Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Adjustable time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

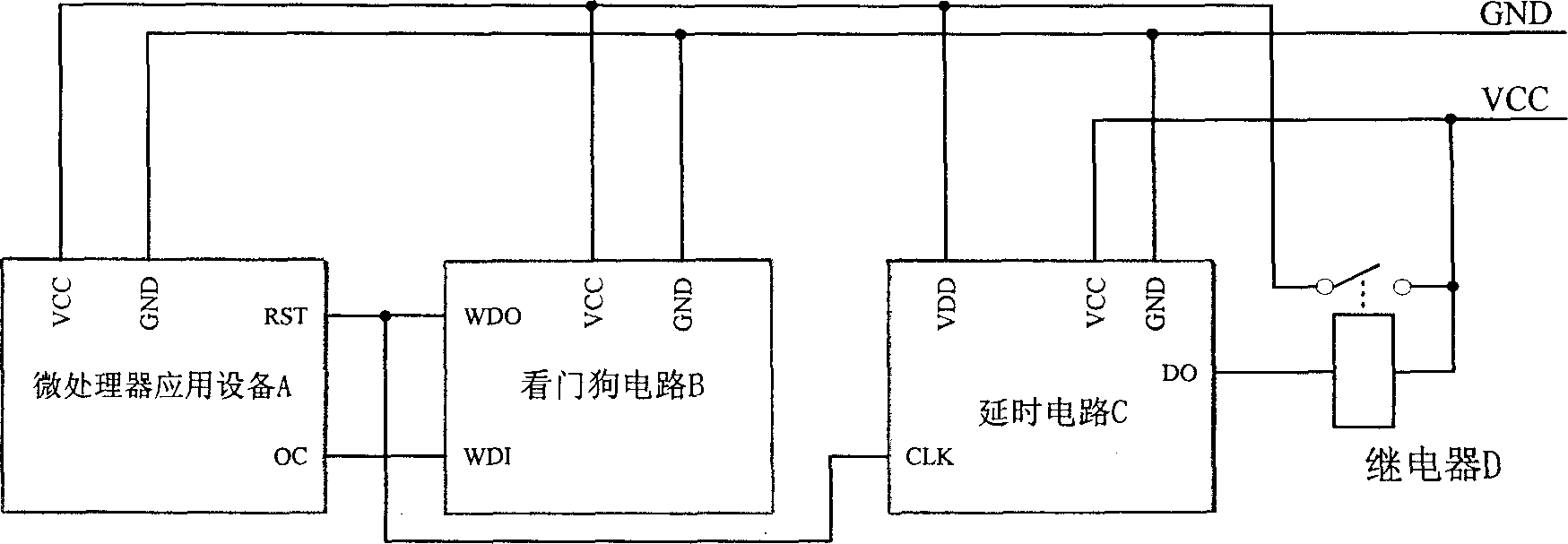

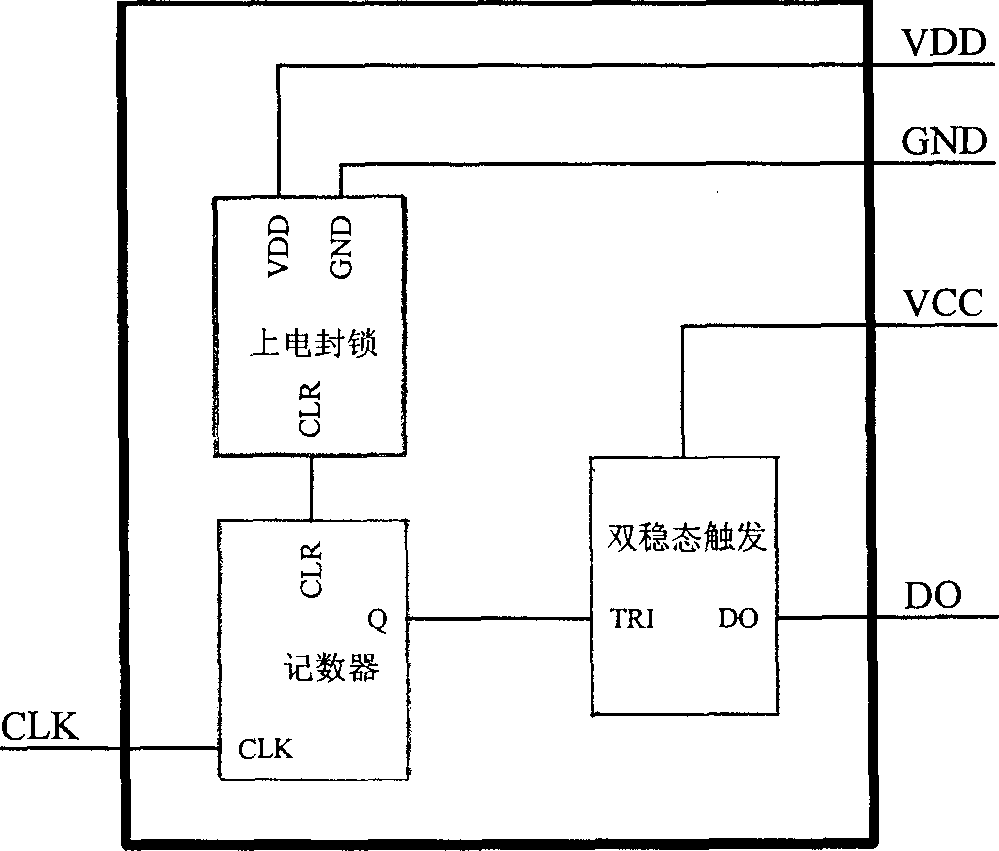

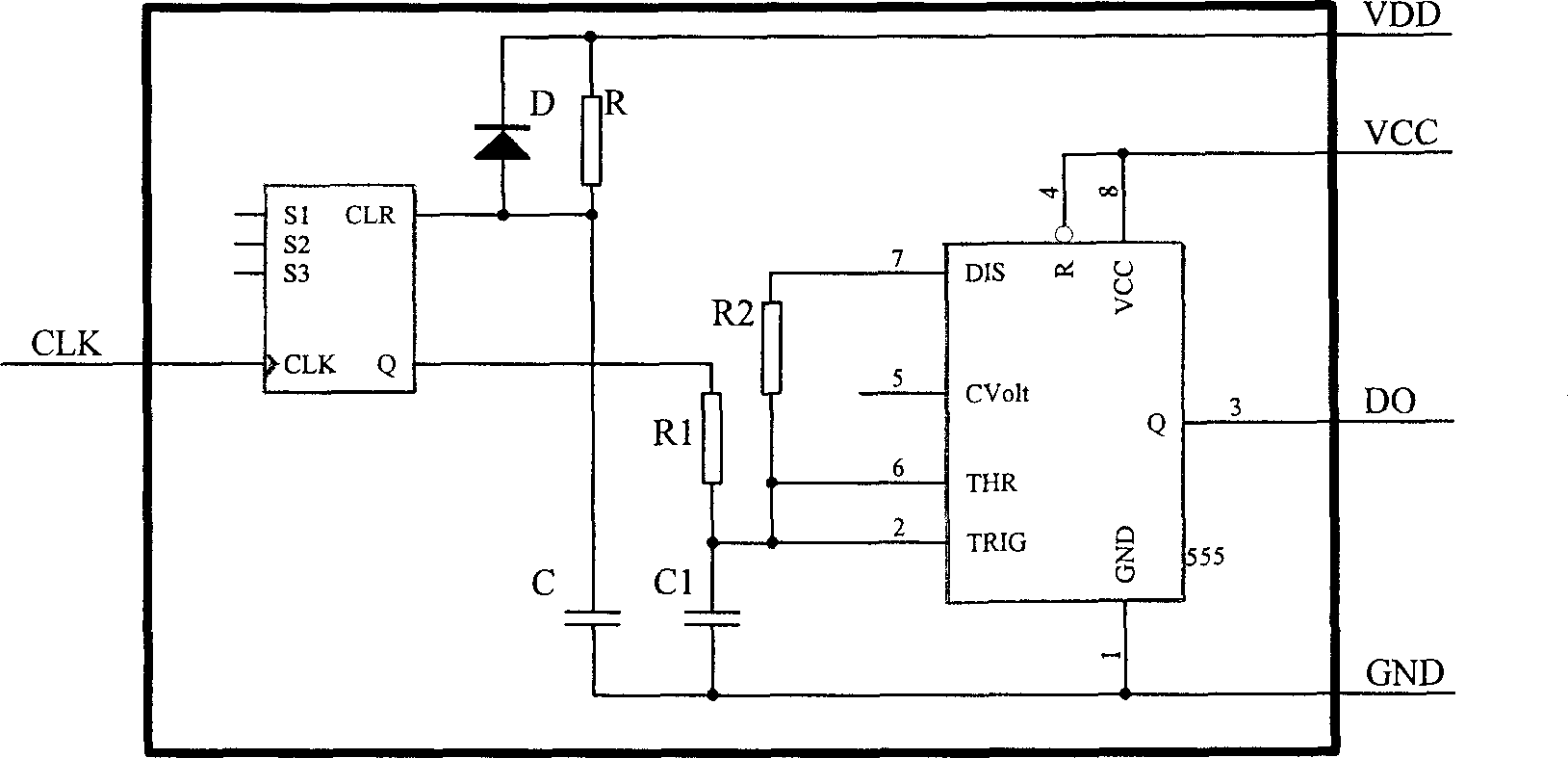

Automatic power down rebooting device

An automatic restart ¿C up device from power failure adds a delay circuit and a relay on hardware equipped with watchdog circuit. It is feature as triggering relay to act for cutting off power input end of microprocessor application device after certain amount of reset pulse is detected by delay circuit, restoring relay to be original state for reswitching on microprocessor application device after a period of time.

Owner:ZTE CORP

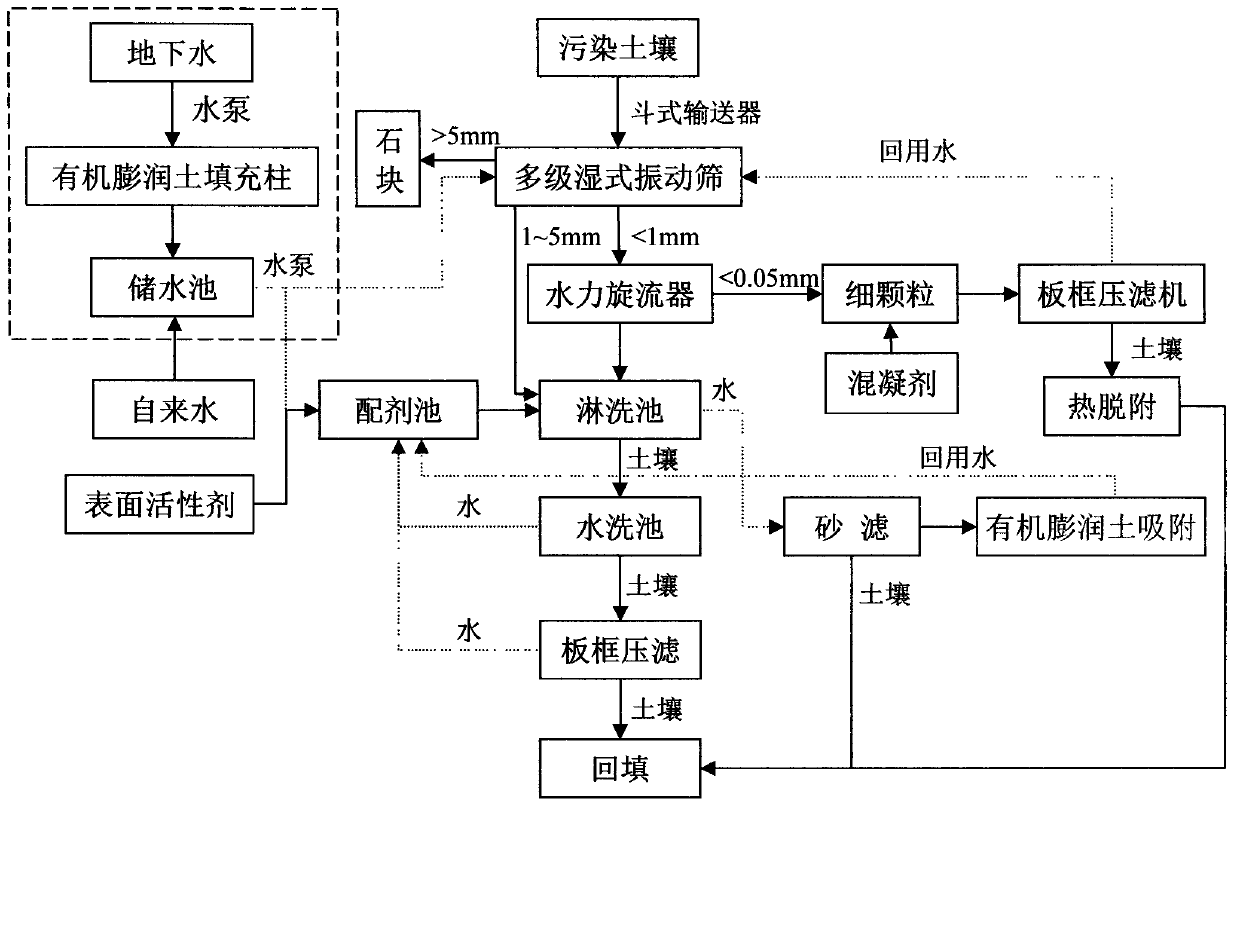

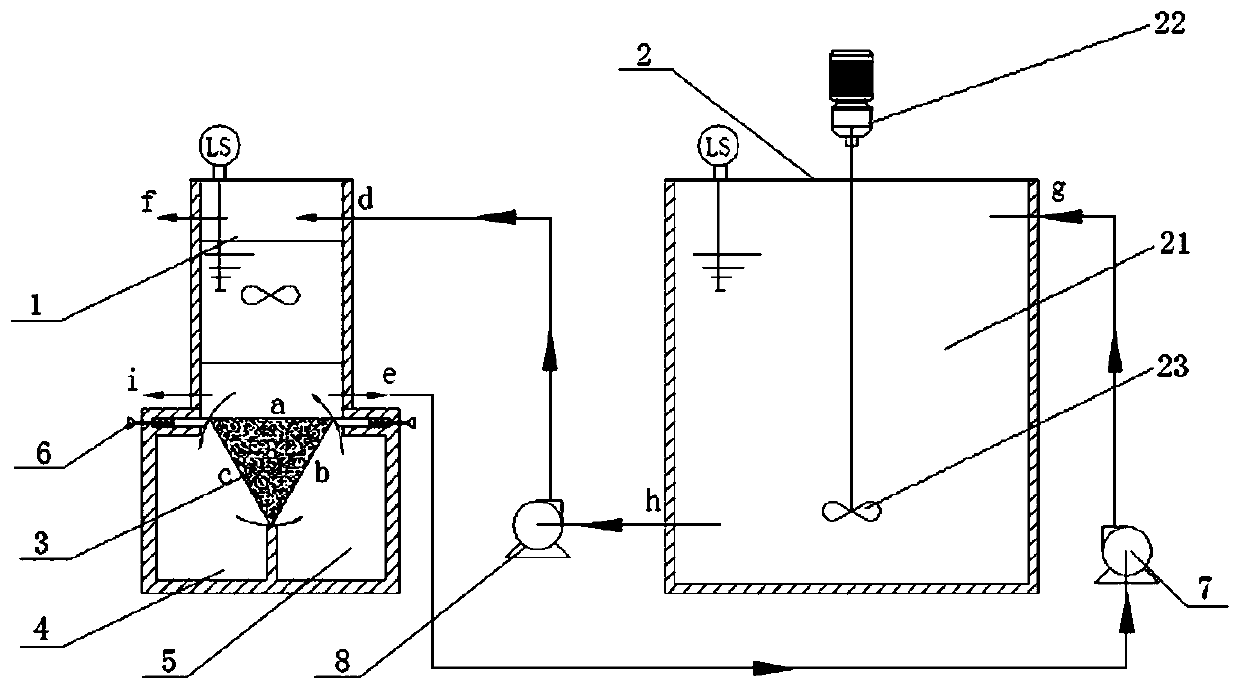

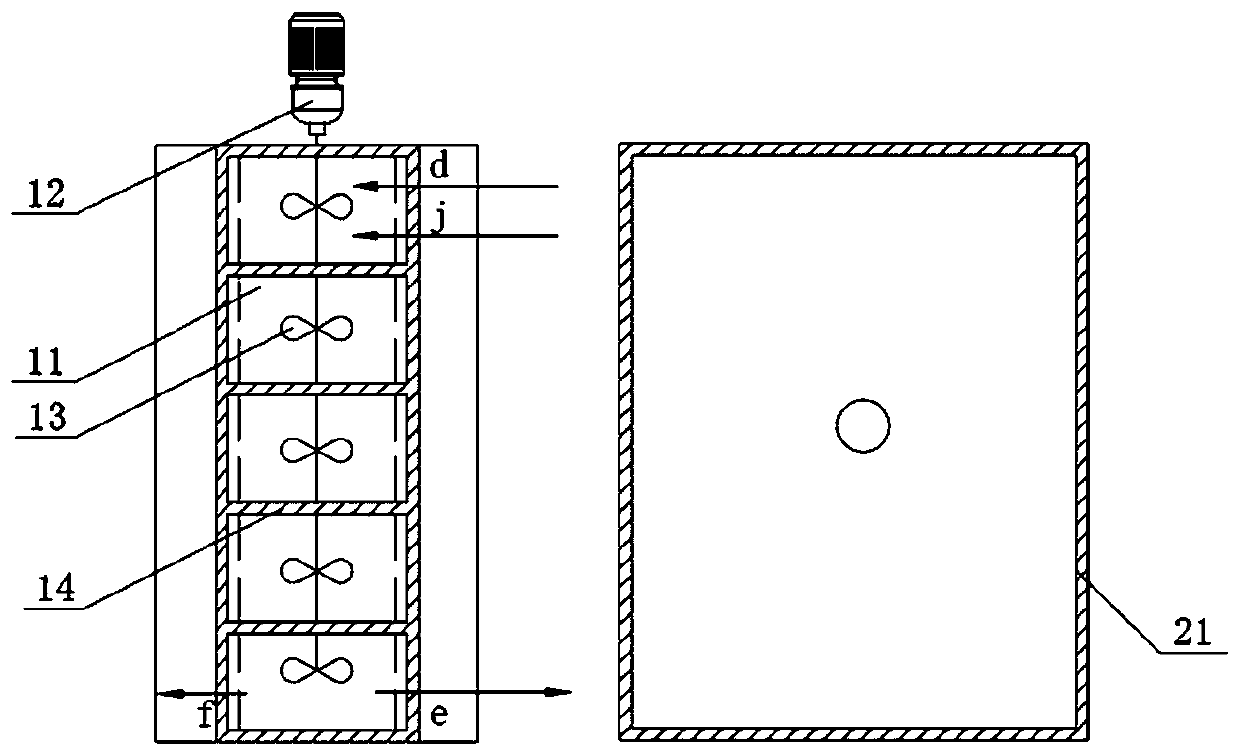

Polluted site underground water processing-soil ex-situ leaching restoration integral method

