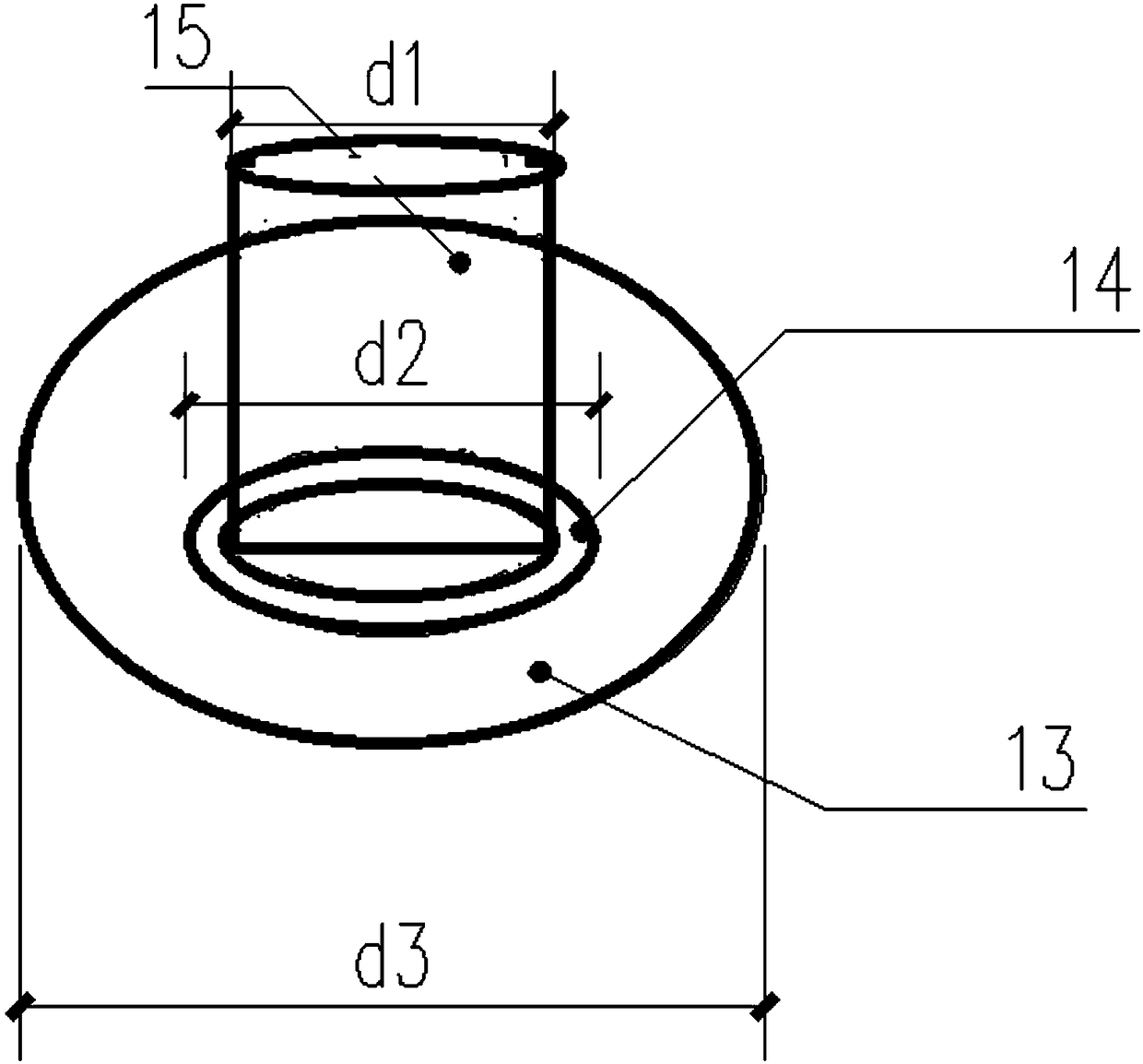

Construction scheme of floating air-rib composite water-pillow pneumatic membrane structure

A construction plan and technology of inflatable membranes, applied in special structures, building components, fire protection, etc., can solve the problems of complex construction and large impact on the performance of membrane structures, and achieve the effect of low price and preventing the overall structure from collapsing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Firstly, check whether the membrane materials including the air ribs and the air bearing membranes meet the national standards and standards, and carry out lofting, cutting and pre-assembly of the membrane materials; after the stress seams of the membrane materials are hot-melt connected, the boot pads are fixed, and finally the air ribs are fixed. The components are connected with the boot pad and thermally fused with the air-bearing film; next, an air-tight chamber is installed on a semicircular end face of the air-bearing film, and an air-tight door is installed on the side of the air-tight chamber. The joints and the joints between the air bearing membrane and the ground are reinforced; then water pillows are installed inside the air bearing membrane, and sling components are installed outside the air bearing membrane; after all the slings are connected, the air bearing membrane and the air rib structure are inflated And fill water into the water pillow; finally inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com