Control system and method of additive manufacturing laser formation system integrated equipment

A laser forming and system integration technology, applied in the field of additive manufacturing, which can solve the problems of powder contact, harm to human health, powder waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

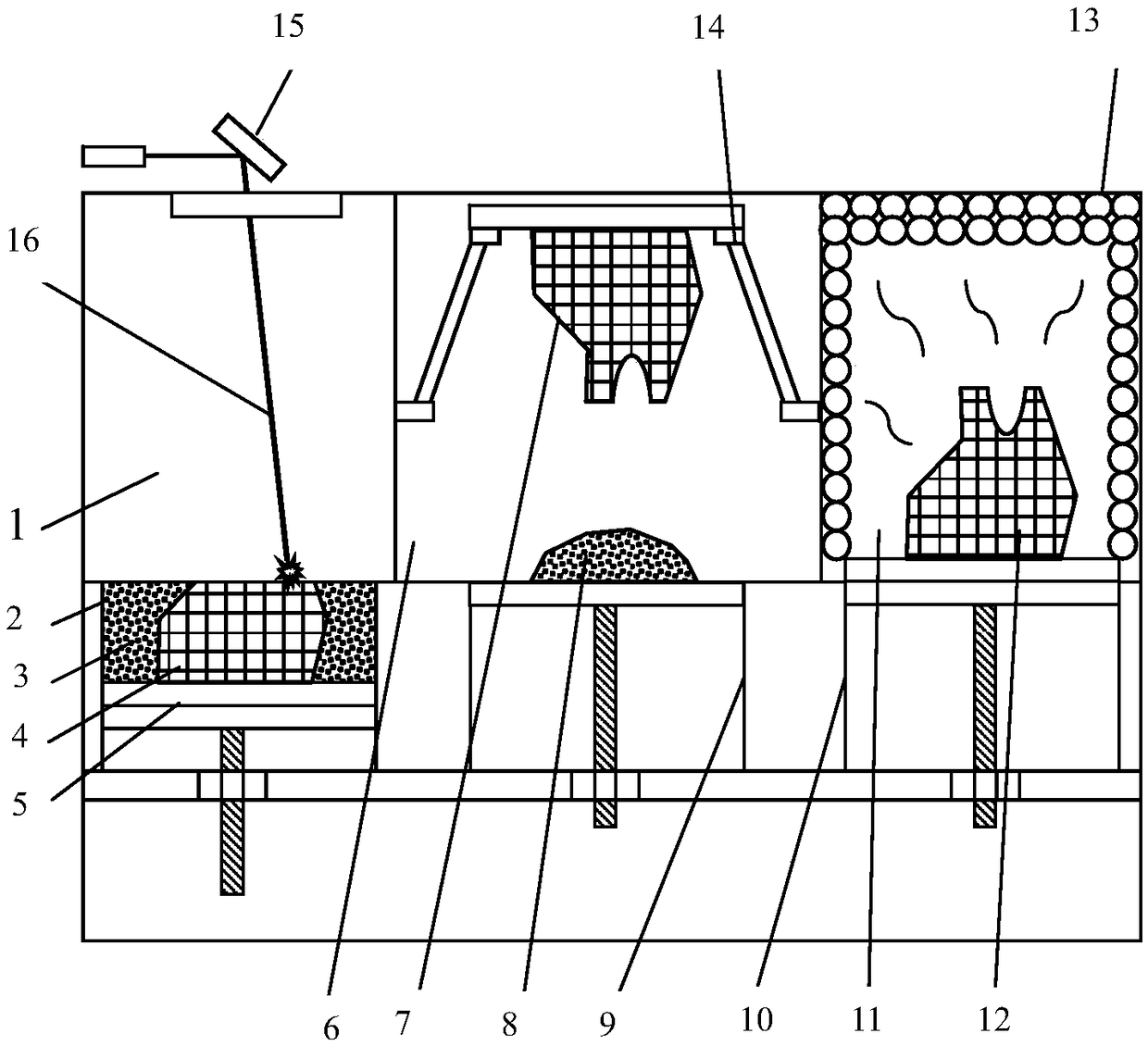

Embodiment 1

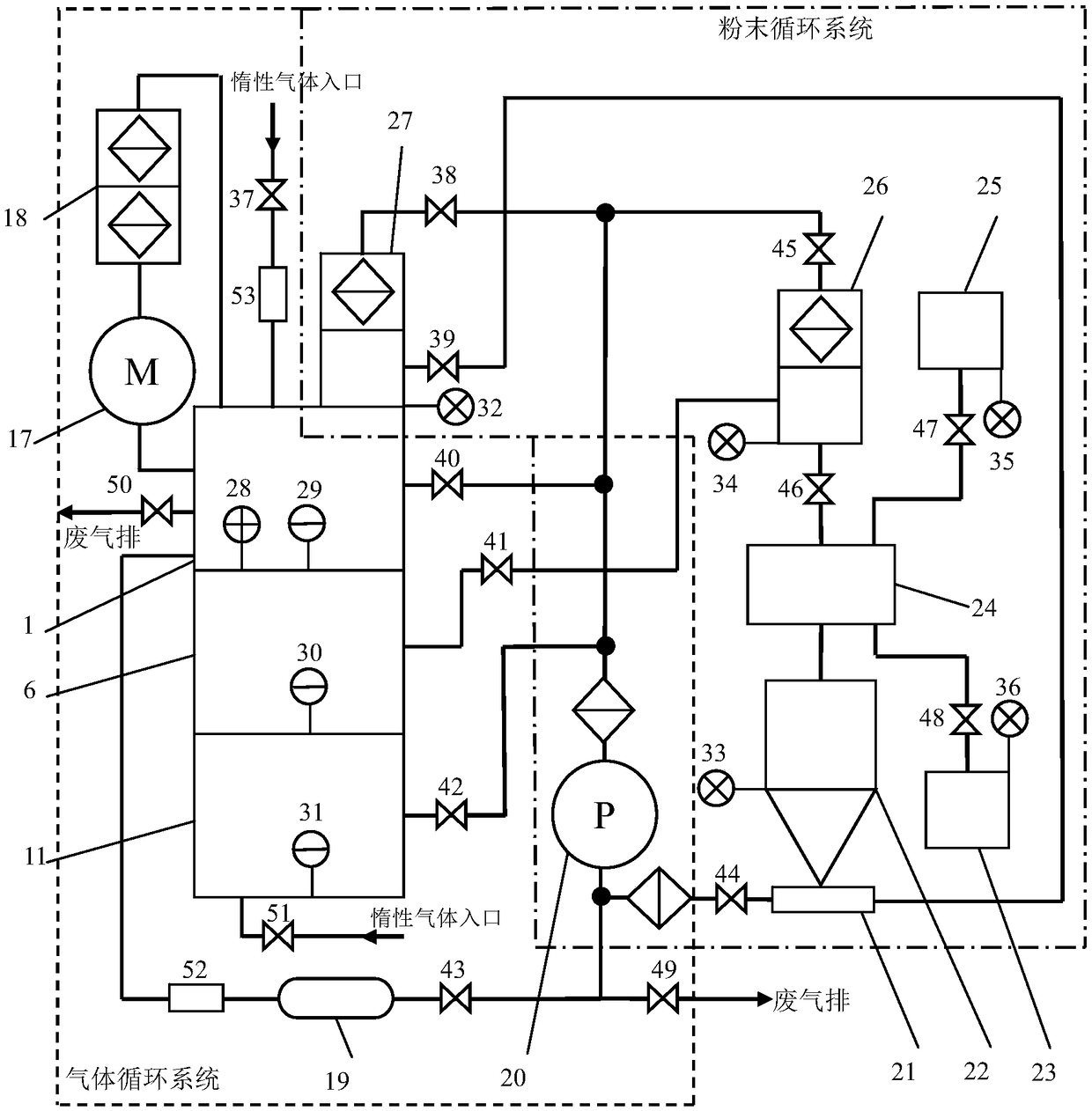

[0060] see figure 2 , this embodiment provides a control system for an integrated equipment of an additive manufacturing laser forming system, including:

[0061] Powder circulation system, used for the delivery of laser forming module powder and the recovery and recycling of post-processing module powder;

[0062] The powder circulation system includes a feed tank 25, a screening device 24, a storage tank 22, a receiving device 26, a feeding device 27, and a vacuum unit 20; the feed tank 25, the screening device 24, and the storage tank 22 , feeding device 27, vacuum unit 20 and storage barrel 22 are connected in sequence, and the post-processing chamber 6, receiving device 26 and the intake end of vacuum unit 20 are connected in sequence, and the receiving device 26 is connected with screening device 24. The feeding barrel is used to add powder to the system, and the storage barrel is used to store the system powder and provide a continuous supply of powder to the discharg...

