Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

82results about How to "Address adverse effects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

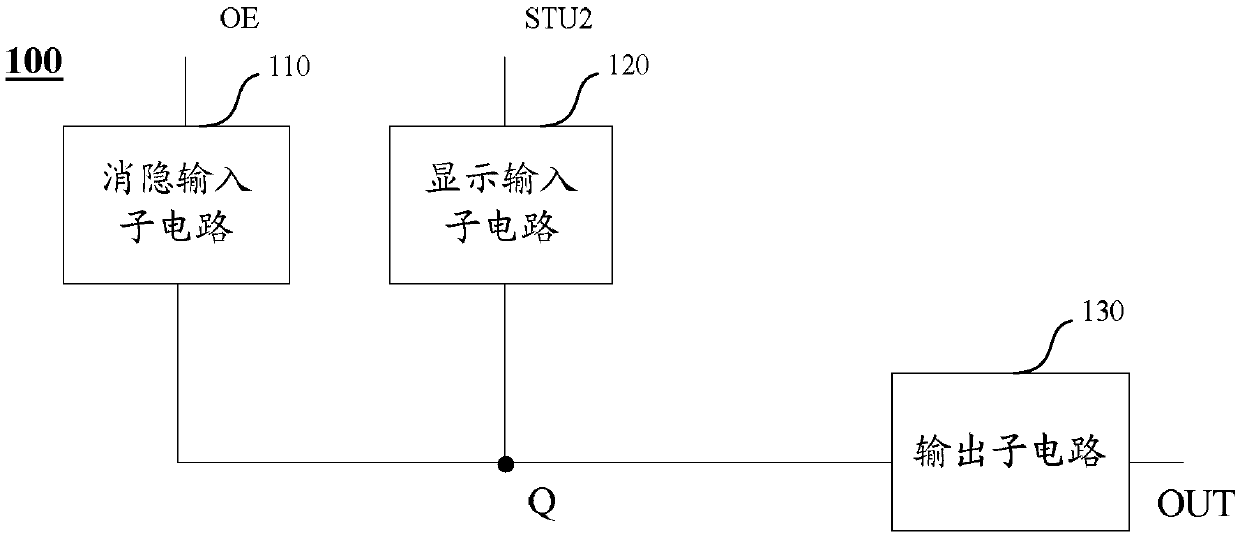

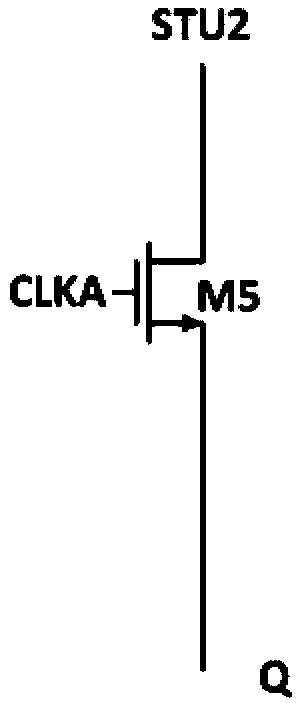

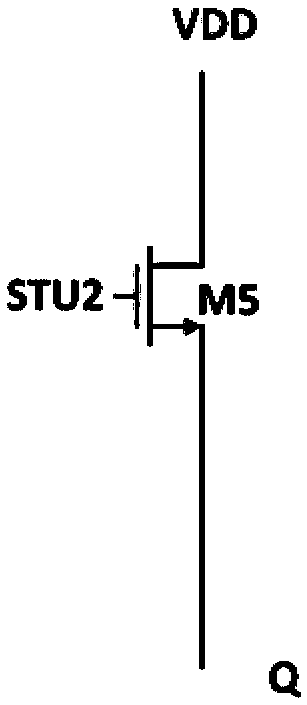

Shift register unit, gate driving circuit, display device, and driving method

InactiveCN108682397AAddress adverse effectsReduce adverse effectsStatic indicating devicesDigital storageVIT signalsDisplay device

The invention discloses a shift register unit, a gate driving circuit, a display device, and a driving method. The shift register unit comprises: a first input sub-circuit, configured to receive a display input signal from a display input terminal and input a display output control signal to a first node in a display period of one frame according to the display input signal; a second input sub-circuit, configured to receive a random input signal in a display period of a frame and input a blanking output control signal to the first node in a blanking period of a frame according to the random input signal; and an output sub-circuit, configured to output a composite output signal via an output terminal under the control of the first node.

Owner:BOE TECH GRP CO LTD +1

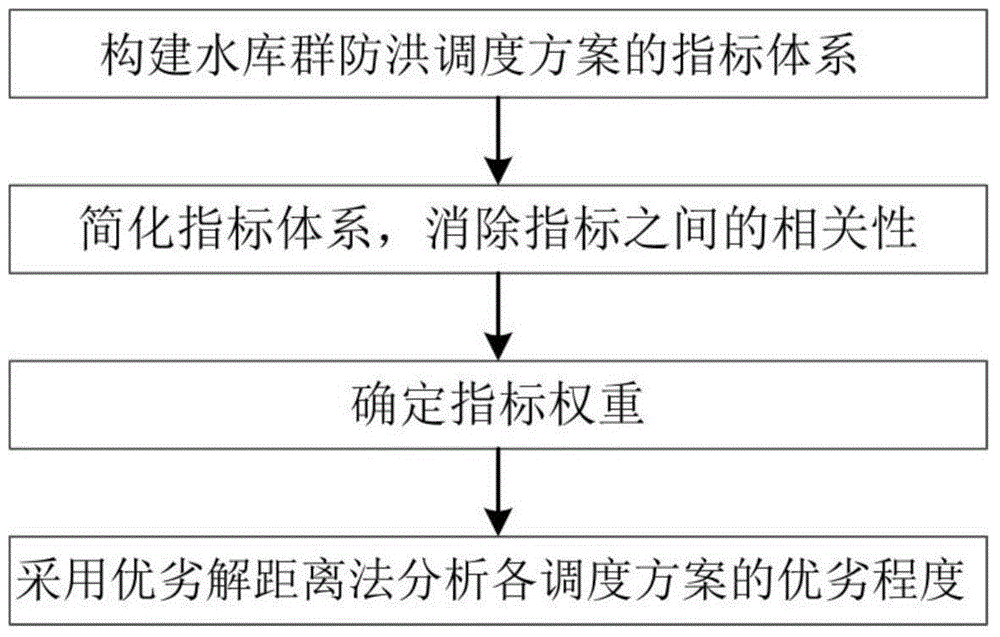

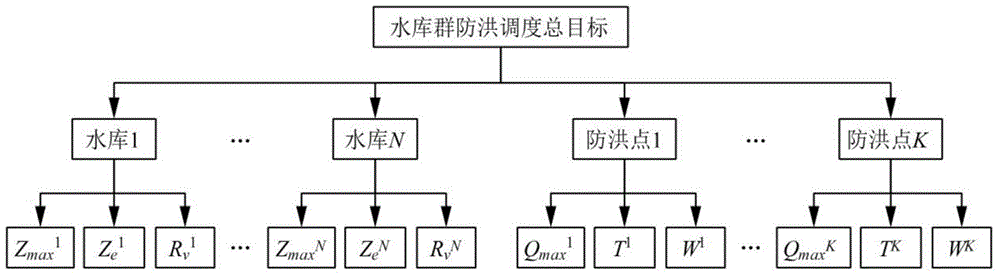

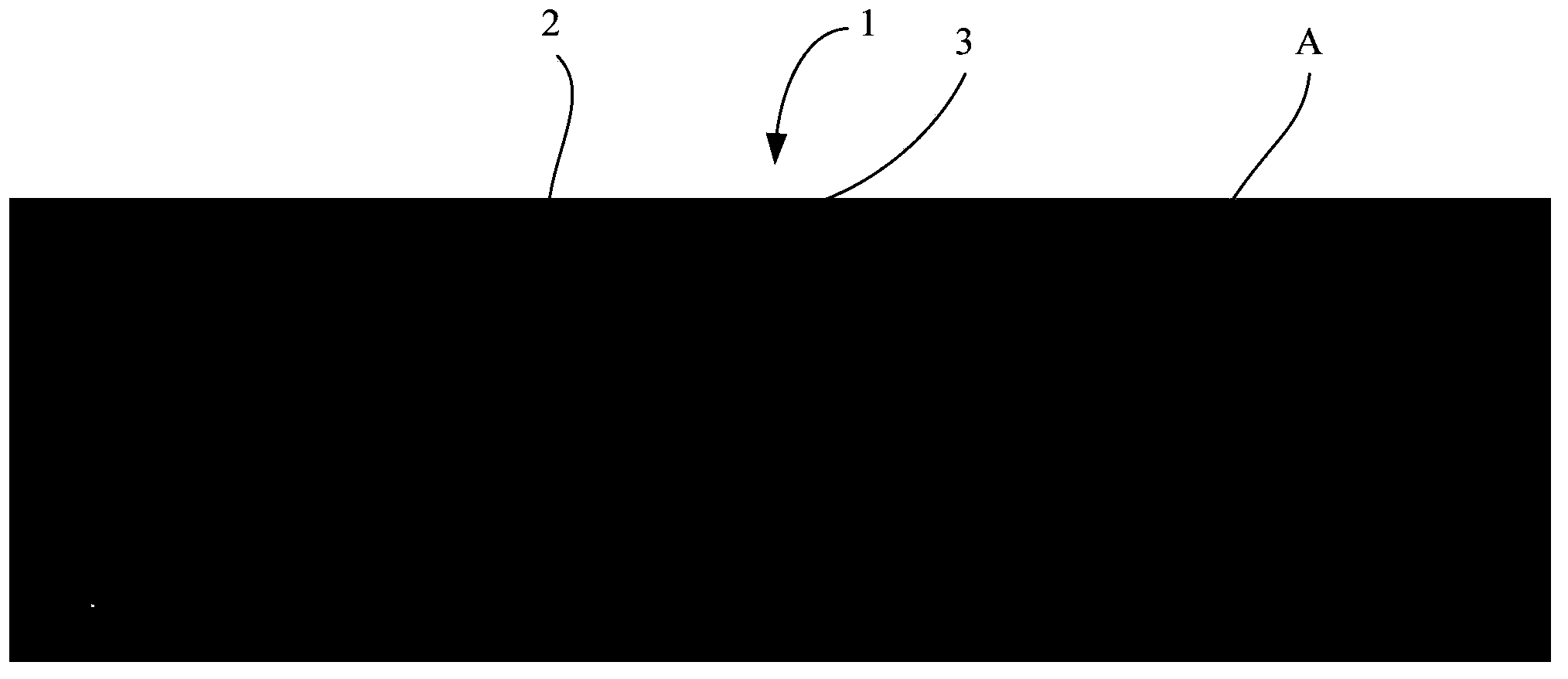

Reservoir group flood control scheduling scheme optimization method taking index correlation into consideration

InactiveCN105046376AAddress adverse effectsSimple calculationClimate change adaptationForecastingResearch ObjectEntropy weight method

The invention discloses a reservoir group flood control scheduling scheme optimization method taking index correlation into consideration. The method comprises the following steps: constructing an index system for reservoir flood control scheduling schemes; measuring the degree to which the indexes in the index system are correlated by using a correlation analysis approach, converting the index system into a new index system of which the indexes are independent of each other by using a principal component analysis approach, and reducing the dimension of the original index system; calculating the weight of each index in the new index system by using an improved entropy weight approach; and analyzing the goodness of each scheduling scheme by taking the new index system and the weights of the indexes as input of a technique for order preference by similarity to an ideal solution. According to the method of the invention, the influence of index correlation to scheme screening is taken into consideration, and the research object is expanded from a single reservoir to a reservoir group. By adopting the method, the problem about index correlation in scheme selection can be solved effectively, and the dimension of the index system can be reduced. A powerful tool is provided for reservoir group flood control scheduling scheme optimization under the condition that the indexes are correlated.

Owner:HOHAI UNIV

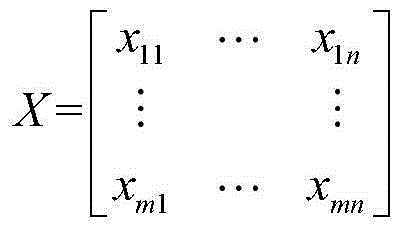

Active calcium oxide with calcium carbide dreg as raw material, desulfurizing agent, calcium carbide raw material and preparation method of active calcium oxide

ActiveCN105948091AProtect environmentReduce usageCalcium/strontium/barium oxides/hydroxidesMaterials scienceCalcium carbide

The invention relates to the technical field of active calcium oxide, desulfurizing agents, calcium carbide raw materials and preparation methods of active calcium oxide, in particular to active calcium oxide with calcium carbide dreg as a raw material, a desulfurizing agent, a calcium carbide raw material and a preparation method of active calcium oxide. The active calcium oxide with the calcium carbide dreg as the raw material is obtained through the following steps: firstly, the calcium carbide dreg is subjected to filter pressing, and primary wet dreg is obtained. According to the active calcium oxide with the calcium carbide dreg as the raw material, the desulfurizing agent, the calcium carbide raw material and the preparation method of active calcium oxide, the calcium carbide dreg is turned into wealth, accordingly, the problem of adverse influence on the environment due to stacking of a large amount of calcium carbide dreg is solved, and the environment is effectively protected; besides, utilization of mineral resources such as limestone is reduced, the mineral resources such as the limestone are saved, and the idea of harmonious development of economic development and environment protection is realized; meanwhile, according to the active calcium oxide with the calcium carbide dreg as the raw material, the desulfurizing agent, the calcium carbide raw material and the preparation method of active calcium oxide, the purity of the desulfurizing agent can be improved; moreover, the cost of the calcium carbide raw material for producing calcium carbide is lower, and industrial application prospect is realized.

Owner:新疆中泰创安环境科技股份有限公司

Preparation method of TEM sample

ActiveCN103698170AAchieve preparationFast preparationPreparing sample for investigationIon beamAdverse effect

The invention discloses a preparation method of a TEM sample. The method combines the advantages of ion milling and focused ion beam methods used in the prior art. The sample of a designated area can be obtained by a focused ion beam, thus saving the time needed by polishing in the prior art and realizing fixed-point sample preparation. An amorphous layer at an imaging end face is removed by ion milling so as to solve the damage of the focused ion beam on the imaging end face and further decrease the thickness of the TEM sample, thus avoiding the overlap phenomenon. Thus, the preparation method of a TEM sample provided by the invention can realize rapid fixed-point sample preparation, and at the same time solves the problem that the amorphous end face and overlap can generate adverse effects on imaging during cutting.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Synthesized metal cutting fluid taking poly-alpha olefin as base oil and preparation method thereof

InactiveCN103242933AImprove the lubrication effectPromote degradationBase-materialsPolyolefinActive agent

The invention discloses a synthesized metal cutting fluid taking poly-alpha olefin as base oil, and the synthesized metal cutting fluid comprises the poly-alpha olefin, a nonionic surface-active agent, an anionic surface-active agent, an antirust, a cosolvent, an extreme pressure agent, a defoaming agent, a bactericide and water. The preparation method comprises the following steps of: sequentially adding the defoaming agent, the extreme pressure agent and the bactericide to the poly-alpha olefin base oil, and uniformly stirring to form an oil system; adding the antirust to the water, uniformly stirring to form a water system; and uniformly mixing the water system and the oil system, and then stirring and dripping the nonionic surface-active agent, the anionic surface-active agent and the cosolvent at the same time to finally obtain the synthesized metal cutting fluid taking the poly-alpha olefin as the base oil. The synthesized metal cutting fluid has the advantages of excellent viscosity-temperature property, lubricity, biodegradability, low toxicity and low harmfulness on human bodies and the environment and usage period longer than the usage period of the traditional cutting fluid and is suitable for the cutting machining of high-accuracy and high-demand metal workpieces.

Owner:SHANGHAI INST OF TECH

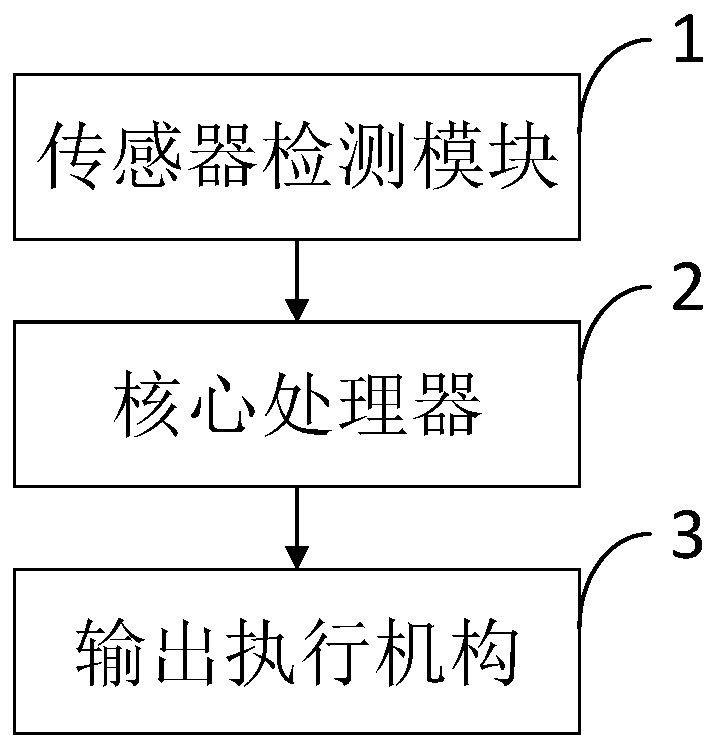

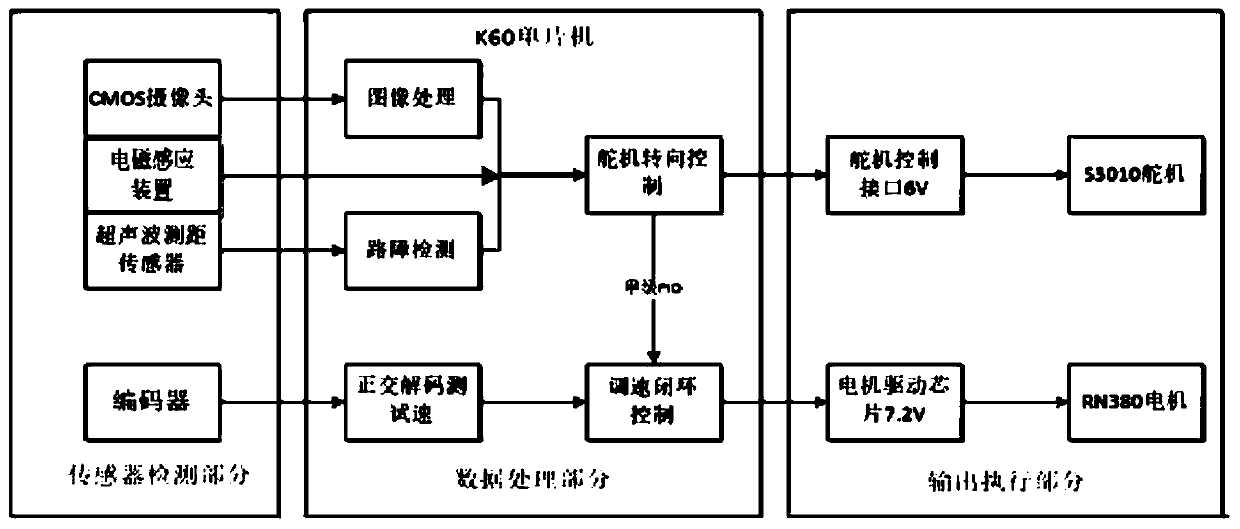

Intelligent vehicle control system and method based on gray scale camera detection

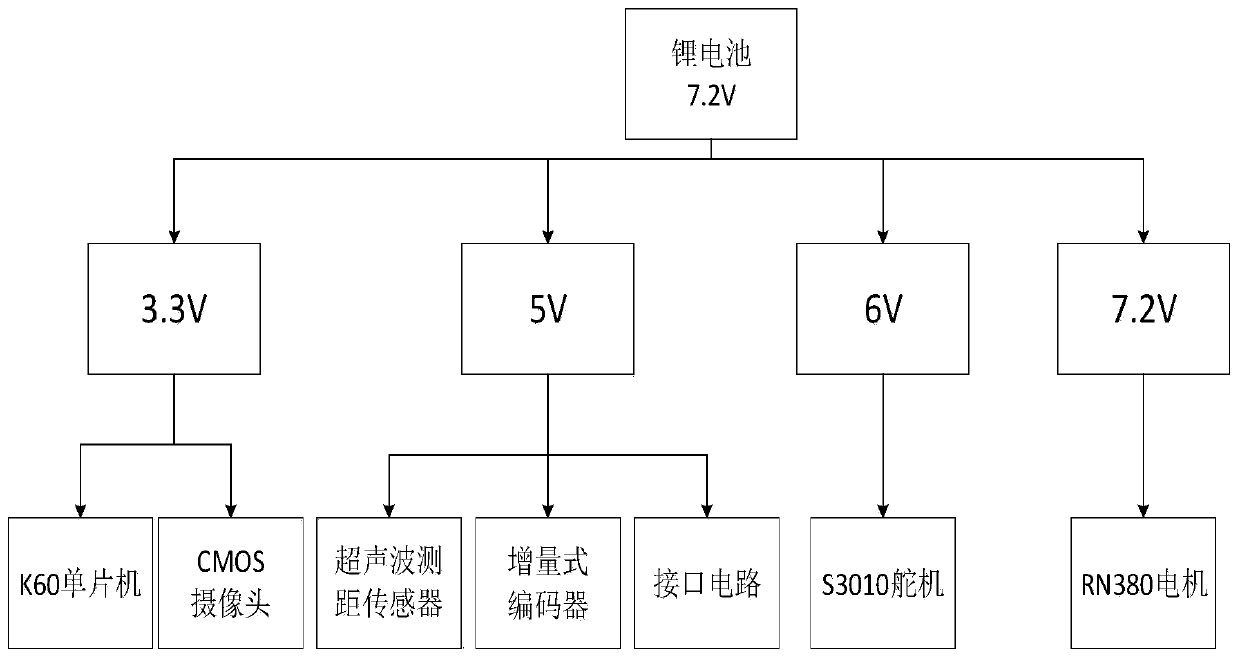

PendingCN111123954AEasy accessMeet collectionPosition/course control in two dimensionsInformation processingMultiple sensor

The invention belongs to the technical field of artificial intelligence and intelligent control, and discloses an intelligent vehicle control system and a method based on gray scale camera detection,and the system comprises a sensor detection module which is used for obtaining road information through a CMOS gray scale camera, an ultrasonic ranging sensor and an electromagnetic induction device;meanwhile, an incremental encoder is used for obtaining real-time speed data of the trolley; the core processor is used for correspondingly processing various detected data, acquiring the expected speed of the trolley and identifying obstacles; meanwhile, trolley speed conversion control and steering engine steering control are conducted; and the output executing mechanism comprises a steering engine, a motor and a trolley. The invention discloses a control system for acquiring more road information, performing planning decision and performing intelligent information processing by utilizing multi-sensor auxiliary detection, which can ensure that a trolley strictly follows a preset track to run, can effectively judge a complex path and improves the tracking efficiency of the trolley.

