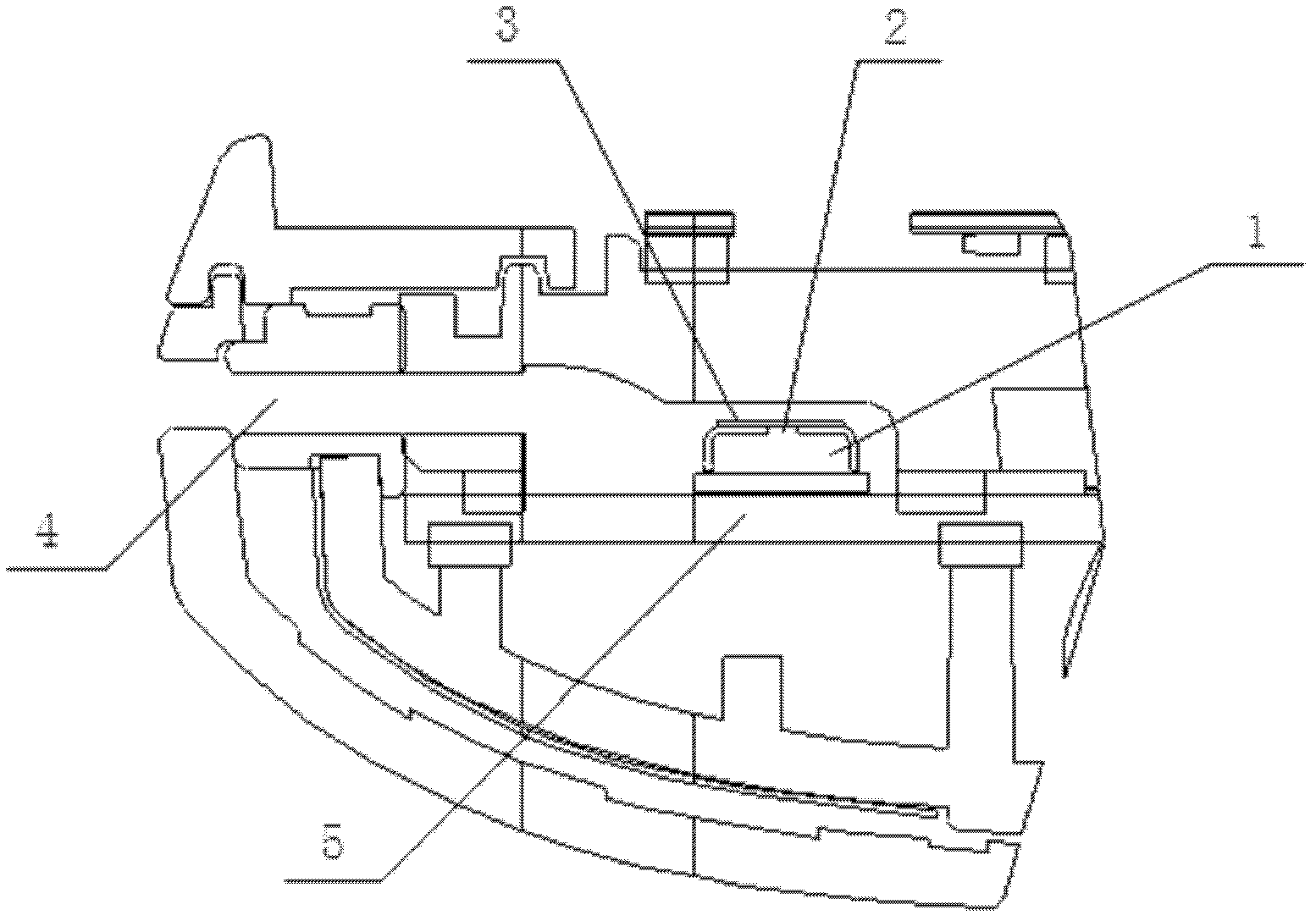

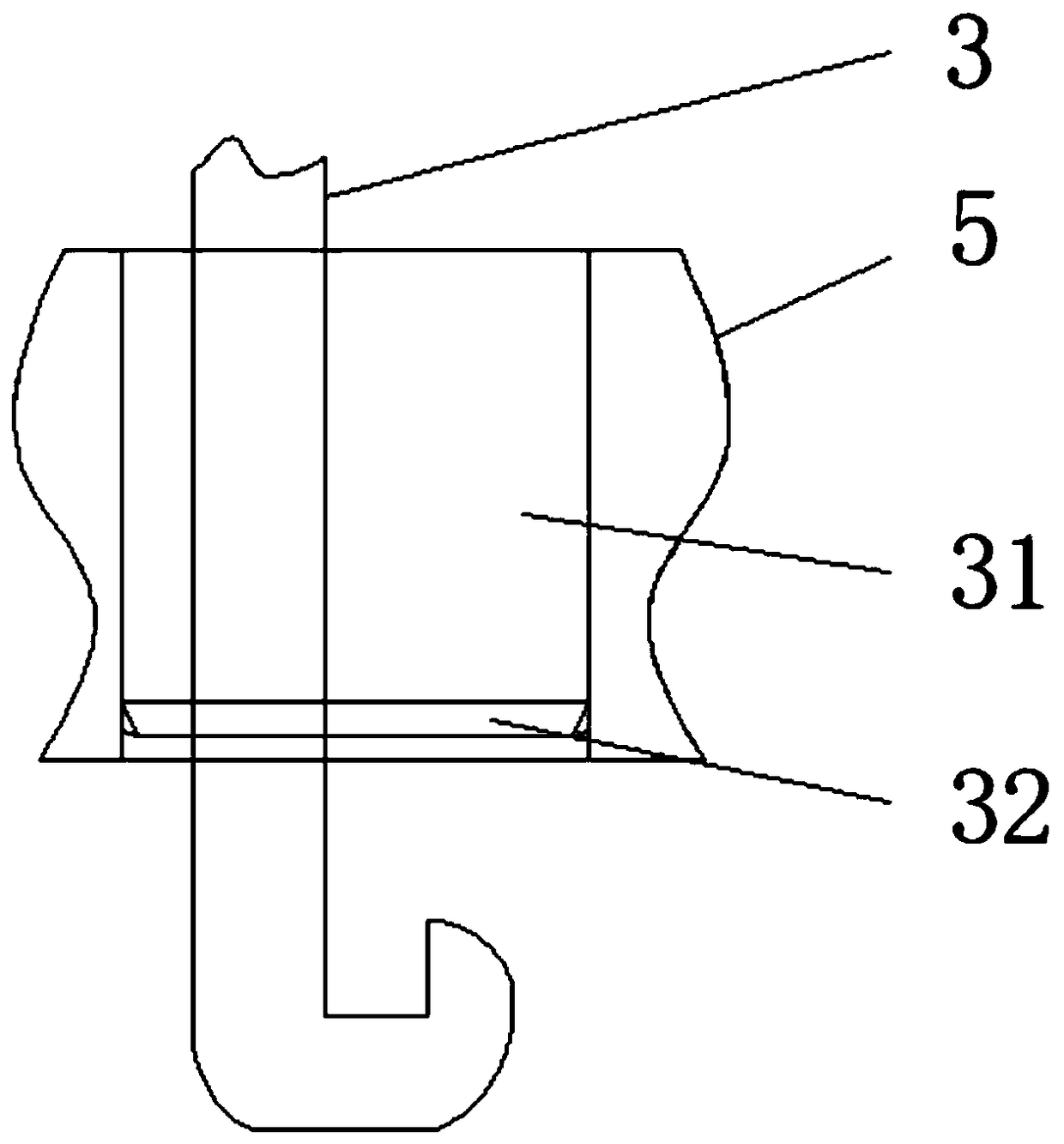

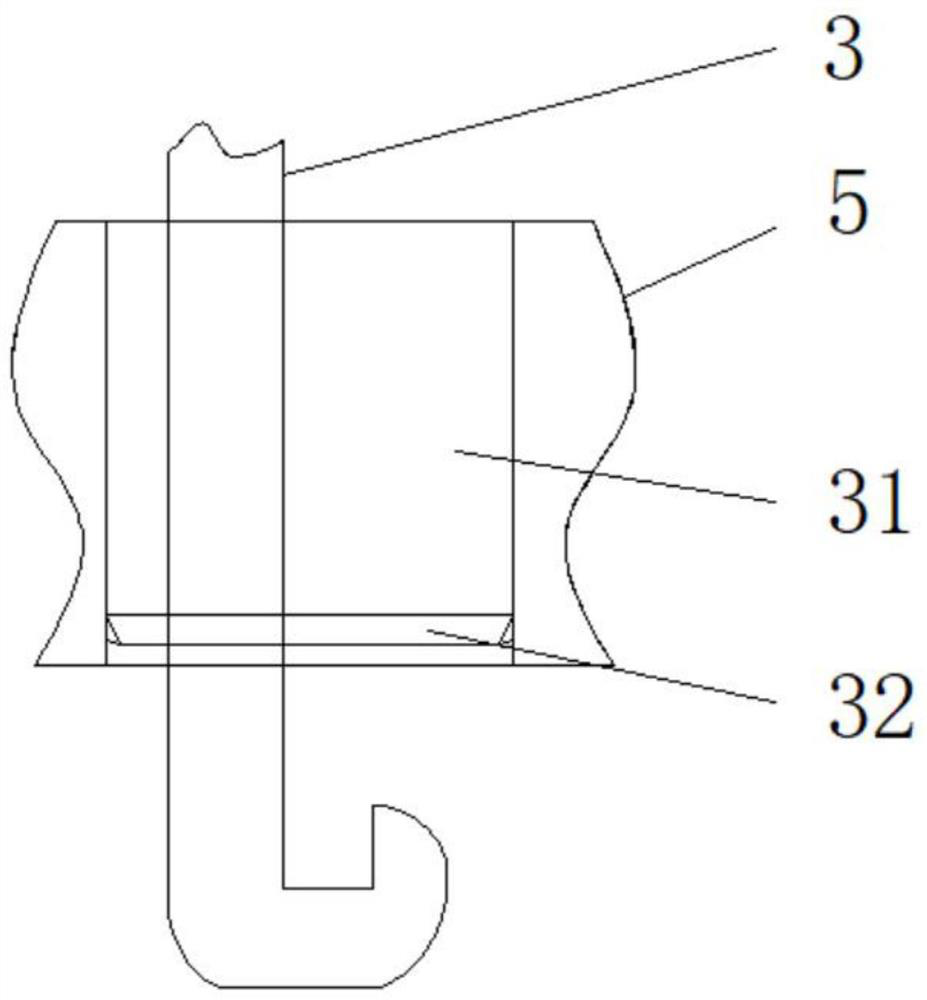

Microphone dustproof structure and assembling method thereof

InactiveCN102611954APlay the role of dust protectionProtect directlyMouthpiece/microphone attachmentsDeaf-aid setsInlet channelCommunication quality

The invention relates to a microphone dustproof structure, comprising a microphone body and a circuit board. The microphone body is arranged in a microphone sound inlet channel, is fixed on the circuit board, and is provided with a sound inlet and a dustproof device covering the sound inlet. After the microphone dustproof structure disclosed by the invention is adhered on the surface in an assembling process, the dustproof screen is immediately adhered on the sound inlet of the microphone body, thus the risk of pollution by dust impurity can be avoided in the processes of assembling a machine and conveying the machine, the damage on a vibration film due to the dust in a communication terminal machine can be avoided, and the protection on the microphone is more direct and complete; simultaneously, the microphone dustproof structure has a dustproof function when being used by a user, the risk of microphone disability is reduced to the maximum extent, and the communication quality and the microphone reliability are improved.

Owner:GUANGDONG BUBUGAO ELECTRONICS IND

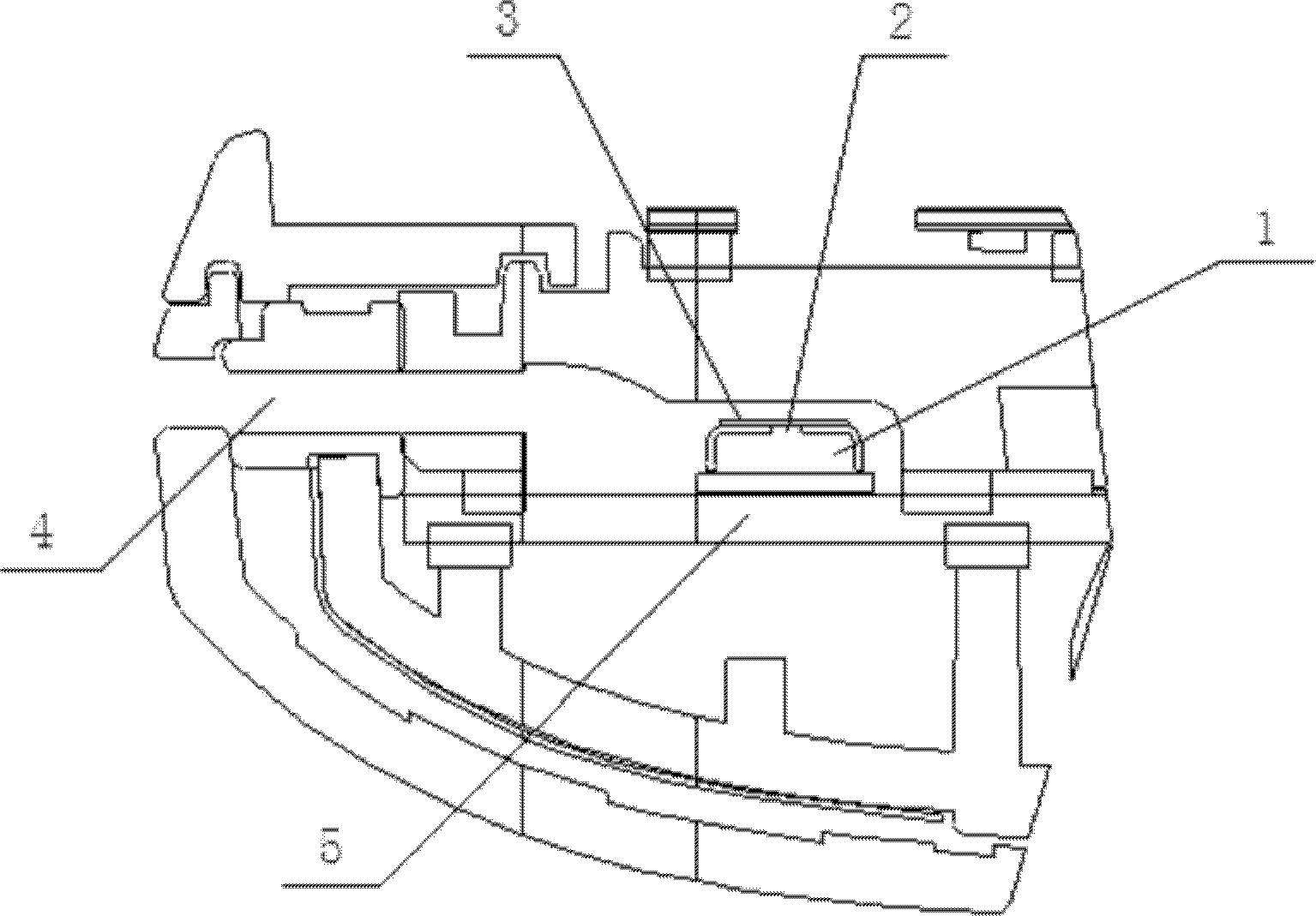

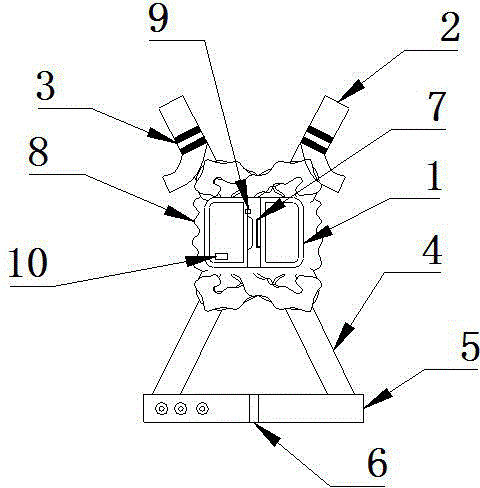

Safety device and method for climbing pole

The invention relates to a safety device and method for climbing a pole. The device comprises a chest band, wherein a shoulder band is arranged at the upper end of the chest band; a tightening snap joint is arranged on the shoulder band; a bellyband is arranged at the lower end of the chest band; a protective waistband is arranged at the lower end of the bellyband; a waistband buckle is arranged on the protective waistband; a snap joint is arranged on the chest band; safety air sacs which cover the whole side faces are arranged on the outer side faces of the chest band, the shoulder band and the bellyband; an inflating device which is controlled by virtue of a control switch is arranged in each of the safety air sacs; a fixing ring is arranged on the back of the chest band and is connected with a protective rope through a fixing lock; the other end of the protective rope is connected with a speed differential self controller; a hanger is arranged at the upper end of the speed differential self controller; a pressure sensor is arranged on the pressure-bearing surface of the hanger. The safety device provided by the invention generally has the advantages of thorough protection, safety, relaxedness, complete protection and convenience in use.

