Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Achieve heat retention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Integral type thermal insulation building

ActiveCN101684671AReduce indoor temperature fluctuationsReduce the weight of the structureConstruction materialSolid waste managementThermal insulationFly ash

The invention discloses an integral type thermal insulation building, which belongs to the technical field of building engineering. The problem to be solved is to provide the integral type thermal insulation building. The adopted scheme is that the integral type thermal insulation building at least uses one of an inorganic thermal insulation structure layer and an inorganic thermal insulation layer, wherein the inorganic thermal insulation structure layer is formed by combining one or two of inorganic thermal insulation load-bearing concrete and inorganic thermal insulation load-bearing building blocks; and the inorganic thermal insulation load-bearing concrete comprises the following components in a mixing weight ratio (kg / m<3>) of concrete composite light bone admixture to cement to sandto stone to porcelain granule to fly ash to water to concrete admixture of (6-225):(200-800):(300-700):(500-1,600):(150-650):(10-600):(80-400):(0.1-200). The integral type thermal insulation buildingcan be widely applied to the technical field of buildings.

Owner:李珠 +1

Colored reflection heat insulation coating

InactiveCN102464924AReduce radiant heat gainReduce surface temperatureAnti-corrosive paintsReflecting/signal paintsThermal insulationHigh reflectivity

The invention discloses a colored reflection heat insulation coating, comprising acrylic acid emulsion, titanium dioxide, infrared reflection pigment, calcium carbonate powder, powdered steatile, kaolin powder, dispersant, wetting agent, antifoaming agent, thickening agent, film forming auxiliary agent, and antiseptic. The heat insulation principle of the reflection heat insulation coating is high reflectivity, thus the heat of solar radiation can be effectively reduced. According to the invention, the colored reflection heat insulation coating disclosed herein is used for coating the exterior walls of buildings, can reduce the surface temperature of the buildings by 10-20 DEG C, thus the energy consumption of air conditioning is saved; the colored reflection heat insulation coating can be used in hot-in-summer and warm-in-winter area hot-in-summer and cold-in-winter area and the like, thus the effects of heat preservation and heat insulation are achieved; the colored reflection heat insulation coating has excellent energy saving effect; and compared with the prior art, the colored reflection heat insulation coating has remarkable substantial characteristics and significant progress.

Owner:SHANGHAI STO

Composite architectural heat-insulation coating and preparation method thereof

InactiveCN105199520AEfficient fillingImprove liquidityRadiation-absorbing paintsReflecting/signal paintsEmulsionMicrosphere

The invention discloses a composite architectural heat-insulation coating and a preparation method thereof. The composite architectural heat-insulation coating is formed by mixing the following ingredients by mass: 25 to 40 parts of water, 0.3 to 0.9 part of a thickening agent, 0.1 to 0.3 part of a multifunctional additive, 0.3 to 1.2 parts of an ageing resistant additive, 0.2 to 0.5 part of a wetting agent, 0.5 to 2.0 parts of a dispersing agent, 0.4 to 1.3 parts of a mold inhibitor, 0.2 to 0.5 part of an antifoaming agent, 2 to 5 parts of a film-forming additive, 8 to 20 parts of a pigment, 6 to 13 parts of a heat-insulation functional additive formed by mixing two or three of phase change microcapsules, hollow glass microspheres and polymeric microspheres, and 38 to 52 parts of an emulsion. The composite architectural heat-insulation coating is favorable in appearance, excellent in storage stability, equal to or lower than 1.06 g / cm<3> in density, equal to or lower than 0.065 W / (m.k) in heat conductivity, larger than 10 DEG C in heat-insulation temperature difference, favorable in washability and brushability, and excellent in heat-insulation effect.

Owner:东莞暨南大学研究院 +2

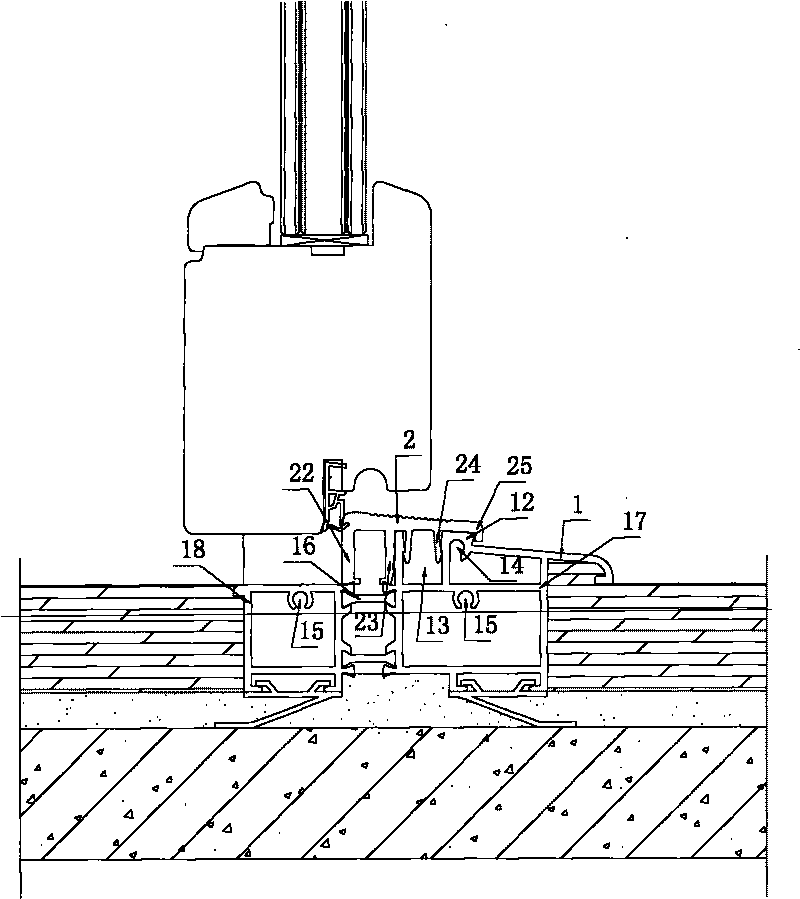

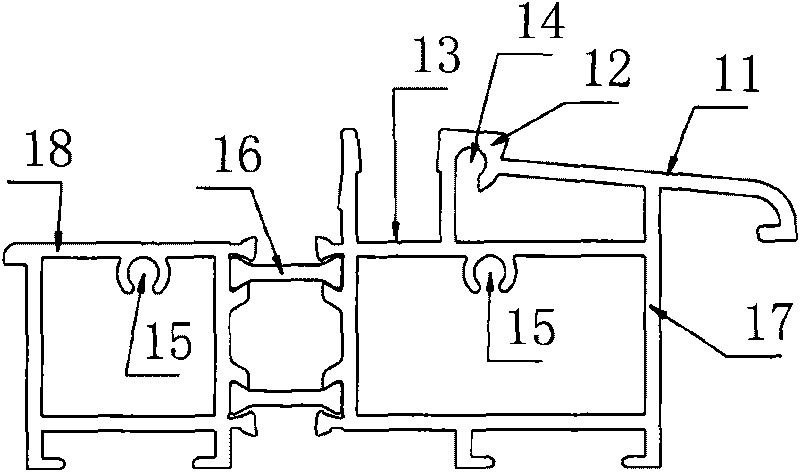

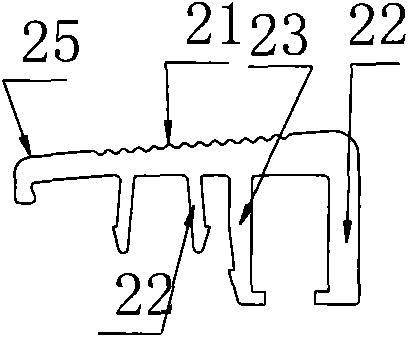

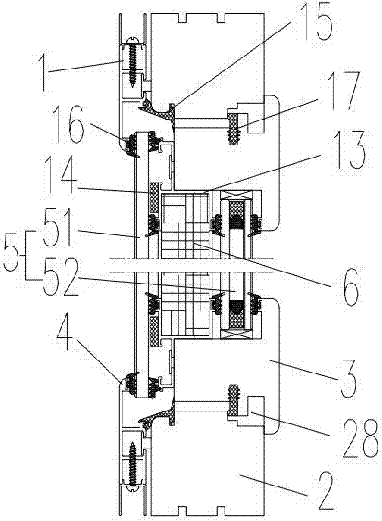

Novel door sill of vertical hinged door

ActiveCN101709618AGuaranteed tightnessEasy to useSills/thresholdWing arrangementsEngineeringEnergy conservation

The invention relates to a door sill device, in particular to a door sill of a vertical hinged door. The novel door sill of the vertical hinged door consists of an aluminum alloy door sill section material, a door footplate and two door sill fixing blocks, wherein the two door sill fixing blocks are arranged at two ends of the aluminum alloy door sill section material; the aluminum alloy door sill section material is provided with an inclined plane, a lug boss is arranged on the inclined plane, and the rear end of the lug boss is provided with a U-shaped groove; the door footplate is made of a high tenacity material; and the upper surface of the door footplate is provided with an inclined plane, the front section is provided with a hooking part, the bottom part is provided with a n-shaped rail, a supporting plate and a baffle plate are arranged below the rear part of the inclined plane, the hooking part is buckled on the lug boss, the n-shaped rail is buckled in the U-shaped groove, and the baffle plate leans against the rear end face of the aluminum alloy door sill section material. The door sill not only ensures the sealability of the vertical hinged door and achieves the effects of heat preservation and energy conservation, but also considers the convenience for daily passing of people, and simultaneously prevents the damages to the door sill caused by tramples in daily lives, and prolongs the service life of the vertical hinged door.

Owner:浙江瑞明节能门窗技术有限公司

Colored porcelain (or colored pottery)-surface light coal gangue building blocks

InactiveCN101775871AAchieve heat retentionMeet the requirementsConstruction materialTunnel kilnSlurry

The invention relates to colored porcelain (or colored pottery)-surface light coal gangue building blocks prepared by the steps of: adding waste glass dust, clay, pulverized fuel ash and straws (or shells) in coal gangue raw materials by proportioning to prepare building block base materials and making the base materials into (hollow or porous) coal gangue building blocks by machines; then preparing kaolin, argil, feldspar, quartz, pigment and the like into building block surface material by proportioning, wherein the building block surface material colored porcelain slurry or colored pottery slurry; respectively coating the colored porcelain slurry or the colored pottery slurry on the surfaces of building block biscuits, piling up on a kiln car, and roasting in a tunnel kiln through drying to form the colored porcelain (or colored pottery)-surface light coal gangue building blocks through roasting, wherein building block bodies form sintered coal gangue micropore-shaped light bodies, and the surfaces of the building bodies form sintered colored porcelain (or colored pottery) surfaces. The colored porcelain (or colored pottery)-surface light coal gangue building blocks is beneficial to achieving the functions of self heat preservation and self decoration of monomer-material finished walls.

Owner:张金法

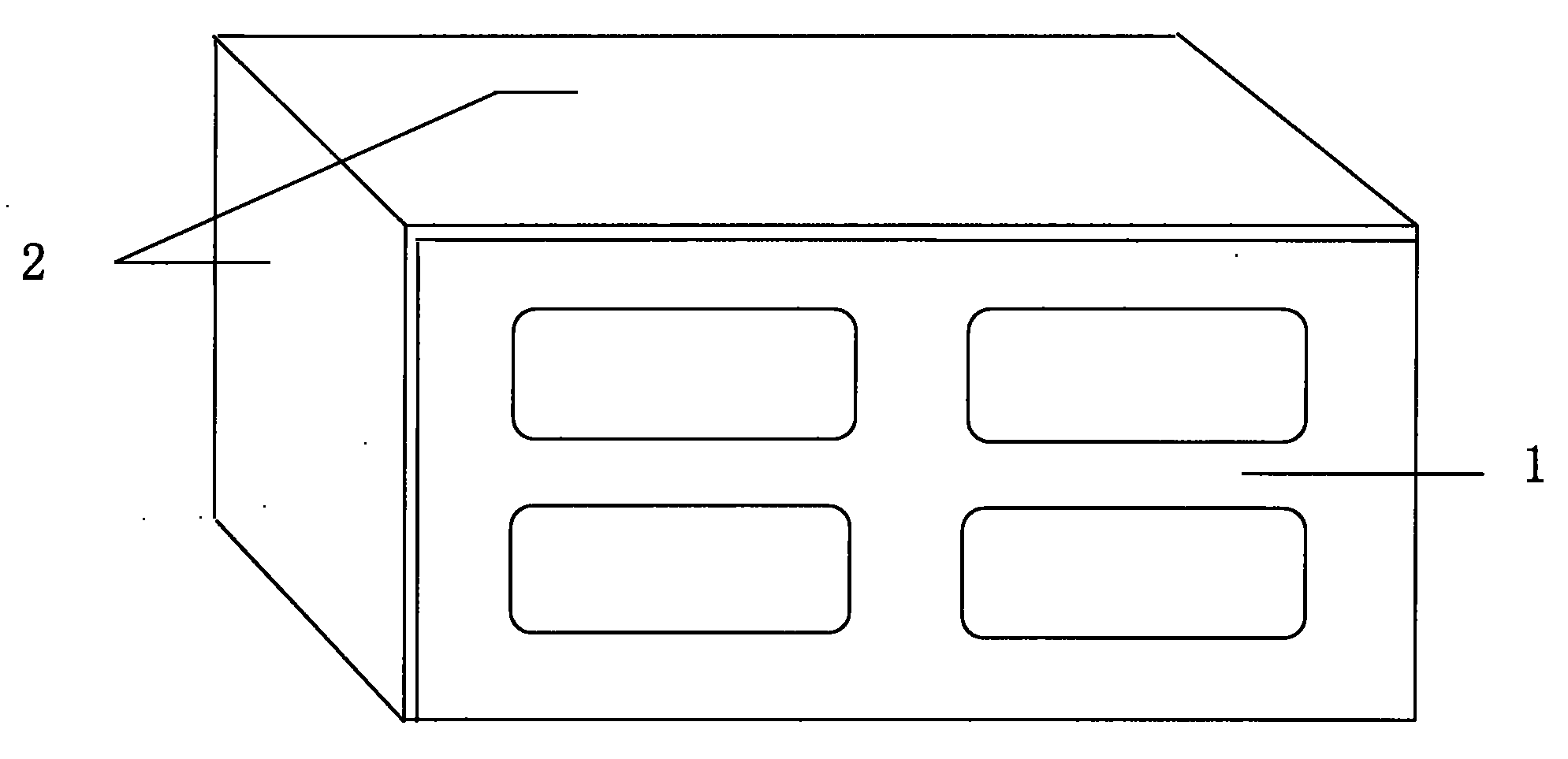

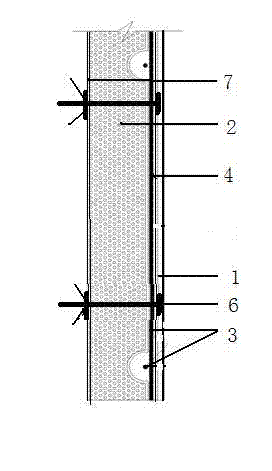

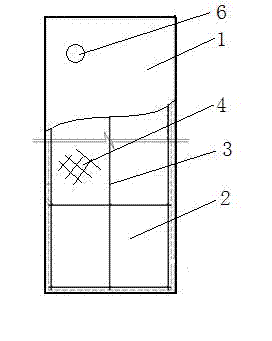

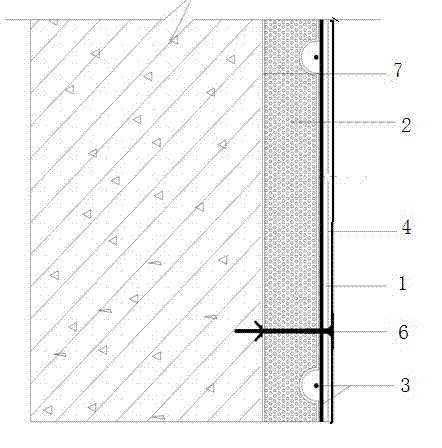

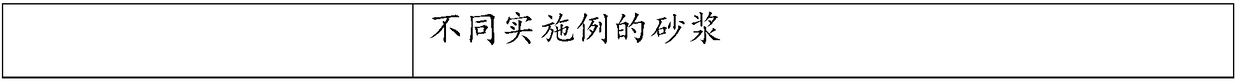

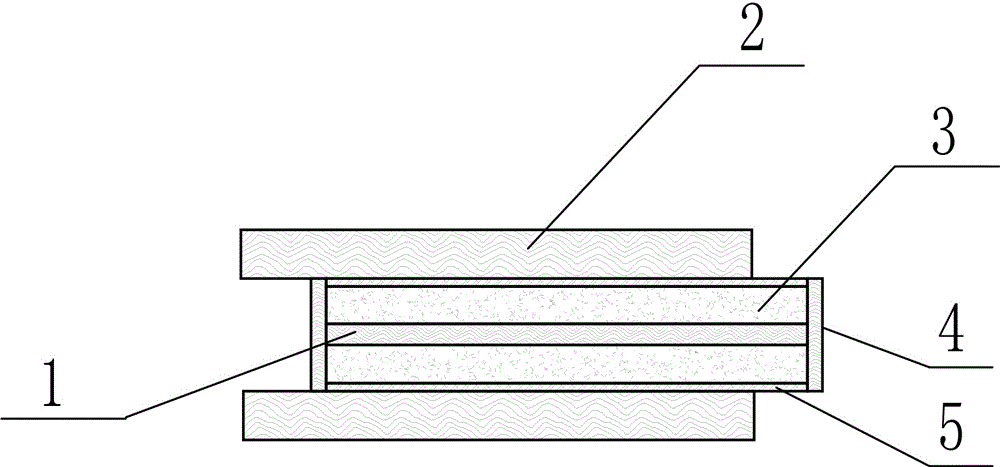

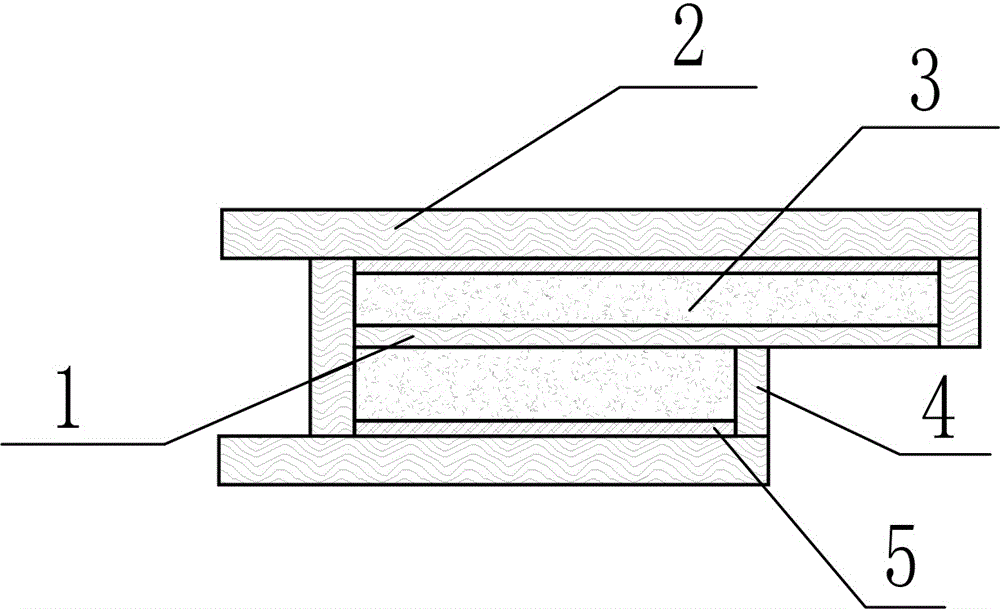

Extrusion molding composite thermal insulation plate integrated with main body structure concrete