Owner:HUBEI NORMAL UNIV

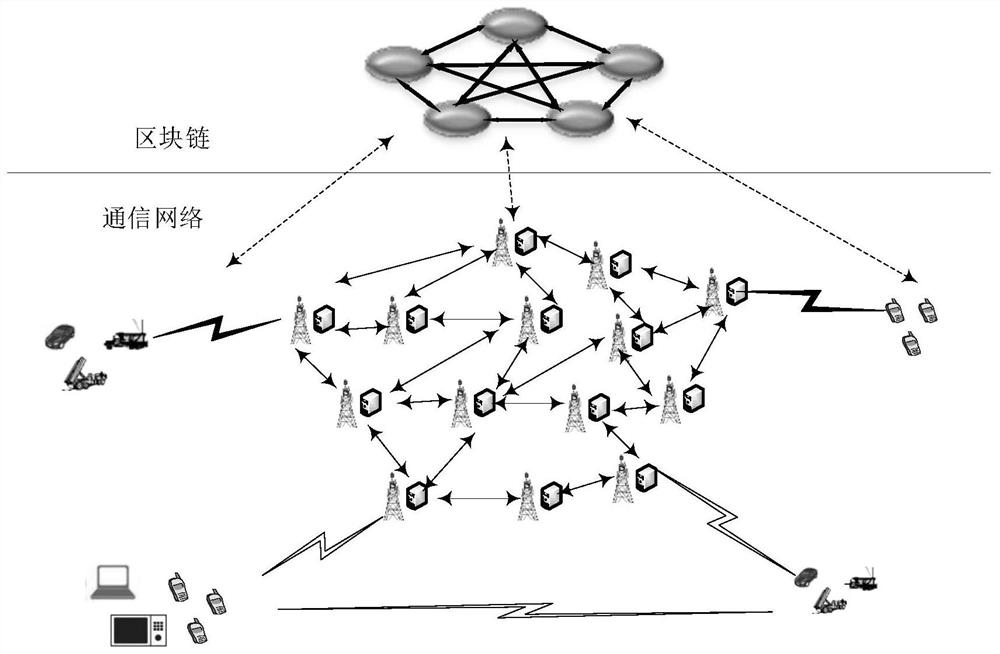

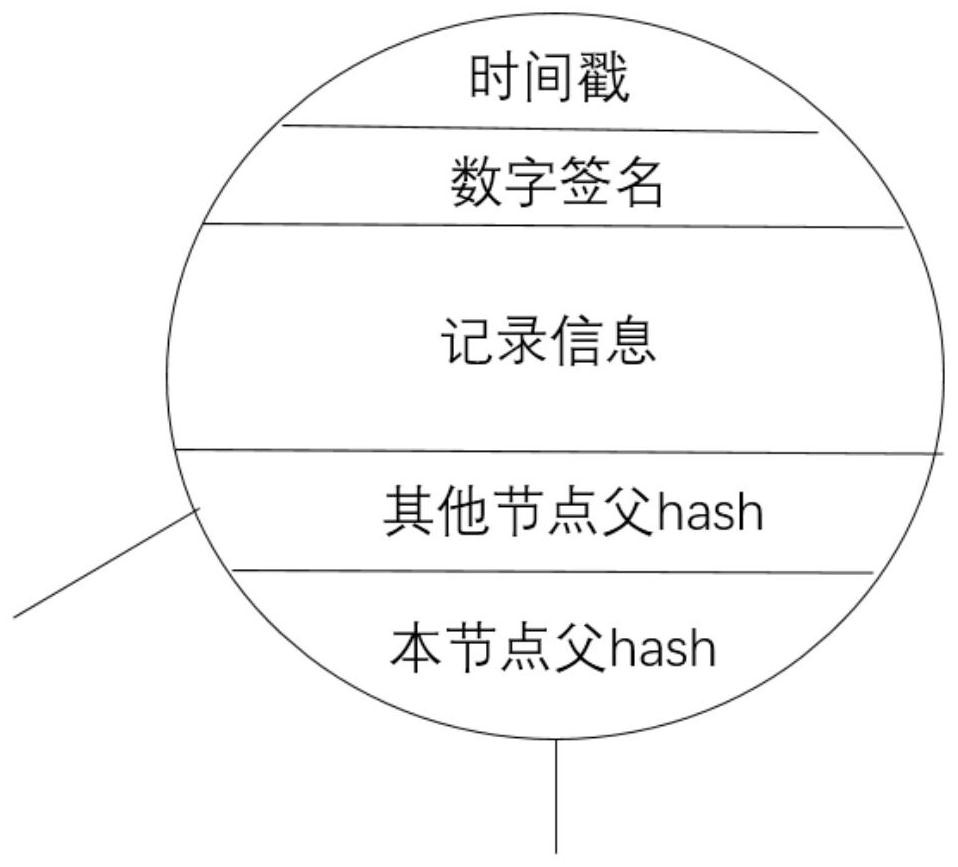

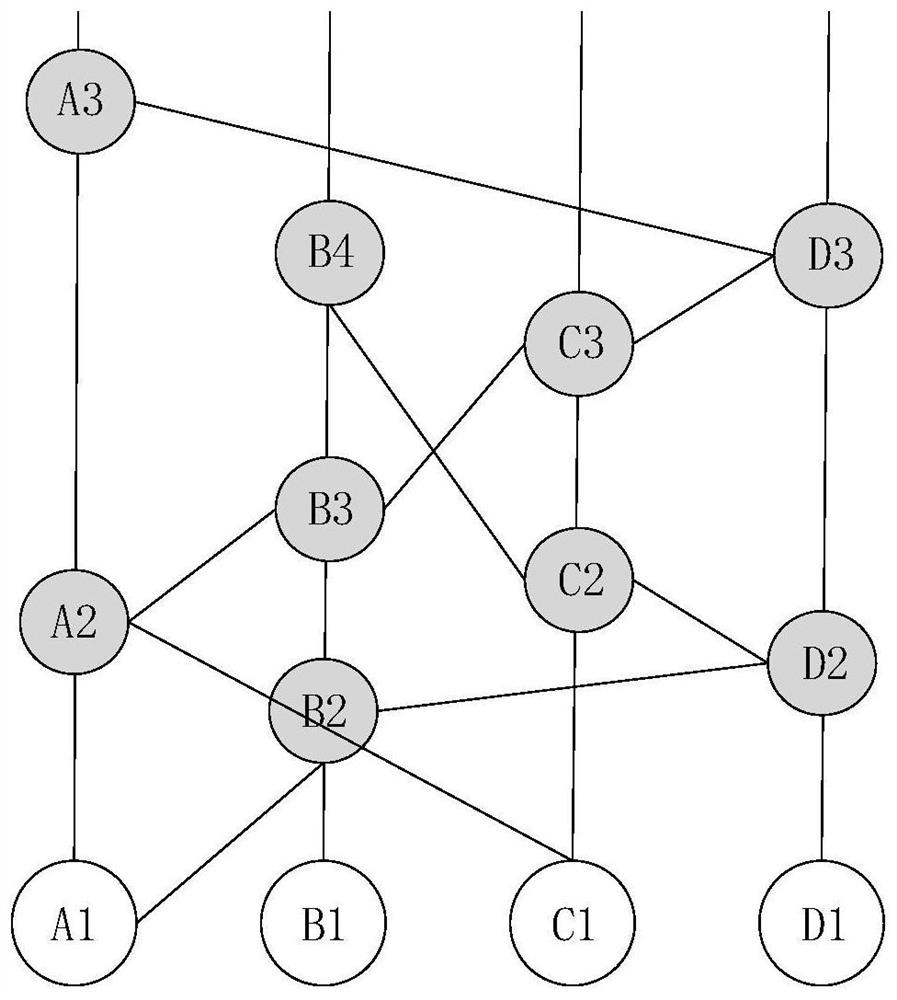

Data security sharing method based on hash map and federated learning

PendingCN111930698AFast convergenceHigh precisionEnsemble learningEpidemiological alert systemsGossip algorithmsEngineering

The invention discloses a data security sharing method based on a hash map and federated learning. Detection of a federated learning local model is added into a hashgraph consensus algorithm of a block chain 3.0 technology; dishonest nodes are prevented from providing an error model; meanwhile, the federated learning data model is realized through a method of carrying out weighted aggregation on alocal model. The method comprises the following steps: 1) adding detection on the federated learning local model into a block chain 3.0 technology hash graph consensus algorithm to prevent dishonestnodes from providing an error model; and 2) the dishgraph node detection process mainly comprising the following steps of: generating an event, performing Gossip communication, performing consensus byadopting a virtual voting algorithm, and realizing successful detection of dishonest nodes in a federal learning process based on a data security sharing model of hash and federal learning.

Owner:NANJING XIAOZHUANG UNIV

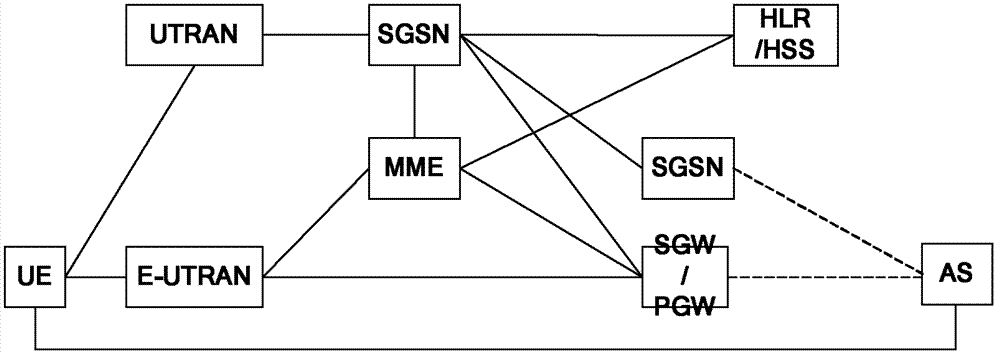

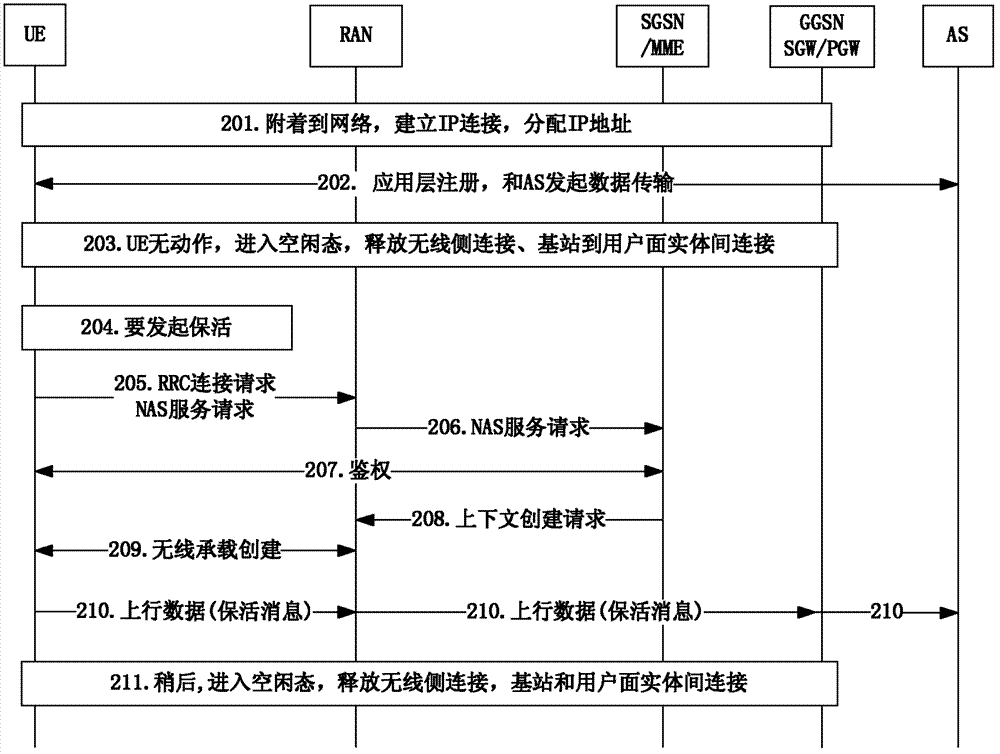

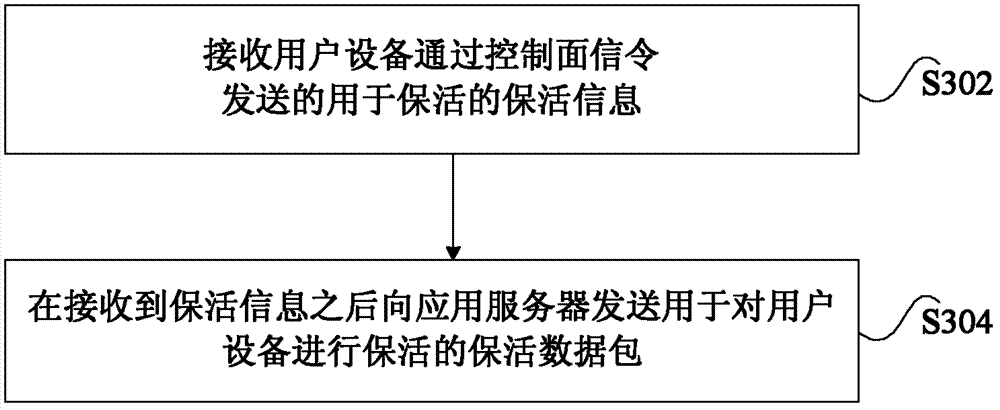

Application data processing method and device

InactiveCN103096293AAddress adverse effectsThe effect of reducing resource consumptionConnection managementNetwork data managementData packUser device

The invention discloses an application data processing method and a device. The method comprises that application data which is sent by a user experience device through a control plane signaling can be received; after the application data is received, the application data is sent to an application servicer through an internet protocol (IP) data packet. The application data processing method and the device can be used for resolving the problem that a terminal and the application servicer are keep alive to bring negative effects in the relative technologies. The application data processing method and the device is used for achieving to reduce resource consumption effects of the system because of keeping alive frequently.