Owner:国网河南禹州市供电公司

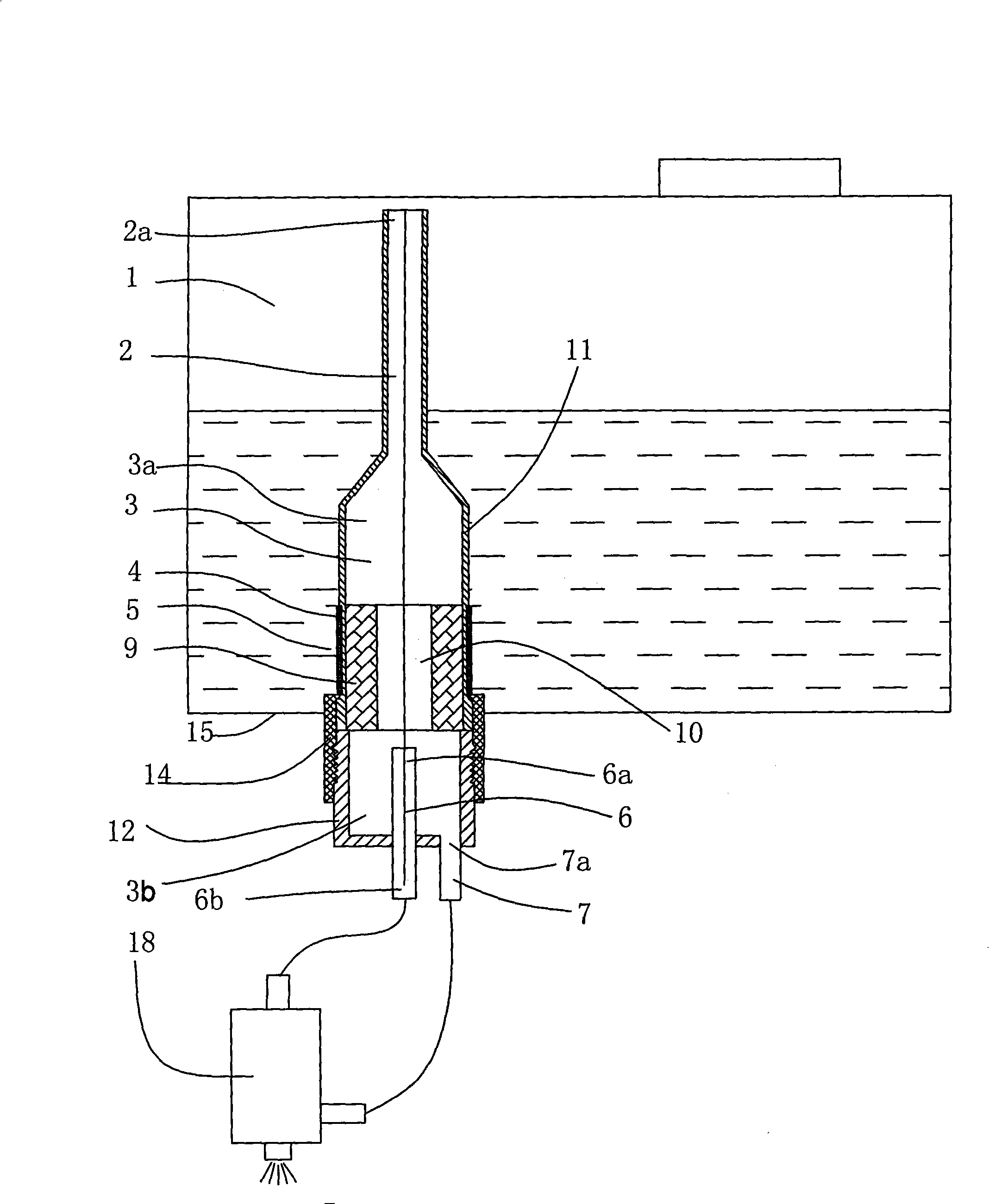

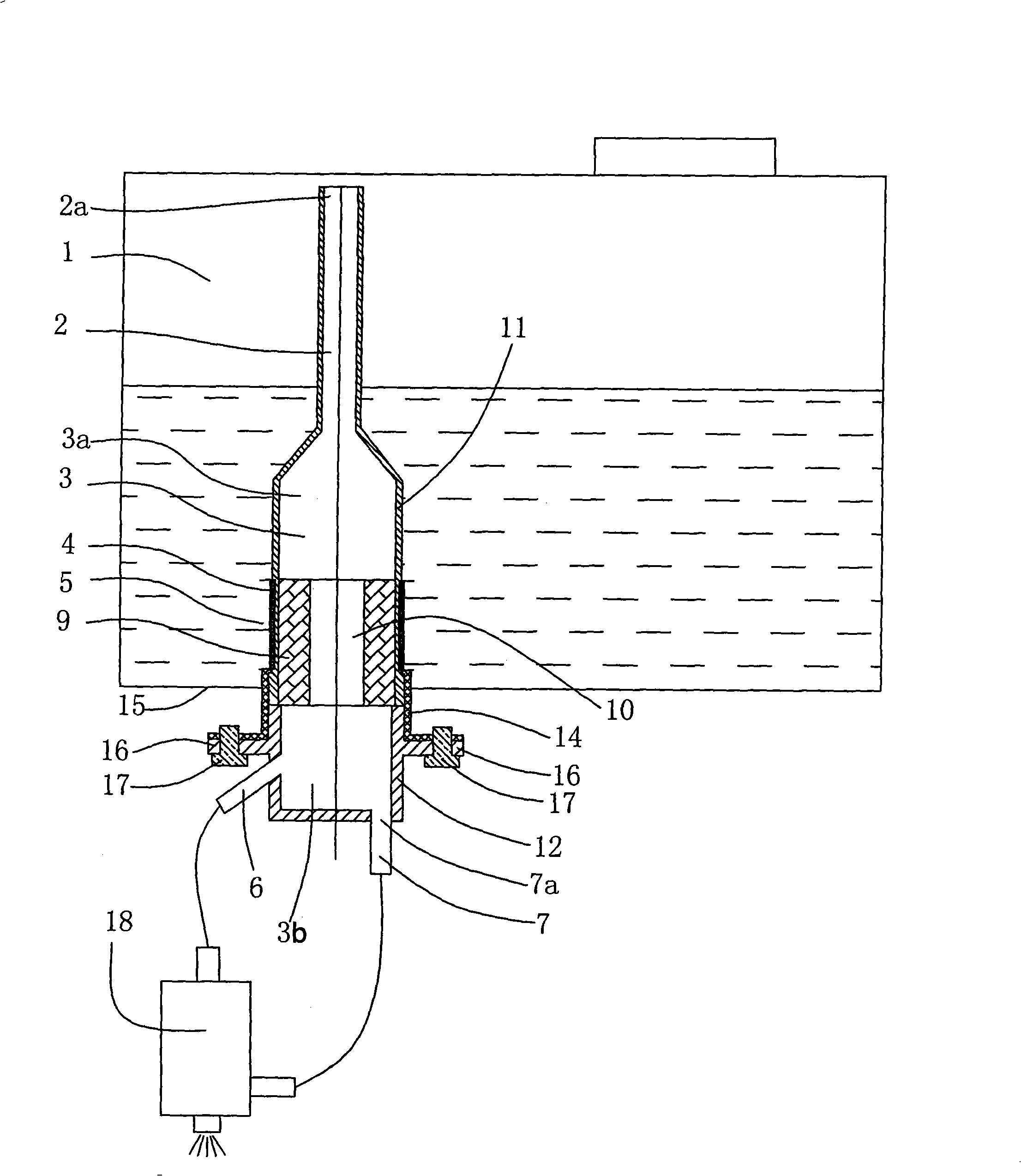

Filtrating type vapor-liquid separating device

InactiveCN101311522AGuaranteed to workExtended service lifeLiquid degasificationMachines/enginesVapor liquidSprayer

A filtering gas-liquid separation device belongs to the technical field of fuel supply of an engine which includes an exchange cubage and an oil return tube used for receiving the return oil of the fuel sprayer; an exhaust channel is arranged above the exchange cubage; an oil outlet tube used for supplying oil to a fuel sprayer is arranged below the exchange cubage; an oil inlet used for leading the fuel to enter the device from an oil box is arranged in a fuel box; a multiple fuel filters are arranged between the oil inlet and the exchange cubage; the outlet of the oil return tube is arranged in the exchange cubage so as to lead the distance to be larger than the size of the largest confusion area of the liquid of the oil return tube and lead the air bladders of the oil return tube to be incapable of entering the oil outlet tube. The invention can be suitable for a pulse electric fuel spraying system which not only ensures the fuel steams to be exhausted in time, increase the filtering of multiple fuels and lead the fuel spraying system to work reliably, but also can carry out complete protection on the fuel sprayer and obtain further improvements on the productive performance and beautiful performance simultaneously.

Owner:塞尔福(厦门)工业有限公司

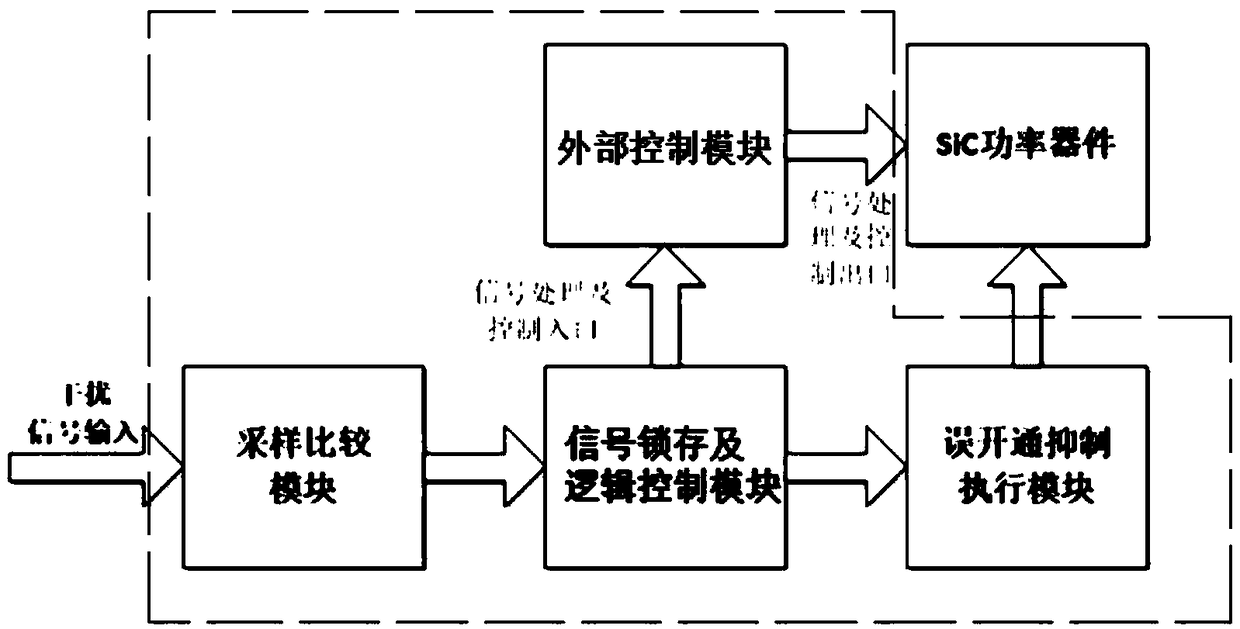

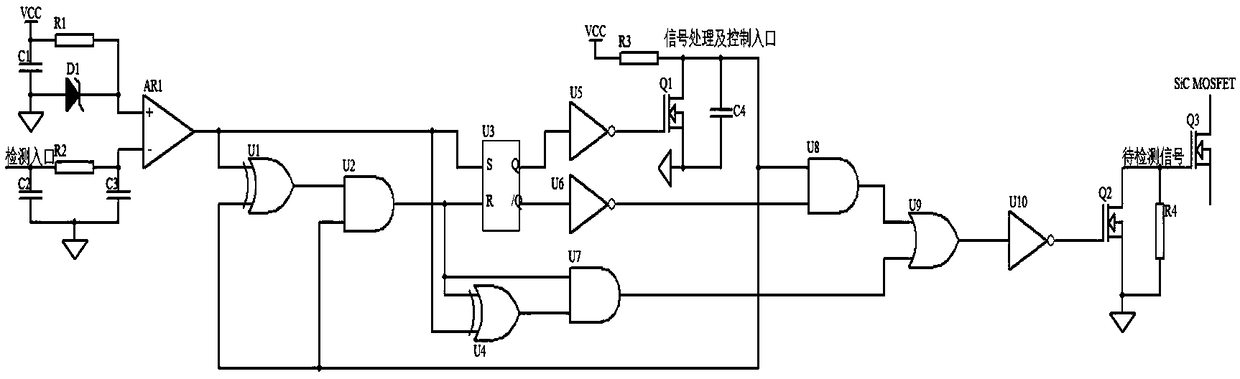

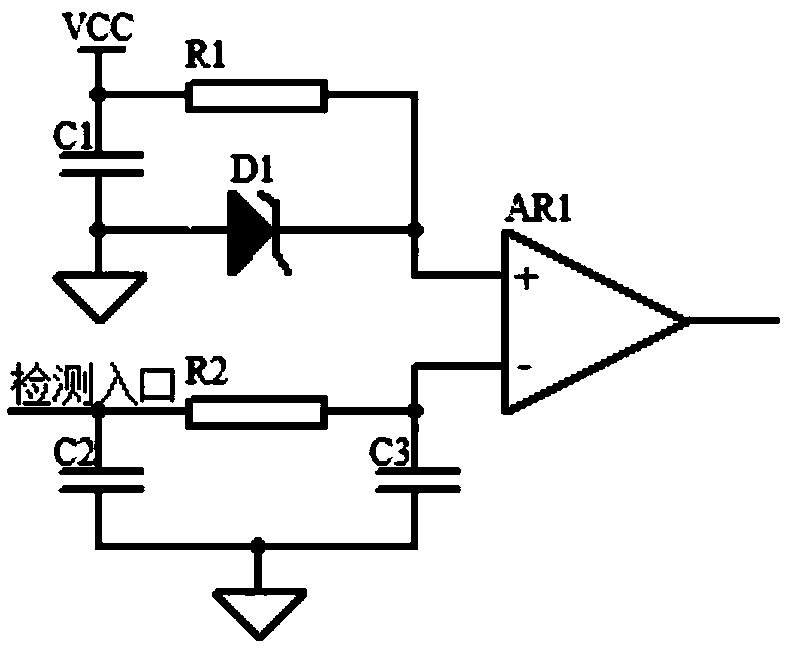

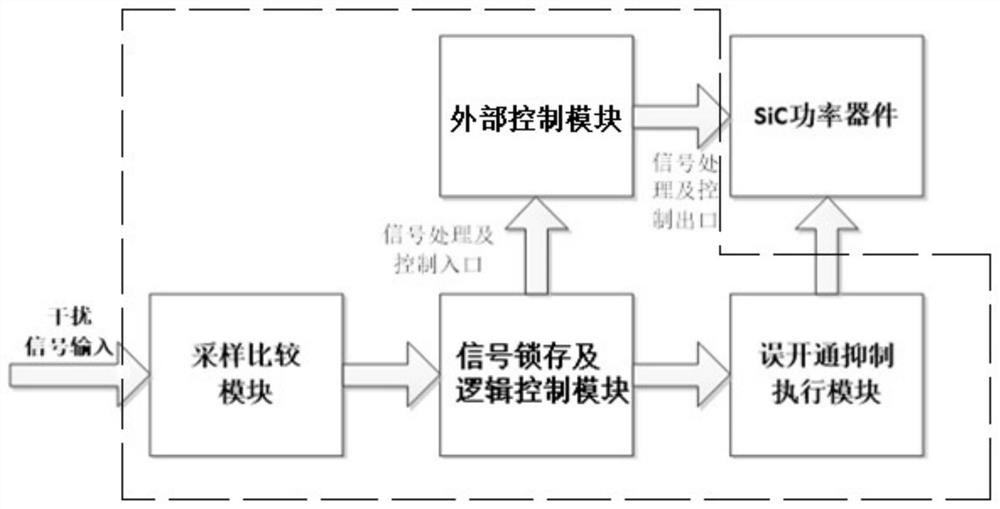

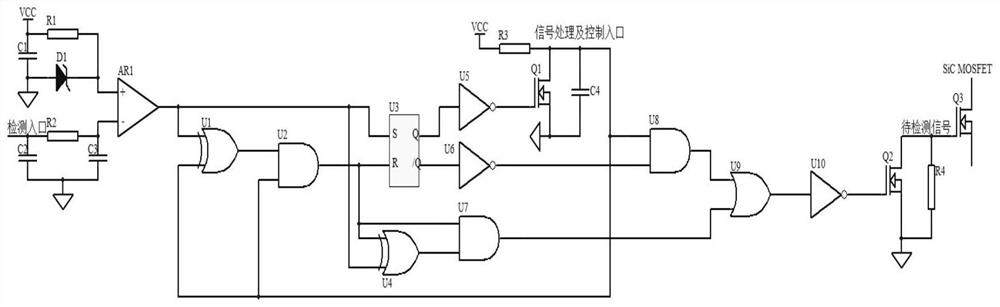

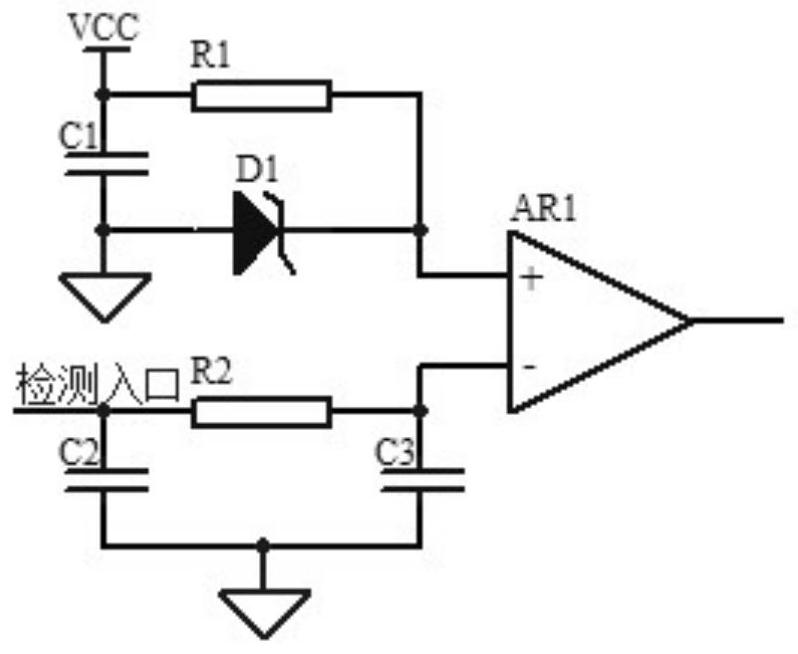

SiC MOSFET driving protection circuit and protection method thereof

The invention belongs to the technical field of circuit control, and in particular relates to a SiC MOSFET driving protection circuit and a driving protection method thereof. The circuit comprises a sample comparison module, a signal latch and logic control module, an external control module, and a false turn-on suppression execution module. The driving circuit can solve the false turn-on problemcaused by various reasons during the SiC MOSFET as well as monitoring the frequency of a false turn-on suppression signal through a processor so as to judge the current circuit working environment andadjust the on-off frequency and the working state of the SiC MOSFET in real time, thereby greatly increasing the reliability of the circuit and prolonging the service life of the device.

Owner:北京长峰天通科技有限公司

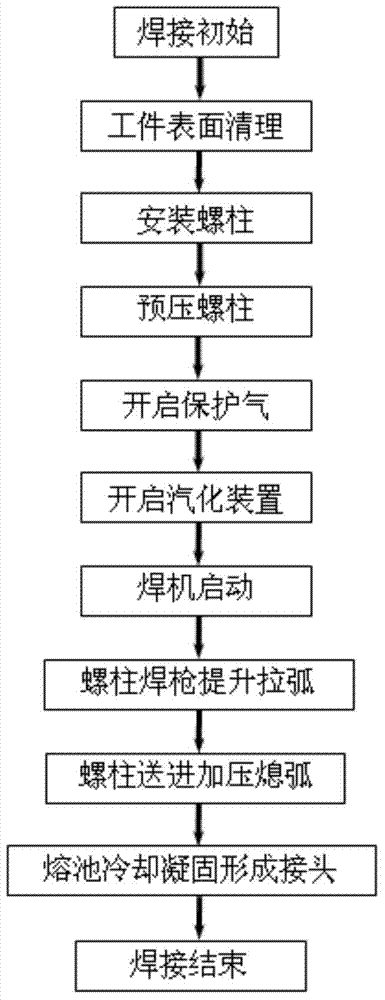

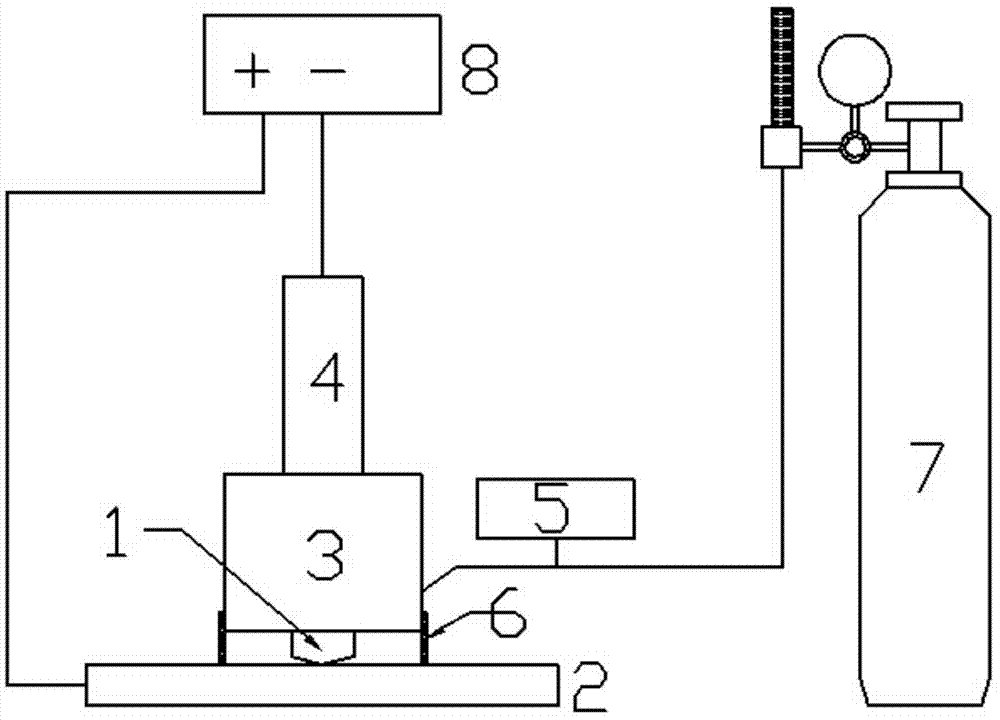

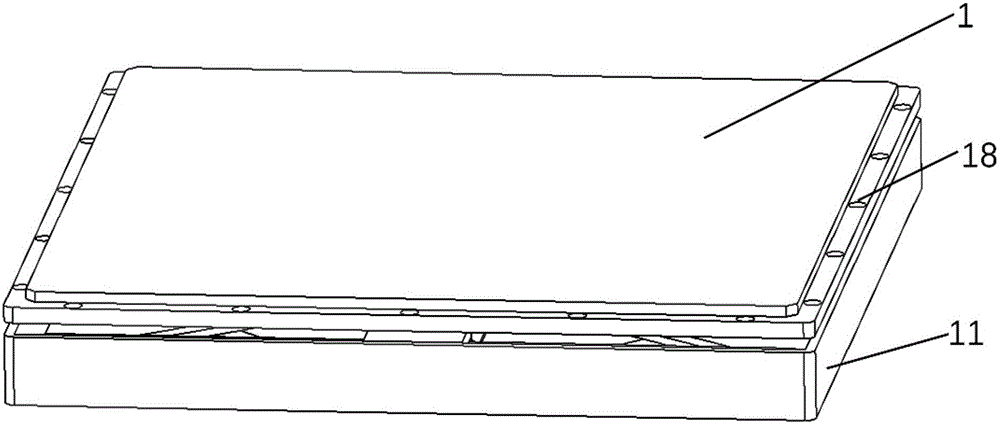

Aluminum alloy stud welding method to remove oxidation film with vapor state brazing flux

InactiveCN104741746AGood removal effectThorough protectionArc welding apparatusWelding/soldering/cutting articlesShielding gasCarbon Dioxide / Helium

The invention discloses an aluminum alloy stud welding method to remove an oxidation film with the vapor state brazing flux. The aluminum alloy stud welding method comprises the steps that the end portion of an aluminum alloy stud is machined into a face with a 150 degrees taper angle, and clearing on the end portion and the portion of an aluminum plate to be welded is conducted; a self-designed sealing air hood is installed outside a welding gun stud jacket, and a vaporizing device is joined up at the entrance position of the air course of the sealing air hood; the aluminum plate is arranged horizontally and is connected to the ground, the stud is installed, and the welding gun are compressed at the position to be welded vertically downward; the shielding gas is opened, arc striking is prepared to conduct after normal air delivering is finished, the vapor state brazing flux is jetted through a control circuit before the moment of arc striking, and welding is completed. The aluminum alloy stud welding method has the advantages that middle and large diameter aldural stud can be welded, the application range on plate thickness is wide, the operation of the welding process is easy, the intensity of the a welded joint can reaches to 90 % that of the stud, and the fusing rate of the welding joint reaches to 100 %.