InactiveCN102817420AAchieve heat retentionReach structureSynthetic resin layered productsHeat proofingThermal insulationMesh reinforcement

The invention belongs to the technical field of constructional engineering and relates to an extrusion molding composite thermal insulation plate integrated with main body structure concrete. The extrusion molding composite thermal insulation plate integrated with main body structure concrete is characterized in that one face of an extrusion molding plate is provided with mutually crossed arc-shaped grooves, two faces of the extrusion molding plate are both provided with an adhesion agent protective layer, and reinforcing steel bars are arranged in the extrusion molding plate grooves. The reinforcing steel bars form a reinforcing steel bar mesh on the extrusion molding plate, the reinforcing steel bar mesh is provided with fiberglass cloth, a thermal insulation mortar layer wraps the reinforcing steel bar mesh and the fiberglass cloth, and the thermal insulation mortar layer is combined with the extrusion molding plate through the adhesion agent to form a thermal insulation plate. The thermal insulation plate is provided with an anchoring bolt hole, the thermal insulation mortar layer corresponding to the anchoring bolt hole is provided with a countersink, an anchoring bolt is arranged in the anchoring bolt hole, and the other end of the anchoring bolt extends out of the extrusion molding platen and the adhesion agent protective layer and is fastened through a nut. The extrusion molding composite thermal insulation plate integrated with main body structure concrete is good in fireproofing safety, simplifies construction procedures, can improve construction progress, lowers building cost, can achieve industrialized production, is better guaranteed in quality of all aspects and avoids potential quality hazard including hollowing, cracking, water seepage, falling-off and the like brought by complicated operation sequence to the largest extent.

Owner:山东隆济时节能科技股份有限公司

Low-smoke thermal insulation material and preparation method thereof

The invention relates to the technical field of a thermal insulation material and a preparation method thereof, in particular to a low-smoke thermal insulation material and a preparation method thereof. The preparation method comprises the following steps of: step 1. accurately measuring materials; step 2. carrying out banbury mixing on the materials to obtain rubber No. 1; step 3. slicing the rubber No. 1 to obtain rubber slices No. 1; step 4. putting into an open mill, adding an accelerator; step 5. adding to an extruder for extrusion and molding; step 6. feeding a molding material into a drying oven for foaming to obtain rubber hoses; and step 7. introducing into a water tank for cooling; and step 8. shearing and packaging. The low-smoke thermal insulation material has the advantages ofno fiber, no dust, anti-condensation, soft surface and high anti-aging degree and is environmentally friendly and non-toxic; and when the low-smoke thermal insulation material is burned, smoke is reduced by 50%.

Owner:WINCELL INSULATION CO LTD

Ecological functional compound fertilizer and preparation method thereof

ActiveCN104692959AAvoid churnAvoid freezing to deathBioloigcal waste fertilisersSewage/sludge fertilisersMicroorganismEnvironmental resource management

The invention belongs to the field of fertilizers for crops and particularly relates to an ecological functional compound fertilizer and a preparation method thereof. The ecological functional compound fertilizer is prepared from the following main components: sludge, a compound fertilizer, a microbial agent, an organic waste, a soil heating agent and an oxygen supplier. The sludge obtained from the treatment of municipal domestic wastewater and the organic waste serve as organic matters, contain multiple nutrients and can be combined with the compound fertilizer to increase the utilization rate of the compound fertilizer and increase the content of organic matters in soil; the added soil heating agent can preserve the temperature around the roots of crops in deep soil and prevent crops from being frostbitten and frozen to death; the added oxygen supplier can supply oxygen to microorganisms in soil and cells in crop roots to increase the activity of the microorganisms in soil and the crop roots, accelerate the absorption of the ecological compound fertilizer, enhance the adversity, disease and cold resistance of crops, improve the structure and fertility of soil and promote the growth of crops; the pollution of sludge to environment can be reduced, and the sludge can be reutilized; and the ecological compound fertilizer is safe to people, animals and environment and is natural, innoxious and environmentally friendly.

Owner:广西绿友农生物科技股份有限公司

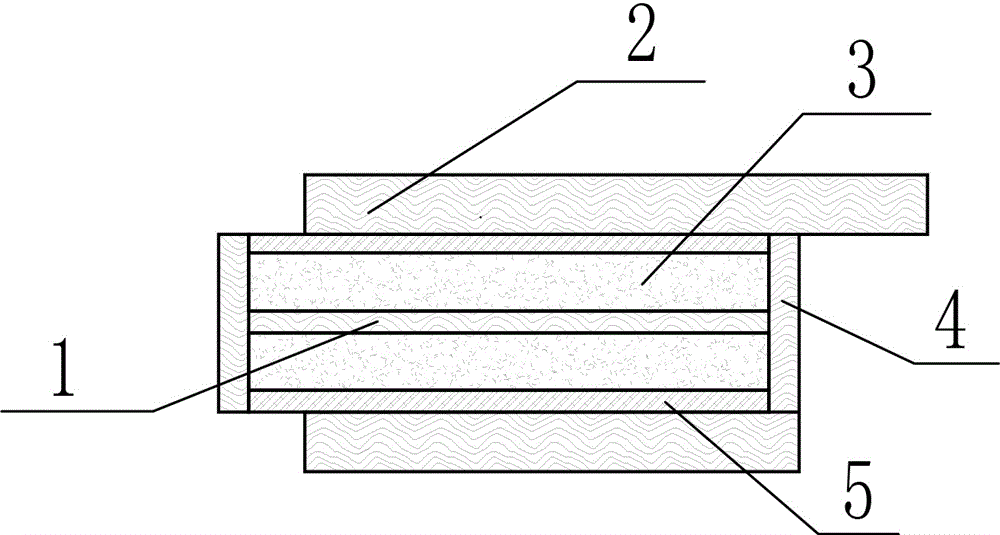

Prefabricated composite wallboard and preparation method thereof

PendingCN108149818AAchieve high thermal performanceImprove insulation effectWallsClimate change adaptationFiberFire protection

The invention provides a prefabricated composite wallboard and a preparation method thereof. The prefabricated composite wallboard includes a first decorative protective layer, a reinforcing layer, asecond decorative protective layer, a vacuum insulation board layer and a structural layer which are sequentially attached; the first decorative protective layer and the second decorative protective layer are a mortar layer, the reinforcing layer is a high-strength fiber gridding cloth or a steel wire mesh sheet, and the structural layer is a reinforced concrete layer. According to the prefabricated composite wallboard and the preparation method thereof, the first decorative protective layer, the reinforcing layer, the second decorative protective layer, the vacuum insulation board layer and the structural layer are connected into a whole through connecting pieces, and the five layers of materials adopt strengths and avoid weaknesses, so that the integrated effects of lightness and thinness, high thermal insulation, fire protection, high strength, and high thermal performance are achieved. The prefabricated composite wallboard is more convenient to transport and install, the utilization of the building area is improved, and the problem that existing wallboards cannot integrate fire prevention, thermal insulation, lightness and thinness, and load bearing is solved.

Owner:SANY CONSTR TECH CO LTD

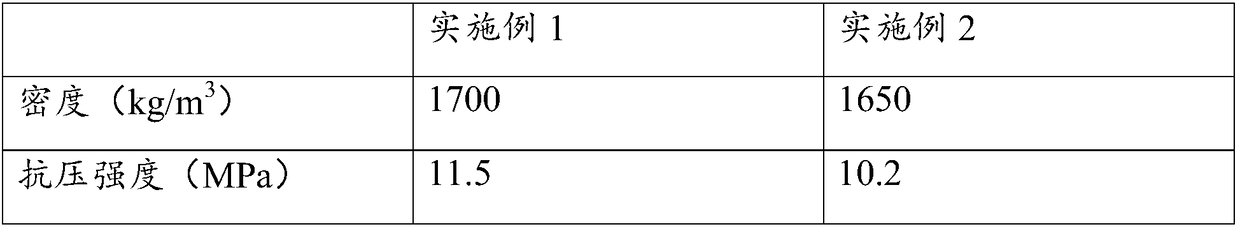

Novel fruit tree anti-freezing support device made of magnesite material

InactiveCN107896762ANo pollution in the processReduce investmentPlant protective coveringsFruit treeAnti freezing

The invention discloses a novel fruit tree anti-freezing support device made of a magnesite material. The device comprises a flange, pull rods, a cross arm and a supporting rod, wherein the supportingrod is made of the magnesite material, and the flange is detachably connected to the top of the supporting rod; the pull rods are arranged on the periphery of the supporting rod uniformly and evenly,and the upper end of each pull rod is detachably connected to the flange plate; the lower end of each pull rod is detachably connected to the cross arm, and the cross arm is circular and is arrangedon the periphery of the supporting rod. The device is mainly designed for frost prevention / freezing prevention and disaster reduction of evergreen fruit trees in the frost period. The structure of thedevice is firmer, flexible and convenient to operate compared with a method for pulling fruit branches by ropes. The device is mainly used for freezing prevention / frost prevention of the evergreen fruit trees such as mangos, oranges and grapefruits. After the fruit picking period, a frost prevention / freezing prevention cover is additionally installed according to weather changes and clamped tightly with fasteners to achieve the anti-freezing and heat-preserving effects.

Owner:四川邦通农业机械有限公司

Method for preparing basalt porous heat-preserving material

A method for preparing a basalt porous heat-preserving material includes the steps that basalt, screen glass, calcium carbonate, silicon carbide, manganese oxide, magnesium carbonate and sodium silicate are ball-milled to obtain batch; then the batch is contained in a mould and heated, foamed, cooled and annealed to room temperature, and the basalt porous heat-preserving material is obtained. By means of the method, waste can be used easily, the environment is protected, the prepared high-strength porous material is low in foaming temperature, basalt directly serves as the main material, the preparation process is simple, and the prepared porous heat-preserving material is high in structural strength, low in water absorbing rate, small in density and low in heat conductive coefficient. Production cost of the foaming porous material can be effectively reduced, the environment is protected, waste is turned into wealth, and economic benefits and environment protection benefits are obvious.

