Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

190results about How to "Guaranteed dwell time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

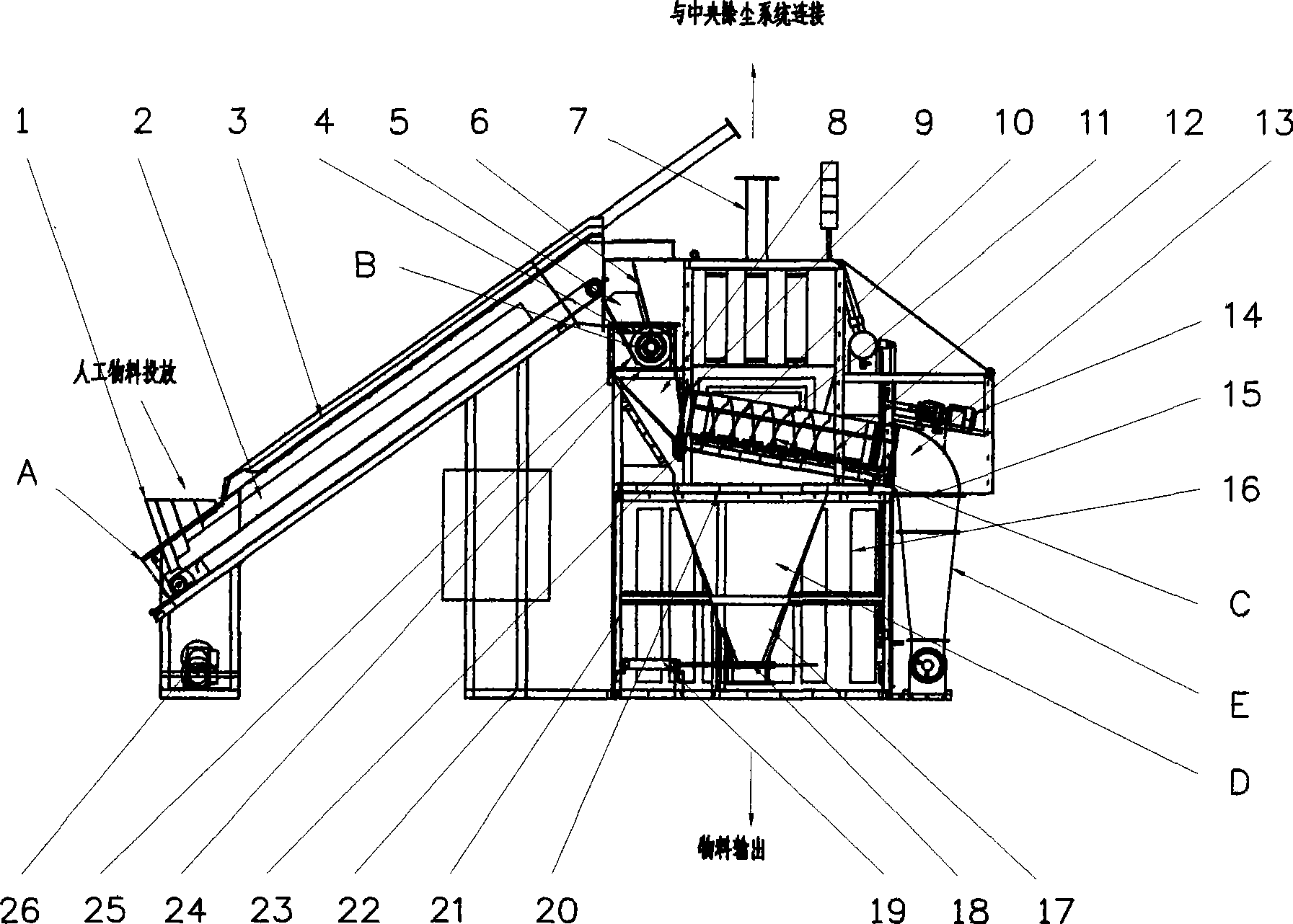

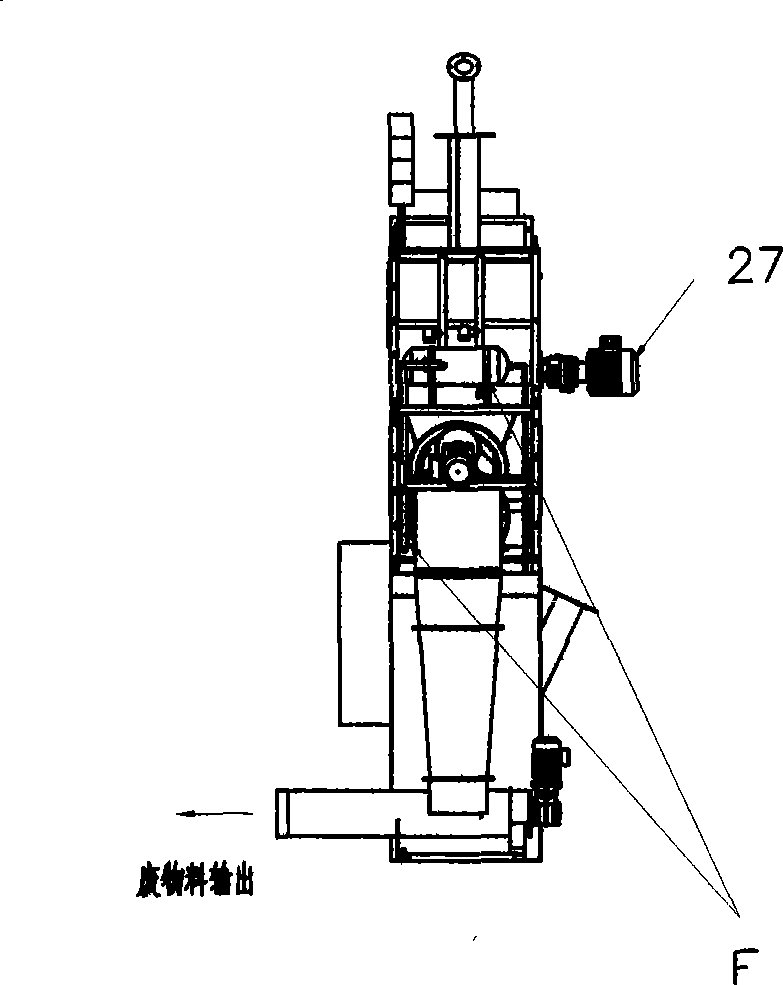

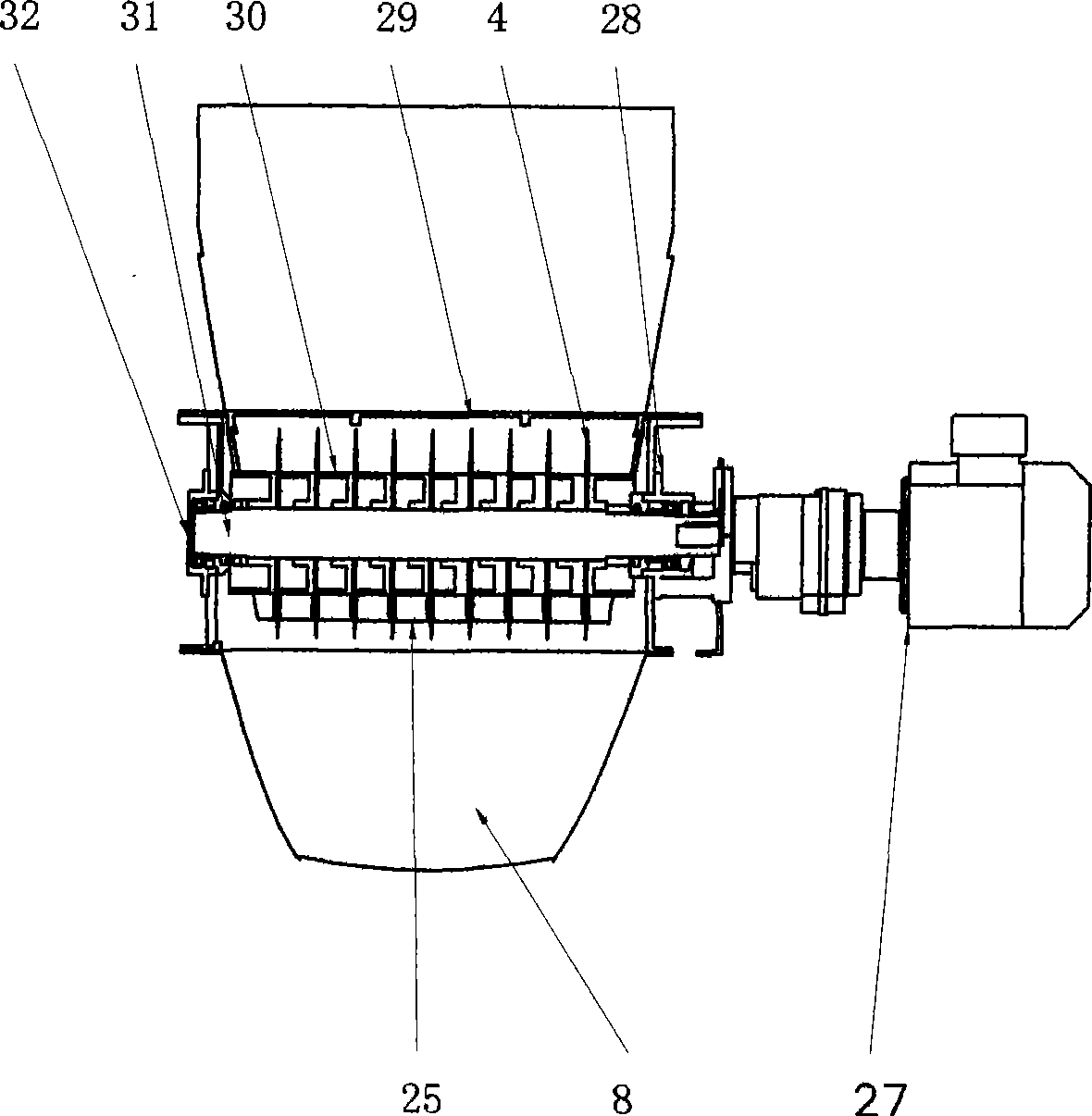

Full automatic unpacking unloader

The invention relates to a solid material unpacking machine, in particular to a full automatic unpacking and unloading machine, which is characterized in that: all stages of mechanisms are connected through flanges; a bag breaking mechanism, a screening mechanism and a material output mechanism are arranged on a main body frame; the outer surface of the main body frame is connected with a surface panel in a splicing mode; the surface panel on the top of the main body frame is provided with a main dust removal outlet; and a channel formed from the feeding inlet end of a feeding mechanism to the outlet end of the material output mechanism and the outlet end of a waste bag output mechanism is a one-way communication channel. The full automatic unpacking and unloading machine has the advantages that the machine has high work efficiency, energy conservation, environmental protection, small volume, light weight and the like, can safely and stably separate solid materials from packages in automatic high-speed running, and convey the materials to downstream equipment, while the waste packages enter a waste bag recovery device for recovery, and the machine can particularly meet the requirements of unloading, separating and collecting toxic and corrosive powder, and particle materials.

Owner:HANRUI PUZER BULK HANDLING TECH SHANGHAI

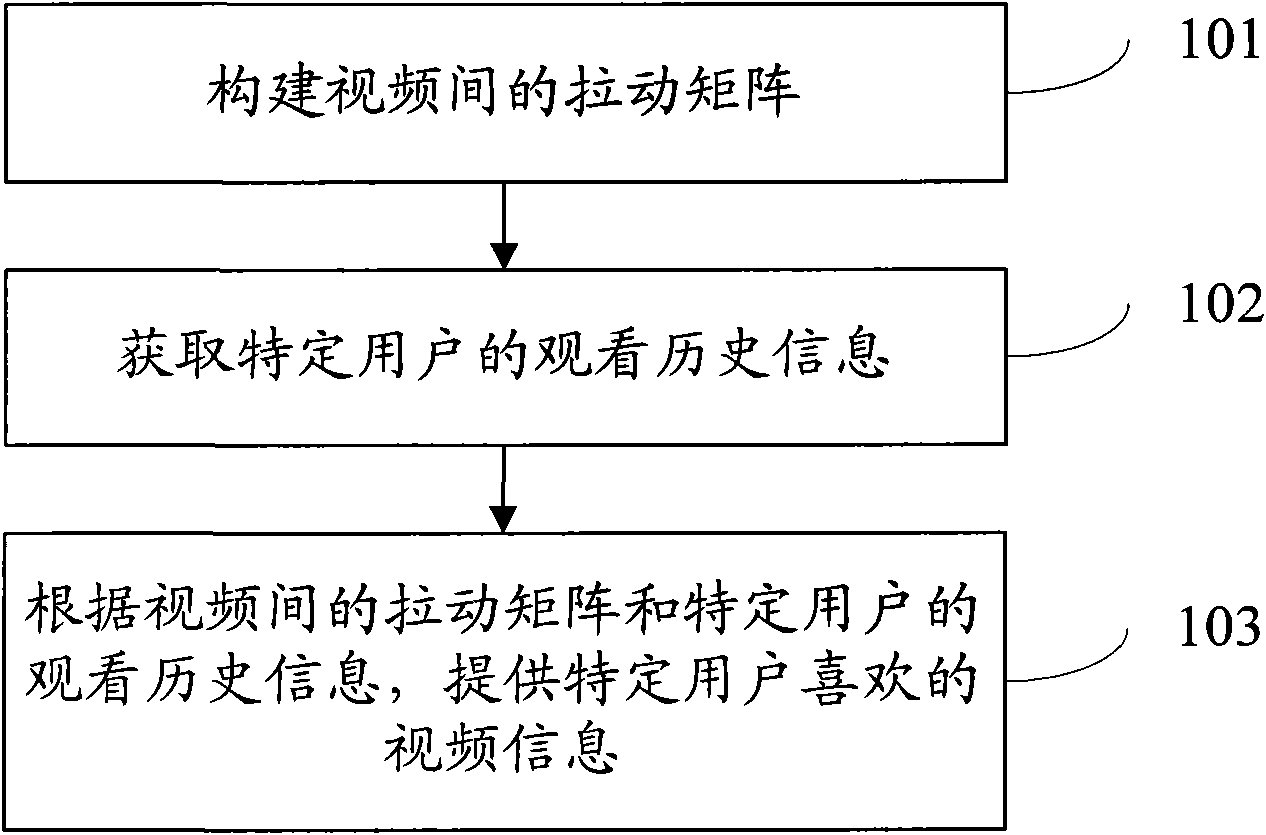

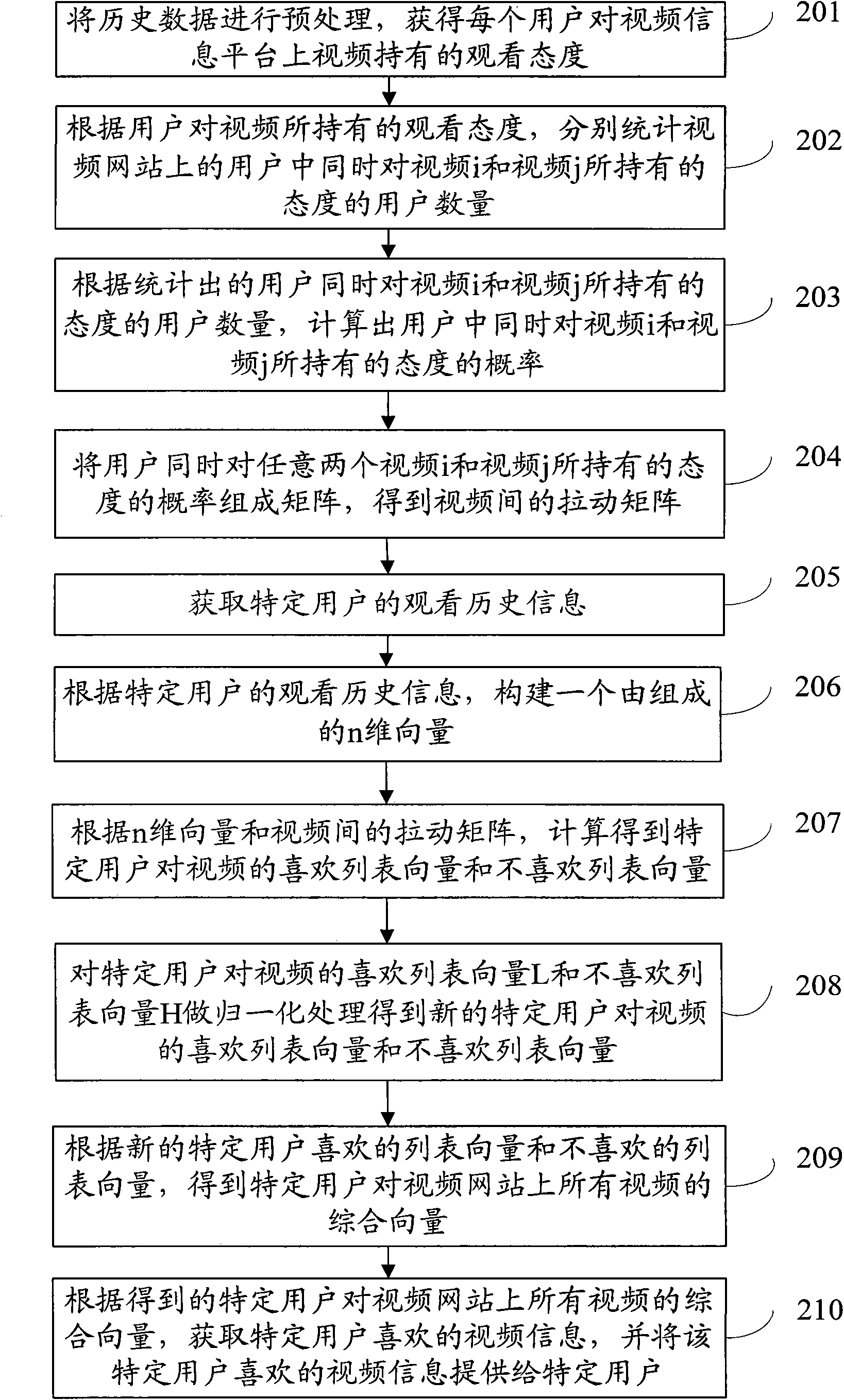

Method and device for acquiring video information

ActiveCN102486796AGuaranteed dwell timeSpecial data processing applicationsResidence timeLibrary science

The invention discloses a method and a device for acquiring video information, which belong to the field of the Internet. The method comprises the following steps: constructing pull matrixes among videos; acquiring the watching history information of a specific user; and offering video information enjoyed by the specific user according to the pull matrixes among the videos and the watching history information of the specific user. The device comprises a constructing module, an acquisition module and an offering module. According to the embodiment of the invention, the pull relations among all the videos are obtained through the watching history information of all users, and then, the habit and the preference of the specific user are analyzed according to the watching history information of the specific user by combining with the pull matrixes constructed among the videos, and the videos probably enjoyed by the specific user are recommended, thereby, the residence time of the user is ensured.