InactiveCN103230931AAdjustable dosageAdjustable stirringContaminated soil reclamationWater storage tankGroundwater remediation

The invention discloses a polluted site underground water processing-soil ex-situ leaching restoration integral method. The method comprises the steps that: extracted underground water is purified by using organic bentonite, and is discharged into a water storage tank and is used in a soil leaching process; with a multilevel wet vibration sieve, stones and coarse sand are separated from soil; a soil suspension liquid obtained by sieving enters a hydrocyclone; fine particles smaller than 0.05mm are processed and discharged into a frame filter press, and pollutants are removed with a thermal desorption method; particles larger than 0.05mm and the coarse sand are delivered into a leaching tank; a leaching liquid is a surfactant solution; stirring and ultrasonic processing are carried out, and standing sedimentation is carried out; upper-layer water phase is subjected to filtering and organic bentonite purification, and is discharged into a dispensing tank; lower-layer soil is delivered into a washing tank; stirring and ultrasonic processing are carried out, and standing sedimentation is carried out; soil phase is discharged into the frame filter press; and the soil reaches a standard and can be backfilled. With the method, underground water and soil synchronous restoration and leaching liquid recycling are realized. The method is easy to realize, and can be widely applied. The method can be used in polluted site soil and underground water restoration projects.

Owner:ZHEJIANG TAOHUAYUAN ENVIRONMENTAL PROTECTION TECH

Ecological restoration system for agricultural non-point source polluted farmland tail water

PendingCN107244739AAchieve serializationRealize the purpose of energy savingWater contaminantsWater aerationWater flowEngineering

The invention provides an ecological restoration system for agricultural non-point source polluted farmland tail water. The system comprises a compound biological purification bed, wherein the compound biological purification bed is sequentially divided into an anaerobic section, an anoxic section and an aerobic section in the horizontal direction; the anaerobic section and the anoxic section are separated by a first partition plate provided with a water flow hole; the anoxic section and the aerobic section are separated by another first partition plate provided with a water flow hole; a height difference is formed between the water inlet and the water outlet of each of the anaerobic section, the anoxic section and the aerobic section; the anaerobic section and the aerobic section are filled with a filler for biofilm formation; the anoxic section is divided into n+1 sections by n guide plates provided with water flow holes; a height difference is formed between the water inlet and the water outlet of each section in the anoxic section; and an aeration pipe is further arranged in the aerobic section. The ecological restoration system achieves the effects of continuous purification process, adjustable biological treatment time, no need of sewage pumping, energy saving and consumption reduction. The compound biological purification bed is combined with other units to form a better ecological restoration system which is formed by sequentially connecting a grassed swale, a desilting basin, a simulated ecological ditch, a bioretention pond, the compound biological purification bed and an ecological system pond. The preferred system is more comprehensive in treatment process and higher in purification efficiency.

Owner:HUNAN AIRBLUER ENVIRONMENTAL PROTECTION TECH

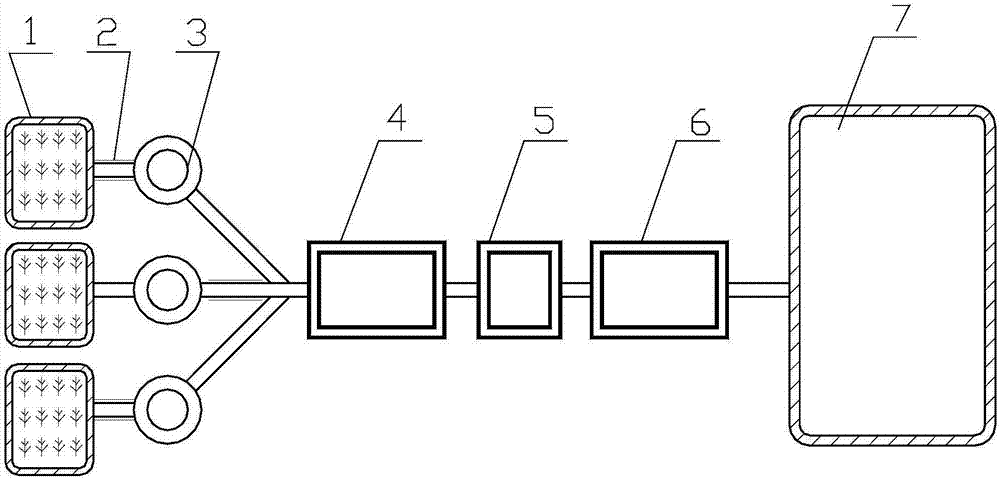

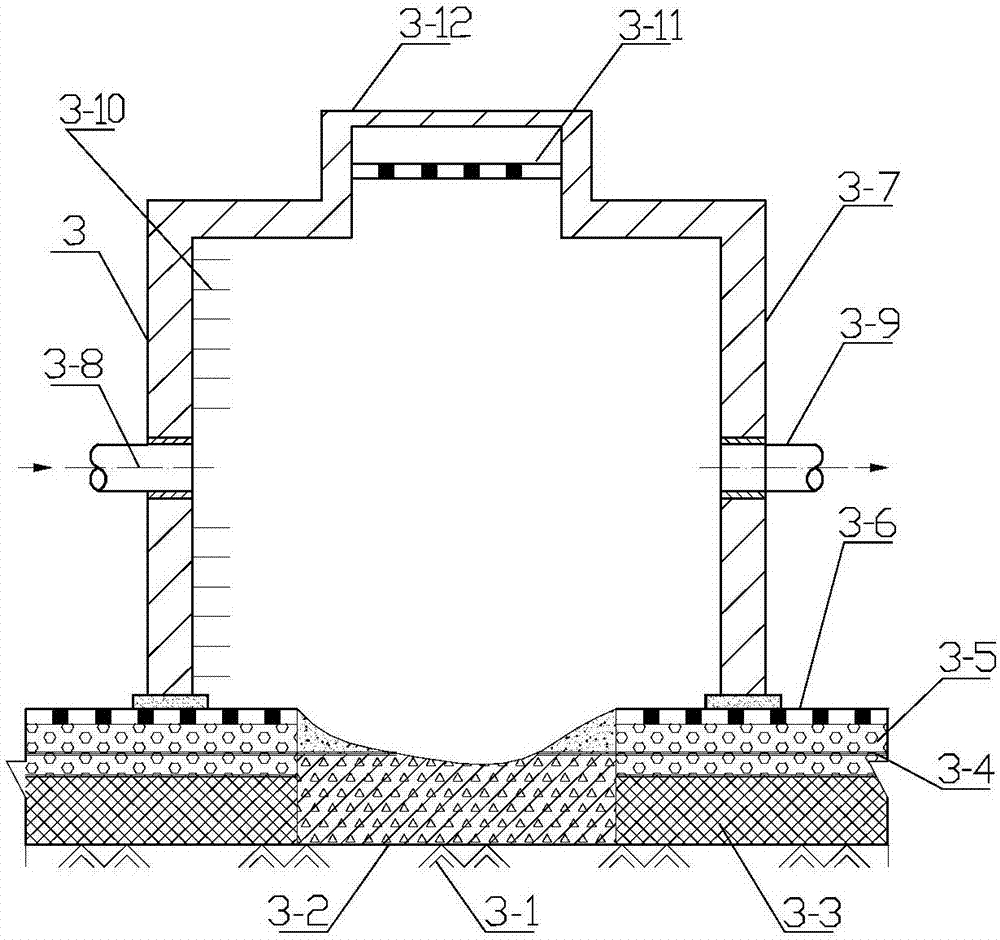

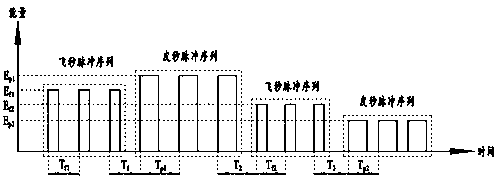

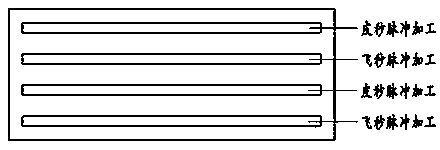

Processing method for micro-nano structure of array of ultrafast laser combined pulse sequence

InactiveCN109079314AAdjustable timeImprove processing efficiencyLaser beam welding apparatusMicro nanoPicosecond laser

The invention provides a processing method for a micro-nano structure of an array of an ultrafast laser combined pulse sequence. The processing method comprises the following steps: grinding and polishing and cleaning and drying the surface of a workpiece, and fixing the workpiece to an ultra-precision platform; starting a laser generator through a laser controller to emit a laser beam by means ofan industrial control computer and adjusting the ultra-precision platform to determine a workpiece processing region till the surface of the workpiece is focused by laser; during processing, selecting a femtosecond laser or a picosecond laser through a laser controller to emit the laser beam to achieve ultrafast laser pulse free combination through a light path switching module, and carrying outprocessing according to a needed micro-nano structure; and after processing, taking the workpiece down, and cleaning and drying the workpiece to obtain a finished product. The invention provides a novel combination mode of a laser processing process in micro-nano material processing. Femtosecond laser or picoseconds laser can be selected according to the processing demand, and an ultrafast laser pulse sequence can be combined flexibly by way of light path switching, so that the processing efficiency and quality of the micro-nano structure are improved effectively.

Owner:GUANGDONG UNIV OF TECH

Method and apparatus for growth of large size nonlinear optical crystal by copple and inoculating crystal

ActiveCN101503819AImprove cleanlinessWell mixedAfter-treatment apparatusFrom frozen solutionsNonlinear optical crystalEngineering

The invention relates to a method for growing a large size non-linear optic crystal through the linkage of a crucible and a seed crystal. In the growth process of growing the non-linear optic crystal through a molten salt method, the seed crystal is placed in a fused mass or on the surface of the fused mass; and the seed crystal and the crucible rotate synchronously and oppositely according to a certain rotation period. A device comprises a crystal growth device and a controller capable of driving the seed crystal and the crucible to rotate synchronously and oppositely according to the certain rotation period. The synchronous and contrarotational rotation period comprises the following steps: rotating acceleratively, rotating at a uniform speed, rotating deceleratively and stopping rotation in turn in a first direction; and then rotating acceleratively, rotating at a uniform speed, rotating deceleratively and stopping rotation in turn in a second direction opposite to the first direction. The synchronous and contrarotational rotation of the seed crystal and the crucible with an adjustable rotating speed facilitates the impurity removal in an early growth period of the seed crystal, grows a single crystal with a regular shape, and reduces or even eliminates the risk of the breaking of the seed crystal caused by an oversize moment resulting from the overweight of the seed crystal.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Retarding-type cement grinding aid

InactiveCN106082761AImprove early and late strengthSpeed up the flowPolyaspartic acidCement grinding

The invention relates to the technical field of cement additives, particularly a retarding-type cement grinding aid. The retarding-type cement grinding aid is prepared from the following raw materials in parts by weight: 18-28 parts of triethanolamine, 12-24 parts of diethanolisopropanolamine, 2-8 parts of sodium tartrate, 5-17 parts of coco fatty acid diethanol amide, 8-16 parts of sodium gluconate, 6-14 parts of polyaspartic acid and 50-70 parts of water. The retarding-type cement grinding aid has favorable retarding effect, can enhance the early strength and later strength of cement, and is beneficial to enhancing the impermeability and freeze-thaw resistance of hardened concrete.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