Owner:ZTE CORP

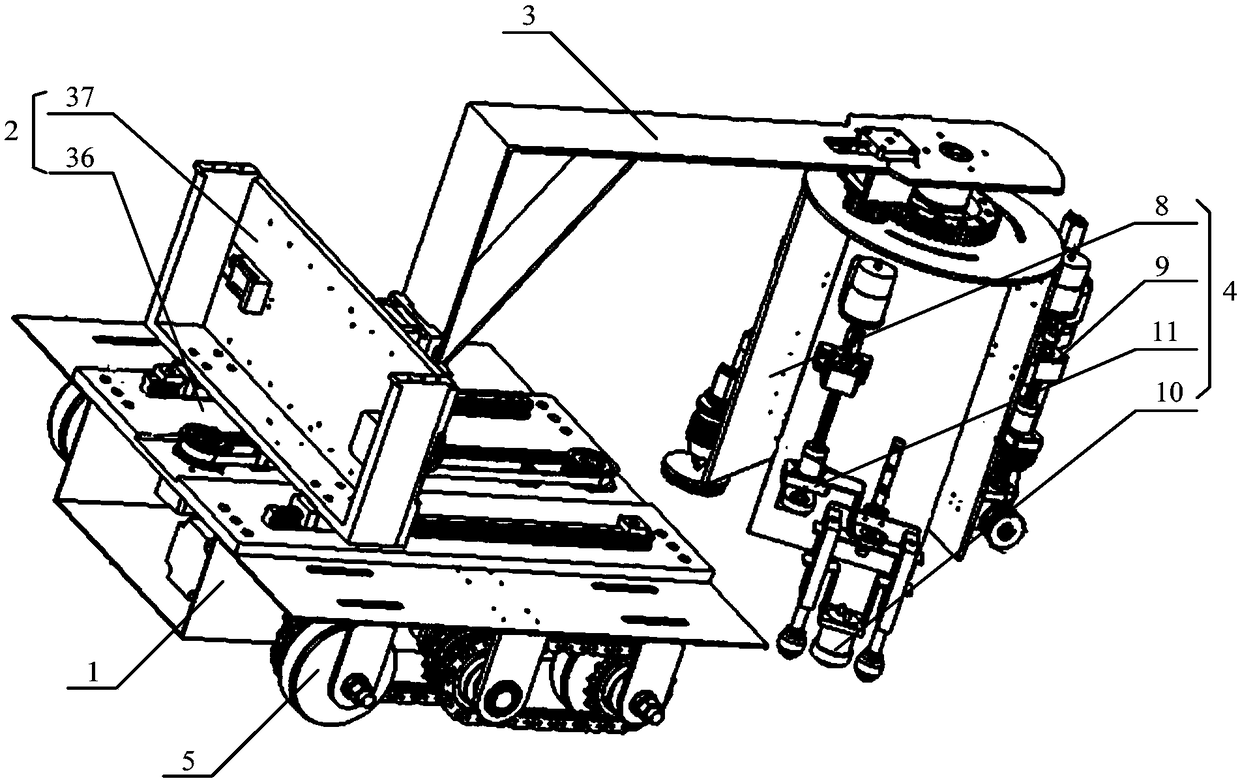

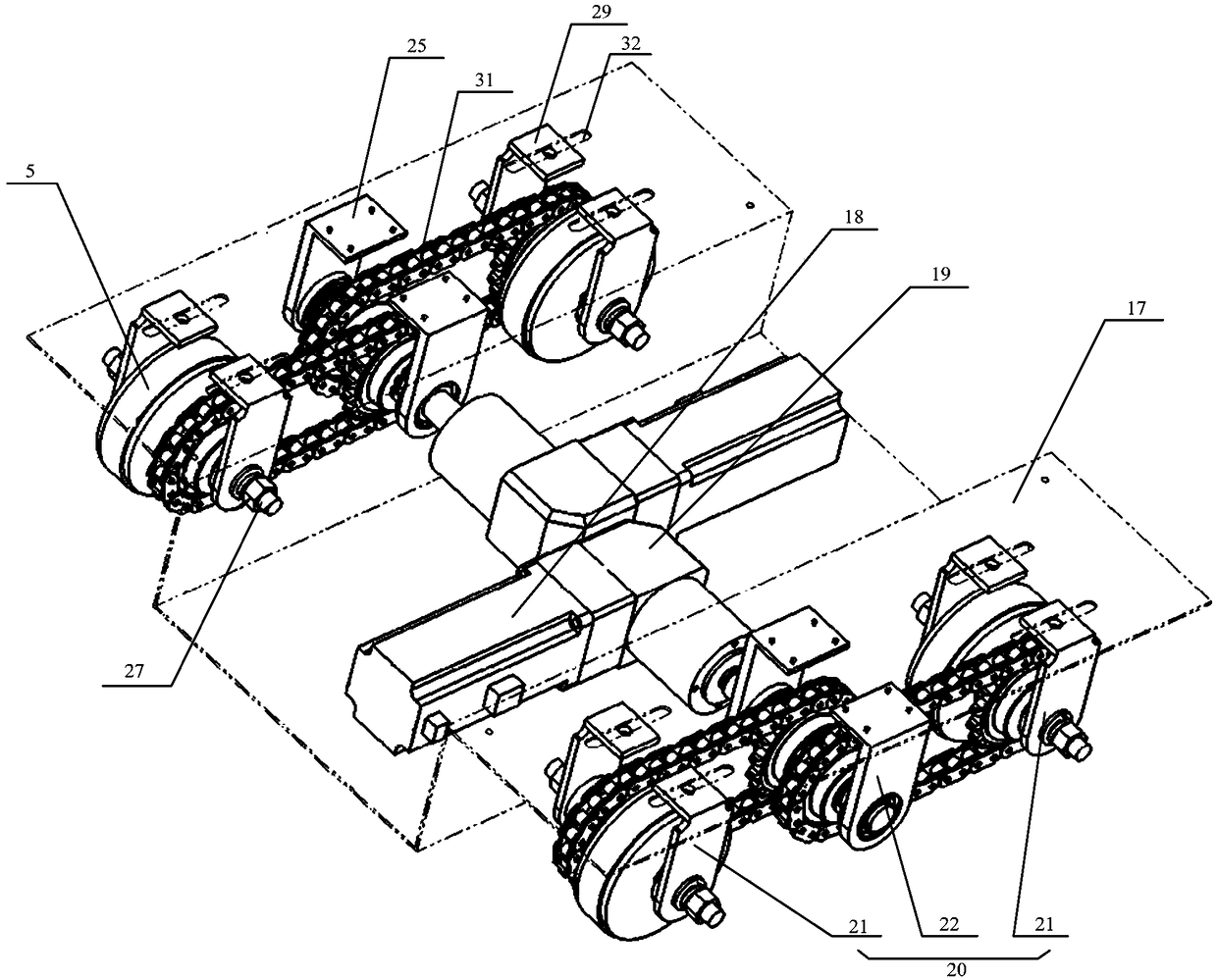

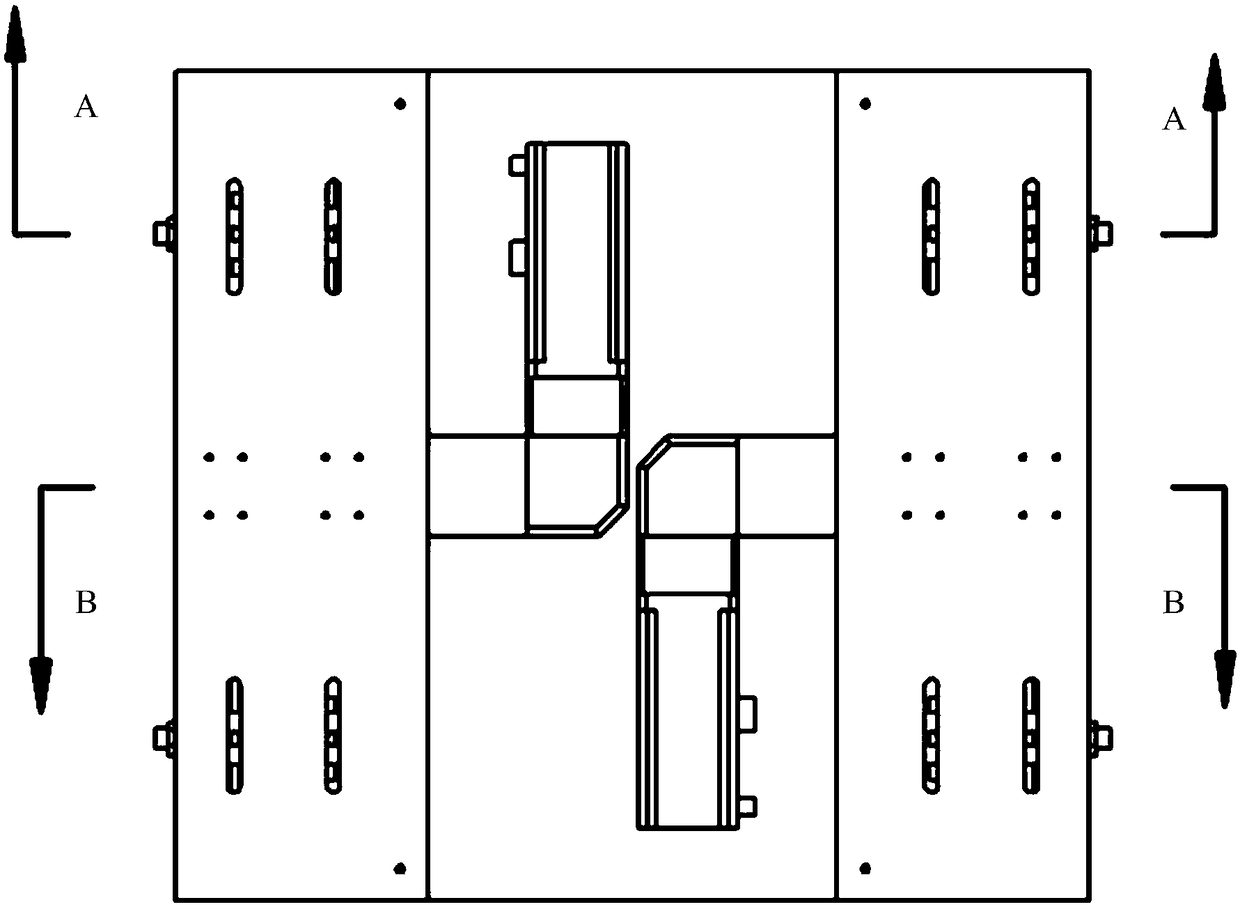

Thickness detection device applied to surface of large-sized metal tank body

ActiveCN108759737ALess amount of smearEnhanced couplingUsing subsonic/sonic/ultrasonic vibration meansEngineeringMetal

The invention relates to a thickness detection device applied to the surface of a large-sized metal tank body and belongs to the equipment intelligent detection technological field. The thickness detection device applied to the surface of the large-sized metal tank body comprises a device body, an XY direction motion module, a supporting turntable module, a Z direction working module and a controller; the device body is provided with a driving mechanism A and a magnetic wheel; the XY direction motion module is mounted on the device body; the supporting turntable module comprises a supporting frame, a driving mechanism B and a connecting disc, wherein the supporting frame is connected with the XY direction motion module, and the driving mechanism B is mounted on the supporting frame and connected with the connecting disc; the Z direction working module comprises a sweeping module, a couplant applying module, a thickness detecting module and three telescopic mechanisms, wherein the threetelescopic mechanisms are a telescopic mechanism A, a telescopic mechanism B and a telescopic mechanism C respectively, wherein the telescopic mechanism A is connected with the sweeping module, the telescopic mechanism B is connected with the couplant applying module, and the telescopic mechanism C is connected with the thickness detecting module. The device can replace manual operation to detectthe thickness of the metal tank body.

Owner:SOUTHEAST UNIV

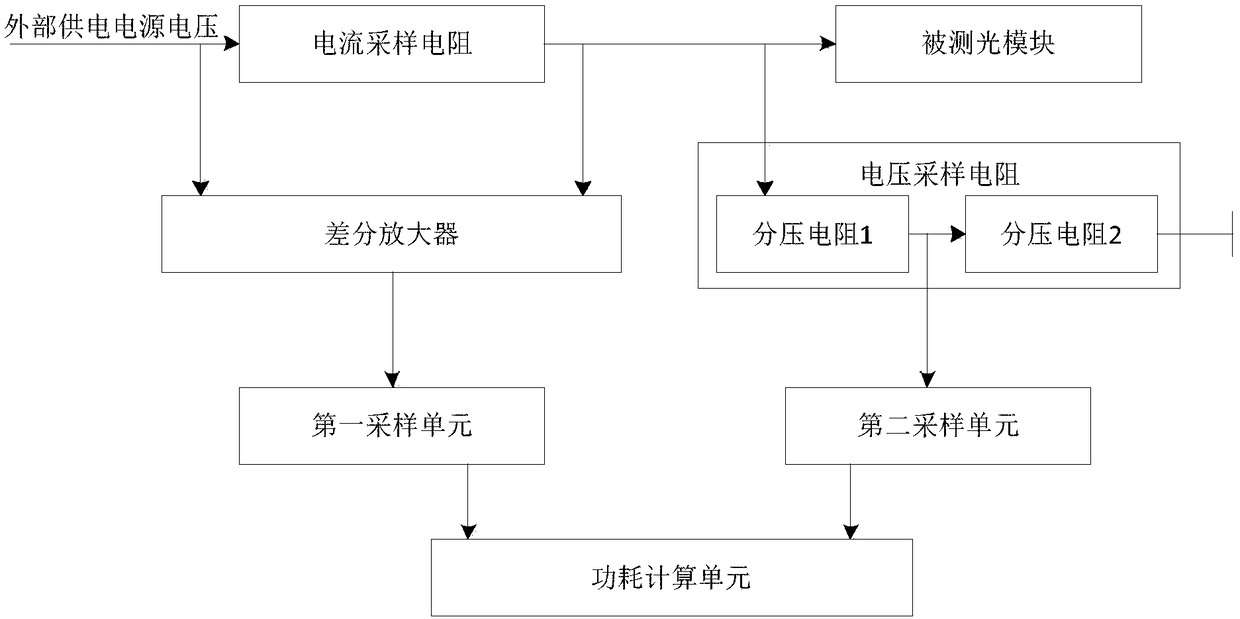

Power consumption measurement circuit and method for optical module

InactiveCN109450528AAddress adverse effectsWide range of power consumptionElectromagnetic transmissionDifferential amplifierMeasurement precision

The invention relates to the field of optical communication, and discloses a power consumption measurement circuit and method for an optical module. The power consumption measurement circuit comprisesa current sampling resistor, a differential amplifier, a voltage sampling resistor, a first sampling unit, a second sampling unit and a power consumption calculation unit; the two ends of the currentsampling resistor are connected to an external power supply and the measured optical module respectively; the two input ends of the differential amplifier are connected to the two ends of the currentsampling resistor respectively, and the output end of the differential amplifier is connected to the input end of the first sampling unit; the first end of the voltage sampling resistor is connectedto the second end of the current sampling resistor, and the second end of the voltage sampling resistor is connected to the input end of the second sampling unit; the output end of the first samplingunit and the output end of the second sampling unit are connected to the power consumption calculation module; and the power consumption calculation module is used for calculating the power consumption of the measured optical module according to sampling values of the first sampling unit and the second sampling unit. According to the power consumption measurement circuit and method, the power consumption measurement precision is high and can reach + / -3%, and the measurement range is wide.

Owner:DONGGUAN MENTECH OPTICAL & MAGNETIC

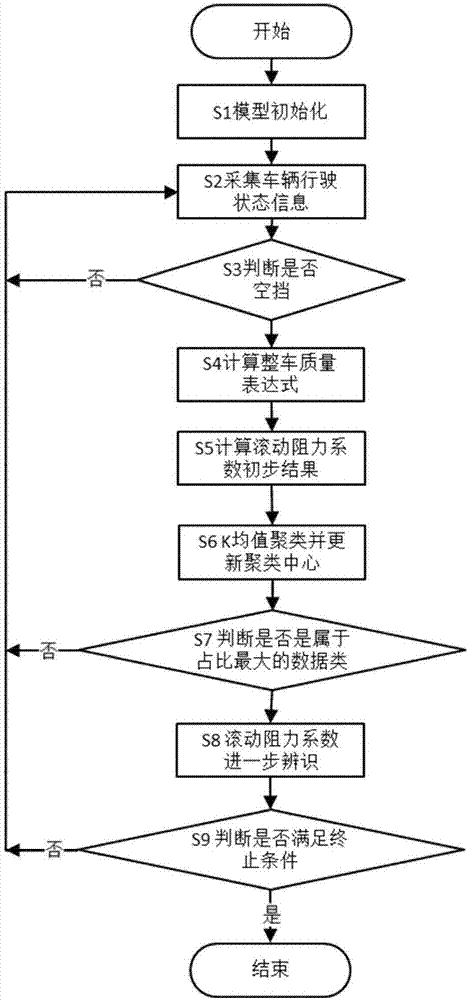

Tire rolling resistance coefficient online identification method

InactiveCN107229801AAddress adverse effectsEliminate the effects of recognitionGeometric CADDesign optimisation/simulationRolling resistanceVehicle driving

The invention relates to a tire rolling resistance coefficient online identification method. Firstly, an identification model is established through travel equations, and then online identification of the tire rolling resistance coefficient is achieved in combination with an online cluster identification algorithm. The original travel equation and the differential travel equation are integrated for establishment of the identification model, the influence on the whole vehicle mass is eliminated, and the defect that formerly, the rolling resistance coefficient is calculated by depending on the whole vehicle mass is overcome. The tire rolling resistance coefficient is measured through a sliding test in the traditional technology, and the traditional technology is limited by a single test environment and cannot adapt to the complex working condition of vehicle driving. The established online identification algorithm can online acquire important parameters of a whole vehicle and adapt to different vehicle running states and road environments.

Owner:JILIN UNIV

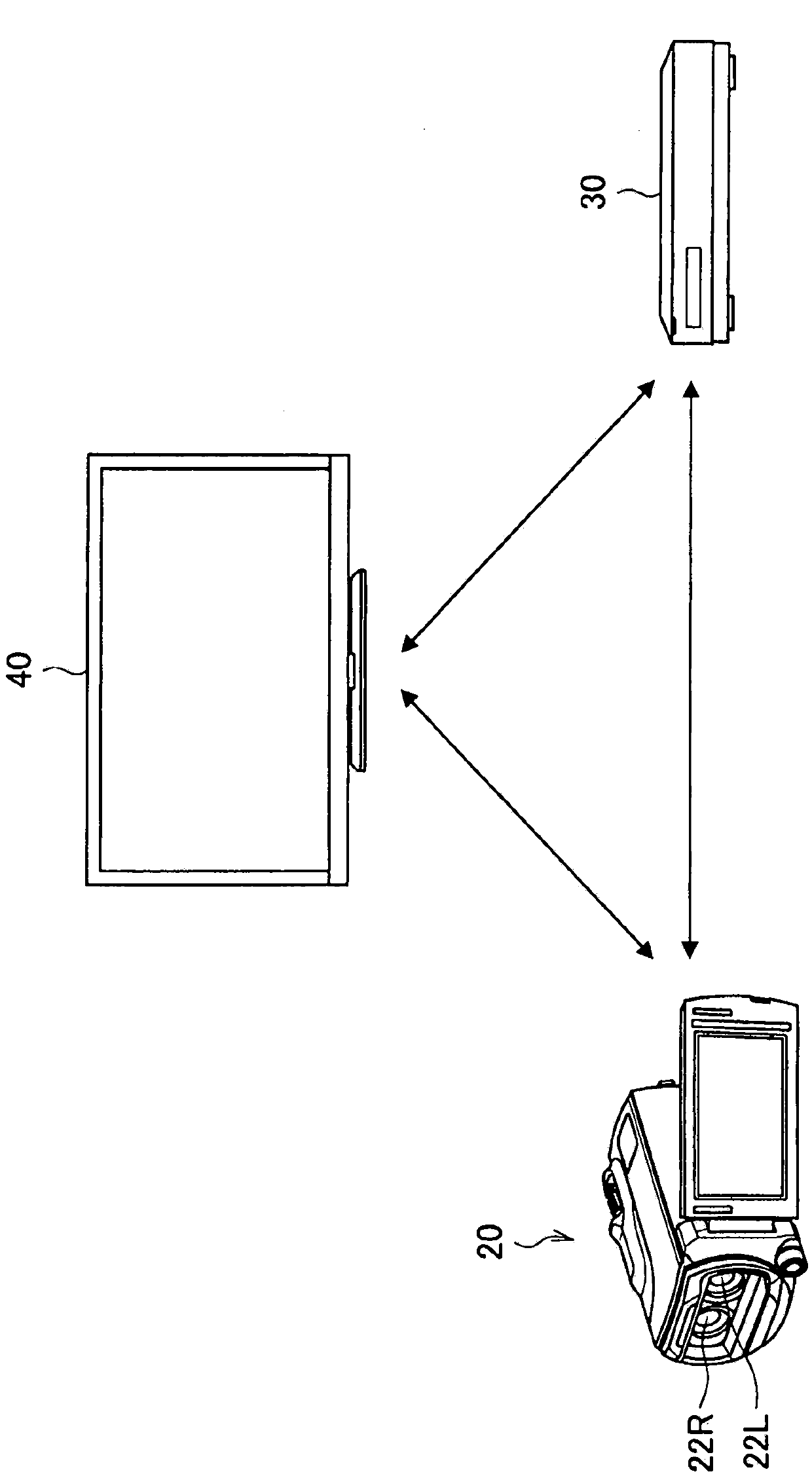

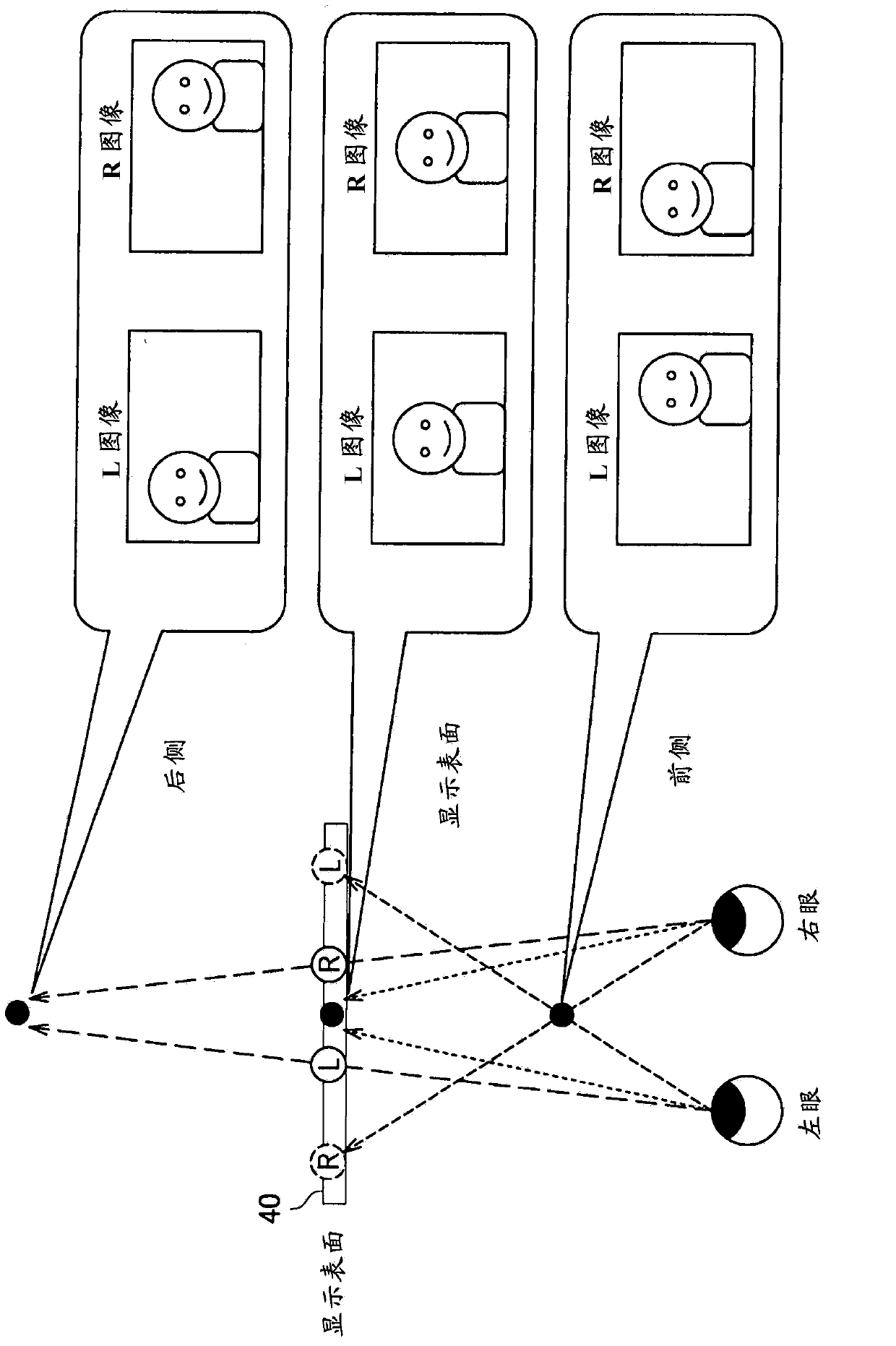

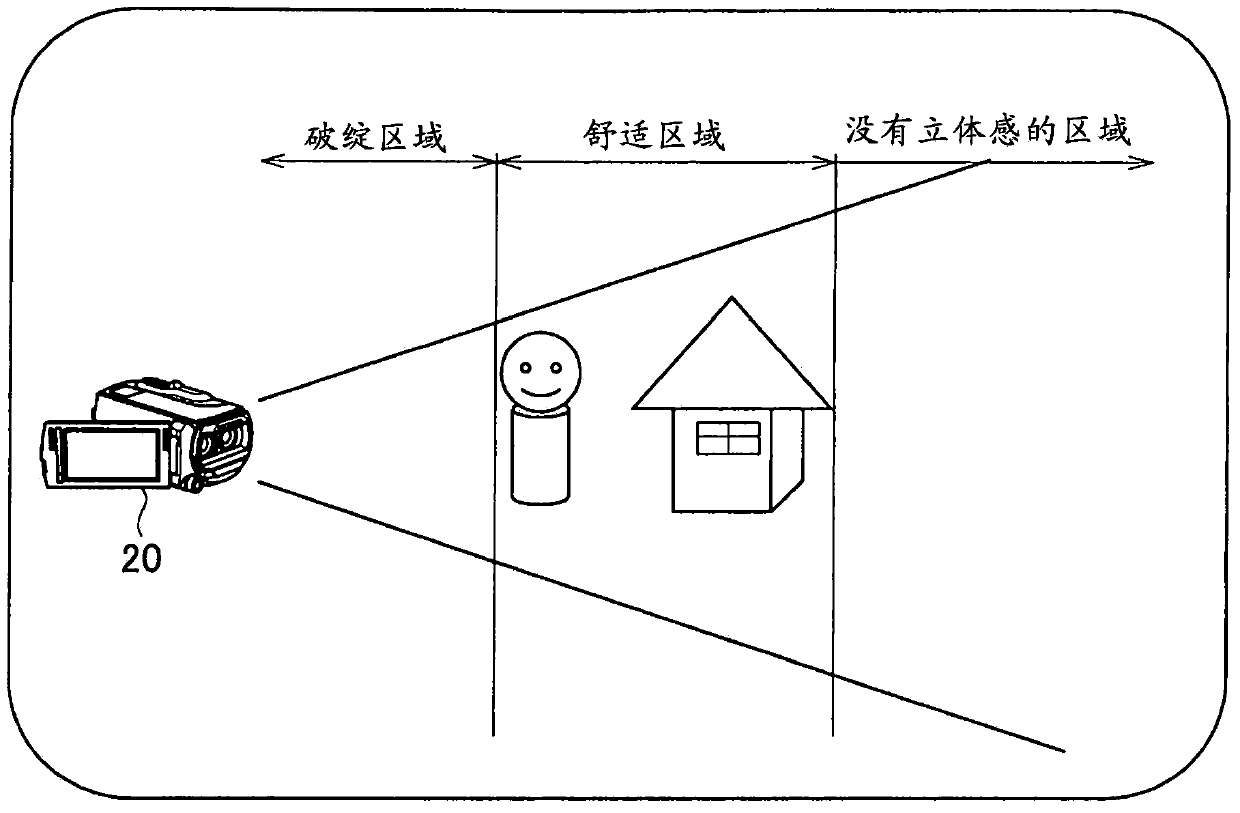

Visual disparity adjusting apparatus, image processing apparatus, and frame format

InactiveCN104012087AAddress adverse effectsTelevision system detailsColor television detailsParallaxImaging processing

A visual disparity adjusting apparatus comprises: a visual disparity adjusting unit that performs a visual disparity adjustment between left-eye and right-eye images obtained by image pickup; and a data processing unit that associates metadata, which is related to the visual disparity adjustment, with image data including the left-eye and right-eye images.