Owner:SHAANXI UNIV OF SCI & TECH

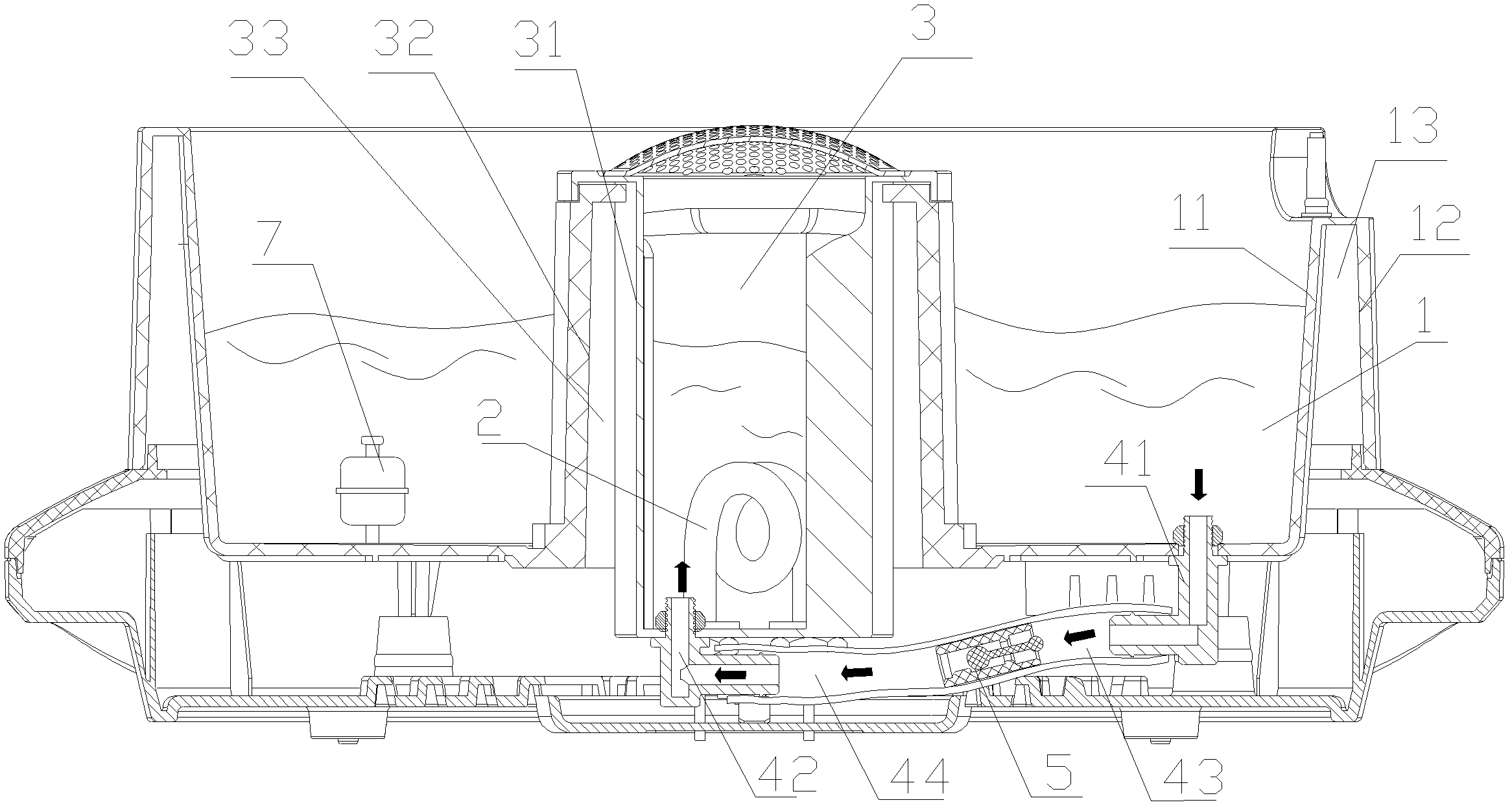

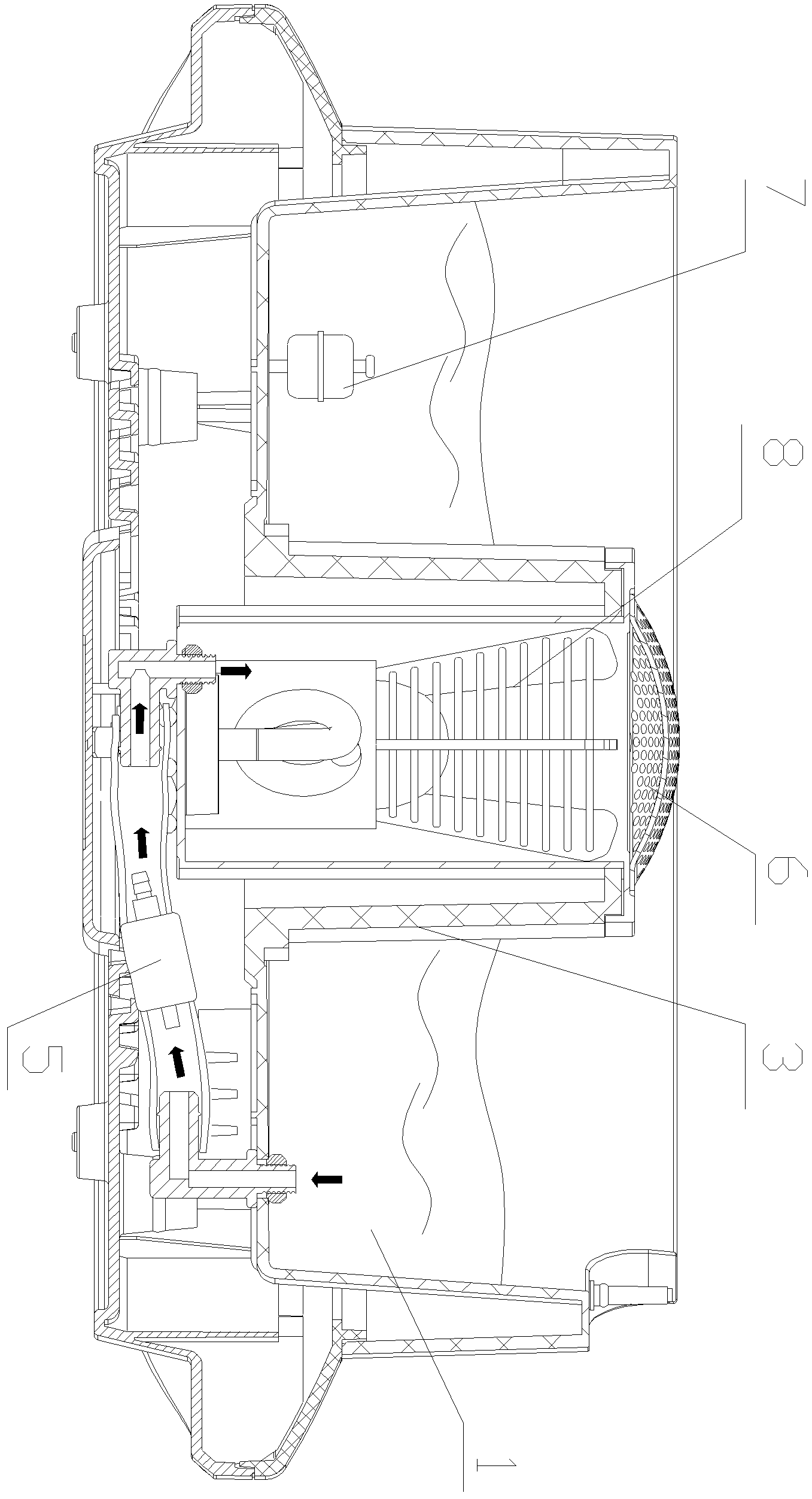

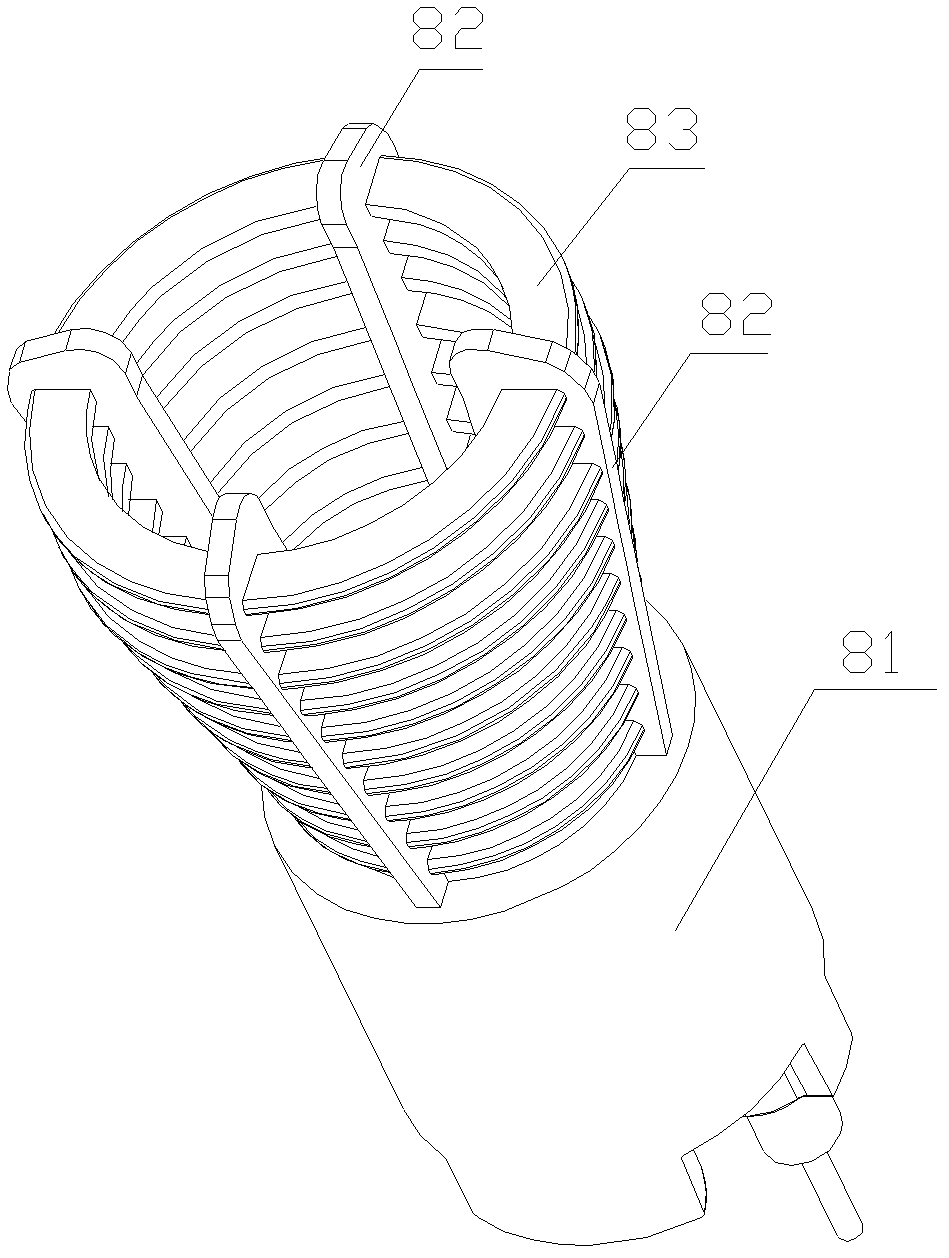

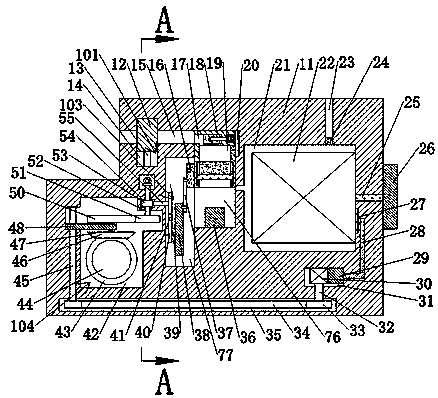

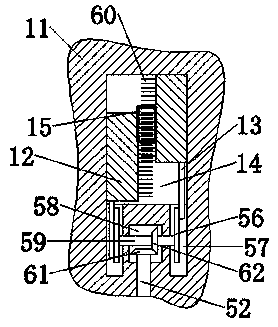

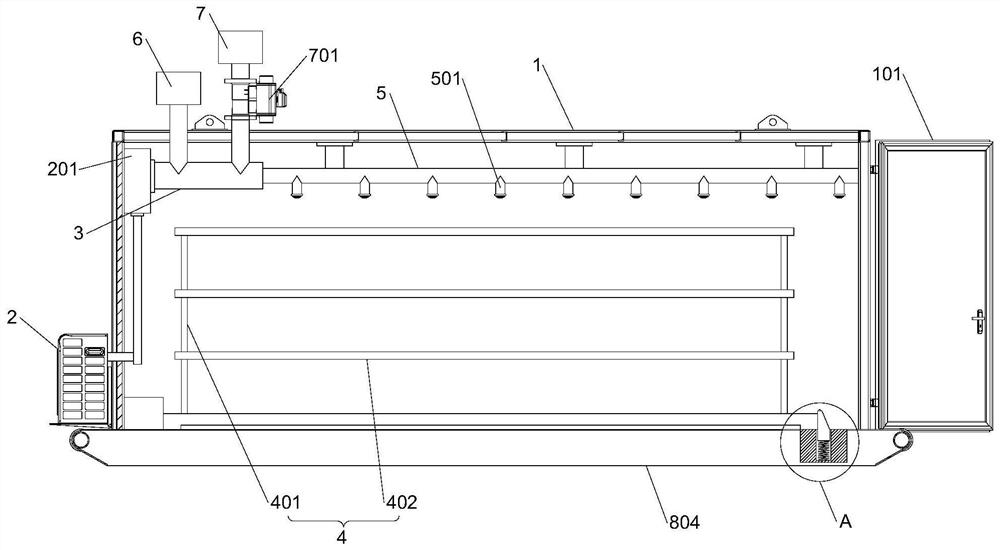

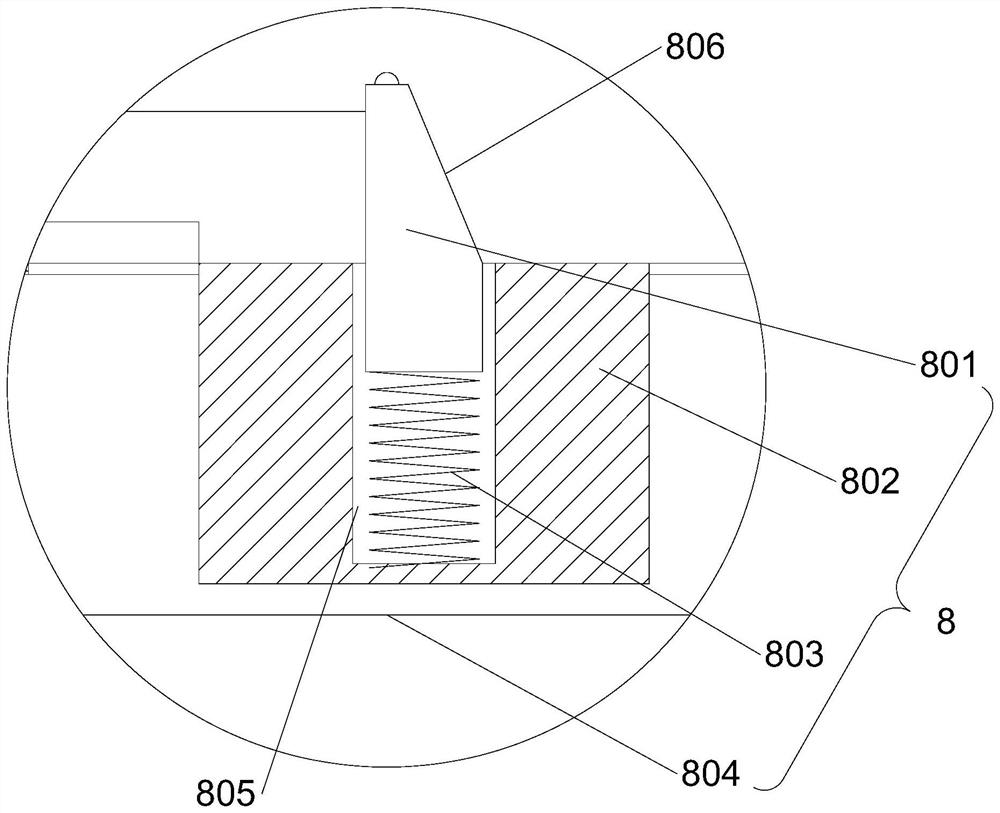

Steam generating device of electric steamer

ActiveCN102551512AAchieve heat retentionAchieve functionSteam cooking vesselsWarming devicesWater deliveryEngineering

The invention discloses a steam generating device of an electric steamer. The steam generating device comprises a water tank and a heating device in the water tank; an energy gathering cup is fixed in the water tank, a water delivery passage for delivering water in the water tank into the energy gathering cup is arranged in the water tank, and a switching valve is arranged in the water delivery passage; the heating device is positioned in the energy gathering cup, and the energy gathering cup is provided with a top opening for outputting steam to the outside; and a radiator is arranged in the energy gathering cup, and the radiator comprises a base in a shape of reverse cup body, supporting rods arranged on the base and made of heat conducting material and radiating fins fixed on the supporting rods. The steam generating device has the advantages of capability of completely isolating a water source and low energy waste.