Owner:TENCENT TECH (SHENZHEN) CO LTD +1

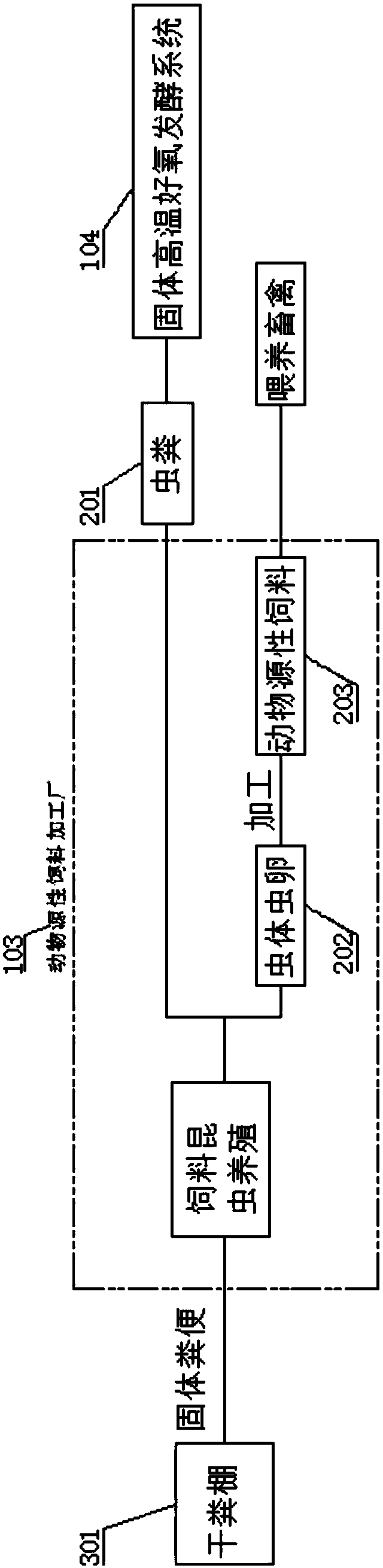

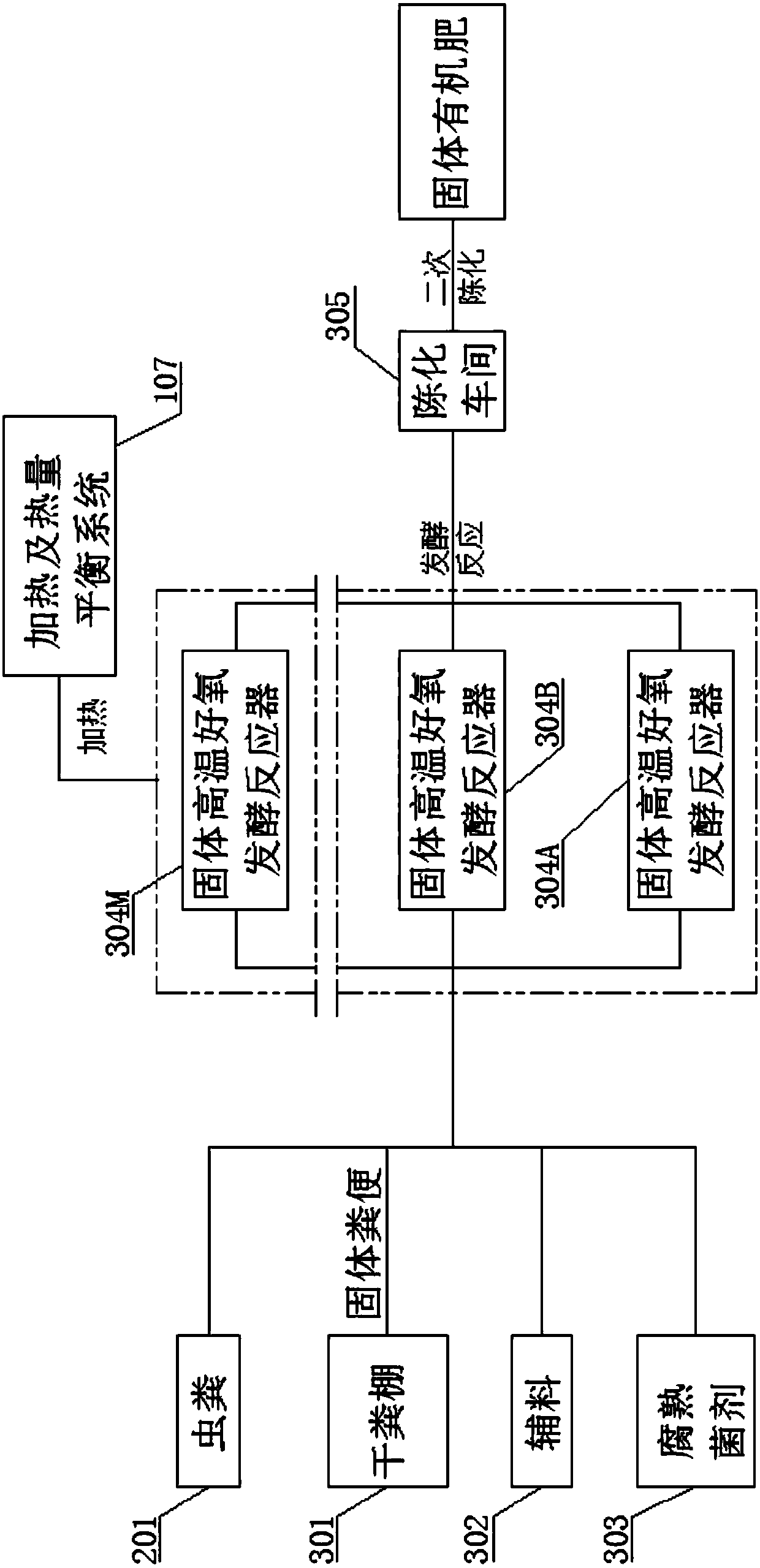

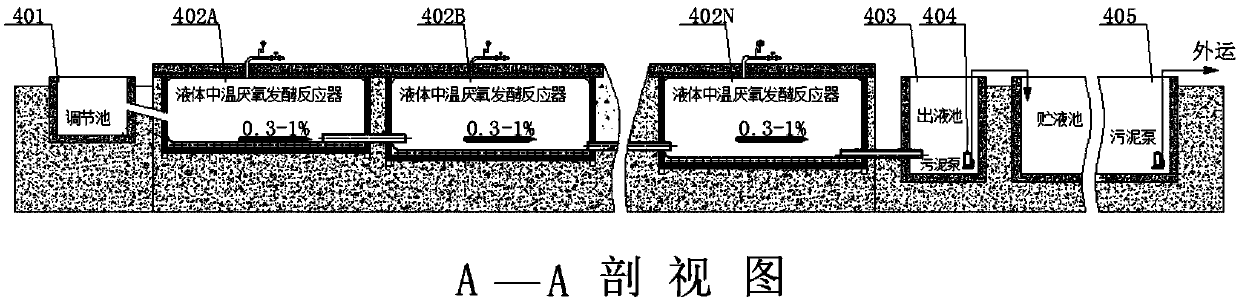

Ecological treatment system and method for pollution of livestock and poultry farm based on combination of planting and breeding

ActiveCN107759254AReduce distractionsHighly consistent qualityBio-organic fraction processingFabaceae cultivationPig farmsFeces

Owner:汪深

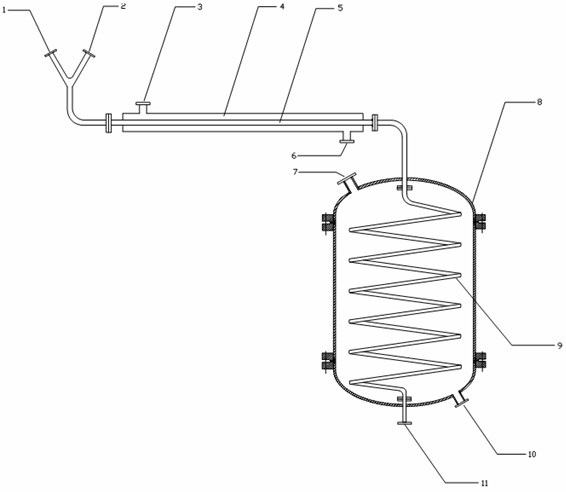

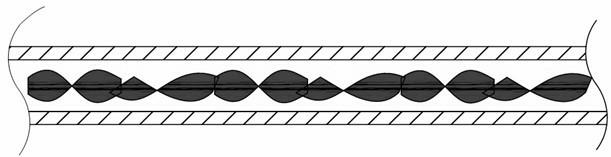

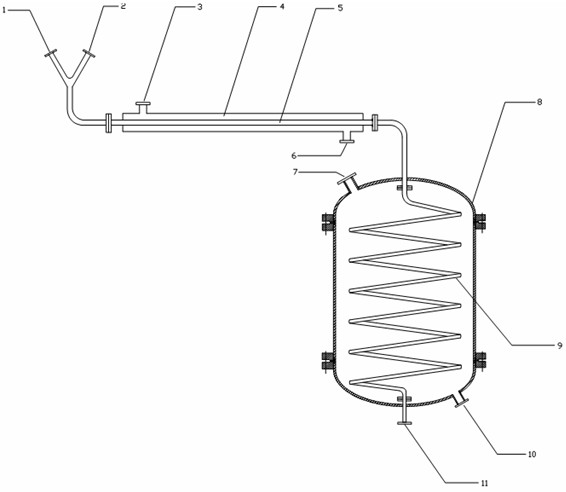

Pipe reactor with static mixing device

InactiveCN102553512AEasy to processImprove the mixing effectFlow mixersChemical/physical/physico-chemical stationary reactorsHeat carrierProcess engineering

The invention discloses a pipe reactor with a static mixing device. The pipe reactor with the static mixing device comprises a Y-shaped fluid feed port, a static mixing device, and a pipe reacting device, wherein the Y-shaped fluid feed port is provided with a fluid inlet A and a fluid inlet B, and the static mixing device comprises a jacket and an SK-type static mixer; a jacketed inlet and a jacket outlet are arranged on the jacket, and the pipe reacting device comprises a reacting device shell and a pipe reactor; a heat carrier inlet and a heat carrier outlet are arranged on the reacting device shell, and one end of the SK-type static mixer is connected with the Y-shaped fluid feed port; and the other end of the SK-type static mixer is connected with the pipe reactor. According to the pipe reactor with the static mixing device, two streams of fluids have a good mixing effect at a low flow and a flow rate, the mixing and the reaction process of the two streams of fluids are carried out at different temperatures, and part of raw material is avoided being pre-reacted, so that the mixing and the reaction process of the two streams of fluids are safer and more stable. The pipe reactor with the static mixing device is suitable for the mixing reaction process of the two streams of fluids at a low flow and a flow rate.

Owner:ZHEJIANG UNIV

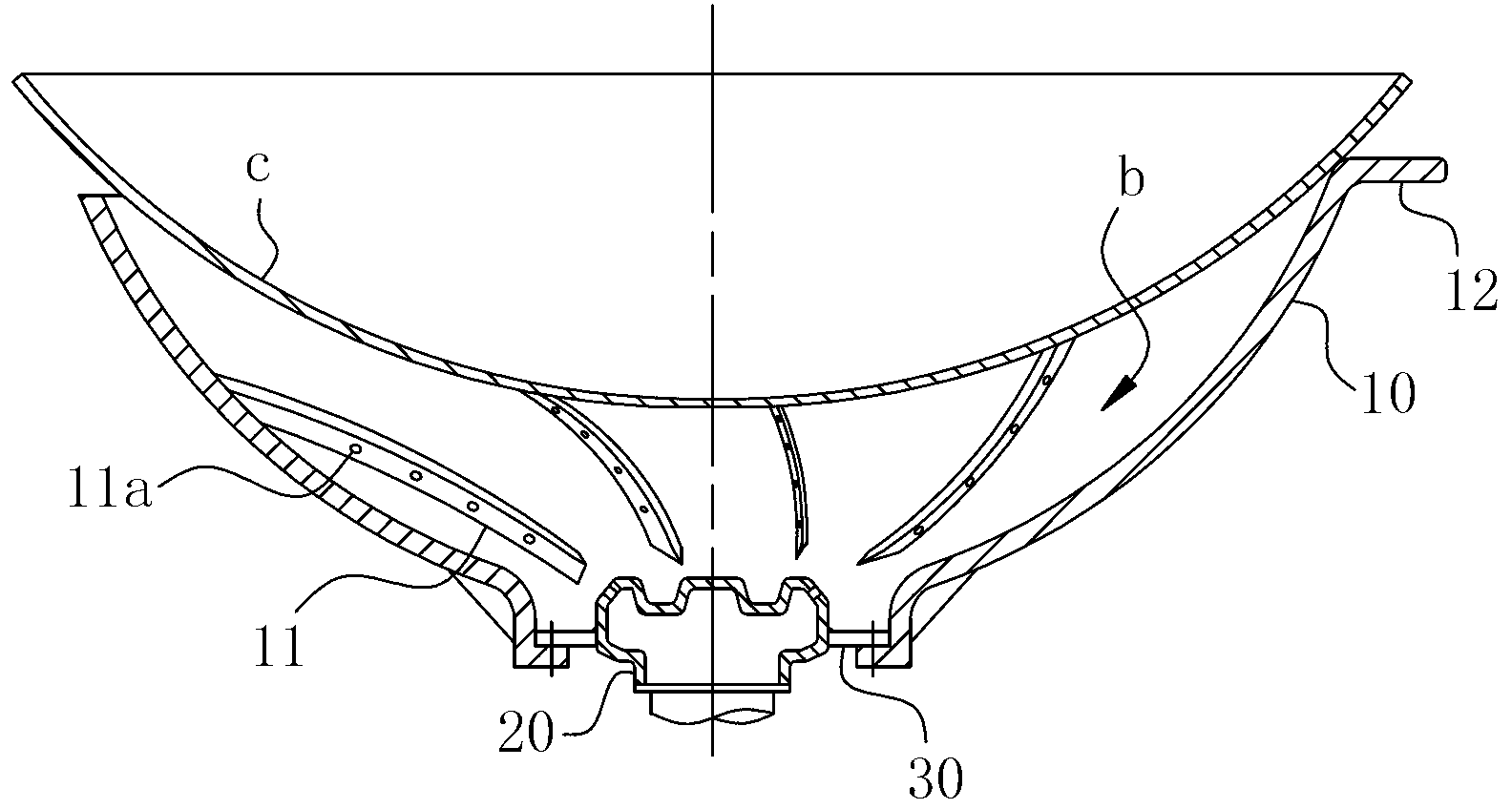

A vertical roller mill

InactiveCN102284322AImprove adaptabilityInorganic adjustment of grinding forceGrain treatmentsHydraulic cylinderSlag

The invention relates to a vertical roller mill, which comprises a vertical main rotating shaft arranged on a machine body, wherein a speed reducer and a motor are connected to the lower end of the main rotating shaft sequentially; a grinding bowl is arranged at the upper end of the main rotating shaft; the upper part of the inner side of the grinding bowl contacts a plurality of grinding rollers; the grinding rollers arranged on the grinding roller shaft by a bearing; the grinding roller shaft is connected to one end of a rocker arm; the middle part of the rocker arm is hinged to the machinebody; the other end of the rocker arm is hinged with the upper end of a hydraulic cylinder; the lower end of the hydraulic cylinder is arranged on the machine body; a central feed pipe which aligns with the grinding bowl downwards is arranged on the top of the machine body; and a discharge hole is formed below the grinding bowl on the machine body. The vertical roller mill has the advantages of convenience for oil injection, high yield, low energy consumption, large processing capacity, high efficiency and sealing performance, adjustable grinding force and the like, is easy to maintain and overhaul, and the technical problems of enrichment of steel slag and iron granules, high abrasion of the mill, difficulty of overhauling of equipment and the like are solved radically.