Owner:SONY CORP

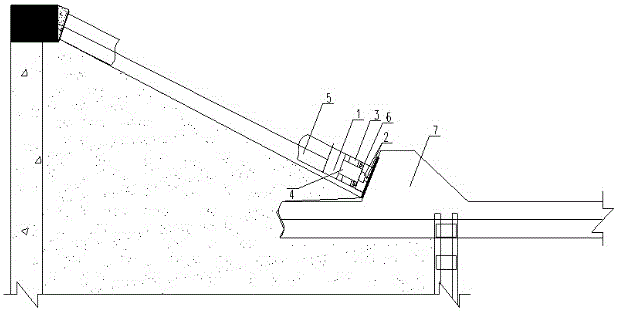

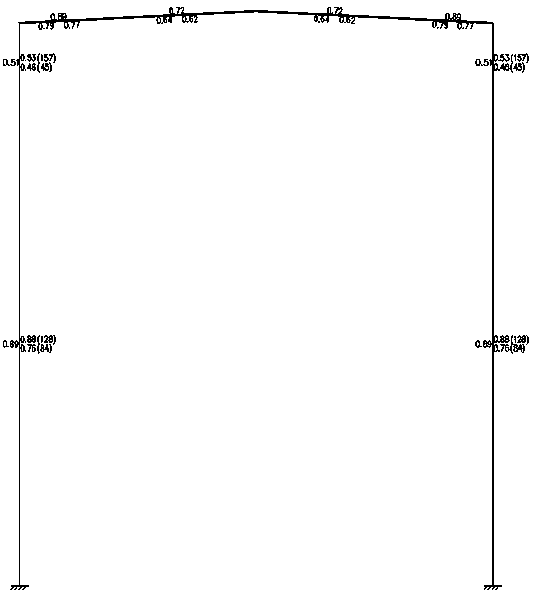

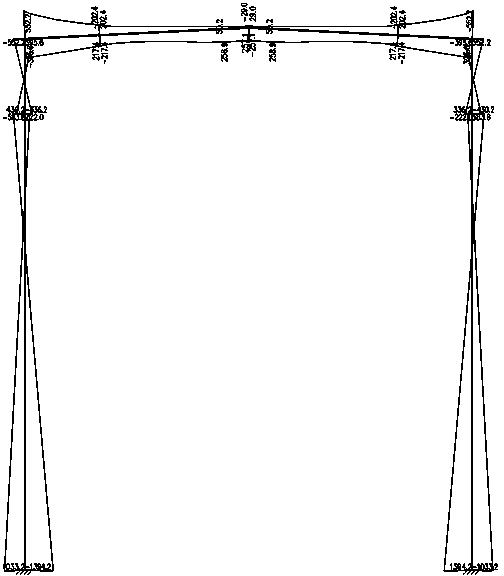

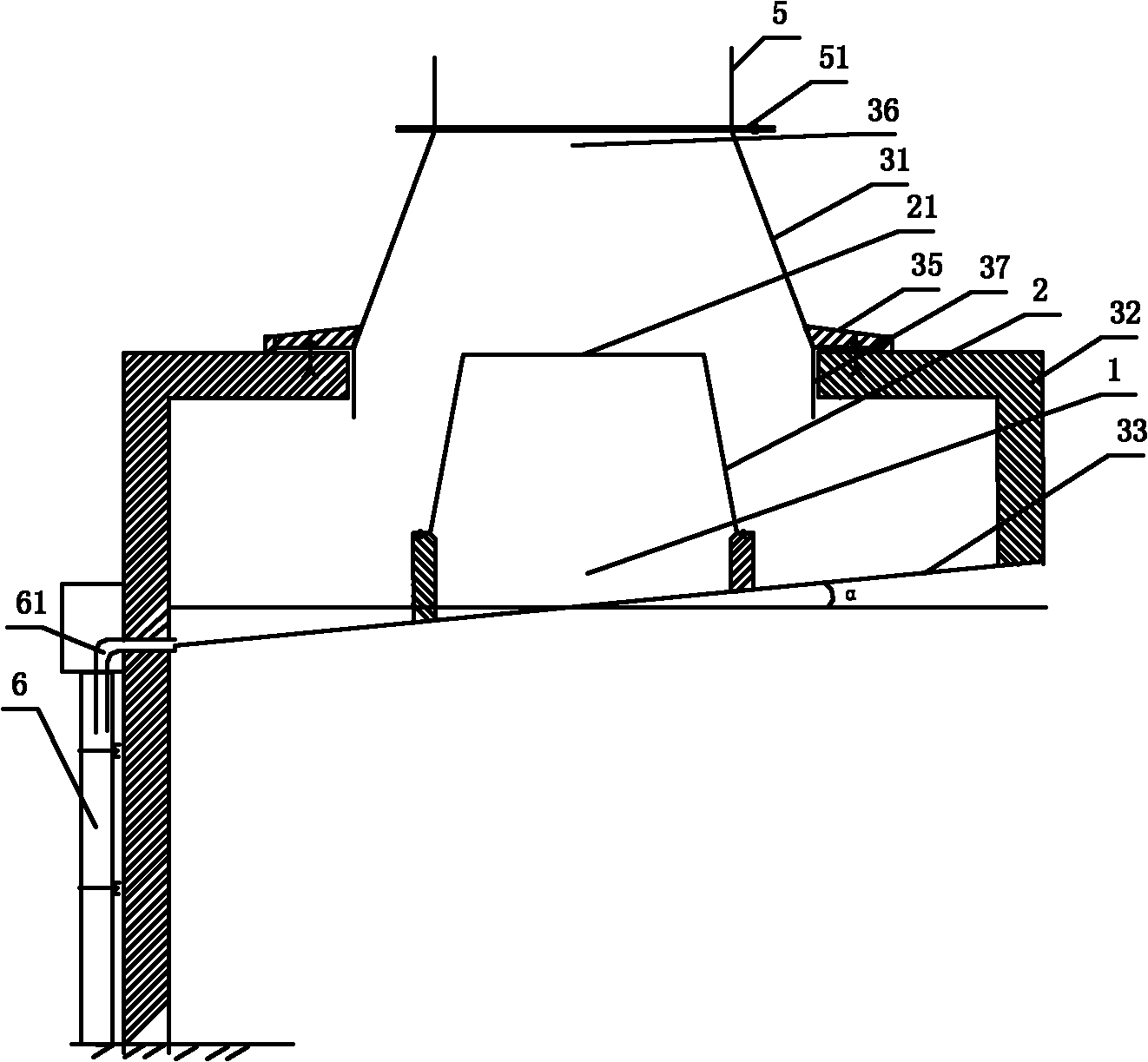

Steel support axial force monitoring system capable of applying prestressing force

The invention discloses a steel support axial force monitoring system capable of applying prestressing force. The steel support axial force monitoring system capable of applying prestressing force comprises a connecting piece, an axial force meter, a supporting steel pipe body and a bracket. One end of the axial force meter is welded to an end plate of the connecting piece, and the other end of the axial force meter abuts against the bracket. A steel pipe sleeve is additionally arranged at the end of the axial force meter. One end of a flange plate of the connecting piece is directly welded to the supporting steel pipe body, and the other end of the flange plate of the connecting piece is cut into an arc and welded to the axial force meter. A cushion block is arranged between the connecting piece and the axial force meter. Hydraulic jacks are arranged on the two sides of the cushion block. By the adoption of the steel support axial force monitoring system capable of applying prestressing force, the problem that when the distance between a foundation pit supporting body and a land boundary line is too small and the elevation of a locking beam is different from that of a horizontal supporting system, negative influences on a foundation pit are caused by excessive deformation of the locking beam or an underground diaphragm wall is effectively solved.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

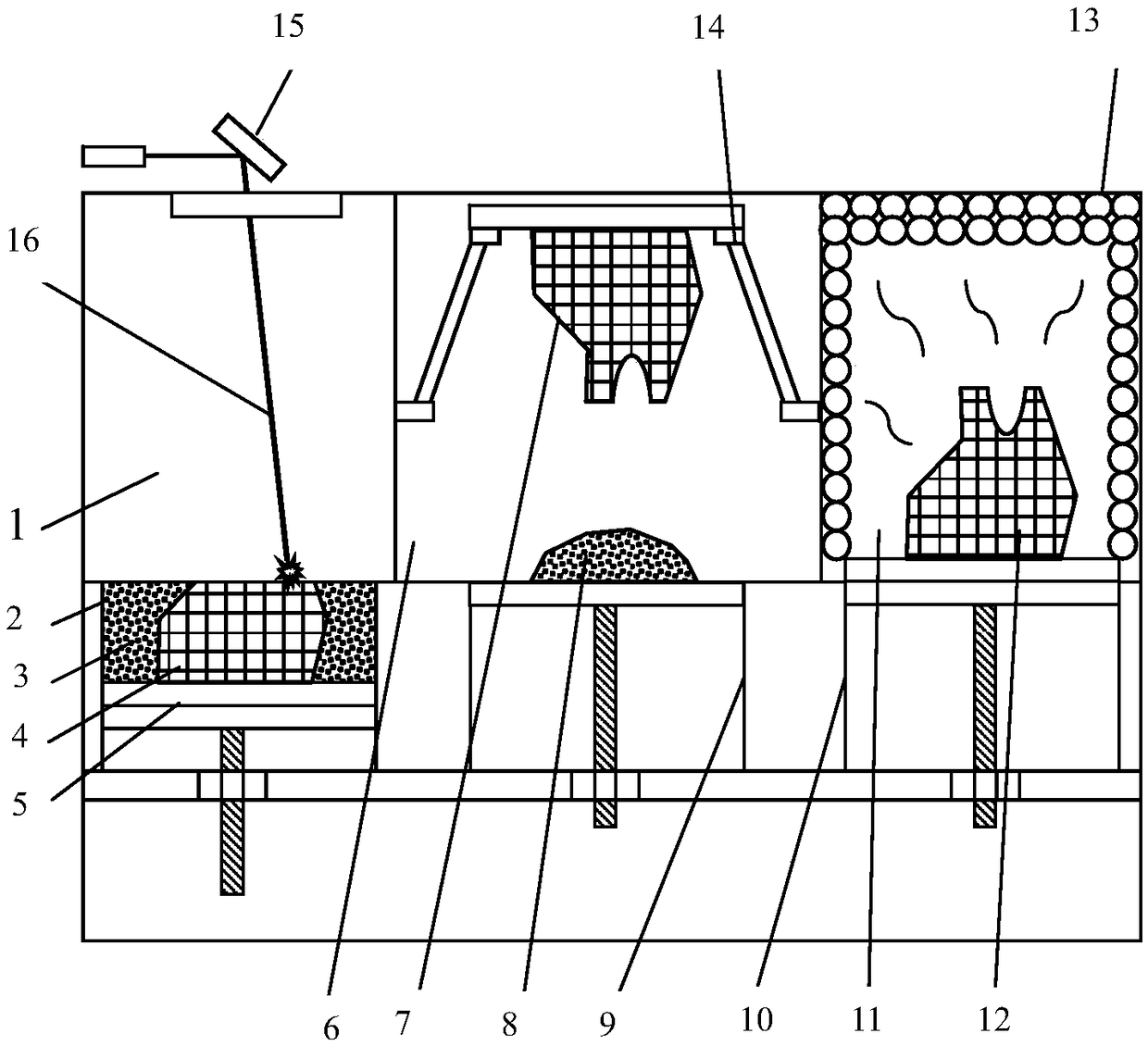

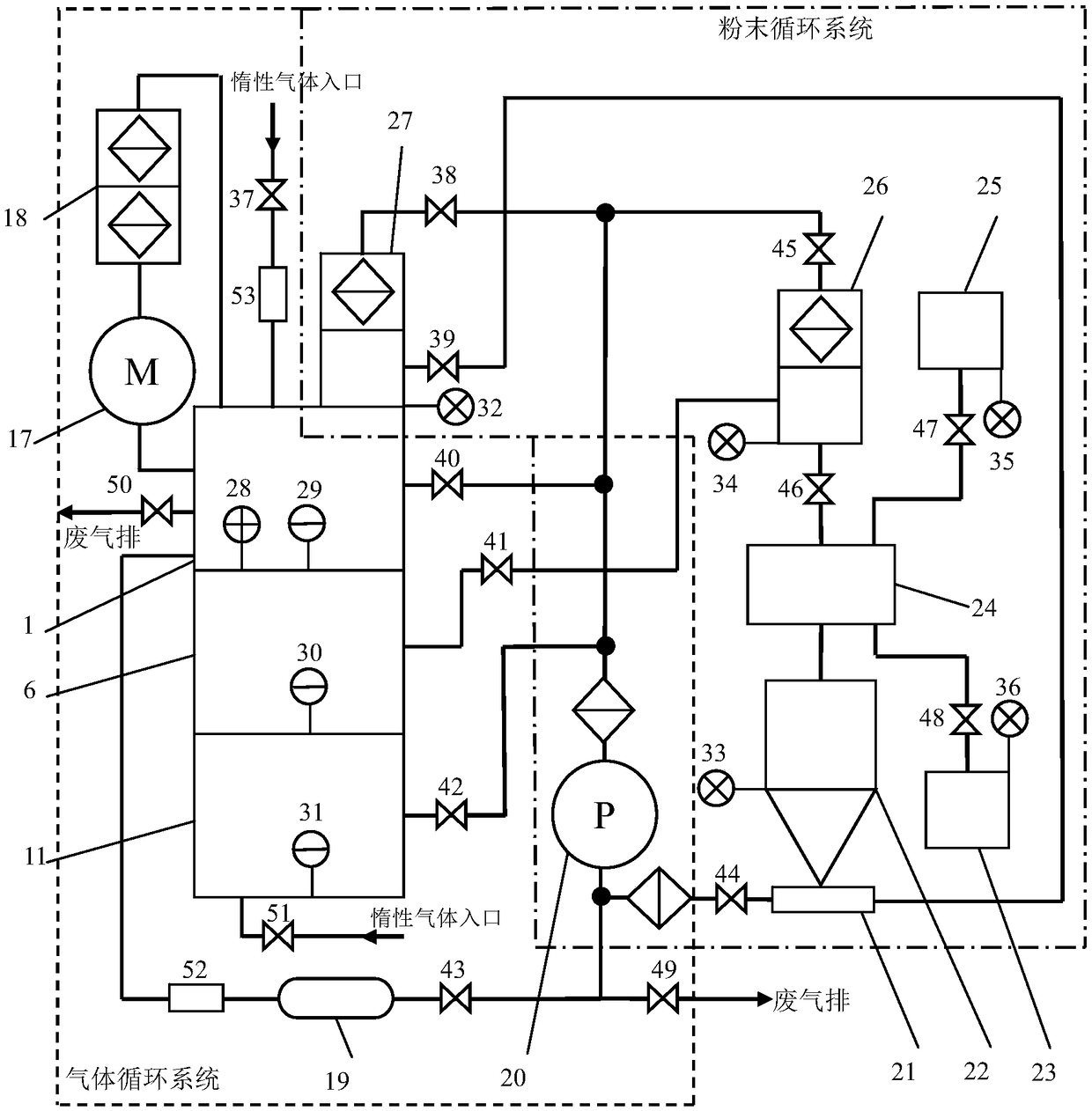

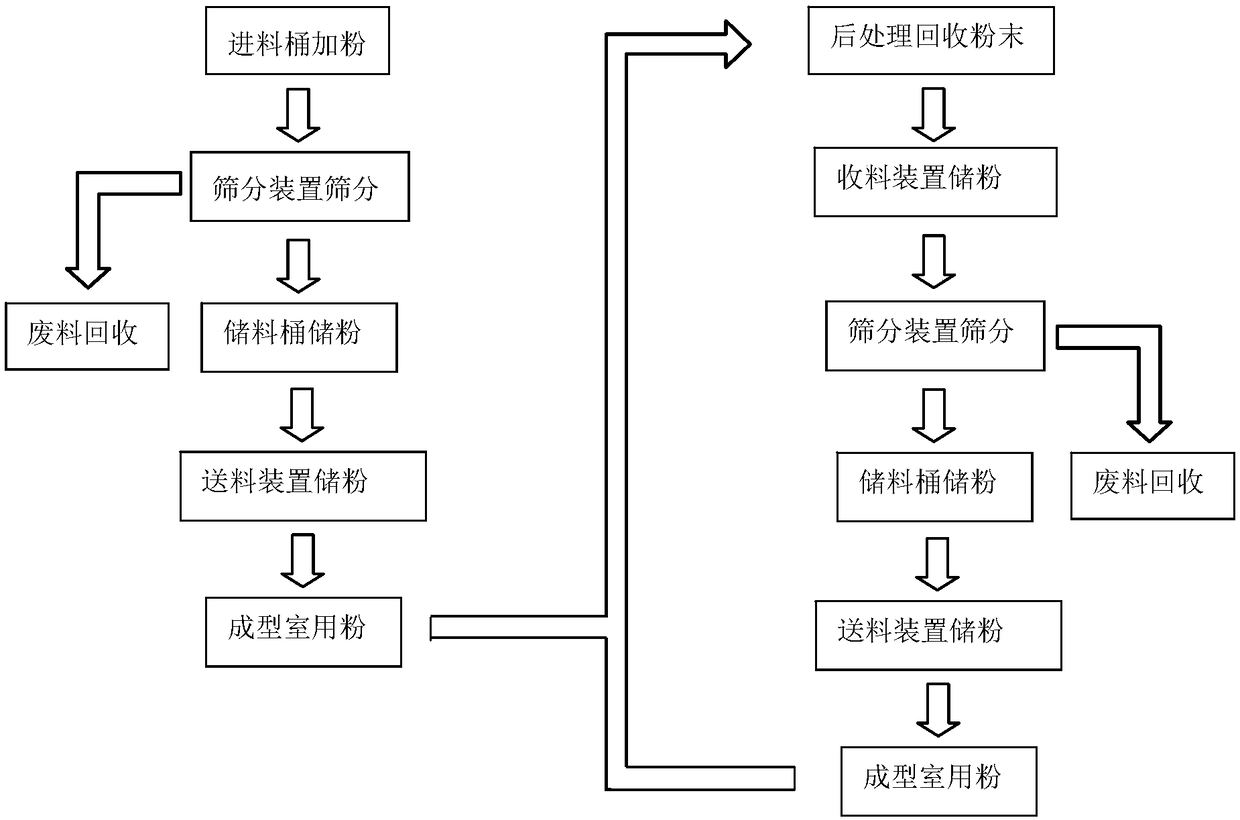

Control system and method of additive manufacturing laser formation system integrated equipment

PendingCN108971492ASolve operational problemsAddress adverse effectsAdditive manufacturing apparatusIncreasing energy efficiencyIntegrated devicesControl system

The invention relates to a control system and method of additive manufacturing laser formation system integrated equipment and belongs to the technical field of additive manufacturing. The control system comprises a powder circulation system and a gas circulation system. The powder circulation system comprises a feeding barrel, a screening device, a material storage barrel, a collecting device, afeeding device and a vacuum unit. The gas circulation system comprises a vacuum unit, an inertia gas inlet, a gas storage tank, a circulation pump and a filter. According to the control system and method of the additive manufacturing laser formation system integrated equipment, through effective control over all the relevant devices of the powder circulation system, powder feeding to a laser formation module is achieved, and cyclic utilization of powder in a post-treatment chamber in a post-treatment module is also achieved; through control over all the devices of the gas circulation system, inert gas shielding protection of the laser formation module and high-vacuum-degree environment of a heat treatment module are achieved; and in this way, the efficiency of an additive manufacturing technological process is improved, waste of metal powder and inert gas is reduced, the operation environment of operation personnel is improved, and powder harm is lowered at the same time.

