Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

128results about "Settling tank with pump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Petroleum recovery and cleaning system and process

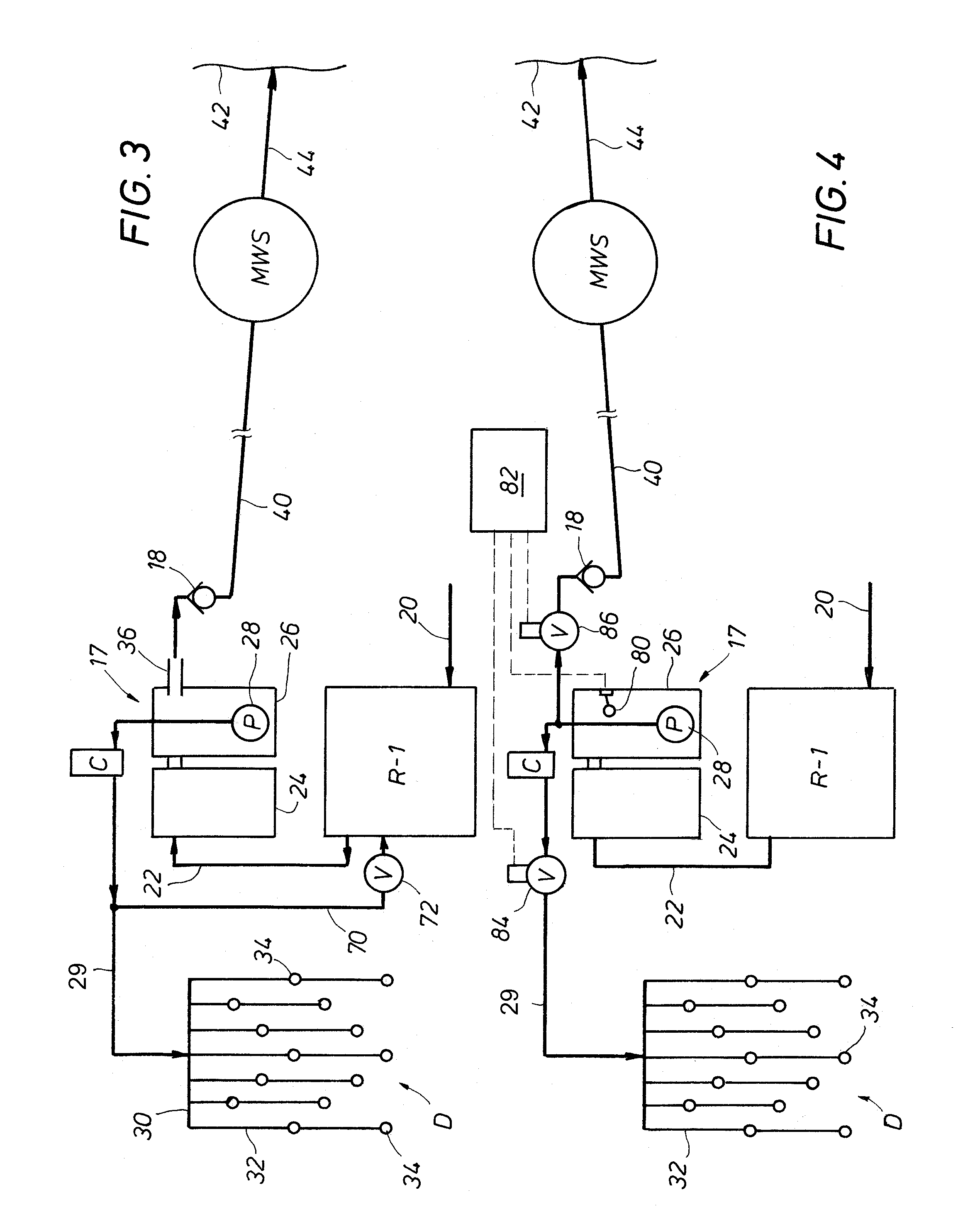

InactiveUS20050161372A1Enhancing petroleum recoveryIncrease productionInorganic/elemental detergent compounding agentsLiquid separation auxillary apparatusProcess equipmentPetroleum product