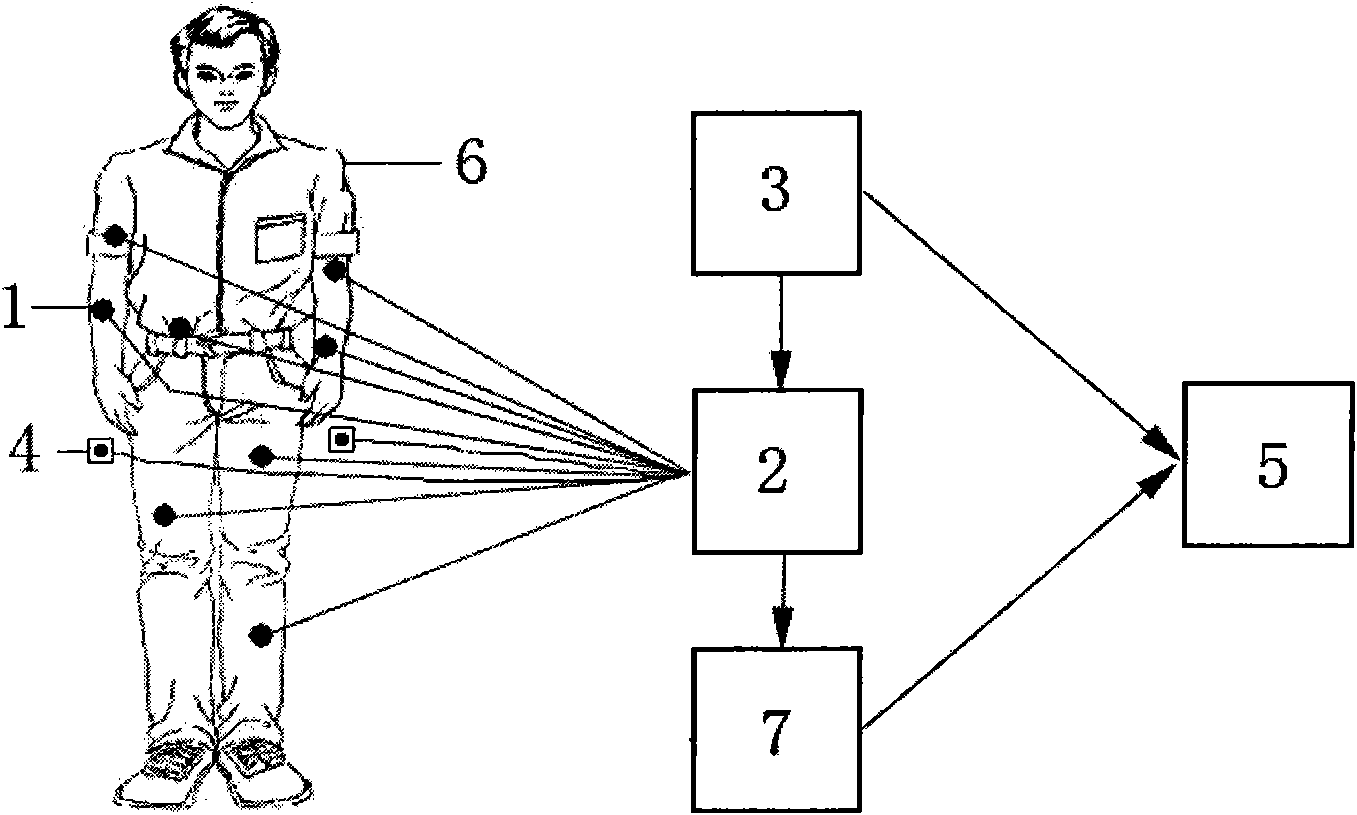

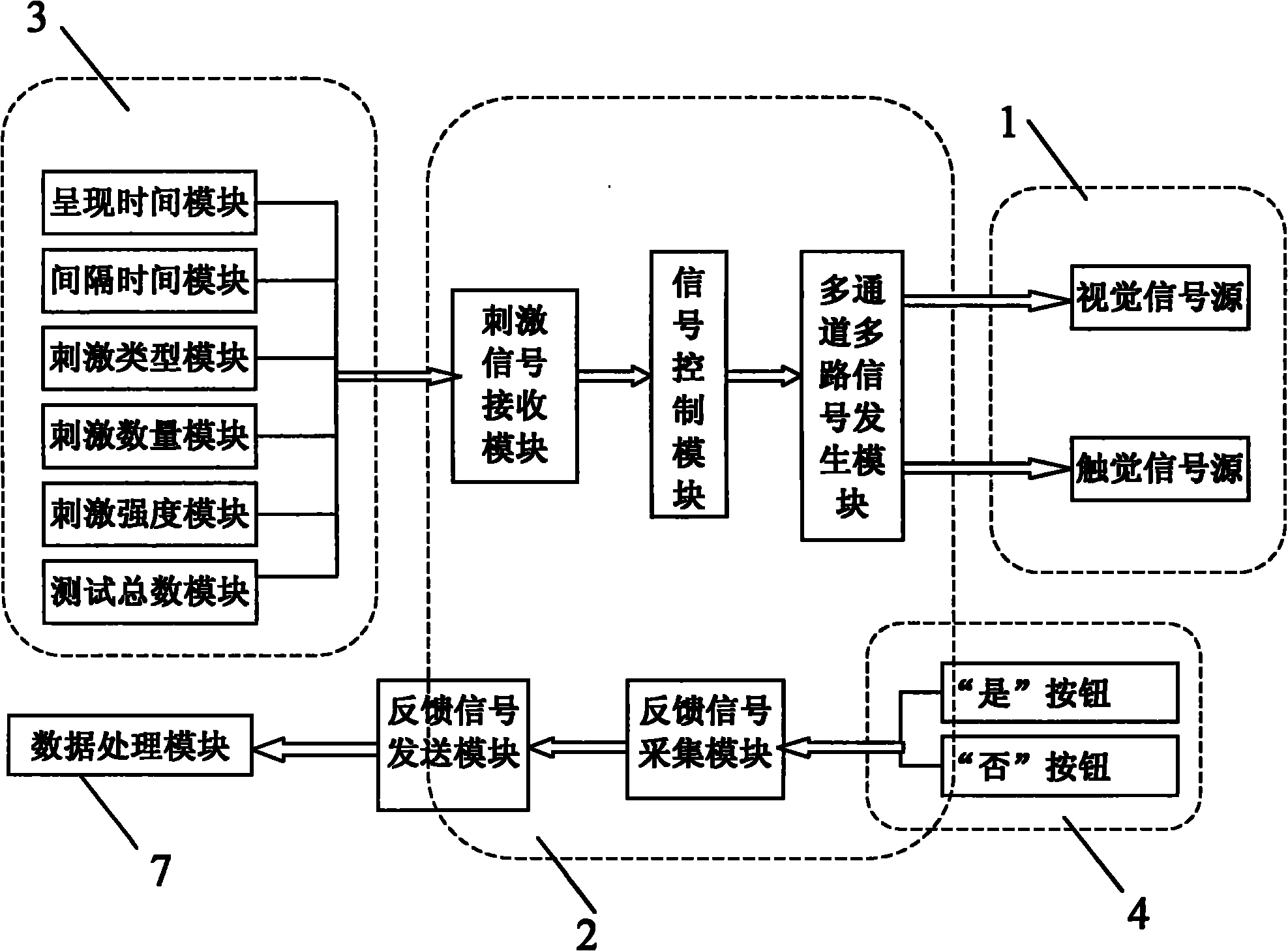

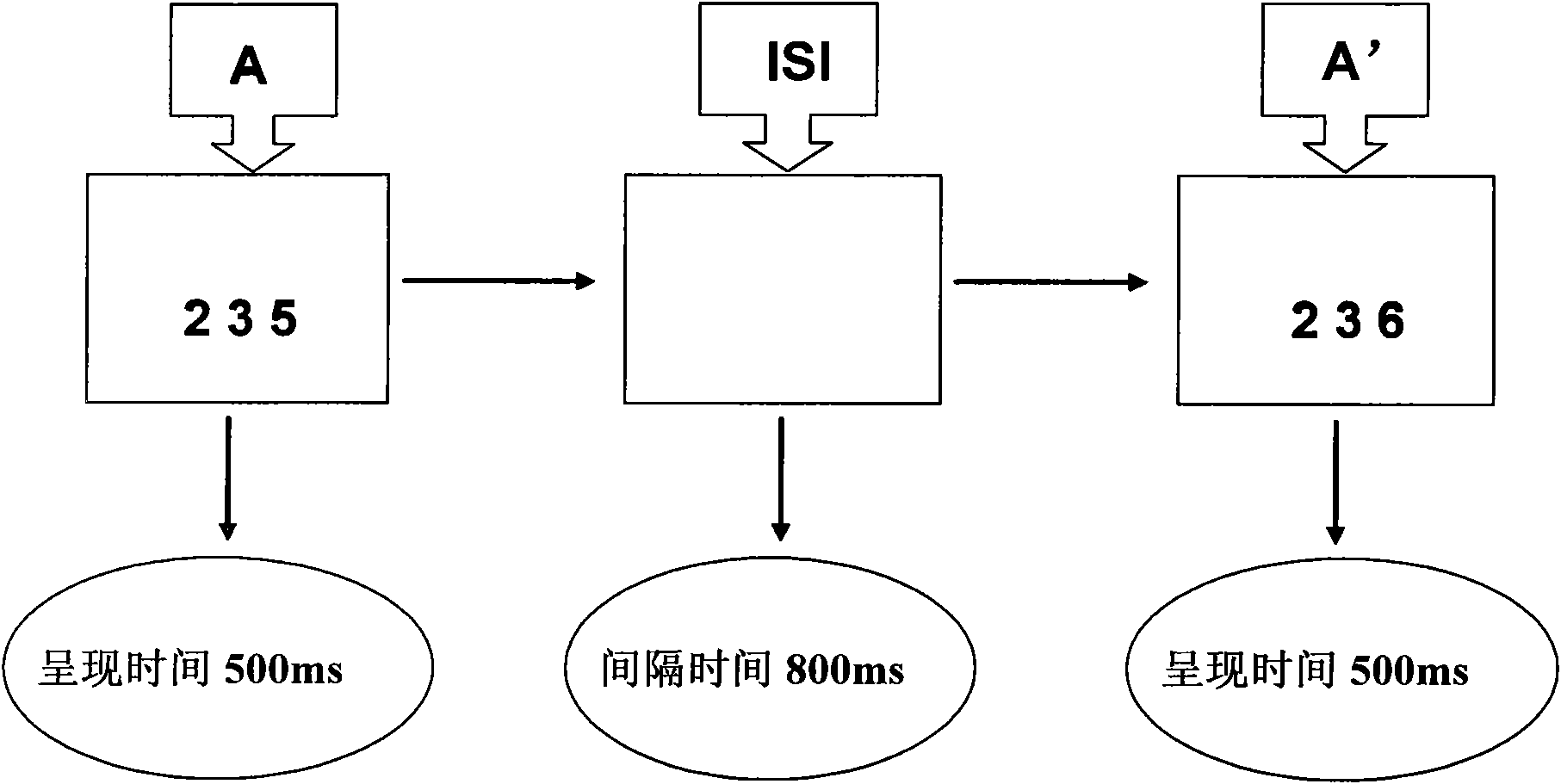

Vision and touch tester and visual and tactual sensitivity testing method

InactiveCN101972149AAdjustable stimulation intensityAdjustable timeSensorsPsychotechnic devicesTouch PerceptionHaptic memory

The invention discloses a vision and touch tester and a vision and touch sensitivity testing method. In the vision and touch tester, a parameter testing module of a parameter setting and signal generating module is respectively connected with the input end of a stimulating signal receiving module; the output end of the stimulating signal receiving module is connected with the input end of a signal control module; the output end of the signal control module is connected with the input end of a multi-channel multi-path signal generation module; the output end of the multi-channel multi-path signal generation module is respectively connected with a vision signal source and a touch signal source; a 'yes' button and a 'no' button are respectively connected with the input end of a feedback signal acquisition module; the output end of the feedback signal acquisition module is connected with the input end of a feedback signal sending module; and the output end of the feedback signal sending module is connected with a data processing module. Besides conventional vision, touch and double-channel combined tests, the invention also can realize the researches of touch alarms, sports touches, touch memories, vision and touch combined motion perception phenomena, and the like.

Owner:ZHEJIANG SCI-TECH UNIV

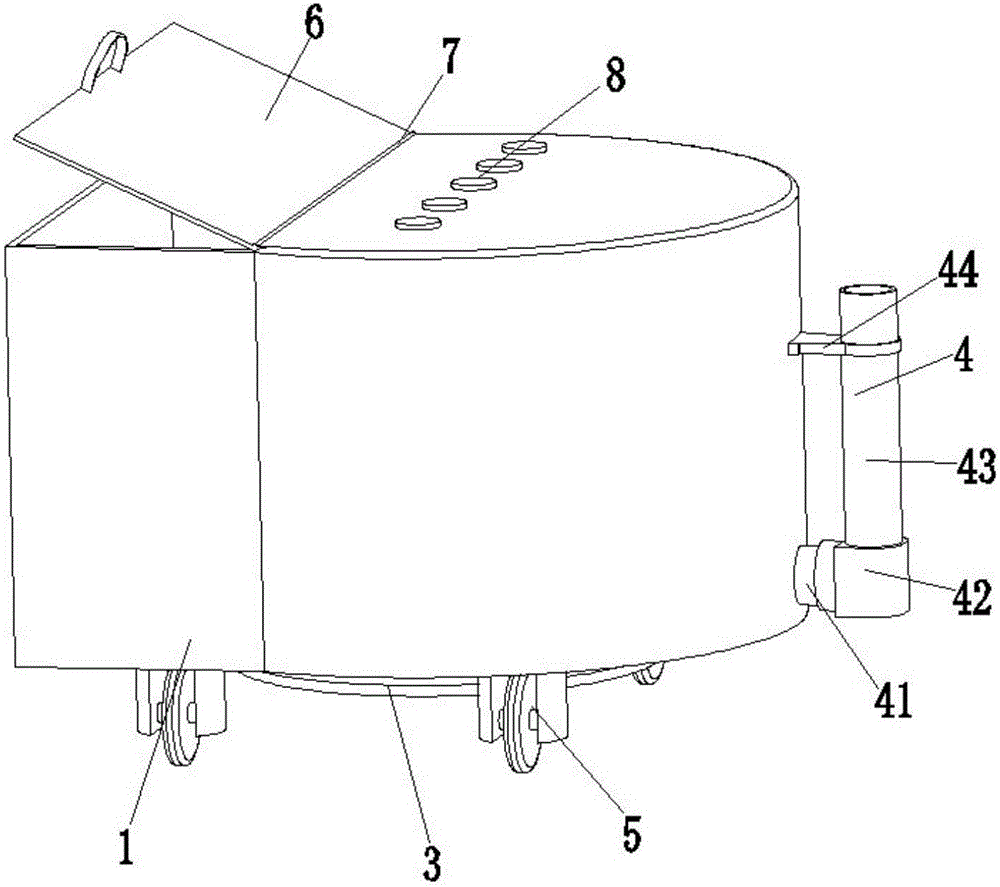

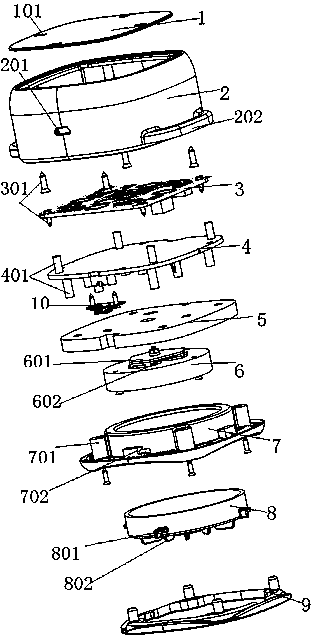

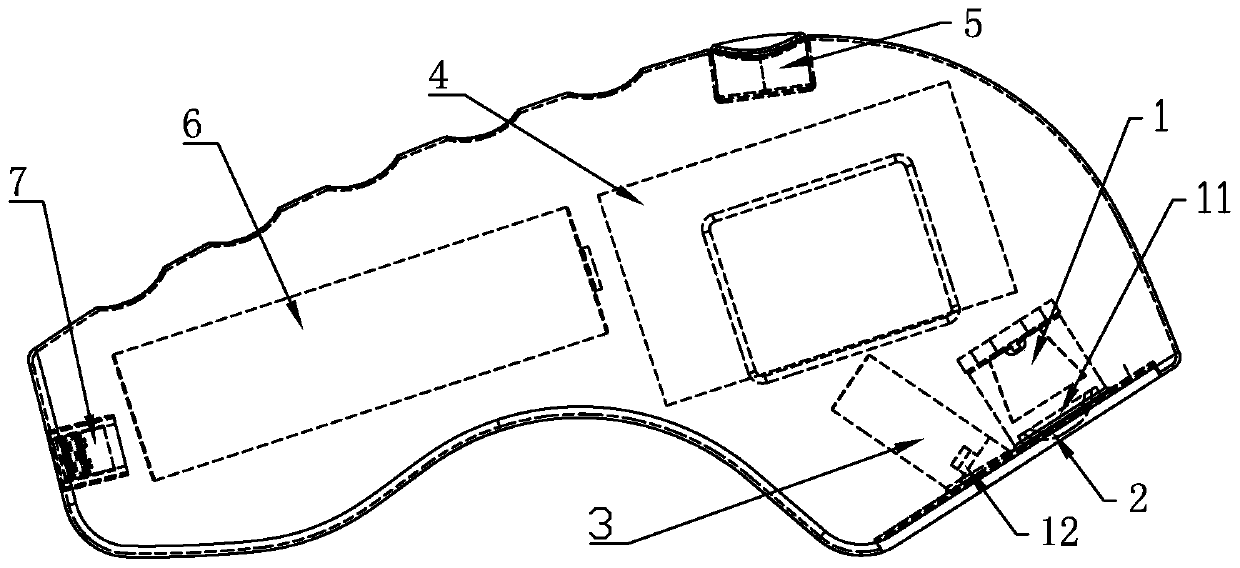

Intelligent foot tub having comprehensive massage functions

ActiveCN105963111AEasy to controlPrecise movement positionMechanical apparatusDevices for pressing relfex pointsWater storageMassage

The invention relates to an intelligent foot tub having comprehensive massage functions. The foot tub comprises a water storage barrel, massage devices, a heater, a water drainage device, universal wheels, a barrel cover, a hinge and adjusting switches, wherein the massage devices are located inside the water storage barrel; the heater is mounted at the lower end of the water storage barrel and is an electric heater; the water drainage device is mounted on the outer side wall of the back end of the water storage barrel; the universal wheels are uniformly and symmetrically mounted on the lower end surface of the water storage barrel; the barrel cover is located right above the front end of the water storage barrel and is connected with a semi-oval cover plate of the water storage barrel through the hinge; a handle is arranged on the barrel cover; the adjusting switches are mounted on the upper end surface of the semi-oval cover plate of the water storage barrel. The foot tub can massage soles and toes of human feet synchronously during foot bathing, the massage comprehensiveness is high, and the limitation that common foot massage devices can only massage a certain part of a foot is broken through; meanwhile, the heating water temperature, time and frequency are adjustable, simple and convenient drainage is realized, and the foot tub is more applicable to life at home.

Owner:芜湖康特电器股份有限公司

Flexible electric heating film heating layer and preparation method thereof

ActiveCN112566290AImprove adsorption capacityConductiveHeating element materialsChemistryCarbon nanotube

The invention discloses a flexible electric heating film heating layer containing a composite high-molecular polymer conductive framework material and a preparation method thereof, and the flexible electric heating film heating layer is prepared by dipping the composite high-molecular polymer conductive framework material in electric heating slurry, curing and then carrying out hot pressing treatment. The composite high-molecular polymer conductive framework material is a flexible porous material and has a continuous three-dimensional porous structure; and the material comprises a first high-molecular polymer, a second conductive high-molecular polymer (high-molecular conductive polymer), a doped graphene-based composite nanosheet material and a carbon nanotube. The flexible heating film heating layer prepared by the method can overcome the problems that an electric heating layer in the prior art is poor in interface bonding property and bending resistance, filler is easy to fall off,the material consumption of the heating layer is not adjustable and the like.