Owner:TIANJIN SUMEIR ENVIRONMENTAL PROTECTION INVESTMENT

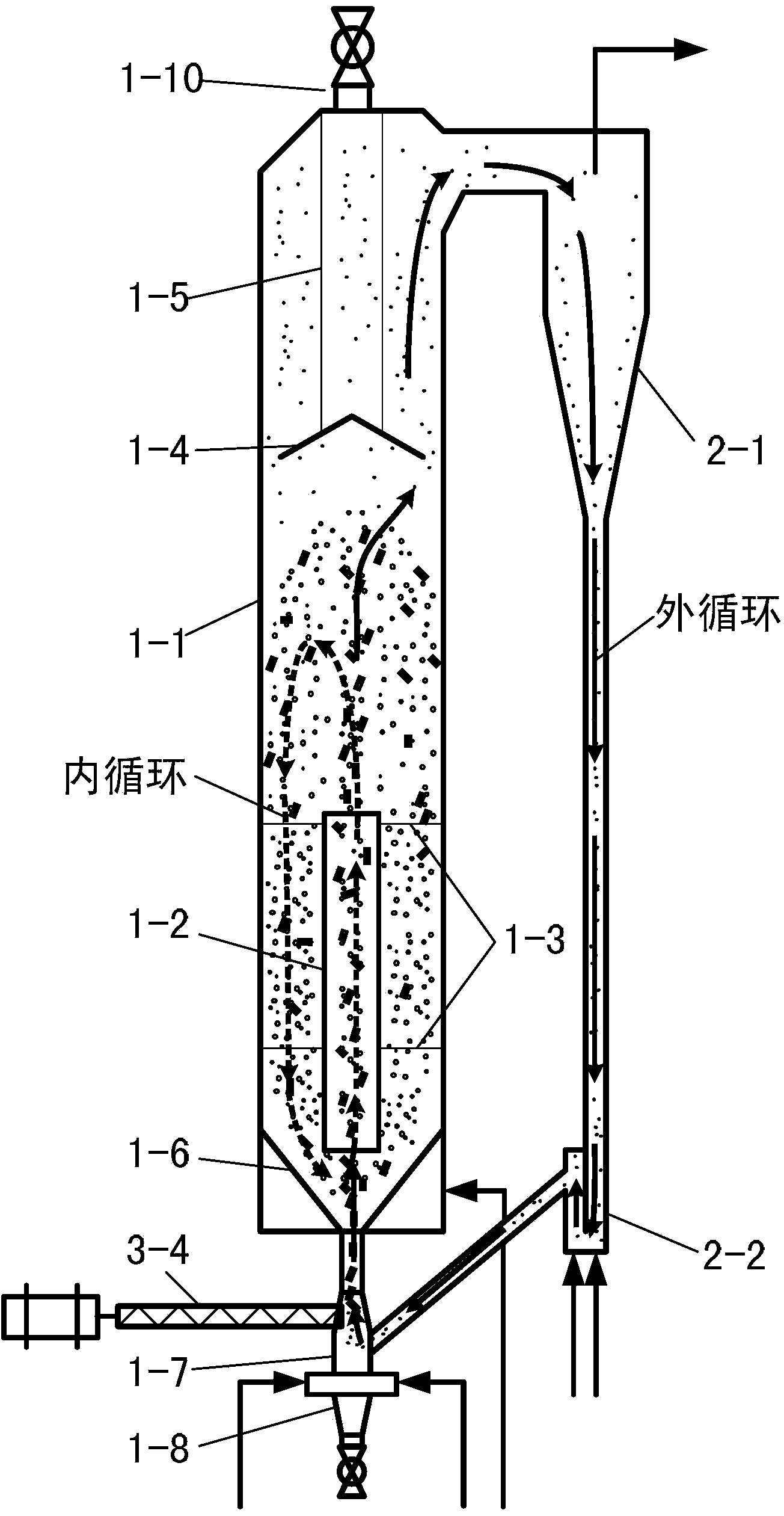

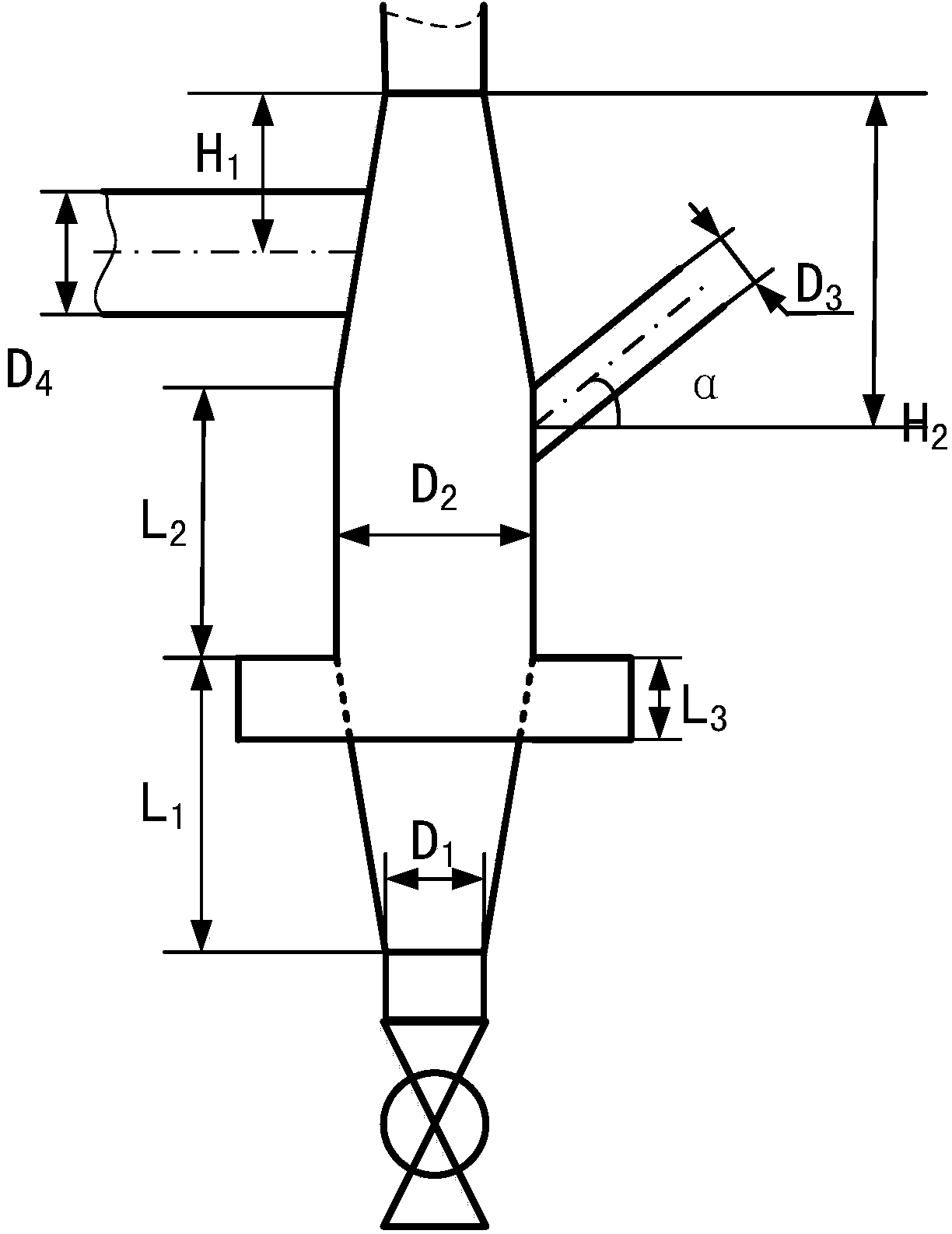

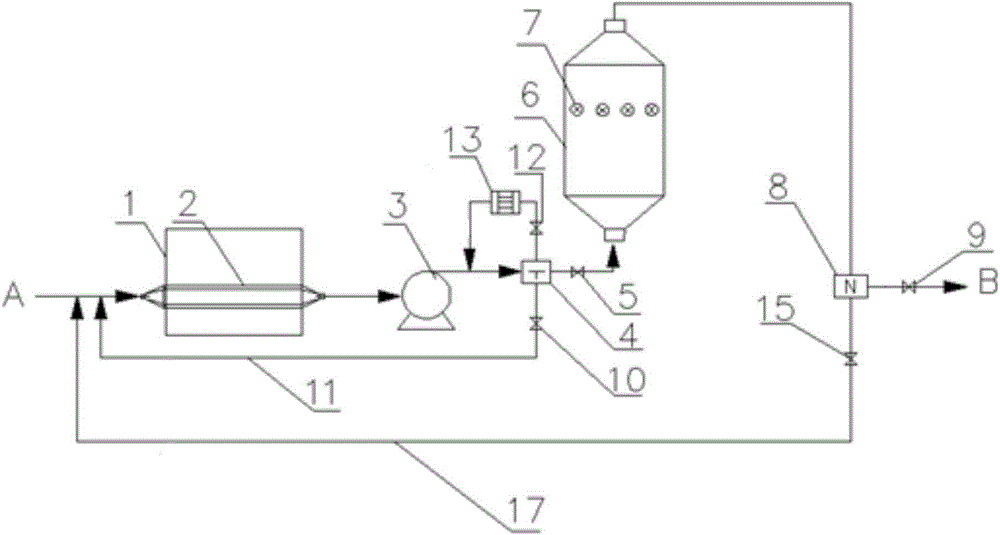

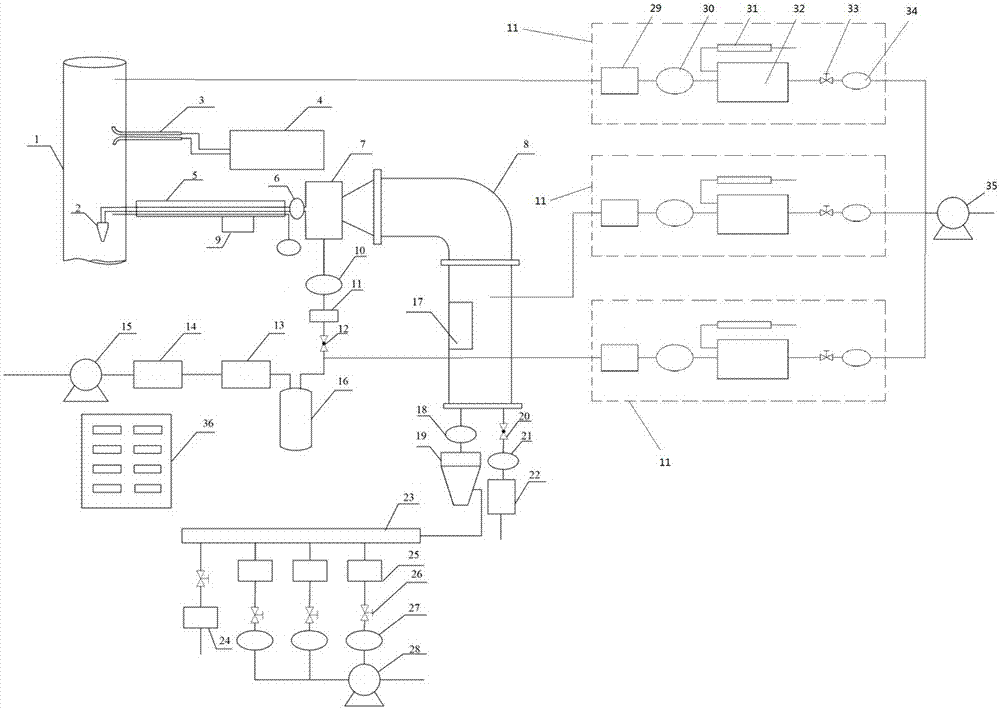

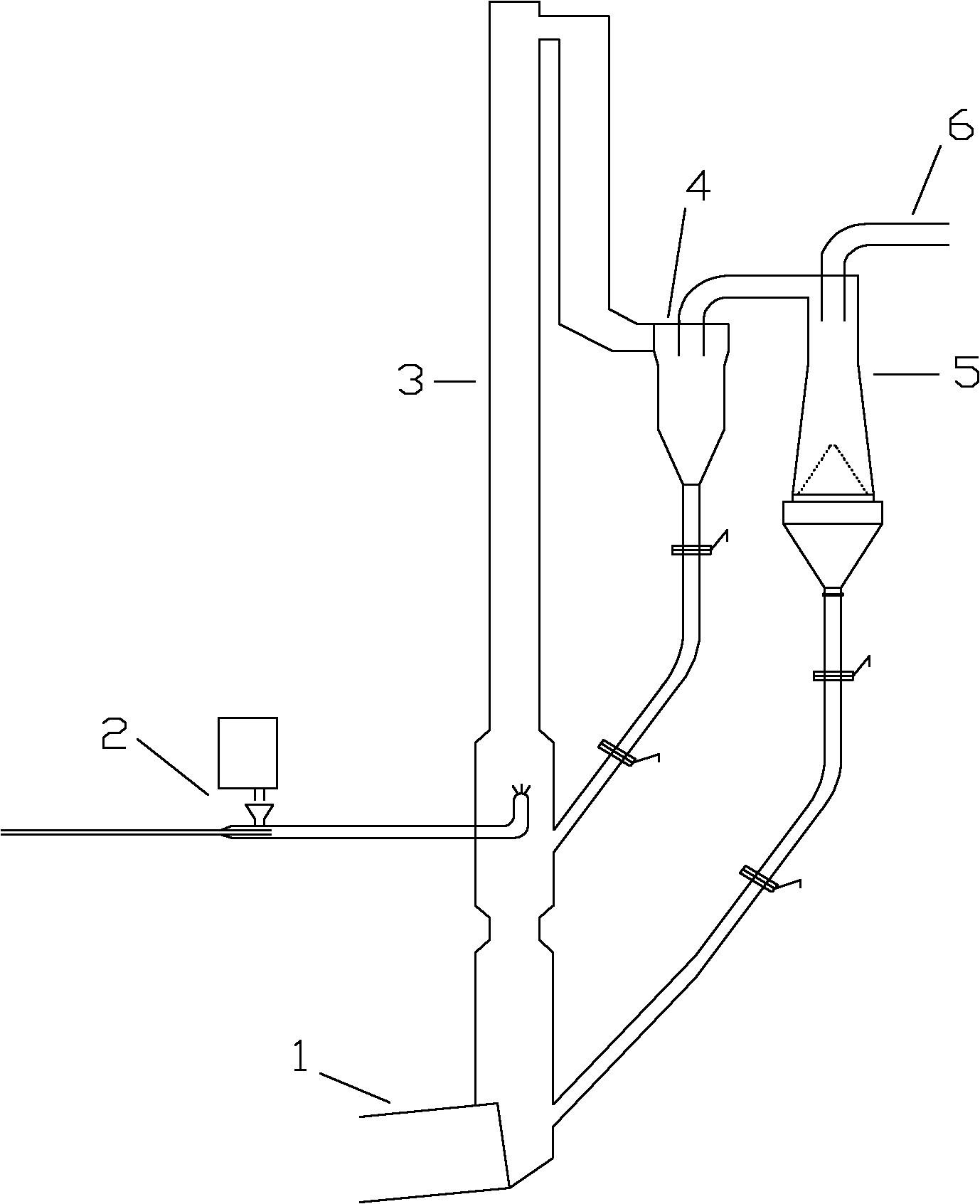

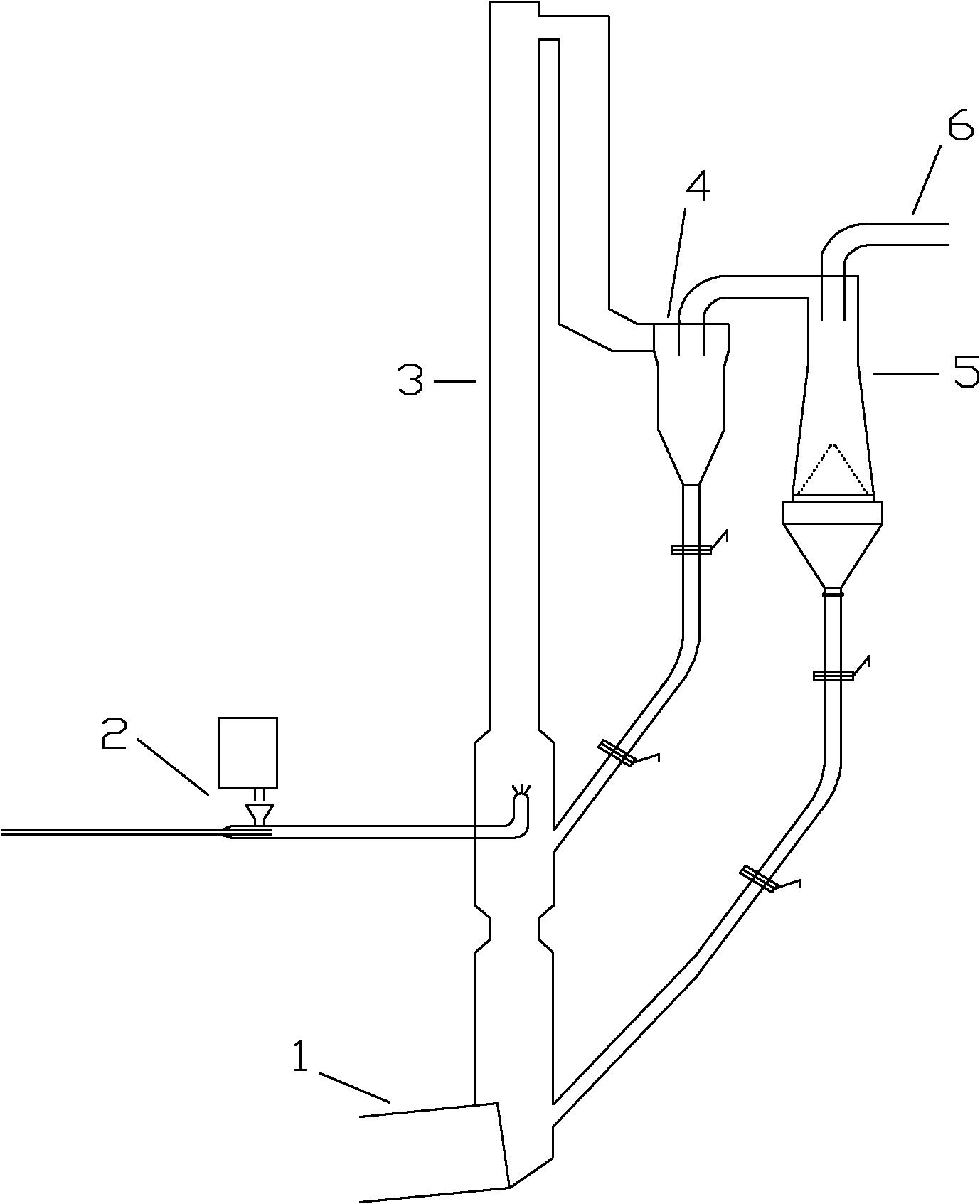

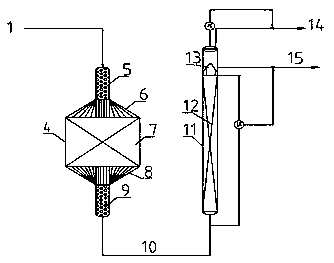

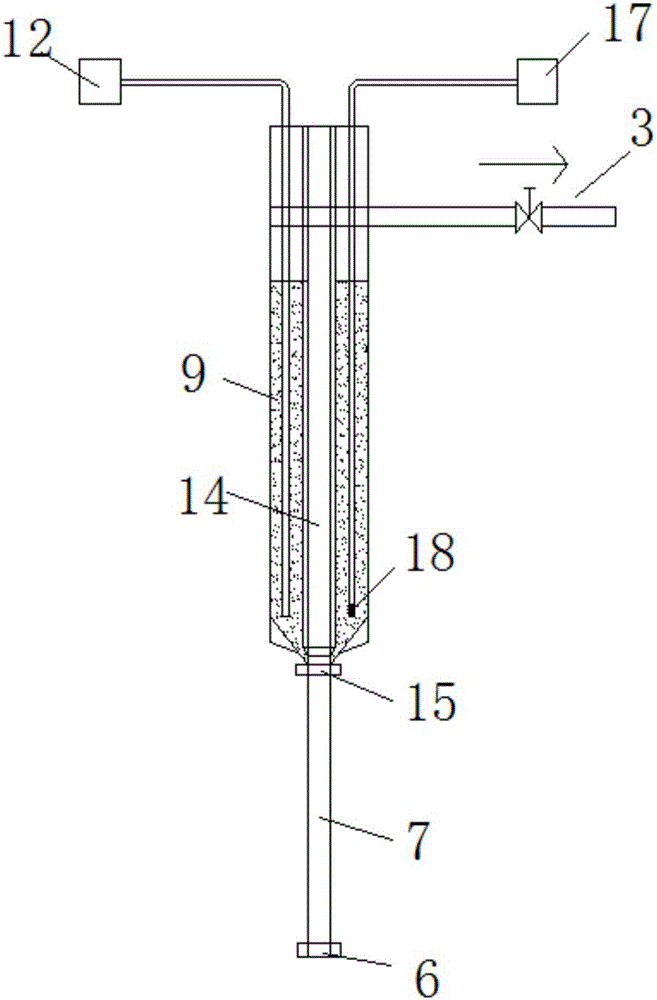

Biomass quick cracking device based on internal-external circulation spouted fluidized bed

ActiveCN103756712AShort stayGuaranteed dwell timeBiofuelsLiquid hydrocarbon mixture productionFluidized bedRetention time

The invention discloses a biomass quick cracking device based on an internal-external circulation spouted fluidized bed. The biomass particles are added through a bottom feeding chamber and conveyed into a pyrolysis reactor by spouted wind and generate a violet pyrolysis reaction through a guide pipe and a spouting area; the unreacted relatively large biomass particles form internal circulation along with a circulation medium through an annular space area; a catalyst and the unreacted tiny biomass particles are separated from the reaction area along with the pyrolysis gas and then return back into the bottom feeding chamber through a cyclone separator and a return feeder to form external circulation, and generate a pyrolysis reaction again. The device can perfectly meet the requirements of short gas phase retention time and sufficient solid phase reaction of the biomass pyrolysis technology, and the structure is simple and easy to enlarge; meanwhile, the external circulation of the catalyst particles and the early premixing and preheating thereof with the biomass particles in the bottom feeding chamber facilitate the direct efficient contact and sufficient mixing of the catalyst particles and the biomass particles, the utilization efficiency of the catalyst can be effectively improved, and the dosage of the catalyst is reduced.