Owner:AQUA TECH LLC

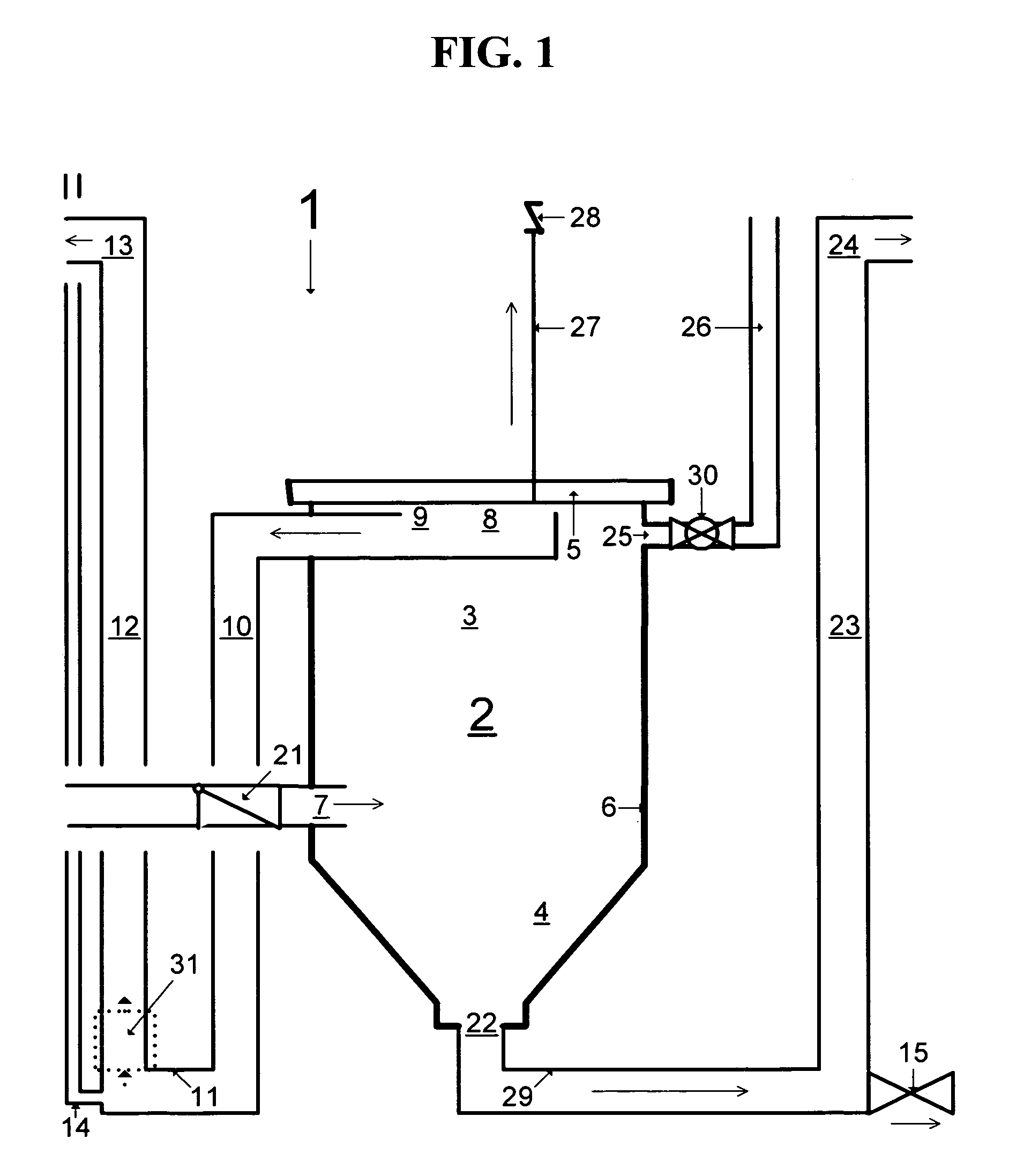

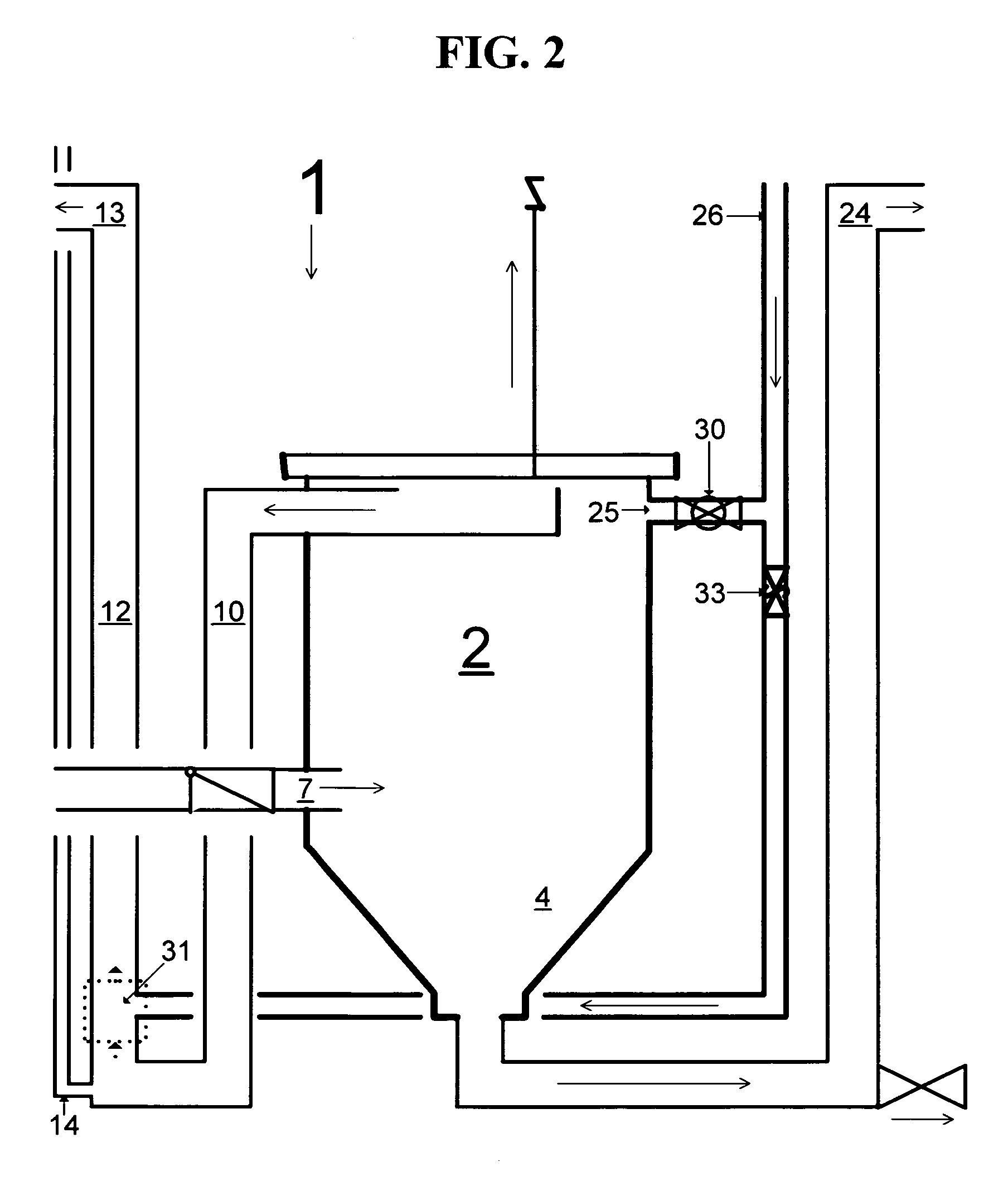

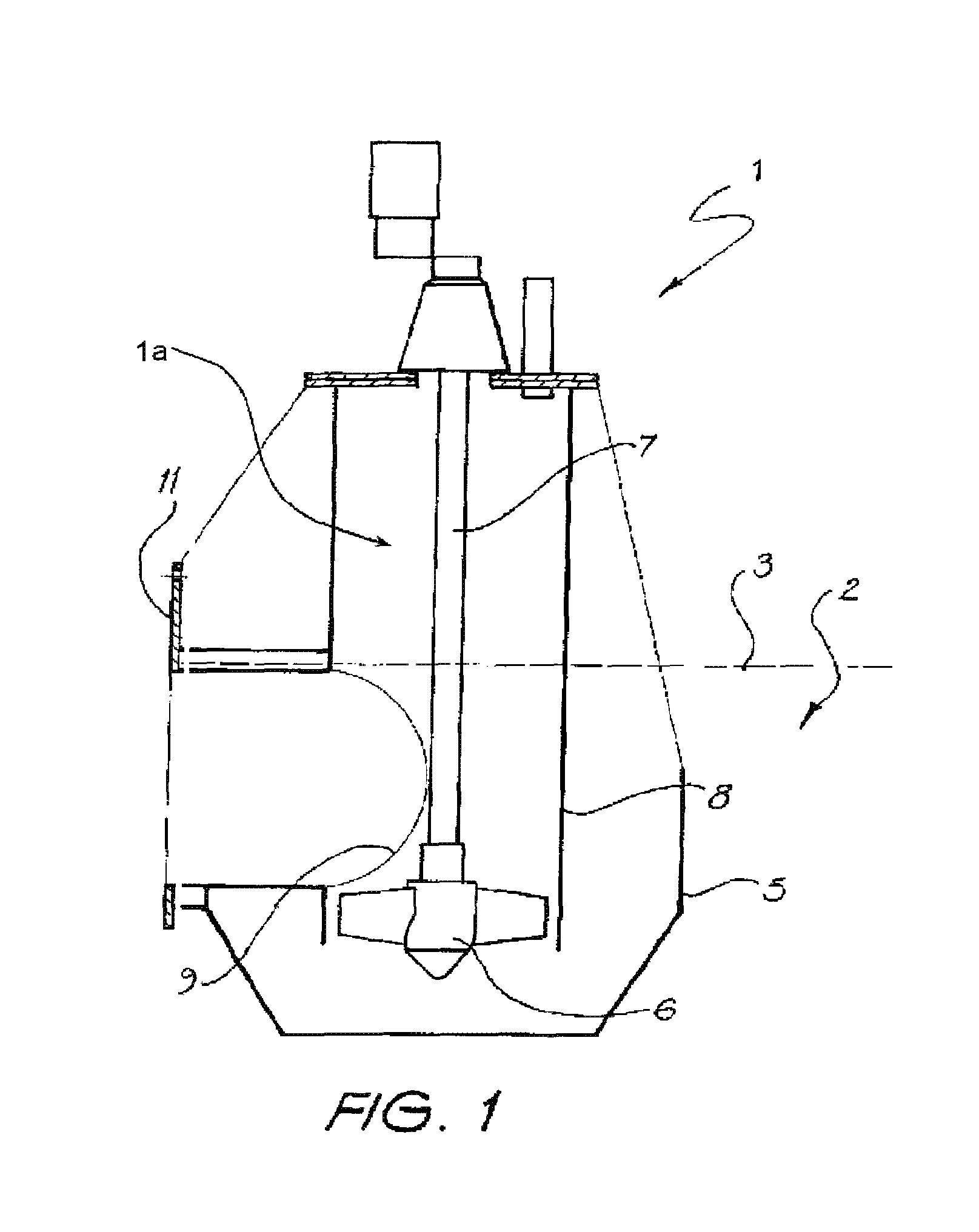