Owner:SHENZHEN DELONG ELECTRICAL APPLIANCE CO LTD

Hot cut sealing device of film coating equipment

PendingCN108298145AImprove stabilityAdjustable timeWrapper twisting/gatheringMechanical engineeringFilm-coated tablet

The invention discloses a hot cut sealing device of film coating equipment. The hot cut sealing device comprises an upper cutting device, a lower cutting device, a pressing stacking device and a filmpulling device. The hot cut sealing device is applicable to PE films and BOPP films. By means of optimization of a cutter structure, according to practical production requirements, cutter hot sealingtime and temperature and cooling air blowing time can be adjusted, quite high flexibility is provided for practically producing products with different sizes and using PE films and BOPP films with different widths and thicknesses, hot sealing time can be effectively shortened, cut incision firmness is improved, film breakage and sticking phenomena are avoided, and the device is of an important significance in improving production efficiency and enhancing technology stability.

Owner:上海得尼机械有限公司

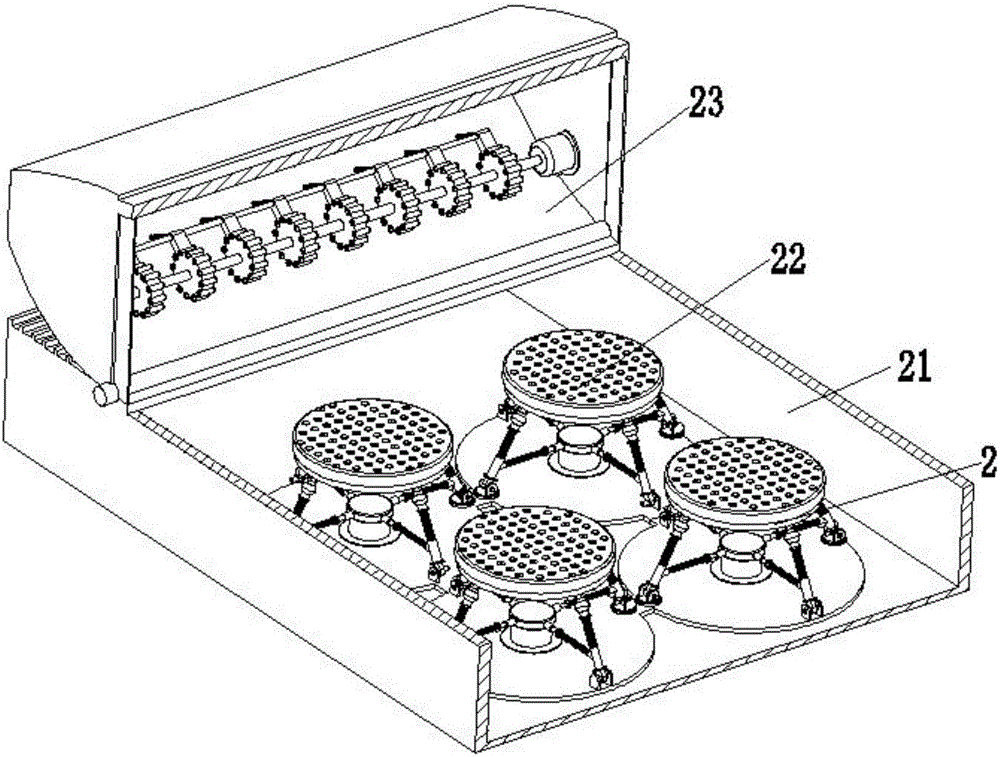

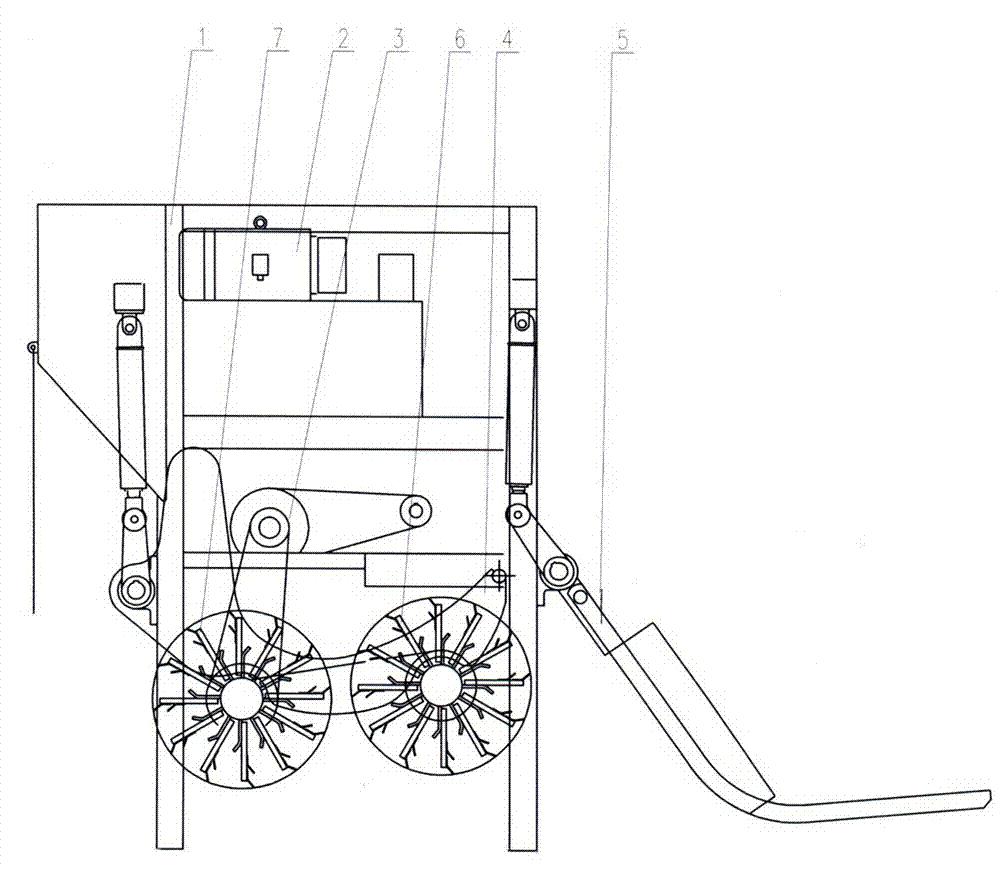

Hydraulic control flexible automatic debristling machine for pig slaughtering

InactiveCN102894057ASimple structureEasy to operateSlaughtering accessoriesElectrical controlEngineering

The invention relates to a hydraulic control flexible automatic debristling machine for pig slaughtering, in particular to hydraulic control flexible automatic debristling equipment in the pig slaughtering processing process. The hydraulic control flexible automatic debristling machine is characterized in that a sleeve roller chain is sheathed on a chain wheel and a back flexible debristling roller, a plurality of U-shaped fence sheets are arranged around U-shaped fences, the bottom layer of the U-shaped fences is provided with a stainless steel hole plate, a plurality of U-shaped fences are welded and connected with connecting rod shafts of a hydraulic oil cylinder into a whole, a scooping rake is in an L shape and is connected with the connecting rod shafts of the hydraulic oil cylinder, the flexible automatic debristling device consists of a rubber plate and a steel debristling plate, the steel debristling plate is riveted at the front end of the rubber plate, a water spraying device is arranged at the upper end of a machine frame, and a controller arranged on an electric control box is used for respectively regulating the debristling time and the pig inlet and outlet time. The hydraulic control flexible automatic debristling machine has the effects that the structure is simple, the operation is convenient, the debristling space is large, the production efficiency is high, the debristling time is short, the pig body volume is large, the injury on the pig body is small, the dewatering phenomenon cannot occur, and the hydraulic control flexible automatic debristling machine is widely used for automatic debristling processing equipment for pig slaughtering.

Owner:福瑞珂食品设备(济宁)有限公司

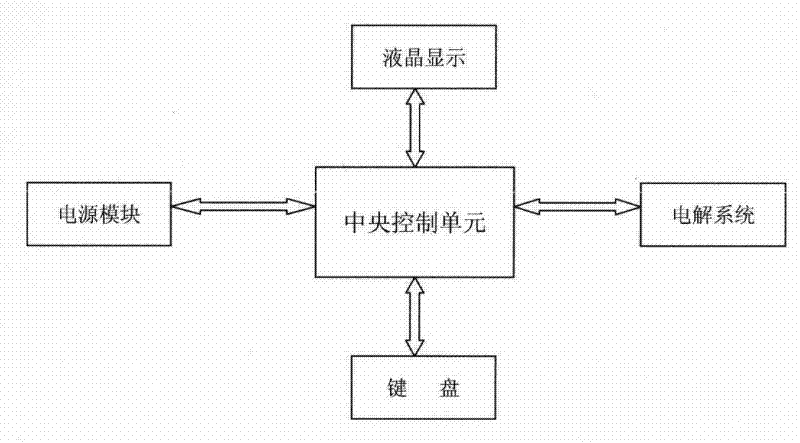

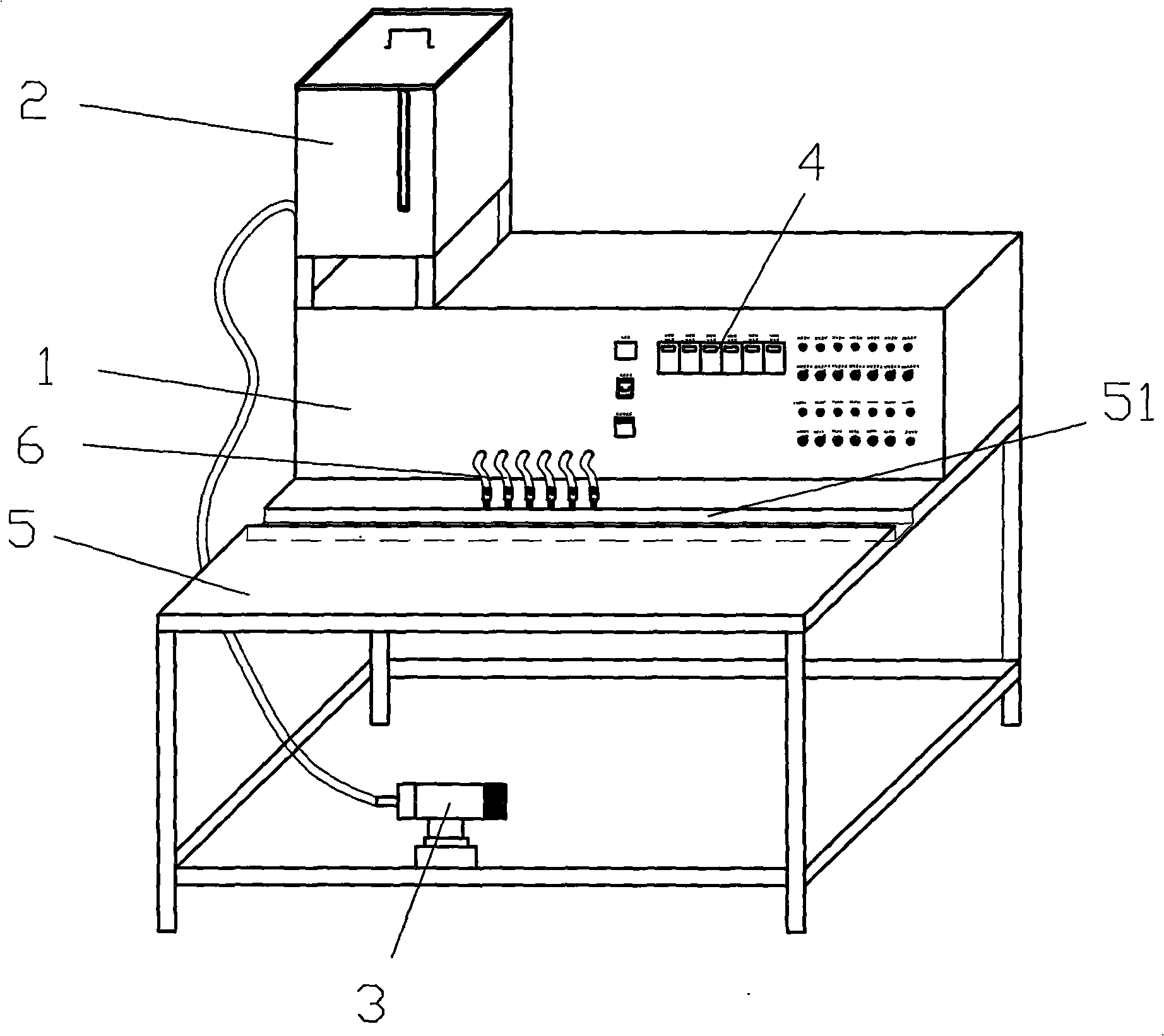

Online electrochemical measuring device

InactiveCN102539505AAdjustable speedAdjustable timeMaterial analysis by electric/magnetic meansPeristaltic pumpAutomatic control

The invention discloses an online electrochemical measuring device, belonging to the technical field of electrochemical analysis and quantitative analysis. The online electrochemical measuring device comprises a microcomputer control system and an electrolytic cell system, a microcomputer control peristaltic pump and an electromagnetic valve are used for taking a sample and a blending agent according to a certain proportion and putting the sample and the blending agent into a liquid-phase reagent cup, a micro-sample injection pump is used for conveying a liquid phase to an electrolytic cell constituted by a three-electrode system and an electrolyte at a certain speed, three electrodes in the electrolytic cell are connected with an electrochemical workstation, after the liquid conveying of the micro-sample injection pump is finished, the electrochemical workstation is automatically triggered to enter into a detection procedure, and after the detection procedure is completed, the device is used for judging whether liquid drainage and cleaning are required or not and waiting for the coming of next measurement time. The device has the advantages of simple structure and good stability, and can be operated manually or automatically and be widely applied to measuring systems of the electrochemical workstations.

Owner:JIANGSU JIANGFEN ELECTROANALYTICAL INSTR +1

Handheld household moxibustion apparatus

PendingCN108542761AEasy to operateAdjustable intensityDevices for heating/cooling reflex pointsTherapeutic coolingPhysical medicine and rehabilitationBandage

Provided is a handheld household moxibustion apparatus. The household moxibustion apparatus comprises a box body (2) provided with various devices, when a touch pad, a base, a bottom and the like arein use, the moxibustion apparatus can be applied to corresponding acupuncture points of the body in hand, or a bandage runs through snap rings at the two sides of the moxibustion apparatus and is tiedto the corresponding acupuncture points or parts of the human body, a corresponding moxibustion mode is selected through touch buttons on an operation panel to perform moxibustion, the temperature during moxibustion and the moxibustion time can be adjusted by adjusting the buttons, the moxibustion strength and time can be adjusted, the moxibustion mode is operated simply, a professional moxibustion person is not needed, moxibustion can be carried out at home for own or families, and the traditional Chinese medicine and moxibustion can be popularized to the public.