Owner:ZHEJIANG SUPOR ELECTRICAL APPLIANCES MFG CO LTD

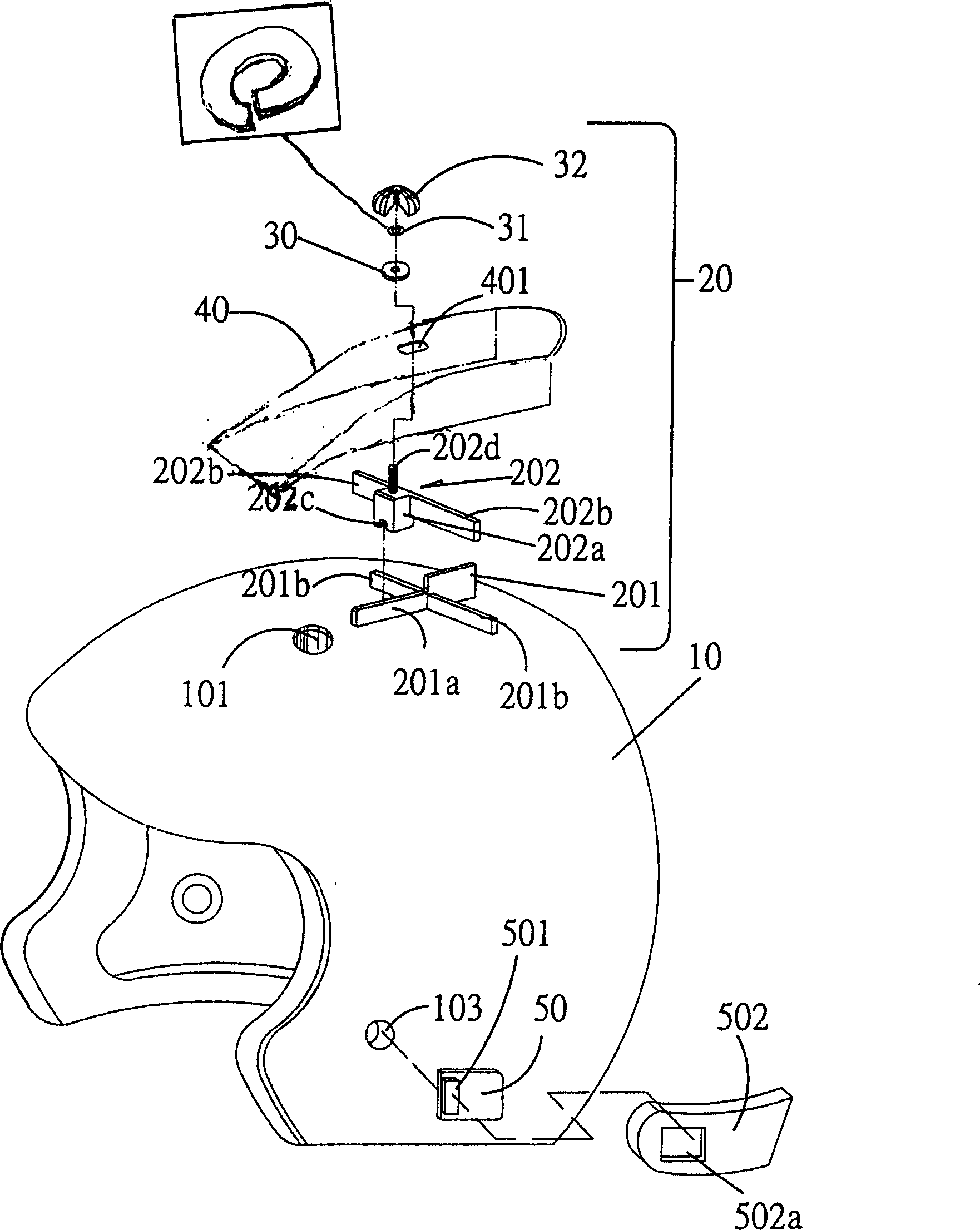

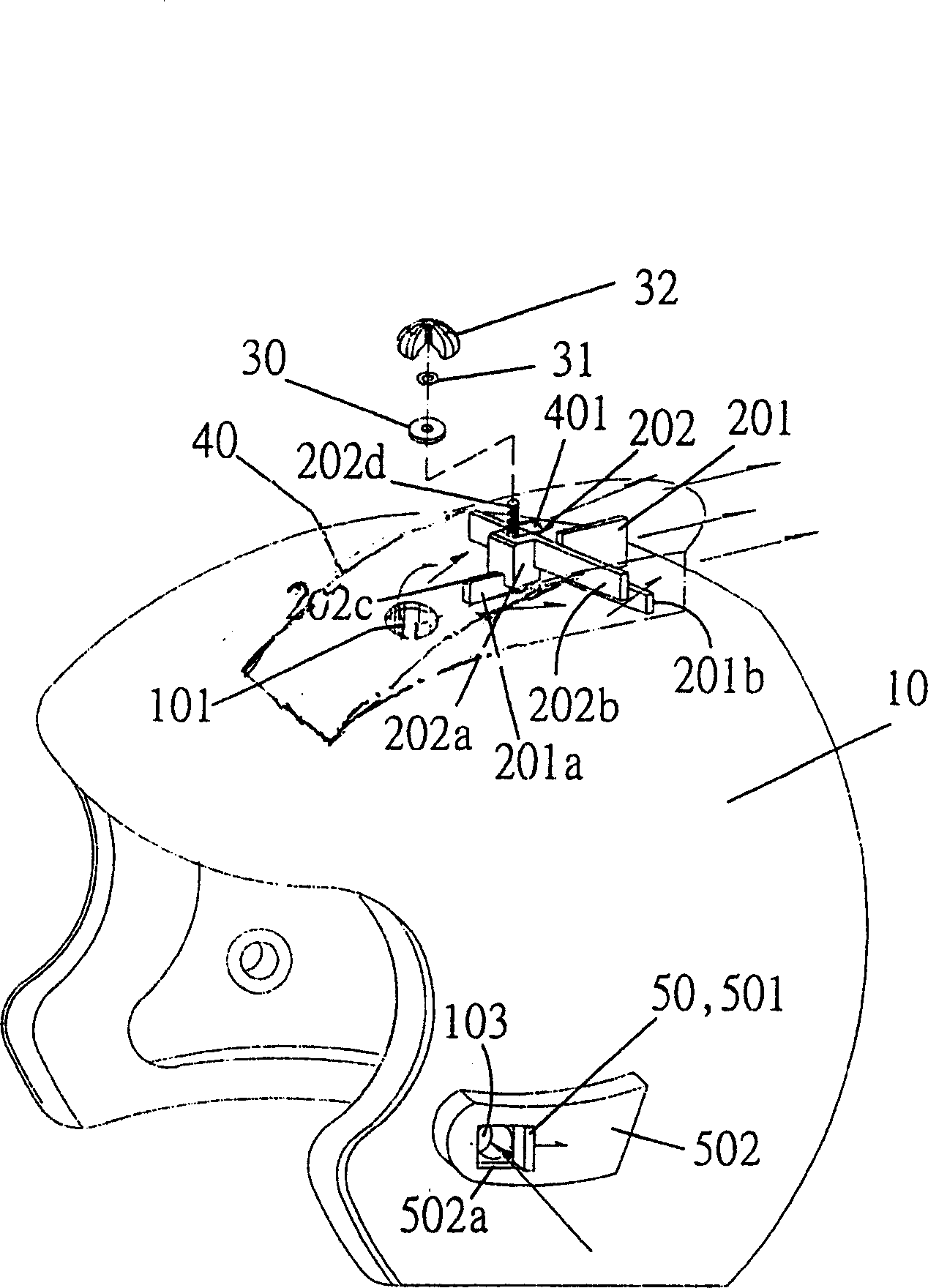

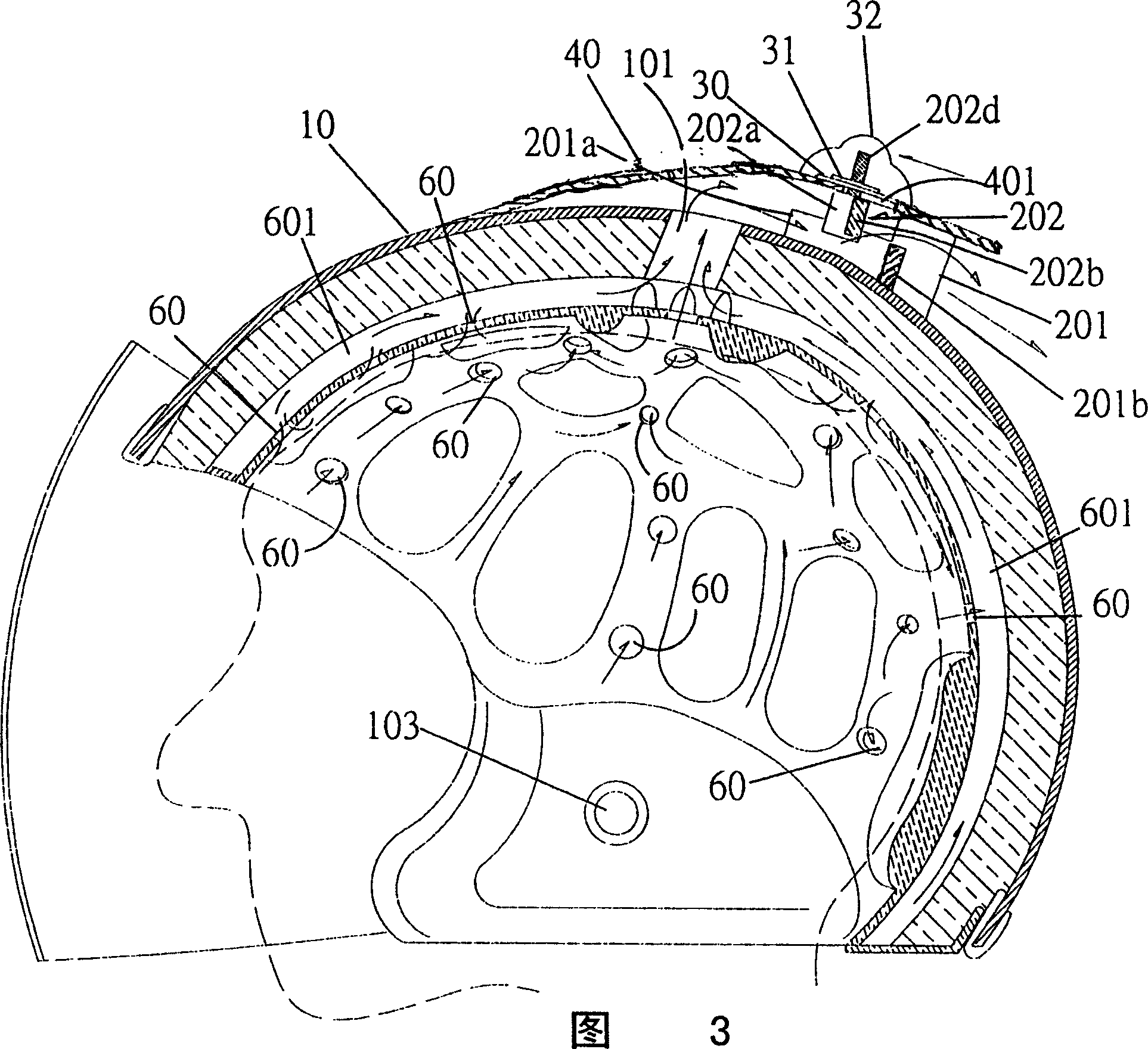

Plusing device for control damper of ventilate safety helmet

The invention is a gain apparatus for airflow control valve body of ventilative safety cap, comprising an airflow control valve body equipped behind the big circular hole on the top of the ventilative safety cap, a valve plate, a cover casing with orifices, and a warming sheath. The airflow control valve body can be adjusted according to temperature variation to achieve the goal of cool in summer and warm in winter. The movable valve can be pushed forward in summer to make the air flow out of the cap from the space between the valve and the rain baffle, and can be pushed backward in winter to form an enclosure with the rain baffle and block heat radiation from the safety cap.

Owner:马 樟清 +1

Non-combustible rock wool composite thermal-insulating board for buildings

InactiveCN106245795ALow costEasy constructionMacromolecular adhesive additivesHeat proofingEngineeringUltimate tensile strength

The invention discloses a non-combustible rock wool composite thermal-insulating board for buildings. The non-combustible rock wool composite thermal-insulating board comprises a base board, wherein the base board is a rock wool board, the front side and the back side of the rock wool board are coated with first bonding glue layers, the first bonding glue layers bond with gridding cloth, the gridding cloth is coated with second bonding glue layers, and the first bonding glue layers and the second bonding glue layers use the same bonding glue. The provided composite thermal-insulating board can be used for external wall thermal insulation in a conventional manner and can also be used as a building template to be poured on a wall directly; a thermal insulation layer is not required, the non-combustible rock wool composite thermal-insulating board is low in cost, more economical and practical, convenient to construct, low in waste, economical and environment-friendly, saves labor and materials, meets national thermal insulation and fire prevention rules and is high in weather fastness and strength, and the service life of the composite thermal-insulating board is as long as that of the wall.

Owner:ZHEJIANG WOHUA ENVIRONMENTAL TECH CO LTD

Protector for improving performance of new energy vehicle battery

ActiveCN110808435AIncrease mileageImprove efficiencySecondary cellsAutomotive batteryElectrical battery

The invention discloses a protector for improving the performance of a new energy vehicle battery, which includes a body and a battery pack. The body is provided therein with a heating chamber. The battery pack is fixedly arranged between the front and rear walls of the heating chamber. The left side of the heating chamber is in communication with a lifting cavity. The left side of the lifting cavity is in communication with an air intake cavity and a transmission cavity. The air intake cavity is located above the transmission cavity and is in communication with the outside. The protector canenable the battery pack of a new energy vehicle to still have high use efficiency in severe cold winter weather, and controls the frictional heat generation and air pressurized temperature rise through the mechanical transmission of a vehicle's power shaft during the start and travel of the new energy vehicle, enables the hot air to directly preheat the battery pack of the new energy vehicle, cangreatly improve the efficiency of the battery pack and increase the endurance mileage of the new energy vehicle in cold winter.