Owner:SOUTHEAST UNIV

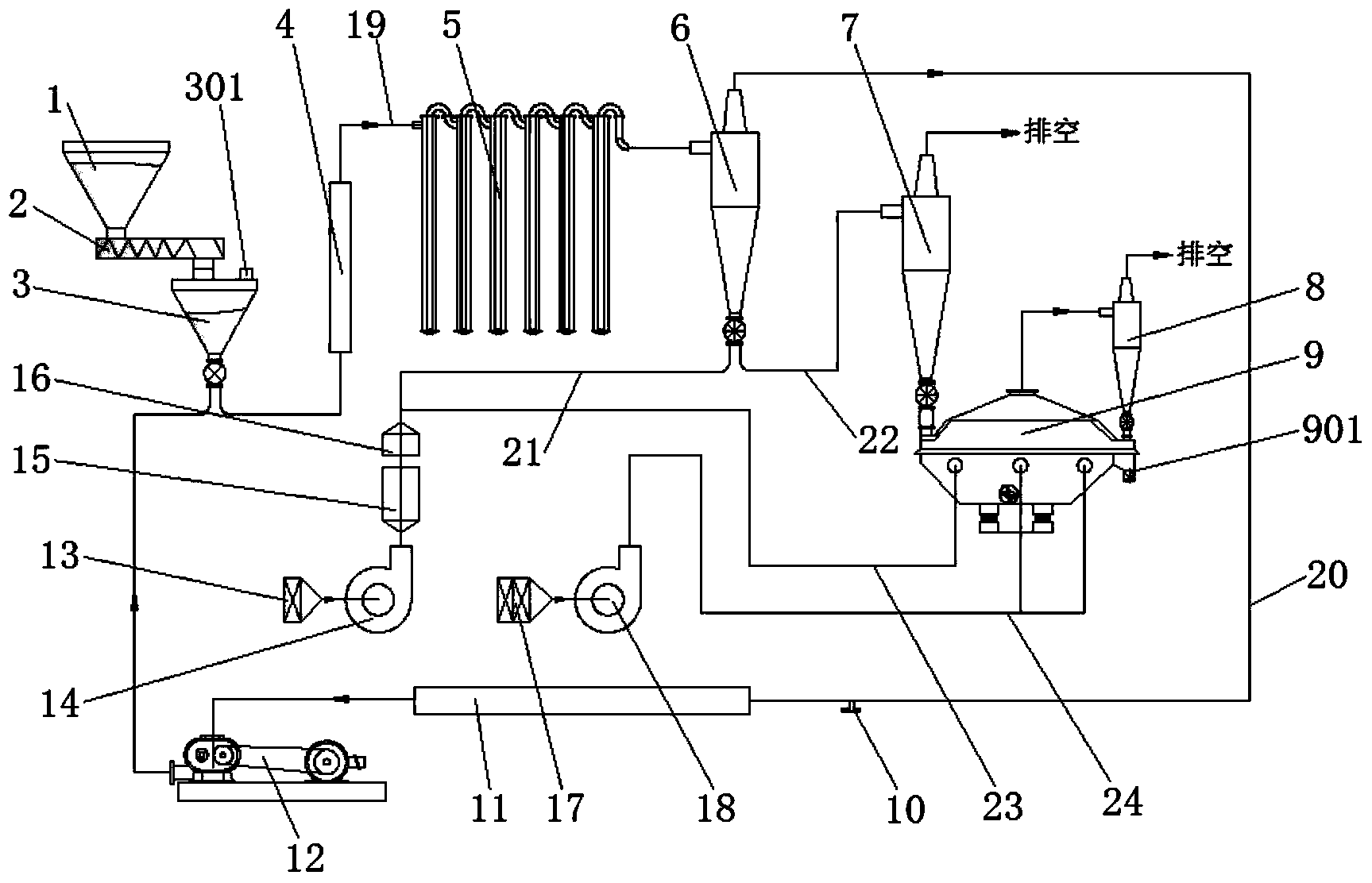

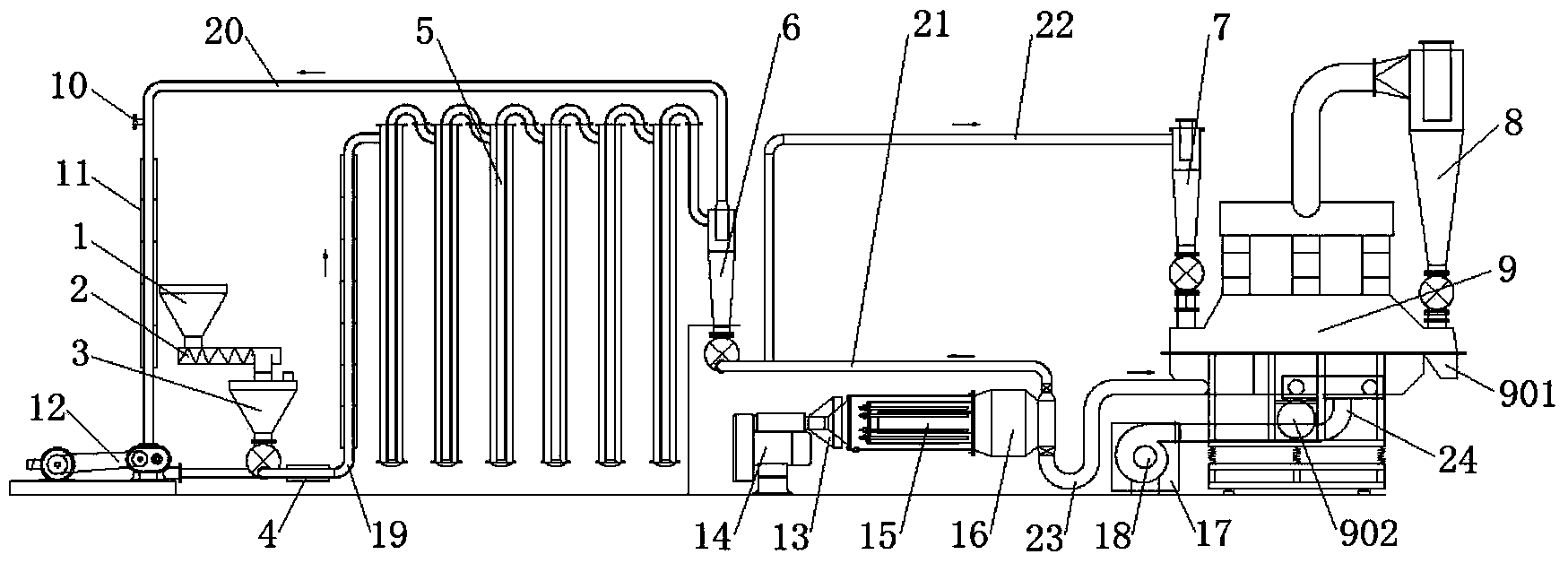

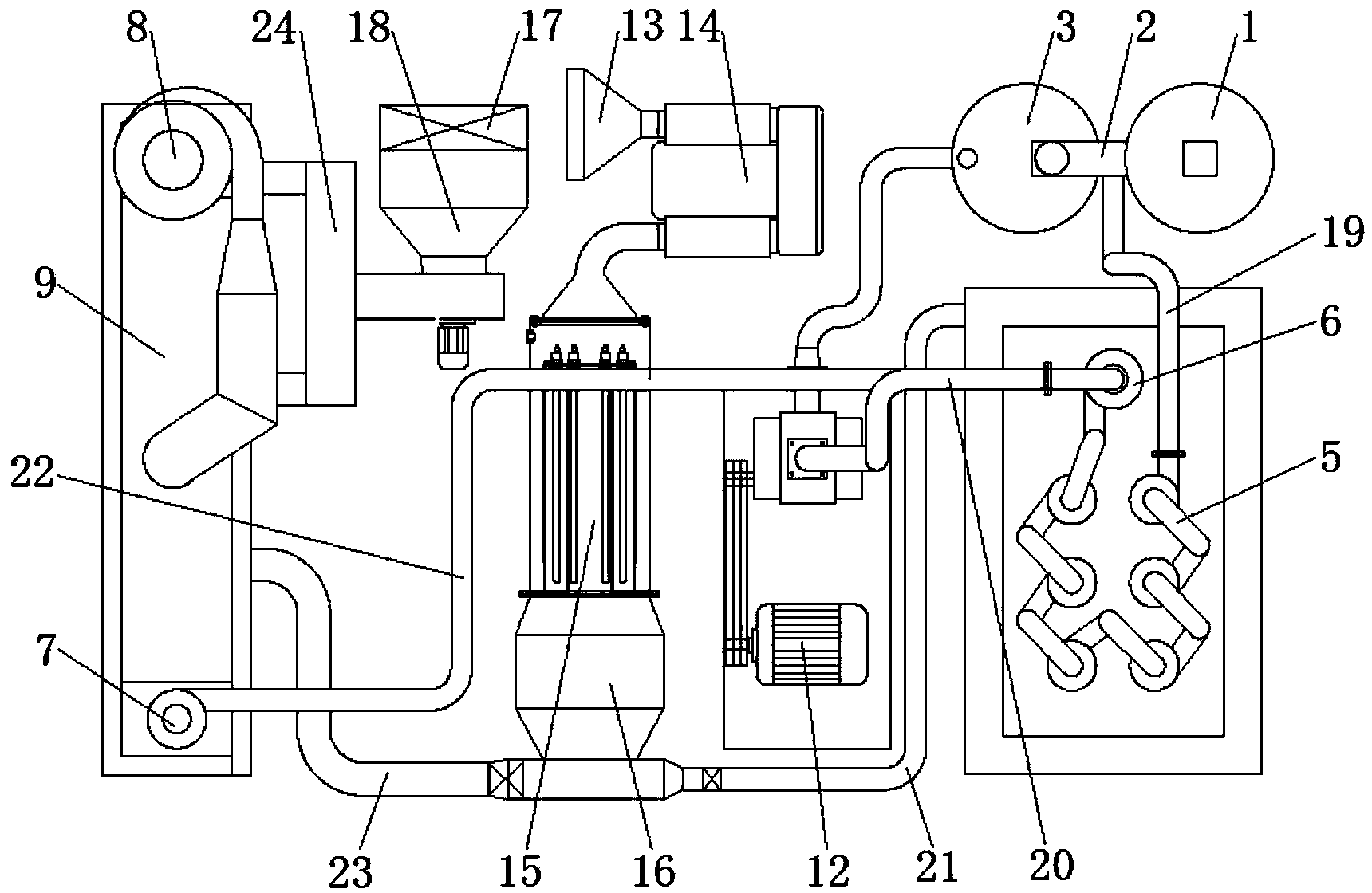

Technology and system of powder body superheated steam sterilization

The invention discloses a technology and a system of powder body superheated steam sterilization, and belongs to the field of material sterilization and drying. The technology comprises the following steps: (1) adding a powder body material steam into a superheated steam stream; (2) controlling the superheated steam stream to form a cyclone stream, so that the material is dispersed in the cyclone stream, and utilizing the steam heat for sterilization for 3-10 seconds, and controlling the sterilization temperature within the range of 120-250 DEG C; (3) causing the steam stream to form cyclone stream, and utilizing the centrifugal force to separate the material and the steam stream; (4) utilizing the dried hot wind to dry the material, and utilizing dried cold air to cool the dried material; (5) performing steam and temperature compensation on the steam stream in the step (3), and participating in the superheated steam stream feeding technology in the step (1). The invention further discloses a system of powder body superheated steam sterilization. According to the invention, the technology is convenient in operation and simple in device structure, realizes automatic and continuous sterilization production, is low in consumption for sterilization, and is greatly increased in production efficiency.

Owner:FANQUN DRYING EQUIP FACTORY WUJIN CITY

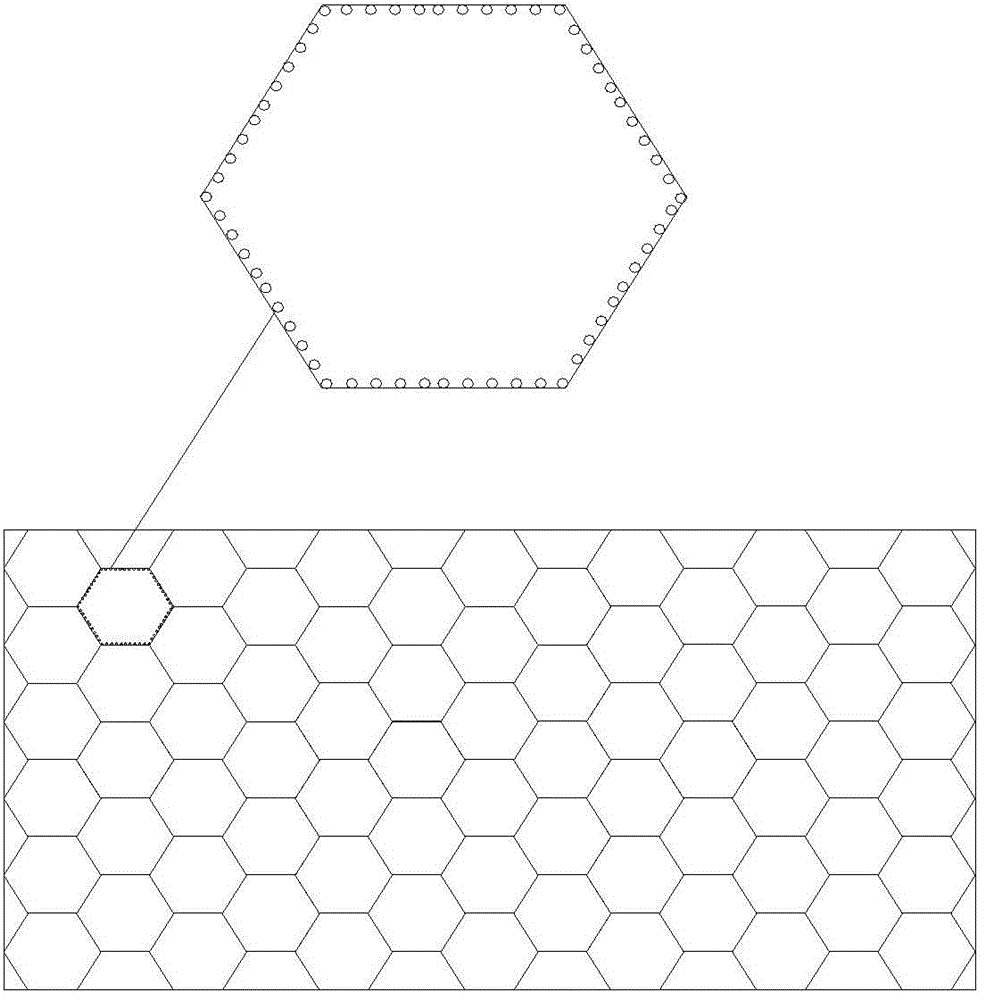

Honeycomb active carbon supported catalyst plate

InactiveCN104785234AAchieve degradabilityAchieve functionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsUltraviolet lightsCatalytic oxidation

The present invention relates to a honeycomb active carbon supported catalyst plate, wherein honeycomb active carbon is adopted to support a catalyst, the catalyst support material selects aluminum honeycomb, 2-5 layers of the active carbon with characteristics of porous surface and large specific surface area are sprayed on the aluminum honeycomb surface so as to increase the contact area of the ultraviolet light, the reaction gas and the catalyst, then 2-5 layers of the catalyst are sprayed, and the catalyst loading amount is 1-40%. The catalyst has effects of effective photo-induced electron and hole compounding inhibition, photo-induced electron and hole service life prolonging, and catalytic oxidation efficiency improving, and further has advantages of simple manufacturing method, large specific surface area, good catalyst dispersion, run-off resistance, and the like.

Owner:SHANDONG ACAD OF ENVIRONMENTAL SCI

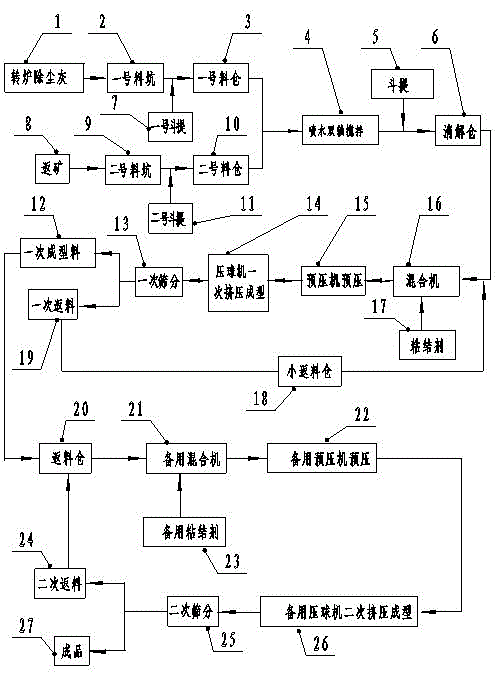

Manufacturing method of converter fly ash pressed balls

ActiveCN104593589AImprove ball pressing efficiencySimple production processProcess efficiency improvementAdhesiveDust control

The invention relates to a manufacturing method of converter fly ash pressed balls. The manufacturing method sequentially comprises the following steps: feeding converter fly ash to a #1 stock bin and feeding return mines to a #2 stock bin; feeding the converter fly ash and return mines to water spray double shafts to be stirred for pumping water and stirring, and then feeding the mixture to a digestion cabin to be digested through a shared bucket elevator; after digesting the converter fly ash and return mines in the digestion cabin for a time not shorter than half an hour, feeding the converter fly ash and return mines into a mixing machine and uniformly mixing with an adhesive; pre-pressing by using a prepresser, then primarily extruding and molding by virtue of a ball press machine, wherein after primary screening, overtails are primarily molded materials, which are fed into a return cabin; after the return cabin is filled, pressing finished products, adding a standby adhesive for the primarily modeled materials in a standby mixture, and pre-pressing by the standby prepressor, secondarily extruding and molding by using a standby ball press machine and secondarily screening to obtain overtails which are finished products; and after pressing the converter fly ash and return mines in the digestion cabin, re-filling the digestion cabin to start pressing. According to the manufacturing method provided by the invention, the ball pressing efficiency is not less than 12.5 ton / h.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

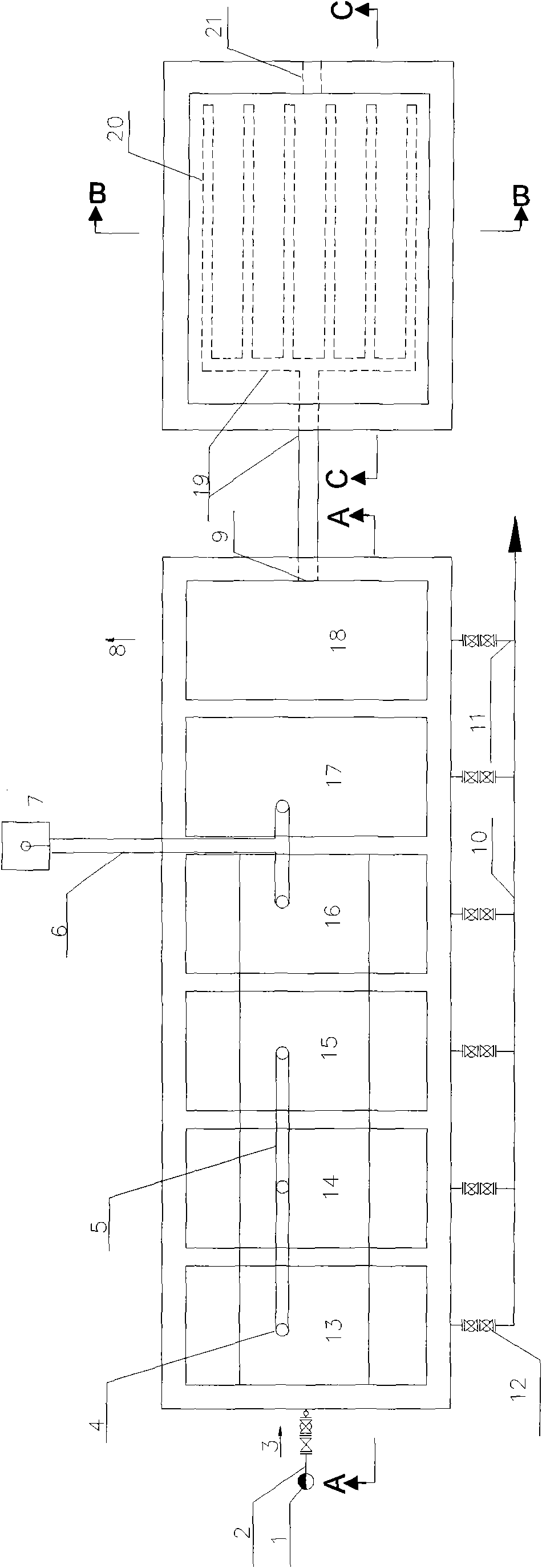

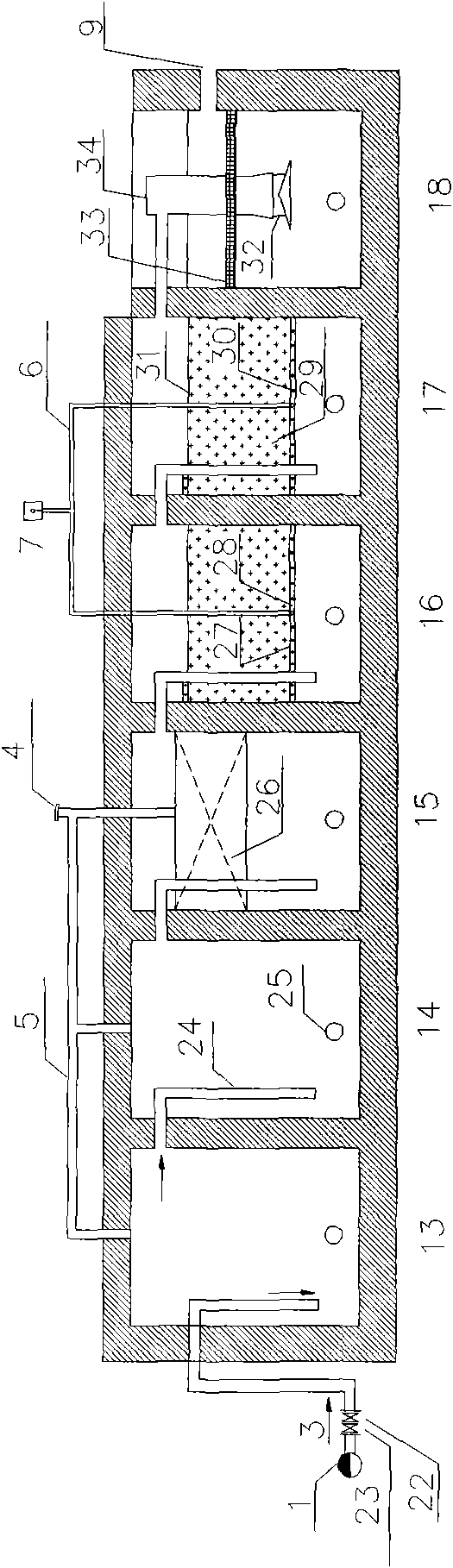

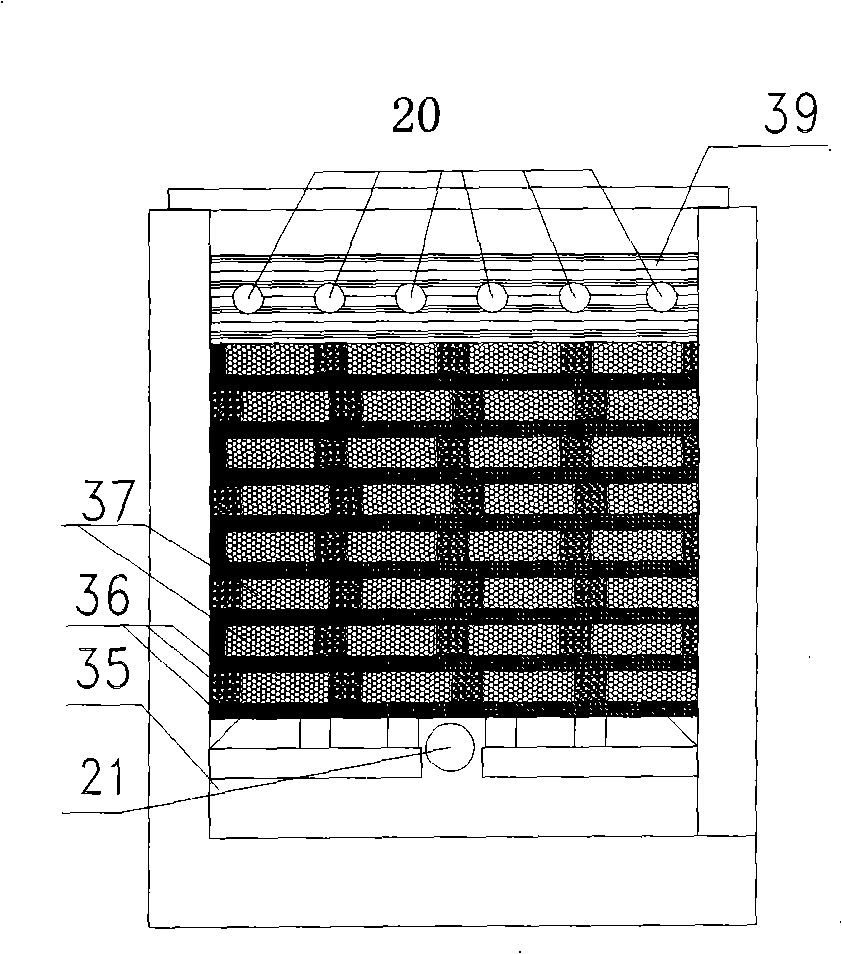

Method for treating village sewage and specific device thereof

InactiveCN101525204ASolve the blockageStrong ability to remove organic matterTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentProcess moduleWater quality

The invention discloses a method for treating village sewage and a specific device thereof. The specific device comprises a sump pump and a multifunctional deflection processing module connected with the sump pump. The multifunctional deflection processing module consists of three anaerobic units which are named Pool 1-3, two aerobic units which are named Pool 4-5, and a depositing unit named Pool 6; the pools are connected by pipelines. The anaerobic units are all provided with vent holes; the aerobic units are both provided with suspended upper and lower metal meshes; compartments between the metal meshes are filled with fillings; the lower layer of metal mesh is provided with a gas distributing hole which is connected with an aeration machine. The detailed operation steps of the method are described in the specification. The method and the specific device of the invention integrates physical processing techniques including depositing, filtering and the like, and biochemical processing techniques including anaerobic oxidation, aerobic oxidation and the like, thereby degrading organic substances in the sewage, fixing inorganic salt and reducing nutriment like nitrogen and phosphorus. The method and the specific device have the advantages of large hydraulic load and excellent processed water quality. Therefore, the method and the specific device are especially suited to national conditions of our country.