Owner:武汉左点科技有限公司

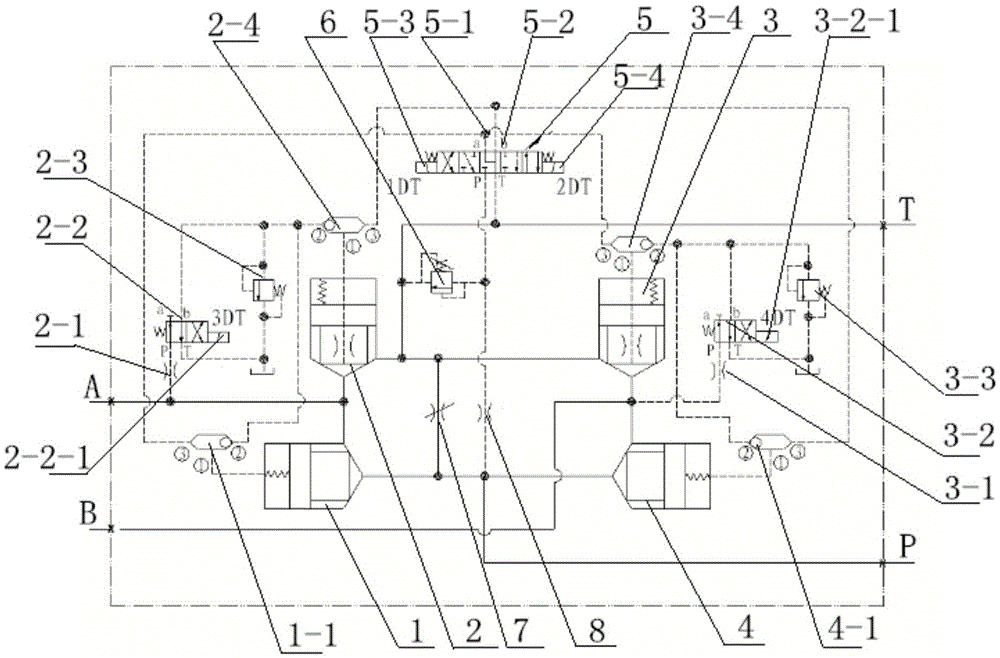

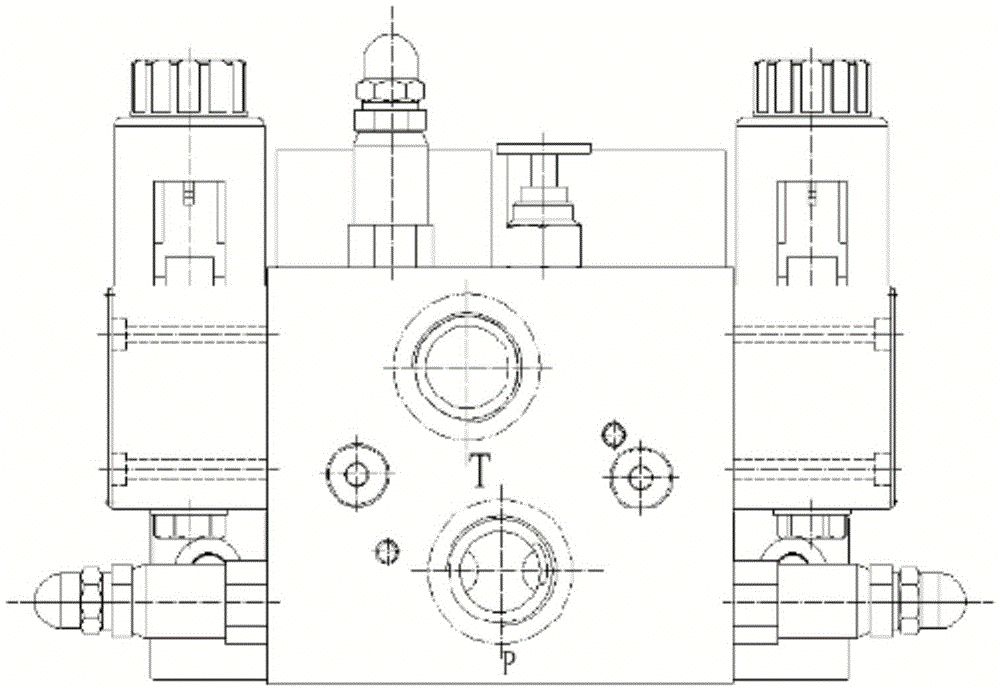

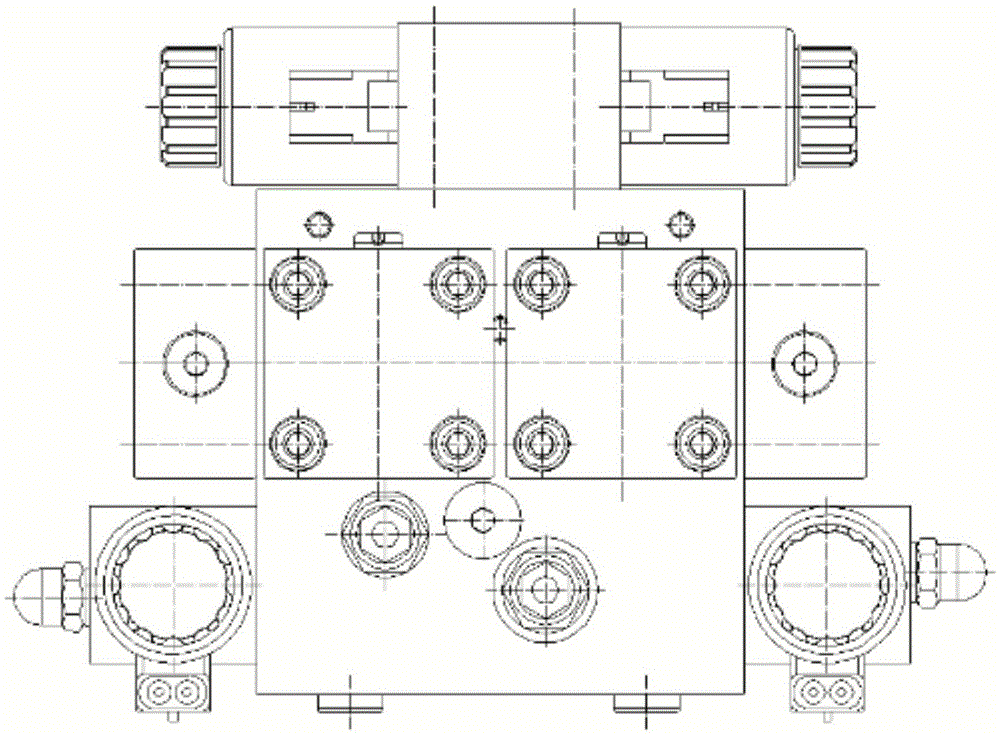

Two-way cartridge type vibration control valve with simple structure

InactiveCN105673604AAdjustable timeAdjustable speedFluid-pressure actuator safetyServomotor componentsStop timeThrottle

The invention belongs to the field of two-way plug-in vibration control valves, and specifically relates to a two-way plug-in vibration control valve with simple structure, which includes a valve body on which a plug-in cavity is formed, an oil inlet port, and a return valve. Oil interface, the first working interface and the second working interface; the main circuit, the main circuit is inserted in the insertion cavity of the valve body, including four two-way cartridge valves and a three-position four-way electromagnetic reversing The pilot direction control circuit composed of the valve, the vibration stop sub-circuit and the no-load oil return sub-circuit; an adjustable throttle valve is also set on the valve body between the oil inlet port and the oil return port to adjust the flow into the motor. The invention has the advantages of reducing the hydraulic impact of the road roller when it starts to vibrate, shortening the vibration stop time, avoiding the resonance of the whole machine, and realizing the switching of two kinds of amplitudes and adjusting the vibration frequency within a certain range. The hydraulic system is simpler and the production cost is lower. Lower pros.

Owner:PERMCOTIANJINHYDRAULIC INC

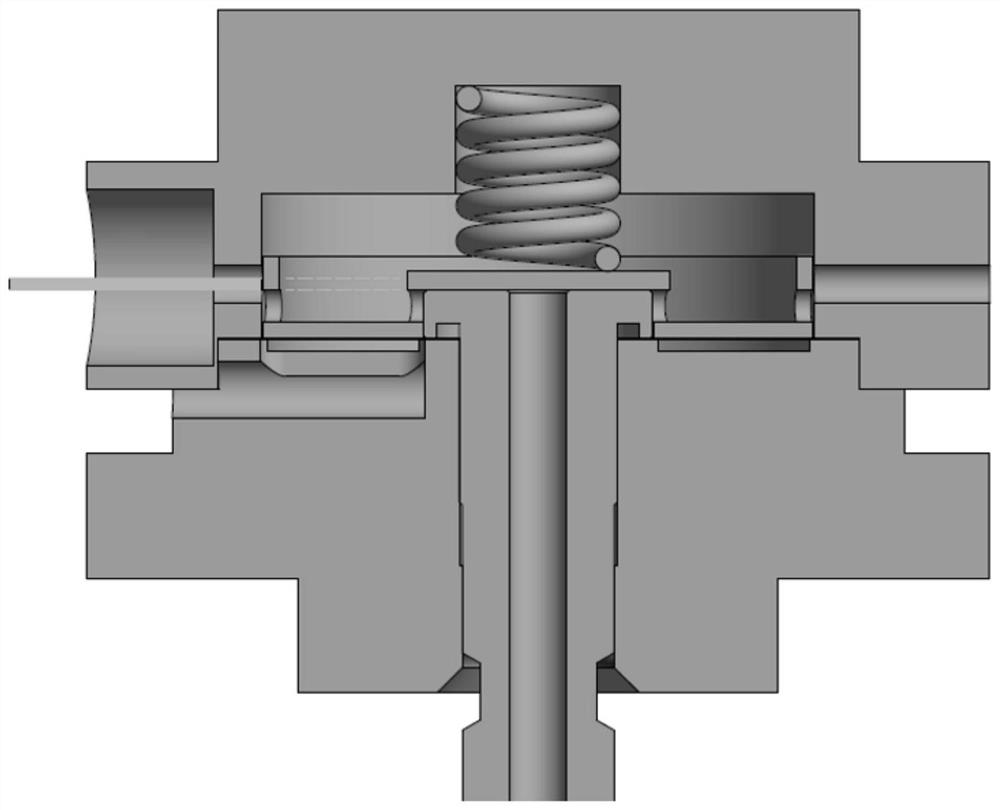

High-speed electromagnetic pulse gas valve device

PendingCN111750160AAdjustable timeAdjustable air intakeSpindle sealingsOperating means/releasing devices for valvesWorking pressureElectromagnetic pulse

The invention discloses a high-speed electromagnetic pulse gas valve device. A cavity is formed between a valve body (18) and a gas chamber shell (6) to serve a a gas chamber, a gas inlet (7) is usedfor introducing working gas into the cavity, and the diffusion time of a magnetic field generated by a disc-shaped coil (16) and passing through a stainless steel sheet (13) is less than 1 microsecond. The gas inlet (7) is designed in the upper portion of the back surface of a piston (12), and the gas flows through a piston hole (11) in the piston (12), so that the pressure difference of the two sides of the piston (12) and the elastic force of a spring (9) act together to serve as a restoring force for the piston (12) to be closed downwards, thereby reducing the motion time of the closing process. By adjusting the magnitude of pulse current of the disc-shaped coil (16), the pop-up height of the piston (12) can be adjusted so as to change the movement time of opening and closing of the piston (12) and the gas intake amount. The disc-shaped coil (16) is isolated out of the gas chamber through the stainless steel sheet (13). Tests prove that a gas valve can be used for pulse gas intake of flammable and explosive gases such as hydrogen, and the bearable working pressure of the gas can be more than 0.3 Mpa.

Owner:UNIV OF SCI & TECH OF CHINA

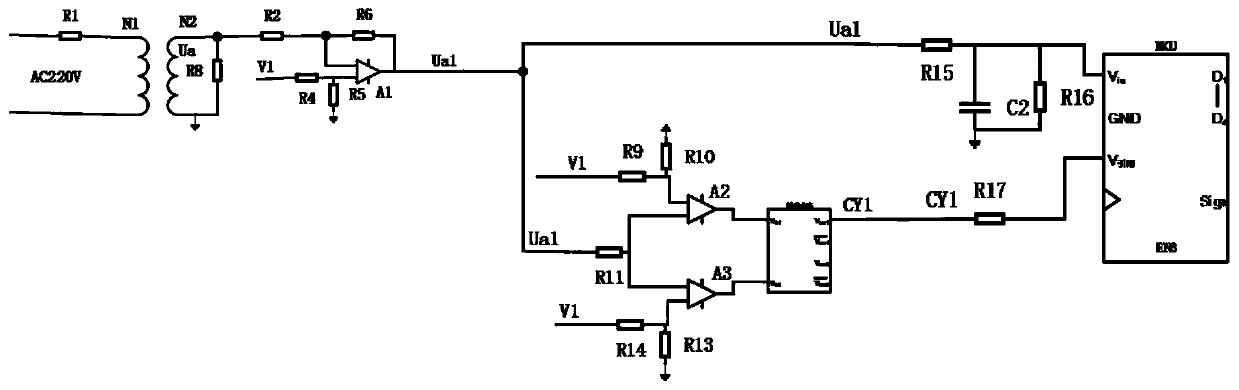

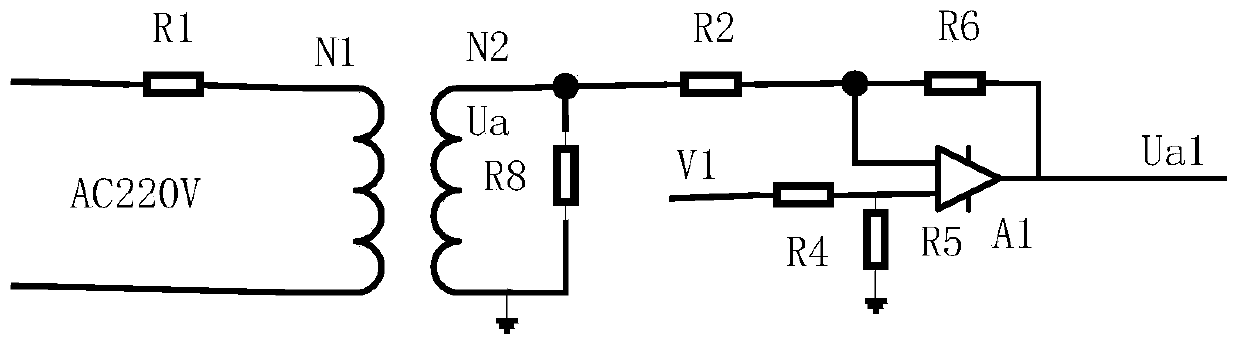

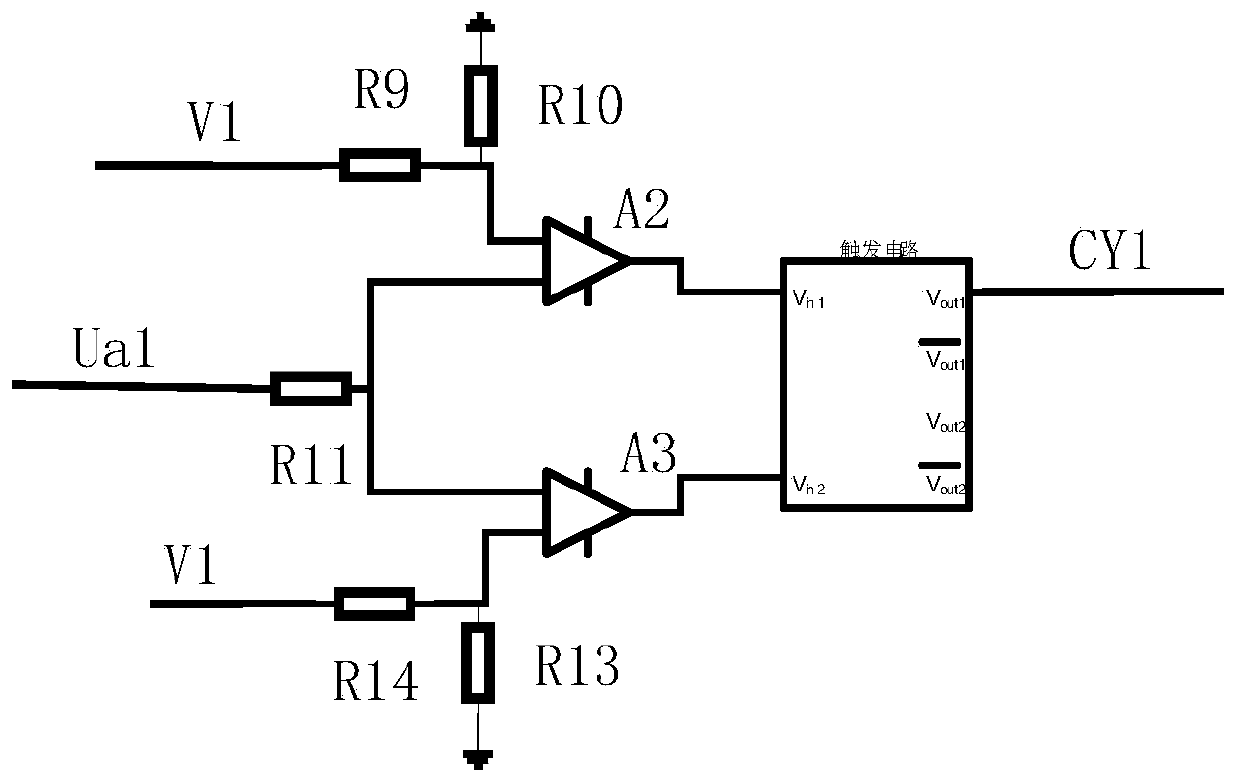

Embedded feeder terminal residual voltage detection circuit

InactiveCN110954738ATransient interference avoidanceImprove accuracyCurrent/voltage measurementSignal processing circuitsInterference resistance

The invention discloses an embedded feeder terminal residual voltage detection circuit, which comprises a power supply circuit, a residual voltage signal processing circuit, a comparison circuit, a signal trigger circuit, a telemetry collection circuit and a micropower processor, wherein the output end of the residual voltage signal processing circuit is respectively connected with the comparisoncircuit and the remote measurement collection circuit, the comparison circuit is connected with the signal trigger circuit, and the trigger circuit and the residual voltage signal processing circuit are connected with the micropower processor. The problems of mechanical action delay, power supply power-taking time delay and asynchronous mechanical performance are solved, the electronic detection circuit is stable and reliable, the anti-interference capability is extremely high, and the purposes that the feeder terminal effectively detects residual voltage in a short time and quickly isolates faults are achieved.