Owner:天津镭明激光科技有限公司

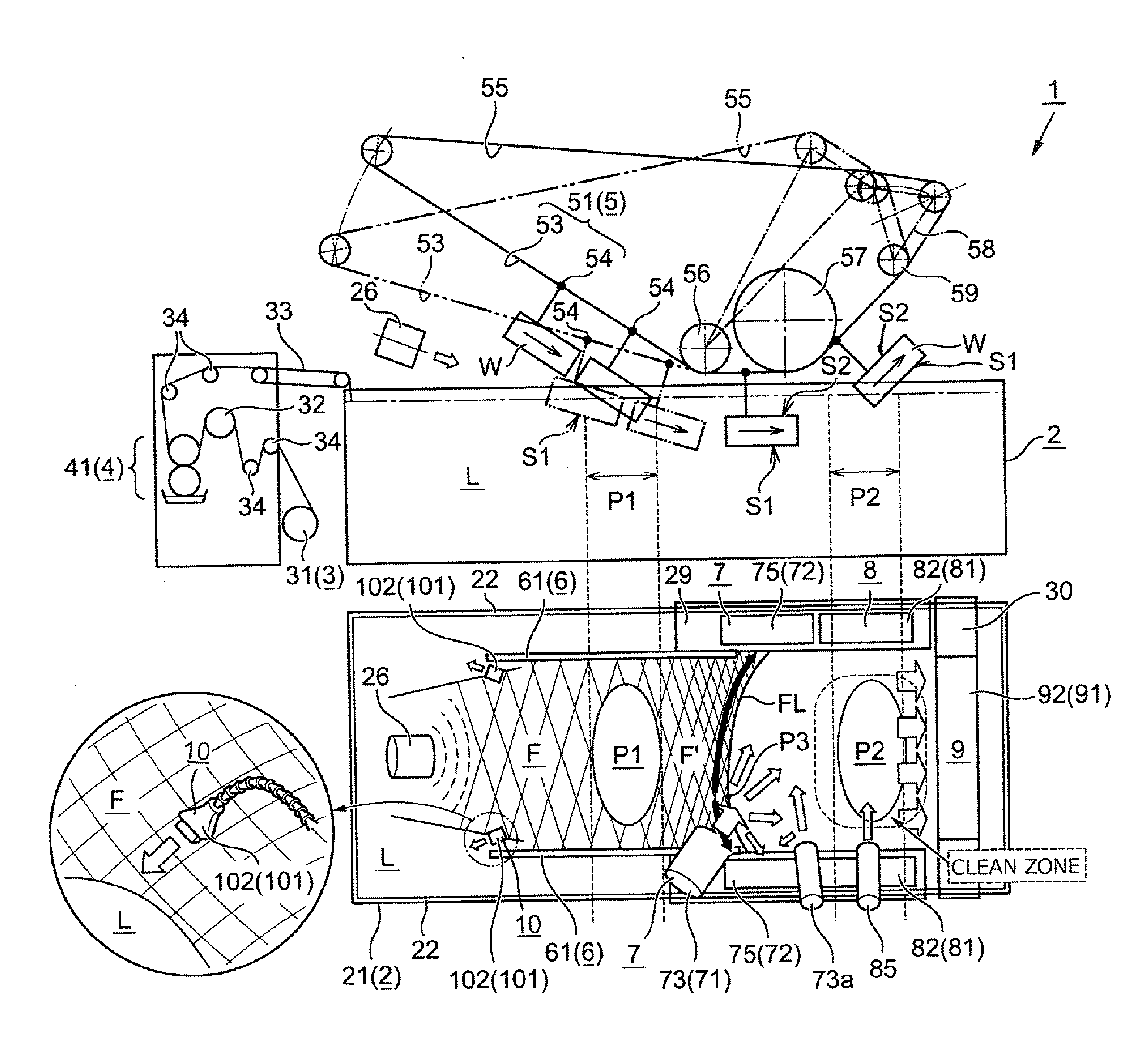

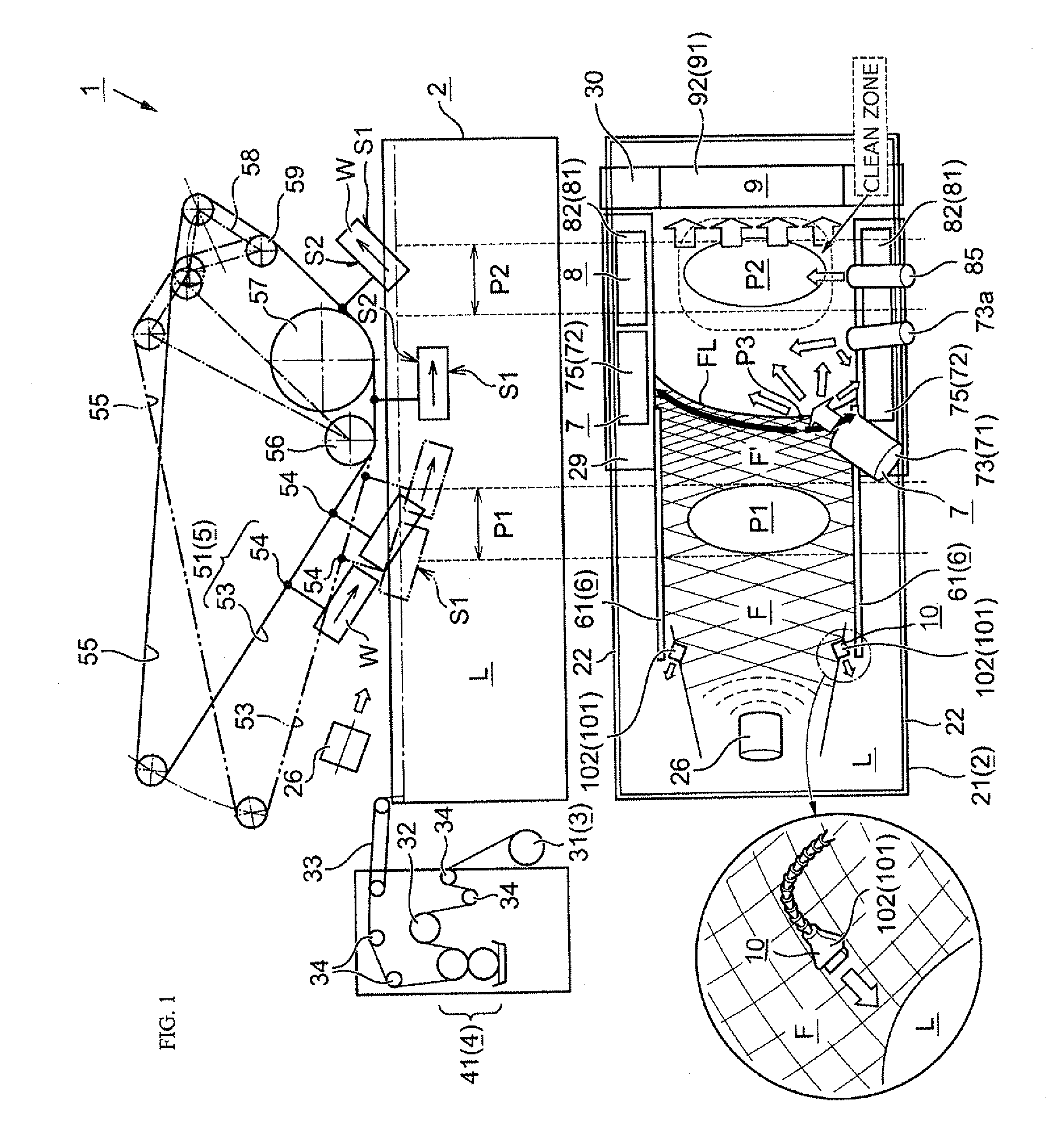

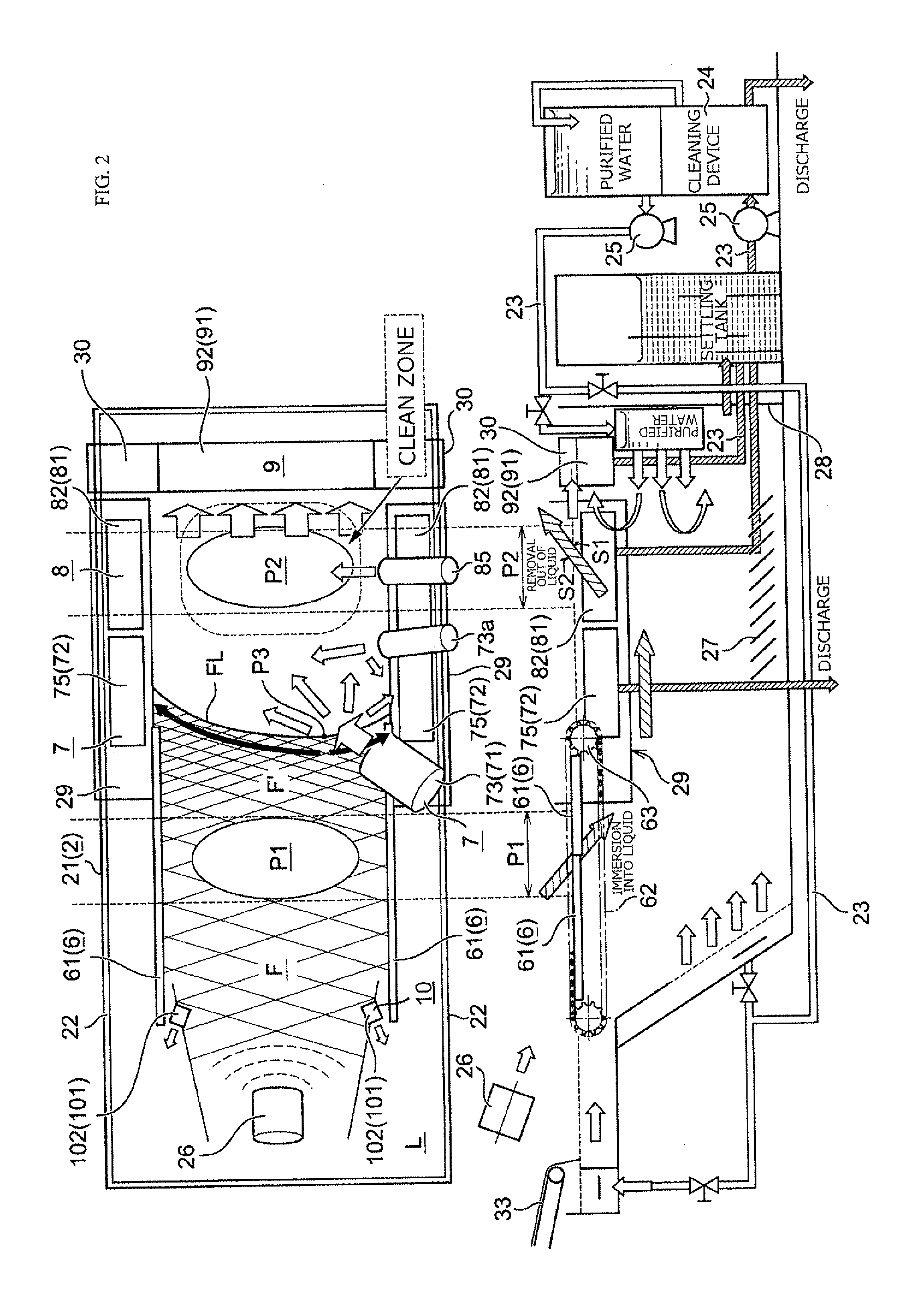

Method for collecting liquid surface residual film, method for transferring liquid pressure using same, collection device therefor, and liquid pressure transfer device using same

ActiveUS20120227769A1Collected quickly and reliablyLow chanceTransfer printingDecorative surface effectsEngineeringLiquid surfaces

Owner:TAICA

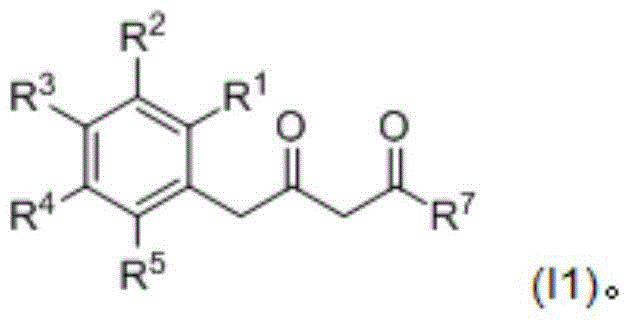

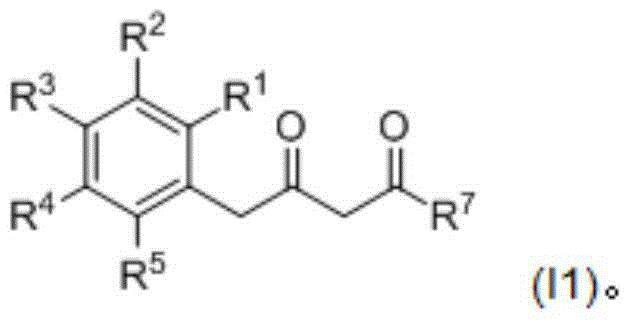

Preparation method of sitagliptin intermediate

ActiveCN103910634AHigh yieldHigh purityOrganic compound preparationCarboxylic acid esters preparationSitagliptinOrganic solvent

The invention relates to a preparation method of a sitagliptin intermediate. The method utilizes a low-toxicity organic solvent as a reaction solvent, realizes high-yield preparation of a high-purity desired product, is conducive to safe production and is suitable for industrial production.

Owner:SUNSHINE LAKE PHARM CO LTD

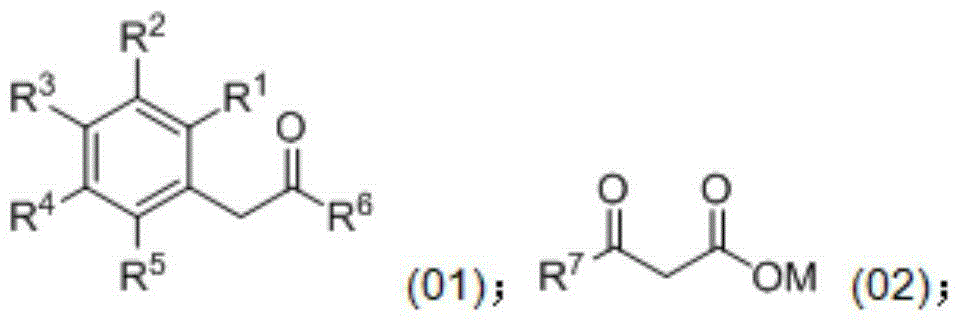

On-site surveying and mapping work system for engineering surveying and mapping

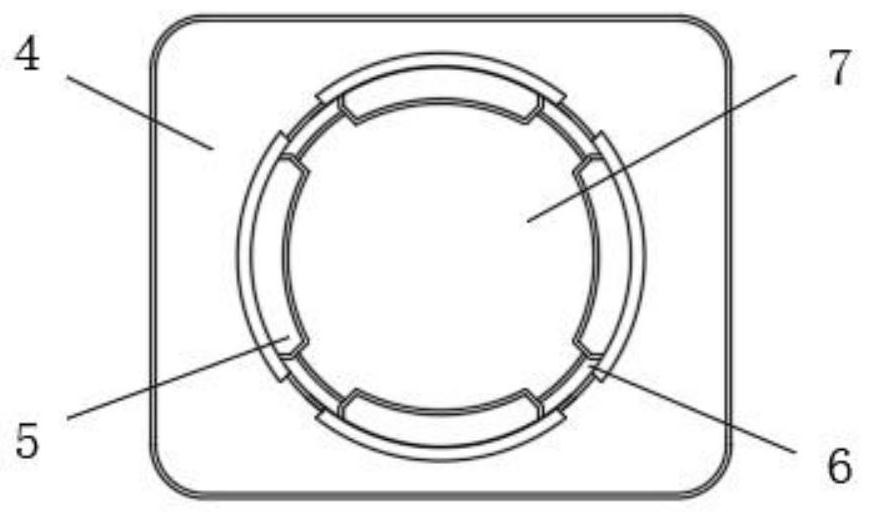

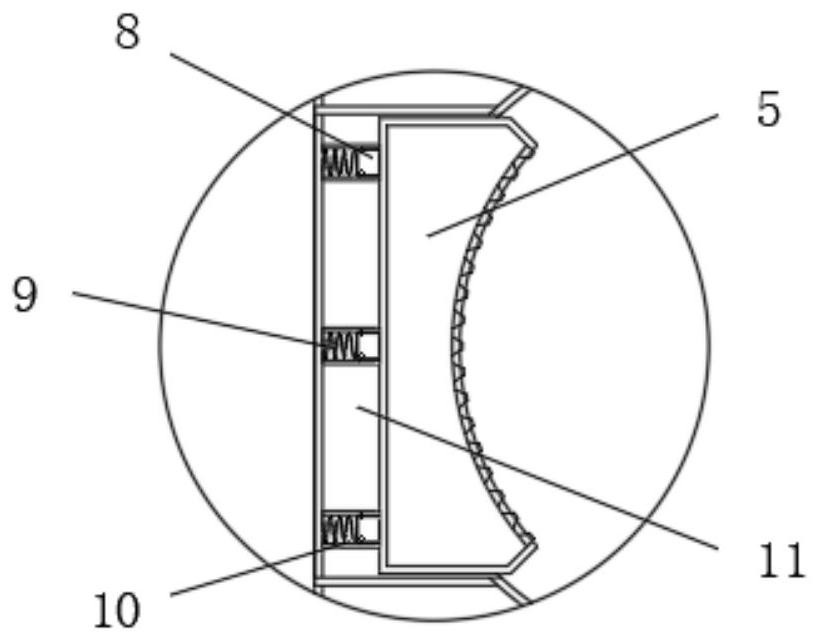

InactiveCN112082050AGuaranteed clamping forceWon't hurtNon-rotating vibration suppressionLeaf springsStructural engineeringMachine

The invention discloses an on-site surveying and mapping work system. The on-site surveying and mapping work system comprises a surveying and mapping machine body, a tripod and a fixing base, whereinthe fixing base is fixed to the surface of the top of the tripod, a mounting groove is formed in the surface of the top of the tripod, and the bottom of the surveying and mapping machine body is fixedin the mounting groove; containing grooves are formed in the inner wall of the interior of the mounting groove, a fastening clamping pad is arranged in each containing groove, the outlines of the outer ends of the fastening clamping pads are of an inwards-concave arc structure, guide columns are fixedly connected to the bottom of the rear end of each fastening clamping pad, guide grooves are formed in the inner wall of the bottom of each containing groove, the guide columns correspond to the guide grooves, and each guide column is fixed to the corresponding guide groove; and a spring fixedlyconnected to inner wall of the inner end of each guide column and the inner wall of the inner end of each guide groove. Through the designed fastening clamping pads, the surveying and mapping machinebody is installed in the mounting groove of the fixing base and clamped and fixed by the fastening clamping pads to prevent from deviating, and the surveying and mapping machine body cannot be damagedwhile the clamping force of the fastening clamping pads is guaranteed through the springs.