Owner:CHINA IRRIGATION & DRAINAGE DEV CENT +2

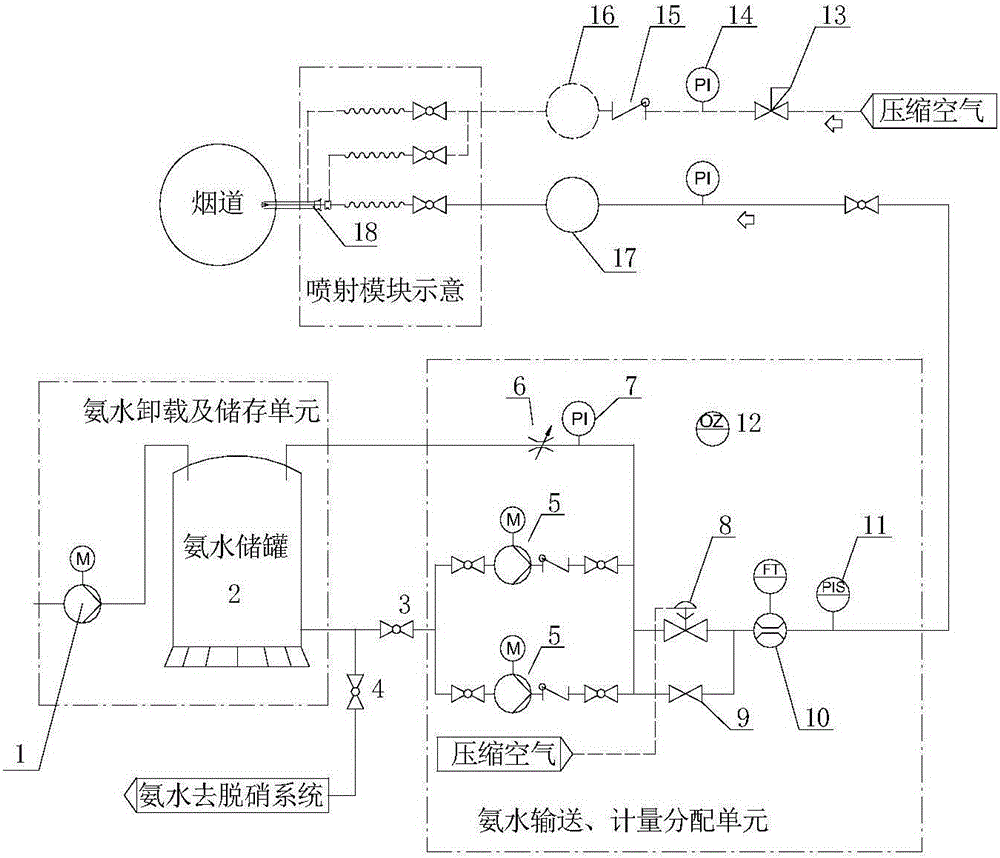

Desulfurization system and method for flue gas of cement kiln furnace

ActiveCN106166437ALess investmentReduce the investment cost onceGas treatmentDispersed particle separationFlue gasSulfur

The invention relates to a desulfurization system and method for flue gas of a cement kiln furnace. The desulfurization system comprises an ammonia water storing tank, conveying pumps, spraying guns, a cement decomposing furnace, a cement kiln pre-decomposing system and an automatic control system, wherein the cement kiln pre-decomposing system comprises a multi-stage pre-heater; the ammonia water storing tank communicates with the spraying guns through the conveying pumps; and spraying points of the spraying guns are located at an outlet of a cyclone barrel of a second-stage pre-heater. The desulfurization method comprises the following steps of I, preparing a 15-25% ammonia water; II, performing real-time detection on the concentration of SO2, and according to the concentration of the SO2 in flue gas, calculating and adjusting the spraying amount of the ammonia water through the automatic control system; and III, according to the spraying amount of the ammonia water, which is obtained through calculation in the step II, injecting the ammonia water which is pressurized through the conveying pumps to the spraying guns, and spraying the ammonia water into the cement kiln pre-decomposing system, wherein the spraying points of the spraying guns are located at the outlet of the cyclone barrel of the second-stage pre-heater. According to the desulfurization system and method disclosed by the invention, the desulfurization efficiency can reach 95% or above, the desulfurization efficiency is high, the ammonia-sulfur ratio is 2-2.5, and the operating cost is low.

Owner:NANJING C HOPE ENVIRONMENTAL SCI & TECH

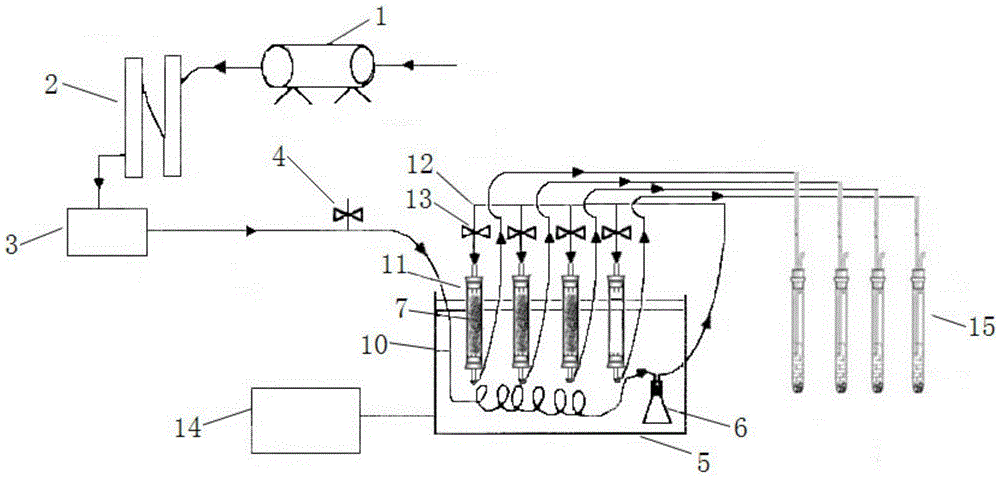

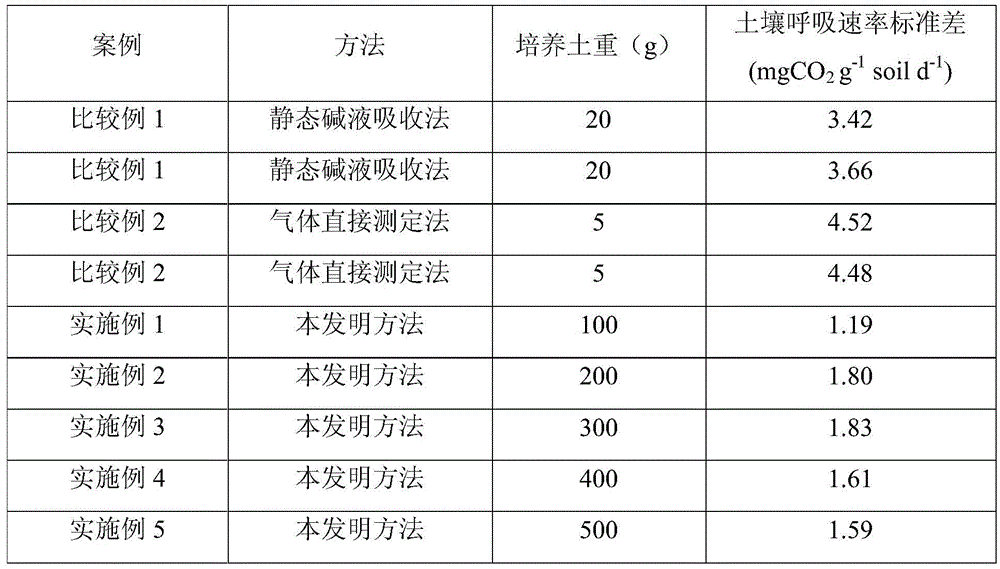

Device and method for dynamically and continuously measuring soil respiration rate and isotope composition by adopting large sample

InactiveCN105467038ARealize dynamic continuous measurementImprove detection efficiencyChemical analysis using titrationComponent separationAir filterIsotopic composition

The invention discloses a device and a method for dynamically and continuously measuring soil respiration rate and isotope composition by adopting a large sample. According to the invention, an air pump is used for driving air to pass through a soda lime column and an air filter so as to produce clean CO2-free air, and the clean CO2-free air is used for steadily carrying CO2 produced by soil respiration to dynamically enter a detection device, so as to achieve dynamic and continuous measuring, and therefore, the detection efficiency is improved; and meanwhile, a plurality of vertically-arranged cylindrical culture tubes with openings at two ends are designed as soil culture tubes, and when in detection, culture soil is filled to reach 1 / 2 to 3 / 4 of the volume of the soil culture tube, so that the soil weight of each soil culture tube is 100-500g, and the clean CO2-free air enters from the lower end of the soil culture tube and flows out from the upper end of the soil culture tube, thus realizing detection on large samples, and improving the accuracy and the representativeness of detection data.

Owner:CHONGQING THREE GORGES UNIV

Negative pressure adiabatic flash tank and adiabatic flash vaporizaiton method for tar phenylethylene recovery

InactiveCN1508106AGuaranteed dwell timeAvoid entrainmentDistillation purification/separationFlash distillationVapor liquidTar

The present invention relates to a negative-pressure adiabatic flash tank and adiabatic flash method for recovering tar styrene. Said invention is characterized by that it adopts the following measures: removing in-tank vapor-liquid separation member, adopting sector prolate mouth feeding sprayer and optimizing flash tank diameter and in-tank vapor-liquid separation space height, under the condition of 15-25 KPaA and 120-150 deg.C operating negative-pressure adiabatic flash tank, two-phase flow feeding rate at spraying hole place is 10-20 m / sec. and in-tank vaporized gas apparent life velocity is 0.9-1.4 m / sec.

Owner:CHINA PETROLEUM & CHEM CORP +1

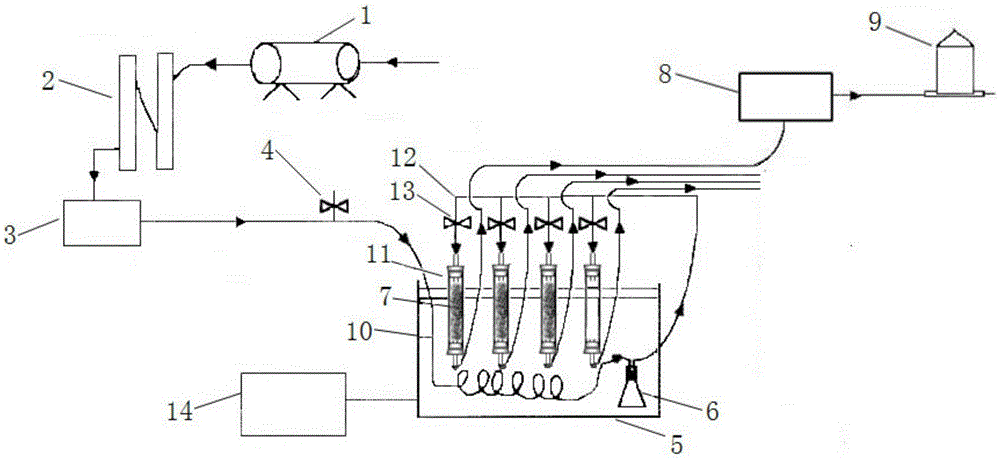

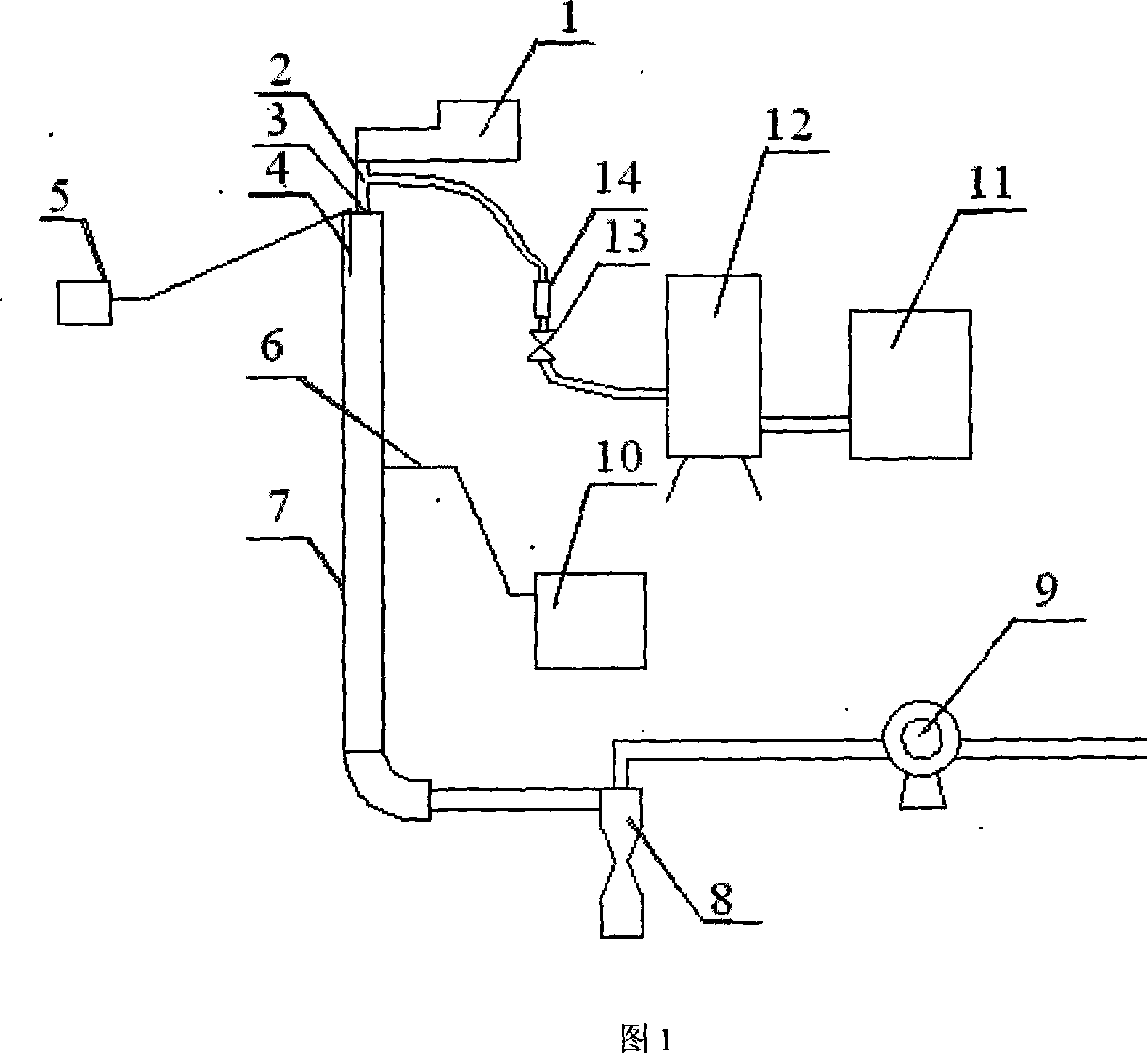

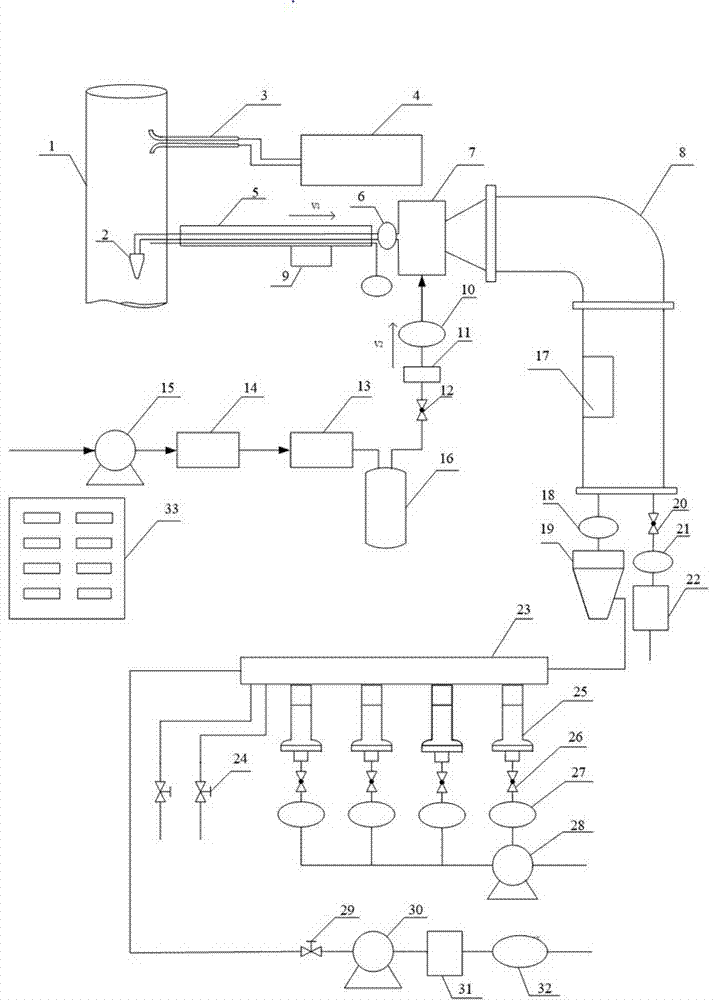

Microwave heating ammonia water reduction and denitrification treatment system and flue gas denitrification method thereof

ActiveCN104437065AAffect stabilityAvoid affecting furnace temperatureDispersed particle separationMicrowaveSolenoid valve

The invention discloses a microwave heating ammonia water reduction and denitrification treatment system and a flue gas denitrification method thereof. The system comprises a microwave tubular furnace, a forced draught blower, a temperature sensor, a denitrification reaction cavity and a concentration sensor, wherein the outlet a chamber of the microwave tubular furnace is connected with the inlet of the forced draught blower by virtue of a pipeline; the outlet of the forced draught blower is connected with the temperature sensor by virtue of a pipeline; the temperature sensor is connected with the bottom inlet of the denitrification reaction cavity by virtue of a pipeline provided with a first solenoid valve; the top outlet of the denitrification reaction cavity is connected with the concentration sensor by virtue of a pipeline; the concentration sensor is connected with the inlet A of the chamber of the tubular furnace by virtue of a second flue gas pipeline provided with a third solenoid valve; and the temperature sensor is connected with the input pipeline A of the chamber of the tubular furnace by virtue of a first flue gas pipeline provided with a second solenoid valve. The system is simple and scientific in denitrification process, the denitrification process is combined with the system, the flue gas emission can effectively meet the requirement on the national flue gas emission standard, and the system can be widely applied to occasions in which denitrification is needed so as to reduce the NOx emission and is wide in application prospects.