Owner:LIYANG HUAPENG ELECTRIC POWER METER

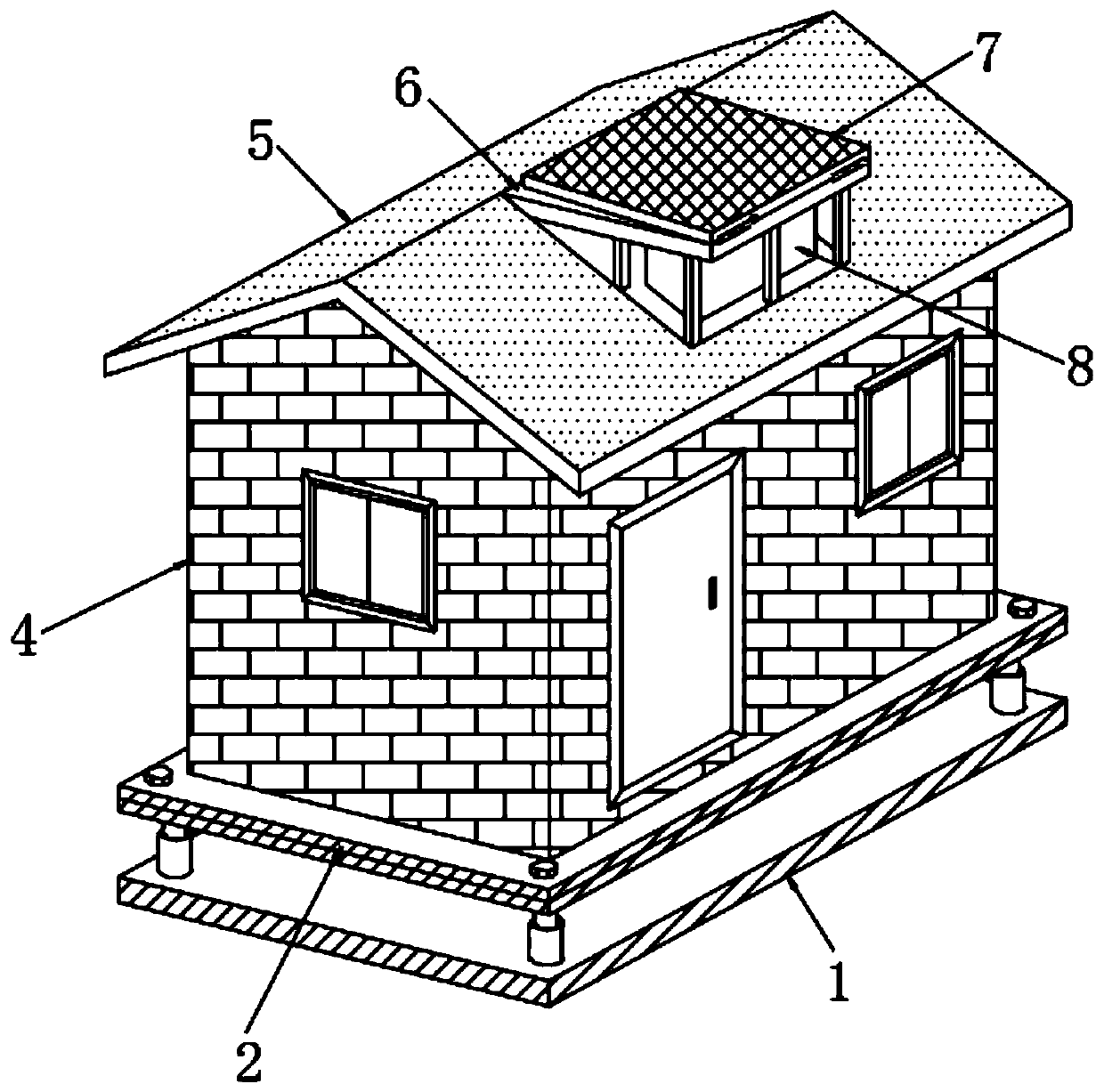

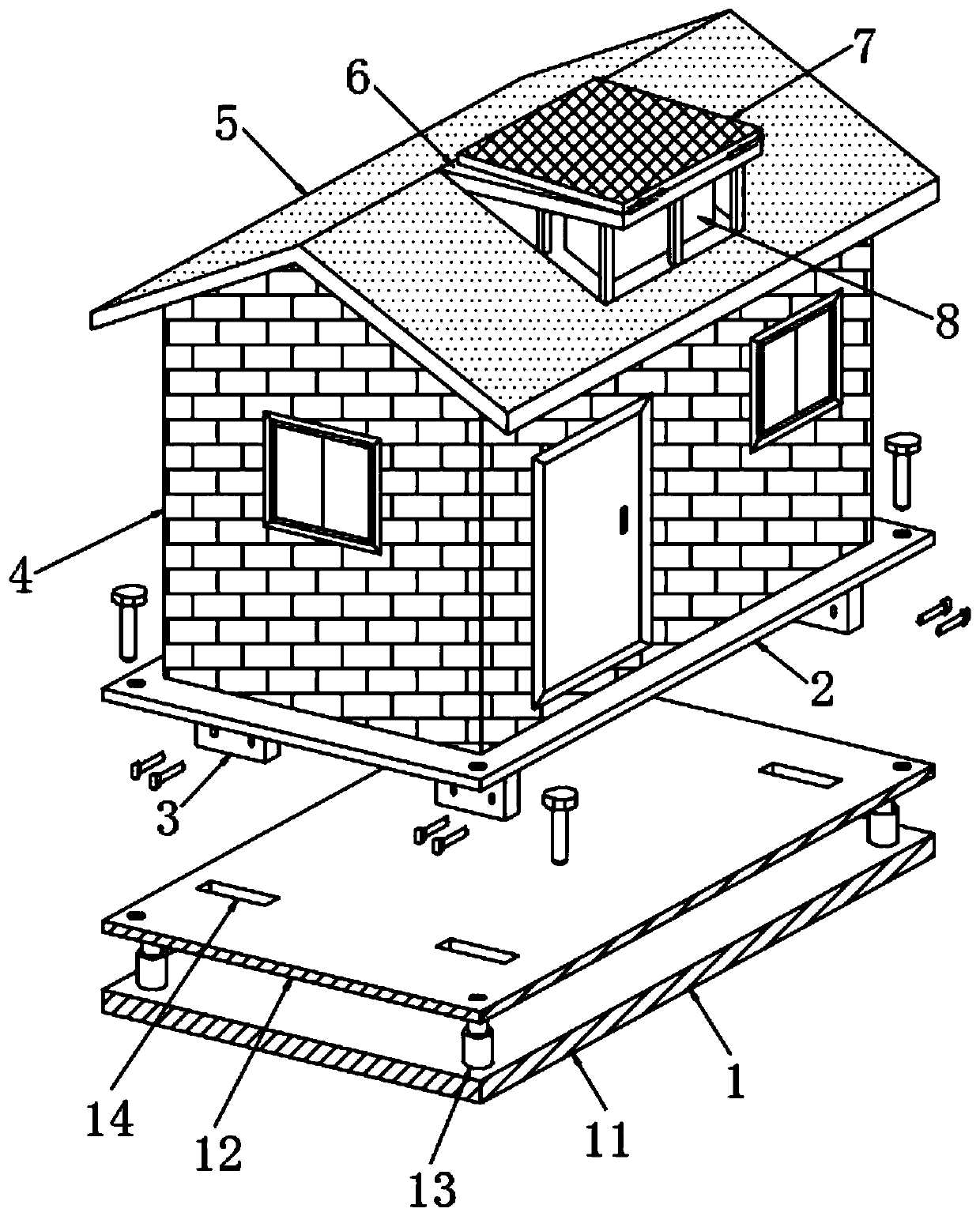

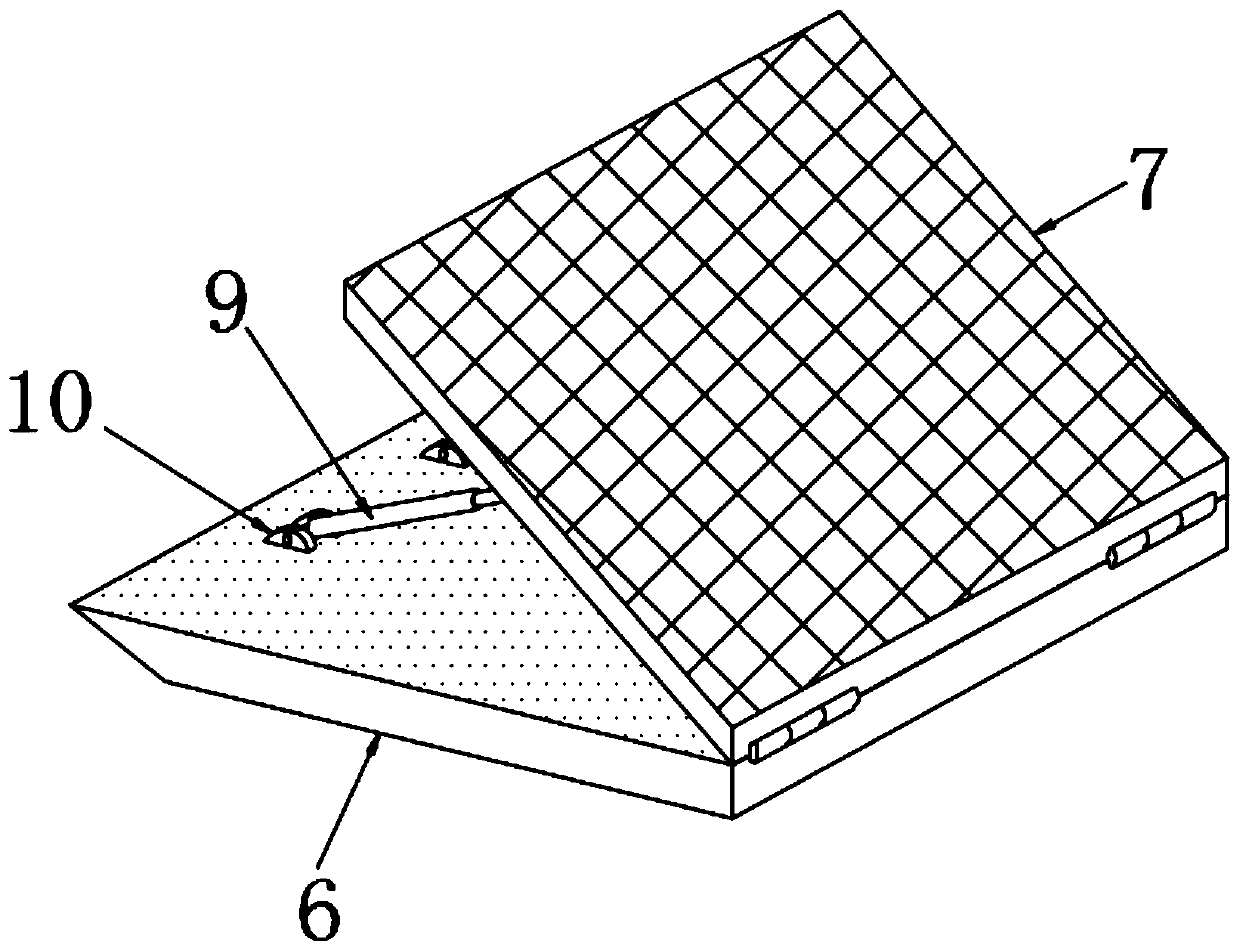

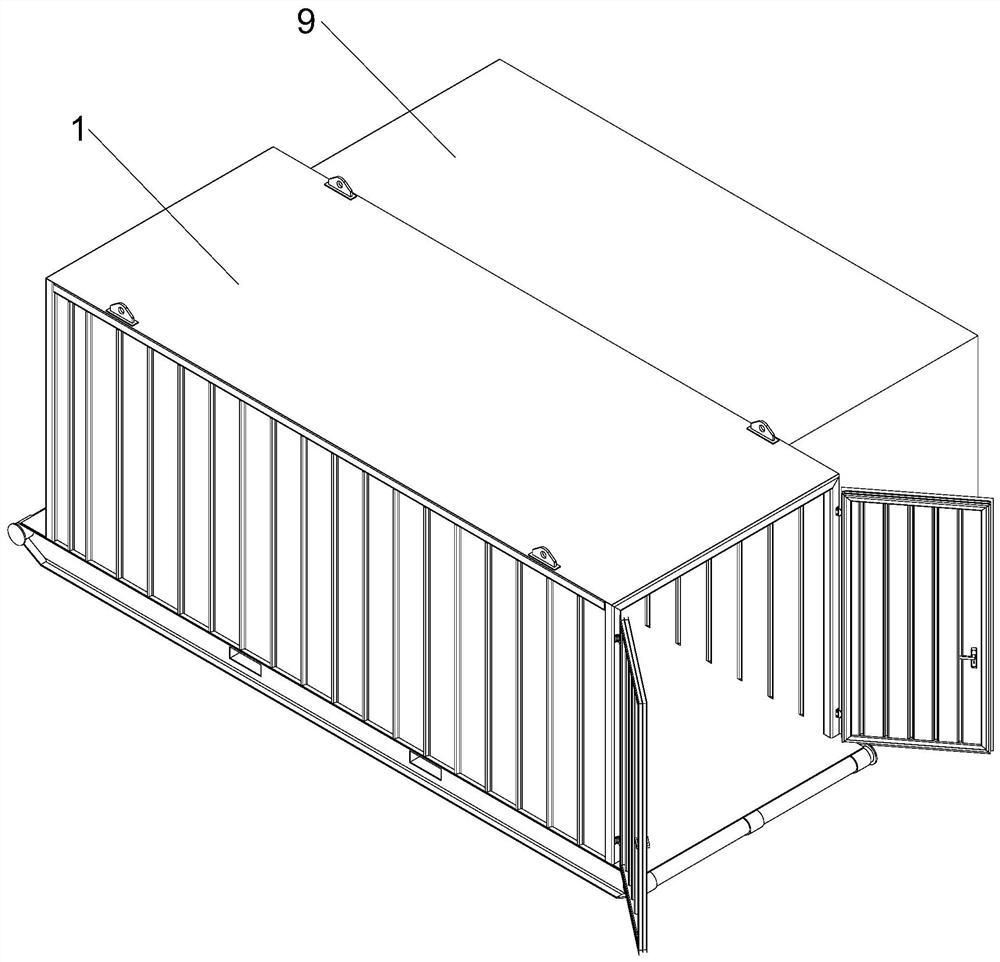

Integrated assembling type steel structure building

PendingCN110714527AEasy to adjustImprove practicalityPhotovoltaic supportsBuilding roofsElectric power equipmentArchitectural engineering

The invention discloses an integrated assembling type steel structure building, and relates to the technical field of steel structure buildings. The integrated assembling type steel structure buildingcomprises a waterproof platform, wherein a fixed seat is fixedly arranged on the top part of the waterproof platform; a clamping block A is arranged on the lower surface of the fixed seat in a way ofpenetrating through the waterproof platform; a wall is arranged on the upper surface of the fixed seat; a ridge is fixedly arranged on the top part of the wall; and a ceiling is fixedly arranged on the upper part of the front side of the ridge. The integrated assembling type steel structure building provided by the invention is scientific and reasonable in structure and low in production cost; through the arranged waterproof platform, a certain waterproof treatment effect can be achieved; meanwhile, through an arranged jack, the height adjustment of the building can be realized, so that the application range is enlarged, and the practicability is improved; and through arranging a solar cell panel, solar radiation energy can be converted into electric energy so as to be used by a power equipment in the building, so that a certain energy conservation and environment protection effect is achieved. A steel structure strengthening layer of the design is installed and disassembled in a time-saving and effort-saving way, so that the working efficiency is effectively improved.

Owner:江苏宝力重工科技有限公司

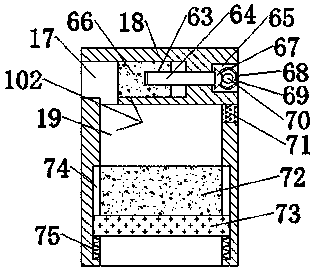

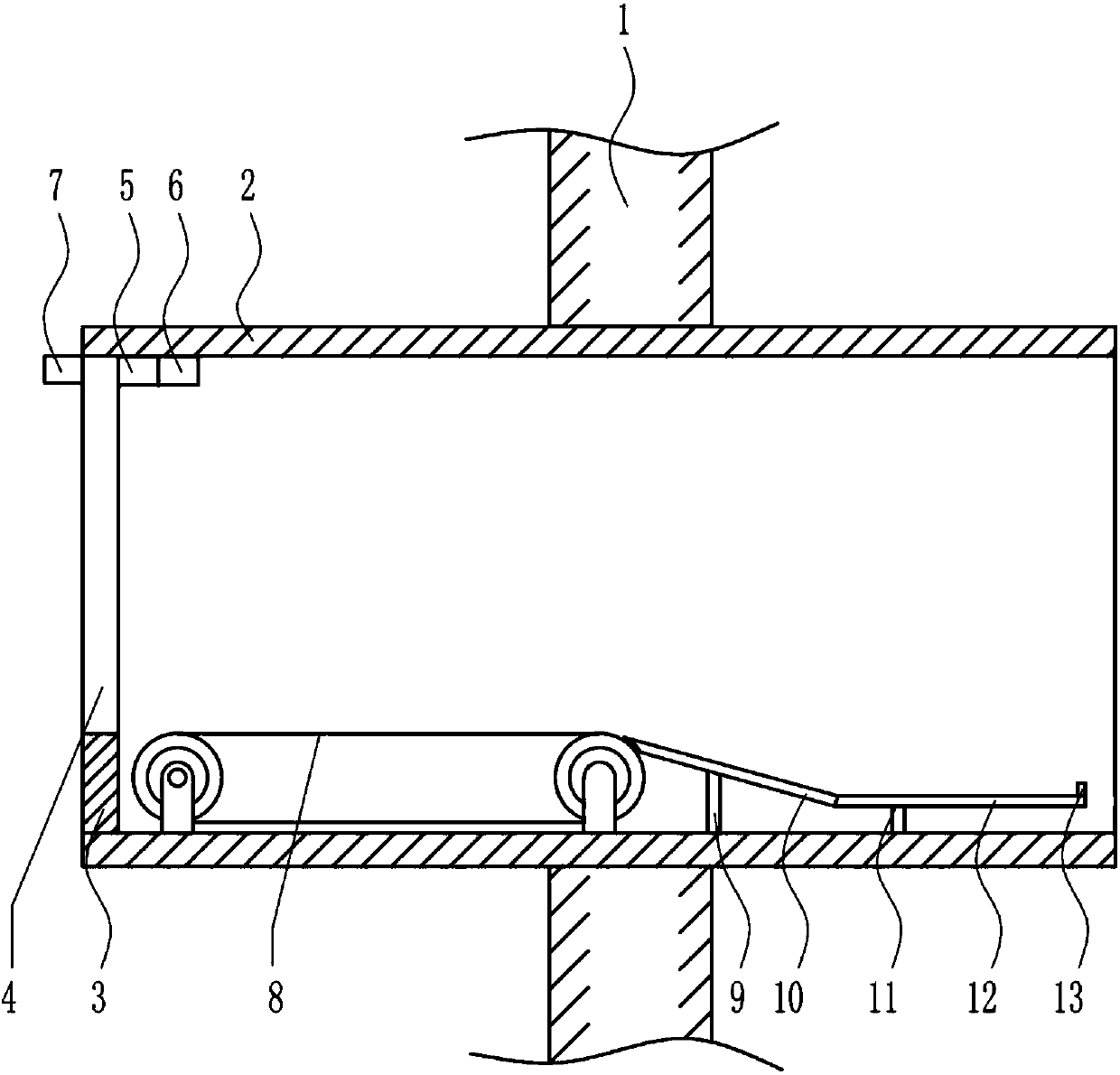

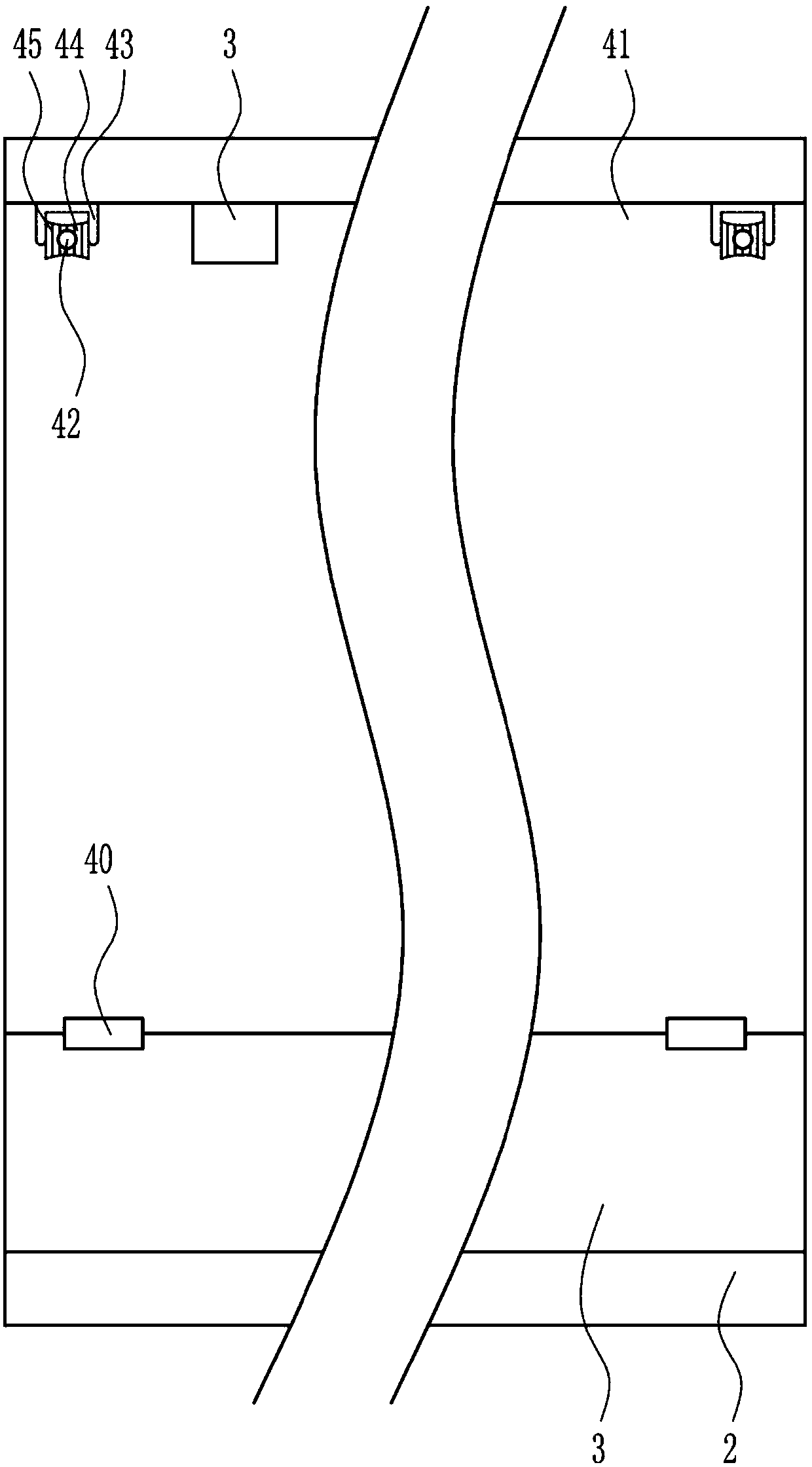

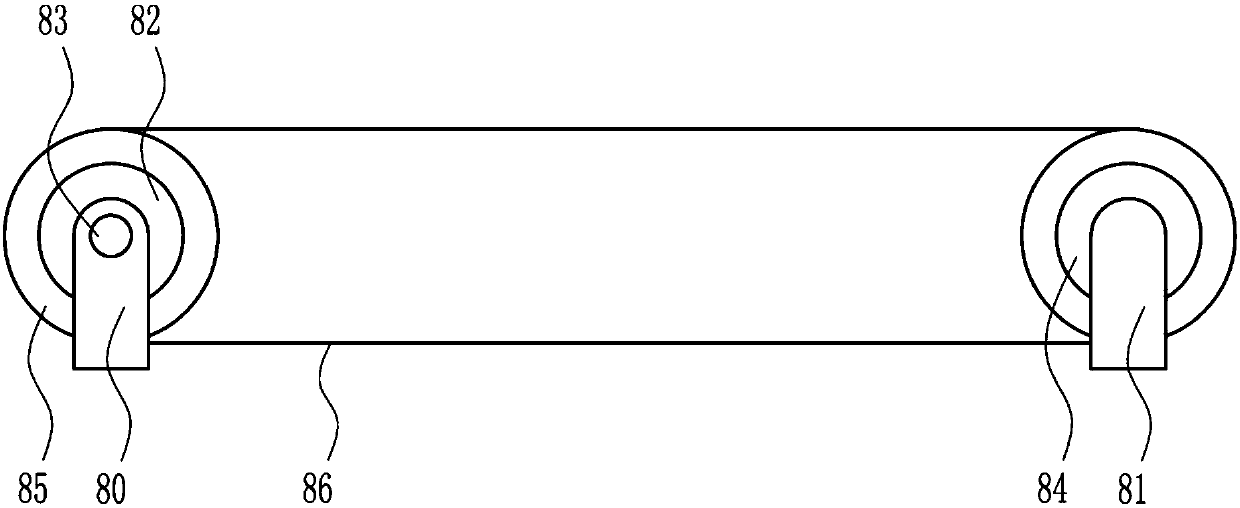

Internet of Things based automatic small household parcel receiving device

ActiveCN107689122AEnsure safetyTo achieve the purpose of refrigerationApparatus for meter-controlled dispensingSoftware engineeringThe Internet

The invention relates to a parcel receiving device, in particular to an Internet of Things based automatic small household parcel receiving device. The Internet of Things based automatic small household parcel receiving device comprises a box, a retaining plate, a door mechanism, a wireless signal receiver and the like. The retaining plate is arranged at the left end of the inner bottom of the boxwhich is arranged on a wall, the door mechanism is arranged at the top of the retaining plate, a small scanner is arranged at the left upper end of the door mechanism, and a wireless signal receiverand a controller are arranged at the left end of the inner top of the box. The Internet of Things based automatic small household parcel receiving device has advantages that automatic parcel receivingcan be realized while heat preservation or refrigeration of parcels can be realized as well; when the parcels need to be refrigerated or put in a high-temperature environment but an owner cannot gethome timely, the owner sends an instruction, and then the controller controls a refrigerator or a heater to start operating.

