A strip steel burr grinding device and debugging method for a finishing unit

A technology of finishing unit and debugging method, which is applied to machine tools suitable for grinding workpiece edges, parts of grinding machine tools, grinding machines, etc., can solve the problems of large space occupation, cumbersomeness, and single targeted design of grinding devices. , to achieve the effect of solving burr defects and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0119] In order to further illustrate the application process of the technology of the present invention, taking a process section of a finishing unit as an example, the debugging process and application effect of the unit applying the present invention are introduced in detail.

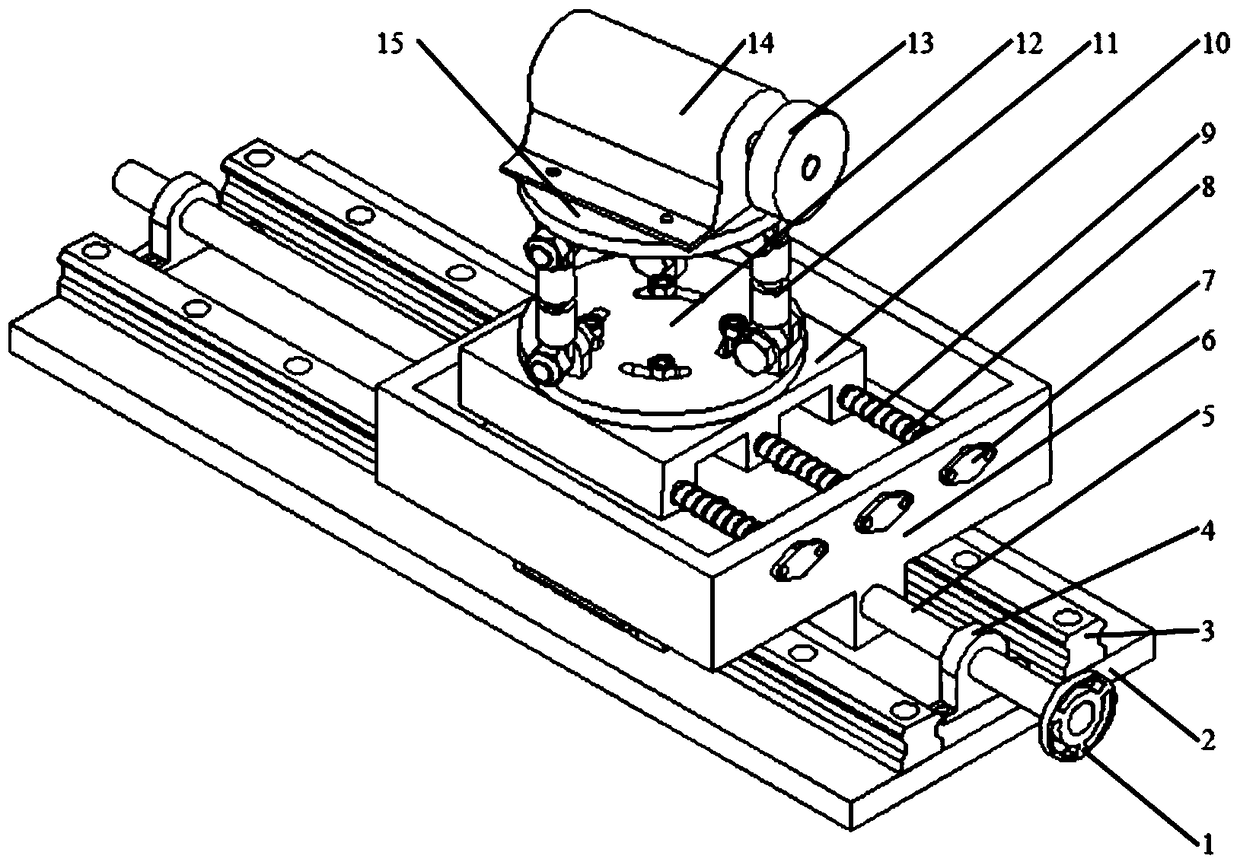

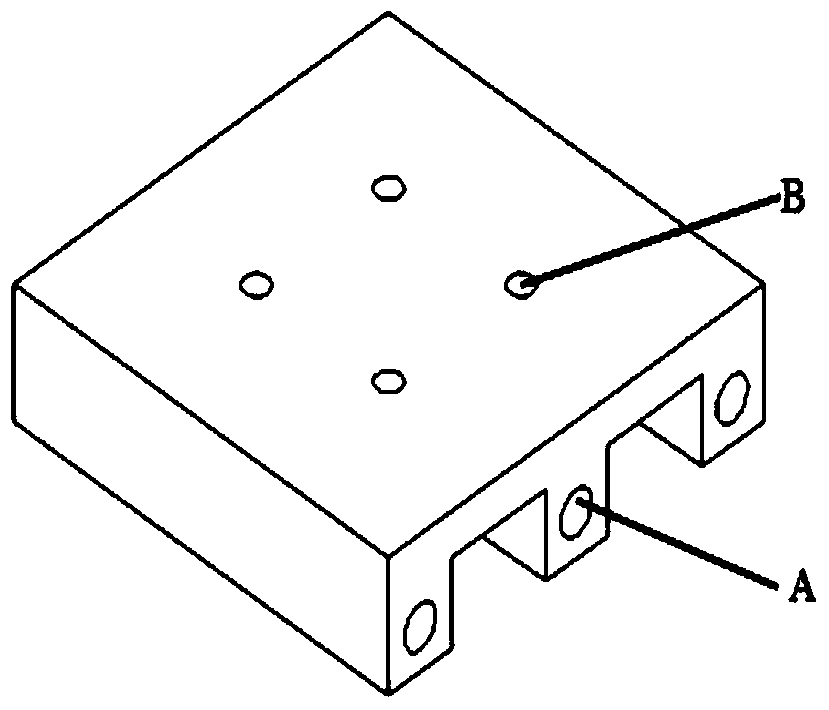

