Washing selecting coal plant modularization building method

A construction method and coal washing technology, which are applied in the construction of buildings, construction, and the processing of building materials, etc., can solve the problems of short plant life, high maintenance cost, high noise, etc., so as to reduce the floor space and reduce the maintenance cost. , the effect of reducing the amount of steel used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

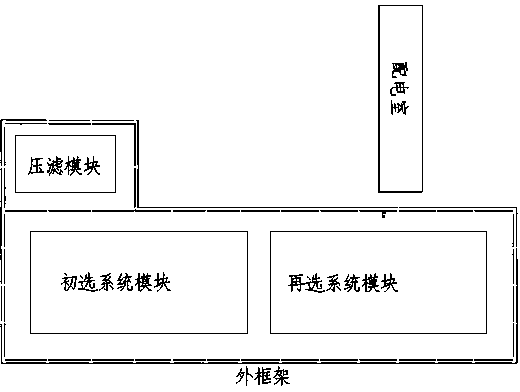

[0050]Now take the main workshop of Yidong Coal Group Kaolinite Concentrator as an example to calculate. The construction site of the project is Xuejiawan Town, Zhungeer Banner, Inner Mongolia, and it is a modular structure. The outside is a closed enclosure with a door-type steel frame, and the inside is an independent module of various processes. The axial length of the outer frame is 98m. The span is 29m and the height is 35m. The outer frame area is 2842m2, about 99500m3. With 20T bridge crane. It contains 3 module equipment supports, A module primary selection system; B module reselection system and filter press workshop module. The three modules are independent steel frame equipment supports.

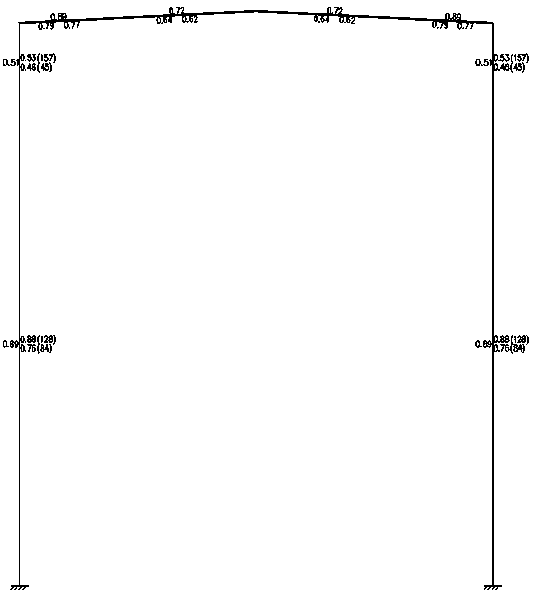

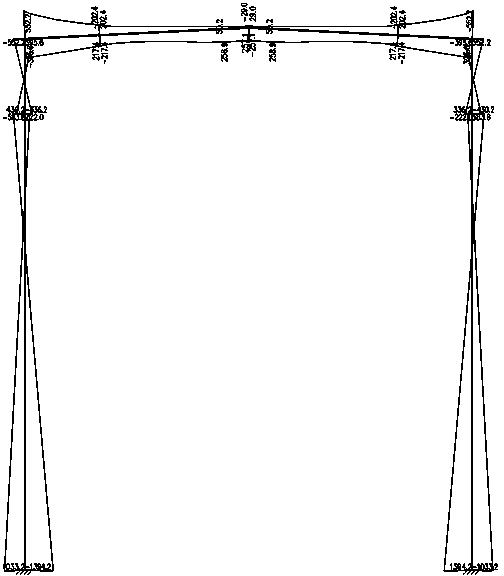

[0051] Outer frame calculation

[0052] The main design basis:

[0053] "Code for Building Structure Loads" (GB50009-2001); 2006 edition

[0054] "Code for Seismic Design of Buildings" (GB50011-2010);

[0055] "Code for Design of Steel Structures" (GB50017-2003);

[0056...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com