Owner:山东诚丰电子工程有限公司

Processing method of anti-shearing and high temperature-resisting composite water-polyurethane heat-insulation pipe

ActiveCN102922651AExtended service lifePrevent high temperature carbonizationThermal insulationPipe protection by thermal insulationInsulation layerMetallurgy

The invention discloses a processing method of an anti-shearing and high temperature-resisting composite water-polyurethane heat-insulation pipe. The processing method is characterized by comprising the following processing steps of: (1) clearing away impurities adhered on the outer wall of a steel pipe; (2) lifting the steel pipe onto a bracket, starting a spray gun to uniformly spray a heat insulation material onto the outer wall of the steel pipe in the form of spray liquid, wherein the spray thickness is 1.5-2.5mm; (3) nesting an external protecting pipe outside the steel pipe through a pipe-penetrating machine within 1-1.5 hours after spraying; and (4) using isocyanate and polyether polyol as spray foaming raw materials, and spraying the raw materials into the external protecting pipe through a foam spraying device so as to form a foam heat-insulation layer. According to the processing method of an anti-shearing and high temperature-resisting composite water-polyurethane heat-insulation pipe, a procedure of spraying the heat insulation material onto the outer surface of the steel pipe is added, so that the coating can play a role of heat insulation and cooling and can improve the product performance; under the use conditions of ultrahigh temperature, the service life of the heat insulation pipe can be prolonged, and the heat insulation pipe can replace a vapor heat-insulation pipe for conveying low-temperature media, so that the input cost is reduced, the purposes of energy saving and consumption reduction are achieved, and the market demand is satisfied.

Owner:河北昊天热力发展有限公司

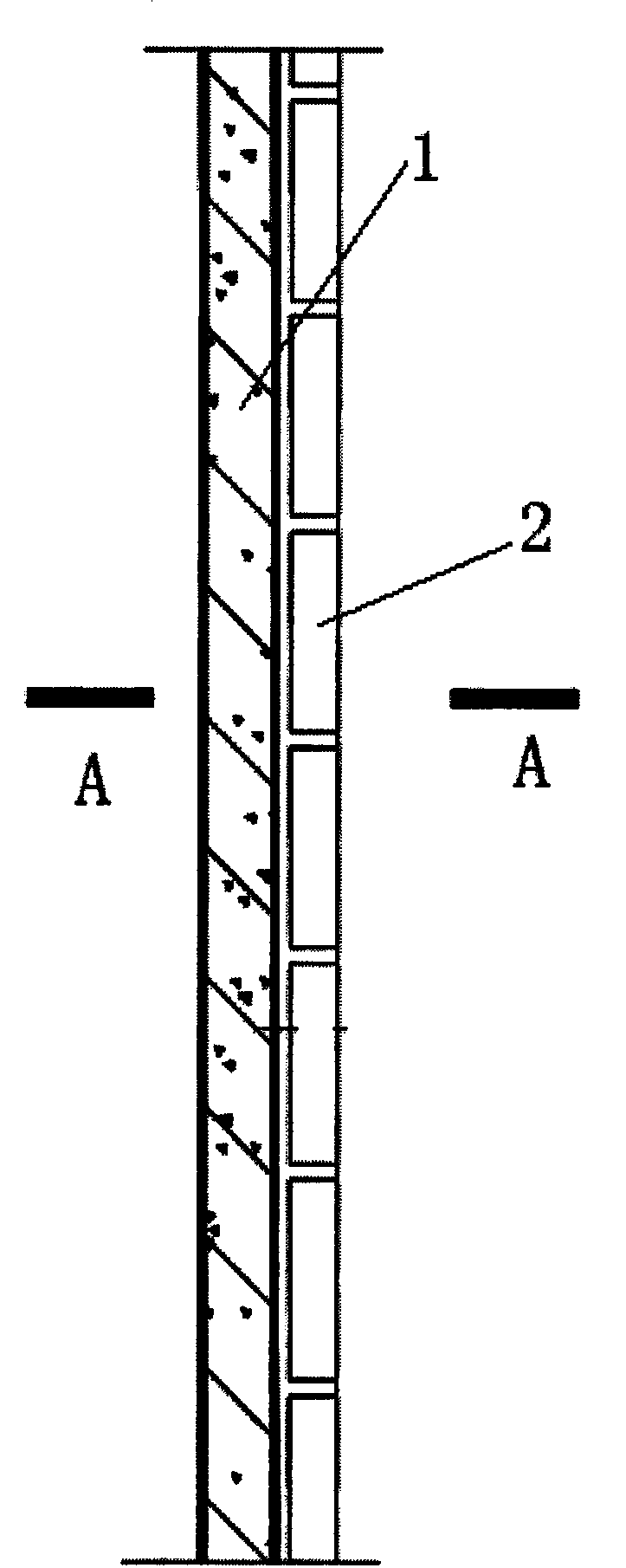

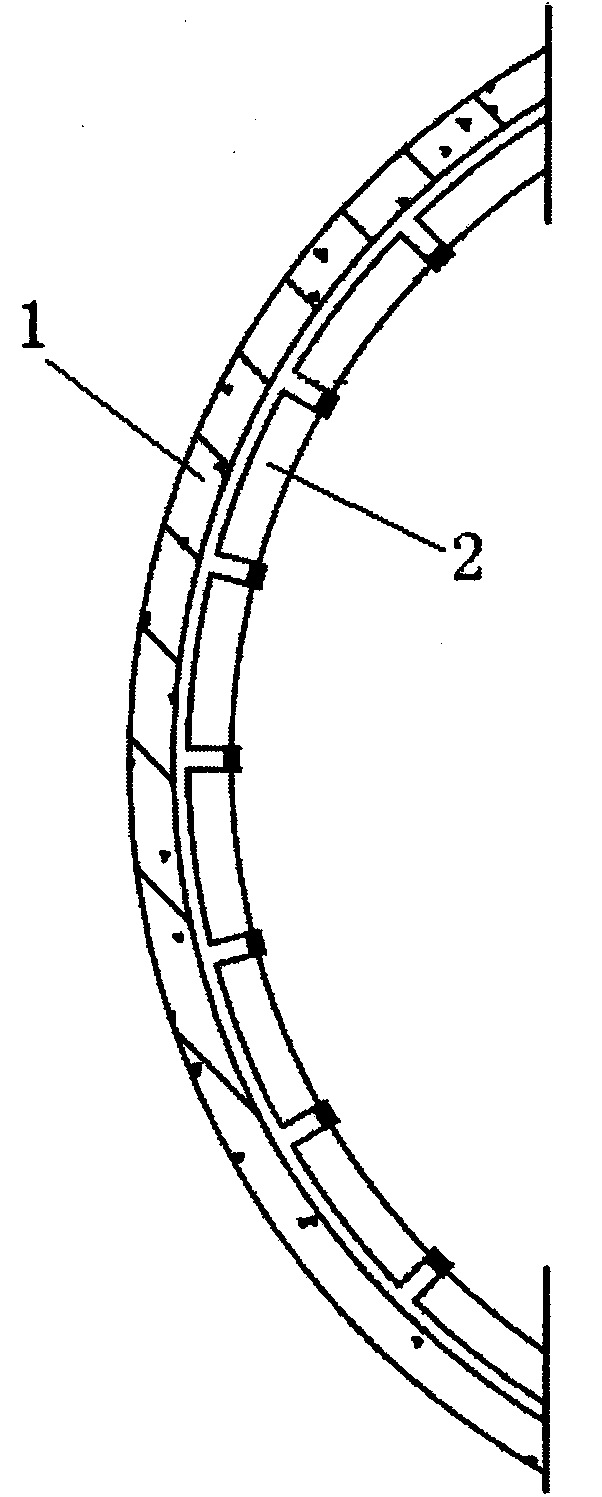

Single-barrel type concrete chimney structure with thermal insulation and anti-corrosion layer

The invention provides a single-barrel type concrete chimney structure with a thermal insulation and anti-corrosion layer. The single-barrel type concrete chimney structure comprises a concrete single barrel. The single-barrel type concrete chimney structure is characterized by furthering comprising a thermal insulation and anti-corrosion layer comprising a bottom coating, an adhesive and glass bricks, the inner wall of the concrete single barrel is coated with the bottom coating, and the glass bricks are attached to the bottom coating through the adhesive. By the use of the single-barrel type concrete chimney structure, the corrosion problem of the chimney caused by the wet smoke after desulfuration of coal-fired power plant is solved. The single-barrel type concrete chimney structure is simple in structure and low in cost. Besides, through the adhesive and the glass bricks, thermal insulation and anti-corrosion functions are achieved.

Owner:上海德昊化工有限公司

Green cultivation method for organic hotbed chives

InactiveCN108293784AImprove disease resistanceIncrease productionClimate change adaptationBulb cultivationDiseasePesticide residue

The invention discloses a green cultivation method for organic hotbed chives. The method comprises the following steps: 1) selecting seeds and raising seedlings; 2) preparing soil and performing fertilization: applying a special organic fertilizer prepared by performing fermentation by using waste asparagus stems as a raw material; 3) performing transplanting and performing field planting; 4), performing water and fertilizer management, wherein top dressing is performed by selecting a slow-release water-soluble fertilizer suitable for growth of the hotbed chives; 5), building a shed frame forcultivation, enabling a black film to cover around the shed frame, and enabling a double-layer black nylon cloth with a microporous structure to cover the upper surface of an arched frame of a shed roof, so as to achieve the purpose of avoiding light and preserving heat; and 6), performing harvesting. The cultivation method provided by the invention is suitable for cultivating and planting the hotbed chives in a low-temperature environment, has simple operation, is ecological and environmentally friendly, adopts a ventilating and lightproof shed-building technology, ensures a non-lighting growth environment of the hotbed chives, increases permeability of the environment, improves the yield and quality of the hotbed chives, enhances disease resistance of the hotbed chives, solves the problems of disease prevention and control and pesticide residues in the planting process of the hotbed chives, and is suitable for a large-scale vegetable plantation for promotion and application.

Owner:弥勒市四园农林发展有限公司

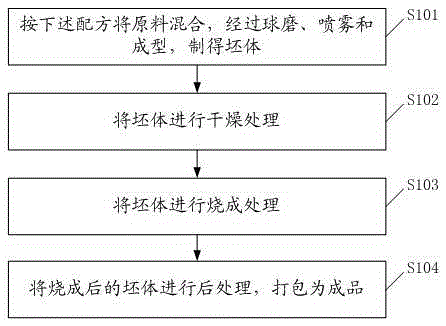

Preparation method of light-weight heat-preservation brick

The invention discloses a preparation method of light-weight heat-preservation bricks. The preparation method includes the steps of 1) mixing the following raw materials comprising: 50-76% of industrial coal slag, 6-20% of a mud material, 4-20% of potassium feldspar, 4-20 parts of sodium feldspar, 4-20% of quartz and 0-15% of polishing residue, and performing ball milling, spraying and moulding to produce a green body; (2) drying the green body; (3) sintering the green body; (4) after-treating the sintered green body, and packaging a finish product. The preparation method is simple in step, is short in sintering time and can save energy resources. The produced heat-preservation brick is solid in texture, is low in specific gravity, is high in porosity, is higher than 1000 DEG C in resistance temperature, can easily resist common fire, is low in heat conductivity and high in pressure resistant strength, and is very suitable for heat insulation of outer walls and indoor heat insulation and sound insulation.

Owner:KEDA INDUSTRIAL GROUP CO LTD

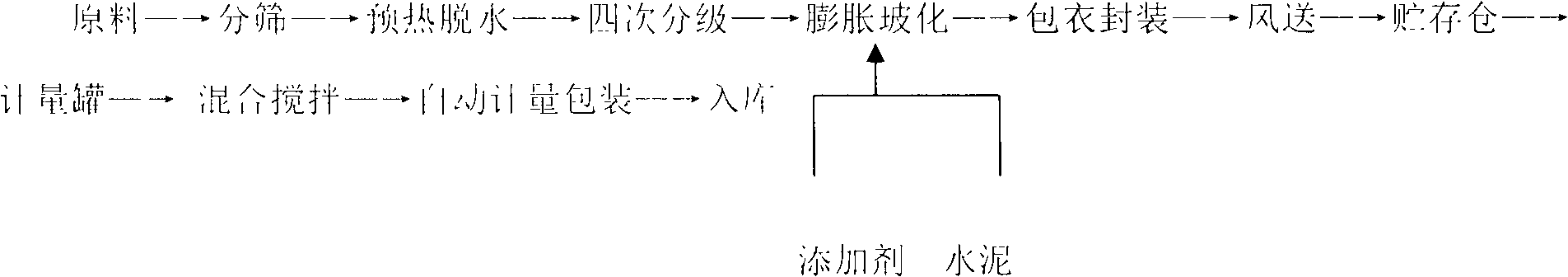

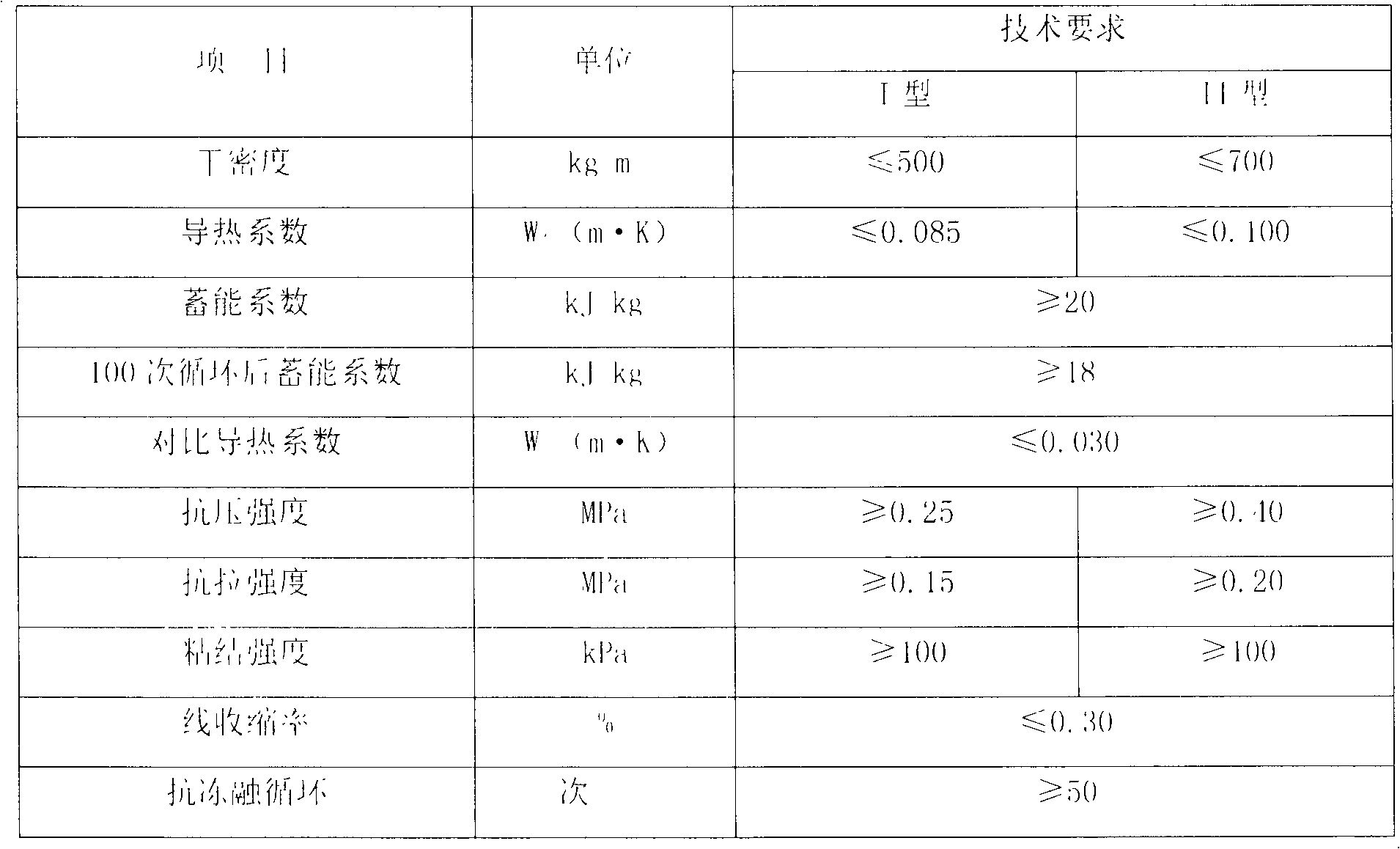

Production method and application of pitchstone expansion vitrified micro-bead energy storage material

InactiveCN102417314AHigh strengthLow thermal conductivityHeat proofingFreeze thawingWeather resistance

The invention discloses a production method and application of a pitchstone expansion vitrified micro-bead energy storage material, belonging to the field of building thermal-insulation temperature-adaptable materials. In the existing thermal-insulation energy saving building materials, expanded polystyrene boards and extruded polystyrene boards as represented by thermal-insulation materials are difficult to satisfy the 65% energy saving requirement, and have the disadvantages of short service life, bad flame resistance and the like. The pitchstone expansion vitrified micro-bead energy storage material disclosed herein overcomes the disadvantages of the material in the prior art, and achieves the following advantages: 1, long service life: the material has the same service life with the building body; 2, good flame resistance: the material achieves the grade-A standard required by GB8621-2006; and 3, good weather resistance: the number of freeze-thaw cycles of the material is 50. Simultaneously, the material has a temperature adjustment function, when the indoor ambient temperature in the daytime is too high, the material can absorb heat in the environment, and when the indoor ambient temperature in the night is low, the material can release heat to the environment, thus the indoor temperature fluctuation is controlled, the use of the air-conditioners and heating systems is reduced, and the energy is saved. The material can be widely applied in building wall, the thermal insulation projects of wall surface, roof, and floor, and the like.

