Device for calcining aluminum oxide clinker by directly utilizing coal powder and method thereof

A technology for calcining alumina and clinker, applied in alumina/hydroxide preparation and other directions, can solve the problems of land and water pollution, lack of good, environmental pollution, etc., achieve low energy consumption and efficient collection, improve reaction speed, reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

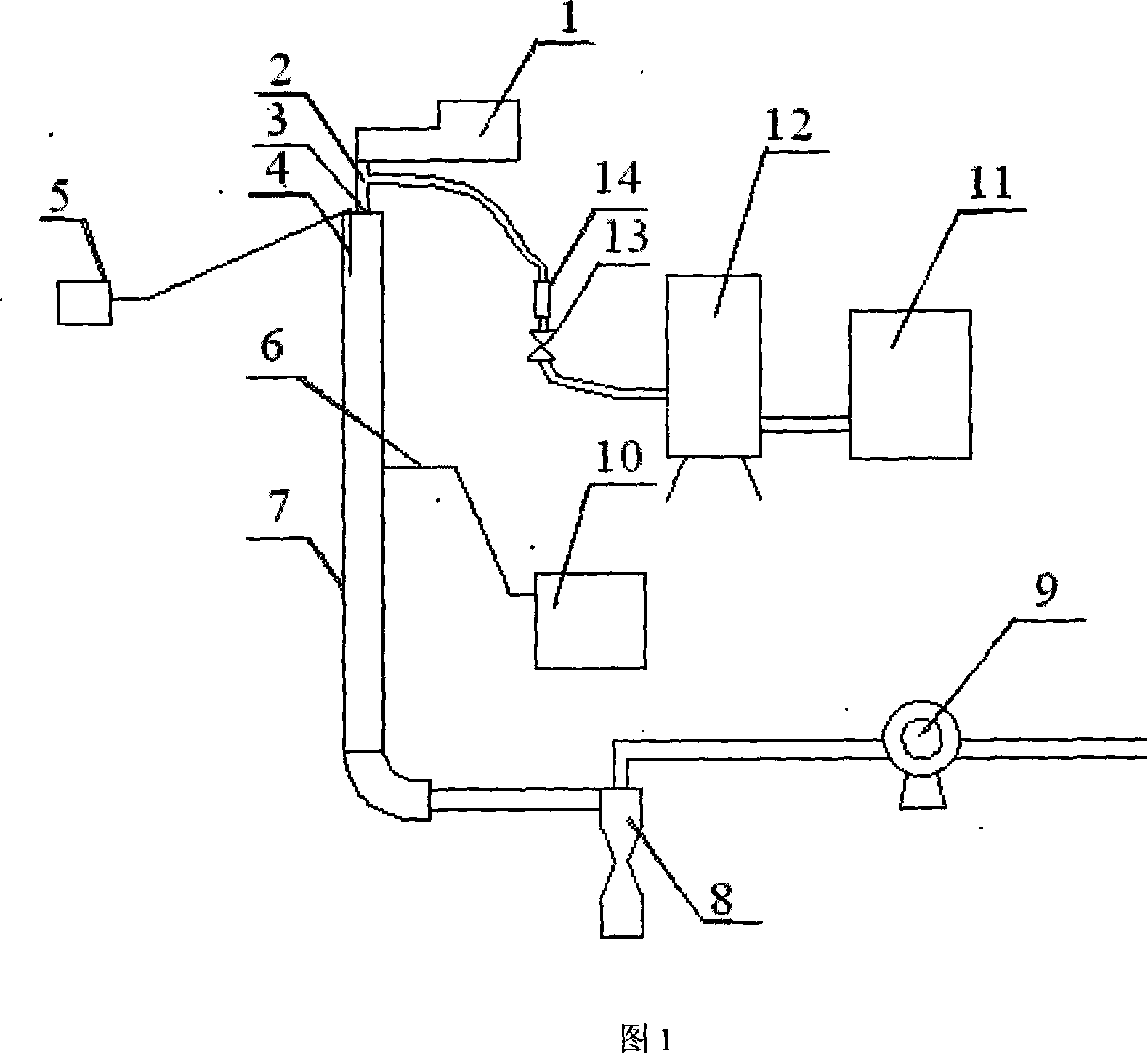

Image

Examples

Embodiment 1

[0047] 1. Select the high-alumina raw coal from the Zhungeer area of Inner Mongolia. The alumina content in the fly ash after normal combustion is 50%, and the ash content is 10%. The local limestone in Xi'an is selected, and the purity of calcium oxide is >90%. Ratio of high alumina coal to limestone: 8:2.

[0048] 2. Use ordinary ball milling method to crush, the ball milling speed is 150 rpm, and the ball milling is continued for 1 hour to prepare powder with an average particle size of less than 100 microns.

[0049] 3. The uniform powder feeding rate of the screw feeder is 300g / min, and the compressed air volume is 0.3m 3 / minute.

[0050] 4. The design height of the furnace is 3 meters, so that the residence time of the coal ash powder in the furnace is 1 second, and the temperature of the furnace is controlled at 1250 ° C to 1300 ° C.

[0051] 5. The fly ash collection device is a cyclone separation and cloth bag separation and an integrated collection device. This...

Embodiment 2

[0053] The difference between this example and Example 1 is that the ratio of high-alumina coal to limestone is 7:3, the mass ratio of calcium aluminate in the obtained alumina clinker reaches 20% to 24%, and the actual conversion rate of alumina clinker reaches 90%. %above.

Embodiment 3

[0055] The difference between this example and Example 1 is that the ratio of high-alumina coal to limestone is 5:5, the mass ratio of calcium aluminate in the obtained alumina clinker reaches 16% to 20%, and the actual conversion rate of alumina clinker reaches 90%. %above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com