Owner:烟台科大正信电气有限公司

DC high-voltage polarity reversal device

ActiveCN105811768AAdjustable timeAdjustable modeApparatus without intermediate ac conversionHigh-voltage direct currentElectrical polarity

The invention discloses a DC voltage polarity reversal device, and the device comprises: a first high-voltage input end which is used for accessing positive polarity high-voltage DC power supply or negative polarity high-voltage DC power, a second high-voltage input end which is used for accessing a high-voltage DC power supply of which polarity is opposite to the first high-voltage input end, a high-voltage output end, a metal guide rod of which one end is jointed with a high-voltage output end and the other end is alternately connected with the first high-voltage input end and the second high-voltage input end, and a driving device which is connected with the metal guide rod through a insulating transmission rod and can drive the connection state of the metal guide rod between the first high-voltage input end and the second high-voltage input end. The device comprises the following advantages of high DC voltage withstand, adjustable reversal time and mode and good electric charge retention effect in switching process.

Owner:TSINGHUA UNIV +3

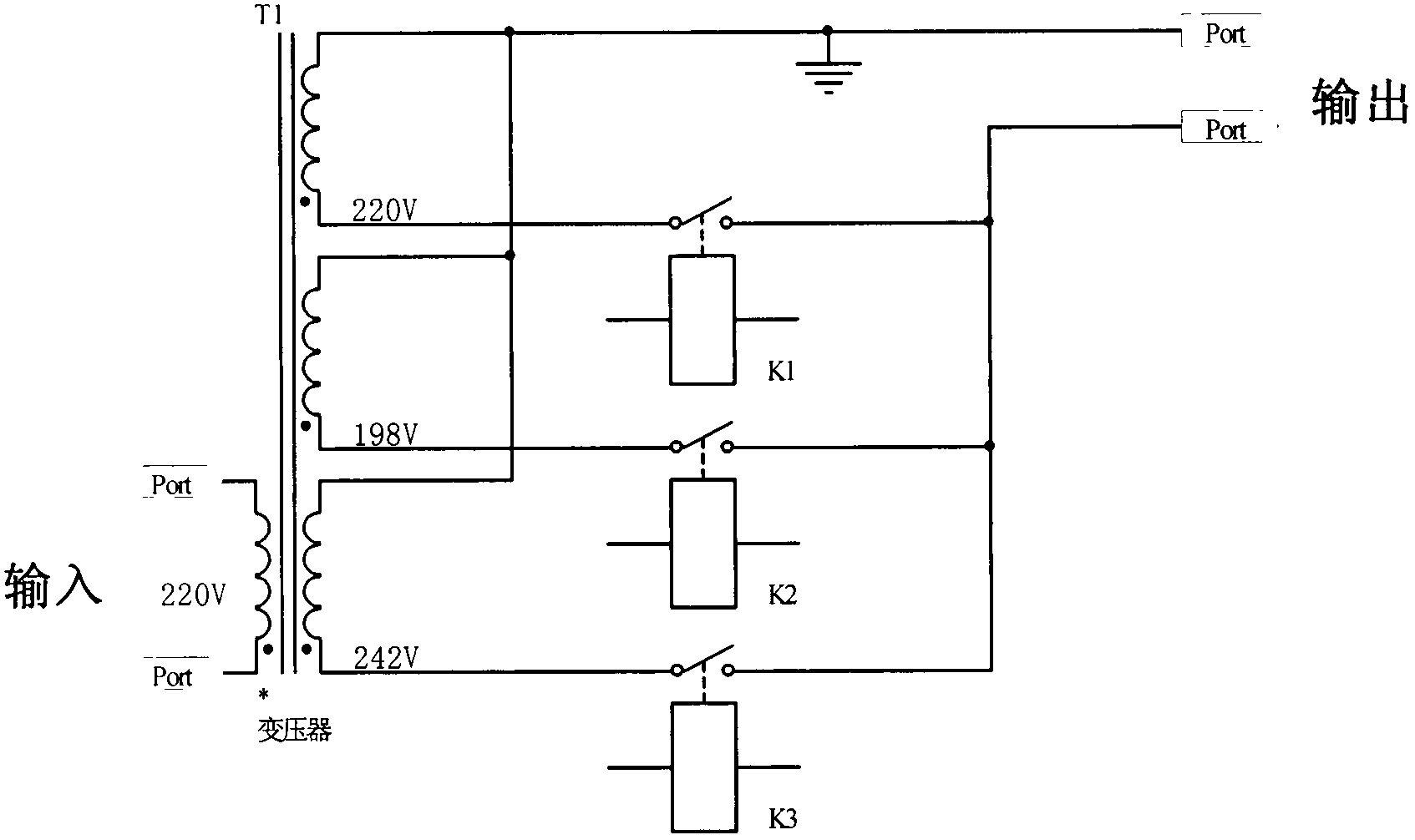

Voltage transient fluctuation instrument

InactiveCN103454478ALow efficiencyImprove work efficiencyCurrent/voltage measurementMicrocontrollerMicrocomputer

Disclosed is a voltage transient fluctuation instrument. The circuit of the voltage transient fluctuation instrument includes an isolation transformer. The isolation transformer input standard input 220VAC, 50HZ voltage changing into a three-way mutual isolation voltage output, wherein the first output voltage is 220VAC, the second output voltage of 198VAC and the third output voltage is 242VAC, a first solid-state relay is serially connected to the circuit of the first 220VAC voltage, a second solid-state relay is serially connected to the circuit of the second 198VAC voltage, a third solid-state relay is serially connected to the circuit of the third 242VAC voltage, control terminals of the three solid-state relays are connected to a single-chip microcomputer, the three-way alternating-current (AC) output voltage is precisely timed through the single-chip microcomputer, the AC voltage is switched for output by using the single-chip microcomputer to control the solid-state relays according to the testing requirements of the AC voltage. By the voltage transient fluctuation instrument, normal operation can be continued during mains supply fluctuation, accurate timing is achieved, and mains supply fluctuation can be simulated.

Owner:西安华强航天电子有限责任公司

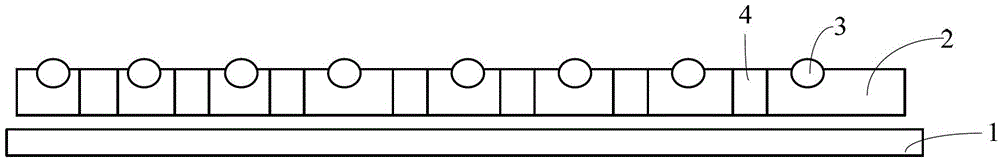

Electrical stimulating jumping cage for rodent and electronic control system thereof

InactiveCN103141402AAdjustable timeAdjustable frequencyProgramme control in sequence/logic controllersTaming and training devicesElectricityElectronic control system

The invention discloses an electrical stimulating jumping cage for a rodent and an electronic control system thereof. The electrical stimulating jumping cage comprises a base plate and a main body, wherein the base plate is arranged in an electrifying mode; the main body is upward vertically arranged from an edge of the base plate; the base plate comprises a fixed base plate and a drawing insert base plate; the fixed base plate is fixedly arranged; the drawing insert base plate is arranged on the fixed base plate in a sliding form; a plurality of wire sets are arranged on the drawing insert base plate; and the wire sets are connected with an external power supply. The electrical stimulating jumping cage for the rodent realizes an avoiding protection-free electrical stimulating jumping cage, solves the frequently happening phenomena of non-conducting and short-circuit, is easy to disassemble and firm and can enhances durability, practicability and aesthetics. The electronic control system can realize a full automatic visual programming interface and can automatically adjust the stimulating time and stimulating frequency.

Owner:SUZHOU UNIV

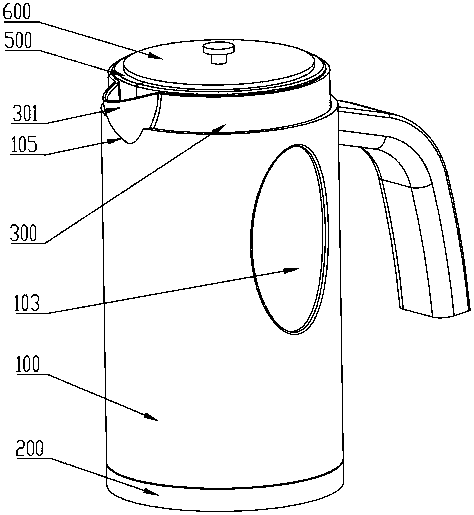

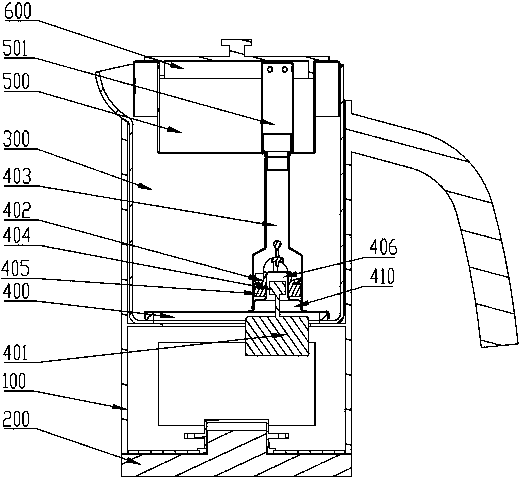

Novel tea making system

PendingCN110037554ARealize active circulating water supplyMeet the technical needs of different tea makingBeverage vesselsControl systemSpiral blade

The invention discloses a novel tea making system. The system comprises a tea making component system and a tea making control system. The tea making component system comprises a teapot base, a teapotshell, a tea soup container for containing tea water, a heating plate, a soaking material container for containing tea leaves and a pot cover. The teapot shell is arranged on the teapot base; the teasoup container is arranged in a tea soup chamber of the teapot shell, the heating plate is arranged at the bottom of the tea soup container, and a motor with an active magnet at the end part is arranged below the heating plate; spiral blades which are internally provided with passive magnets are arranged above the heating plate; the active magnet and the passive magnets form a magnetic joint linkage structure; a drainage blade chamber sleeves the spiral blades; a drainage tube is communicated with the tea soup container and the soaking material container, and a spray head sleeves the upper part of the drainage tube. The tea making system has the main advantages that non-contact connection between the motor and the spiral blades is skillfully achieved through the magnetic force; active circular water supply is achieved by the spiral blades, the technical purpose of making tea in a non-boiling state is effectively achieved, and the temperature and time for making tea are adjustable.

Owner:深圳华曼兄弟科技有限公司

A kind of heating layer of flexible electric heating film and its preparation method

ActiveCN112566290BImprove adsorption capacityConductiveHeating element materialsPolymer scienceConductive polymer

The invention discloses a flexible electric heating film heating layer containing a composite polymer conductive skeleton material and a preparation method thereof. The flexible electric heating film heating layer is impregnated with a composite high molecular polymer conductive skeleton material in an electric heating slurry, After curing, it is obtained by heat-pressing treatment. Wherein, the composite high molecular polymer conductive skeleton material is a flexible porous material with a continuous three-dimensional porous structure; it includes a first high molecular polymer, a conductive second high molecular polymer (high molecular conductive polymer) and doped Graphene-based composite nanosheet materials and carbon nanotubes. The invention prepares the heating layer of the flexible heating film, which can overcome the problems existing in the prior art, such as poor interface bonding of the electric heating layer, poor bending resistance, easy falling off of fillers, and non-adjustable dosage of heating layer materials.

