Laser marking equipment

A laser marking and laser marking technology, which is applied to laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of increasing workload and reducing work efficiency, and achieve the effects of avoiding friction, protecting thoroughly, and improving marking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

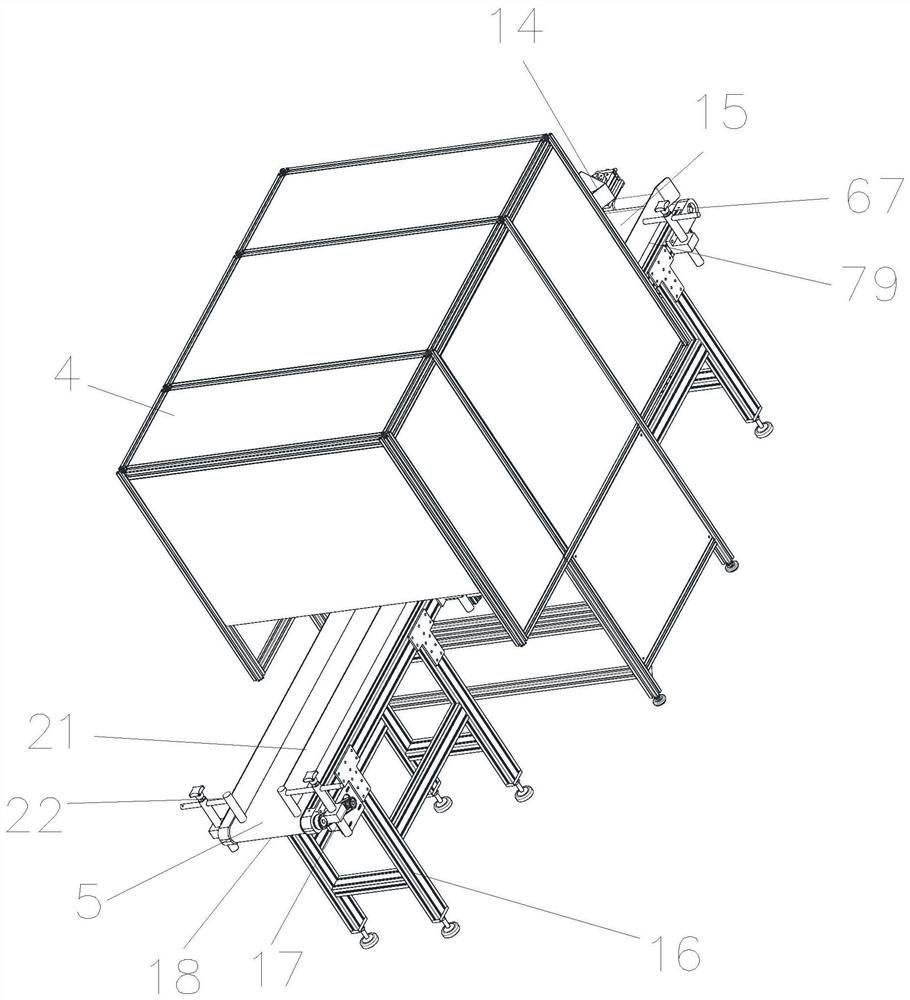

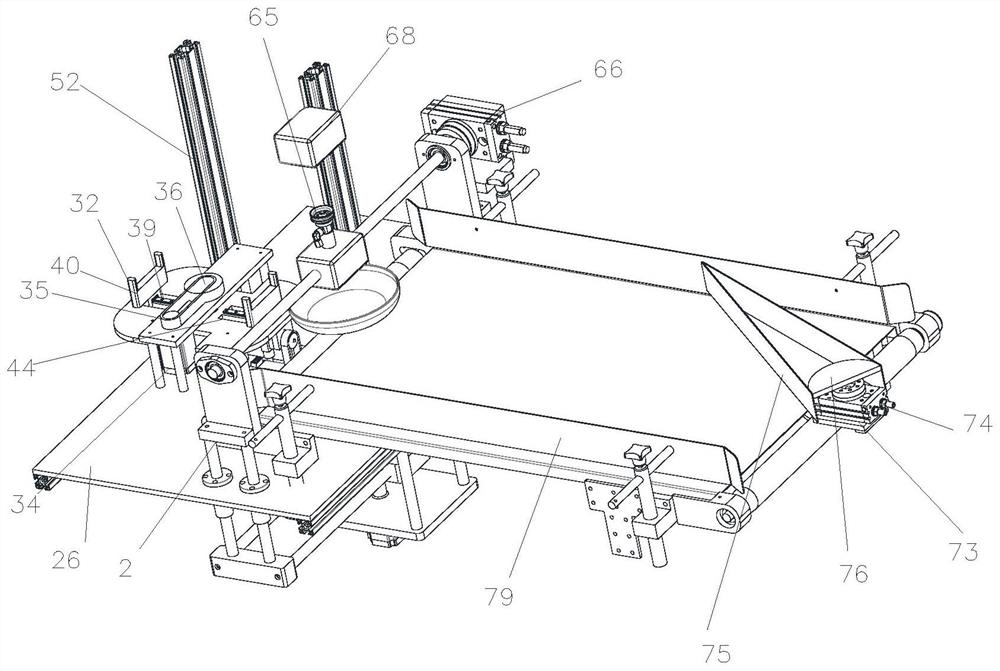

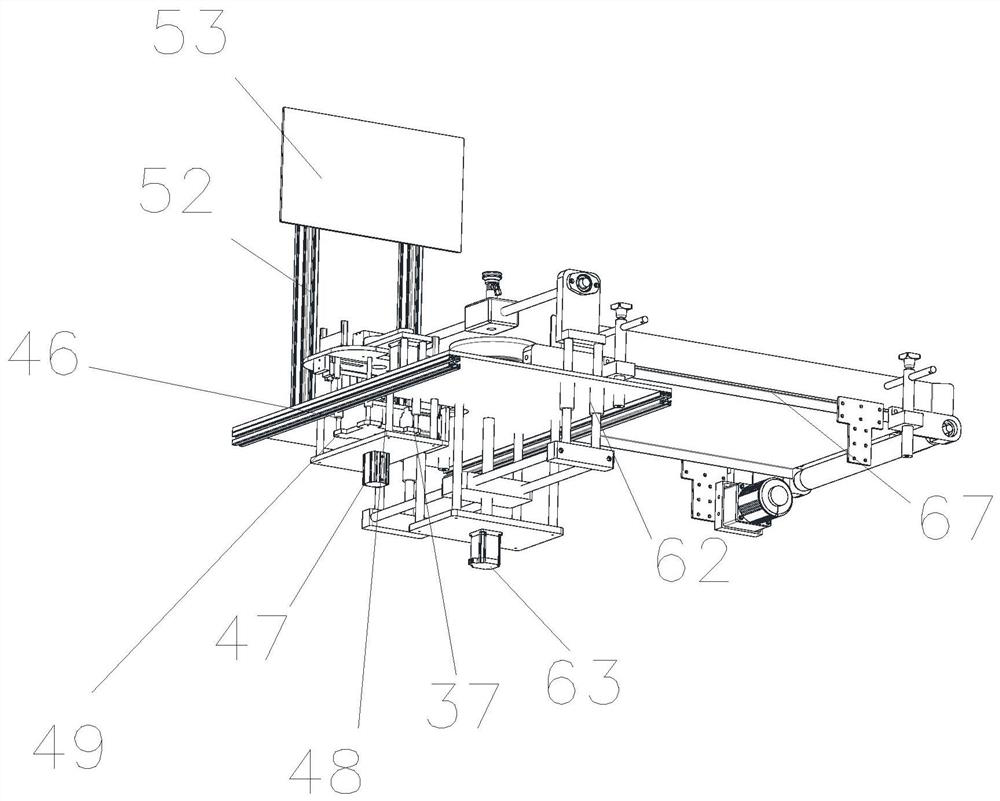

[0030] Embodiment 1 refers to appended Figure 1-13 , laser marking equipment, including a feeding device, a product identification device 11 and a laser marking device 68, one end of the feeding device is a feeding port 5, and the other end is a first transfer port 6, and a laser marking device is provided behind the first transfer port device, a connection and diversion device 3 is provided behind the laser marking device, a positioning turntable is provided between the first transfer port and the laser marking device, and a conveying device 9 for transporting products from the first transfer port to the positioning turntable and then to the laser marking device , the side of the positioning turntable is provided with a product identification device, and the feeding device includes a feeding bracket 16, a first transmission motor 17, a conveyor belt assembly 16, an inclined baffle 21 and an L-shaped support frame 1, and one end of the L-shaped support frame is a vertical sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com