Owner:逄增彬

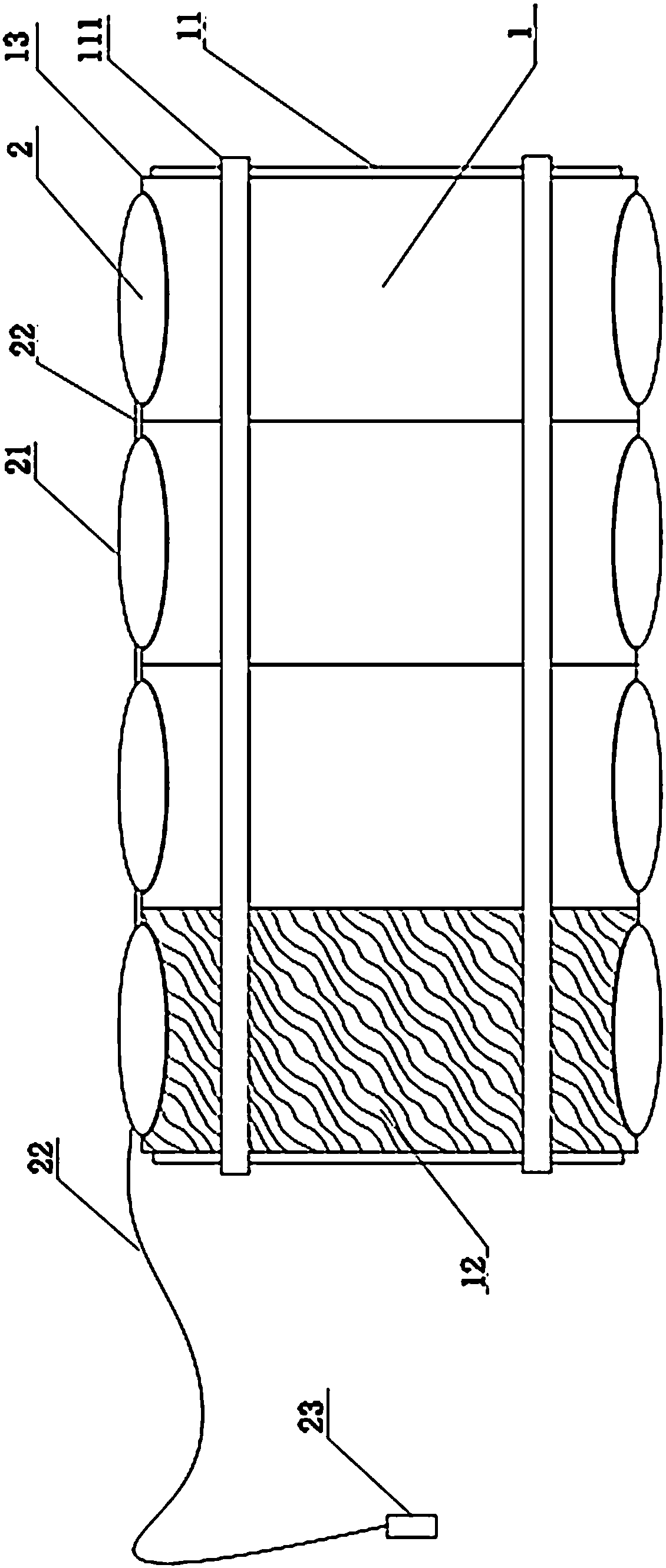

Construction scheme of floating air-rib composite water-pillow pneumatic membrane structure

ActiveCN108277885AAvoid spreadingAchieve fire resistanceExtraordinary structuresFire proofingHeat fusionPublic Facility

The invention discloses a construction scheme of a floating air-rib composite water-pillow pneumatic membrane structure, and belongs to the technical field of membrane structure construction. The construction scheme comprises the steps of mounting of air rib assemblies, inspection of memebrane materials, setting-out of membrane pieces, clipping of the membrane pieces, pre-assembling of the memebrane materials, heat fusion connection of memebrane material force-bearing seams, connection of the memebrane materials and an exit and entrance, edge corner treatment of the memebrane materials, treatment of the water-pillow memebrane in the memebrane materials, arranging of a supporting sling, mounting of the membrane structure and the like. The construction scheme of the floating air-rib composite water-pillow pneumatic membrane structure aims to improve the fireproof performance of the floating air-rib composite water-pillow pneumatic membrane structure while the characteristics of low costof the membrane structure and the simple construction process are prominent, and therefore, the construction scheme mainly embodies reasonable mounting of the water pillow and perfect fusion of the water pillow and the membrane structure; and no waste residue, waste gas, waste water and noise are generated in the construction process, pollution and destruction to the surrounding environment are eliminated, the attractive form of buildings, structures and public facilities can be shaped to form landscapes and scenic spots , and beautifying of the urban environment is facilitated.

Owner:深圳市三鑫膜结构有限公司

Multi-layer structure composite board manufactured by squeezing glue-free straw boards at high temperature

InactiveCN104989032ASolve the problem of not being suitable for interconnecting socketsSolve technical problemsBuilding componentsJoistEngineering

The invention discloses a multi-layer structure composite board manufactured by squeezing glue-free straw boards at a high temperature. The two large faces of a composite core board are each provided with a layer of composite outer layer wood board in a composite mode. The composite core board comprises a center skeleton board on the center layer. The two large faces of the center skeleton board are each provided with one layer of glue-free straw board in a composite mode. The outer large face of each glue-free straw board is provided with a fireproof board in a composite mode. A five-layer board formed by the glue-free straw boards, the fireproof boards and the center skeleton board has two opposite flush side faces. The two flush side faces are each provided with a layer of peripheral skeleton board in a composite mode. The two opposite side faces of the two composite outer layer wood boards are flush with the outer edges of the side faces of the peripheral skeleton boards on the same sides as the two composite outer layer wood boards. The composite board has the advantages of being free of glue and air pollution, low in density and light, has the enough connecting performance and strength, is good in flexibility and enables a wall to achieve self bearing, no joist is needed, deformation is avoided, the multi-layer structure composite board has the advantages of water resistance, impact resistance, radiation resistance and the like, and the service life of the board is as long as that of a building.

Owner:烟台金田科技有限公司

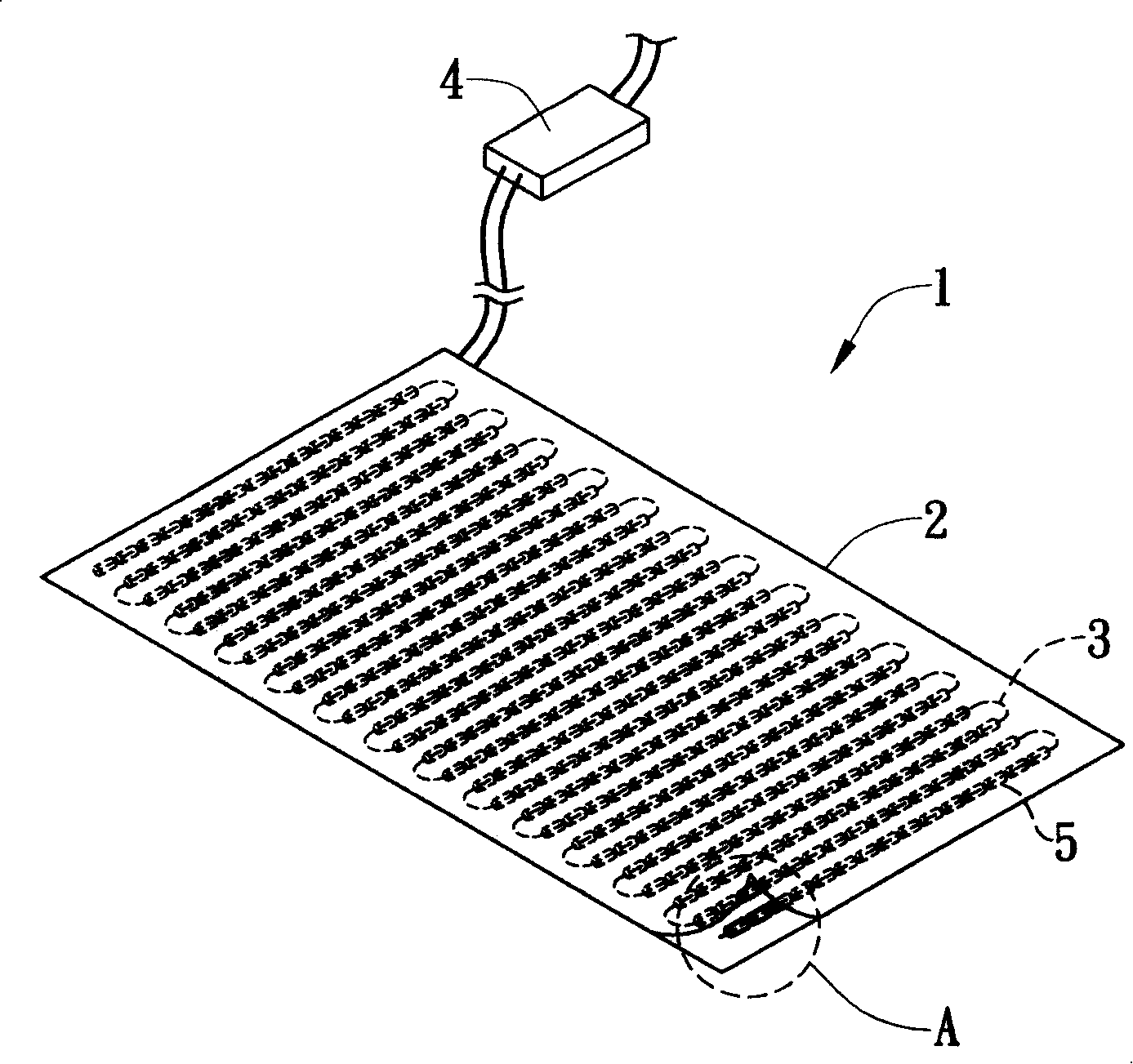

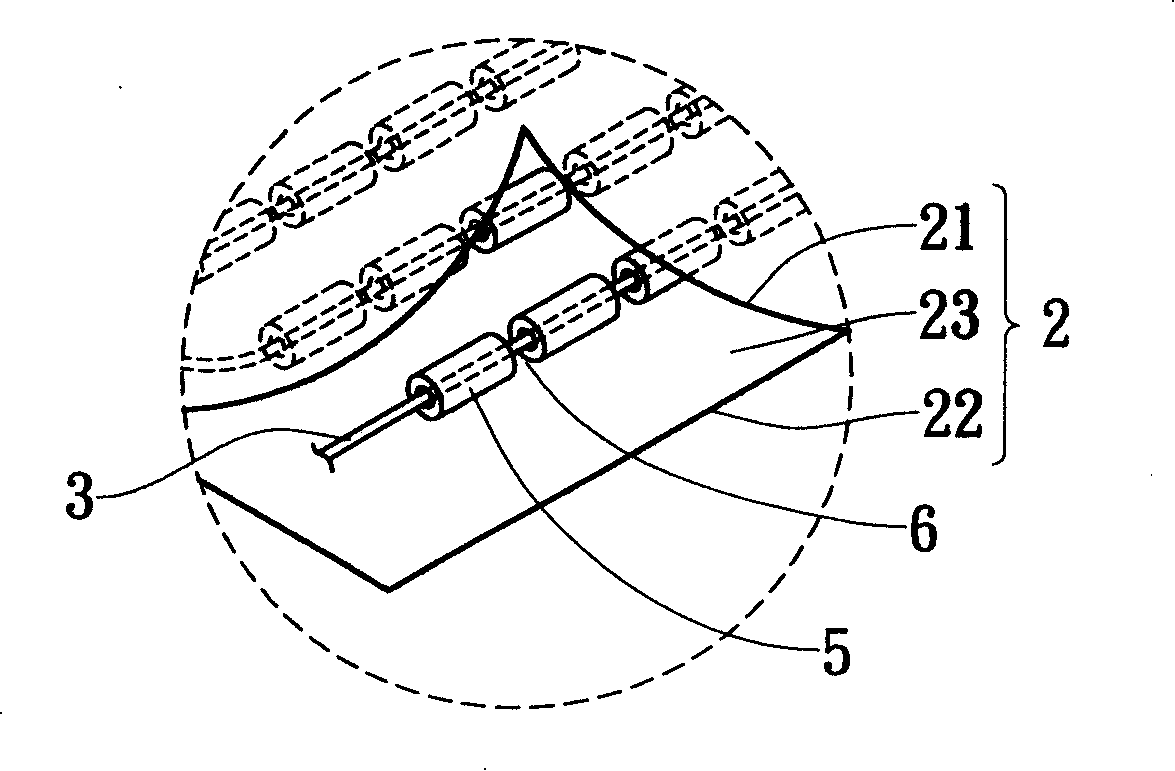

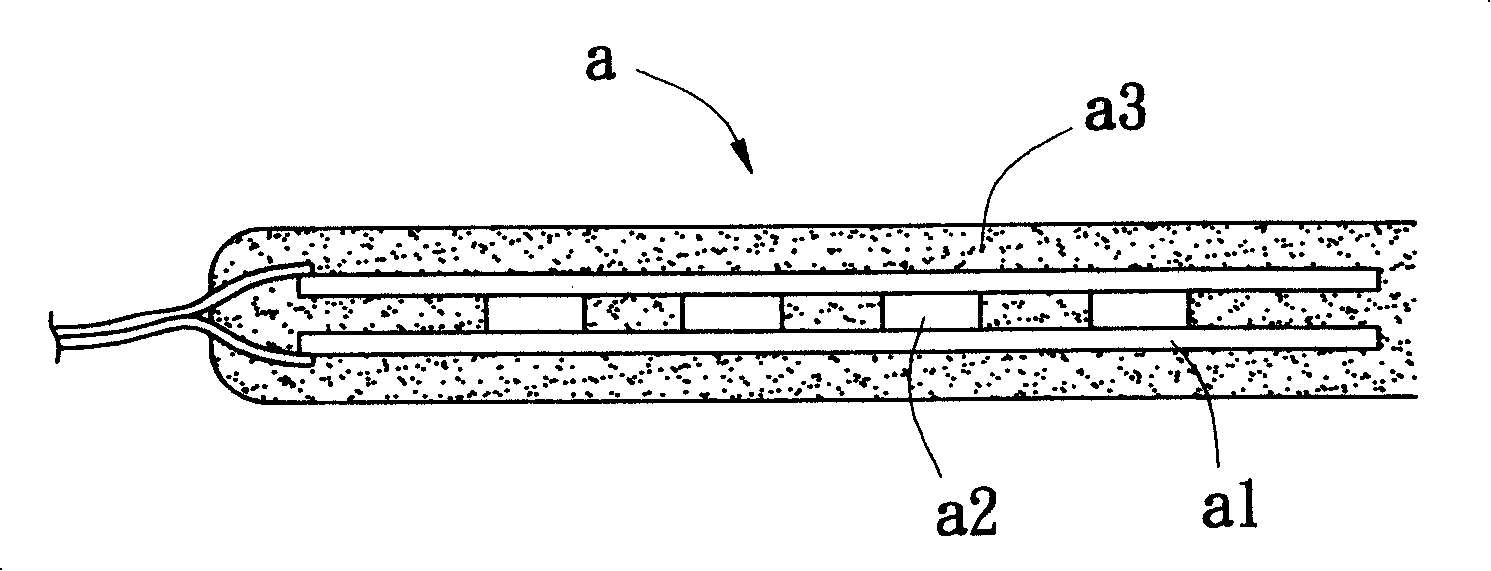

Hot compress pad

ActiveCN101161218ASave electricity energyAchieve health effectsHeating element shapesTherapeutic coolingEngineeringFar infrared

A fomenting pad is in a bag arranged with a heating wire, and with a plurality of thermal insulating components coupling on the heat wire. While electrifying, a controller controls the heating temperature of the heating wire, so as to supplying human body to foment, during fomenting course, the thermal insulating components absorb the partial heat generated by the heat wire, so as to continuously radiating heat by the thermal insulating components and prolong the fomenting time after electric broken and the heating wire stops heating. When carrying out, the thermal insulating components can radiate far infrared ceramic pipe, so during fomenting course, radiate far infrared at the same time, to achieve human body health effect.