Owner:中化地质江苏岩土工程有限公司

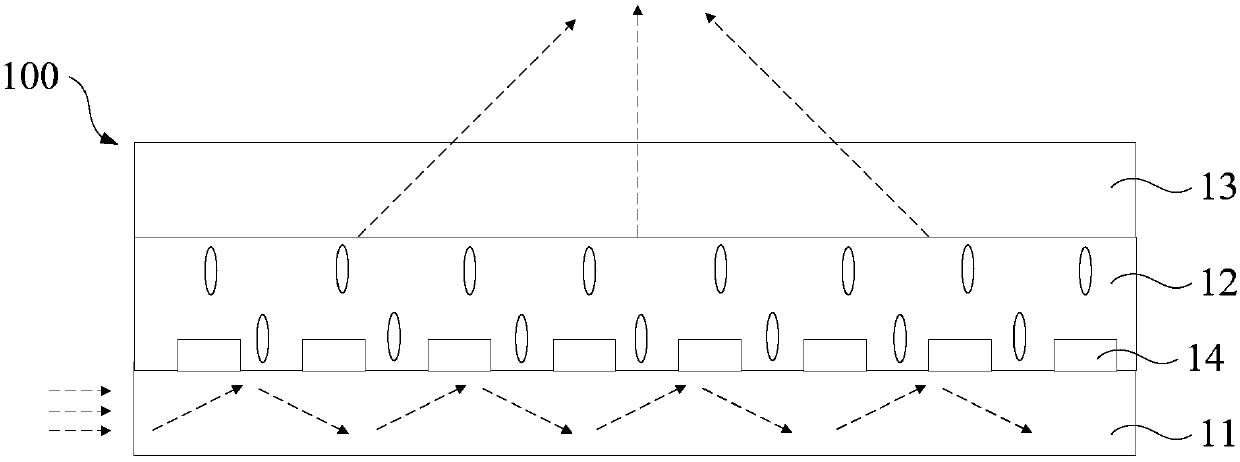

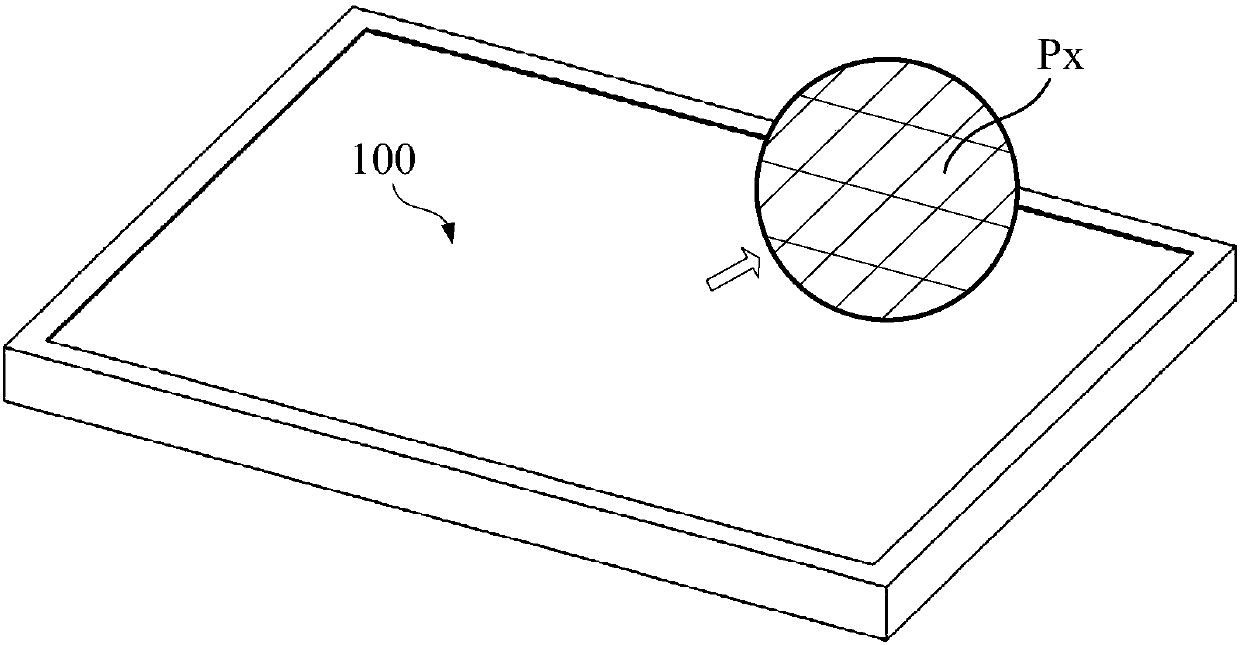

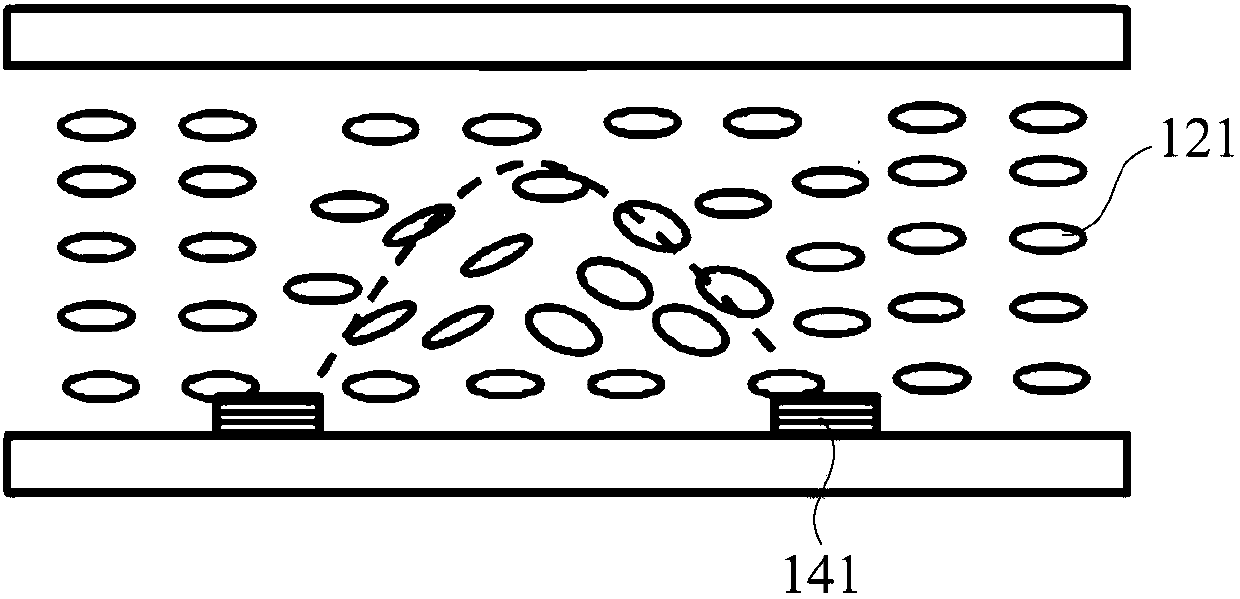

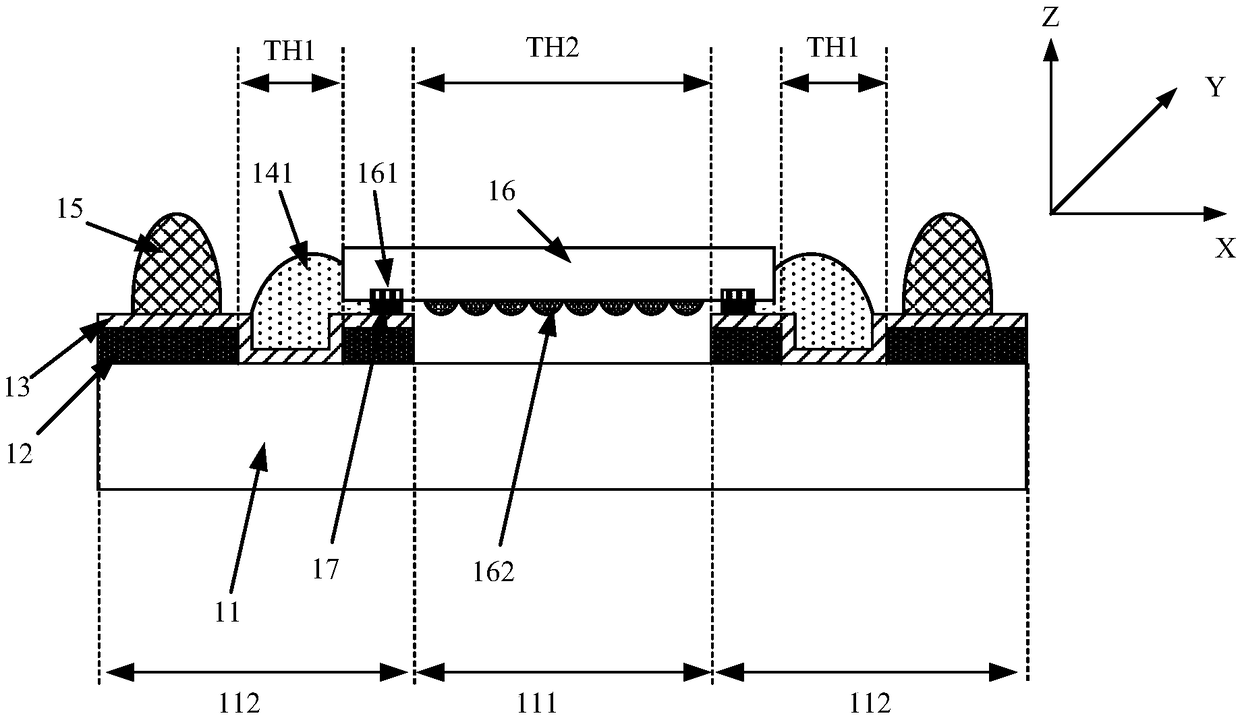

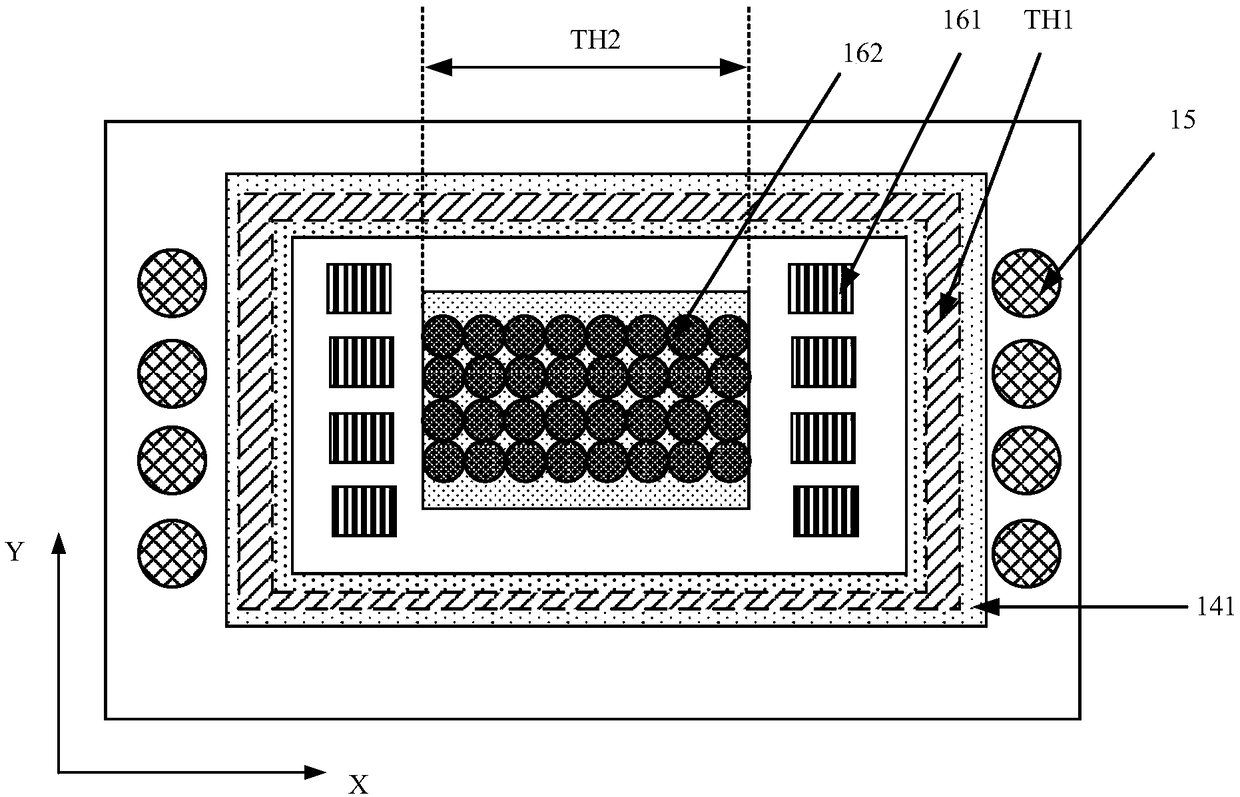

Display panel and display device

ActiveCN108051962AAddress adverse effectsHigh transparencyNon-linear opticsGratingLiquid-crystal display

The invention provides a display panel and a display device and belongs to the technical field of displaying. The display panel comprises a liquid crystal layer and a first electrode layer arranged onone side, in the thickness direction, of the liquid crystal layer; the first electrode layer includes multiple first electrodes arranged in each subpixel area along a first direction; the liquid crystal layer in each subpixel area is used for forming a liquid crystal color selection grating when preset voltage is loaded to the multiple first electrodes in the corresponding subpixel area; the liquid crystal color selection grating is used for, when there is predetermined light entering, forming transmitting light along a predetermined emerging direction which the corresponding subpixels have;the color of the transmitting light is that the corresponding subpixel area of the liquid crystal color selection grating has. The problem can be solved that a grating structure may cause adverse influence to display products; liquid crystal display products with higher transparency and less weight and thickness can be produced.

Owner:BOE TECH GRP CO LTD

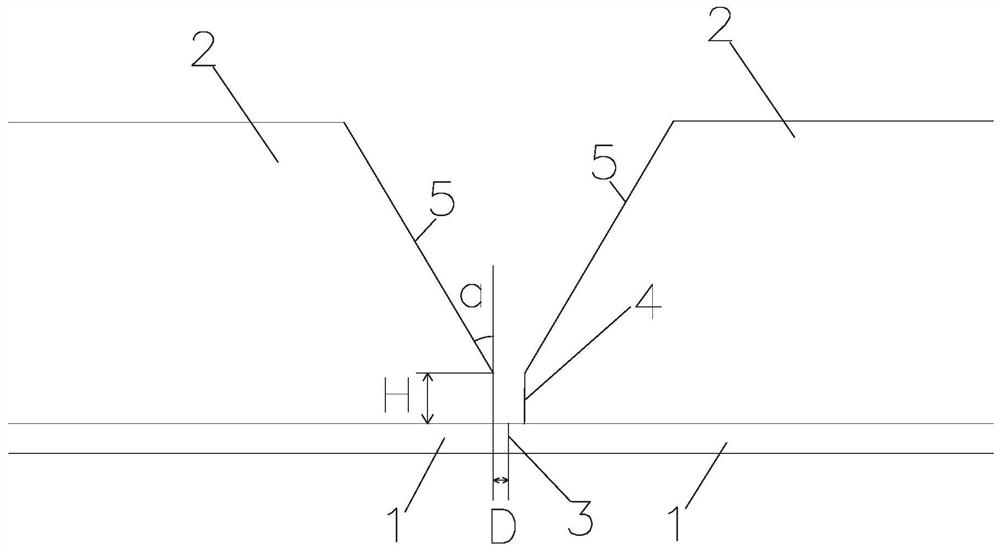

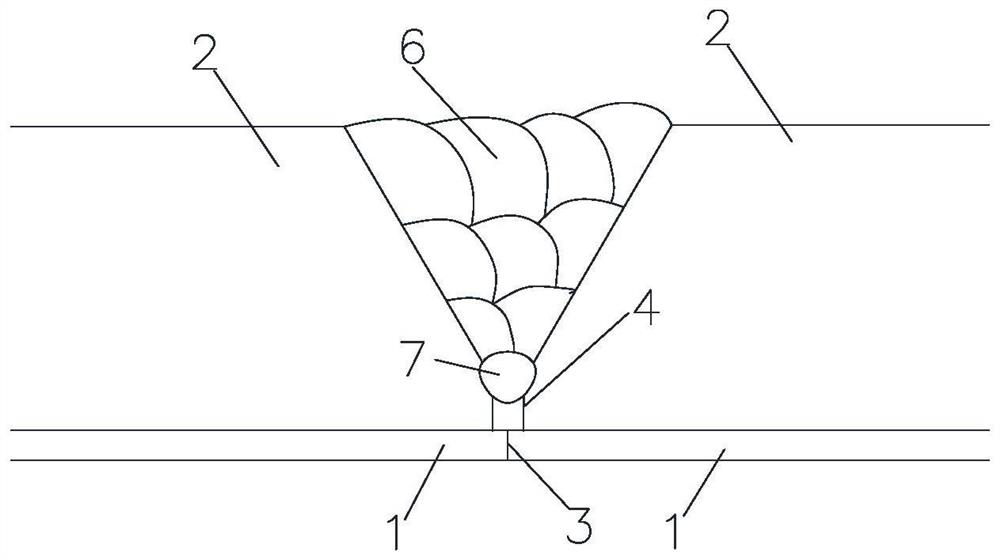

Interlayer-free butt welding method and welding structure for bimetal composite plate

ActiveCN113070575AMelting achievedImprove performanceLaser beam welding apparatusButt weldingComposite plate

The invention relates to the field of welding production, in particular to a butt welding method for a bimetal composite plate, which does not use a middle transition layer for welding, avoids adverse effects caused by contact and mixing of elements in a matrix layer and a composite layer through a melt by arranging a weld groove, selecting a welding method and optimizing a process, and therefore the mechanical property and the corrosion resistance of a welding joint are ensured. The butt welding method comprises the following steps of a, preparing materials, specifically, forming a base body layer truncated edge structure and a base body layer groove structure; B, cleaning weld joints and surfaces near the weld joints; C, assembling, specifically, enabling two plates to be in butt joint, and fixing the bimetal composite plates through a tool clamp; and d, welding, firstly, welding a composite layer welding seam by adopting a laser welding method, then, welding the part of the truncated edge structure of the base body layer by adopting electric arc welding, and finally, finishing the remaining welding bead of the welding seam needing to be welded by adopting an electric arc welding or laser composite welding method. The butt welding method is particularly suitable for the butt welding process of the bimetal composite plate.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

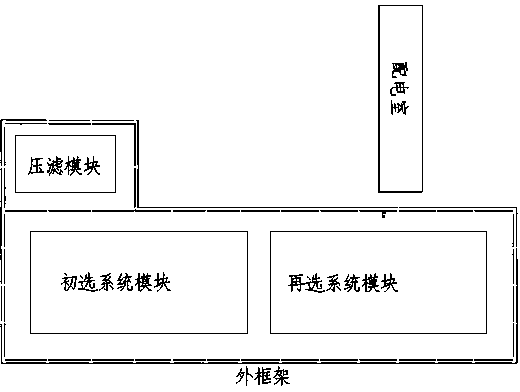

Washing selecting coal plant modularization building method

ActiveCN103362314AReduce maintenance costsAddress adverse effectsBuilding material handlingProcess engineeringEngineering

A washing selecting coal plant modularization building method is characterized by comprising the following steps that first, a main plant house outer frame module is mounted, a traveling trolley is mounted; second, washing selecting coal equipment which needs to be mounted is divided into a plurality of sets according to a washing selecting coal production technology; third, a steel structure frame type mounting frame module is designed for each set of washing selecting coal equipment; fourth, the mounting frame modules are mounted in advance or conveyed into the mounted main plant house outer frame module to be mounted on site, mounting of the mounting frame modules is completed; columns of the mounting frame modules are fixedly connected with a foundation, so the vibration generated by the washing selecting coal equipment is directly transmitted to a base, influence of generated vibration on the main plant house outer frame module is avoided, service life of the main plant house outer frame module is prolonged; fifth, the washing selecting coal equipment is arranged on the mounting frame modules, and machine test operation is carried out. According to the washing selecting coal plant modularization building method, cost is lowered, resonance is reduced, and service life is prolonged.

Owner:XUZHOU ZM BESTA HEAVY STEEL STRUCTURE

Self-igniting green bricks based on construction wastes

InactiveCN108774048ASolve pollutionAddress adverse effectsCeramic materials productionCeramicwareFire brickAsphalt

The invention discloses self-igniting green bricks based on construction wastes. The self-igniting green bricks are prepared from the following raw materials in parts by weight: 30-45 parts of concrete blocks, 15-25 parts of waste plastics, 10-16 parts of asphalt, 20-30 parts of clay, 10-16 parts of mud, 8-14 parts of waste bamboo wood, 10-20 parts of coal and a right amount of water. The self-igniting green bricks are prepared by taking the construction wastes as a main raw material, thus greatly reducing the cost of brick making, solving the pollution, caused by the construction wastes, to the environment, and being also in line with the sustainable development of green environmental protection; furthermore, a large amount of fuel is saved in a kilning process; the raw materials in the green bricks are used for firing bricks by means of self-ignition; therefore, the self-igniting green bricks based on the construction wastes have a good market application prospect, solve the troubleof the construction wastes to construction sites and the problem of centralized stacking, avoids environmental pollution and are conducive to environmental protection.