Owner:SOUTH CHINA UNIV OF TECH

PM2.5 (Particulate Matter 2.5) source analyzing and sampling device based on carbon dioxide concentration control

InactiveCN104729891AReduce manufacturing difficultyLow costWithdrawing sample devicesFlue gasAir pump

The invention relates to the field of environmental monitoring equipment and particularly relates to a PM2.5 (Particulate Matter 2.5) source analyzing and sampling device based on carbon dioxide concentration control. The PM2.5 source analyzing and sampling device comprises a flue gas collecting assembly, a mixing residence chamber, a PM cutter and a sampling analysis unit, wherein the flue gas collecting assembly is connected to the mixing residence chamber, and the mixing residence chamber is connected to the sampling analysis unit through the PM cutter. The PM2.5 source analyzing and sampling device further comprises a second flowmeter, an air conveying unit, three carbon dioxide detecting units and a detecting air pump, wherein the flue gas collecting assembly, the air conveying unit and the mixing residence chamber are respectively connected to the carbon dioxide detecting units and then are connected to the detecting air pump. According to the PM2.5 source analyzing and sampling device, the traditional stationary pollution source sampling manner is adopted, the existing products can be subjected to improvement processing, the difficulty of manufacturing is lowered, the cost is relatively low, and thus, popularization is facilitated.

Owner:NANJING ASSEN ENVIRONMENT TECH

Material conveying method for horizontal reactor of potassium manganate

InactiveCN102161512ARealize continuous operationLess investmentChemical/physical/physico-chemical stationary reactorsManganates/permanganatesRetention timePotassium manganate

The invention provides a material conveying method for a horizontal reactor of potassium manganate. The method is characterized in that: a multi-stage stirring reaction chamber is arranged inside the horizontal reactor; the reaction chamber is divided into relatively-independent reaction spaces by a deflection plate; and the materials are pushed to flow from the lower part of a previous chamber to the upper part of a next chamber, that is, the materials flow from the lower part of a first chamber to the upper part of a second chamber, and then flow from the lower part of the second chamber to the upper part of a third chamber and by analogy to an outlet of the reactor. The material conveying method provided by the invention effectively solves the problem that the potassium manganate product deposits at the bottom of the reaction materials and can not overflow to the next reaction chamber because the specific weight of the potassium manganate product is higher than that of the materials, increases the retention time of the materials in the reactor, and avoids the 'short-cut' of the materials, therefore, the reaction efficiency and the conversion rate are increased, the continuous operation and continuous reaction is realized, the volume of the reactor is reduced, the heat loss is reduced, the equipment investment and the running cost are reduced, and the floor area occupied by the equipment is reduced. The method can be applied to the reactions of high-grade and low-grade materials, and has a board material applicable range.

Owner:YUNNAN JIANSHUI MANGANESE

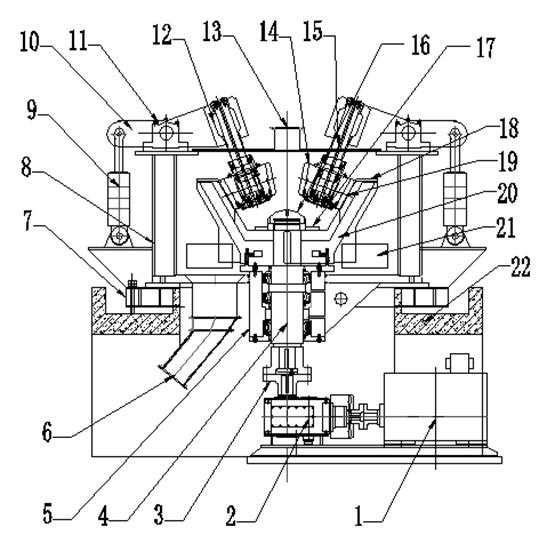

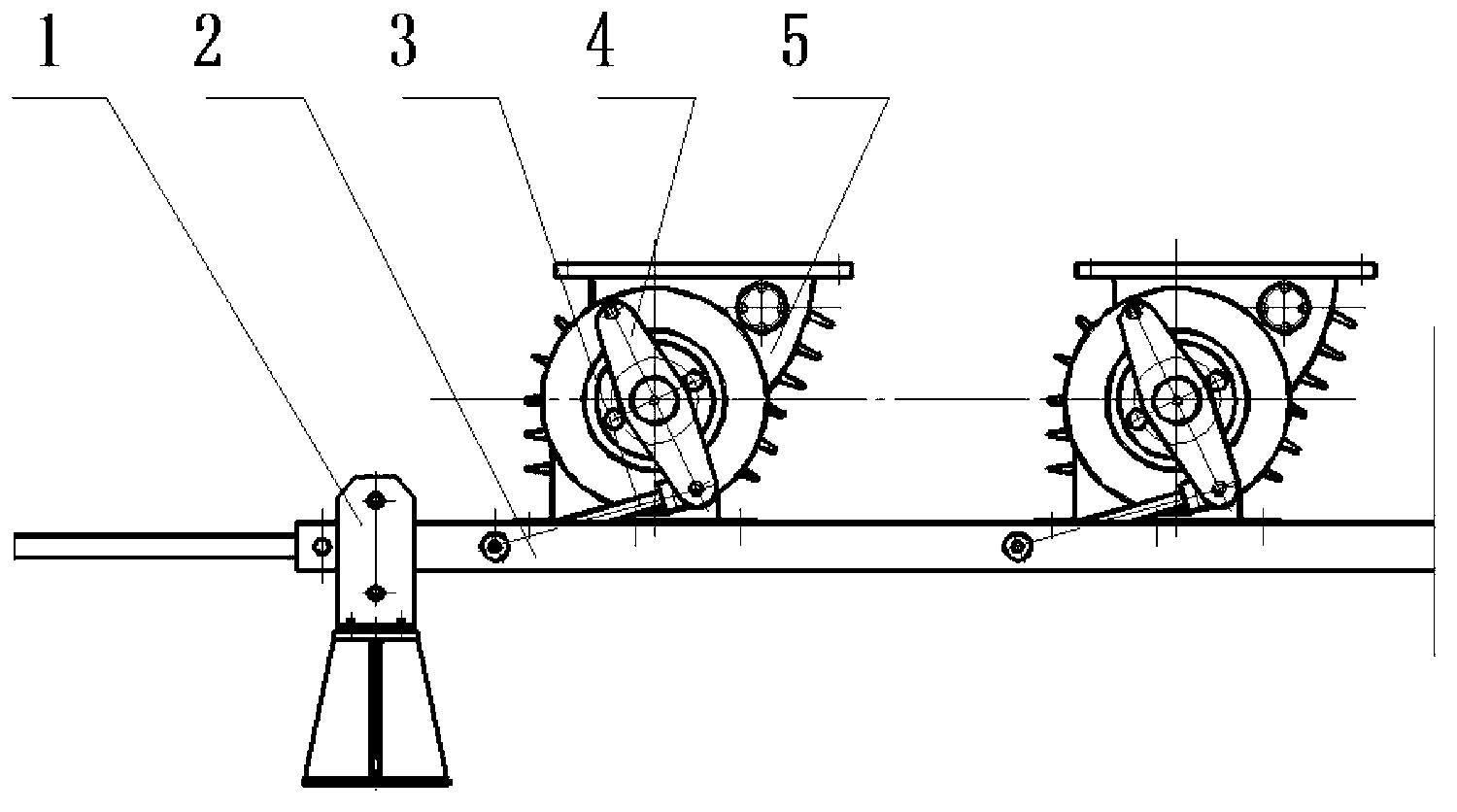

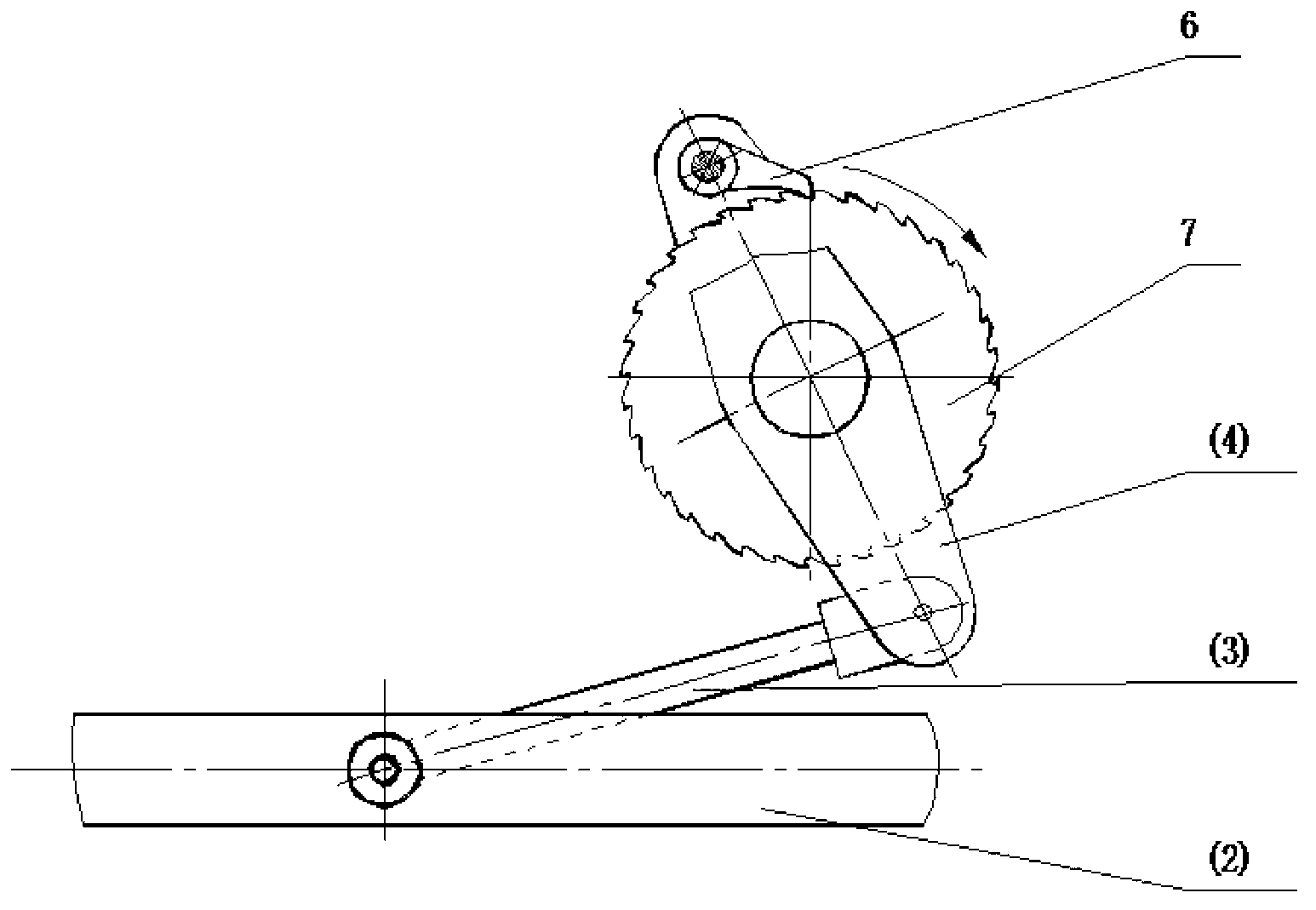

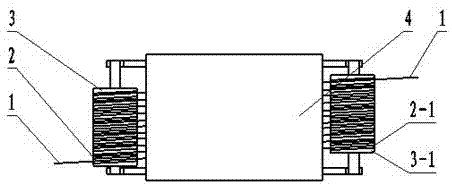

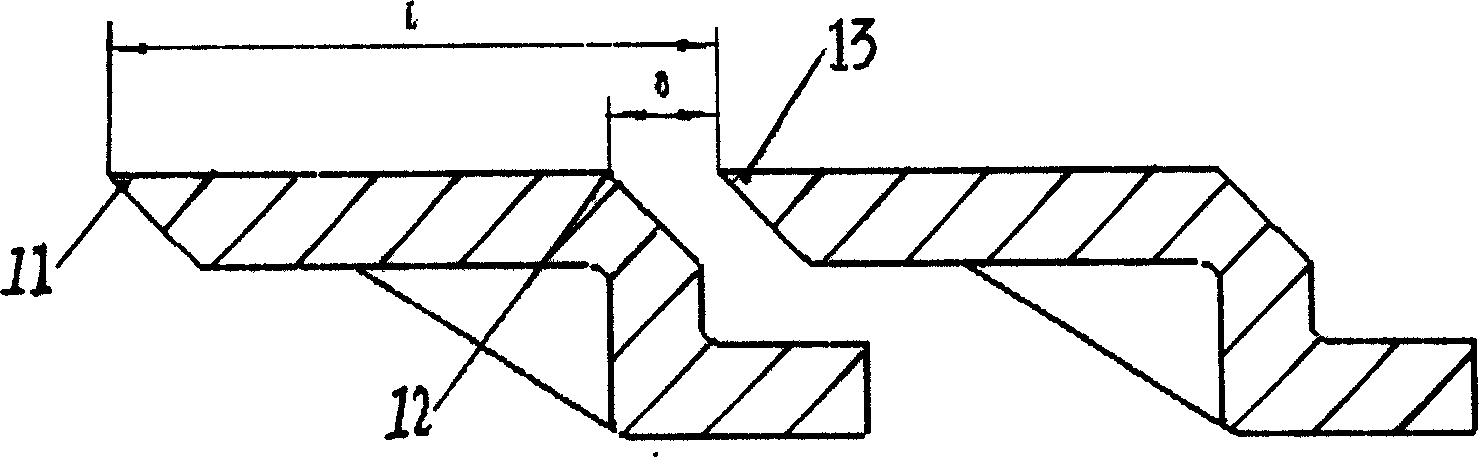

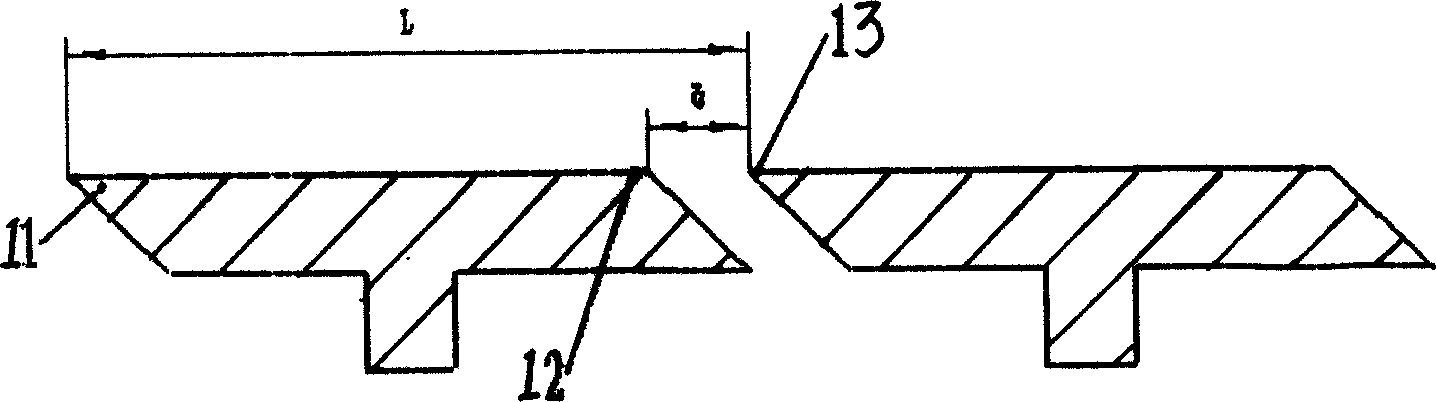

Method and structure for ensuring synchronization of notch wheels of reciprocating material pulverizing machine

ActiveCN103301906AEliminate the difference in the number of ratchet teethGuaranteed dwell timeGrain treatmentsEngineeringResidence time

The invention discloses a method and a structure for ensuring synchronization of notch wheels of a reciprocating material pulverizing machine, which solve the synchronization problem of the notch wheels of the reciprocating material pulverizing machine. The method comprises enabling the angular speeds of the notch wheels to be the same by adjusting the length of a rocking lever. The invention further discloses a structure through which the method is realized, wherein the rocking lever is provided with a length adjusting device. The length adjusting device consists of a rocking lever bolt, a rocking lever nut and a securing nut. The length of the rocking lever is adjusted through the screw-in depth, in the rocking lever bolt, of the rocking lever nut. The condition that the material discharging speed of each pulverizing box is different because of different numbers of notch wheel teeth caused by accumulation error can be prevented. The residence time of petroleum coke inside a tank furnace is ensured, so that guarantee is provided for reliable and stable operation of production.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Device for calcining aluminum oxide clinker by directly utilizing coal powder and method thereof

InactiveCN101148262AAdjustable feedAchieve recyclingAluminium oxide/hydroxide preparationThermal energyHearth

The apparatus for calcining alumina clinker with coal powder includes one hearth with one temperature measuring thermocouple connected to the first temperature controlling instrument to measure the temperature in the upper part of the hearth and one temperature controlling thermocouple connected to the second temperature controlling instrument to control the temperature rise in the hearth, one coal feeder in the inlet of the hearth, one coal powder mixer with burner connected to the coal feeder, one cyclonic separator and one induced draft fan connected to the outlet of the hearth, one flowmeter and one air flow rate regulating valve connected between the coal powder mixer and one air tank, and one air compressor connected to the air tank. During calcining alumina clinker proper amount of calcium containing material is added into high aluminum coal powder, and the present invention has low power consumption for extracting alumina from coal powder.