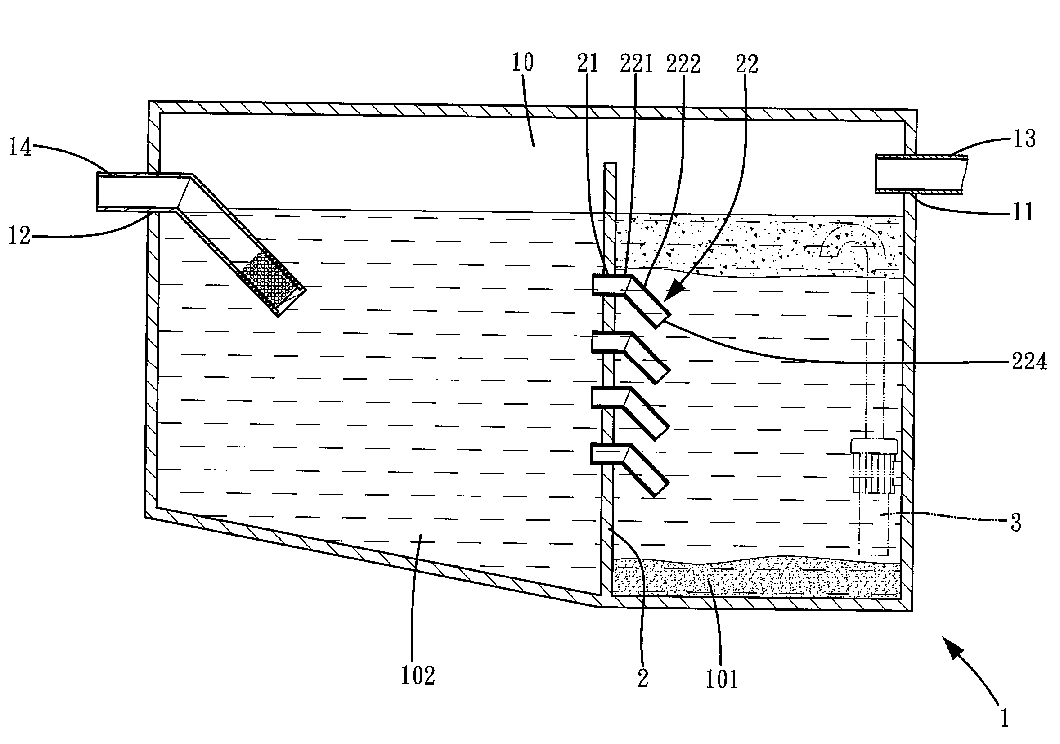

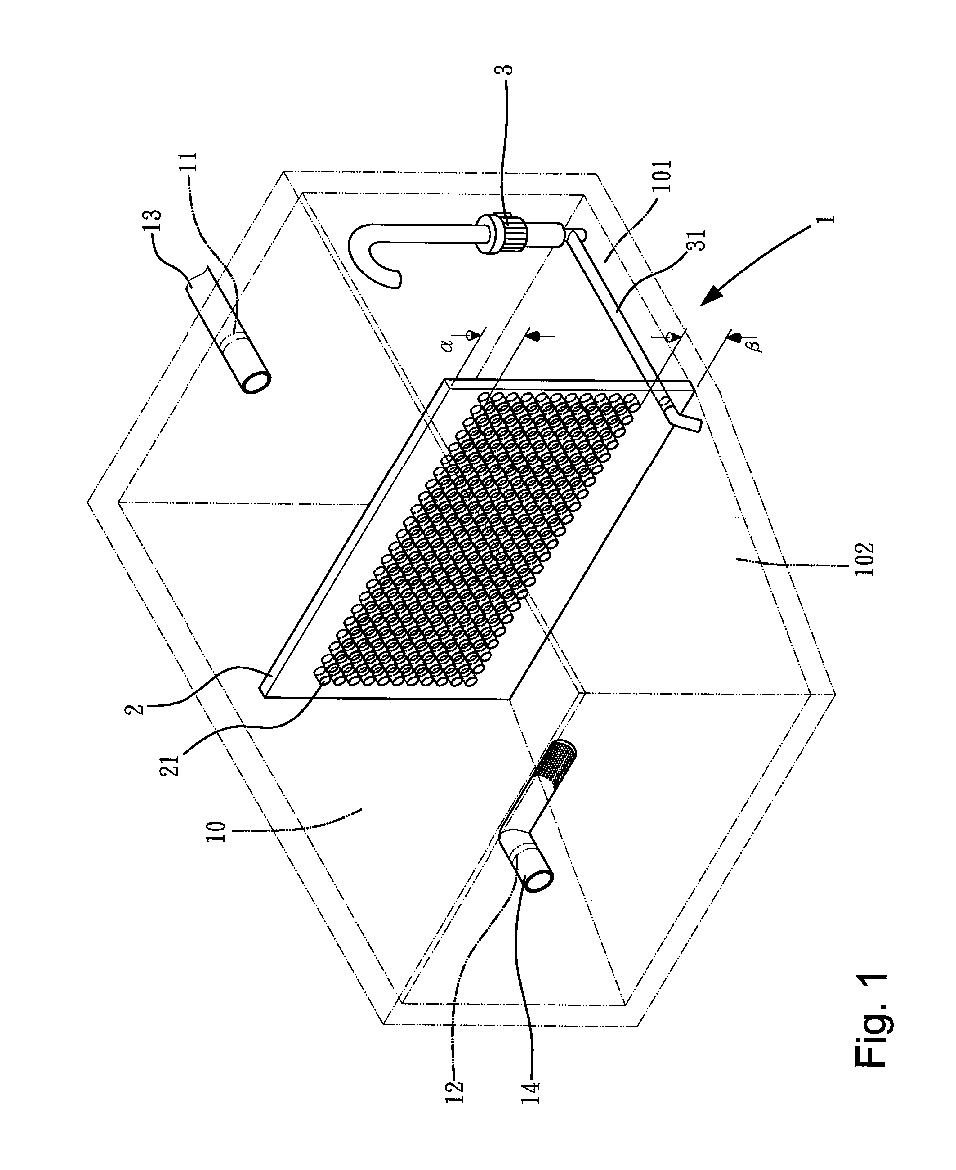

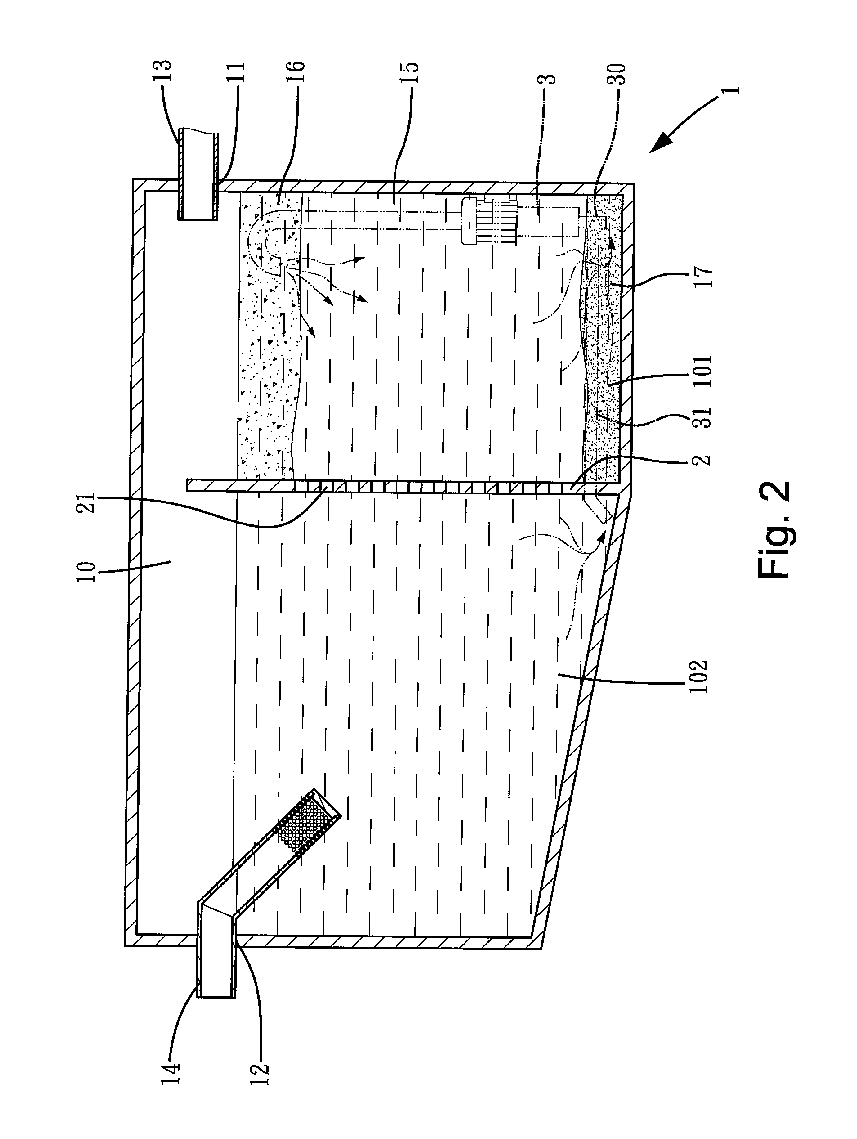

Apparatus and method of separating

InactiveUS7785479B1Low costImprove efficiencyWater/sewage treatment by centrifugal separationSettling tank with pumpOperational costsEngineering