Owner:NANJING UNIV OF SCI & TECH

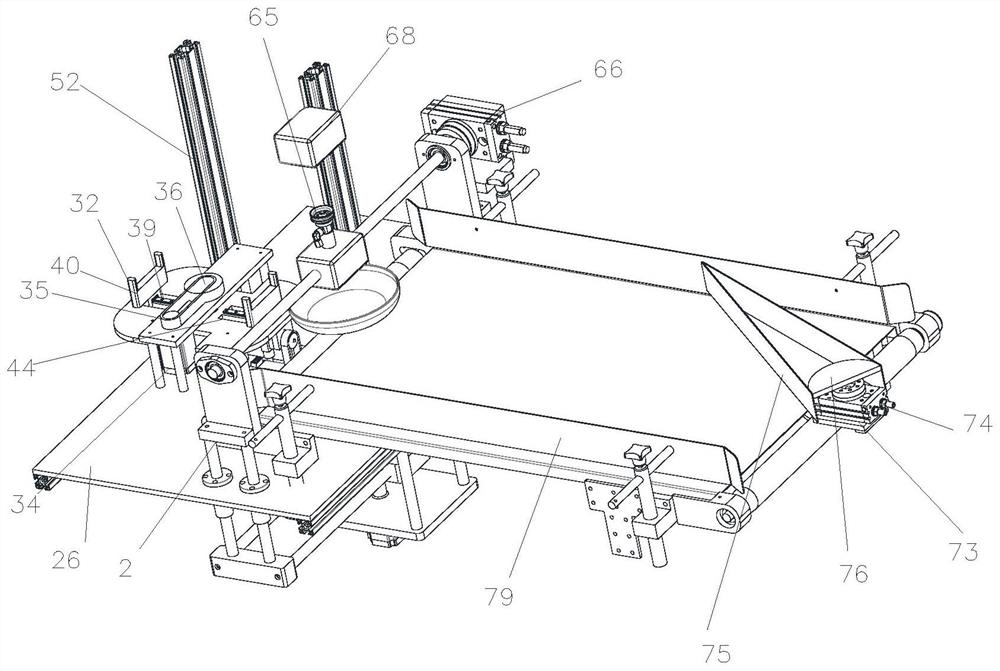

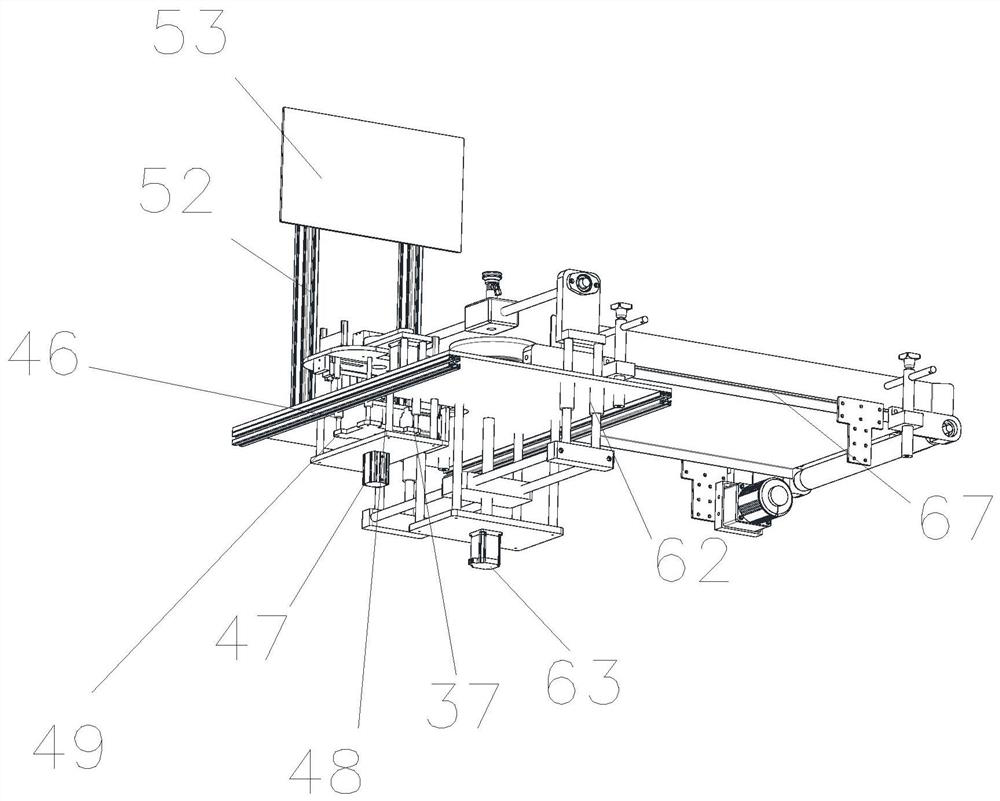

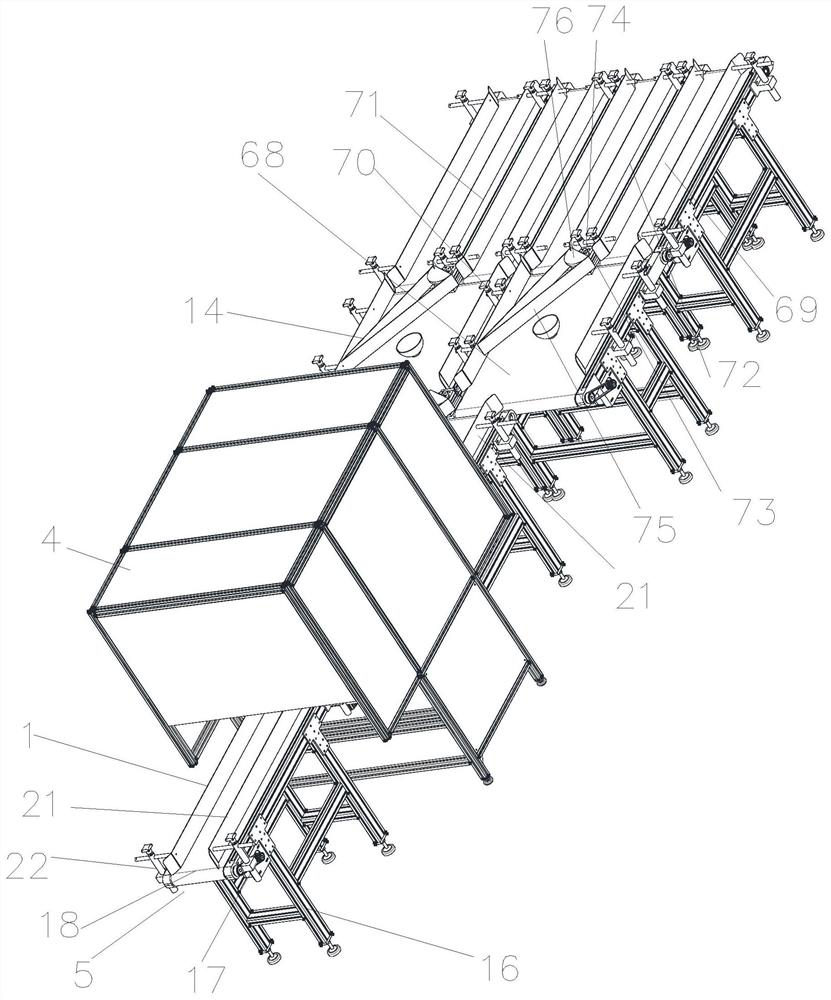

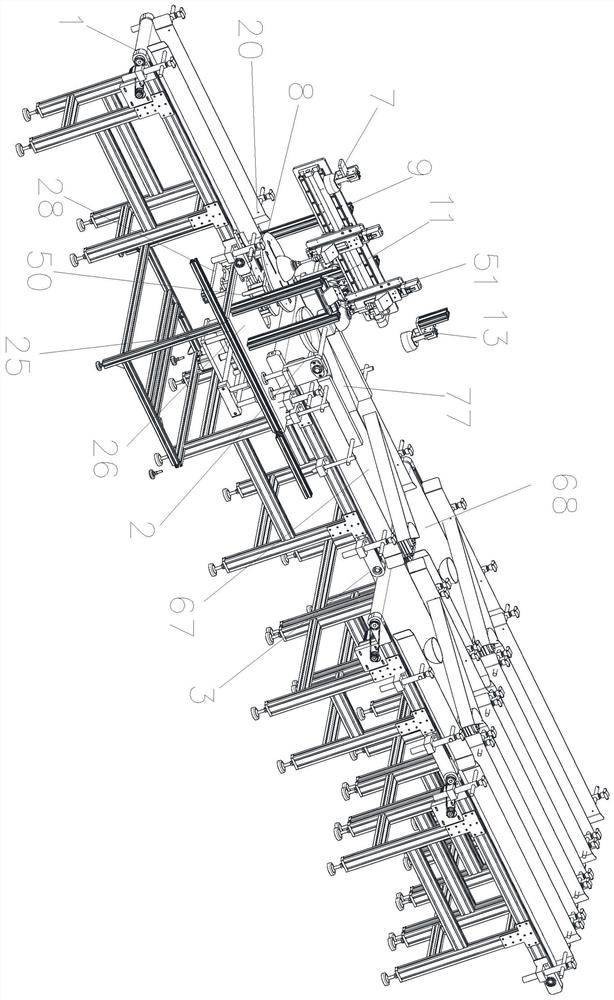

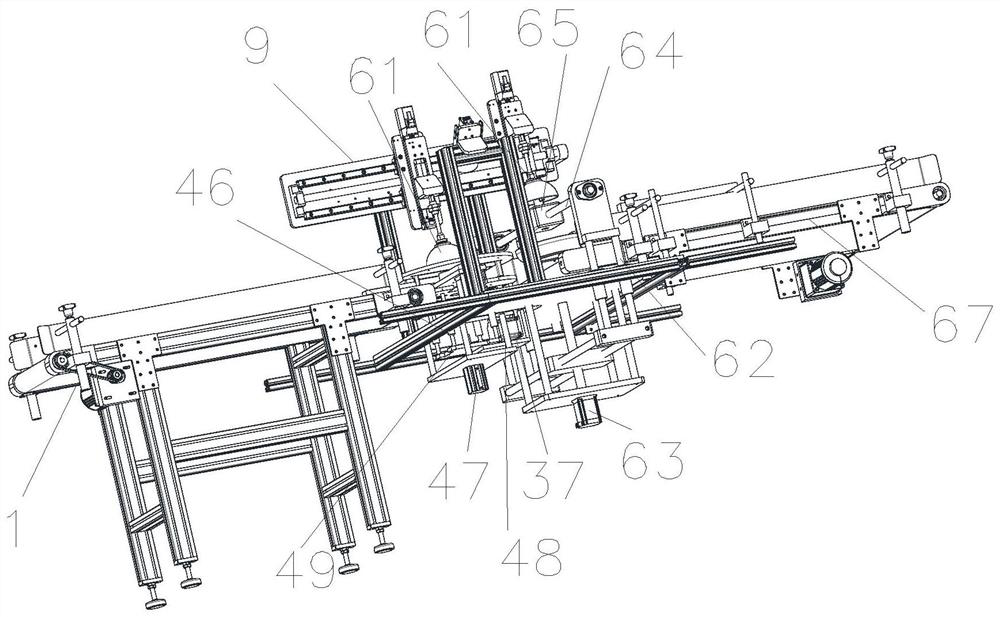

Laser marking equipment

ActiveCN113353595AThorough protectionImprove securitySortingLaser beam welding apparatusEngineeringIdentification device

The invention provides laser marking equipment. One end of a feeding device is a feeding opening; the other end of the feeding device is a first transferring opening; a laser marking device is arranged behind the first transferring opening; a connecting and shunting device is arranged behind the laser marking device; a positioning rotary table and a conveying device for conveying products from the first transferring opening to the positioning rotary table and then conveying the products to the laser marking device are arranged between the first transferring opening and the laser marking device; and a product identification device is arranged on the side of the positioning rotary table. The laser marking equipment has the advantages that the products are thoroughly protected, the safety is high, the orientations of the products are automatically adjusted by recognizing the shapes and the pattern orientations of the products, the laser marking equipment is used for marking according to the patterns and the orientations, and the marking efficiency is improved.

Owner:上海首坤智能科技有限公司

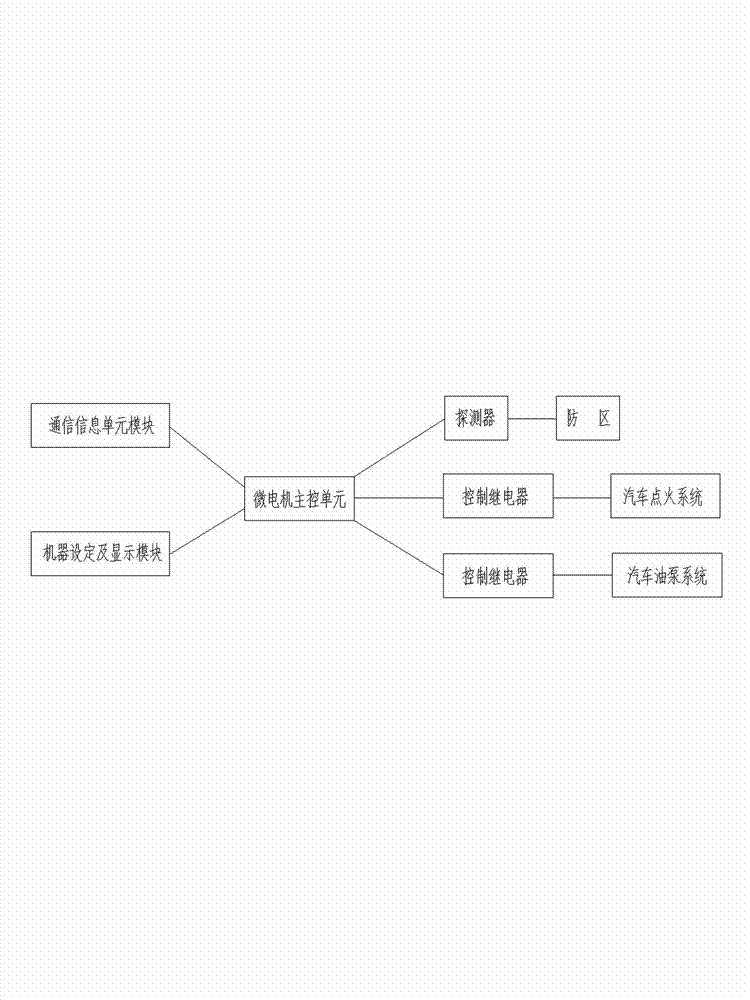

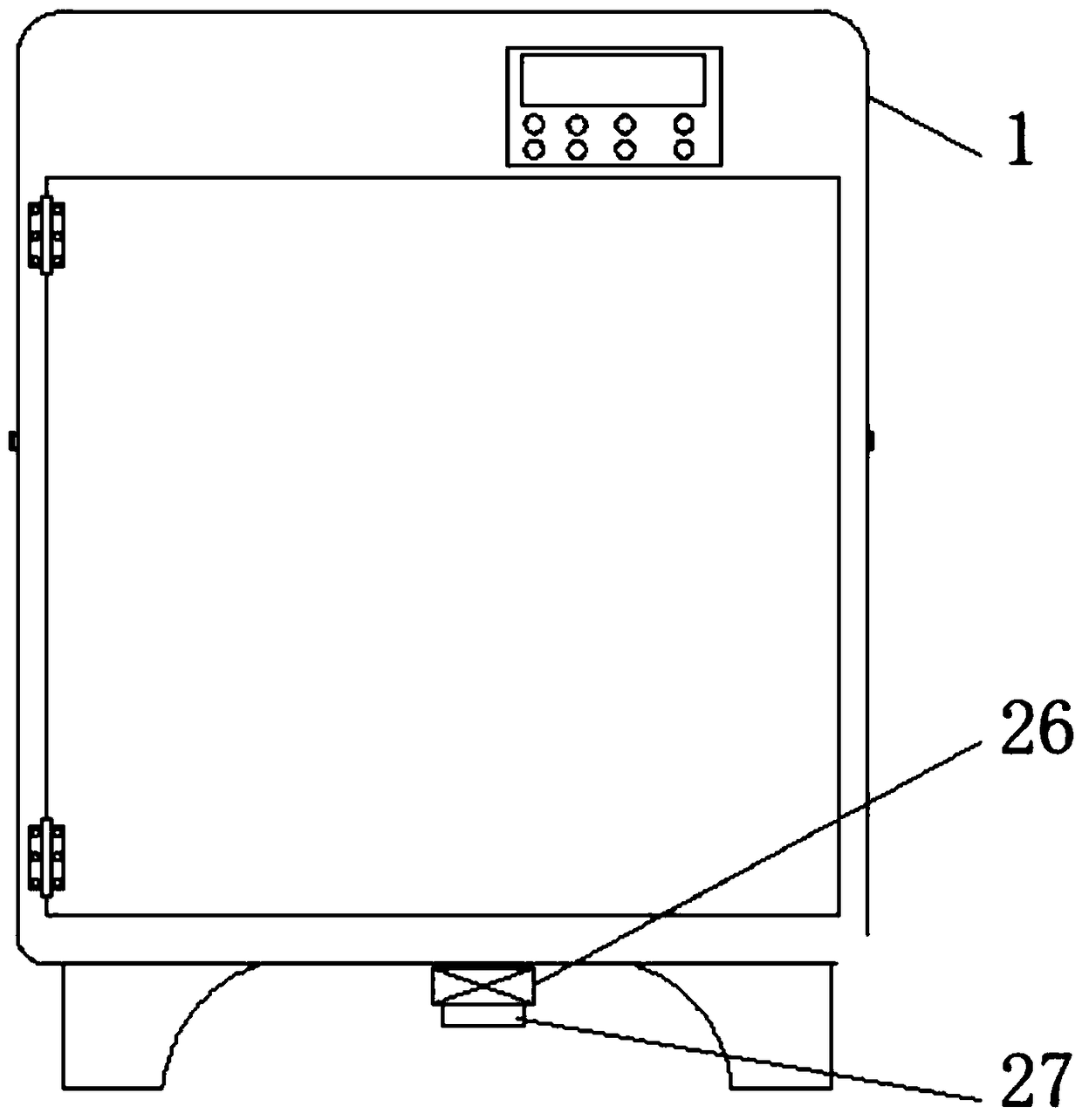

Automotive anti-theft control and alarm dialer

The invention relates to an automotive anti-theft alarm dialer, which comprises a machine body, wherein a microcomputer master control unit is arranged in the machine body, is respectively connected with a communication information unit module and a machine setting and display module and is additionally connected with four defence area detectors; the detectors are connected onto a master control board through leads; through detecting the situations of defence areas to the microcomputer master control unit, the microcomputer master control unit is then used for controlling the defence areas to work; and the microcomputer master control unit is connected onto control relays positioned on an automotive ignition system and an automobile oil pump system through leads.