Owner:XI AN JIAOTONG UNIV

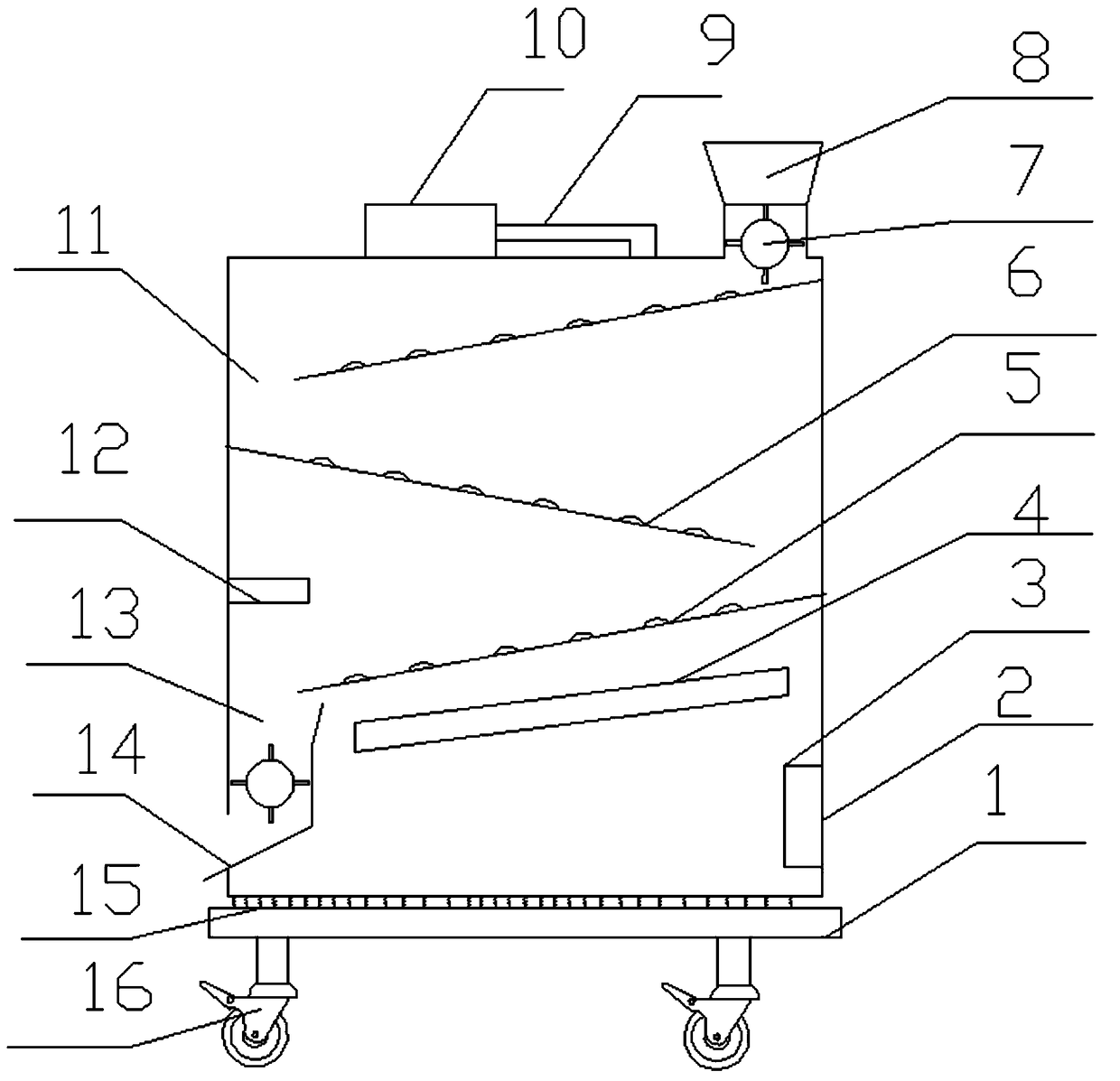

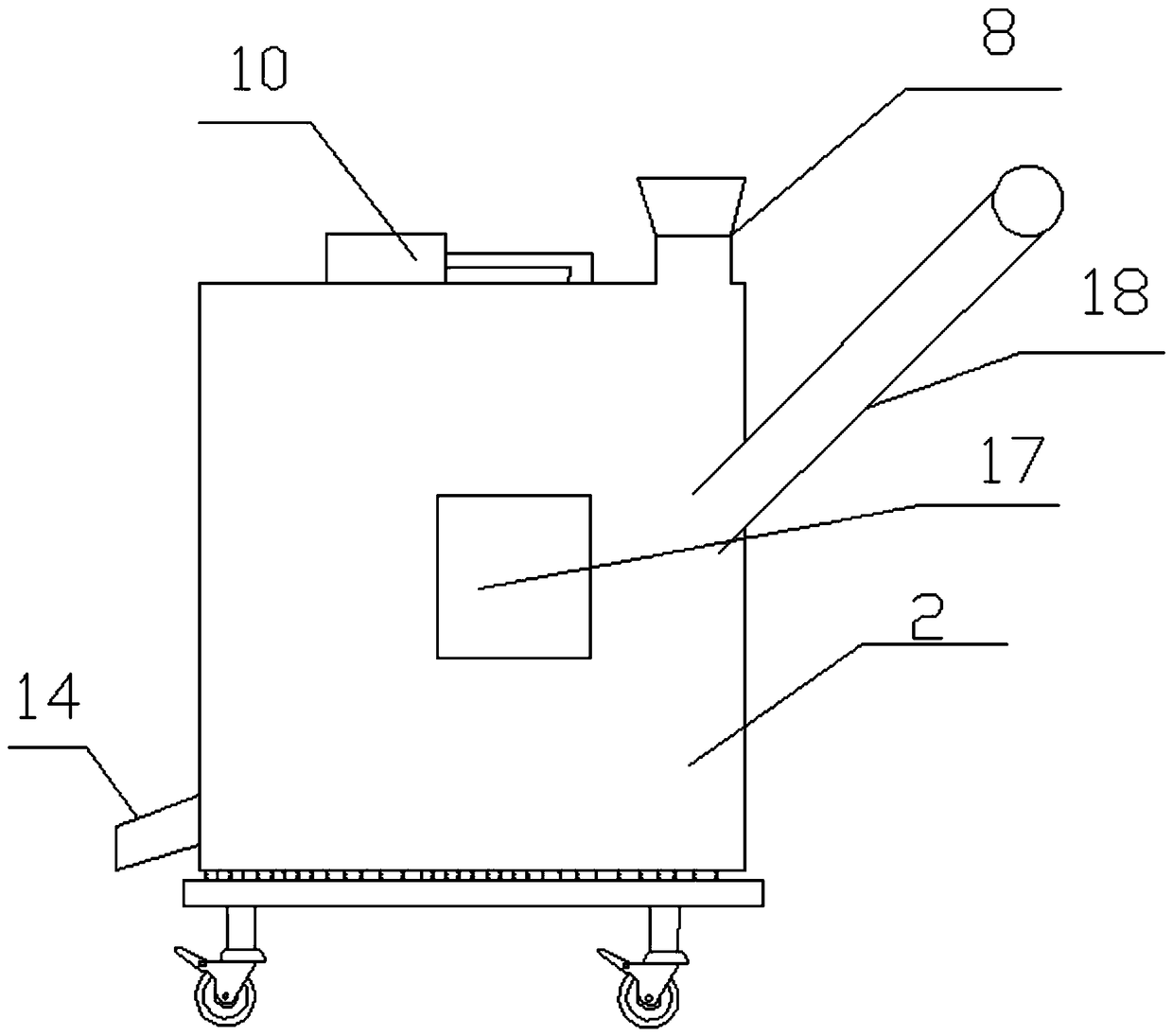

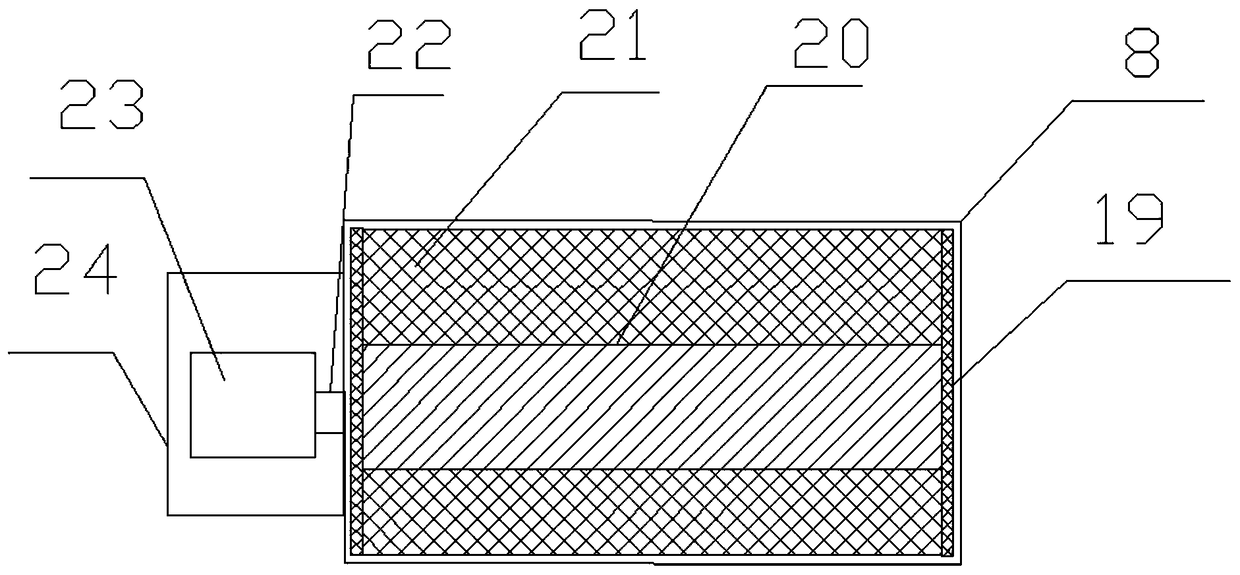

Seed rapid dehumidifying equipment

InactiveCN109442875AIncrease profitVolatileDrying solid materials without heatDrying gas arrangementsEngineeringAgricultural machinery

The invention relates to the technical field of agricultural machinery, and particularly discloses seed rapid dehumidifying equipment. The seed rapid dehumidifying equipment includes a base and a housing, a pushing hand is fixed to the exterior of the housing, the base is arranged at the bottom of the housing, a feeding port is formed in the top of the housing, the feeding port is internally provided with a conveying device, the top end of the housing communicates with an air pipe, the air pipecommunicates with an air pump, a plurality of inclined guiding plates are arranged in the housing, air holes are formed in the guiding plates, falling ports are formed in the tail ends of the guiding plates, a heater is fixedly installed at the bottom of the housing, a temperature sensor and a vibrator are installed inside the housing, a discharging device is installed at the tail end of the lowest guiding plate, the conveying device is arranged inside the discharging device, the lower end of thedischarging devicecommunicates with a discharging port, and an operation display screen is arranged on the side face of the housing. The seed rapid dehumidifying equipment has the advantages that thestructure is simple, the energy utilization rate is high, operation is easy, applicability is high, and safety performance is high.

Owner:周力

Molybdenite concentrate suspended-state roasting process and equipment

ActiveCN102127634ASave flash dryingPrevent sinteringProcess efficiency improvementHigh concentrationSulfur

The invention discloses a molybdenite concentrate suspended-state roasting process, which comprises the following steps of: firstly, conveying molybdenum concentrate to a suspension roaster by using a gas-moving material spraying device through compressed air, and completing heat exchange in a heat exchange area, wherein the temperature of the heat exchange area is 500 to 750DEG C and the retention period is 2 to 15 seconds; secondly, performing oxidation desulfurization reaction in a reaction area of the suspension roaster to obtain roasted high-sulfur sand, wherein the temperature of the reaction area is 550 to 780DEG C, the air speed is 4 to 25m / s, and the retention period is 2 to 15 seconds; and finally, removing residual sulfur from the roasted high-sulfur sand in a rotary kiln at the temperature of between 550 and 780DEG C for 5 to 60 minutes to obtain roasted high-dissolubility molybdenum sand. The invention also provides molybdenite concentrate suspended-state roasting equipment, which overcomes various defects of stacked state roasting and fluidized roasting, has high thermal efficiency and good product quality, greatly shortens roasting time, can obtain the high-dissolubility low-sulfur molybdenum oxide, and ensures that SO2 in flue gas has high concentration and is convenient to recycle for making acid.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

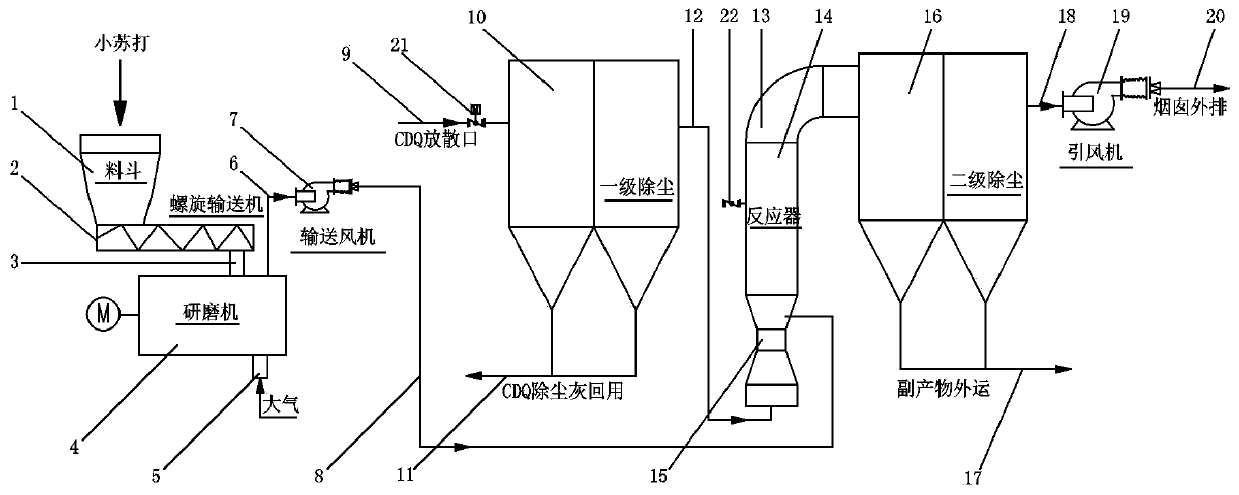

System for CDQ pressure control emitted gas desulfurization and dust removal

PendingCN110280124AEmission reductionNo corrosive effectsDispersed particle separationGrain treatmentsChemical reactionFlue gas

The invention discloses a system for CDQ pressure control emitted gas desulfurization and dust removal, comprising a baking soda hopper, a screw conveyor, a baking soda grinder, a conveying fan, a primary dust remover, a desulfurization reactor, a secondary dust remover and a draught fan. The emitted gas is taken out of an emission port through a pipeline and firstly enters the primary dust remover to remove dust, and the dust-removed emitted gas and the ground baking soda ultrafine powder enter the desulfurization reactor through a Venturi pipe to be uniformly mixed and undergo a chemical reaction in the reactor. The desulfurized flue gas passes through the secondary dust remover and the draught fan and then enters a chimney to be discharged. By the principle of baking soda dry desulfurization and two-stage high-efficiency dust removal, SO2 and dust in the flue gas can be effectively removed to ensure that the treated flue gas meets the latest national special emission limit standard.

Owner:JIANGSU WISDOM ENG TECH

PM2.5 (Particulate Matter 2.5) source analyzing and sampling device based on multichannel parallel feedback control

InactiveCN104729892AReduce manufacturing difficultyLow costControlling ratio of multiple fluid flowsWithdrawing sample devicesFlue gasAir filter

The invention relates to the field of environmental monitoring equipment and particularly relates to a PM2.5 (Particulate Matter 2.5) source analyzing and sampling device based on multichannel parallel feedback control. The PM2.5 source analyzing and sampling device comprises a flue gas collecting assembly, a mixing residence chamber, a PM cutter, a sampling analysis unit, a second flowmeter and an air conveying unit, wherein the second flowmeter is connected between the flue gas collecting assembly and the mixing residence chamber, the air conveying unit comprises an air pump, an air filter, a buffer tank, a first proportional valve, an air conveying sensor unit and a first flowmeter, the air pump is connected to the buffer tank through the air filter, the buffer tank is connected to the first flowmeter through the first proportional valve and the air conveying sensor unit, the first flowmeter is connected to the mixing residence chamber, and the sampling analysis unit is a multichannel parallel sampling analysis unit and can be used for carrying out multichannel simultaneous sampling and controlling sampling flow. According to the PM2.5 source analyzing and sampling device, the traditional stationary pollution source sampling manner is adopted, the existing products can be subjected to improvement processing, the difficulty of manufacturing is lowered, the cost is relatively low, and thus, popularization is facilitated.

Owner:NANJING ASSEN ENVIRONMENT TECH

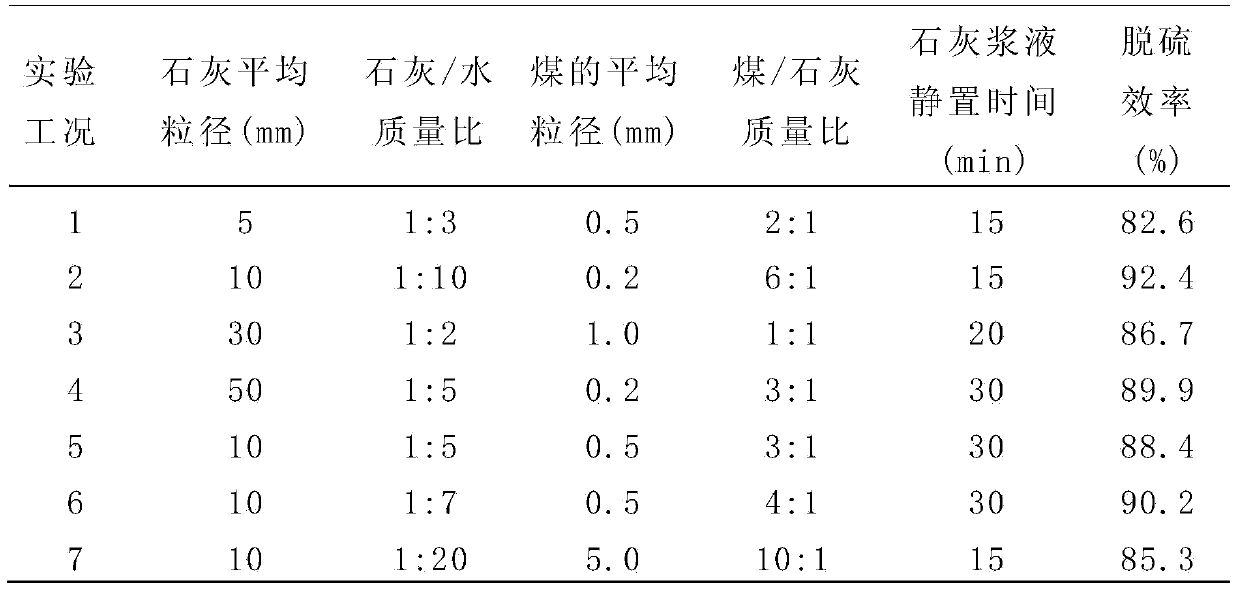

Coal mixture with desulfurization effect and preparation method and application of coal mixture

ActiveCN104208998AIncrease profitImprove self-desulfurization efficiencyDispersed particle separationCalcium hydroxideCoal particle

The invention discloses a coal mixture with a desulfurization effect and a preparation method and application of the coal mixture, relating to the technical field of coal cleaning. The coal mixture with the desulfurization effect is characterized by being prepared by mixing massive lime raw materials, coal particles and water according to a certain ratio, grinding massive lime into ultrafine calcium hydroxide particles which are attached to the surfaces and inner pores of the coal particles and reducing the water content, and the coal mixture can be directly used as a coal processing and utilization raw material. By the method, the self-desulfurization of coal and the utilization rate of a desulfurizing agent can be obviously improved; furthermore, the process of adding the desulfurizing agent into a coal utilization device is simplified, and the investment and the use cost of desulfurizing equipment are lowered.

Owner:TSINGHUA UNIV

Drying device in high-speed rough drawing production line

InactiveCN103712425AGuaranteed dwell timeShorten the lengthDrying machines with progressive movementsDrying solid materialsProduction lineEngineering

The invention discloses a drying device in a high-speed rough drawing production line. The drying device comprises a drying box and conveying rollers arranged at the charge end and discharge end of the drying box, wherein spirally-distributed wire guide grooves are formed in the conveying rollers respectively; wires penetrate through the drying box back and forth along the spirally-distributed wire guide grooves of the conveying rollers at the charge end and discharge end of the drying box, and are finally output from the tail ends of the spirally-distributed wire guide grooves of the conveying roller at the discharge end. Compared with the prior art, according to the drying device, the problems of long length and large floor area of the drying box of the existing drying device in a rough drawing production line can be solved.

Owner:柳城县鼎铭金属制品有限公司

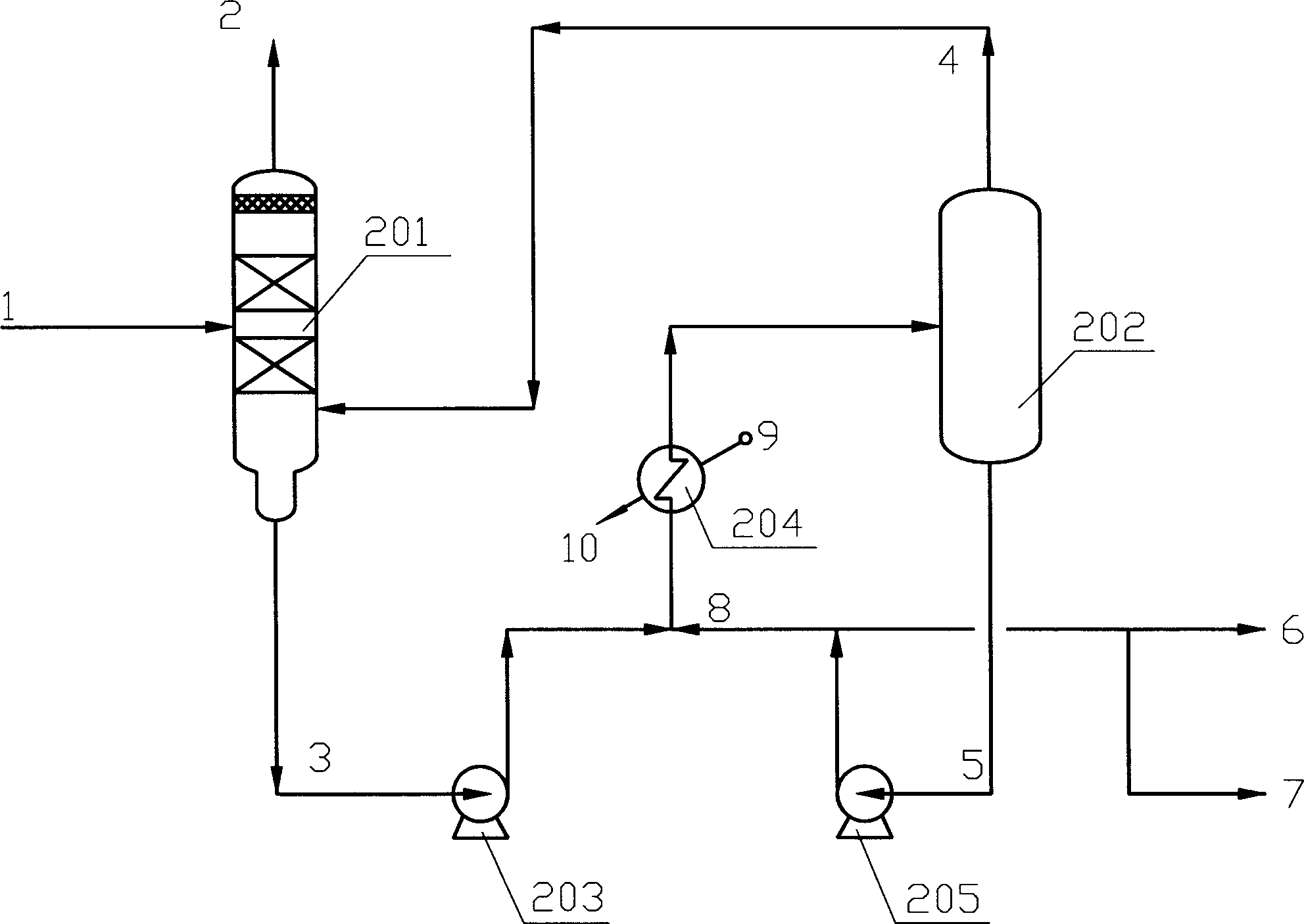

Liquid-phase hydrogenation reaction device and liquid-phase hydrogenation reaction method

