Energy-saving cooking range

A cooker and hearth technology, applied in the field of energy-saving cooker, can solve the problems of difficult to meet the operation requirements of the cooker, restrict the performance of the equipment, and the high utilization rate of heat energy of the cooker. The effect of high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

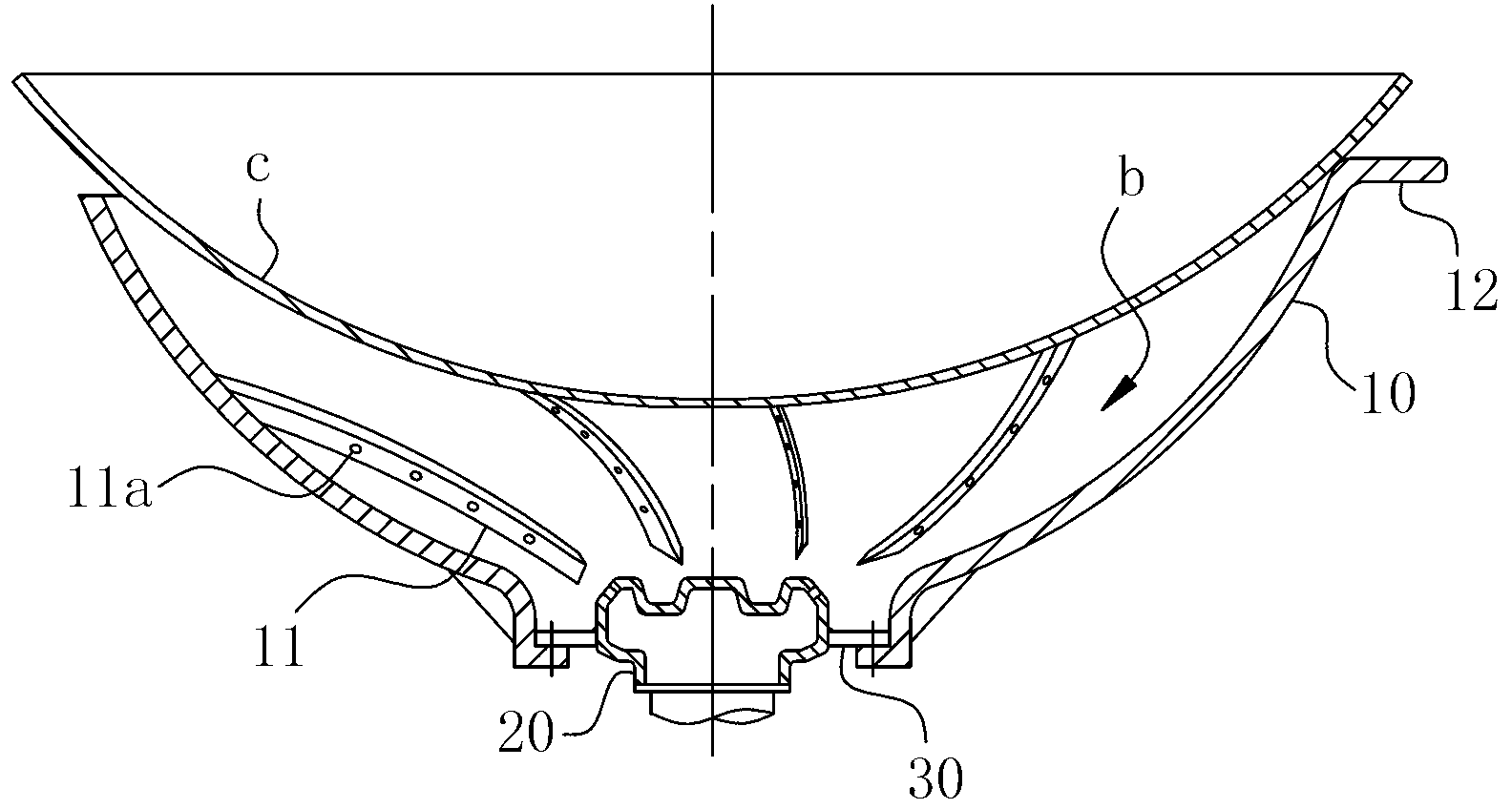

[0029] For further understanding, the following combination Figure 1-3 For concrete structure of the present invention and work flow, make following description:

[0030] The energy-saving cooktop of the present invention includes a furnace 10 , a gas distributor 20 , an ignition needle 41 and an ion flame detector 42 for matching ignition. The hearth 10 is a bowl-shaped structure with a parabolic curved surface and a helical flame guide rib 11. The upper end of the opening is arranged with a leg 12 for placing the pot c. The bottom is hollow and open, and the aperture at the opening is larger than the gas distribution plate. 20 disc diameter. The gas distribution plate 20 is located at the opening of the furnace bottom 10 and arranged concentrically with it. The furnace 10 is installed on the cooktop panel, and its surface coincides with the cooktop panel. The furnace 10, the gas distribution plate 20 and the pot c The space enclosed between them forms the combustion chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com