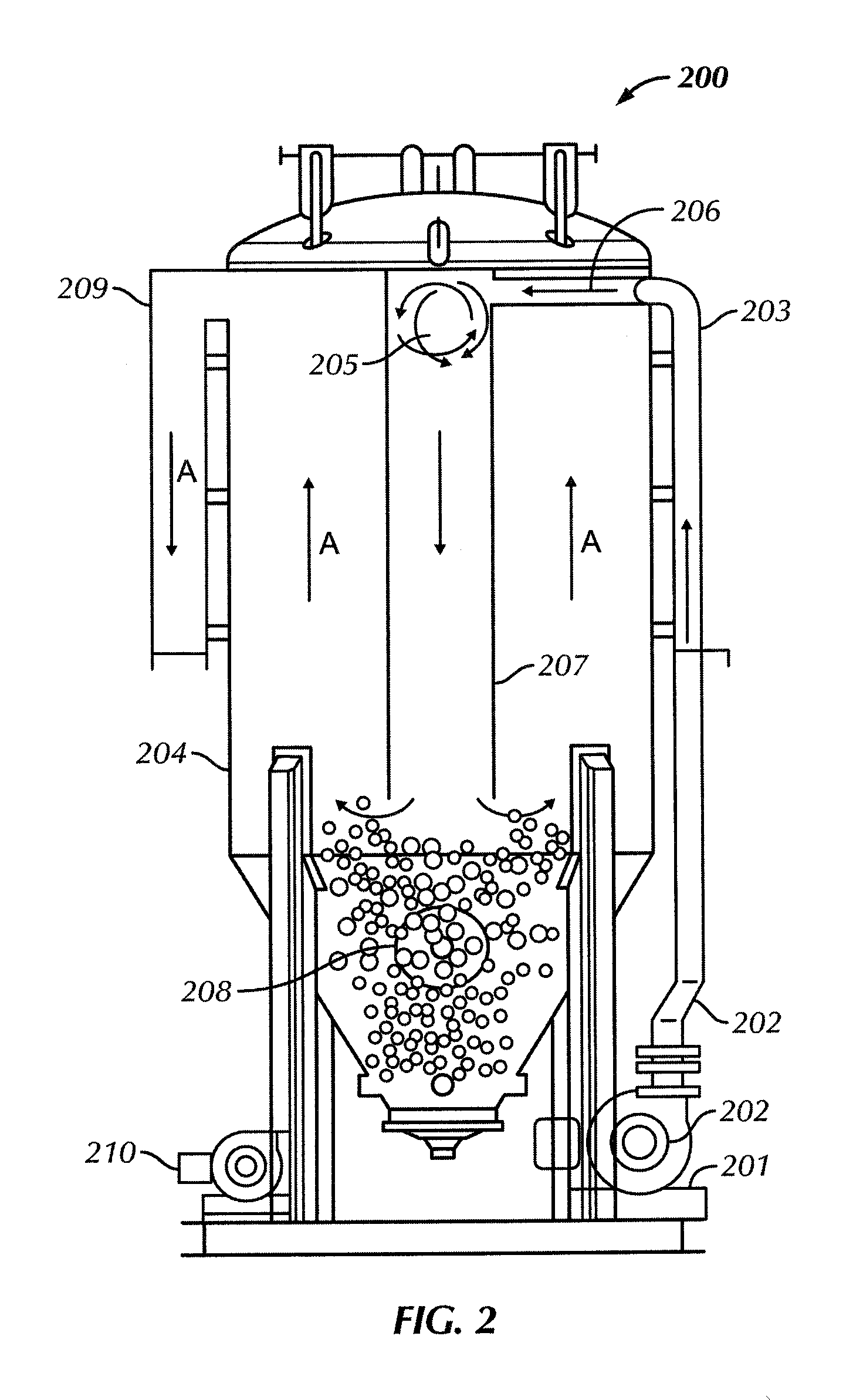

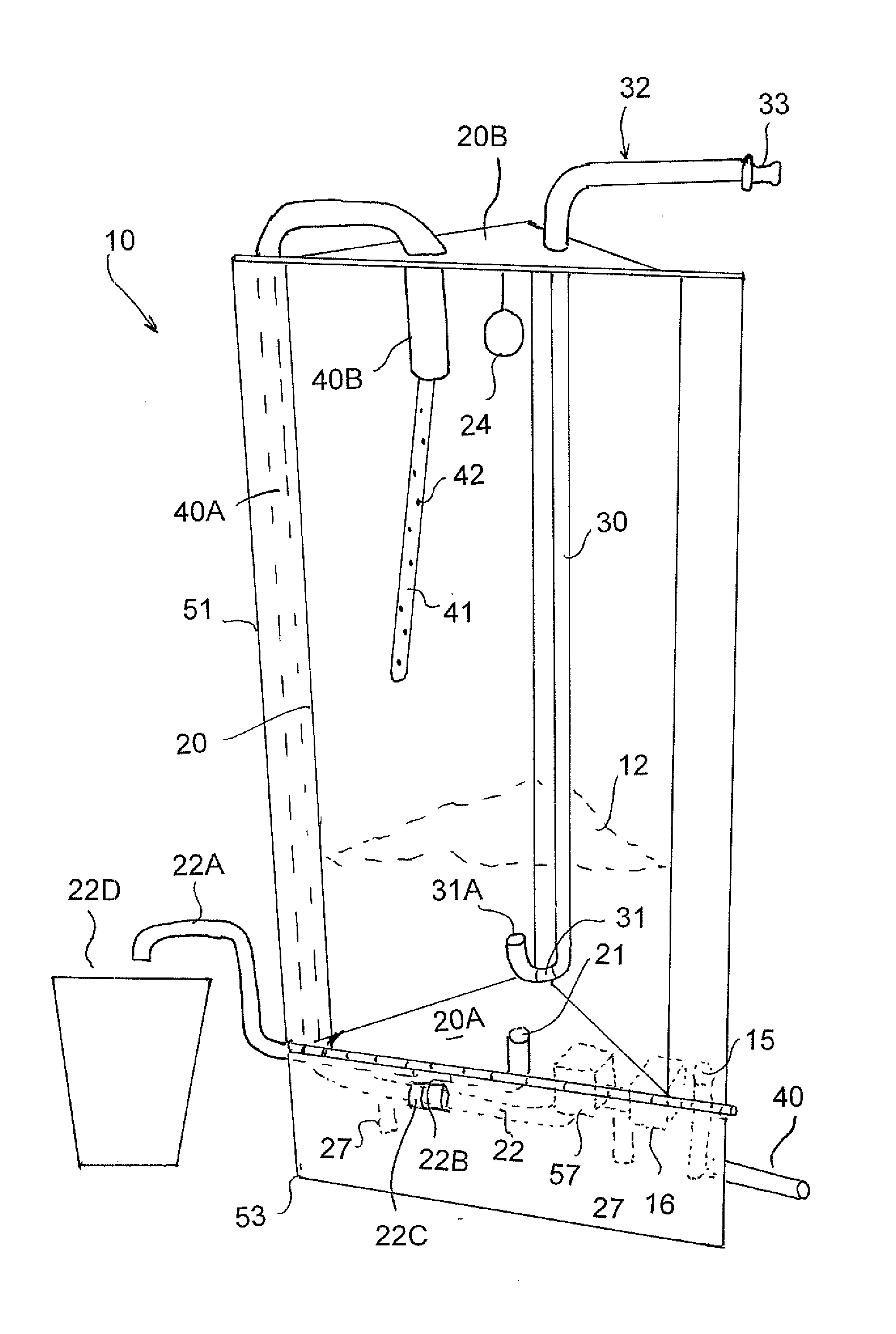

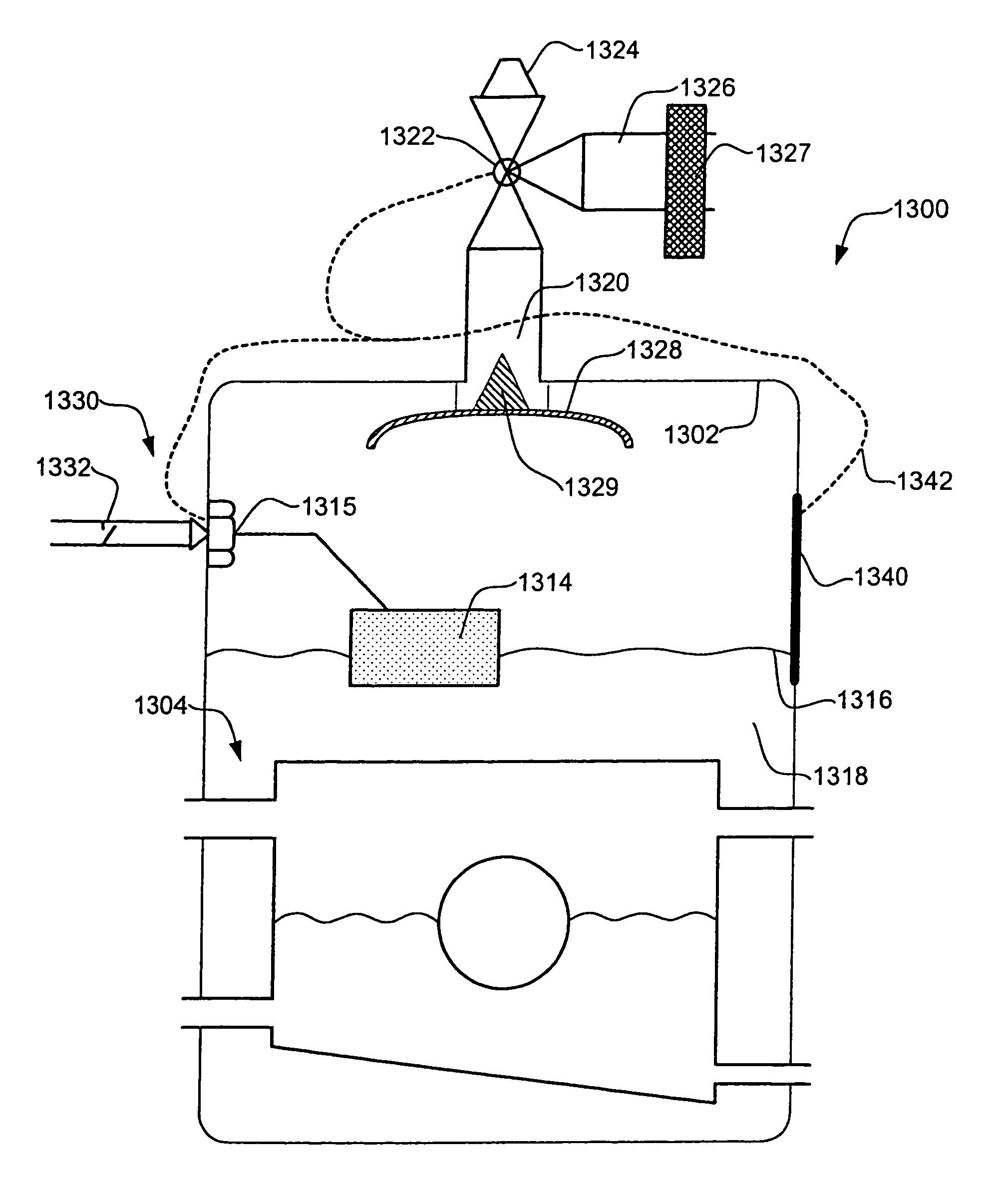

The present invention advances tank-based aquaculture by providing a low cost, high efficiency solid waste separator. The invention combines the simplicity of centrifugal-gravitational separation with the practicality of automatic separator cleaning. Low-pressure air from a blower or air pump induces water flow through the separator. The compressed air source is also used to purge accumulated sludge from the separator and to scour internal separator surfaces. Installation of a captive floating granular media bed within the separator further stabilizes the centrifugal flow pattern, enhances the scouring action during sludge flushing events, and provides substrate for nitrifying bacteria colonization. Separator purging and scouring processes are simply and easily automated with small, low-voltage electric valves and timers. Operational cost-savings are magnified in multiple tank systems where multiple separators are operated by a centralized compressed air system and controller.