Owner:刘焕明 +1

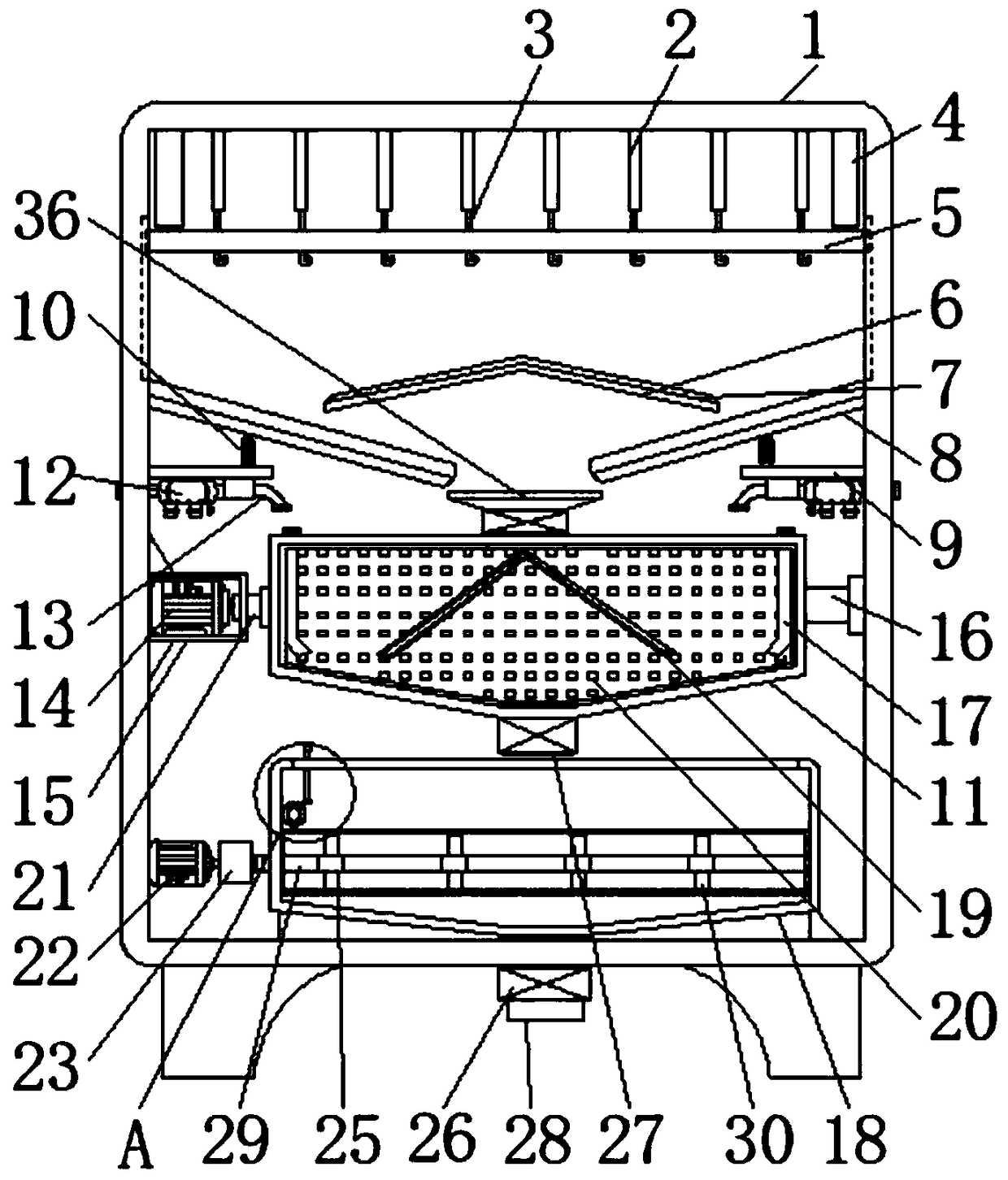

Rolling-type grape stem removal device

Owner:六安市叶集区绿叶果木种植专业合作社

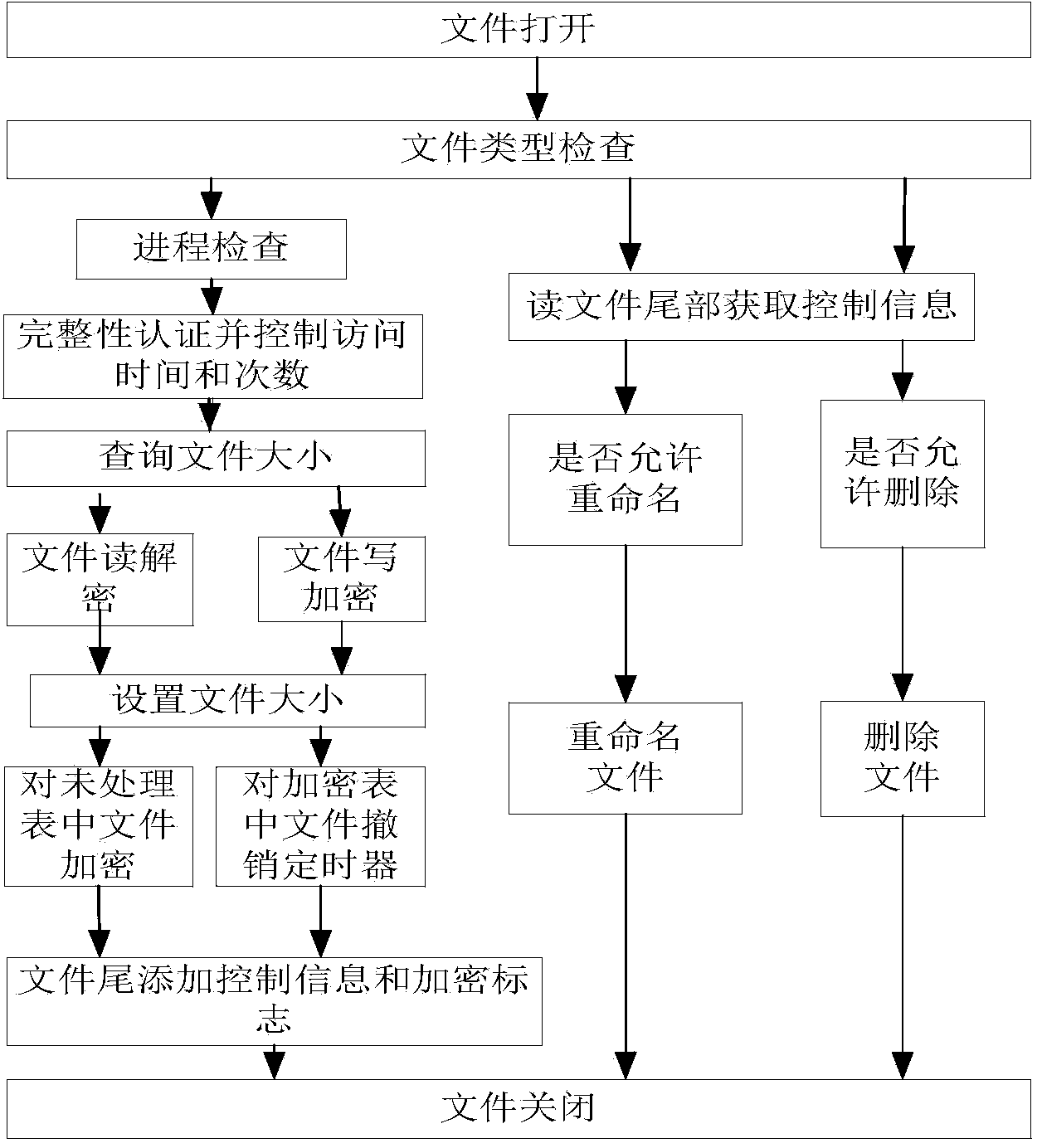

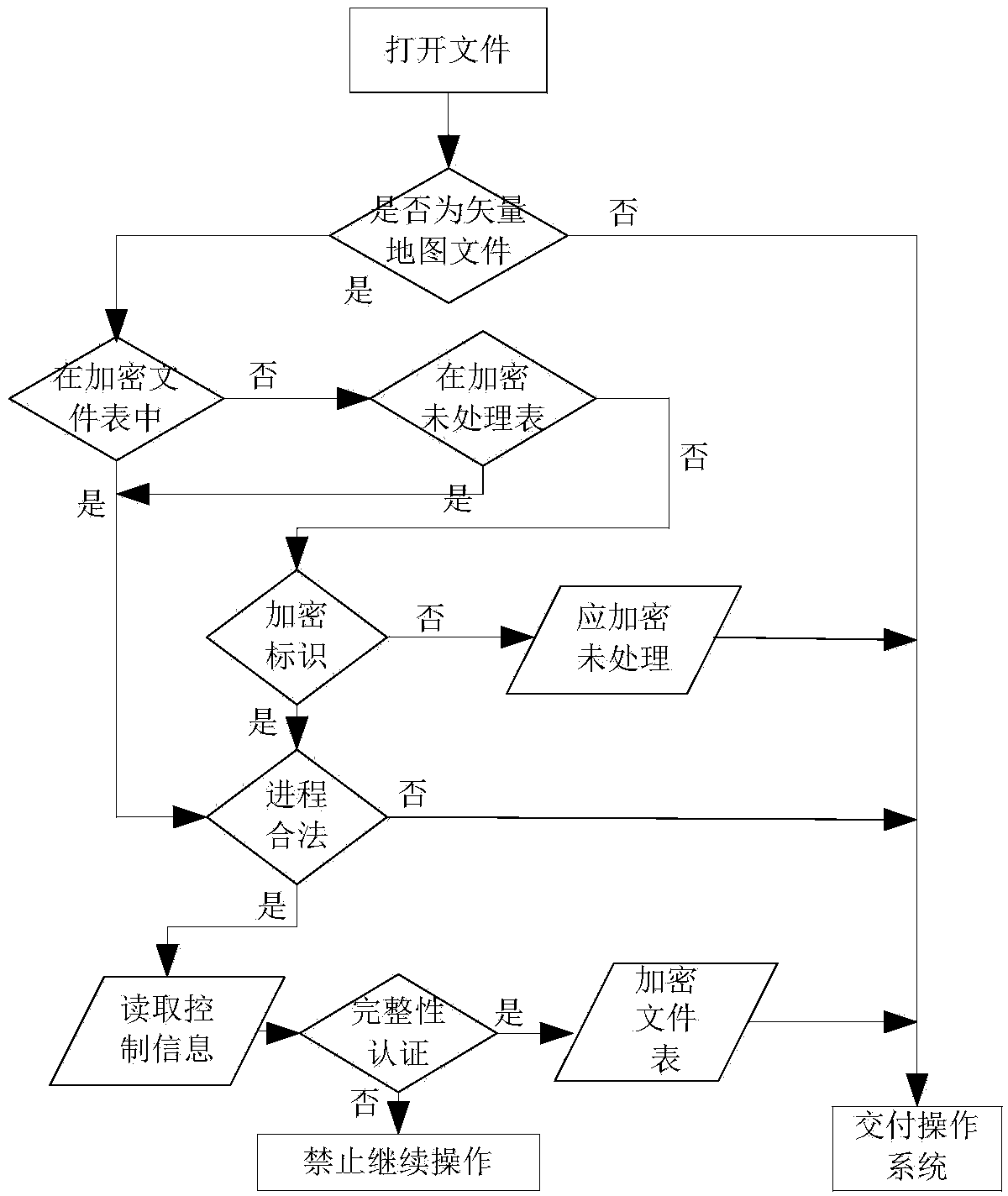

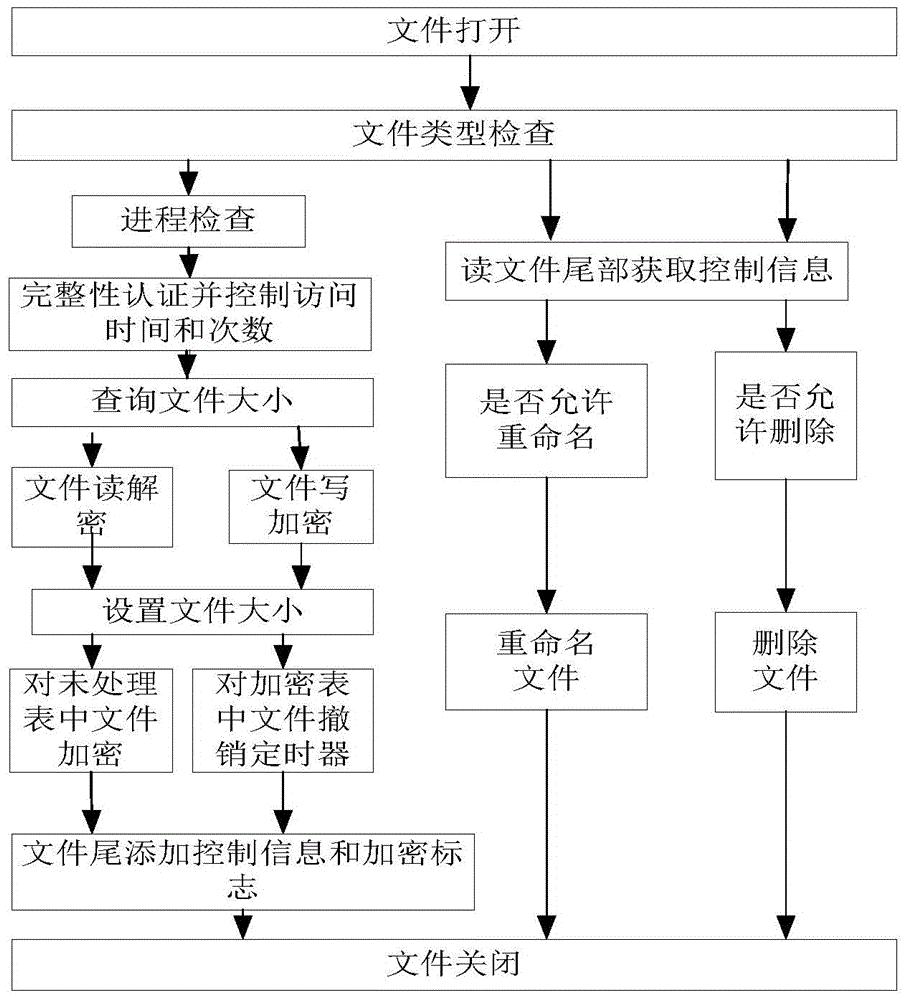

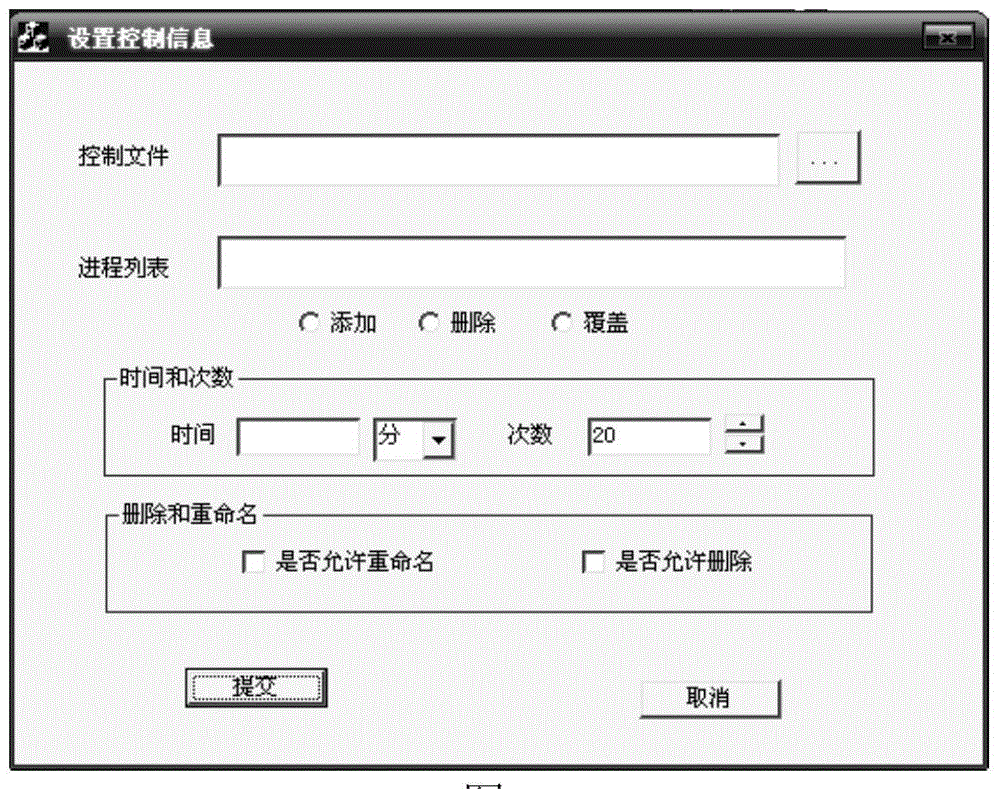

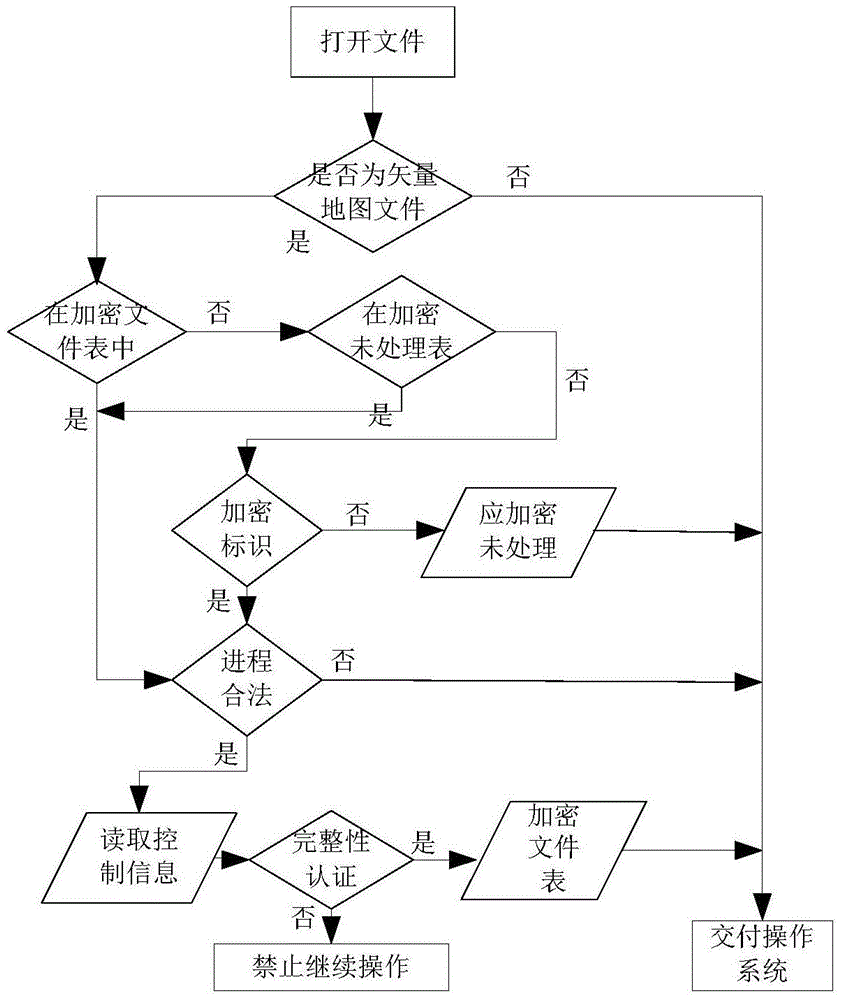

Vector map data protection and access control method based on file filter driver

InactiveCN104036197ASafe storageProtection securityDigital data protectionOperational systemCiphertext

The invention belongs to the fields of cryptography, information security, geographic information systems and digital image processing, and relates to a vector map data protection and access control method based on a file filter driver for carrying out data protection and file access control on a digital vector map. The method comprises the following steps: judging whether a file is a vector map file or not; putting the file into a control list; controlling rule integrity authentication; carrying out the file access control; encrypting and decrypting the file content; hiding the file size and control information; preventing data leakage when closing. According to the vector map data protection and access control method disclosed by the invention, the file filter driver is combined, transparent encryption and decryption and the file access control are carried out on vector map data at the bottom layer of an operating system, so that user operation habits are not affected, and the vector map data on a disk are ensured to be stored in a cipher text form to protect the security of the vector map data. Compared with data watermarking, the vector map data protection and access control method disclosed by the invention protects the vector map more thoroughly and reliably.

