Aluminum alloy stud welding method to remove oxidation film with vapor state brazing flux

A technology of removing oxide film and welding method, applied in welding equipment, welding/welding/cutting items, arc welding equipment, etc., can solve the problems of affecting joint strength, low stud welding quality, and many welding joint defects, etc. The effect of molten pool fluidity, rich film removal mechanism, and thorough molten pool protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

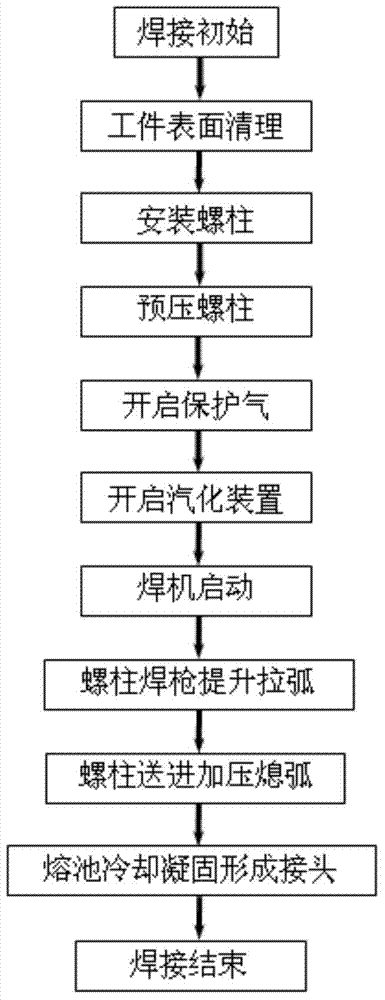

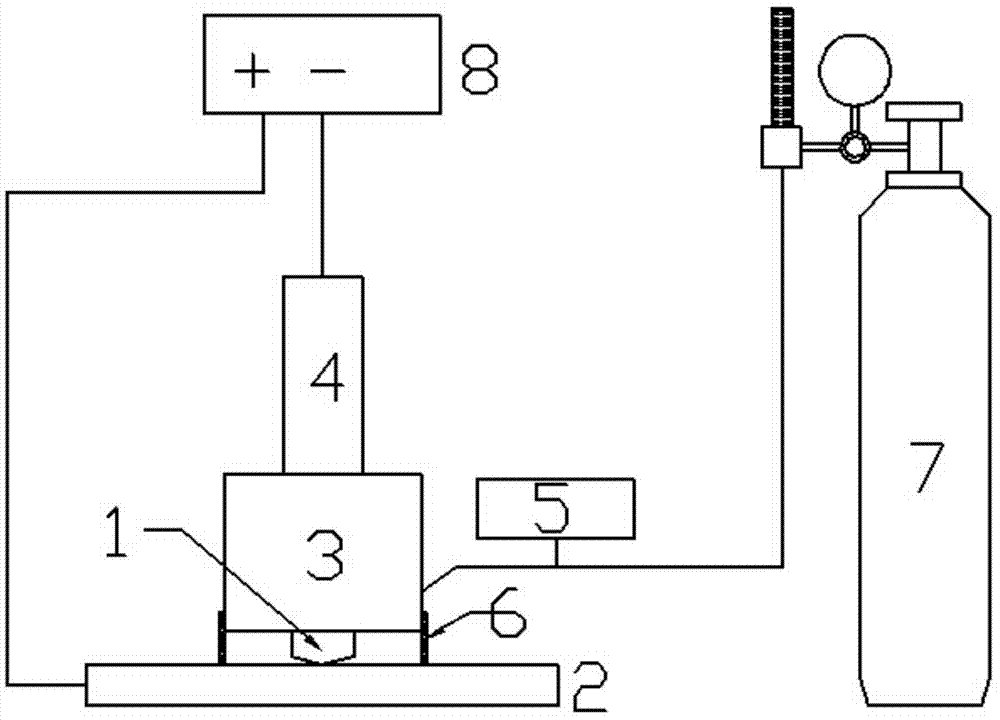

[0025] combine figure 1 , figure 2 , a kind of aluminum alloy stud welding method that utilizes vapor state brazing flux to remove oxide film of the present invention, comprises the following steps:

[0026] Step 1, processing the end to be welded of the aluminum alloy stud 1 into a surface with a cone angle of 150°.

[0027] Step 2, preparing flux, the flux used is made of KF, AlF 3 , ZnF 2 , KCl are mixed according to the mass ratio of 39:56:0.3:14.7, the mixed powder is a nano-powder with a minimum particle size of 25-40nm (drying temperature is controlled at 200°C), and the organic solvent used is ethylene glycol. The flux used is obtained by mixing the mixed powder with an organic solvent. The organic solvent component in the flux can be completely volatilized above 500°C without carbon deposit residue, and the composite flux component is completely melted to remove the oxide film at the molten pool.

[0028] Step 3: Mechanically clean and polish the surfaces of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com