A kind of heating layer of flexible electric heating film and its preparation method

An electric heating film and heating layer technology, applied in the direction of electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of easy falling off of fillers, poor bending resistance, poor interface bonding, etc., achieve uniform filling, overcome local overheating, avoid agglomeration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

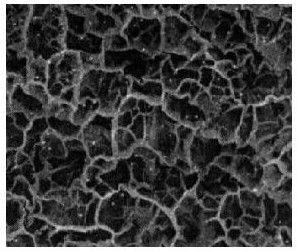

Image

Examples

Embodiment 1

[0091] Preparation of Composite Polymer Conductive Skeleton Material 1

[0092] 1) Add 2g of graphene composite nanomaterials loaded with 12wt% silver and 1.2g of carbon nanotubes into 200ml of 0.5wt% N-methylpyrrolidone aqueous solution under ice bath conditions, mechanically stir evenly; add 0.4g of polyethylene Alcohol powder into solution, after stirring, ultrasonically disperse for 5 minutes, and mix evenly to obtain nanomaterial dispersion.

[0093] 2) Under ice bath and nitrogen inert atmosphere, add 100g of acrylamide powder to the above nanomaterial dispersion, then add 0.5g of nanocellulose whiskers (about 100μm in length) and 6g of sodium hydroxide and stir for 15min; under stirring conditions, Then add 1.5g of methinebisacrylamide crosslinking agent, 0.9g of lauryl methacrylate, 0.1g of tetramethylethylenediamine catalyst, and then slowly add dropwise a solution containing 1.2g of ammonium persulfate, and continue to The reaction was stirred for 2h. The obtained ...

Embodiment 2

[0097] Preparation of Composite Polymer Conductive Framework Material 2

[0098] 1) Under ice bath conditions, add 1.8g of graphene composite nanomaterials containing 15wt% alumina and 1g of carbon nanotubes into 190ml of 0.5wt% N-methylpyrrolidone aqueous solution, and stir evenly; add 0.3g of polyethylene Alcohol powder into solution, after stirring, ultrasonically disperse for 5 minutes, and mix evenly to obtain nanomaterial dispersion.

[0099] 2) Add 80g of acrylamide powder to the above nanomaterial dispersion in an ice bath and nitrogen inert atmosphere, then add 0.5g of nanocellulose whiskers (about 50μm in length) and 5g of sodium hydroxide and stir for 15min; under stirring conditions, Then add 1.2g of methinebisacrylamide crosslinking agent, 0.8g of methacrylic acid, 0.1g of tetramethylethylenediamine catalyst, and then slowly dropwise add an aqueous solution containing 1g of potassium persulfate, and continue to stir for 2 hours after the dropwise addition . The ...

Embodiment 3

[0102] Preparation of electrothermal paste

[0103] 1) Add an equal volume of 15wt% sodium persulfate aqueous solution to 50ml of 5wt% pyrrole solution under ice bath conditions, stir slightly, then add 12.5g conductive carbon black powder (particle size about 5μm), stir and react under ice bath conditions 6h, after the reaction, let it stand for 12h; centrifuge to obtain black carbon black-doped polypyrrole nanoparticles, and disperse it in 30g of 30wt% graphite aqueous dispersion to obtain carbon black-doped polypyrrole particles / graphite dispersion.

[0104] 2) Mix the emulsion type polydimethylsiloxane and benzoyl peroxide at a mass ratio of 100:0.5 at room temperature, stir magnetically for 15 minutes, and let it stand for 2 hours to obtain a transparent polydimethylsiloxane polymer sol About 50g;

[0105] Add 10g of polyvinylidene fluoride resin powder into 90g of N,N-dimethylacetamide solution, and form PVDF resin glue by stirring under heating conditions.

[0106] 3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com