Owner:SHENZHEN DELONG ELECTRICAL APPLIANCE CO LTD

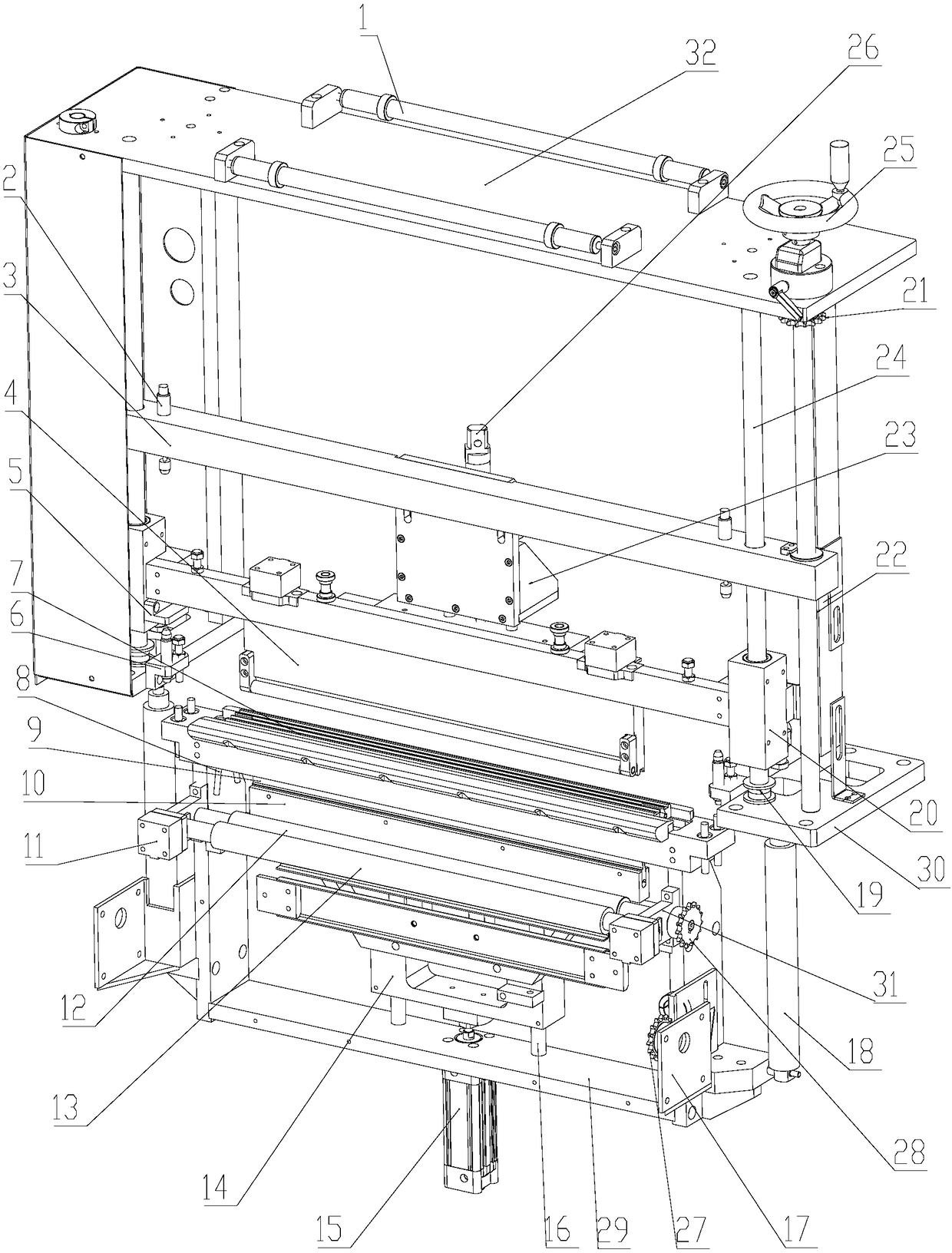

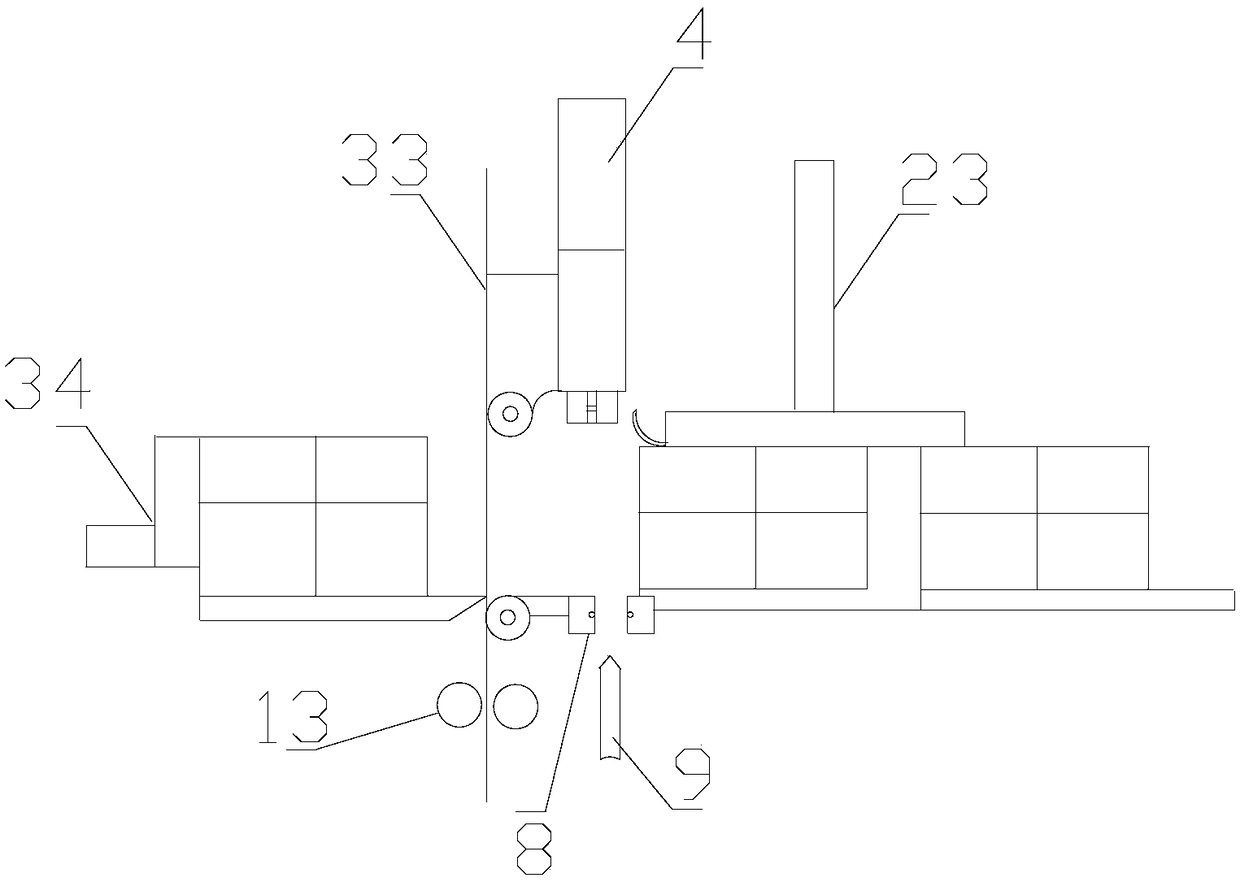

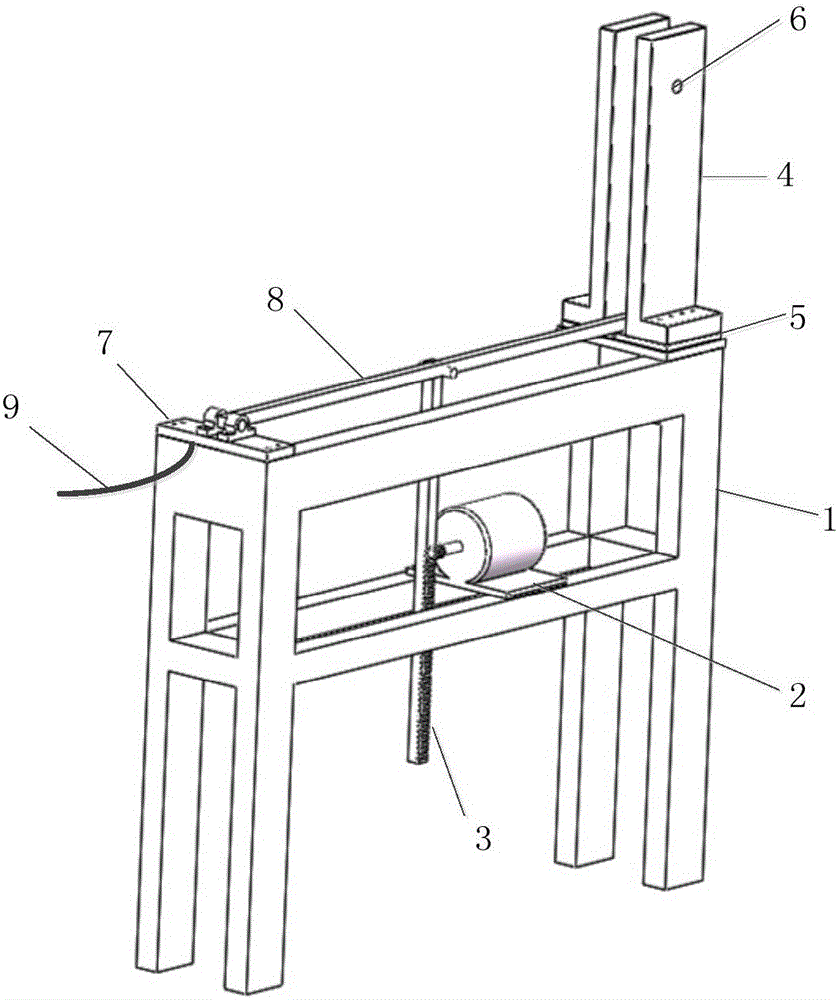

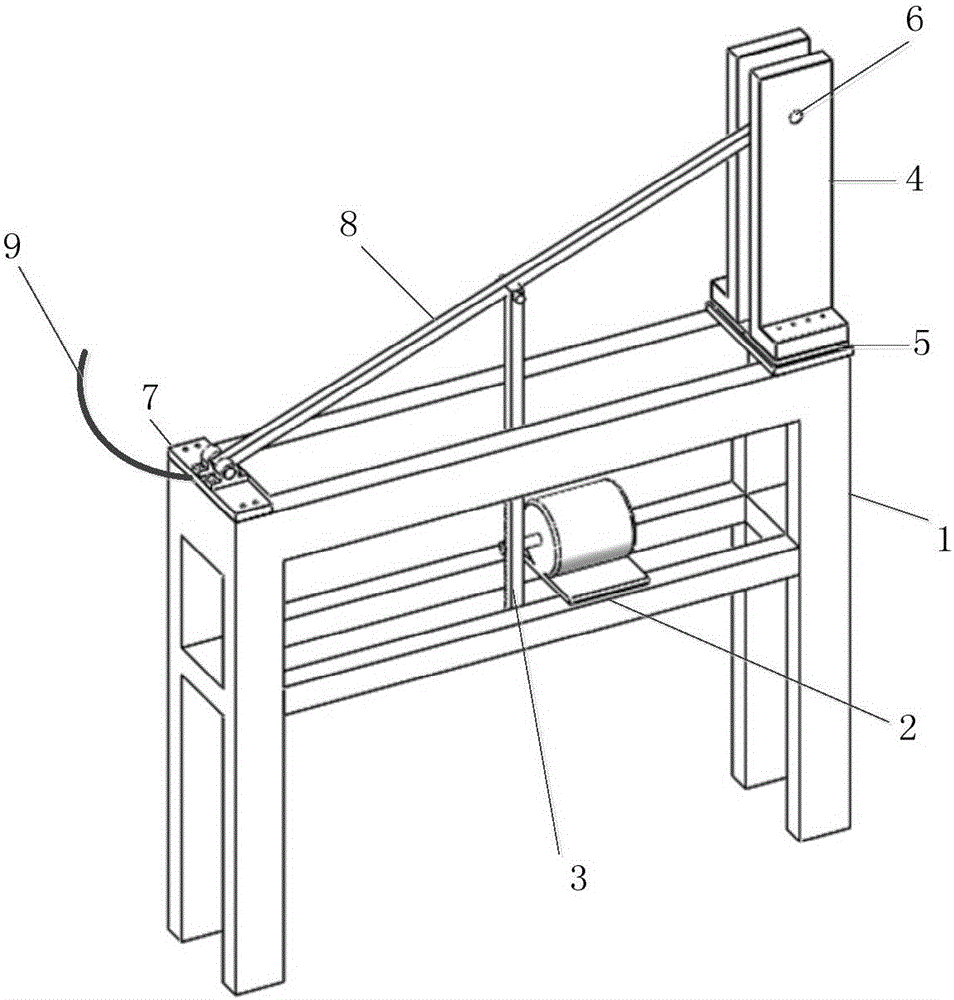

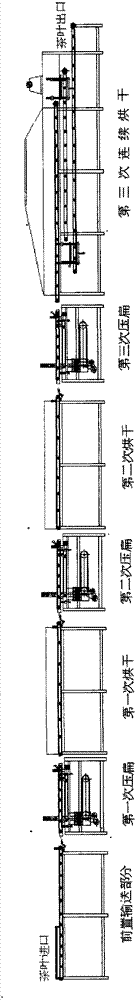

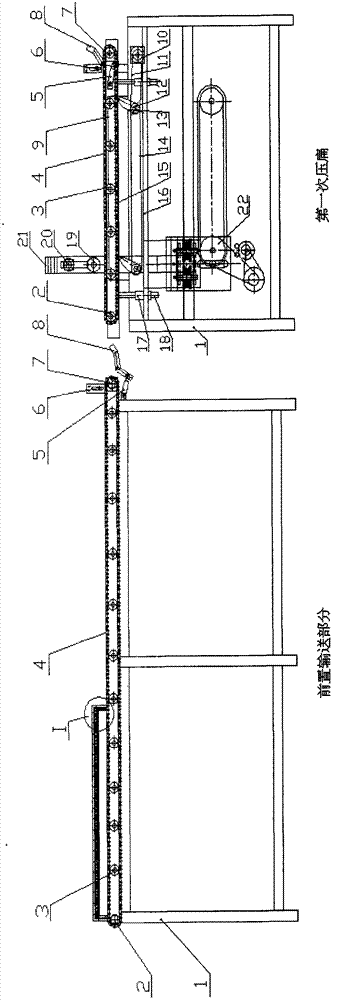

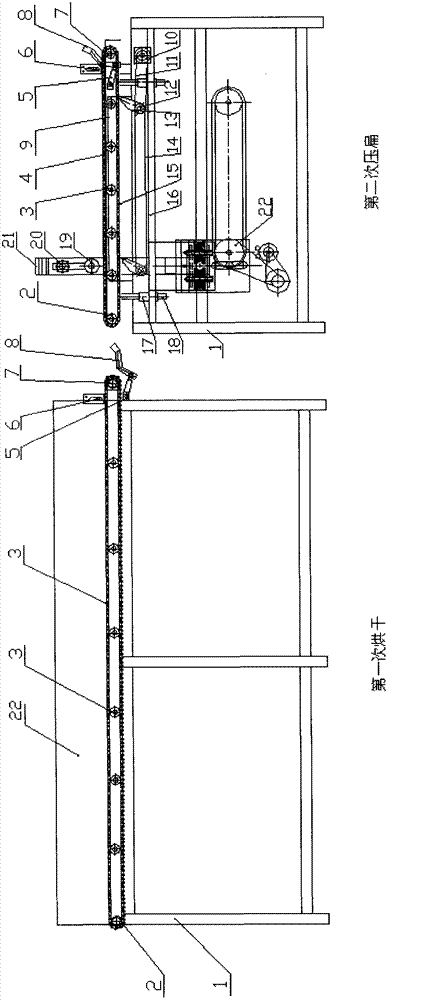

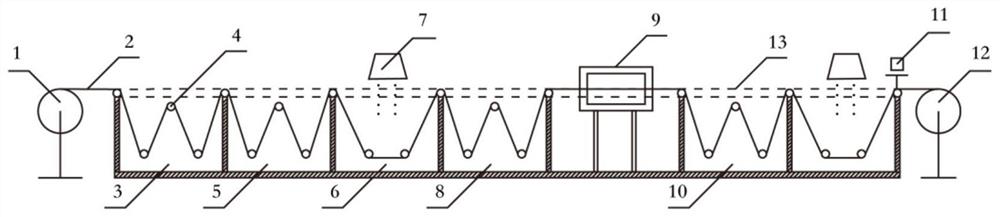

Fully-automatic tea flattening drying streamline

InactiveCN102813013AProcessing technology conforms toImprove qualityPre-extraction tea treatmentEngineeringCam

A fully-automatic tea flattening drying streamline is composed of a sieve part, a prepositioned conveying part, a first flattening part, a first drying part, a secondary flattening part, a secondary drying part, a third flattening part, a terminal continuous drying part, and a PLC control part, and mainly comprises frames (1), chain wheels (2), rollers (3), chains (4), cylinders (5), photoelectric switches (6), speed regulation motors (7), spacing baffle blocks (8), flattening workbenches (9), elevating motors (10), belts (11), camshafts (12), cams (13), belts (14), carriages (15), guide sleeve racks (16), guide sleeves (17), guide pillars (18), pressure rollers (19), pressure roller up-and-down movement mechanisms (20), moveable racks (21), pressure roller left-and-right movement mechanisms (22), an oven (23), a fan (24), cylinder supports (25), lifting cylinders (26), travel switches (27), supporting plates (28), guide sleeves (29), guide sleeve supports (30), guide pillars (31), a swing rod (32), a driving rod (33) and a limiting switch (34). A segment flattening and drying technology of tea leaves is carried out in the invention, and has the advantages of high tea preparation efficiency, good flatness and straightness of the tea leaves, and low labor intensity through the adoption of the fully-automatic line production.

Owner:安徽绿源机械科技股份有限公司

Optical disinfection and sterilization device

PendingCN111467518AAdjust the size of the powerArbitrarily adjust the disinfecting light directionRadiationLight spotLight beam

The invention discloses an optical disinfection and sterilization device. The optical disinfection and sterilization device comprises an optical disinfection and sterilization light source used for emitting a disinfection and sterilization light beam, a light beam shaping device used for shaping the disinfection and sterilization light beam to form a disinfection and sterilization light spot, a marking laser used for emitting a visible marking line, and a laser beam shaping lens group used for shaping the marking line, wherein an included angle is formed between the marking laser and the optical disinfection and sterilization light source, so that the disinfection and sterilization light spot is overlapped with the marking line. The optical sterilization and disinfection effect is utilized, the light power and the irradiation time on a target object are effectively and reasonably adjusted, the device can be operated in a handheld mode, the disinfection and sterilization light directioncan be adjusted at will, the simple, convenient, rapid and dead-corner-free comprehensive sterilization and disinfection effect can be achieved, the disinfection and sterilization position can be indicated through indication light of the device, the injury caused by accidental irradiation to the human body is prevented, and the light power and the disinfection and sterilization time are adjustable.

Owner:济南晶众光电科技有限公司

Liquid electric heating mosquito coil filling machine

InactiveCN101633486ALow failure rateHigh filling accuracyFilling without pressureElectrical controlElectric control

The invention discloses a liquid electric heating mosquito coil filling machine, comprising a worktable surface on which an electric control box is arranged; the top of the electric control box is provided with a medicine chest in which a floating ball liquid level switch connected with a medicine transmission pump is arranged; a discharge port controlled by a time relay is arranged in the electric control box, and a push slot corresponding to the position of the discharge port is arranged on the worktable surface. The filling machine can realize a standard filling quantity by keeping drop height of the medicine chest at the same liquid level and firstly uses the medicine transmission pump to pump liquid medicine to the medicine chest to control quantitative filling of bottles by using the high level of the medicine chest through a pipeline, an electromagnetic valve and the time relay.

Owner:欧义泳

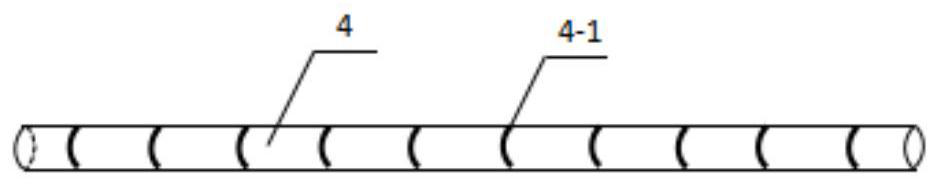

Basalt fiber continuous chemical plating device and application method

PendingCN114107963AImprove mechanizationHigh degree of automationFilament handlingLiquid/solution decomposition chemical coatingElectroless nickelYarn

The invention discloses a basalt fiber continuous chemical nickel plating device and an application method, and belongs to the field of basalt fiber surface treatment equipment. The device mainly comprises a yarn unwinding frame, a guide roller, an oil removal tank, a roughening tank, a cleaning tank, a cleaning device, a palladium-free activation tank, a drying device, a chain transmission device, a plating solution tank, a power mechanism and a winding machine. The preparation method of the electroless nickel-plated conductive basalt fiber comprises the following steps: oil removal treatment, roughening treatment, cleaning treatment, palladium-free activation treatment, drying reduction treatment, electroless nickel plating and cleaning treatment. The device is applied to palladium-free activation chemical nickel plating for preparing the conductive basalt fibers, multiple bundles of fibers can be subjected to chemical plating at the same time, the obtained nickel plating layer is uniform and continuous, and compared with a traditional chemical plating device for preparing the conductive fibers, the device has the advantages of being high in efficiency, low in cost, short in process and capable of achieving continuous preparation.

Owner:重庆智笃新材料科技有限公司 +1

Fireproof material for combining wood material with aerogel and manufacturing method thereof

ActiveCN107775759AReduce manufacturing costSuitable for manufacturingWood treatment detailsWood impregnation detailsCombustionOrganic solvent

The invention discloses a manufacturing method of a fireproof material for combining a wood material with aerogel. The manufacturing method comprises the following steps: (A) an acid accelerant is added in mixed solution of a precursor and an organic solvent for hydrosis reaction to form aerogel solution; (B) alkali accelerant water solution is added in the aerogel solution for condensation reaction to form aerogel water solution; (C) the wood material is dipped in the aerogel water solution for gelation to generate the aerogel to coat the wood material; and (D) the wood material is dried to mold the fireproof material. The invention further discloses the fireproof material for combining the wood material with the aerogel, which is manufactured by using the steps. The fireproof material can achieve excellent fireproof effect, and can pass through a combustion lowest-oxygen-content test.