Owner:HARBIN ENG UNIV

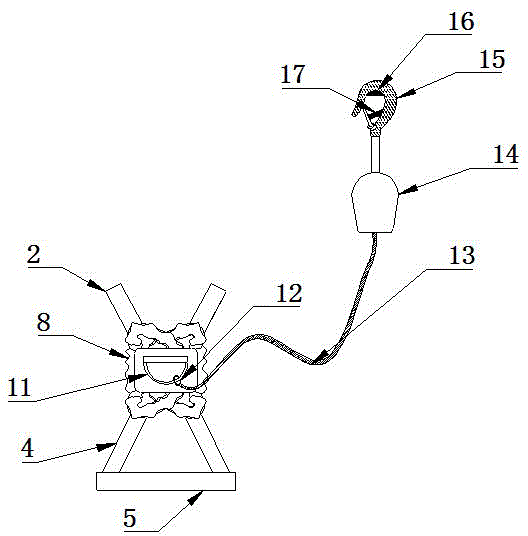

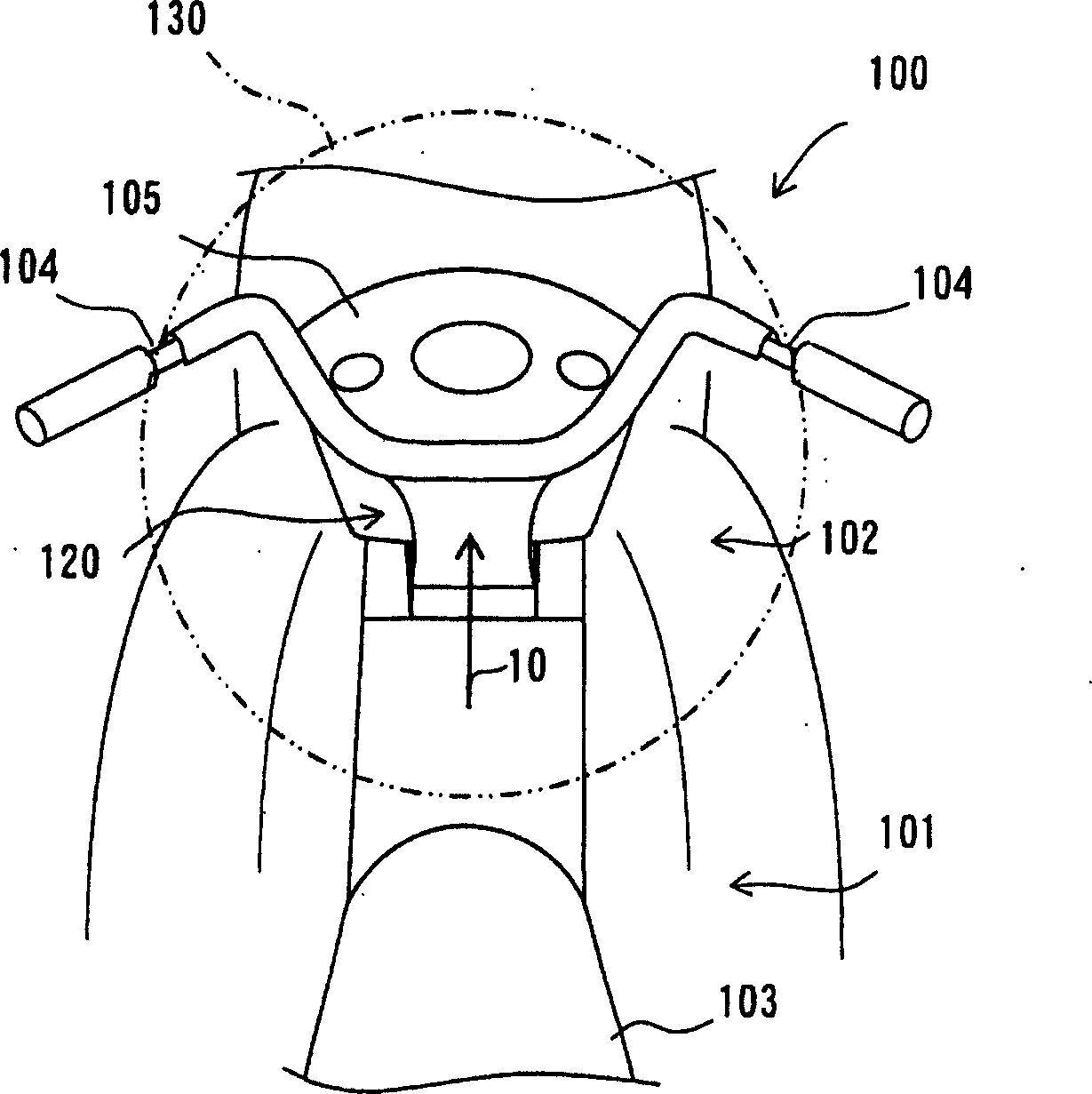

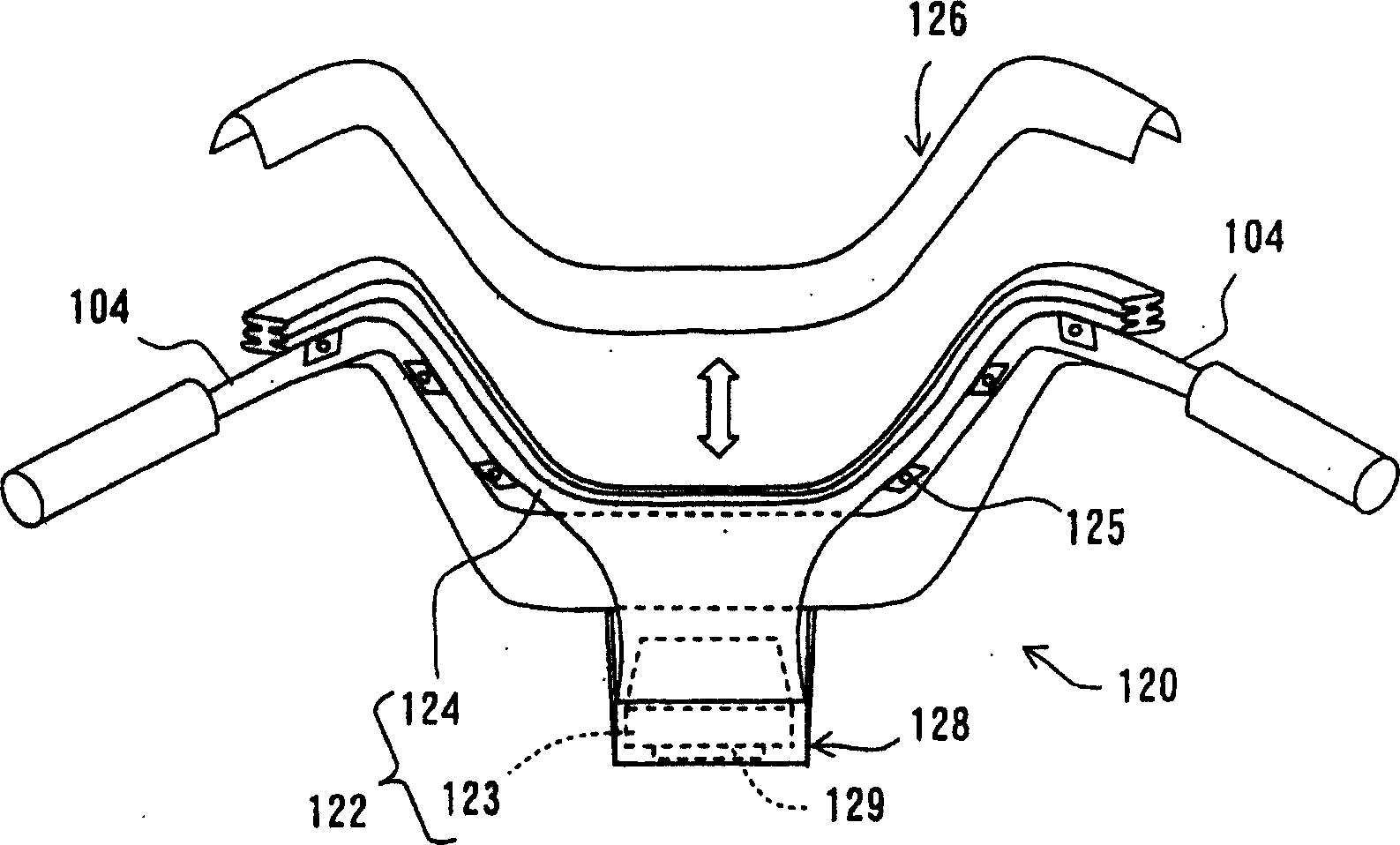

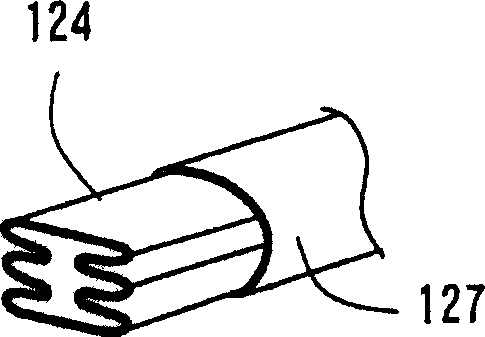

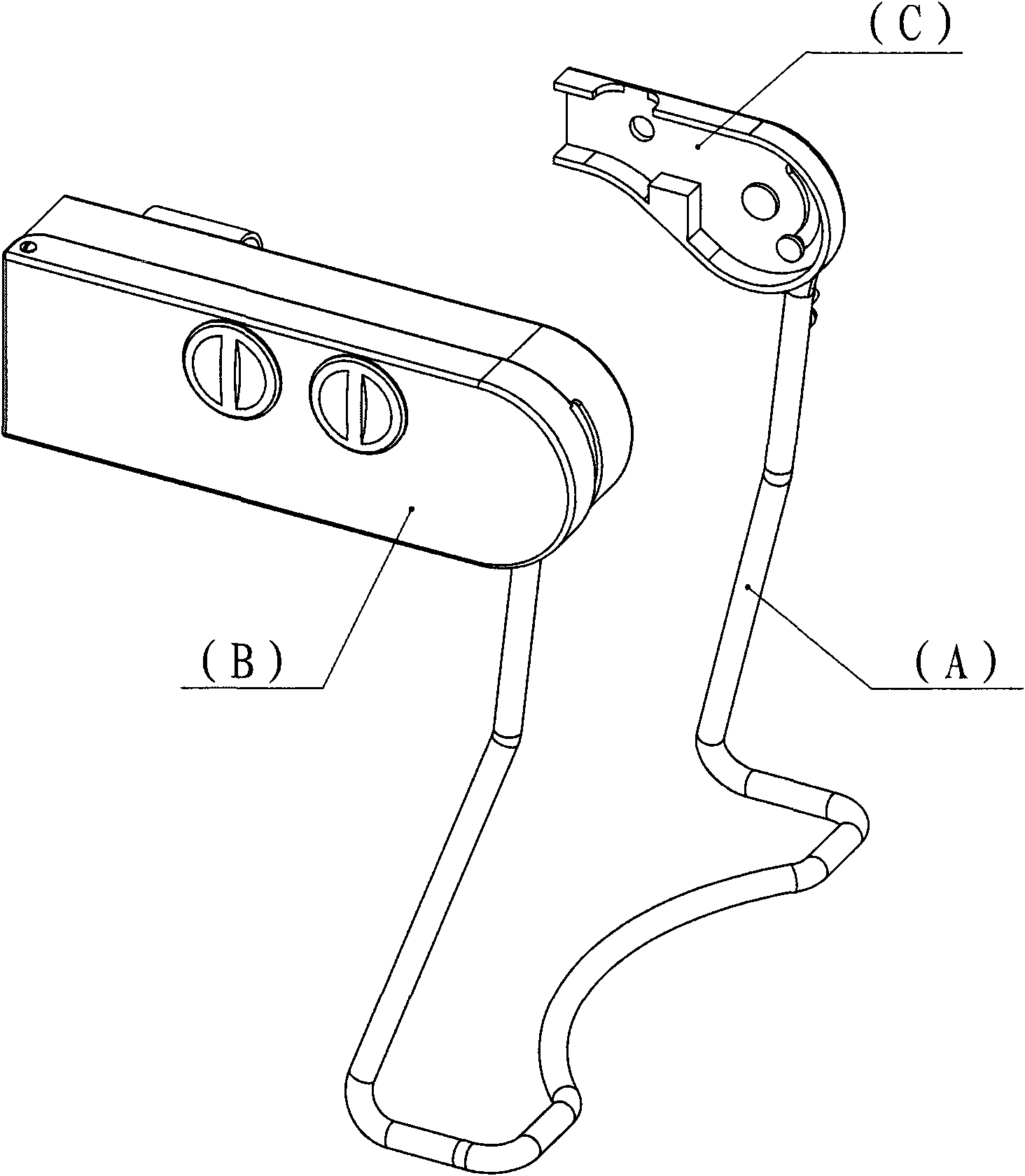

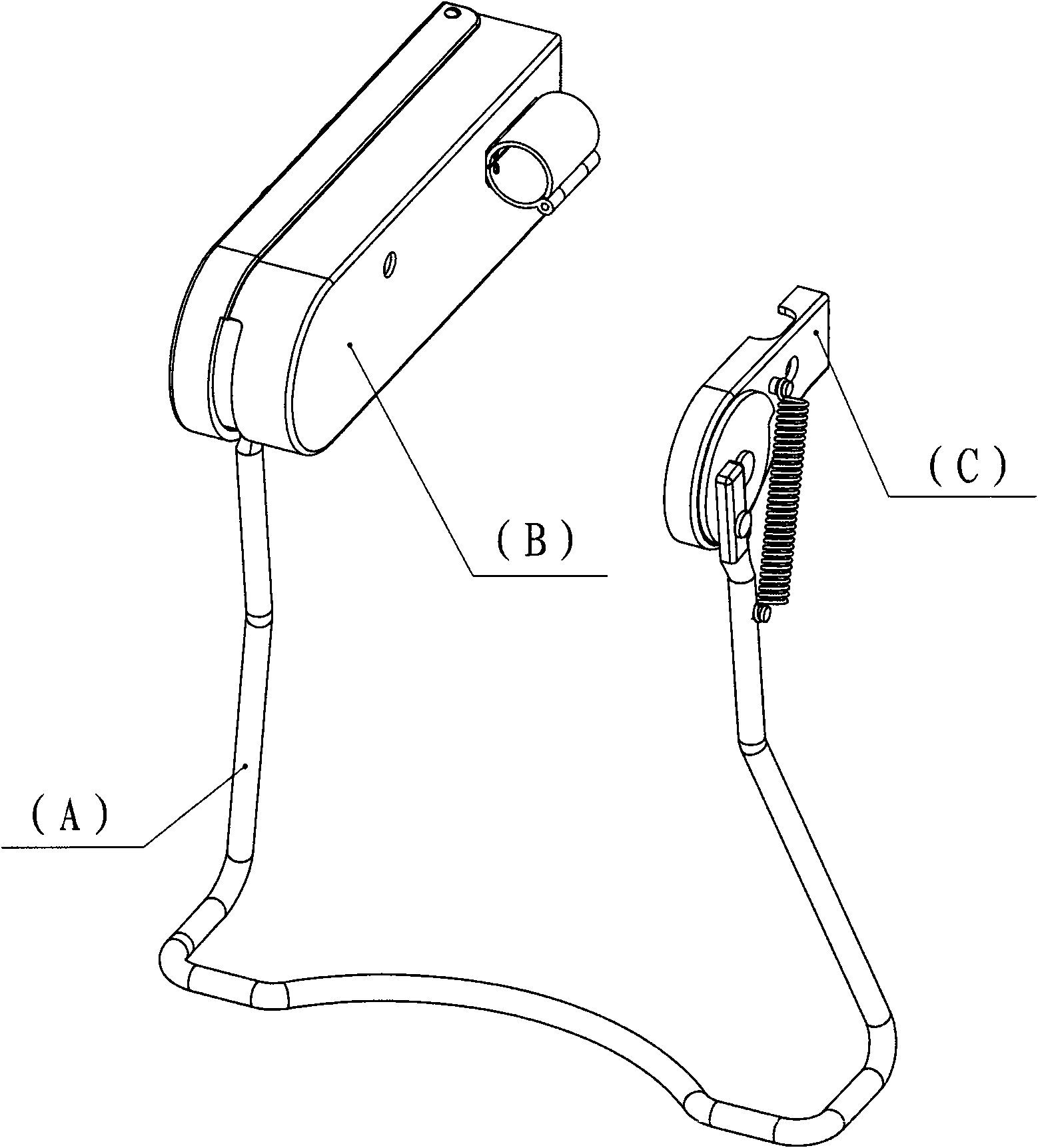

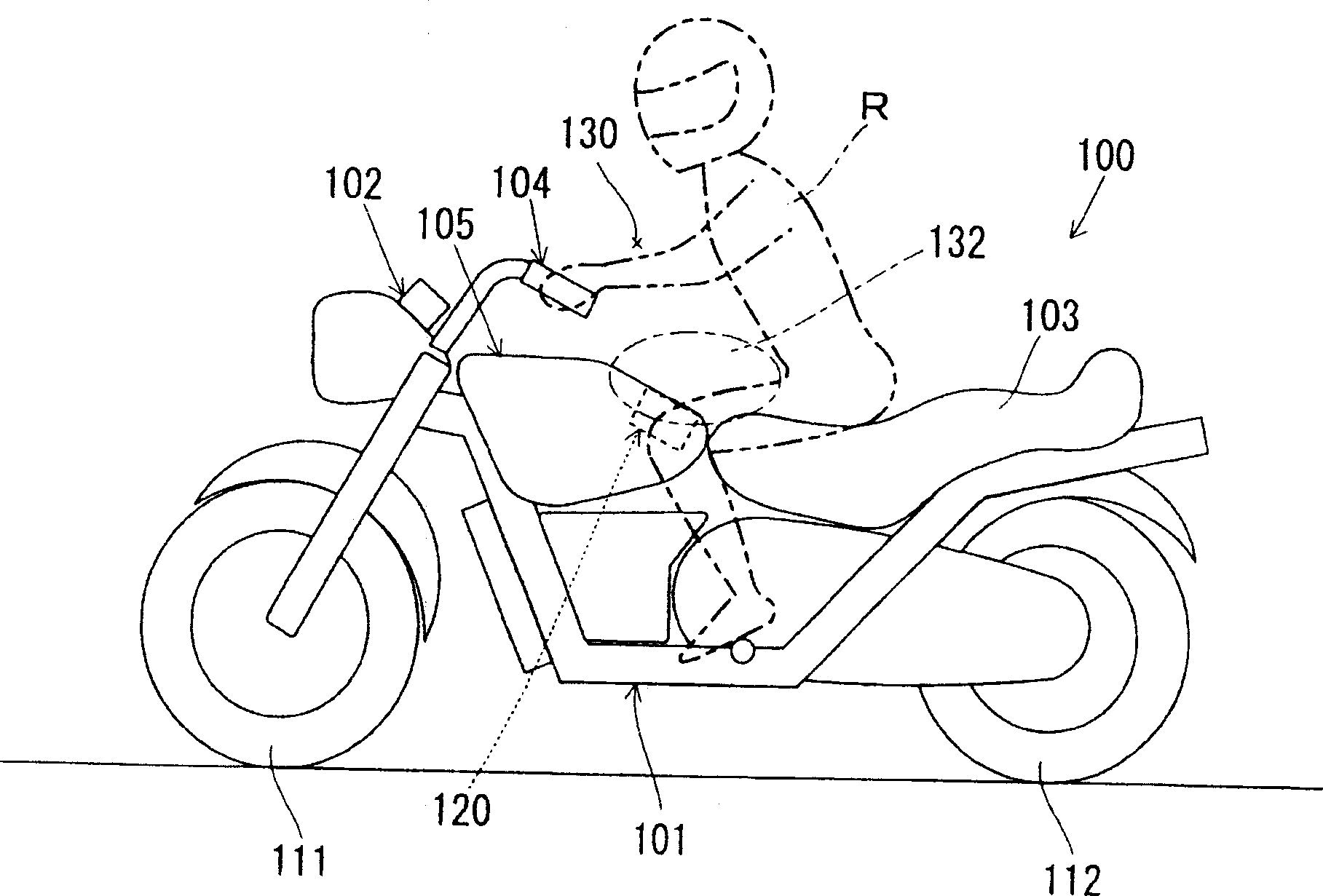

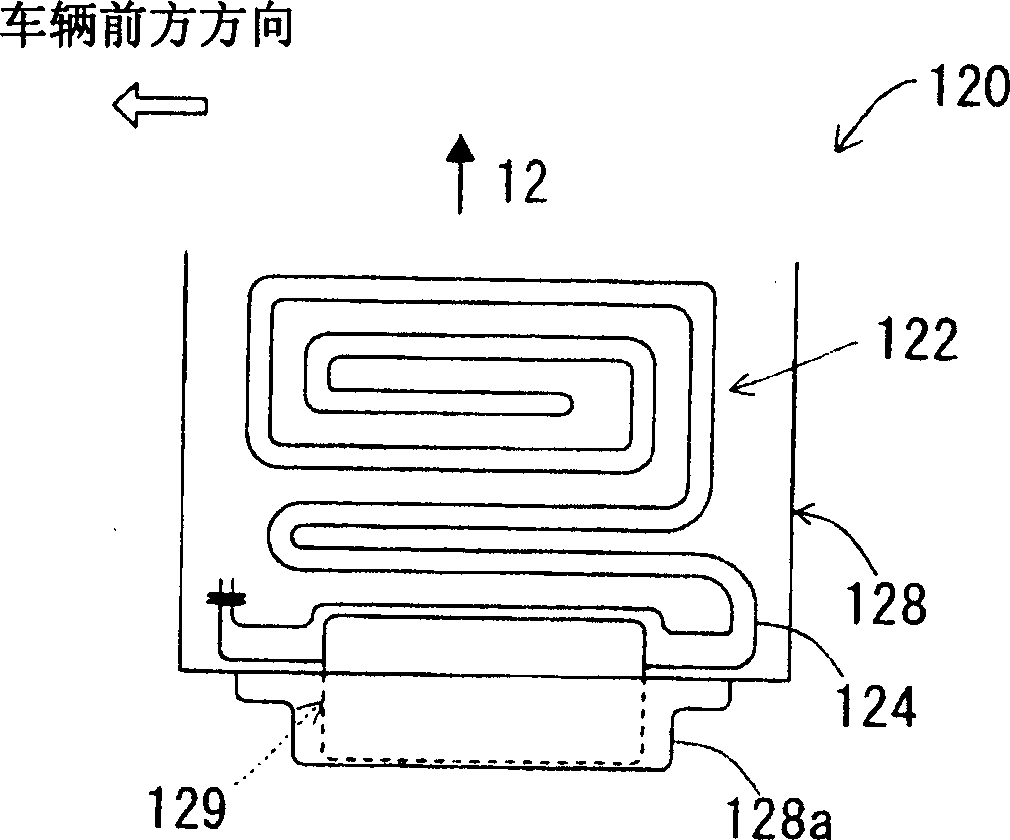

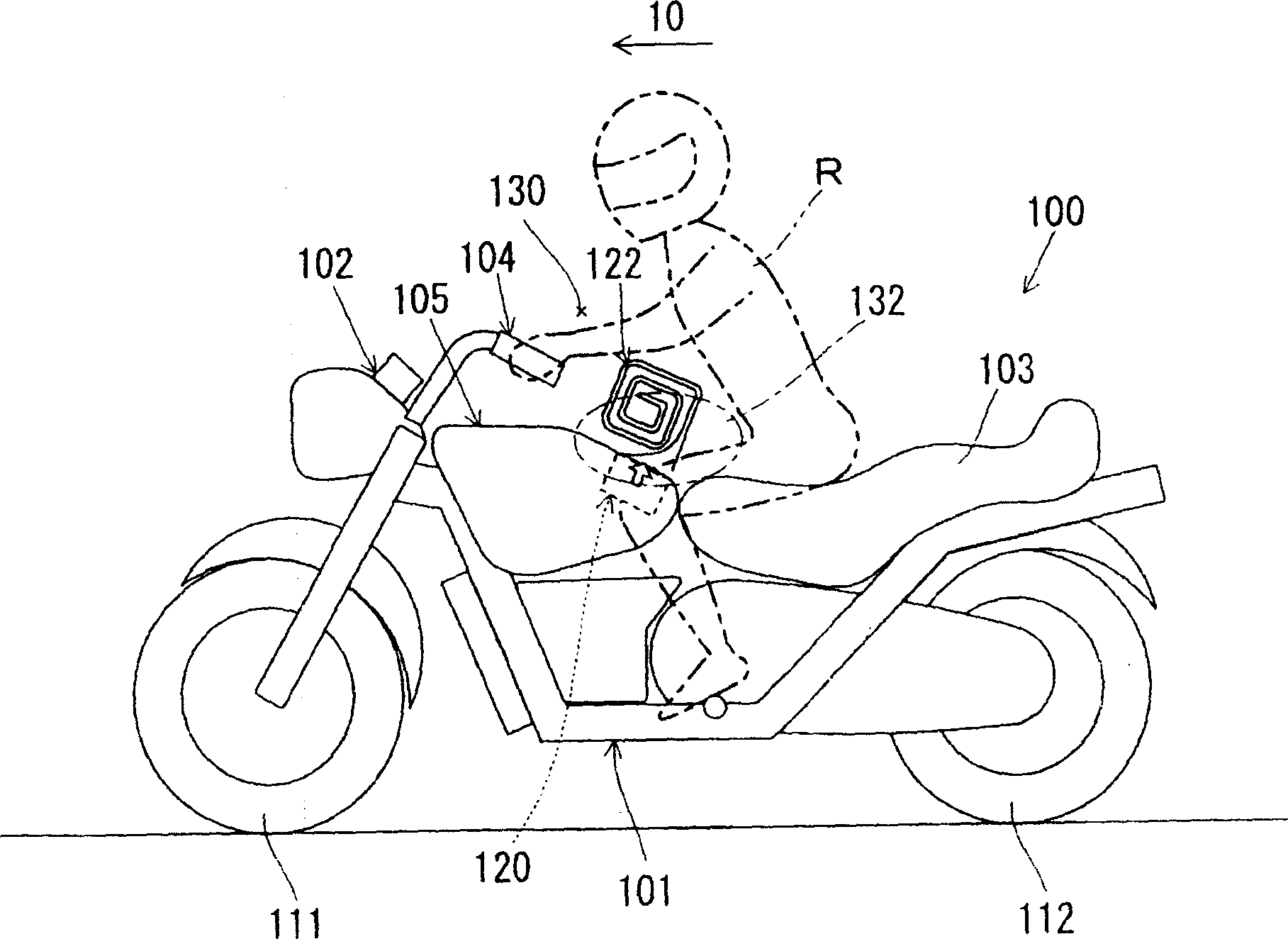

Airbag device and motorcycle with the airbag device

InactiveCN1572642AThorough protectionSmooth expansionPedestrian/occupant safety arrangementCycle safety equipmentsAirbagEngineering

The invention completely protects an occupant in an accident of a motorcycle. This air bag device 320 comprises: an air bag 122 that is loaded in a motorcycle 100, and expanded and inflated in an occupant protecting region formed on the front side of the occupant in a forward collision; and a retainer 128 to accommodate the air bag 122. The air bag 122 is arranged so that a second constitution section 124 as a part of the air bag 122 straddles a handle central section 104a of the handlebar 104 in the longitudinal direction outside the retainer 128, and the arrangement section is attached to the front part of a panel 105 by a fixture 125.

Owner:TAKATA CORPORATION

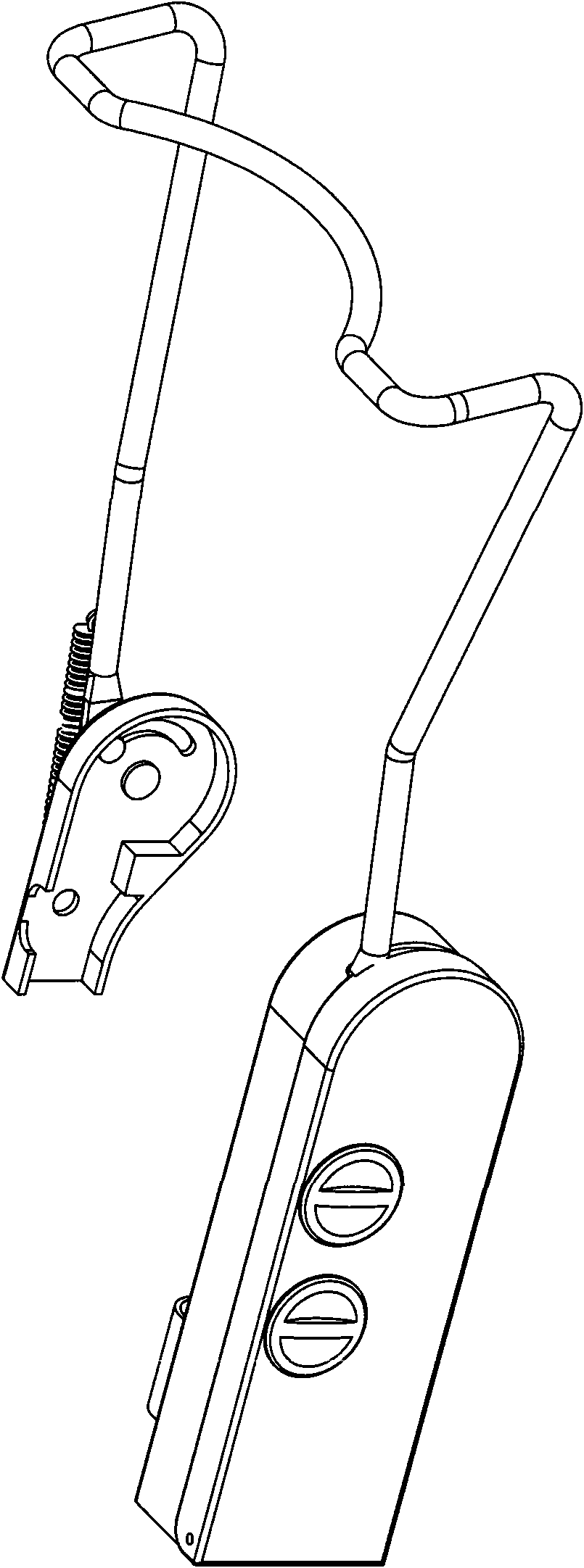

Electric bicycle handle lock unlocked or locked by power key

InactiveCN102060062AThorough protectionEliminate the danger of car lossAnti-theft cycle devicesClutchAnti theft

The invention discloses an electric bicycle handle lock unlocked or locked by a power key. The traditional anti-theft electric bicycle lock has an anti-theft function only under a bicycle-locking action when the anti-theft lock locks an electric bicycle, but the electric bicycle can be automatically locked by only pulling out the key routinely. A bracket rotary positioning system is arranged at the upper end of a bicycle handle bracket, is arranged in a lockable lock and is provided with a direct-current electromagnet. The outer end of an electromagnet slide bar is connected with a moveable pull rod; the moveable pull rod can be inserted into a locking positioning groove at the edge of a rotary positioning wheel fixedly connected to the upper end of the bicycle handle bracket; and then a bicycle handle is locked. When electrified, the electromagnet slide bar retracts, the bicycle handle rotates under the action of the springs and then the bicycle handle is unlocked. A rotary clutch switch controls to connect a power supply only when the bicycle handle is at a vertical position, and a voice prompter plays a prompt for pulling off the key at the moment. After the key is pulled off, the electromagnet slide bar restores and extends to lock the rotary positioning wheel due to the interruption of the power supply. A locking action is eliminated, so that the electric bicycle cannot be stolen when a user forgets to lock the bicycle.

Owner:焦纪平

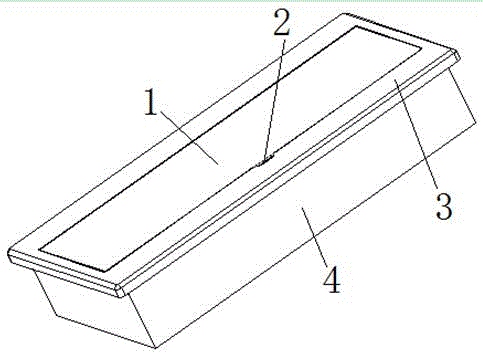

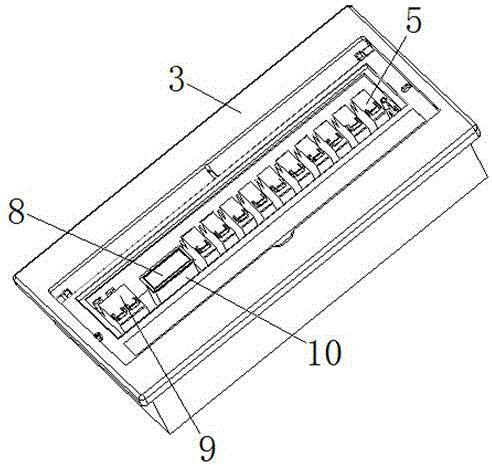

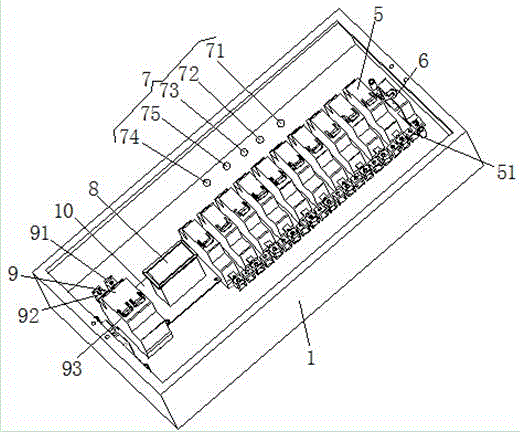

Domestic multifunctional intelligent distribution box

PendingCN106353568AThorough protectionSimple structureSubstation/switching arrangement detailsCurrent/voltage measurementOvervoltageEmbedded system

The invention discloses a domestic multifunctional intelligent distribution box. The domestic multifunctional intelligent distribution box comprises a supporting shell, wherein an opening is formed in the upper end of the supporting shell; fixing blocks are arranged on two sides in the supporting shell; a two-horsepower switch and a detection control board are arranged in the supporting shell; the two-horsepower switch is located on the left side of the detection control board; one-horsepower switches are uniformly arranged on the right side of the detection control board; electric appliances with different powers can be connected through the two horsepower switch and the one-horsepower switches, so that the connection of the electric appliances is matched very well; voltage and current of the electric appliances in a working process can be detected through a voltage detector and a current detector, so that the electric appliances are protected more thoroughly. The domestic multifunctional intelligent distribution box is simple in structure and convenient to mount; current and voltage can be detected and abnormal conditions can be found before tripping operation; and when the current and the voltage have the abnormal conditions, people can be reminded through a buzzer, and indirect protection for the electric appliances is also realized.