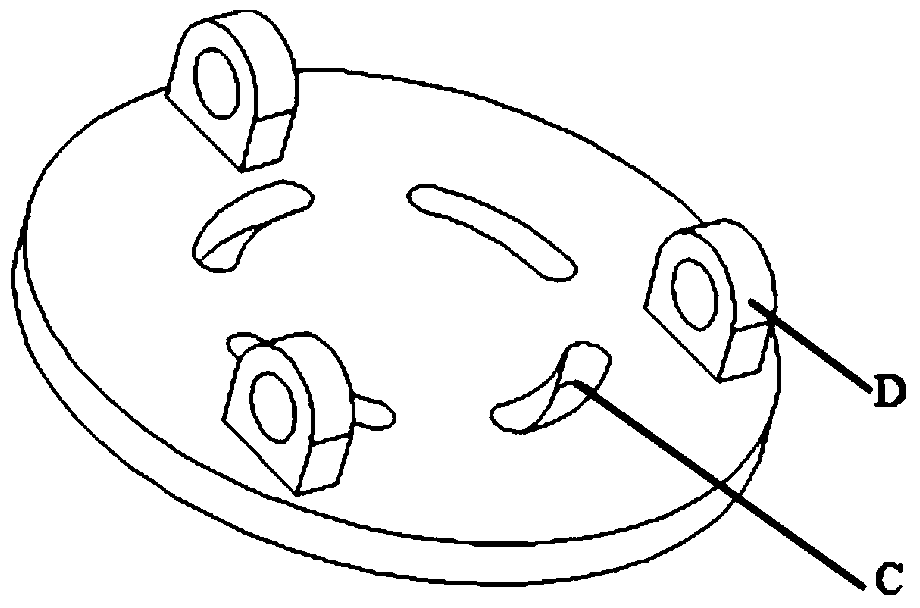

[0120] A strip steel burr grinding device for a finishing unit, comprising a horizontal feed mechanism, a horizontal angle adjustment and locking mechanism, a vertical angle adjustment and locking mechanism, and is arranged on the vertical angle adjustment and locking mechanism, The grinding wheel is used for grinding the strip burrs, and the strip steel burr grinding device is used to adjust the setting direction, inclination angle, direction, contact position, grinding pressure, etc. of the grinding wheel relative to the strip.

[0121] The transverse feed mechanism is used to enable the strip steel burr grinding device to run along the track, so that the grinding wheel can adapt to the change of st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com