Owner:陈 建宏

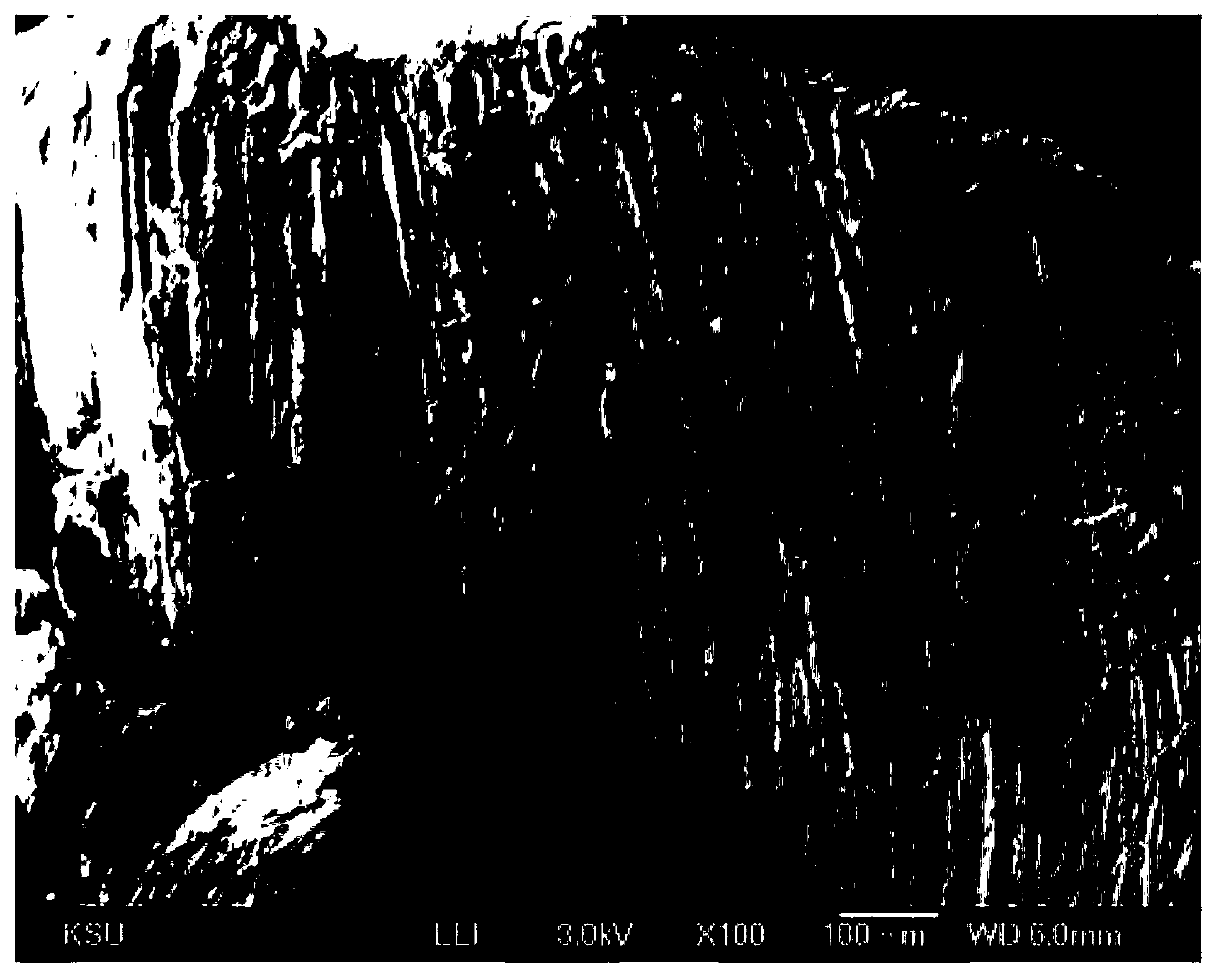

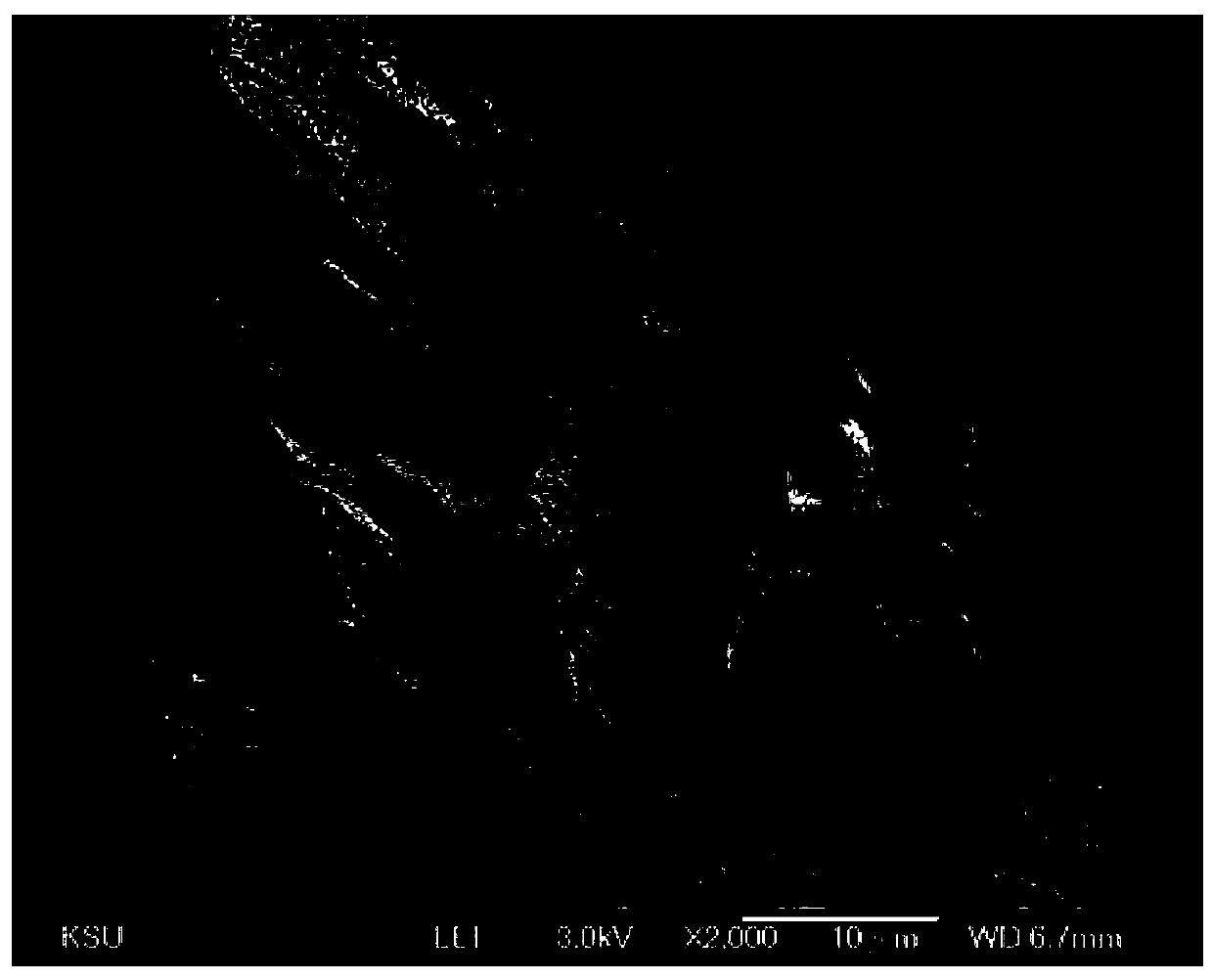

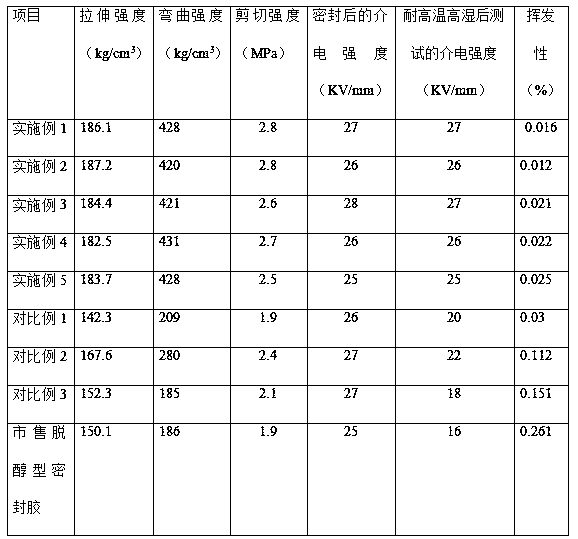

Sealant and preparation method thereof

ActiveCN110591635AReduce volatilityHigh bonding strengthNon-macromolecular adhesive additivesPolymer sciencePolyvinyl chloride

The invention discloses a sealant and a preparation method thereof. The sealant has low volatility, has volatility of 0.01-0.025%, cannot leave oil stain or mist in an electronic product, is safe andenvironmentally friendly, and meets the European Union RoHS standard. The sealant has excellent bonding strength and physical and mechanical properties, the tensile strength can reach 181.2-187.1kg / cm<2>, and bending strength can reach 420-430kg / cm<2>. The sealant has the characteristic of quick drying of solidified surface, and surface drying time and deep curing time can be adjusted, wherein thesurface drying time can reach 1-20 minutes (the temperature is 20-25 DEG C, and the relative humidity is 60%). The sealant has a characteristic of wide applicability, has no corrosion to base materials, and has excellent physical properties to various plastics such as acrylonitrile butadiene styrene (ABS), polyvinyl chloride (PVC), high density polyethylene (HDPE), polycarbonate (PC) and the likeand to coated metals. The sealant has low production requirements and is suitable for mass production, popularization and use.

Owner:HUIZHOU XINHAOYUAN DEV

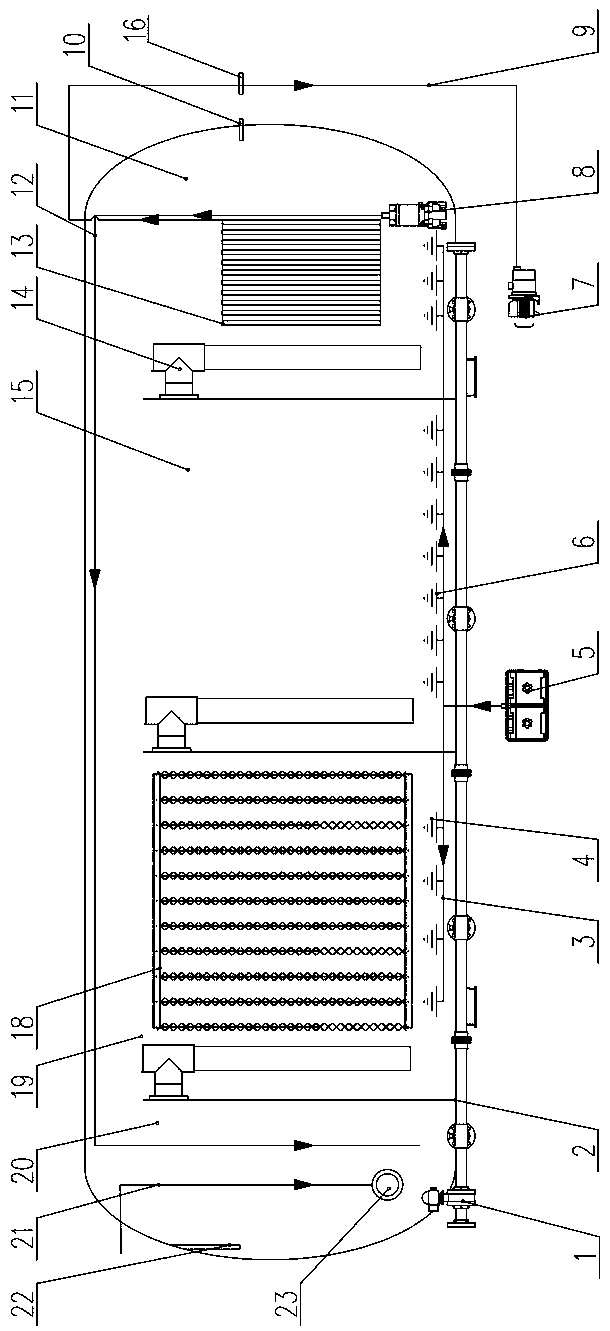

MBR (Membrane Bioreactor) integral sewage treatment equipment with automatic sludge discharge

InactiveCN109160607AEasy to controlTiming and quantitative mud dischargeWater treatment parameter controlBiological treatment apparatusLiquid temperatureControl system

The invention discloses MBR (Membrane Bioreactor) integral sewage treatment equipment with automatic sludge discharge. The equipment comprises a pretreatment zone, an anoxic zone, an aerobic zone anda membrane zone which are partitioned, wherein the membrane zone is provided with an MBR membrane component; a sludge discharge tube with an electronic valve is arranged at the bottom of the pretreatment zone; a sludge concentration detection device is mounted in the pretreatment zone; the sludge concentration detection device is connected with a PLC (Programmable Logic Controller) control system;a temperature sensor is arranged in the membrane zone; the temperature sensor is capable of detecting the temperature of a membrane zone liquid on line and is used for transmitting detection data tothe PLC control system; a water quality detection device for detecting effluent ammonia concentrations is mounted at a membrane effluent outlet; the detection data are transmitted to the PLC control system; the PLC control system is used for calculating a sludge amount to be discharged according to collected temperature data, sludge concentrations, effluent ammonia concentrations and set sludge ages; the sludge amount is achieved by controlling the opening degree of the electronic valve. By adopting the equipment, an automatic sludge discharge mode is adopted, fixed-time fixed-amount sludge discharge can be achieved without manual operation, and system stability can be maintained.

Owner:宁波中车时代电气设备有限公司

Composite high-efficiency circulating water treatment device

ActiveCN105540986BArbitrary control over processing timeOptimize processing timeWater/sewage treatmentMultistage water/sewage treatmentMagnetic separatorEngineering

The invention relates to the field of wastewater treatment, in particular to a circulating regenerating wastewater treatment device. The composite efficient circulating water treatment device comprises a buffer, a reactor, a magnetic separator, a replacing chamber and a regenerating chamber; the magnetic separator comprises three working surfaces which are positioned in the buffer, the replacing chamber and the regenerating chamber respectively; the magnetic separator changes positions of the three working surfaces under driving of a rotating mechanism by means of rotation; the buffer and the reactor form a circulating loop by a water pipeline and a water pump between the buffer and the reactor. Processing time for the wastewater by a magnetic material can be freely controlled in a reaction chamber, reaction is not controlled by time, the positions of respective working surfaces can be freely changed, continuous wastewater treatment work and regenerating work of the magnetic material are facilitated, the magnetic material is well recycled, wastewater treatment cost is greatly reduced, and the device is suitable for using various magnetic materials to perform wastewater treatment work.

Owner:辽宁莱特莱德环境工程有限公司

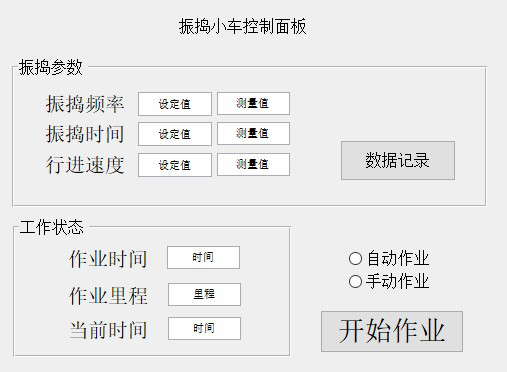

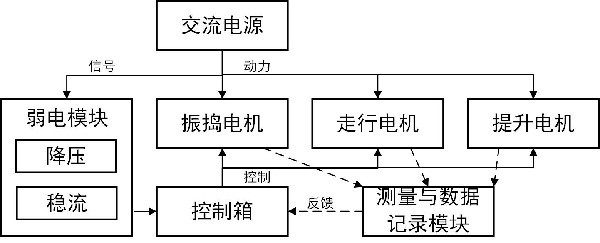

Self-propelled concrete vibrating trolley for ballast bed

PendingCN114150540AMechanizationAdjustable immersion depthRailway track constructionArchitectural engineeringElectric machinery

The invention relates to railway maintenance mechanical equipment, in particular to a self-propelled concrete vibrating trolley for a ballast bed, which comprises a frame, a vibrating unit and a lifting mechanism capable of vertically moving relative to the frame, and track wheels and a traveling motor for driving the track wheels are mounted at the bottom of the frame. Four sliding rails vertically penetrating through the lifting mechanism are installed on the outer side of the rack, a lifting lead screw vertically penetrating through the lifting mechanism is installed in the center of the rack, the lifting lead screw is connected with a lifting motor, and the vibrating units are installed on the lifting mechanism. According to the invention, the mechanization of concrete vibration operation is realized, so that the vibration area covers the cross section of a ballast bed without omission, the problems of vibration omission, excessive vibration and the like are effectively avoided, and the vibration operation efficiency is improved.

Owner:北京铁科普拉塞养路机械设备有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com