Owner:广东顺德弘力达电器科技有限公司

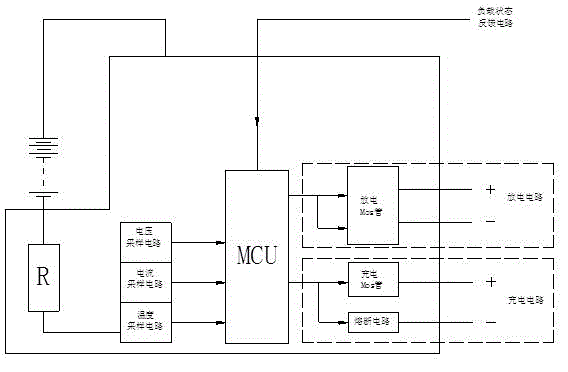

Charge-discharge protective system of lithium battery pack

InactiveCN105322508AIncrease the fuse protection linkThorough protectionBatteries circuit arrangementsEmergency protective circuit arrangementsElectricityMicrocontroller

The present invention discloses a charge-discharge protective system of a lithium battery pack including a voltage sampling circuit, a current sampling circuit, a temperature sampling circuit, a load state feedback circuit, a discharge circuit, a charge circuit and a singlechip computer. The voltage sampling circuit is used for sampling voltage of the lithium battery pack, the current sampling circuit is used for sampling current of the lithium battery pack, and the temperature sampling circuit is used for sampling temperature of the lithium battery pack. Output ends of the voltage sampling circuit, the current sampling circuit, the temperature sampling circuit and the load state feedback circuit are electrically connected with the input end of the singlechip computer separately. The output end of the singlechip computer is electrically connected with the charge circuit and the discharge circuit separately. The charge protective system of the lithium battery pack also includes a fuse circuit, and the fuse circuit is connected with the charge circuit in series. The discharge protective system of the lithium battery pack also includes earth leakage protection. Compared to the prior art, the charge-discharge protective system of the lithium battery pack improves the reliability and safety of the protection control of the lithium battery pack, and avoids safety accidents due to invalid overcharge protection and no-load leakage current.

Owner:SHANGHAI TSING POWER ENERGY TECH

Glove having high mechanical performance, with high resistance to chemical products and/or radiolysis, and method for making same

InactiveCN1486146ALoss of protectionProne to radiolysisGlovesDomestic articlesElastomerHigh resistance

The invention concerns a glove having high mechanical performance, and high resistance to chemical products and / or radiolysis, characterised in that it comprises one or several elastomer layers, identical or different, obtained from solutions of said elastomers in one or several organic solvents or in water, said layers being reinforced, on one or several parts or on the entire internal surface of the glove, with a fabric with high mechanical strength. The invention also concerns a method for making said glove and its uses.

Owner:HUTCHINSON SA +1

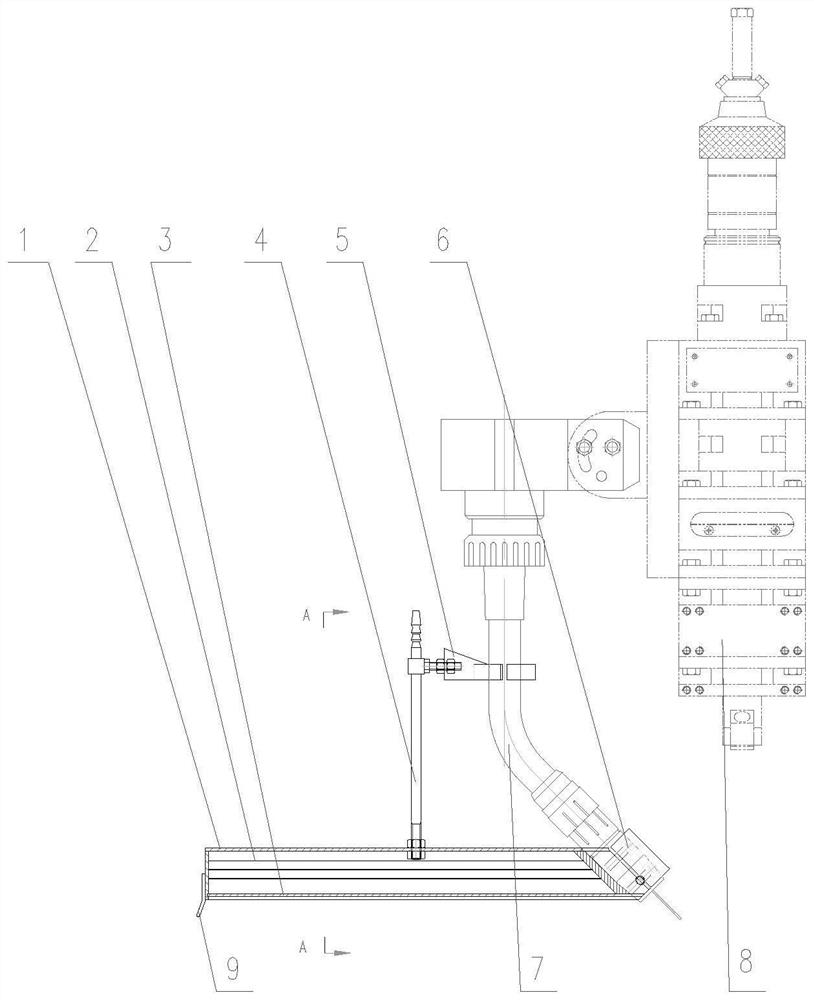

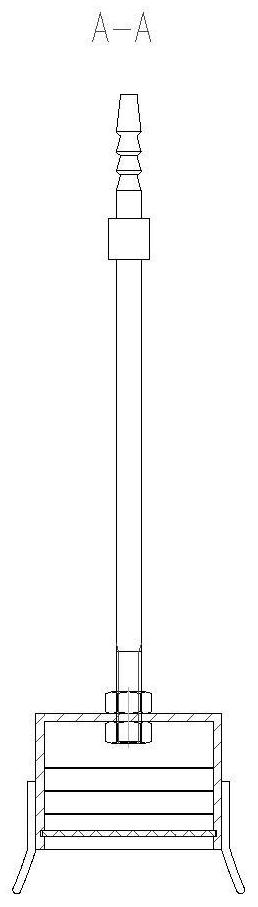

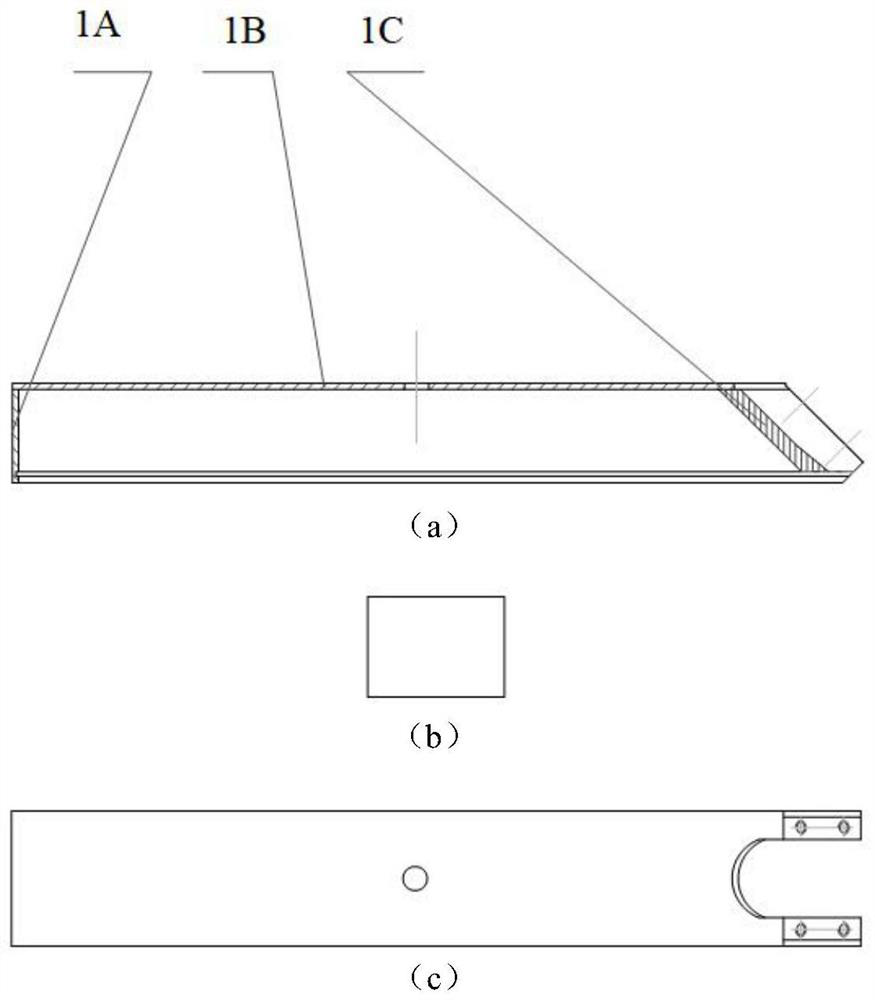

Titanium alloy laser arc hybrid welding 45-degree welding gun welding gas protection dragging cover

PendingCN113977118ATroubleshoot Gas Shielding IssuesProtect the Welding AreaWelding/soldering/cutting articlesLaser beam welding apparatusWeld seamGas protection

The invention provides a titanium alloy laser arc hybrid welding 45-degree welding gun welding gas protection dragging cover. The dragging cover comprises a dragging cover body, a gas sieve plate, a gas outlet plate, a gas inlet connecting pipe, a connecting clamp and a semicircular fixing seat, the dragging cover body comprises a top plate, a 45-degree fixing seat and a rear plate, the gas sieve plate is arranged in the dragging cover body, the gas outlet plate is arranged below the gas sieve plate, the gas inlet connecting pipe comprises a gas inlet pipe body and a sleeve shaft, and the connecting clamp comprises a connecting plate, a connecting clamp body and a fixing clamp. By means of the dragging cover, high-purity argon can be effectively and evenly injected into the titanium alloy welding surface, a titanium alloy welding seam is isolated from air, the gas protection problem during butt welding of titanium alloy laser-arc hybrid welding flat plates can be solved, a welding area is thoroughly protected, and the performance quality of a welding joint is improved.