Embodiment 2

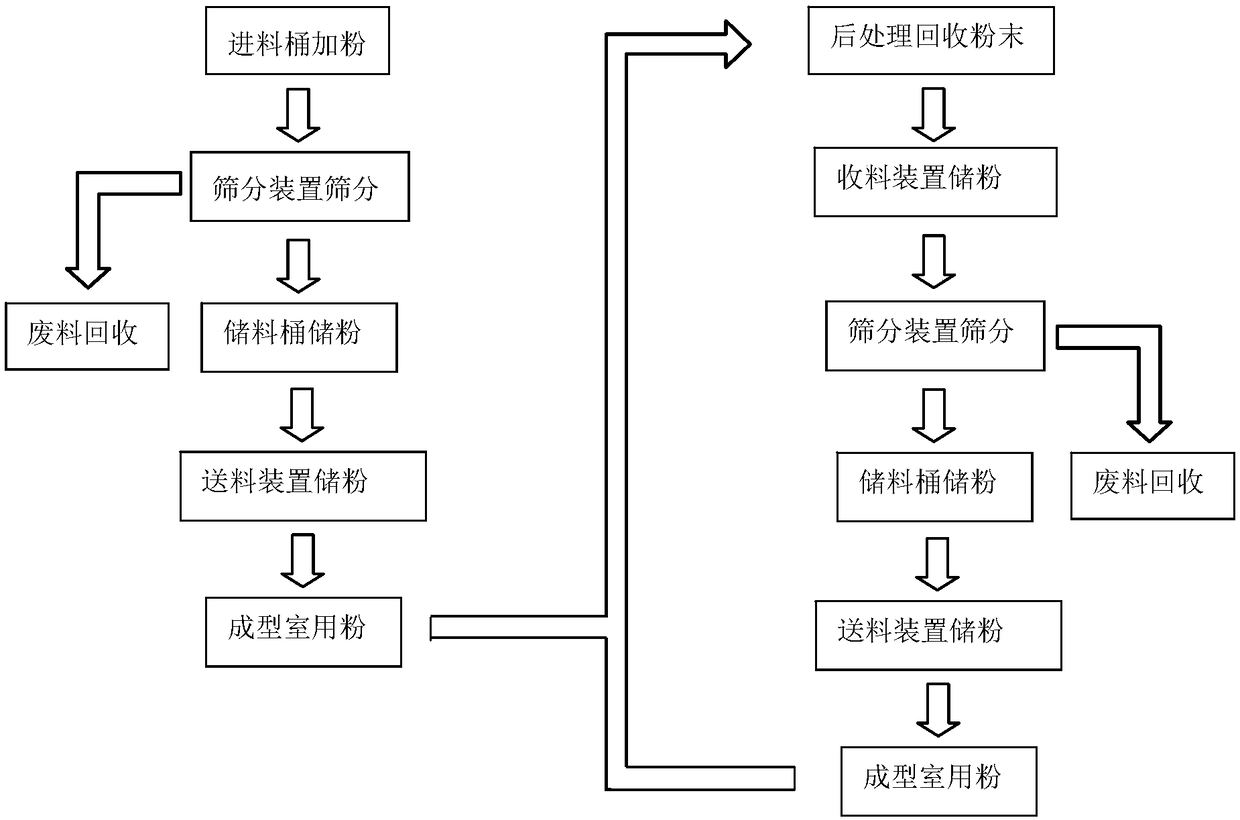

[0075] see Figure 2-6 , this embodiment provides a method for controlling integrated equipment of an additive manufacturing laser forming system, including a method for controlling a powder circulation system and a method for controlling a gas circulation system;

[0076] The control method of the powder circulation system includes a method for conveying the powder of the laser forming module and a method for recycling and reusing the powder of the post-processing module;

[0077] The delivery method of the laser forming module powder is a process of directly sending the newly added powder into the forming chamber 1 of the laser forming module. Including the following steps:

[0078] Step 001: Add powder to the feeding barrel 25, and stop adding powder when the material sensor D35 of the feeding barrel 25 detects that the amount of powder in the feeding barrel 25 is full;

[0079] Step 002: Open the screening device 24, open the switching valve K47 between the feeding bucke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com