Owner:共青城航群电子有限公司

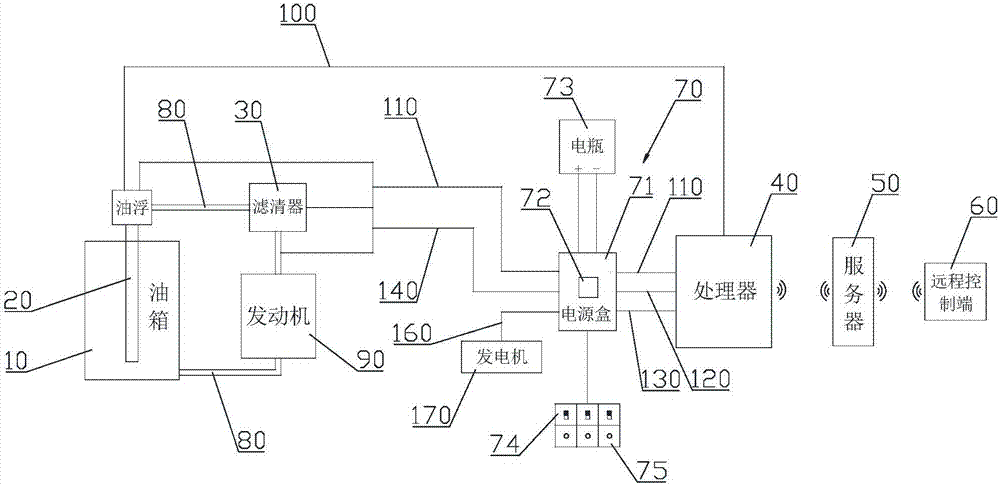

Remote control fuel oil preheating system of diesel vehicle

InactiveCN106894923ARealize constant temperature heating throughout the processReach warm upMachines/enginesThermal treatment of fuelTemperature controlRemote control

The invention discloses a remote control fuel oil preheating system of a diesel vehicle. The remote control fuel oil preheating system of the diesel vehicle comprises an oil tank, a temperature-control digital oil floater, a constant-temperature filter, a processor, a server, a remote control terminal and a power source device. The two ends of the constant-temperature filter are connected with the temperature-control digital oil floater and an engine correspondingly through constant-temperature fuel pipes. The temperature-control digital oil floater is connected with the processor through an oil amount detecting signal line. The processor is connected with the server through wireless signals. The server is connected with the remote control terminal through wireless signals. The temperature-control digital oil floater, the constant-temperature filter and the constant-temperature fuel oil pipes are all connected with the power source device. According to the remote control fuel oil preheating system of the diesel vehicle, through the temperature-control digital oil floater, the constant-temperature filter and the constant-temperature fuel oil pipes, whole-course constant-temperature heating of the whole fuel oil supply loop from the oil tank to the engine is achieved, the purposes of preheating the fuel oil and keeping the temperature are achieved, and the fuel oil is always kept in an appropriate work temperature range; and besides, remote control can be achieved through the remote control terminal, the fuel oil temperature can be conveniently and remotely monitored, and the remote control fuel oil preheating system of the diesel vehicle is safe and high in efficiency.

Owner:青岛迅驰北斗电子有限公司

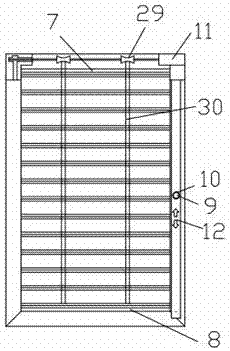

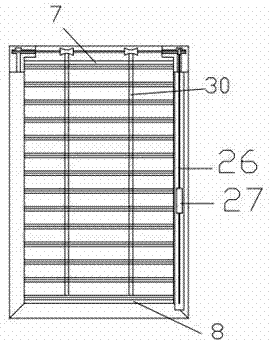

High-performance energy-saving aluminum-wood composite window curtain wall with internal sunshade blinds

InactiveCN107246230AReduce energy consumptionReach deliveryDoor/window protective devicesSealing arrangementsWindow openingToughened glass

The invention relates to a high-performance energy-saving aluminum-wood composite window curtain wall with internal sunshade blinds. The composite window curtain wall comprises an aluminum alloy window frame, a wood sash frame is arranged on the inner side of a wooden frame which is arranged on the inner side of the aluminum alloy window frame, hollow tempered glass is arranged in a glass pinch plate which is arranged at the inner periphery of the aluminum alloy window frame, the hollow tempered glass consists of inner hollow tempered glass and external hollow tempered glass, and the blinds are arranged in a cavity between the inner hollow tempered glass and the external hollow tempered glass. The composite window curtain wall has advantages of convenience in window opening-closing adjustment, arbitrary angle adjustability of the blinds, sound insulation, heat insulation, frosting resistance, damp resistance, high strength in wind resistance and the like.

Owner:浙江英瑞幕墙装饰有限公司

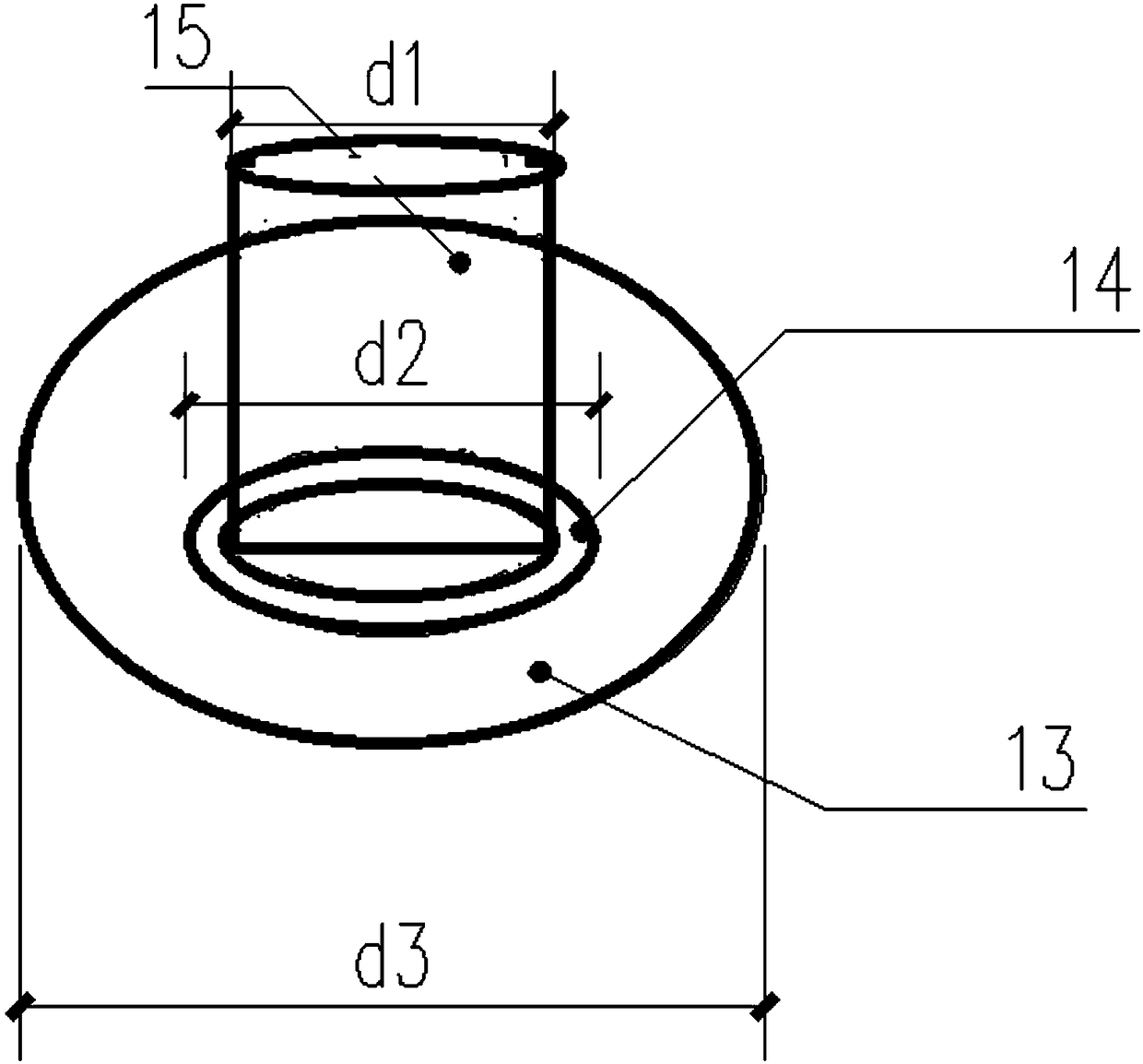

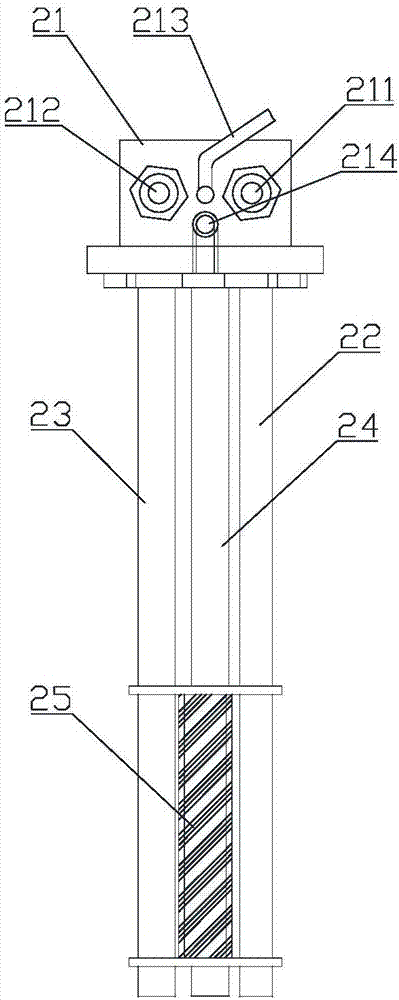

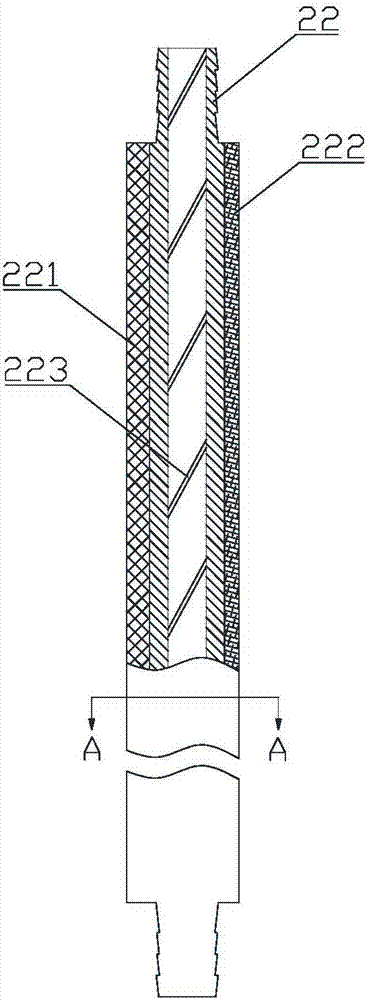

Heat preservation sealing module blocking body

InactiveCN107905759AAchieve heat retentionTo achieve the double effect of isolationSealing/packingWater source heat pumpEngineering

The invention provides a heat preservation sealing module blocking body, particularly belongs to the field of underground water source heat pump system projects, in particular to corollary equipment for an underground heat pump dedicated well. The heat preservation sealing module blocking body comprises a module and an air bag, and is characterized in that the module is composed of end covers, a heat preservation layer and a module body; the heat preservation layer is internally arranged in the module body, the two ends of the module body are sealed by the end covers, and pipeline through holes are reserved in the end covers; the air bag is composed of an annular air bag body, an air pipe and an air mouth; and the annular air bag body is connected with the air mouth through the air pipe, the air mouth is a single-way air guiding device, and the annular air bag body is fixed to the outer side of the module body. The heat preservation sealing module blocking body can conduct sectional sealing separation on a water well or pipeline, and double effects of heat preservation and separation are achieved.

Owner:BINZHOU ARMOR FORCE SOLAR TECH

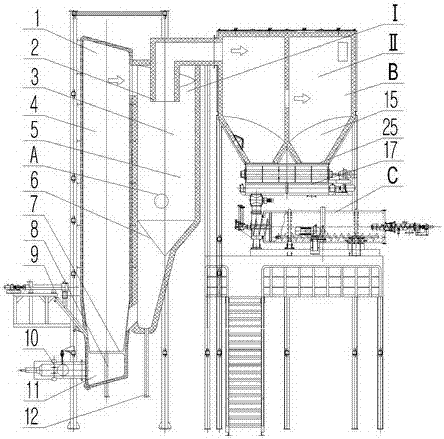

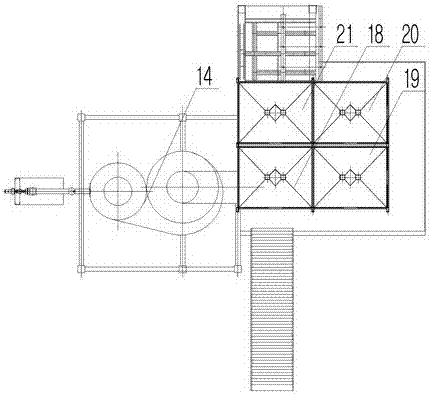

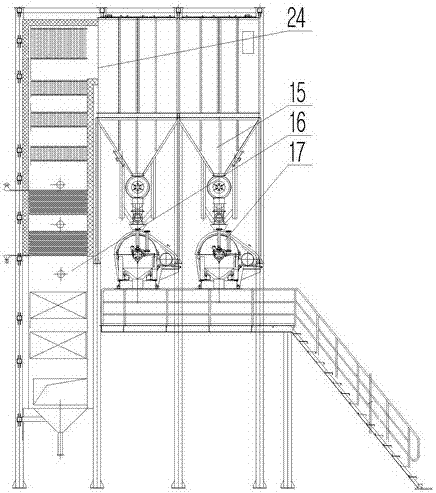

Using method of heat storage, boiling, burning, precipitation and purification device for VOCs waste gas absorbed solid waste

ActiveCN106989400AGuaranteed temperatureGuaranteed dwell timeEmission preventionCombustion technology mitigationTemperature controlSlag

The invention relates to the technical field of waste gas treatment of volatile organic compound, in particular to a using method of a heat storage, boiling, burning, precipitation and purification device for VOCs waste gas absorbed solid waste. The method is characterized in that the technical scheme of heat storage, burning and purification for twice, namely adhesion of molten salt patch based on primary heat storage, boiling, burning and cyclone separation effect and adhesion of molten salt patch based on secondary heat storage, burning and settlement separation effect, is adopted; aiming for the target of improving the burning efficiency and the purification efficiency of the VOCs waste gas absorbed solid waste, a furnace hearth, a heat storage material returning chamber and a heat storage burning settlement chamber are designed, the temperature is controlled to be 850-950 DEG C, the retention time is 5s, and the burn decrement rate of furnace slag is less than or equal to 5%.

Owner:菏泽恩泽建材股份有限公司

Control system for edible mushroom planting

PendingCN113273438APrevent spoilageAdjustable living environmentCultivating equipmentsMushroom cultivationAgricultural scienceControl system

The invention discloses a control system for edible mushroom planting, and relates to the technical field of edible mushroom planting. The control system for edible mushroom planting is characterized in that a movable door is arranged at one end of a box body, a shelf used for planting edible mushrooms is arranged in the box body and provided with a positioning assembly, an air conditioner outdoor unit is arranged on the outer wall of the box body, an air conditioner indoor unit connected with the air conditioner outdoor unit is arranged on the inner wall of the box body, a connecting pipe is arranged at an air outlet of the air conditioner indoor unit, a humidifier and a fan are further arranged at the upper end of the box body and both communicate with the connecting pipe, an electromagnetic valve is arranged between the fan and the connecting pipe, the connecting pipe is connected with a ventilation pipeline, the ventilation pipeline is provided with a plurality of air outlet pipes, and a ventilation opening is formed in the lower end of the box body; and the control system further comprises a control module as well as a temperature sensor, a humidity sensor and a carbon dioxide concentration sensor which are electrically connected with the control module. The living environment of the edible mushrooms can be conveniently controlled; and the freshness of the edible mushrooms in the conveying process is ensured.

Owner:晋城市艾威克科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com