Controllable exhaust gas temperature sub-control phase change air preheating system and preheating method

A technology of air preheating and exhaust gas temperature, which is applied in combustion methods, lighting and heating equipment, indirect carbon dioxide emission reduction, etc., and can solve the problems of difficult control and stability of phase change parameters, high pressure of high-temperature heat-absorbing devices, and reduced equipment safety and other issues, to achieve the effect of thorough protection, improved low-temperature corrosion resistance, and reduced maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

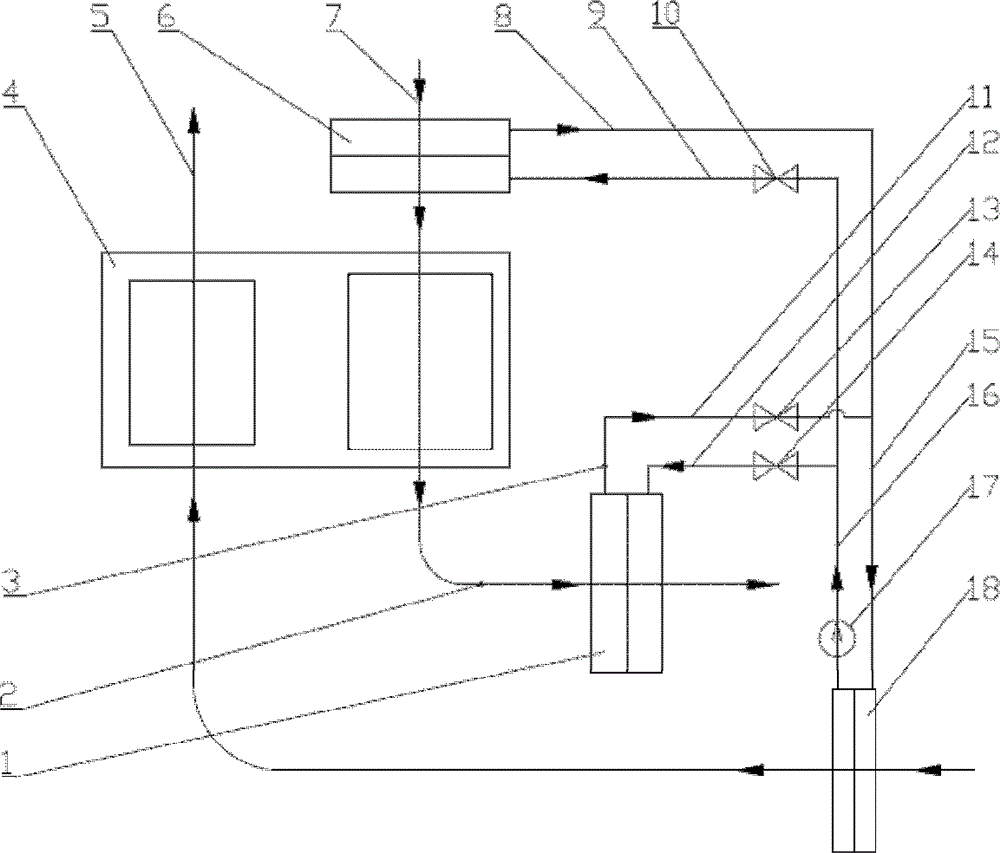

[0051] A separate control phase change air preheating system with controllable exhaust gas temperature proposed by the present invention is shown in the attached figure 1 As shown, the main equipment includes: low-temperature heat absorbing device 1, air-conditioning flue gas temperature sensor 2, low-temperature heat absorbing device parameter sensor 3, air preheater 4, air channel 5, high-temperature heat absorbing device 6, flue gas channel 7, High temperature heat absorbing device steam pipe 8, high temperature heat absorbing device condensate water pipe 9, high temperature heat absorbing device condensate regulating valve 10, low temperature heat absorbing device steam pipe 11, low temperature heat absorbing device condensate water pipe 12, low temperature heat absorbing device steam regulating valve 13 , Low-temperature heat absorbing device condensate regulating valve 14, steam main pipe 15, condensate water main pipe 16, circulation pump 17 and low-temperature exothermi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com