Owner:BEIJING NORTH VEHICLE GROUP CORP

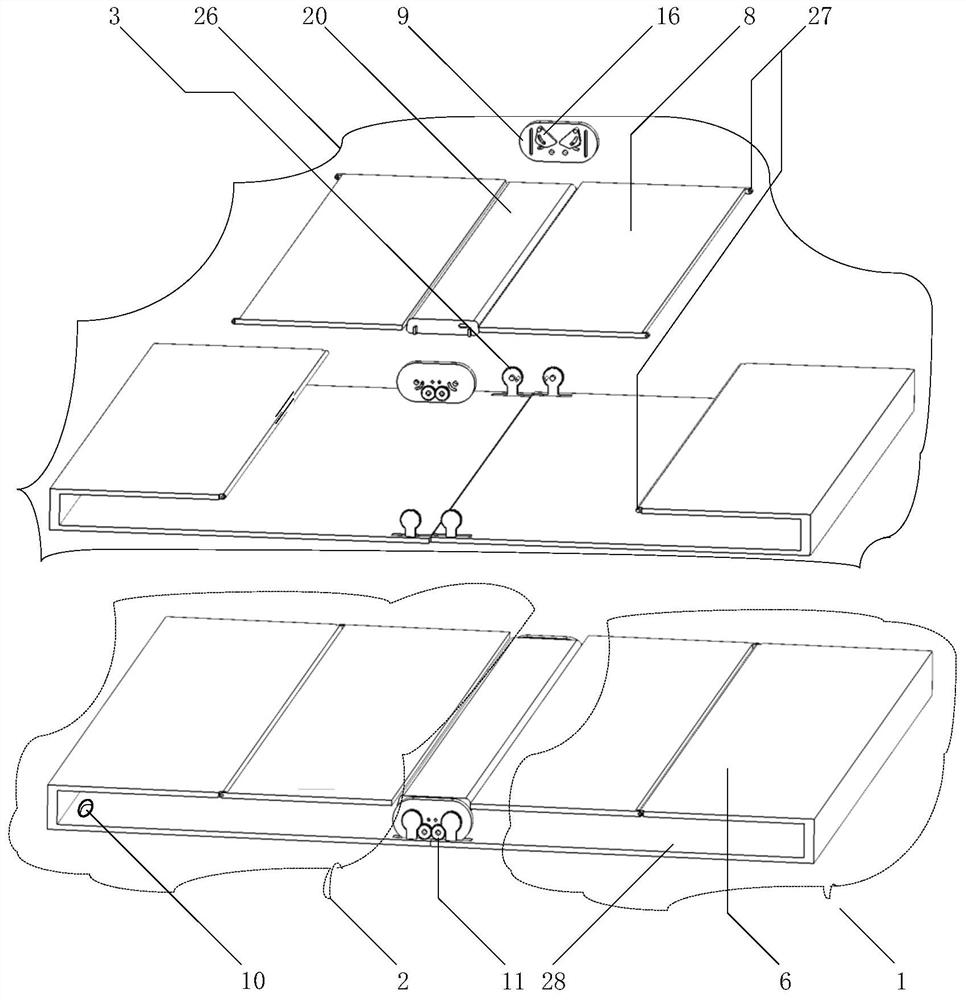

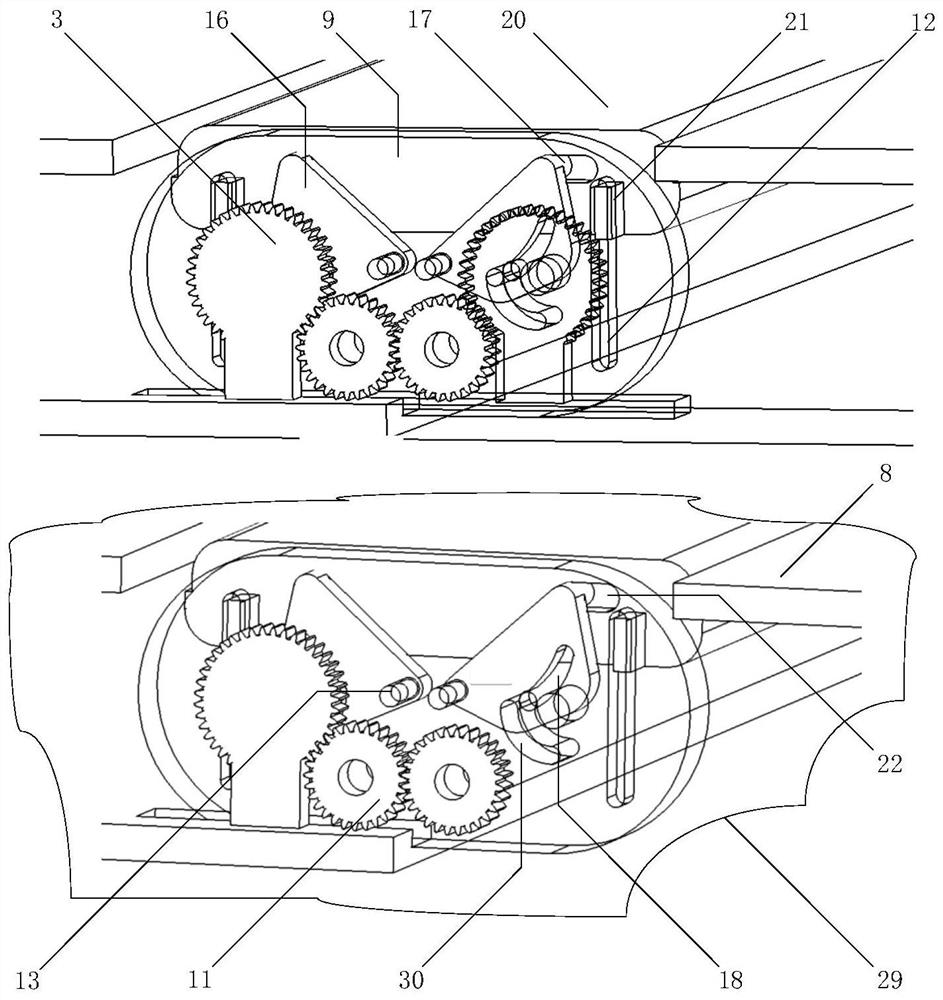

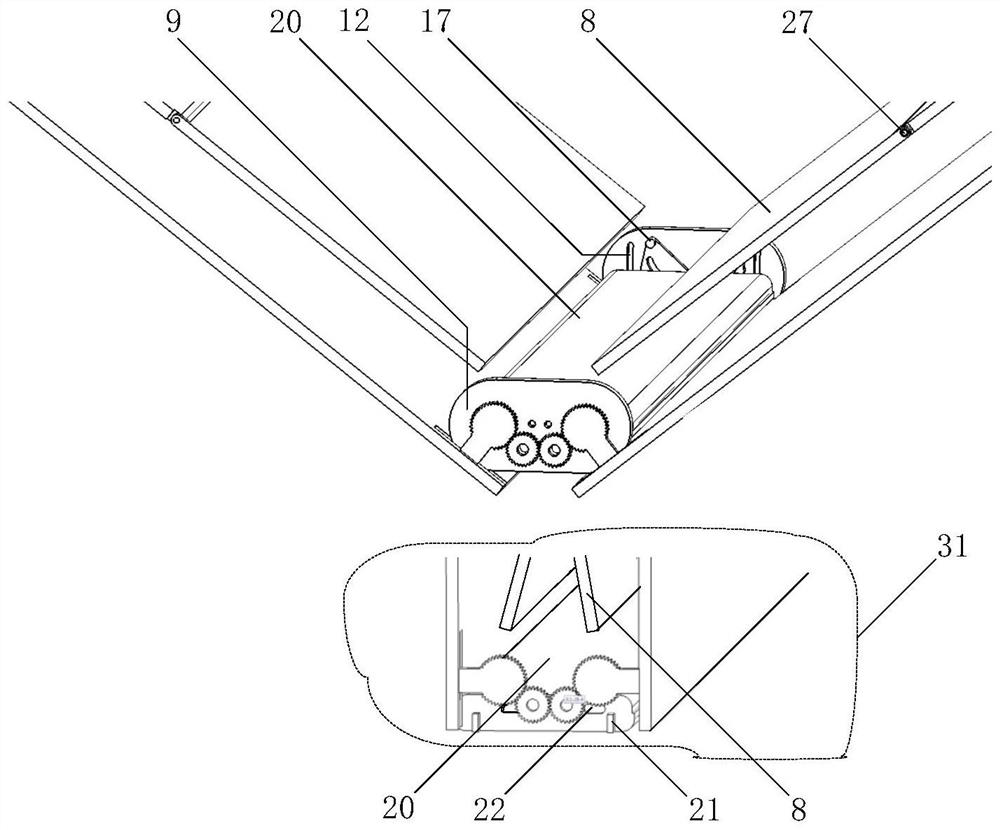

Double-synchronizing-shaft lever poking-clamping type folding screen mobile phone and tablet personal computer

PendingCN111726436ASimple structureImprove the rotation effectDetails for portable computersTelephone set constructionsSoftware engineeringPersonal computer

The invention discloses a double-synchronizing-shaft lever poking-clamping type folding screen mobile phone and a tablet personal computer, and belongs to the technical field of machinery. The main components comprise a mobile phone accommodating cavity or an accommodating cavity front part, an end plate and a lever poking clamp. According to the connection relation, (non-rotating) synchronous gears which are rigidly connected with the mobile phone accommodating cavity or the two ends of the accommodating cavity front part are hinged with hinge shafts of the two end plates, so that the synchronous gears are meshed with transmission gears of which rotating shafts are fixed with the end plates, or the synchronous gears are directly meshed to achieve the purpose of synchronous reverse rotation; the fixed lining plate is used for supporting a mobile phone screen, and hinged shaft connection parallel to the screen is carried out between the hinged shaft hanging lining plate of the mobile phone screen adjacent to the screen folding area and the mobile phone structure; a lever shaft of the lever poking clamp is hinged to a hinge shaft of the end plate, and a poking column at the foremostend of the lever poking clamp is inserted into a shell and screen supporting plate strip poking groove. The protrusions of the shell and screen supporting plate strip are inserted into the end plate guide grooves to limit transverse displacement of the shell and screen supporting plate strip. The double-synchronizing-shaft lever poking-clamping structure is suitable for inwards-folded folding screen mobile phones and tablet personal computers.

Owner:罗天珍

A kind of sic MOSFET drive protection circuit and its protection method

The invention belongs to the technical field of circuit control, and in particular relates to a SiC MOSFET drive protection circuit and a drive protection method thereof. The circuit includes a sampling comparison module, a signal latch and logic control module, an external control module and an execution module for suppressing false opening. The drive circuit can solve the mis-turn-on problem caused by various reasons in the working process of SiC MOSFET. At the same time, the processor can monitor the frequency of the false-turn-on suppression signal, judge the current working environment of the circuit, and adjust the switching frequency and working status of SiC MOSFET in real time. , can greatly increase the reliability of the circuit and prolong the life of the device.

Owner:北京长峰天通科技有限公司

A vector map data protection and access control method based on file filter driver

Owner:HARBIN ENG UNIV

Airbag apparatus motorcycle with airbag apparatus

InactiveCN1861463AThorough protectionPedestrian/occupant safety arrangementCycle safety equipmentsAirbagVehicle accident

Owner:TAKATA CORPORATION

Preparing method of treating fluid for thermal treating in automobile hand brake treating

InactiveCN105463367ANew formula designReasonable formula designSolid state diffusion coatingEmulsionPolyphosphate

The invention relates to the technical field of automotive parts treating, in particular to a preparing method of treating fluid for thermal treating in automobile hand brake treating. Firstly, 10 parts of sodium polyphosphate and 20 parts of water are added into a container and stirred for 5 minutes; then 1 part of sodium carbonate is slowly added and stirred and is continuously stirred for 5 minutes after being added; the 10 parts of acrylate emulsion and 10 parts of water are slowly added and stirred and are continuously stirred for 5 minutes after being added; then 0.5 part of flavonoid glycosides is slowly added and stirred and is continuously stirred for 5 minutes after being added; and finally, 5 parts of xylene and 20 parts of water are slowly added and stirred for 10 minutes. According to the preparing method for the treating fluid, the dissolving property between all materials is improved by adding the materials step by step and reasonably choosing the material adding sequences. Furthermore, the possibility of particle aggregation is avoided, and the thermal treating protection function of the treating fluid is obviously improved.

Owner:WUHU JINYU PETROCHEM EQUIP

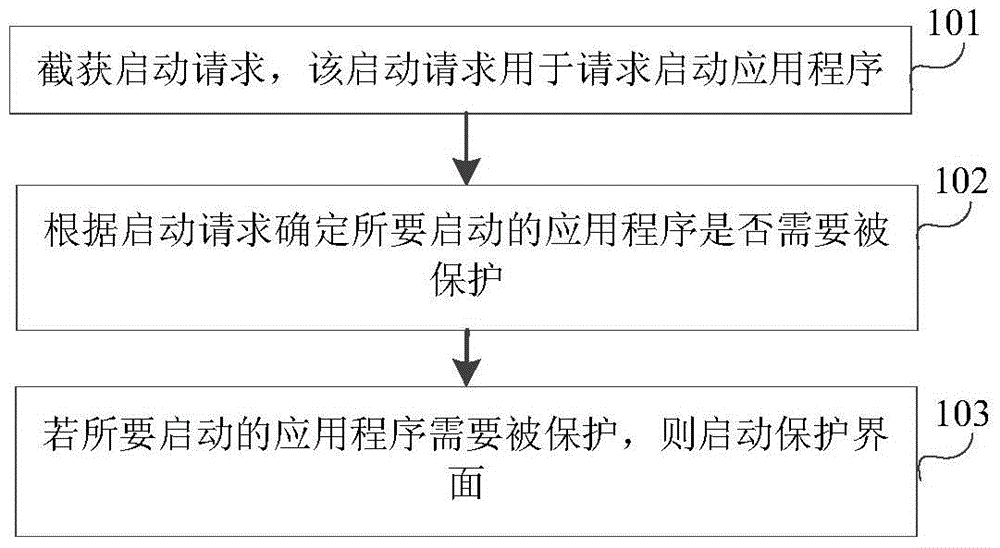

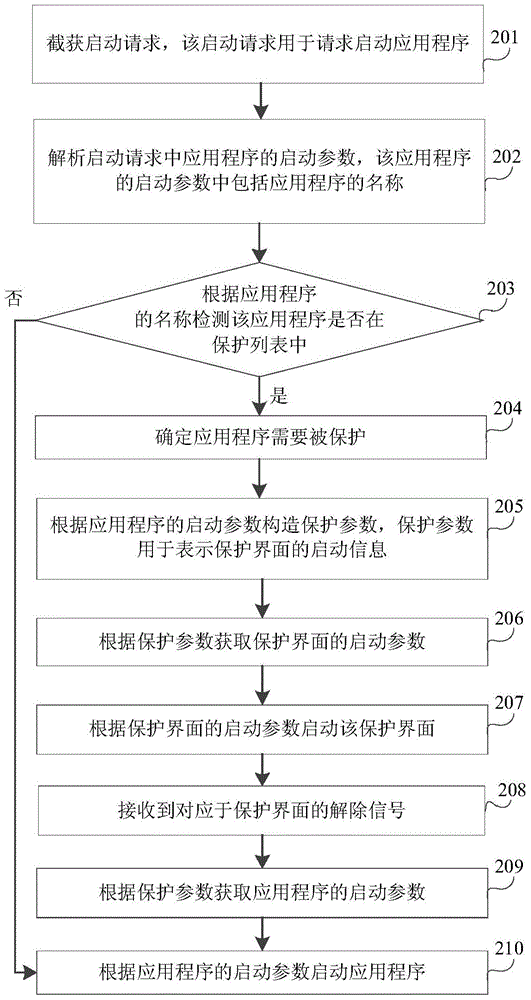

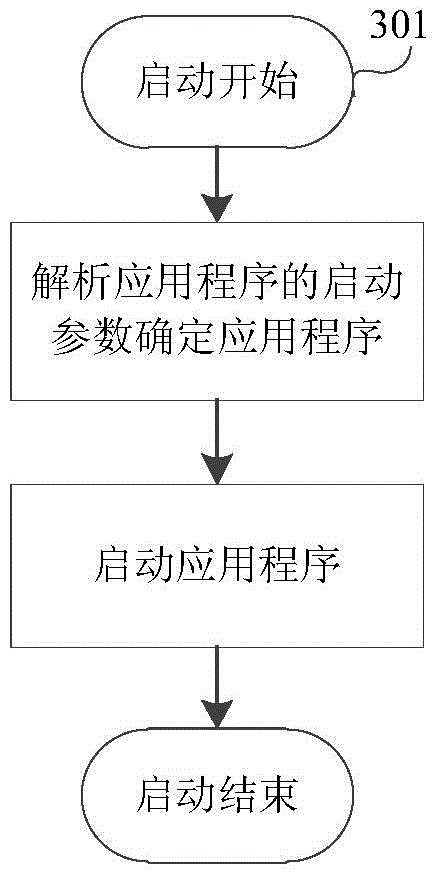

Application protection method, device and terminal

ActiveCN103824003BThorough protectionUnrestricted publicDigital data authenticationProgram loading/initiatingSoftware engineeringApplication procedure

