Fireproof material for combining wood material with aerogel and manufacturing method thereof

A technology of wood material and manufacturing method, which is applied in the direction of wood treatment, impregnating wood, manufacturing tools, etc., can solve the problem of impregnation that has not yet been revealed, and achieves the effects of good safety and stability, reduced production time, and strong bonding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

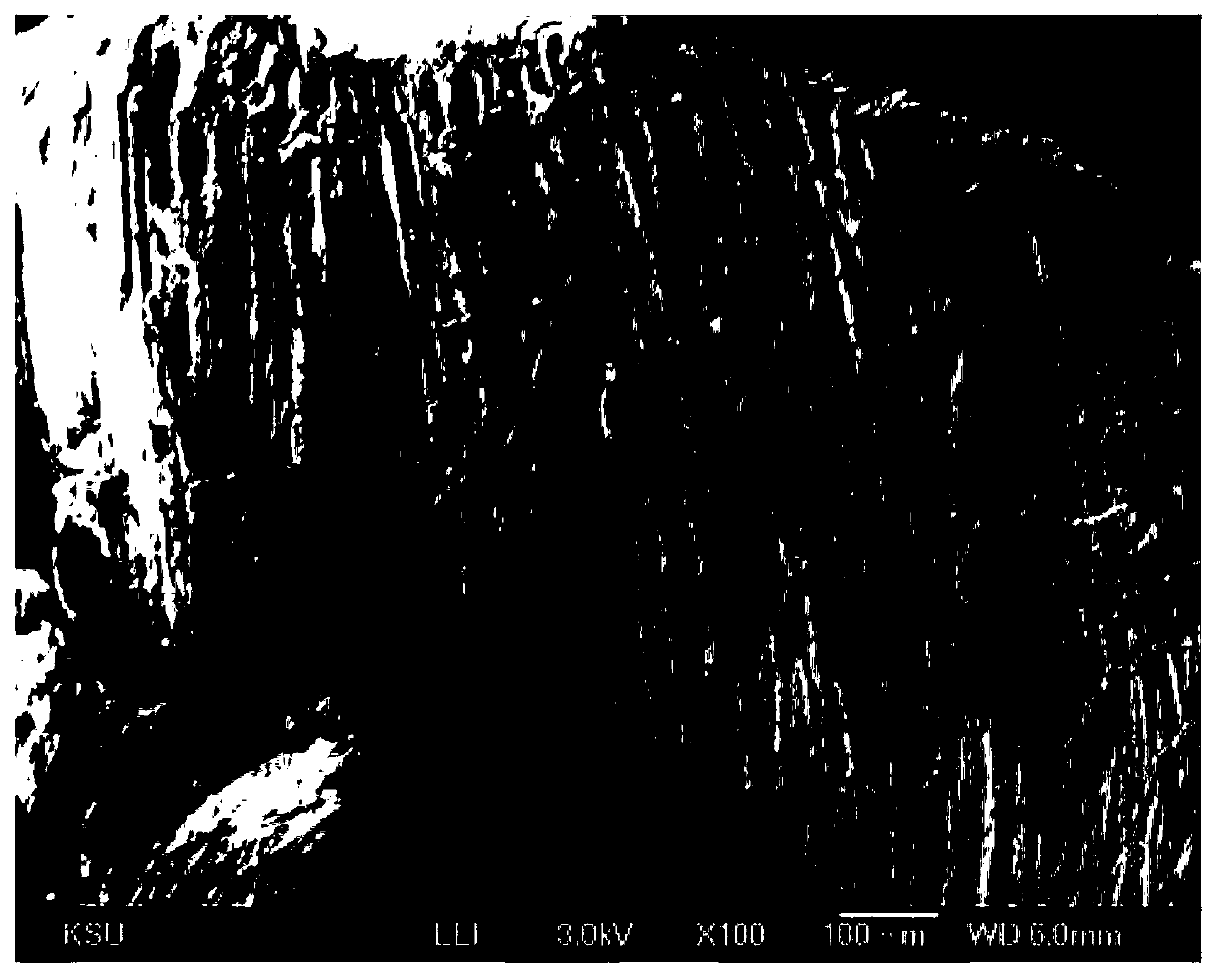

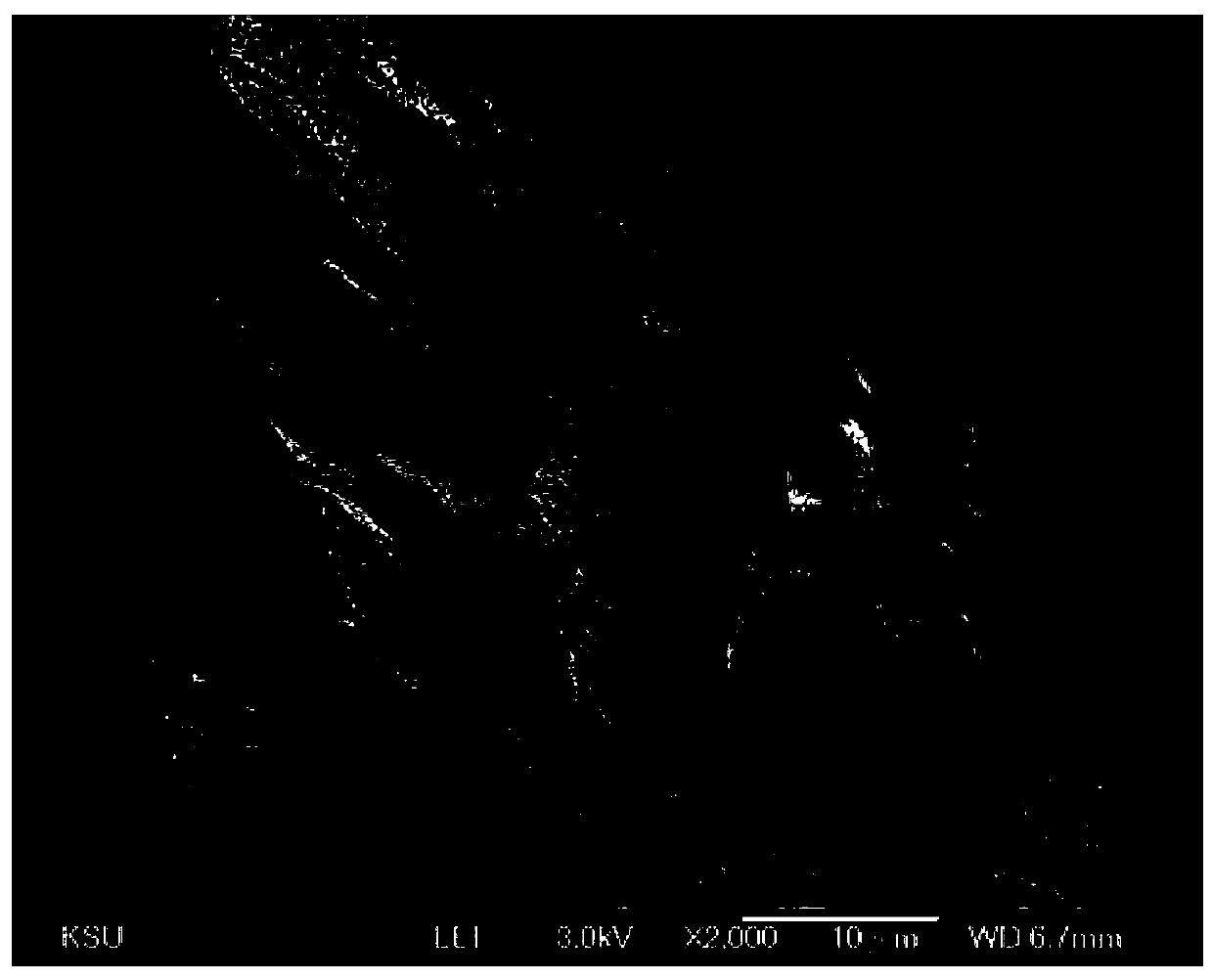

[0032] The present invention contains a kind of wood material combined with airgel fireproof material manufacturing method, please refer to figure 1 As shown, the embodiment of the present invention includes the following steps:

[0033] A. Add an acid catalyst to a mixed solution of a precursor and an organic solvent to cause a hydrolysis reaction to form an airgel solution. This embodiment mainly provides a precursor of an alkoxysilane or a methyl orthosilicate, an organic solvent mixed with water and ethanol, and the molar ratio (mol%) of water and ethanol in the organic solvent The range is 10:1 to 120:8. The precursor and the organic solvent are fully stirred and mixed to form a mixed solution. In addition, the molar ratio of the precursor to water in the organic solvent is higher than 1:4, so that the precursor can accelerate the hydrolysis reaction. That is to say, the molar ratio content of the precursor accounts for 9% to 16% in the mixed solution (this embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com