Dual-sprayer rapid forming system for environmentally sensitive function gradient materials

A functionally graded material, environment-sensitive technology, applied in the direction of liquid material additive processing, additive processing, coating devices, etc., can solve the problem of thickness and length limited printer nozzle fusion and stepping system, limited intelligent structure and intelligent Material design, issues affecting the quality of the printed model, etc., to achieve the best environment-sensitive functional gradient effect, flexible preparation of material components, and optimization of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

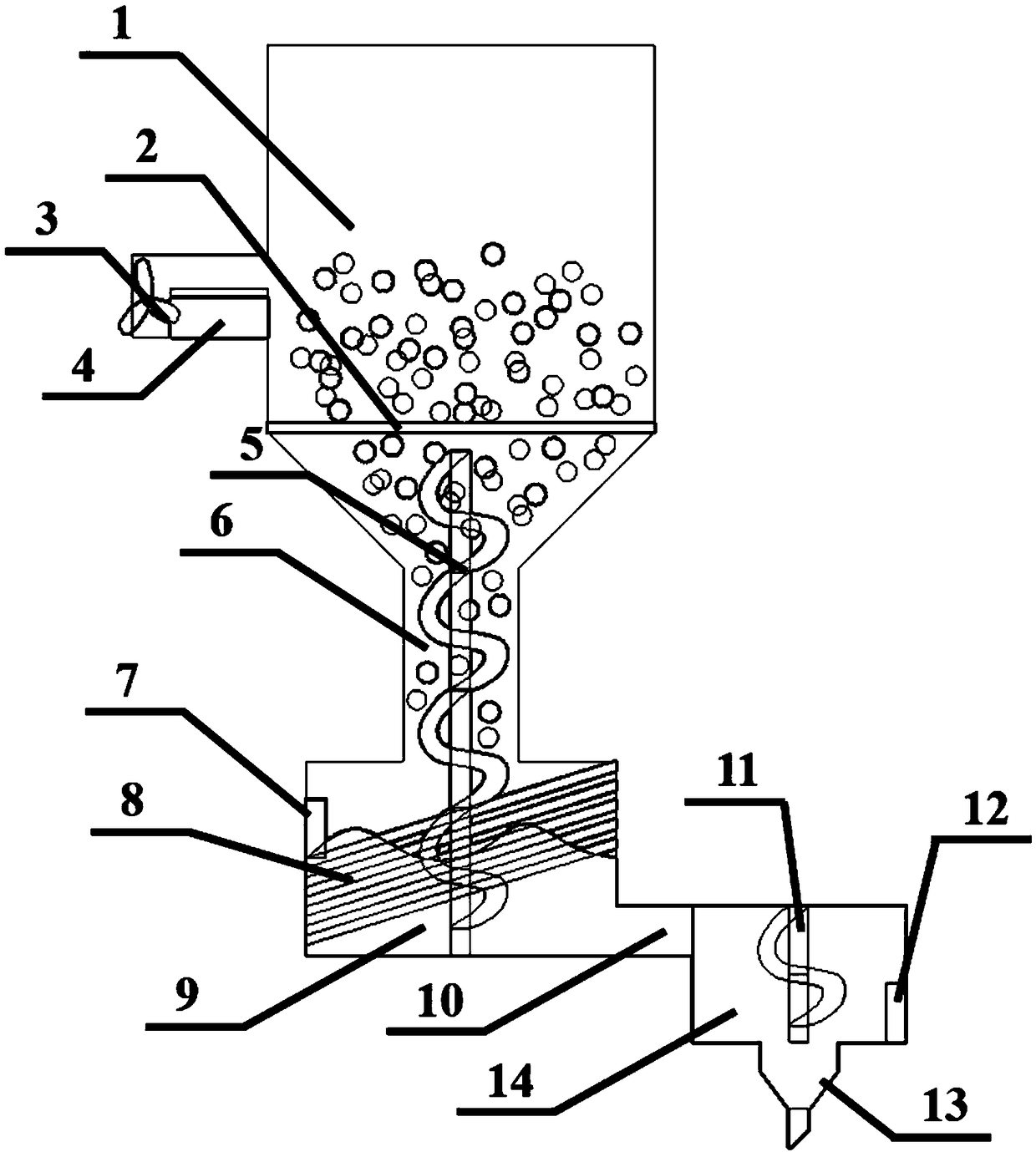

[0063] This embodiment is aimed at the dual nozzle rapid prototyping system of environmentally sensitive functionally graded materials, including a control unit, a printing platform, a frame frame 21 and two nozzle units, the two nozzle units are fixed side by side above the printing platform, the printing platform and two The nozzle units are all fixed on the frame frame, and the control unit is used to control the printing platform to move up and down, and at the same time, it can control the two nozzle units to perform feeding, heating, extrusion and other actions; each nozzle unit includes a feeding and mixing mechanism , heating mechanism and extrusion mechanism:

[0064] The feed mixing mechanism includes a feed hopper 1 , a toner box 4 connected to the feed hopper 1 , a powder blower 3 , a feed partition plate 2 , a feed pipe 6 , and a mixing and conveying screw 5 . The feed hopper 1 is a cylinder with a height of 20 cm and a radius of 10 cm that runs through the trough...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com