Owner:界首市静峰新型建材有限公司

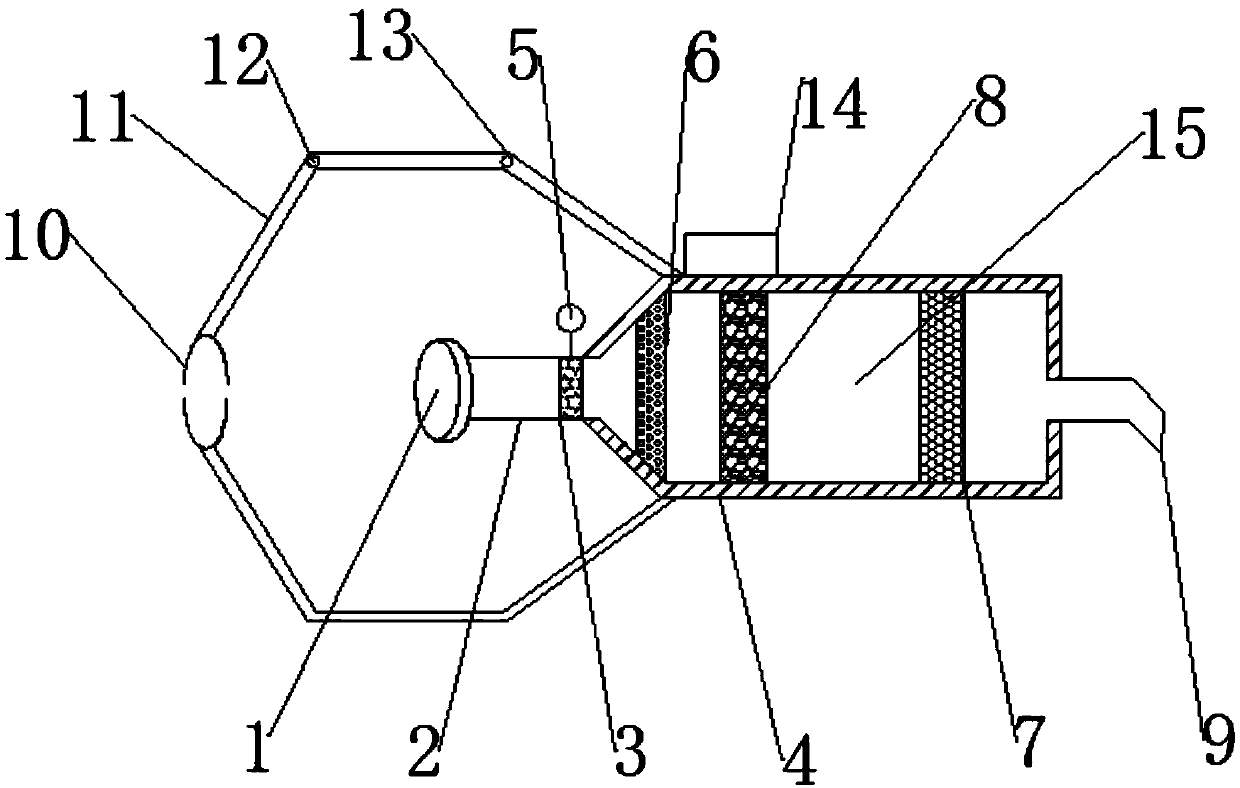

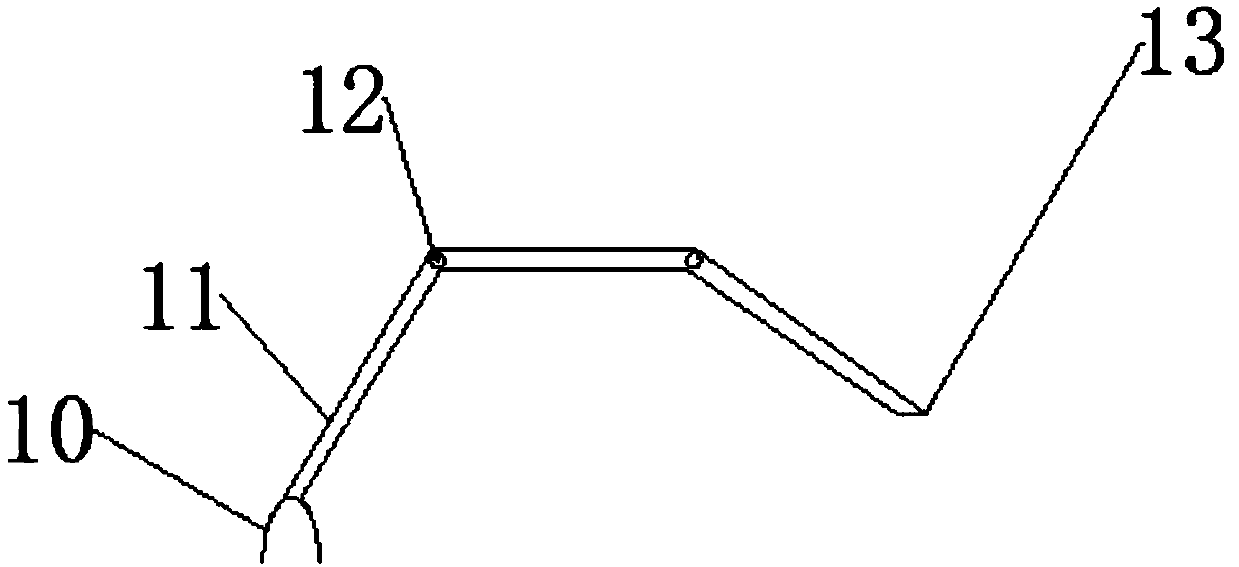

Novel automobile exhaust purification treatment device

InactiveCN107869372ANot easy to fall offAddress adverse effectsExhaust apparatusSilencing apparatusExhaust gasManipulator

The invention discloses a novel automobile exhaust gas purification treatment device, which comprises an exhaust pipe connecting ring, a connecting pipe and a first filter device, the top of the first filter device is fixedly connected with a pull ring, and the right side of the connecting pipe is fixedly connected to the exhaust gas purification device. An anechoic chamber, the exhaust gas purification and anechoic chamber is composed of a sound attenuation plate, the interior of the exhaust gas purification and anechoic chamber includes a second filter device, a third filter device and a fourth filter device, the right end of the exhaust gas purification and anechoic chamber is fixedly connected to an exhaust pipe, A power device is installed at the upper end of the exhaust gas purification and anechoic chamber, and the left side of the upper and lower ends of the exhaust gas purification and anechoic chamber are respectively fixedly connected with stiffeners. The mechanical arm is fixedly connected with the reinforcement ring, the rotating shaft is installed on the mechanical arm, and a reinforcement is added to make the exhaust gas purifier not easy to fall off; the multi-layer filter device design makes the exhaust gas purification more complete.

Owner:NANJING HANERSI BIOLOGY TECHNOLOGY CO LTD

Seedling raising method for cultivating large-scale full crown seedlings of rubber trees

ActiveCN111406569AQuality improvementShort breeding cycleGraftingGrowth substratesIntercroppingHevea brasiliensis

The invention discloses a seedling raising method for cultivating large-scale full crown seedlings of rubber trees. The seedling raising method includes the steps of container selection, embryo seedling selection, base material selection, nursery caressing and seedling hardening and planting. The large-scale full crown seedlings of rubber trees are adopted for planting, the labor for nurturing ina non-production period is reduced, the competitiveness of the rubber seedlings in the non-production period is improved, the non-production period is shortened, and the rubber trees are allowed to enter a cutting-available period 1-3 years earlier than conventional planting. By adopting the method, the seedling raising cycle is short, the cost is low, the seedling quality is good, the planting efficiency and survival rate are high, the rubber tree planting time can be enriched, the problem of forest irregularity caused by replenishing seedlings after planting is solved, the adverse effects ofweeds or intercropping crops on the rubber tree seedings in the non-production period are reduced, a new choice is provided for rubber tree seedling planting materials, the seedling raising method issuitable for planting on relatively flat woodlands or sloping fields, the full stand keeping rate of the rubber tree seedlings after planting of the rubber tree seedlings can be increased, and the cost of nurturing during the non-production period is reduced.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

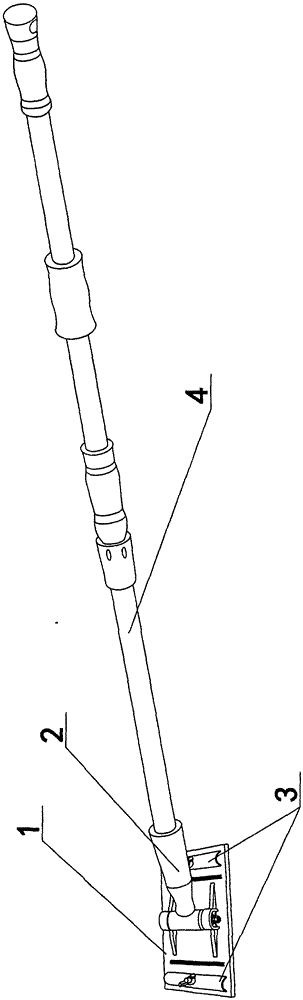

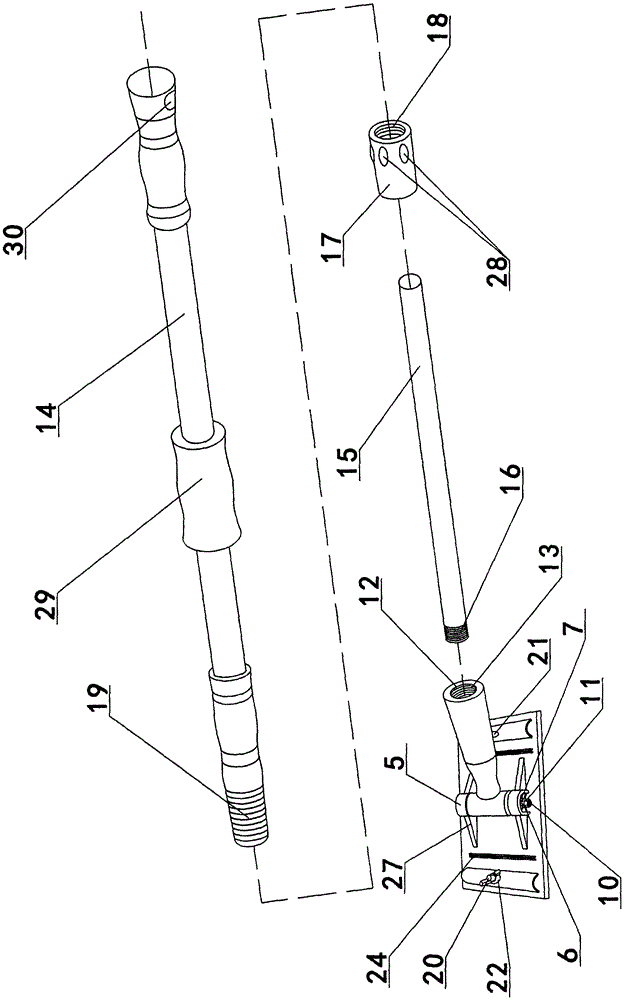

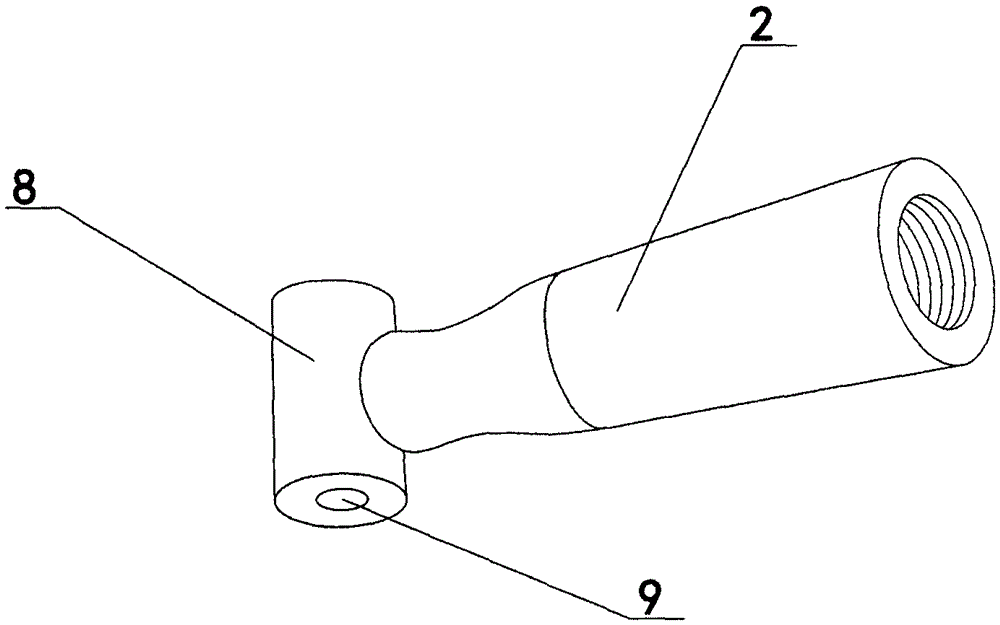

Dustproof abrasive paper holder with detachable telescopic handle

InactiveCN105522492AImprove practicalityVariable operation functionGrinding/polishing hand toolsPulp and paper industrySandpaper

The invention relates to the technical field of abrasive paper holders, in particular to a dustproof abrasive paper holder with a detachable telescopic handle. The dustproof abrasive paper holder with the detachable telescopic handle comprises a holder body, a handheld rod, two abrasive paper fixing claws and the telescopic handle, wherein the holder body is rectangular; two fixing bases used for fixing the handheld rod are arranged on two sides of the middle position of the back face of the holder body; each fixing base is internally provided with a screw shaft mounting ring and connected with the screw shaft mounting ring through a first reinforcing rib; a cylindrical mounting head is arranged at the head portion of the handheld rod; a first round through hole is formed in the middle of the cylindrical mounting head, and the cylindrical mounting head is embedded between the two fixing bases; a long screw penetrates through one screw shaft mounting ring, the first round through hole and the other screw shaft mounting ring sequentially, the two ends of the long screw are fixed with two retainer screws respectively, and the handheld rod rotates freely between the two fixing bases.

Owner:赵济彦

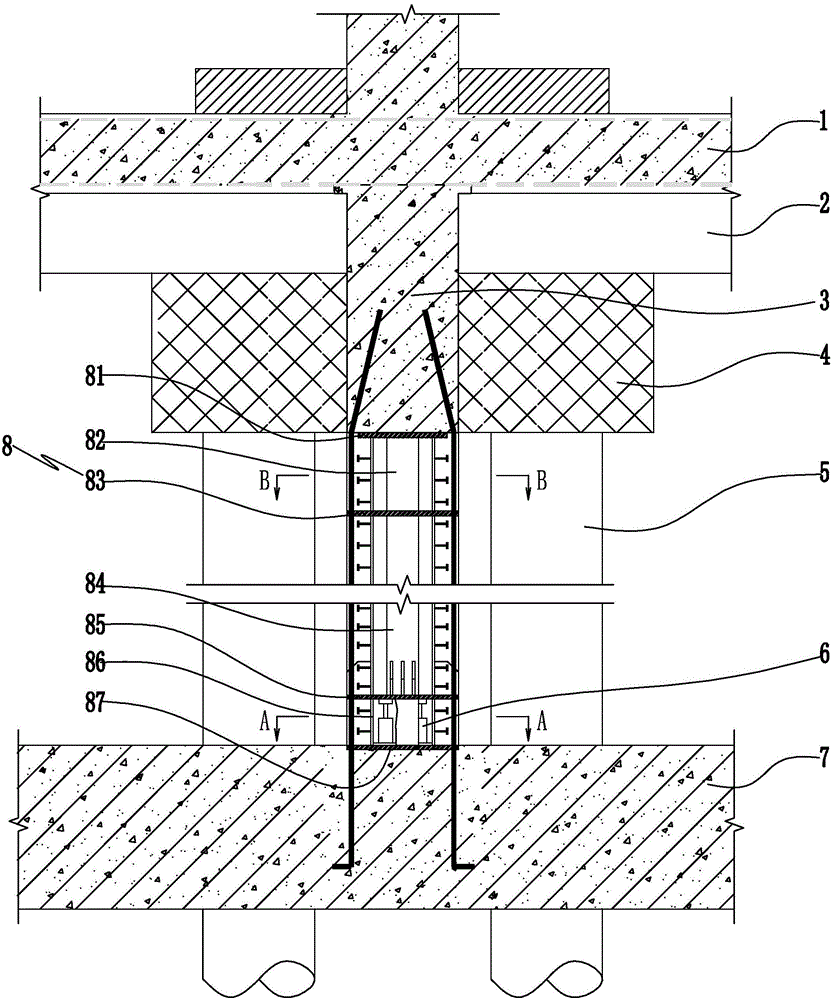

Manufacturing method of vertical deformation control structure of additionally-arranged structure column

ActiveCN105804428AAddress adverse effectsEffective control of vertical deformationBuilding repairsBasementStructural engineering

The invention discloses a manufacturing method of a vertical deformation control structure of an additionally-arranged structure column. By the adoption of the manufacturing method of the vertical deformation control structure of the additionally-arranged structure column, the problem that in the prior art, certain compression difference deformation can be caused in the underpinning and later-stage use processes of an additionally-arranged structure column in an added-storey basement can be effectively solved. The manufacturing method of the vertical deformation control structure of the additionally-arranged structure column sequentially comprises the following steps that A, an added-storey basement base plate of an added-storey basement is poured, and a welded supporting base plate is embedded in the upper surface of the added-storey basement base plate; B, an intra-column section steel column is placed between the welded supporting base plate and the vertical structure column, and a section steel column lower supporting plate is arranged on the lower portion of the intra-column section steel column; C, an ejecting device is placed between the section steel column lower supporting plate and the welded supporting base plate, and then the intra-column section steel column is jacked up through the ejecting device; D, the lower end of the intra-column section steel column is connected with the welded supporting base plate; and E, the ejecting device is dismounted and then taken out.