Owner:XIAOMI INC

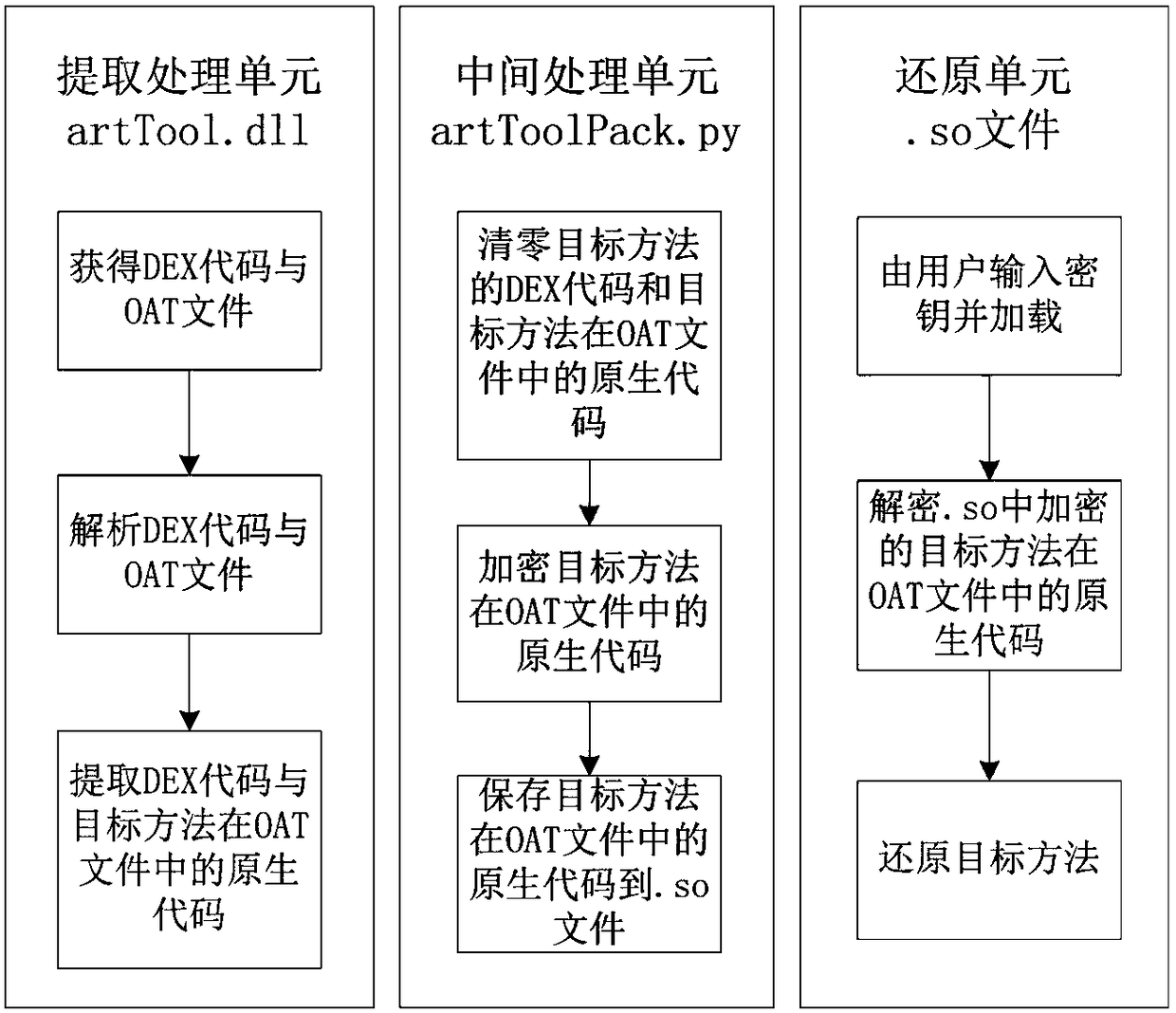

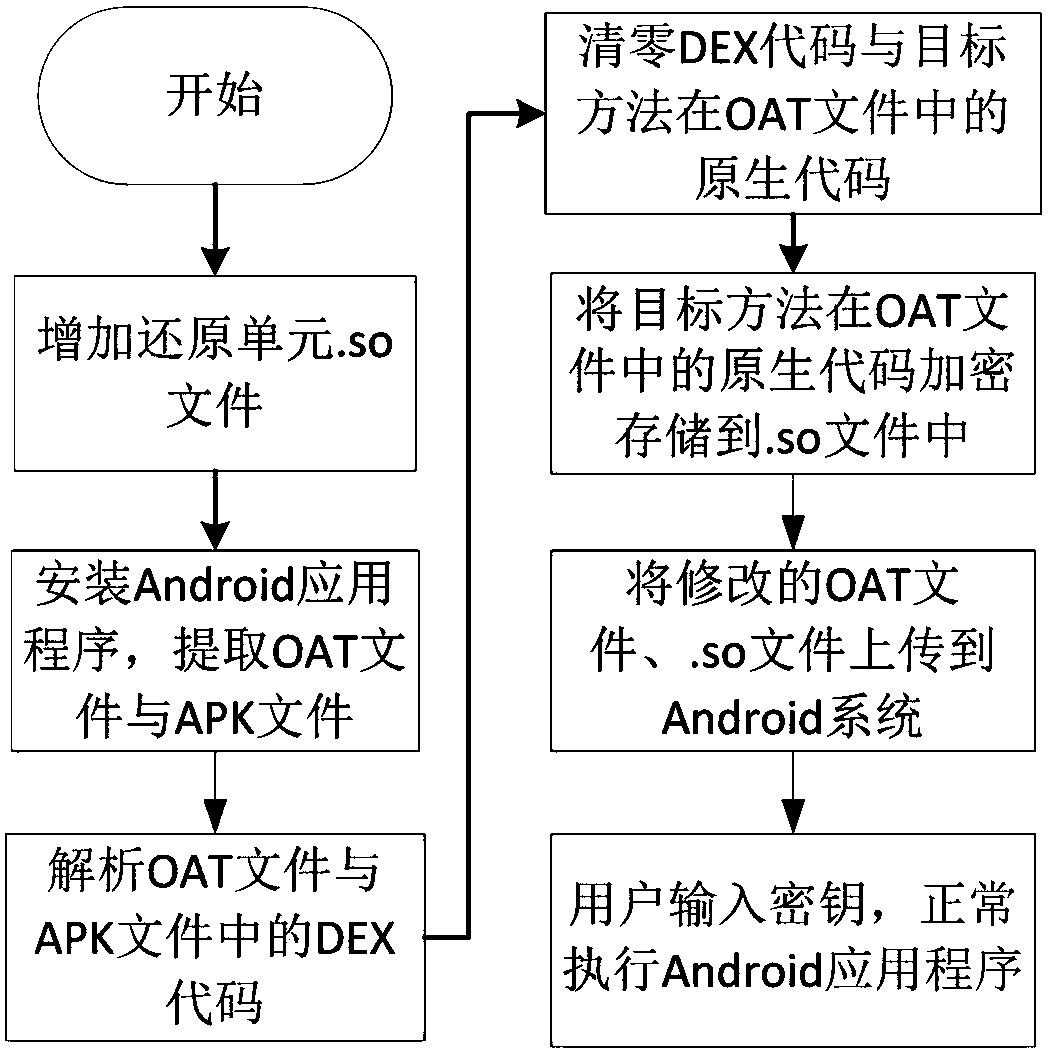

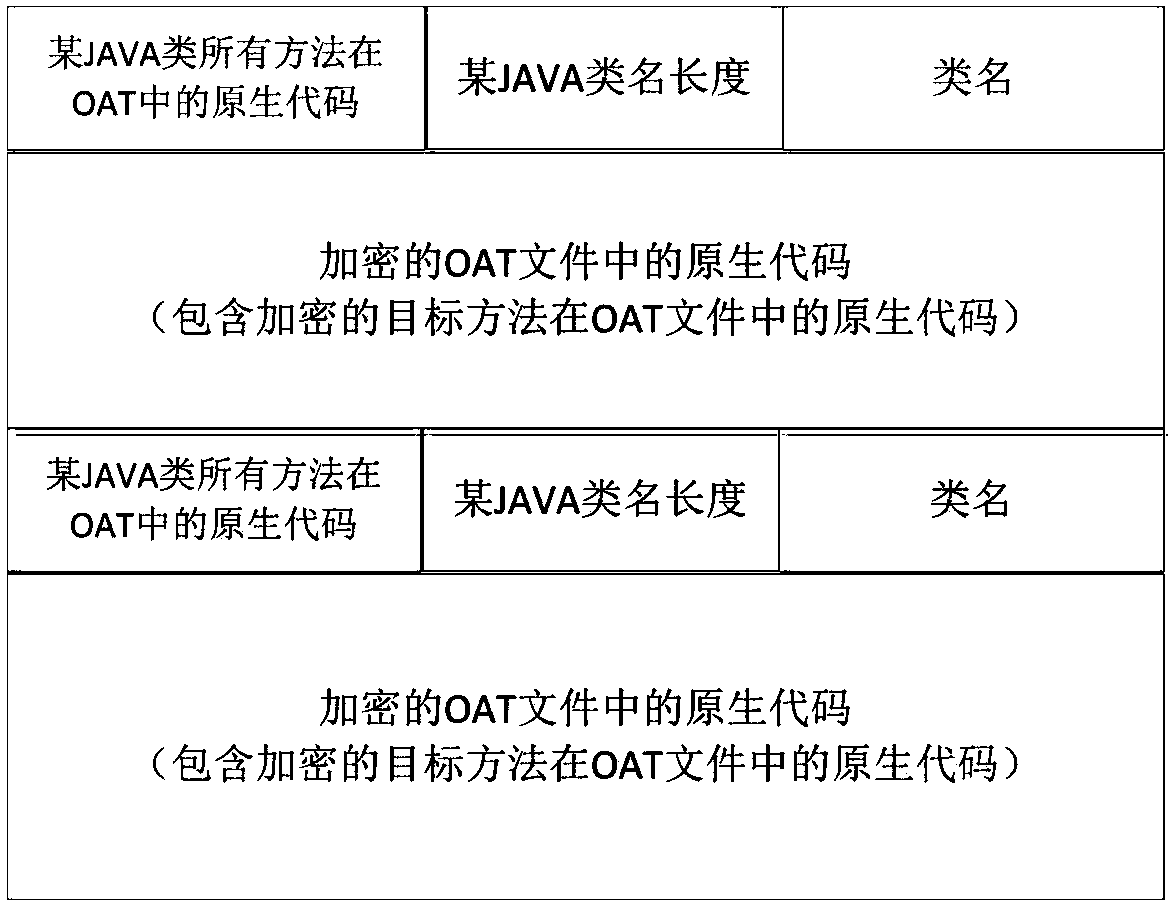

A code protection method for android precompilation

ActiveCN106228041BThorough protectionImprove securityProgram/content distribution protectionCode compilationSoftware engineeringProcessing element

A code protection method for Android precompilation, by constructing an extraction processing unit, an intermediate processing unit and a restoration unit, modifying and processing Android application program files to protect codes. The specific method is to add the .so file in the Android application as the restore unit; when the application is installed, obtain the DEX code of the target method and the native code in the OAT file by extracting the processing unit; encrypt the native code through the intermediate unit, and embed it to the .so file, and clear the DEX code and native code; when the user runs the target method of the Android application program, the user enters the key, and the target method is normally run after the restoration process. The invention proposes a set of practicable methods aiming at the safety defect that the original code in the DEX code and the OAT file in the existing code protection method cannot be completely protected and cannot be dynamically restored by using a password.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

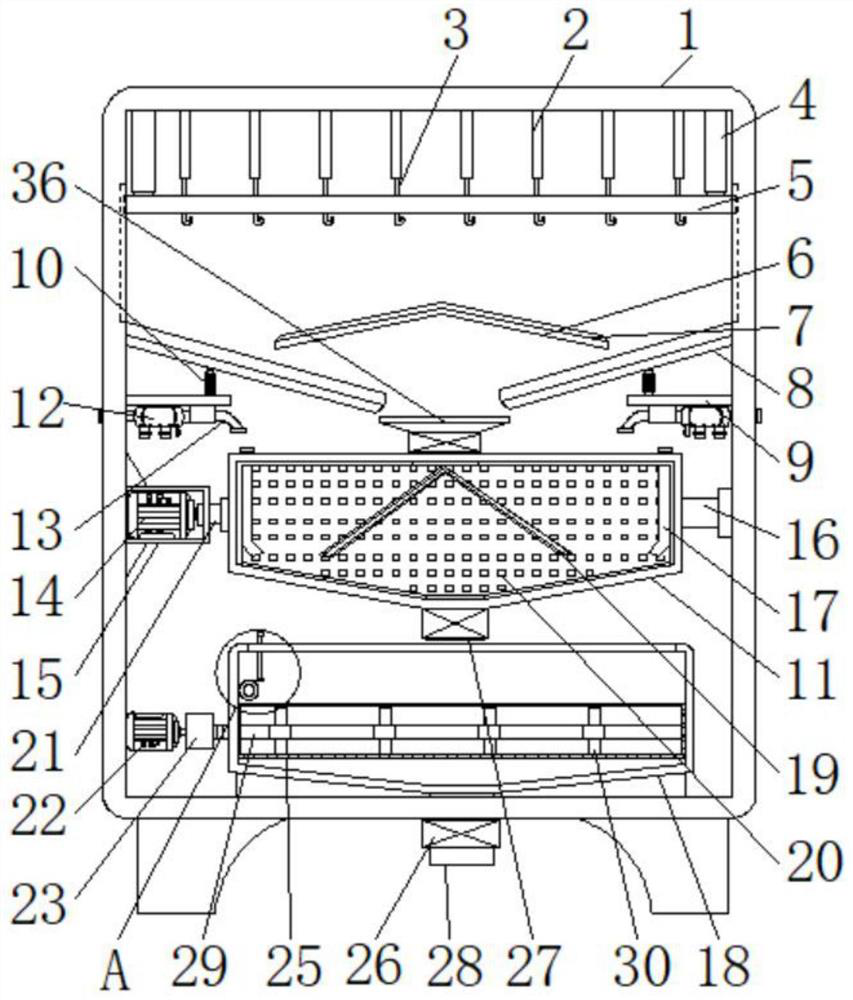

A rolling grape destemming device

ActiveCN109007920BAvoid damageImprove work efficiencyFood treatmentEngineeringStructural engineering

The invention discloses a rolling grape destemming device, which comprises a box body, the left and right sides of the top of the inner wall of the box are fixedly connected with electric telescopic rods, the bottom end of the electric telescopic rod is fixedly connected with a moving plate, and the top of the inner wall of the box is A connecting rod is fixedly connected between the two electric telescopic rods, and a hook is fixedly connected to the bottom end of the connecting rod. The bottom end of the hook runs through the moving plate and extends to one side of the moving plate, and the left and right sides of the inner wall Both are fixedly connected with a deflector, the back of the inner wall of the box is fixedly connected with a first V-shaped plate, and the left and right sides of the inner wall of the box are fixedly connected with a support plate below the deflector. The present invention relates to the technical field of grapes. The rolling grape stemming device removes the thick stems and small stems of the grapes successively, so that the grape stems can be removed more thoroughly, and the grapes can be well protected, which greatly improves the work efficiency and can protect the grapes. Well separated from the stem.

Owner:六安市叶集区绿叶果木种植专业合作社

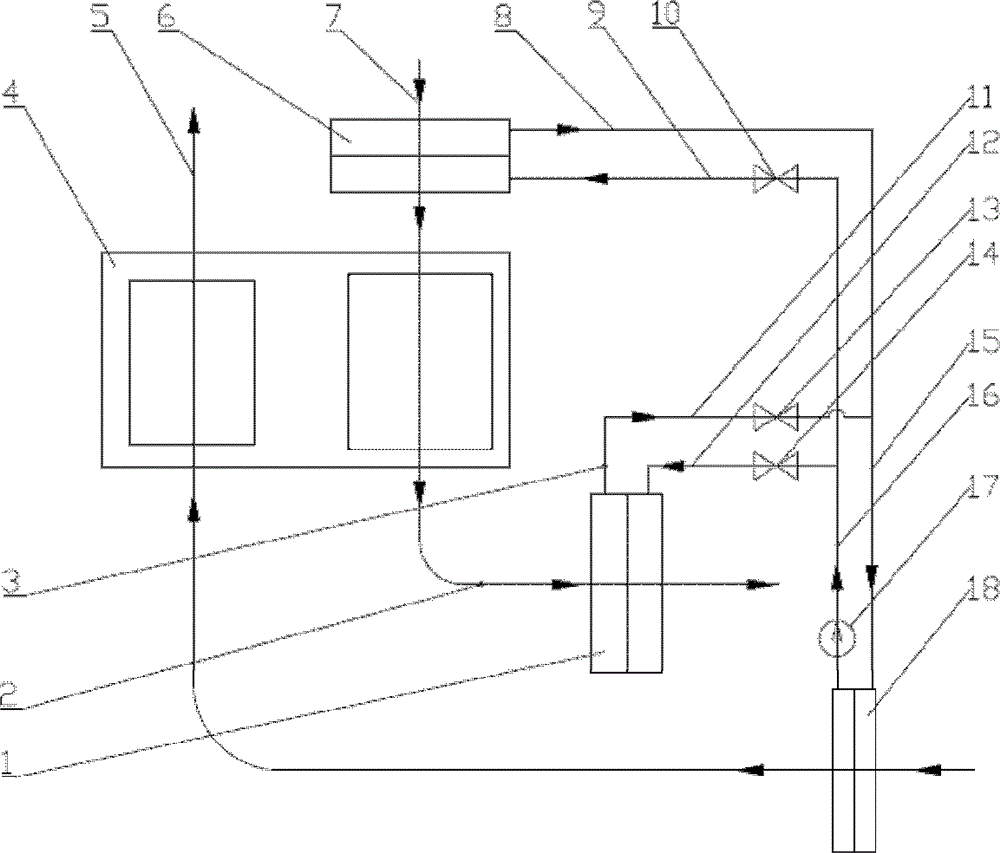

Controllable exhaust gas temperature sub-control phase change air preheating system and preheating method

InactiveCN102889611BIncrease wall temperatureLower exhaust gas temperatureCombustion processIndirect carbon-dioxide mitigationAir preheaterEngineering

The invention relates to a controllable exhaust gas temperature sub-control phase change air preheating system and a preheating method. The preheating system comprises an air preheater (4) and an air channel (5) communicated with the air preheater (4) and a fume channel (7), wherein the front of the air preheater (4) arranged on the air channel (5) is provided with a low-temperature heat release device (18) along an air flow direction; the front and rear of the air preheater (4) arranged on the fume channel (7) are respectively provided with a high temperature heat absorption device (6) and a low temperature heat absorption device (1) along a fume flowing direction; the low-temperature heat release device (18) and a main steam pipe (15) connected with a steam connecting box are respectively communicated with the high temperature heat absorption device (6) and the low temperature heat absorption device (1); and a condensed water main pipe (16) of a condensed water connecting box of the low-temperature heat release device (18) is respectively communicated with the high temperature heat absorption device (6) and the low temperature heat absorption device (1) through branch pipes. According to the change of coal and unit load in the invention, and the waste heat recovery volume and fume exhaust gas temperature are adjusted.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Android application program protection method and system based on instruction confusion

ActiveCN103324872BThorough protectionProgram/content distribution protectionConfusionApplication software

The invention discloses an Android application program protective method and system based on order confusion in the technical field of information safety. A permutation matrix needed when an application program is confused is generated, and binary codes of the Android application program are confused, so that the confused codes can not be reversed. A system mirror image document used for executing the confused application program is generated, a safe executing platform is set up, and the confused application program is executed. The Android application program protective system based on order confusion comprises a matrix generation module, an application program confusion module, an interpreter generating module, a system document generation module and an executing module. The Android application program protective method and system based on order confusion can effectively protect the Android application program from the attack of an attacker suck as reversing and tampering.

Owner:SHANGHAI JIAOTONG UNIV

Automatic defect detecting and sorting device for bowls and dishes

ActiveCN113333326AThorough protectionAccurate detection and sortingSortingStructural engineeringMechanical engineering

Owner:上海首坤智能科技有限公司

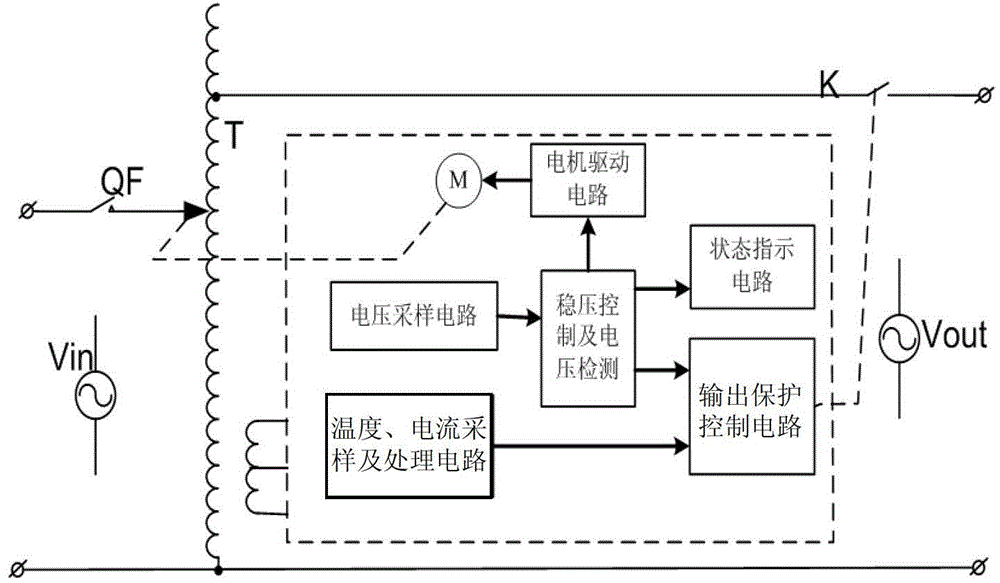

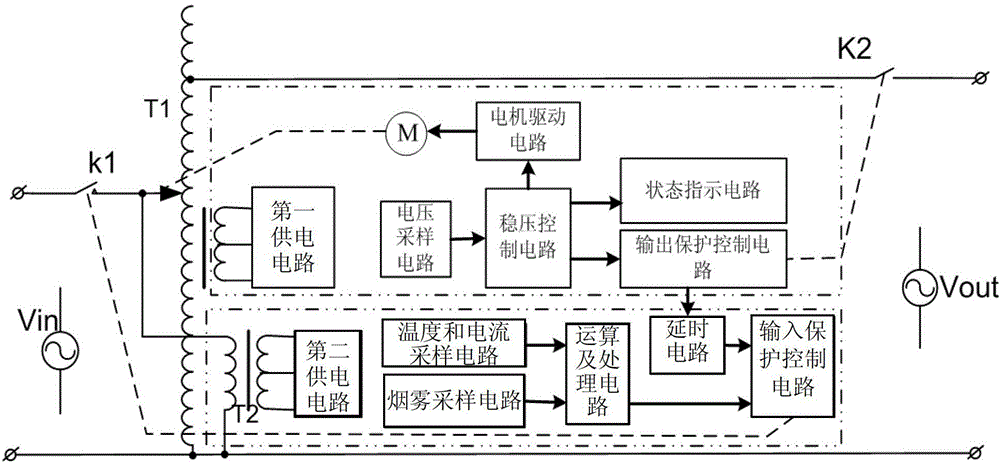

Novel voltage stabilizer with smoke sampling protection

ActiveCN103399613BGuarantee the safety of useImprove protectionElectric variable regulationTime delaysGas detector

A novel voltage stabilizer with smoke sampling protection comprises an output protection control circuit and an input protection control circuit. A voltage sampling circuit, a voltage stabilizing control circuit, a motor driving circuit, and a state indication circuit are arranged beside the output protection control circuit. A temperature and current sampling circuit, a smoke sampling circuit, a calculation and processing circuit, and a time delay circuit are arranged beside the input protection control circuit. The output protection control circuit is connected to the input protection control circuit through the time delay circuit. On abnormal conditions, a coil of an autotransformer T1 heats, the insulation of the coil is destroyed, carbon monoxide or hydrogen gas is given off, or smoke is generated, a gas sensor in the smoke sampling circuit collects carbon monoxide or hydrogen gas or smoke and converts carbon monoxide or hydrogen gas or smoke into electric signals, the calculation and processing circuit processes and amplifies the signals, a switch K1 of the input end of the voltage stabilizer is turned off through the input protection control circuit, the coil of the autotransformer T1 cuts off electricity, and then failures can not further expand, so that the purpose of reliable protection is achieved.

Owner:温州正泰电源电器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com