Owner:HOSFORD MICHAEL HAYS

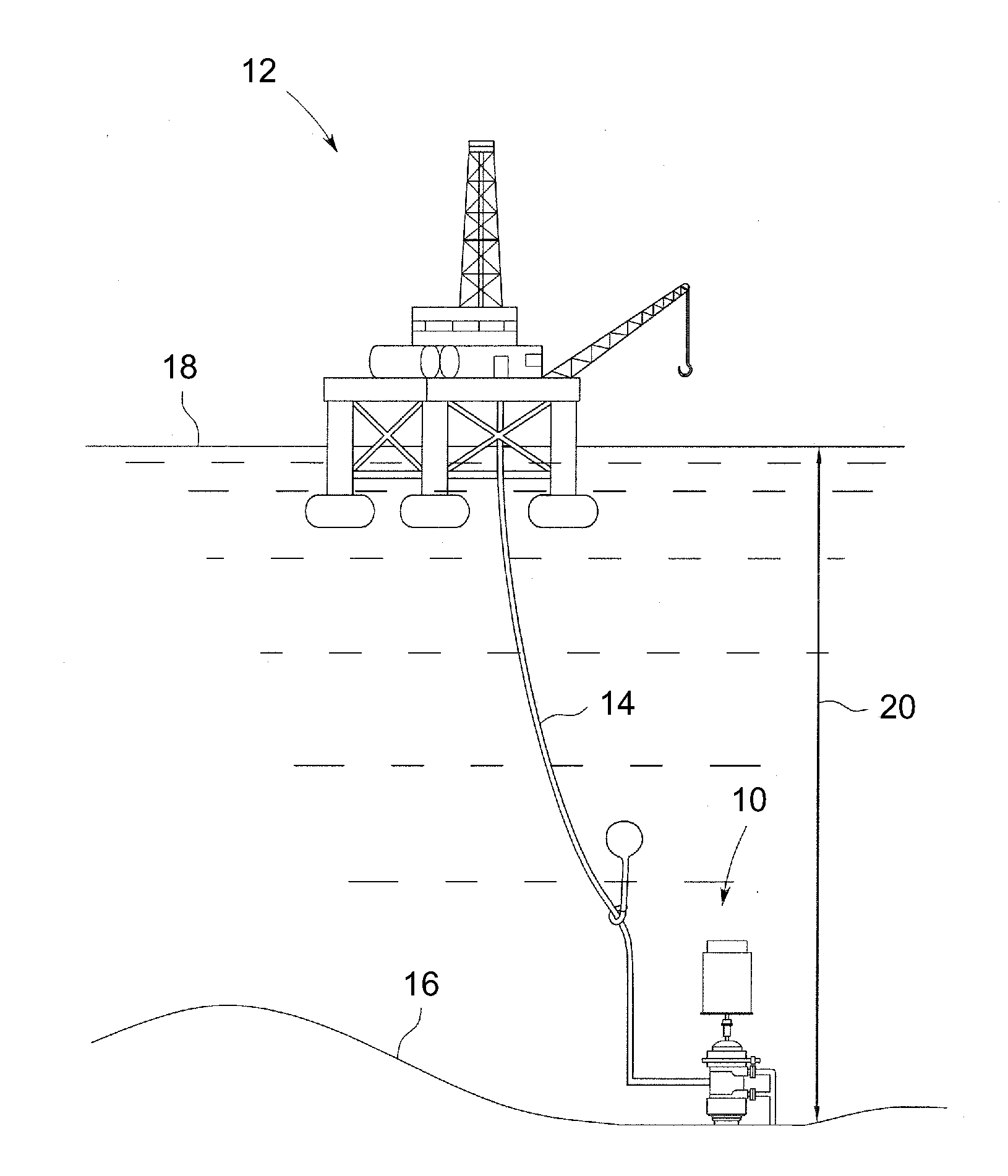

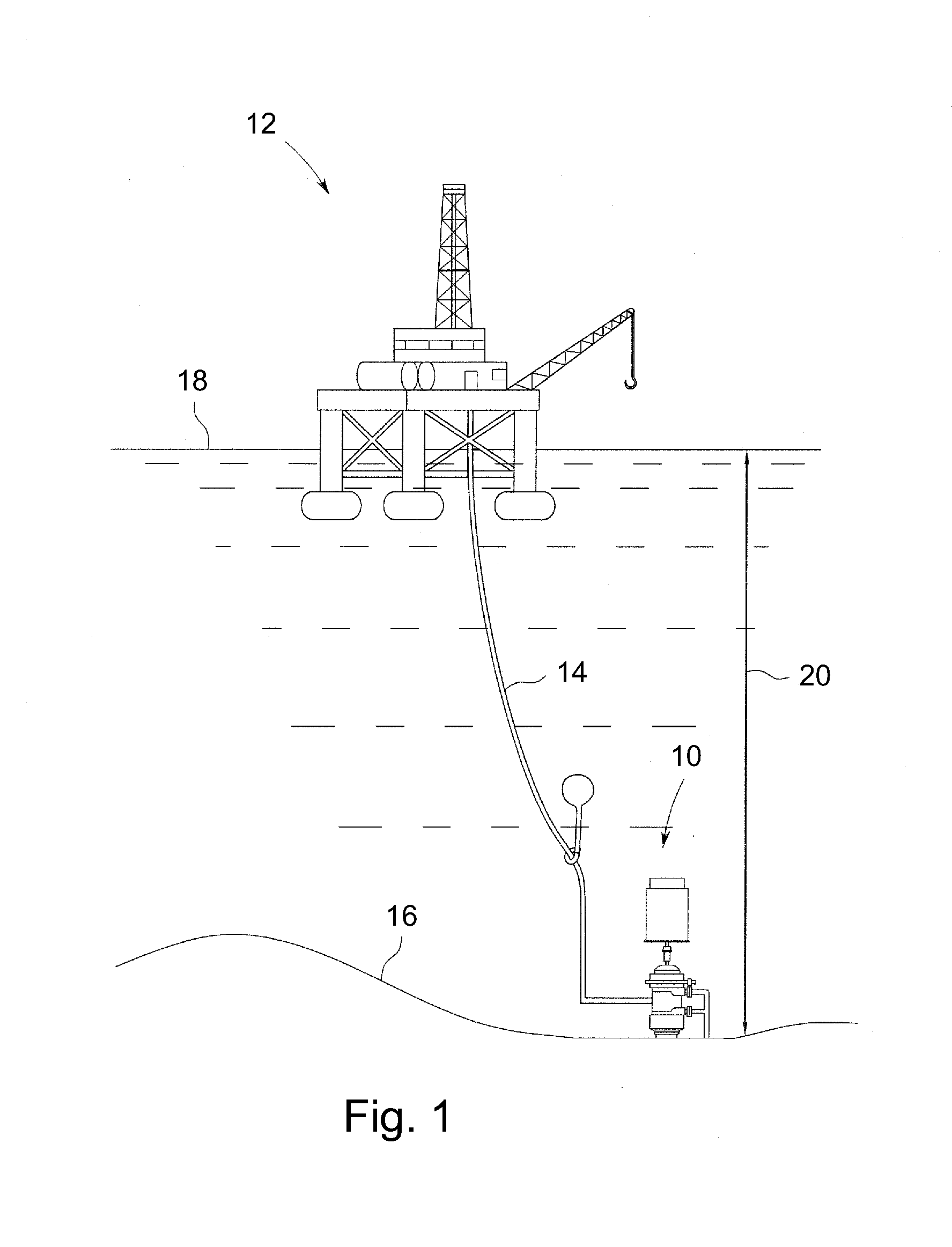

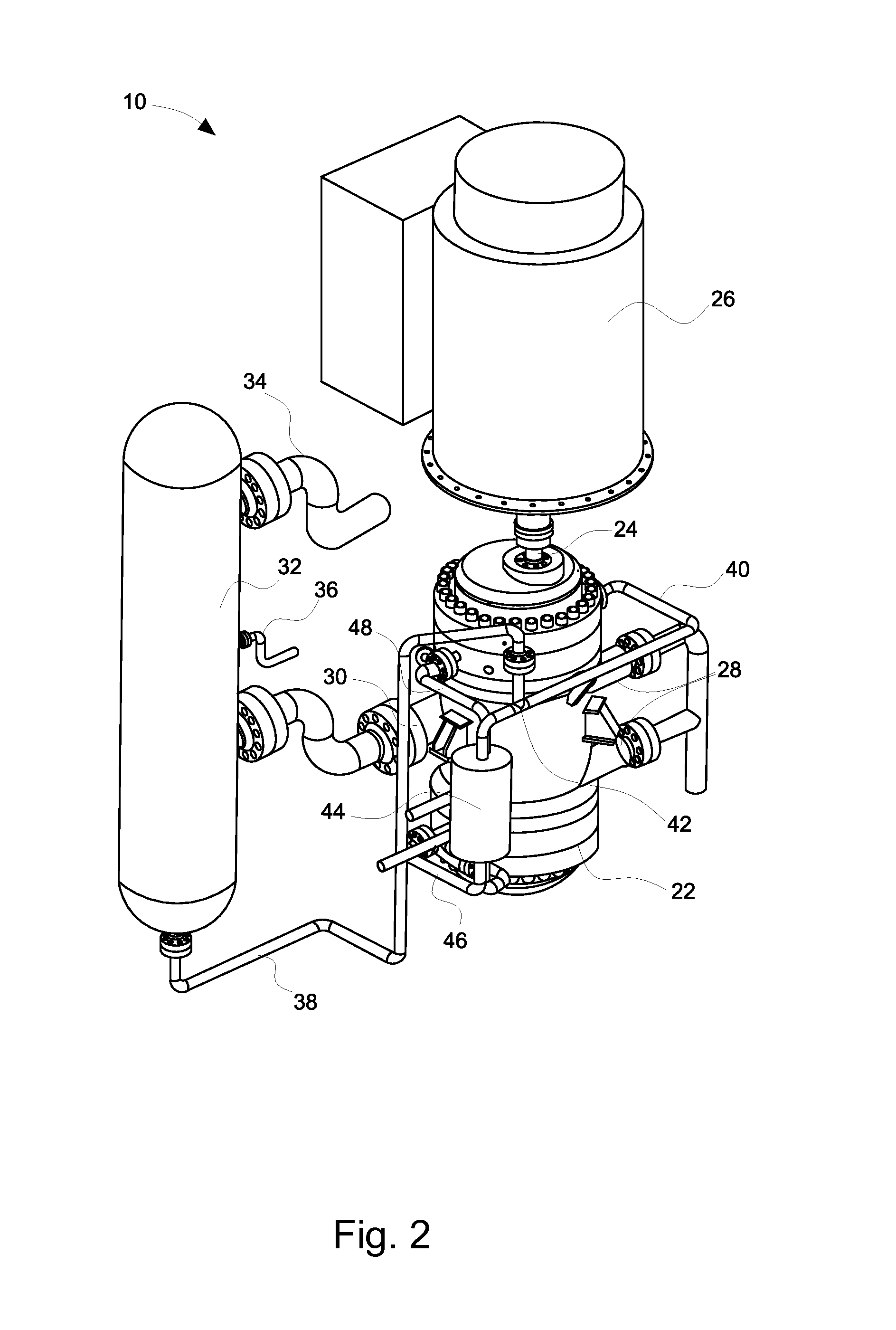

System and method for multiphase pump lubrication

ActiveUS20120048113A1Easy to separateMaintain volumeLiquid degasificationWell/borehole valve arrangementsGas phaseEngineering

A subsea system includes a multiphase pump, configured to transfer a multiphase fluid and a multiphase separator, configured to separate the multiphase fluid into solid, liquid, and gaseous phases. The multiphase separator includes a solid-liquid separation device, which is configured to facilitate separation of the solid phase and the liquid phase from the multiphase fluid. The multiphase separator includes a gas-liquid separation device, which is configured to facilitate separation of the gaseous phase and the liquid phase from the multiphase fluid. The multiphase separator includes a liquid reservoir, which is configured to contain a volume of the liquid phase to be used as a lubricant for the multiphase pump. Finally, the multiphase separator includes a liquid outlet, which is configured to transfer the liquid phase from the liquid reservoir to the multiphase pump.