Owner:ZHEJIANG PROVINCE INST OF ARCHITECTURAL DESIGN & RES

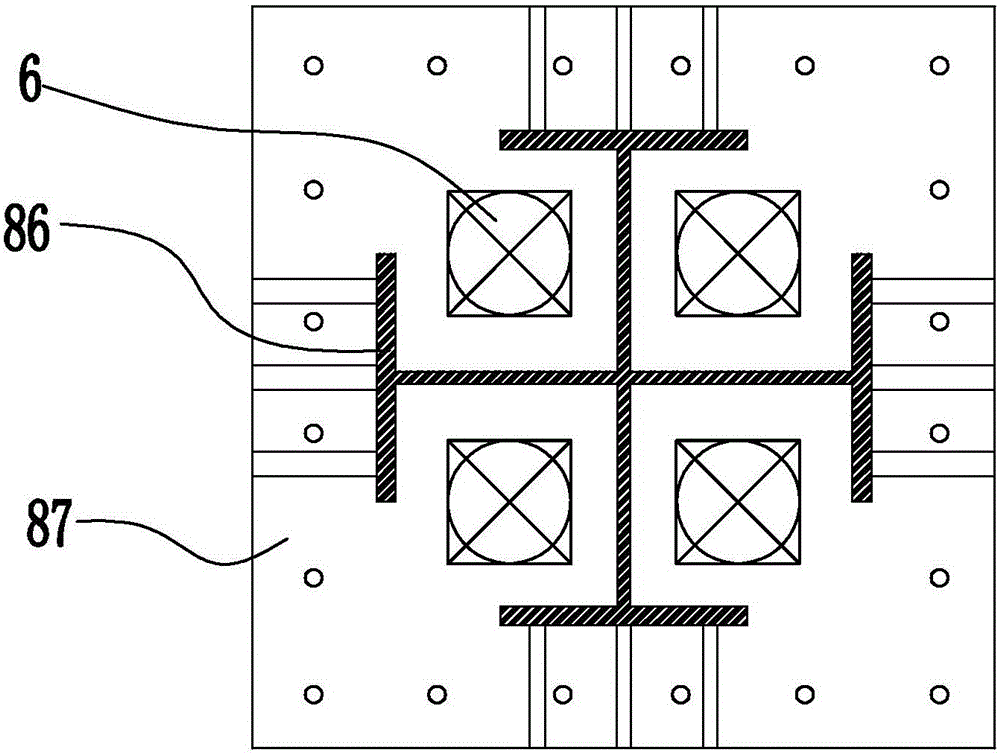

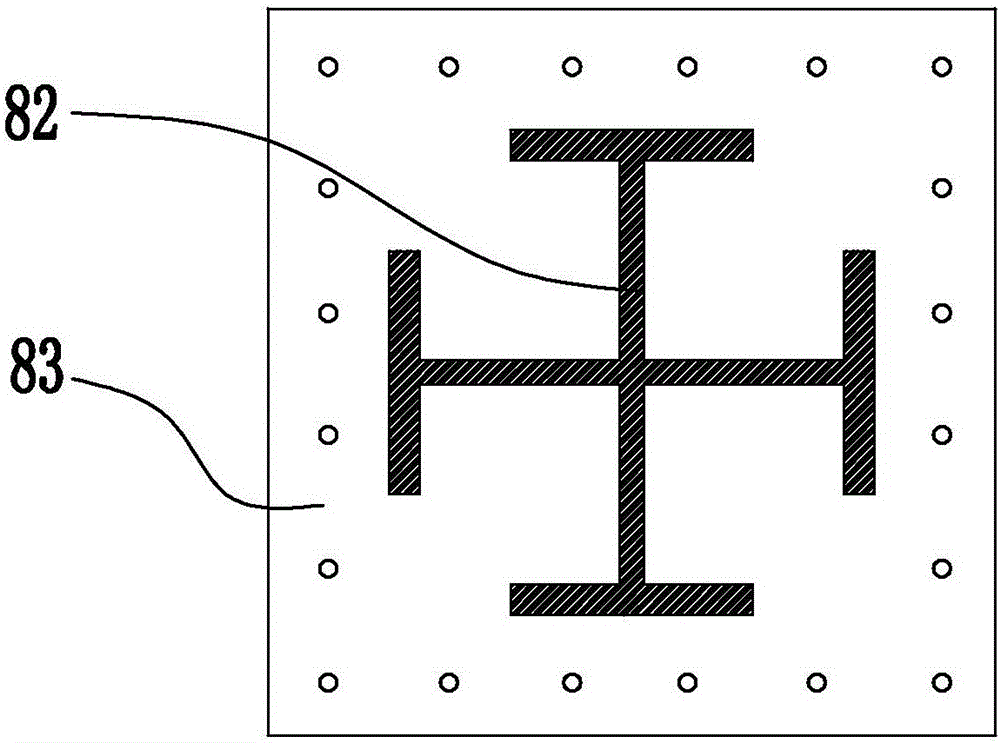

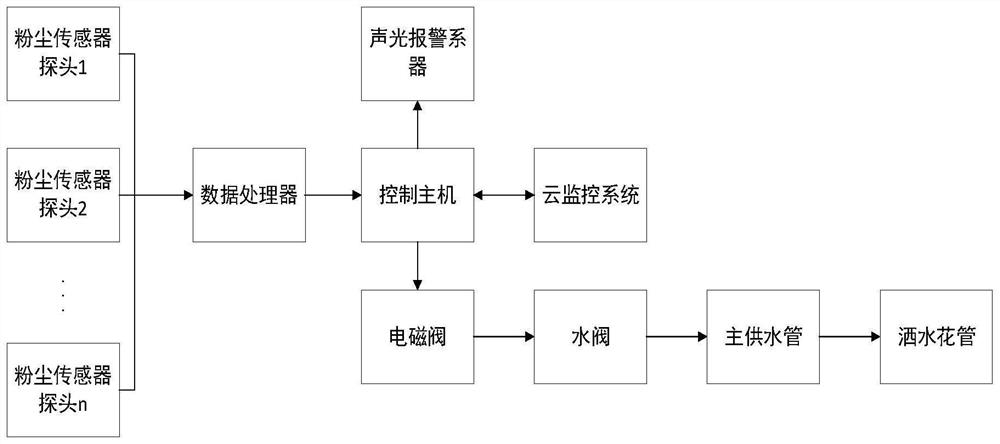

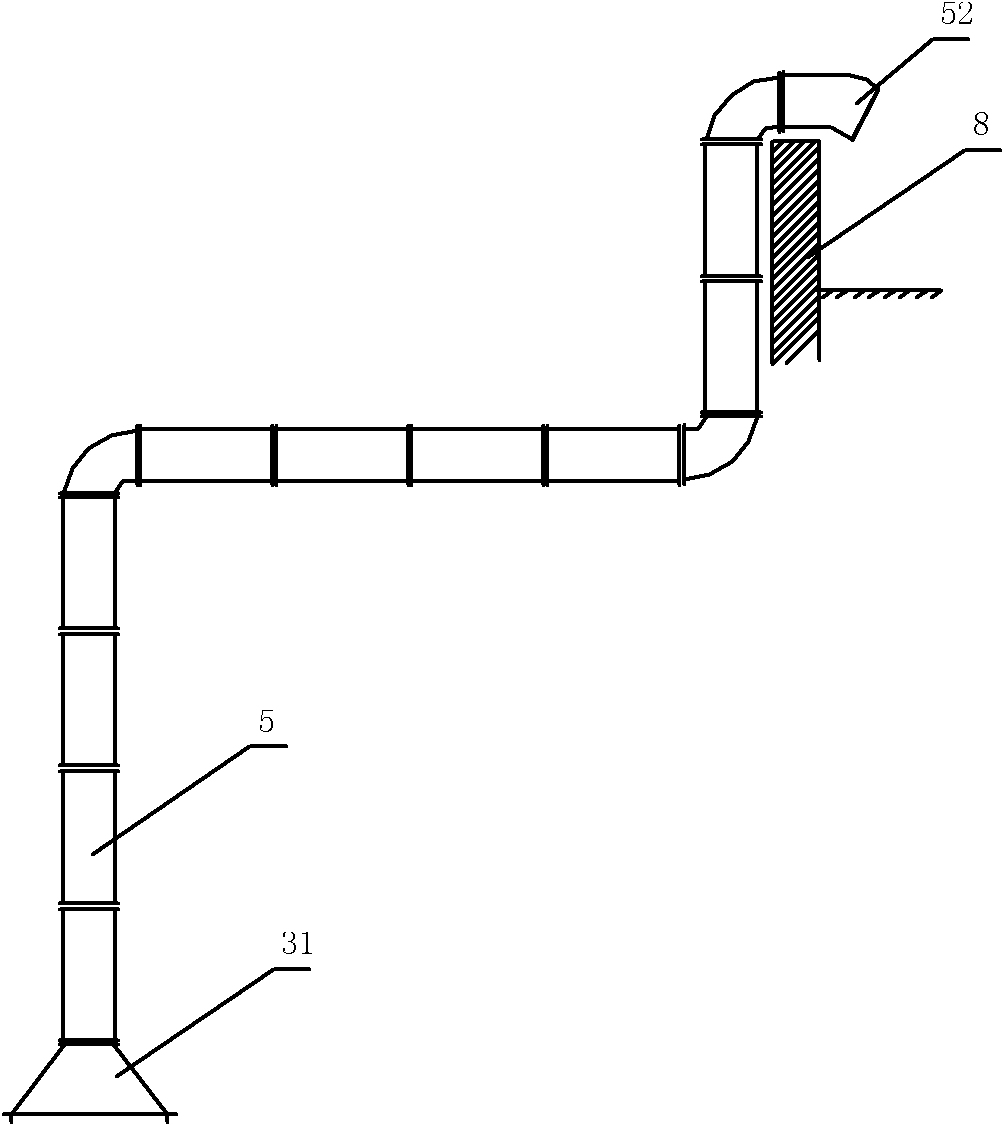

Automatic dust-fall spray control system for tunnel, and control method thereof

PendingCN111810219AInhibition and reduced productionReduce wear rateMining devicesDust removalMonitoring siteSolenoid valve

The invention discloses an automatic dust-fall spray control system for a tunnel, and a control method thereof. The system is composed of a dust sensor, a data processor, a control host, a cloud monitoring system and a water spraying device; through arrangement of a dust monitor in a tunnel operation area, a signal is transmitted to a control center and the cloud monitoring system; dust concentration warning values of at least two different levels are preset; when the dust concentration of a monitoring site reaches or exceeds the warning values of different levels set through the dust sensor,a solenoid valve of the water spraying device is controlled to open for spraying water to a workplace for dust fall; and through control over different opening degrees of the solenoid valve and different water flow rates corresponding to the warning values of different levels, dust of the workplace is reduced. According to the control system, through setting of multilevel warning thresholds, harmsare restrained at the embryonic stage; the system is improved through the process that the signal is transmitted to a water valve, and the purpose that different warning values correspond to different flow and flow rates for dust fall is achieved; and resources are saved, and targeted dust fall is performed.

Owner:SINOHYDRO BUREAU 7 CO LTD

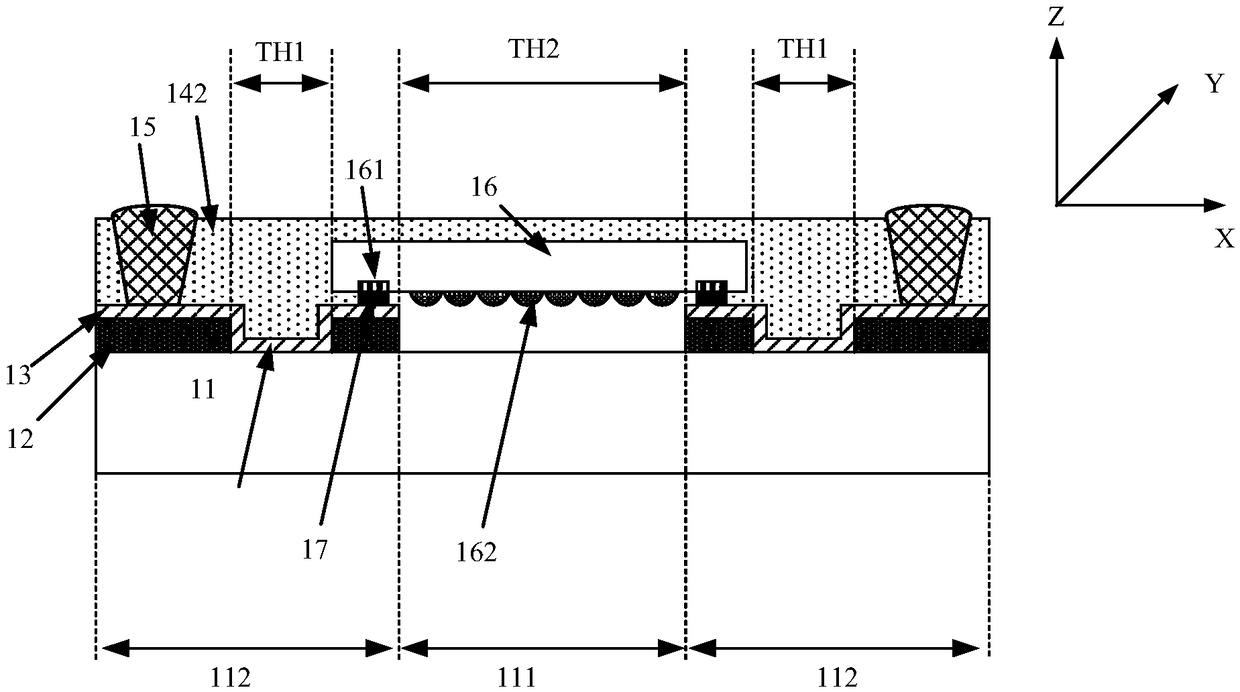

A packaging structure of an image sensor chip and a packaging method thereof

PendingCN109037259AAvoid enteringAvoid direct contactSolid-state devicesRadiation controlled devicesMoistureComputer science

The invention discloses a packaging structure of an image sensing chip and a packaging method thereof, wherein the packaging structure of the image sensing chip passes through the packaging layer, thesubstrate and the image sensing chip form an airtight cavity for setting the image sensing area, and by providing a first groove in the buffer layer, direct contact of the buffer layer with the enclosed cavity is avoided, since the absorbent property of the buffer layer material is generally strong, isolating the buffer layer in contact with the outside from the enclosed cavity, External moisturecan be prevented from entering the enclosed space of the packaging structure of the image sensor chip through the buffer layer, thereby solving the problem that external moisture easily enters the enclosed cavity through the packaging structure of the image sensor chip and has adverse effects on the image sensing area of the image sensor chip.

Owner:CHINA WAFER LEVEL CSP

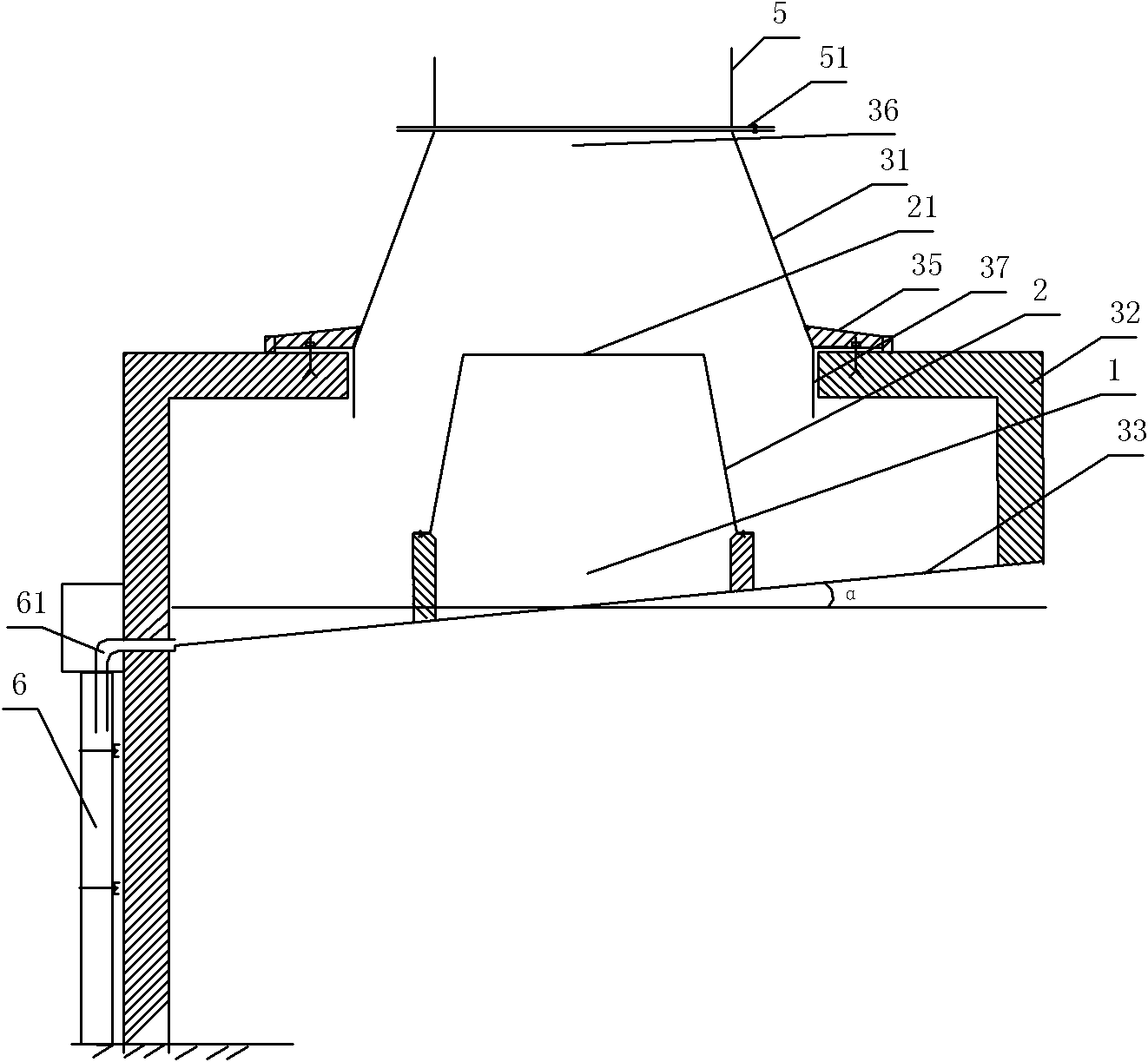

Steam exhaust device of nuclear island auxiliary system

InactiveCN101866700AInviolableSimple structureNuclear energy generationContainmentEngineeringProtection system

The invention discloses a steam exhaust device of a nuclear island auxiliary system, which is used for exhausting bled steam in a water supply system and comprises a flow guide hood which is covered on a bled steam outlet of the nuclear island auxiliary water supply system and used for carrying out pressurization and flow guide on the bled steam, a steam collection hood component which closes thebled steam outlet and the flow guide hood therein is arranged outside the flow guide hood, the upper part of the steam collection hood component is connected with a steam exhaust pipeline which exhausts the bled steam to high altitude, and the lower part is connected with a condensate discharge pipe. The invention provides the steam exhaust device of the nuclear island auxiliary water supply system, which has simple structure and convenient treatment, and can protect the devices in the system and the surrounding environment from being infringed.

Owner:CHINA GENERAL NUCLEAR POWER CORP +1

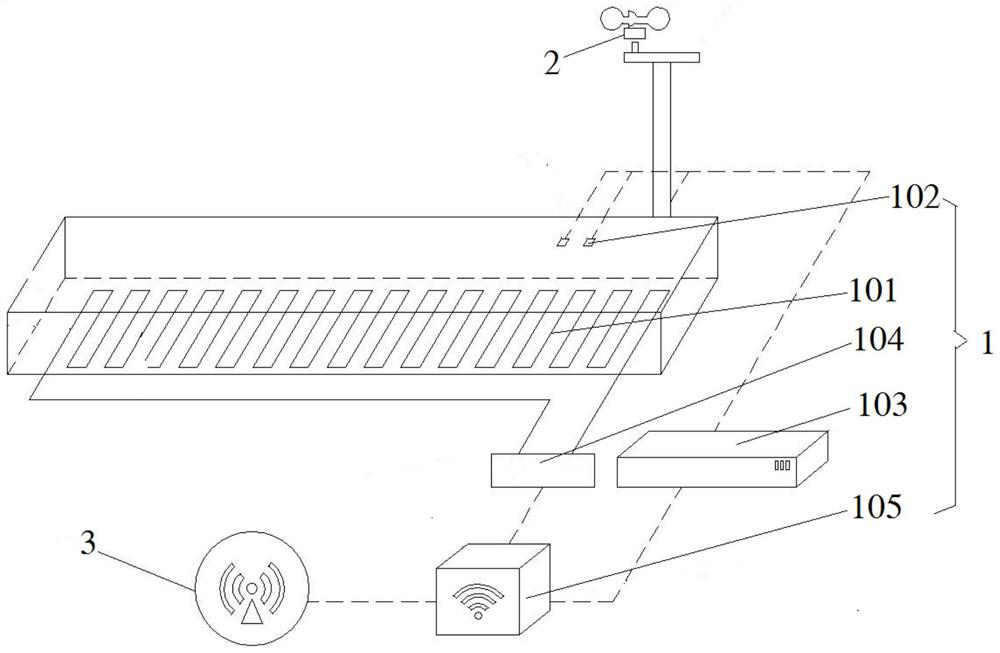

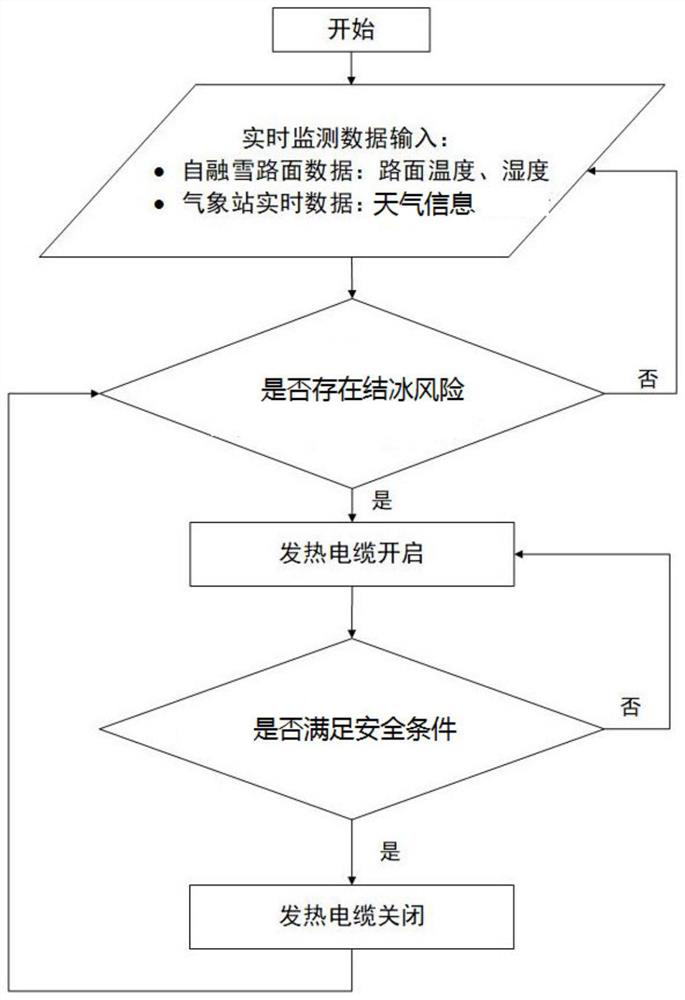

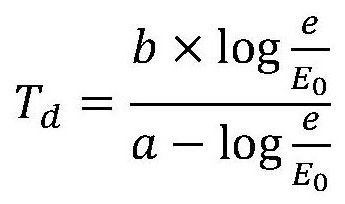

Road surface self-snow-melting system and method with environmental perception function

PendingCN112482128AAddress adverse effectsReduce the incidence of road accidentsPaving detailsRoad traffic safetyData collector

The invention discloses a road surface self-snow-melting system and a method with environmental perception function, the system comprises a plurality of self-snow-melting units uniformly distributed along a whole road section, a plurality of meteorological stations and a management and control center, and each self-snow-melting unit comprises a heating cable buried under the road surface, a temperature and humidity sensor, a data collector and a power switch; the temperature-humidity sensor is arranged on the pavement surface layer; the signal output end of the temperature and humidity sensoris connected with the data collector; the meteorological stations are arranged on the roadside and are used for acquiring real-time weather information of the plurality of self-snow-melting units; thedata collectors and the meteorological stations transmit respective formation to the management and control center through wireless transmission modules. According to the invention, possible icing units and snow accumulation units can be predicted in advance, so that the phenomena of pavement icing and snow accumulation are avoided, the pavement self-snow-melting efficiency is improved, and the traffic safety is ensured; meanwhile, full-route monitoring can be achieved, and macroscopic management and control and road maintenance are facilitated.

Owner:CHANGAN UNIV

Powder puff taking flower and plant powder as filler and preparation method thereof

InactiveCN110522157AAddress adverse effectsAvoid pollutionCosmetic preparationsToilet preparationsAlcoholMass ratio

The invention discloses a powder puff taking flower and plant powder as a filler and a preparation method of the powder puff, wherein the mass ratio of a component A and a component B is 2: 1; the component A comprises the following components in percentage by mass: a1: 55%-57.15% of water; a2: 0.15%-0.3% of N-aminoethyl-gamma-aminopropyltrimethoxysilane ; a3: 1%-1.4% of C16-18 alcohol / PEG-20 orC16-18 alcohol ether; a4: 0.05%-0.07% of an ethylene oxide-propylene oxide block copolymer, a5: 0.5%-1% of bis (hydroxymethyl) imidazolidinyl urea methylparaben propylparaben; a6: 1%-1.2% of ethyleneoxide-propylene oxide segmented copolymer, a7: flower and plant powder: flowers comprise petal calyxes, and plant comprises 40%-42% of plant stems and leaves; and the component B comprises the following components in percentage by mass: b1: more than or equal to 90.0% of polymer of polyethylene glycol and toluene diisocynate, and b2: 2.0% to 5.0% of 1, 3-di isocyanato toluene. The natural flowerand plant powder is adopted as filler to replace traditional mineral fillers, meanwhile, natural plant pigment and smell of the flower and plant powder are used for coloring and perfuming the foam body, the antibacterial effect is good, and the service life is long.

Owner:广州市达戈彩美容科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com