Automatic defect detecting and sorting device for bowls and dishes

A defect detection, fully automatic technology, applied in sorting and other directions, can solve problems such as taking mistakes, breaking porcelain such as bowls and dishes, and increasing the defective rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

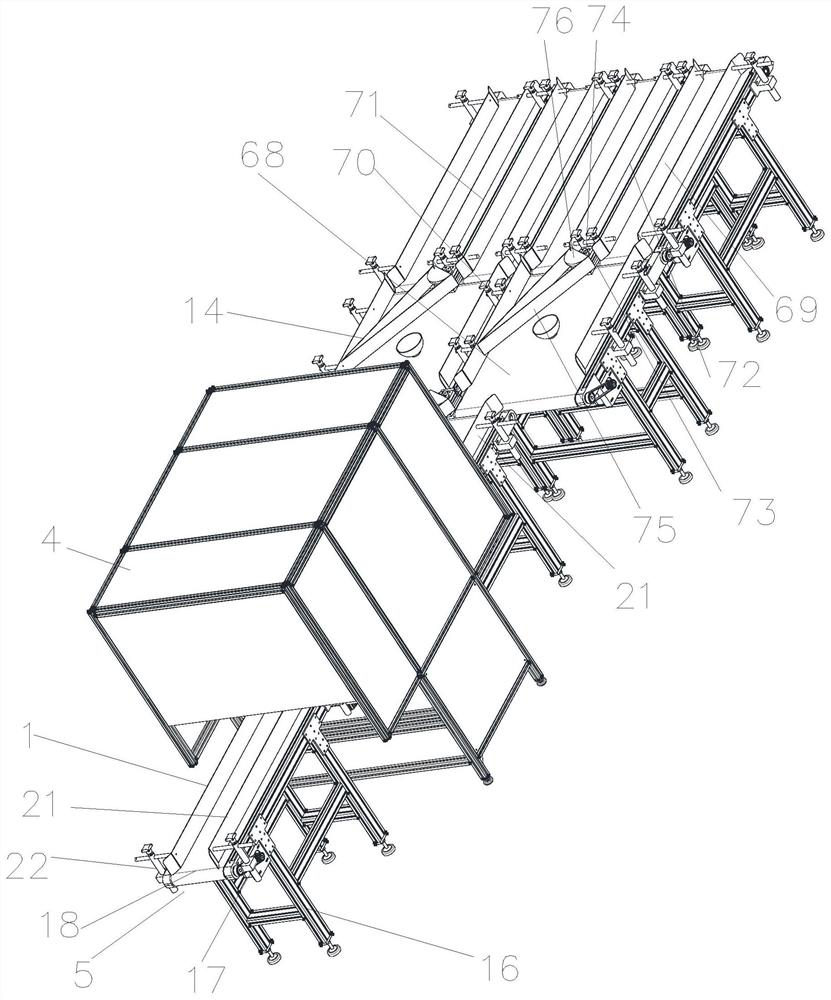

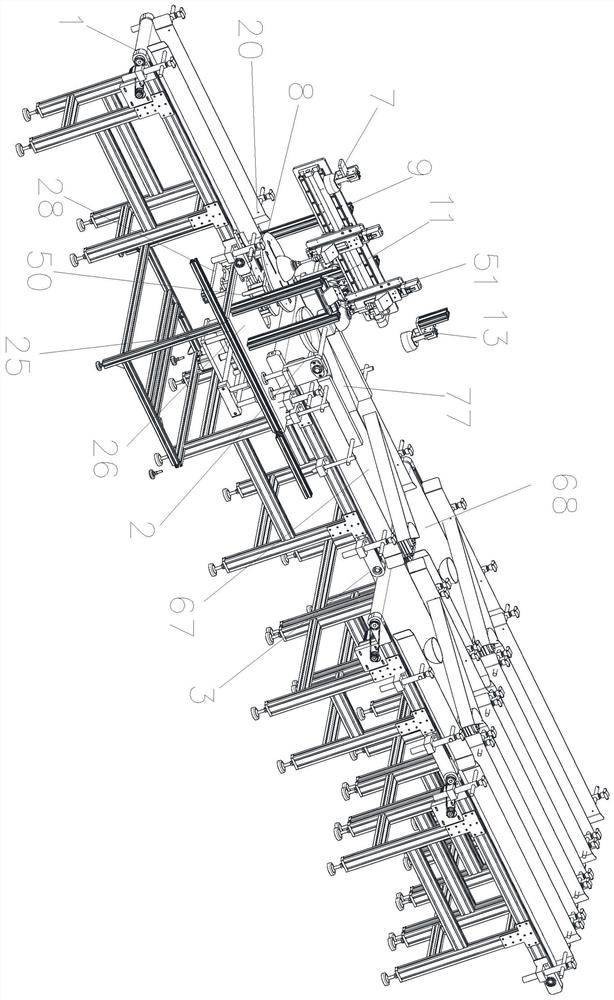

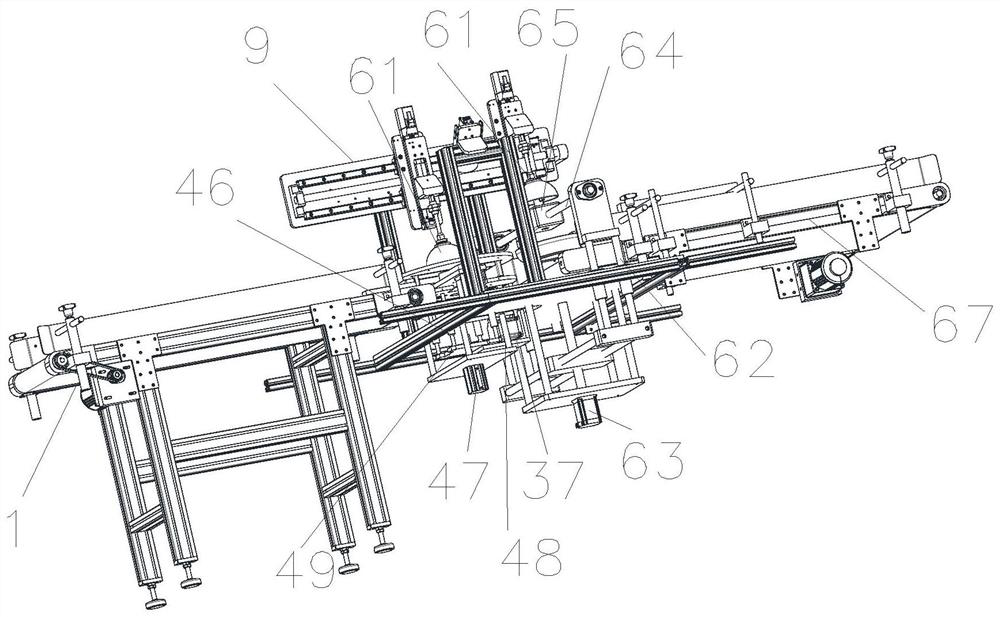

[0027] Embodiment 1 refers to the appended Figure 1-10 , Automatic defect detection and sorting equipment for dishes, including: feeding device 1, turning device 2 and diverting device 3, one side of the feeding device is the feeding port 5, the other side is the first detection port 6, the first detection There is a first detection camera 7 vertically facing the first detection port at the mouth, and a positioning turntable 8 is provided between the top of the first detection port and the overturning device to transport dishes from the first detection port to the positioning turntable and then to the overturning device The conveying device 9, the center of the positioning turntable is the second detection port 10, the side of the positioning turntable is provided with a second detection camera 11, the lower end of the overturning device is provided with a shunt device 3, and the place where the shunt device is close to the overturning device is the third detection port 12, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com