ActiveCN111068587AShorten the flow pathReduced Diffusion EscapeTreatment with hydrotreatment processesChemical/physical processesFluid phaseHydrogenation reaction

The invention discloses a liquid-phase hydrogenation reaction device and a liquid-phase hydrogenation reaction method. The liquid-phase hydrogenation reaction device comprises an efficient hydrogenation reaction zone and an ultra-deep hydrogenation reaction zone, wherein the efficient hydrogenation reaction zone comprises a down-flow type fixed bed reactor and an up-flow type tubular reactor whichare connected in series, the fixed bed reactor is in an up-flow type or a down-flow type, the tubular reactor is in an up-flow type, the ultra-deep hydrogenation reaction zone comprises a plurality of U-shaped tubular reactors connected in series, and the adjacent tubular reactors are communicated through arc-shaped pipes. According to the invention, the liquid-phase hydrogenation reaction deviceis used for carrying out efficient hydrogenation reaction and deep hydrogenation reaction, so that the hydrogenation reaction rate and the reaction efficiency are effectively improved, the hydrogen utilization rate is increased, the hydrogen consumption and the energy consumption are reduced, the total volume of the reactor is reduced, H2S, NH3 and other gases generated in the reaction process are continuously moved out of the reaction system in the reaction process, the continuous high efficiency of the hydrogenation reaction process is maintained, and deep hydrogenation reaction and ultra-deep hydrogenation reaction are realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

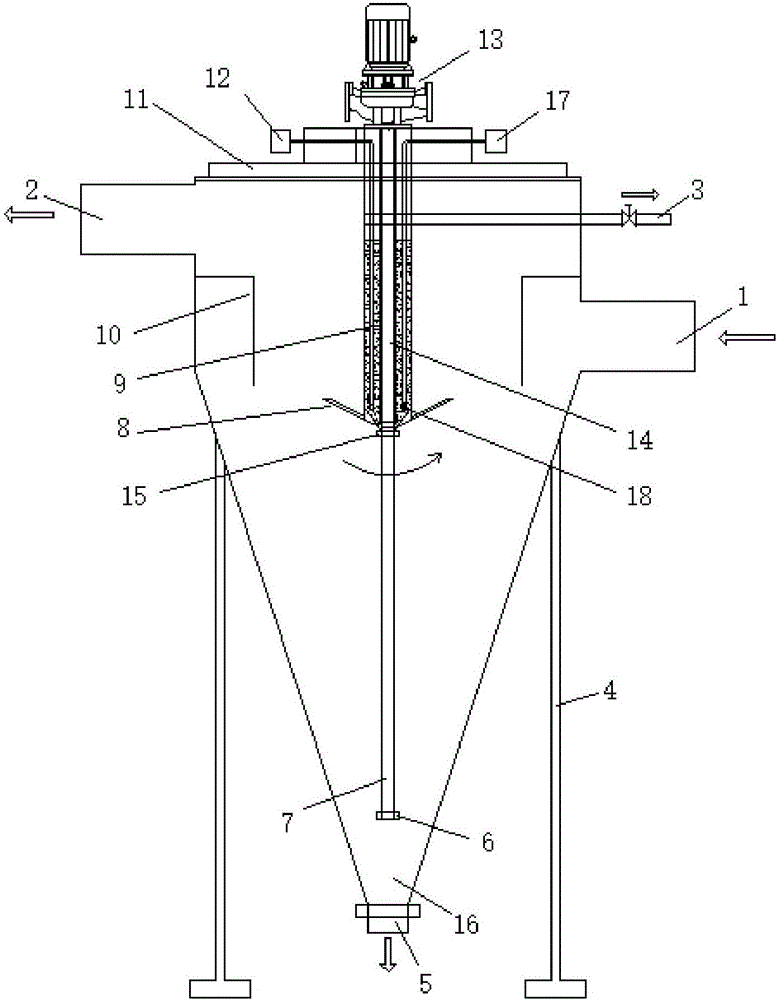

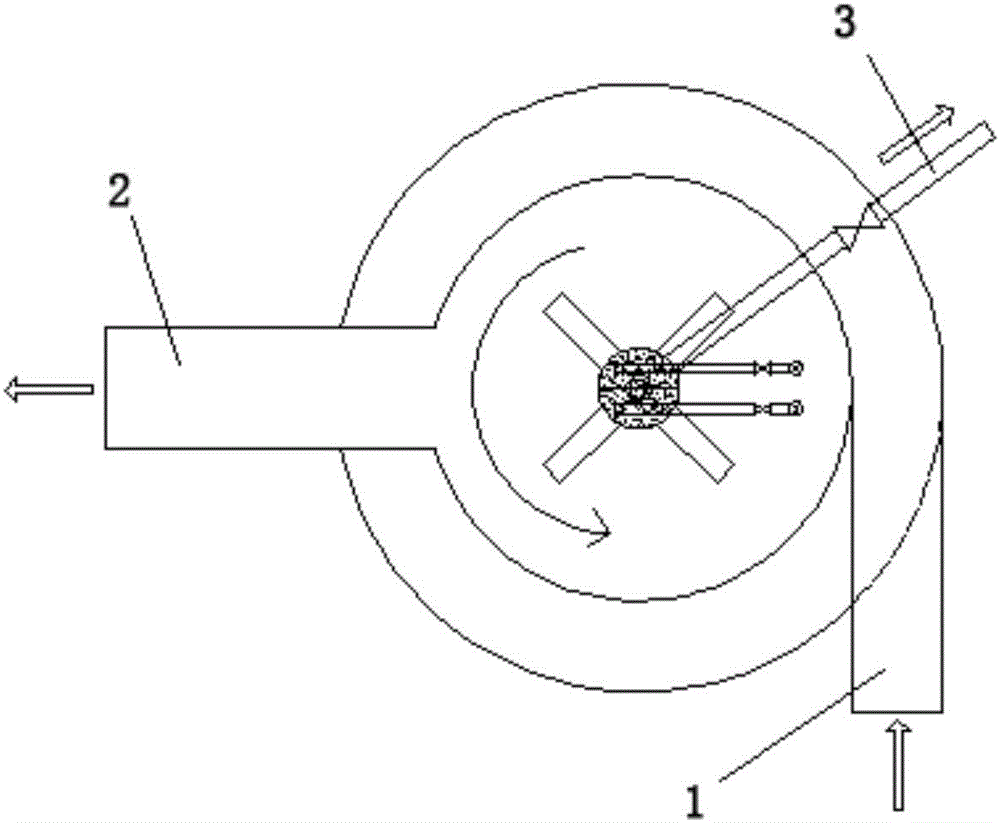

Rotating sand settling device and technology

ActiveCN106178615AEnter high speedEnter without disturbingSettling tank with pumpSedimentation regulating devicesWater flowOutfall

The invention discloses a rotating sand settling device and technology. The device comprises a sand settling tank, wherein the sand settling tank comprises a lower inverted-cone-shaped sand settling area and an upper cylindrical water inlet and outlet area, wherein a water inlet, a water outlet and a flow guiding device are arranged in the water inlet and outlet area; a polluted sand outlet is arranged at the bottom of the sand settling area; water flowing in from the water inlet is guided to the inner wall of the sand settling area by the flow guiding device; a sand washer and stirring blades are further arranged in the sand settling tank; the stirring blades are arranged in the middle of the sand settling tank and between the sand settling area and the water inlet and outlet area; the sand washer comprises a sand suction and discharge pipe, a sand washing tank and a sand washing sewage pipeline; the sand washing tank comprises a lower sand washing area and an upper buffer area; a sand inlet and outlet port is formed in the bottom of the sand washing area of the sand washing tank. With the device and the technology, the water inlet speed can be increased, the treating efficiency of the sand settling tank for sand with the grain size ranging from 25 mu m to 35 mu m can be improved while the separation efficiency of the sand and organic matter can be increased, the treating efficiency can be up to 90%, and the investment and the running cost are saved.

Owner:HUNAN HENGKAI ENVIRONMENT TECH INVESTMENT CO LTD

High-efficiency oily sewage treatment device and method

PendingCN106746048ASave spaceImprove air flotation separation effectWaste water treatment from quariesWater/sewage treatment by centrifugal separationIonHeavy metals

The invention provides a high-efficiency oily sewage treatment method, comprising the following steps: pressurizing to-be-treated oily sewage, and then delivering the pressurized oily sewage into an electric flocculation tank so as to generate a polynuclear hydroxy complex, hydroxide floccules and hydrogen gas bubbles; adding gas-dissolved water into the oily sewage after electrolysis to enable the polynuclear hydroxy complex to adsorb the floccules, sediment grains and large-particle oil drops in the sewage; wrapping the oil drops and the sediment grains with micro-bubbles and hydrogen gas bubbles in the gas-dissolved water; performing cyclone separation to remove the floccules, the large sediment grains and the oil drops; and performing flotation separation on the treated sewage in a full-water low-pressure state to remove the remaining polynuclear hydroxy complex-oil drops, hydroxide floccules-suspended particles, micro-bubbles-oil drops and sediment impurities, so as to obtain purified water. The device and the method provided by the invention can be used for removing oil drops, sediments, colloids, dissolved organic matters and heavy metal ions in sewage at the same time, bacteria and viruses in water can also be killed without adding chemical reagents, and the water quality after treatment is stable and reaches the standards.

Owner:XIAN SITAN ENVIRONMENT TECH CO LTD

Life refuse incinerator

The domestic refuse incinerator includes incinerator body and fire grate assembly. The incinerator body has refuse inlet and smoke outlet in the upper part, air inlet and slag outlet in the lower part, and hearth divided into the first combustor and the second combustor. The incinerator has fire grate assembly inside the first combustor and divided into three stepped parts, the second combustor in the top front of the first combustor, smoke inlet in the back of the first combustor and smoke outlet in the front of the second combustor, cyclonic unit installed inside the second combustor for the fume to burn spirally and fully inside the second combustor for over 2 sec.

Owner:徐万禄

Energy-saving cooking range

The invention relates to the field of cooking range infrastructures, in particular to an energy-saving cooking range. The energy-saving cooking range comprises a hearth, and more than three flame guide ribs circumferentially and uniformly distributed along an internal wall of the hearth, wherein the hearth is in a cylindrical or bowl-shaped structure; a gas distributing disk and an ignition part matched with the gas distributing disk for ignition are arranged at the bottom of the hearth; the energy-saving cooking range is provided with air inlets used for allowing air to enter in the hearth and / or in a position where the gas distributing disk is matched with the hearth; the flame guide ribs extend from the bottom of the hearth to the top of the hearth sequentially; and arrangement directions of the flame guide ribs are different from a generatrix direction of the hearth. According to the energy-saving cooking range, a flow-through route of a flame can be changed by an artificially designed flame path, so that a purpose of prolonging the attachment time of the flame on the internal wall of the hearth can be achieved; an effect of improving heat exchange is further exerted; the energy-saving cooking range is simple in structure and convenient to realize; and the low manufacturing cost and the low use cost of the energy-saving cooking range can be ensured effectively.

Owner:ANHUI HANSUM INSTR EQUIP

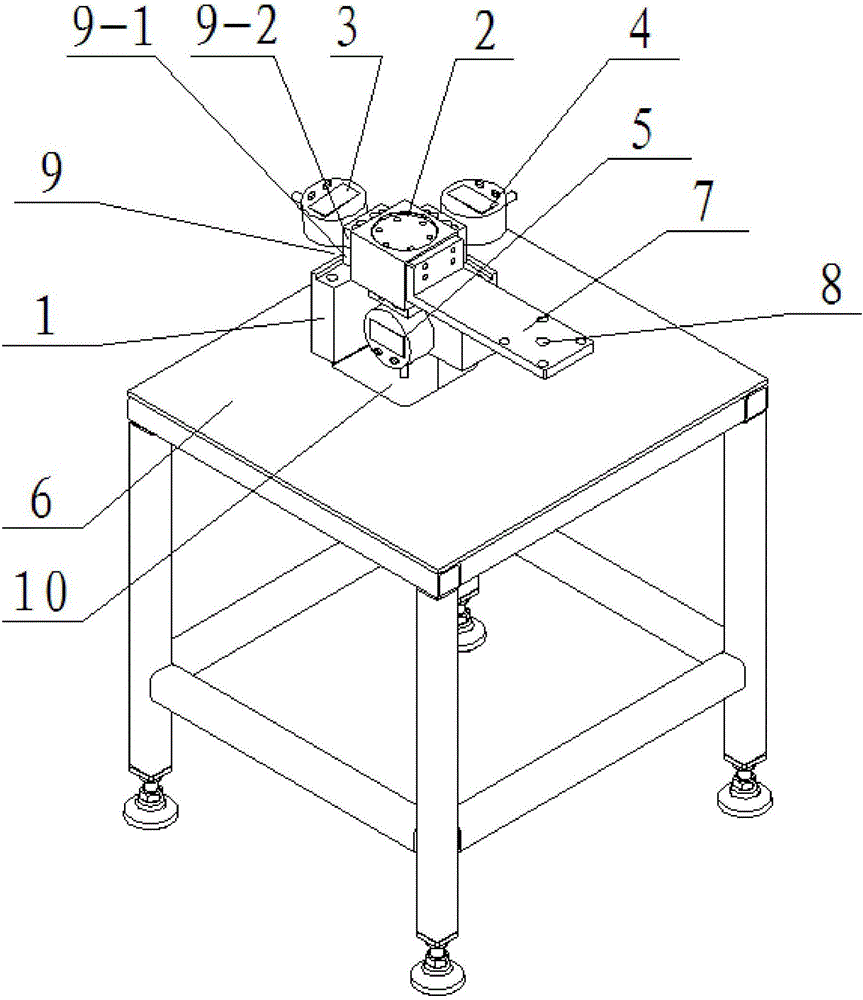

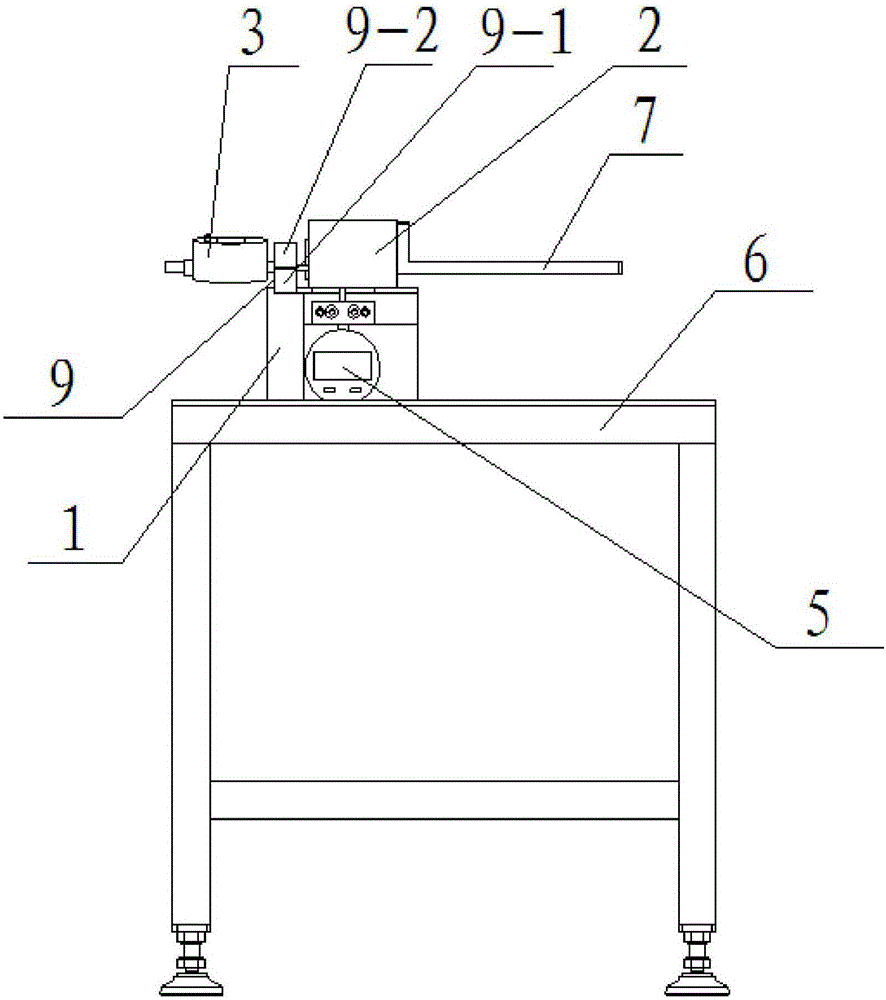

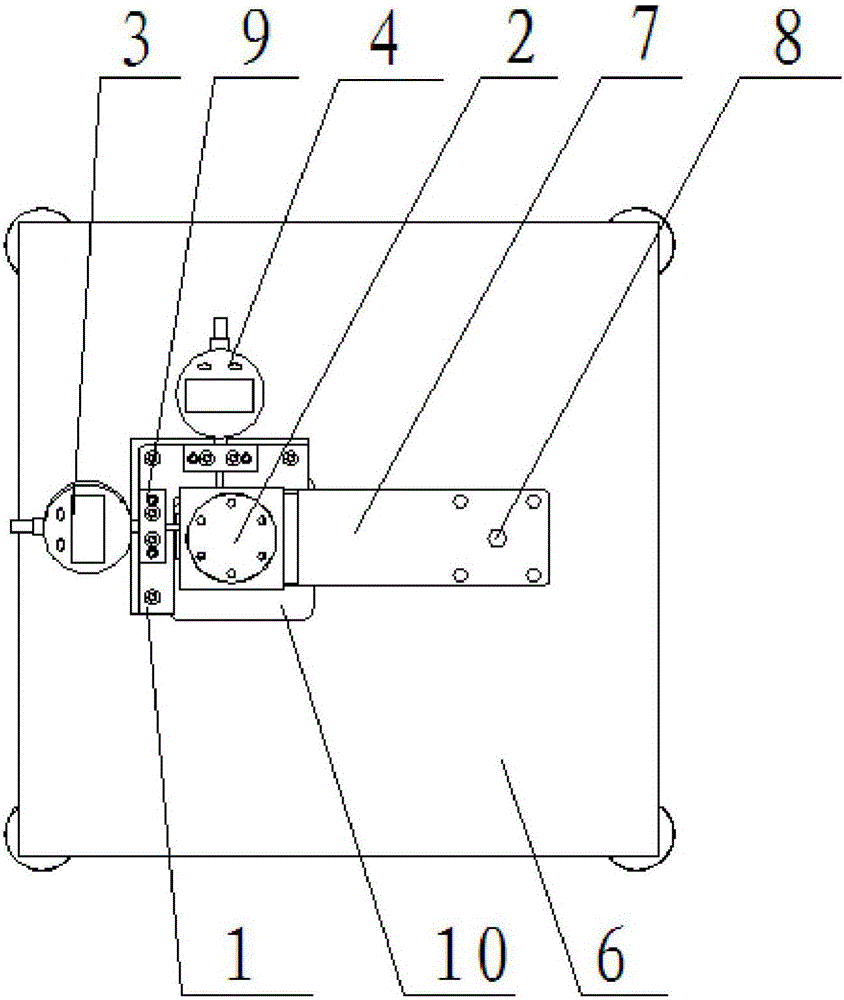

Simple robot precision detecting device and method

PendingCN106839933ASimple structureEasy to operateMechanical measuring arrangementsSimulationMechanical engineering

The invention relates to the technical field of robot detection, in particular to a simple robot precision detecting device and method. The device comprises a fixing base and a load block which is used for being installed at the tail end of a robot. The fixing base is provided with an X-axis dial indicator, a Y-axis dial indicator and a Z-axis dial indicator, wherein the axis of the measuring head of the X-axis dial indicator, the axis of the measuring head of the Y-axis dial indicator and the axis of the measuring head of the Z-axis dial indicator are perpendicular to one another; when the robot drives the load block to move to the fixing base, the load block separately abuts against the measuring head of the X-axis dial indicator, the measuring head of the Y-axis dial indicator and the measuring head of the Z-axis dial indicator. The simple robot accuracy detecting device and method have the advantages that the load block is driven by the robot to move to the fixing base, the three faces, perpendicular to one another, of the load block abut against the three dial indicators respectively, readings of the dial indicators are taken, the moving precision of the arms of the robot is detected through multimetering, the structure is simple, the operation is convenient, and the cost is low.

Owner:CHONQING HUASHU ROBOT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com