Owner:VETCO GRAY SCANDINAVIA

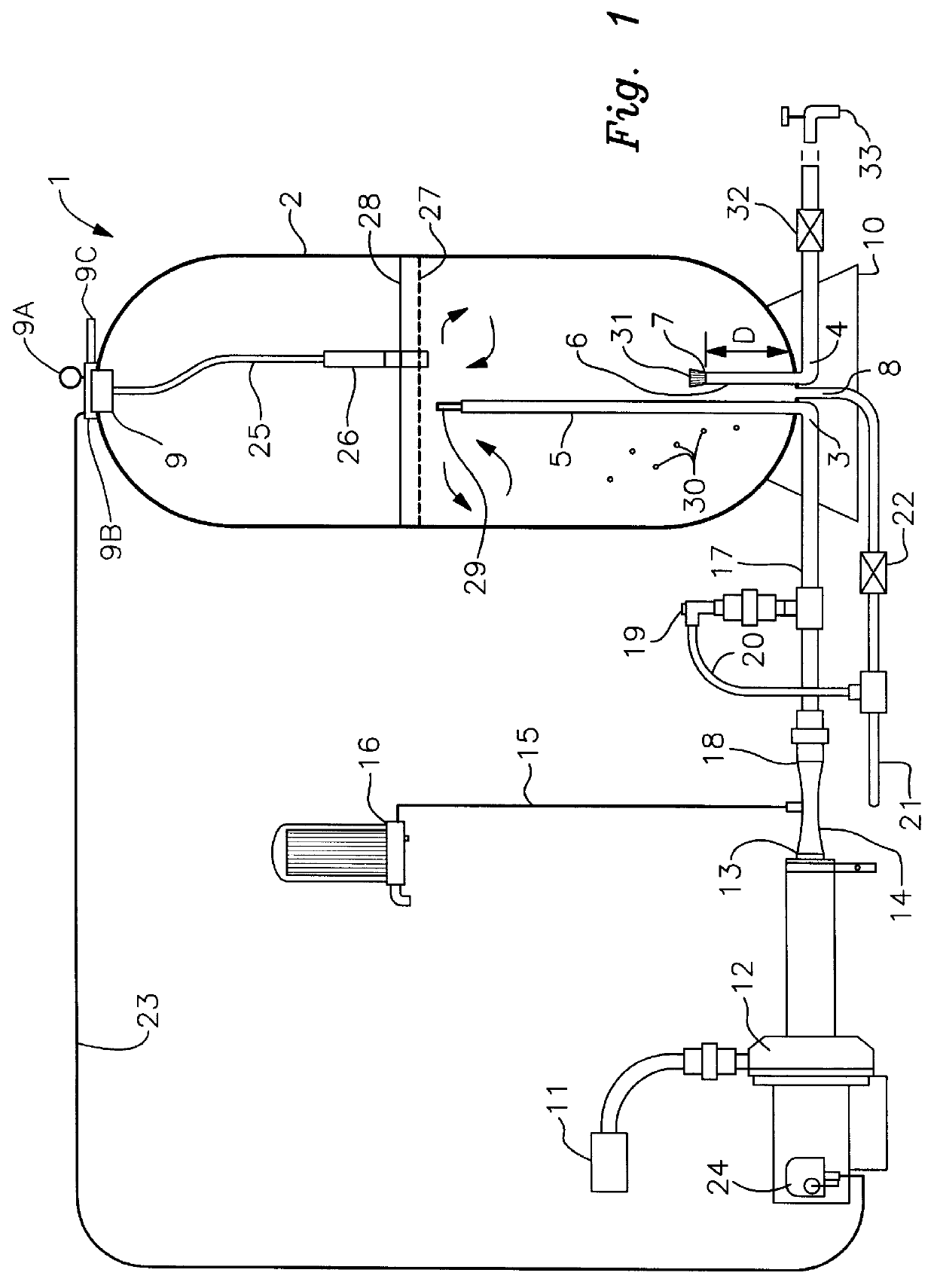

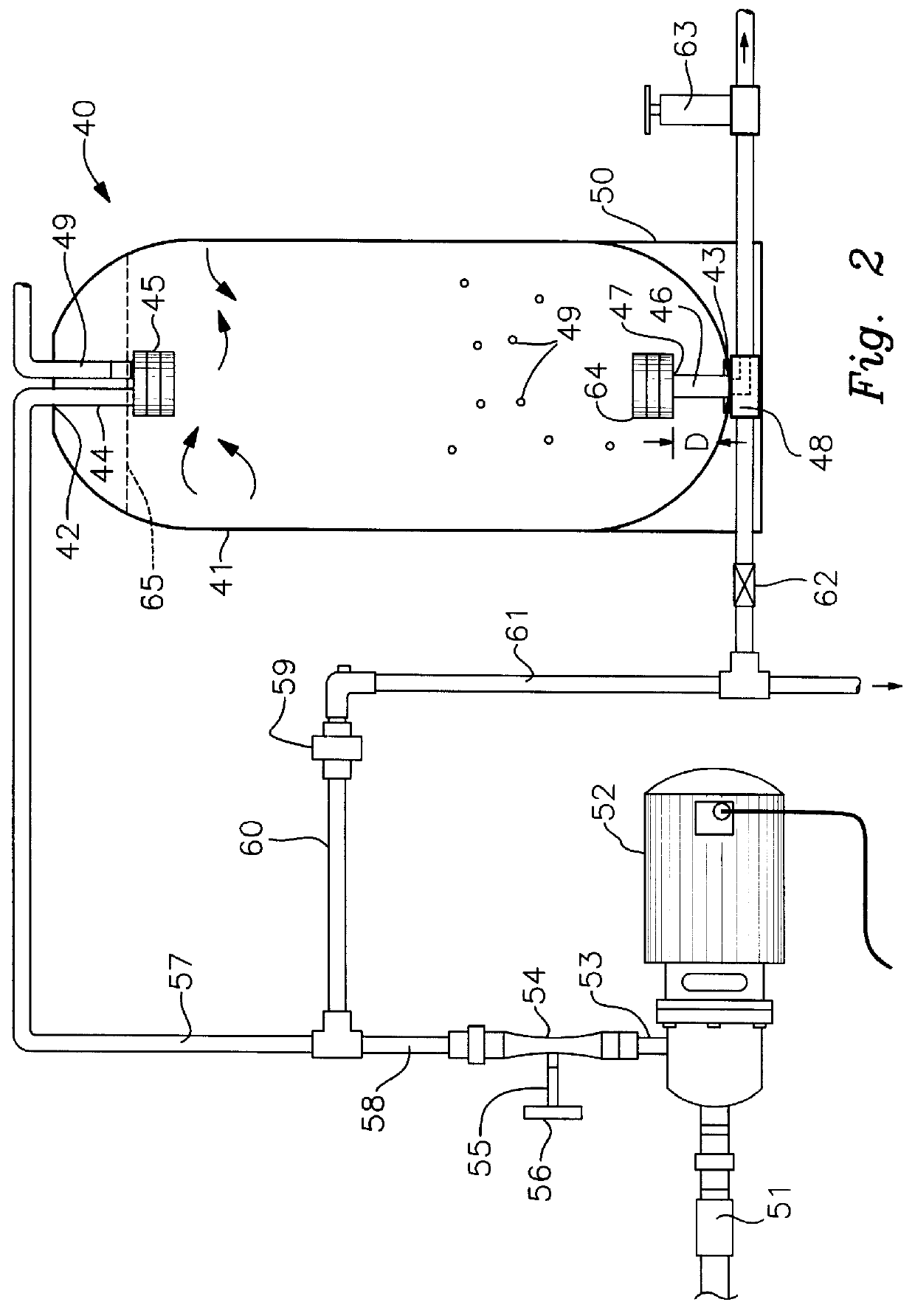

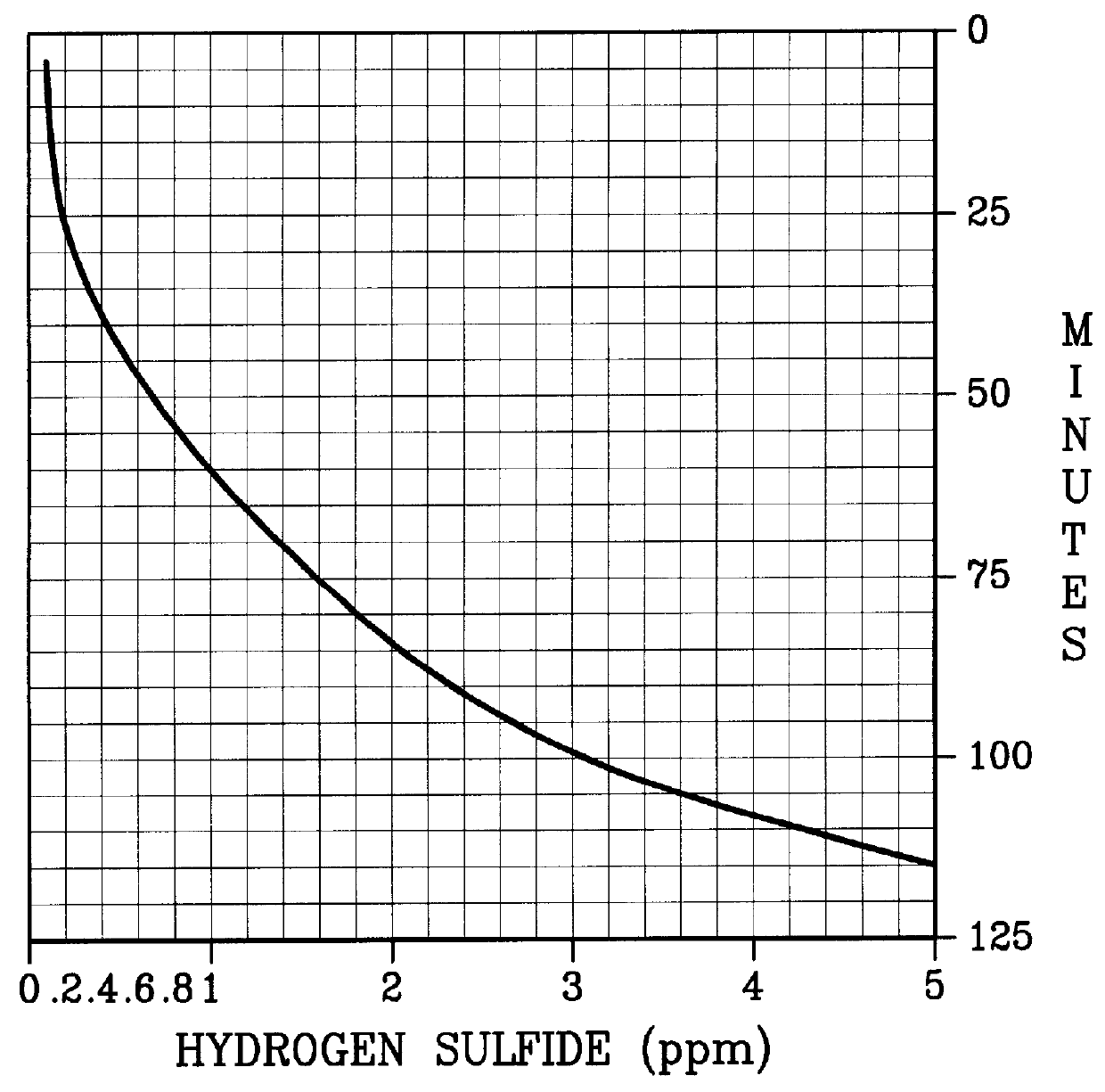

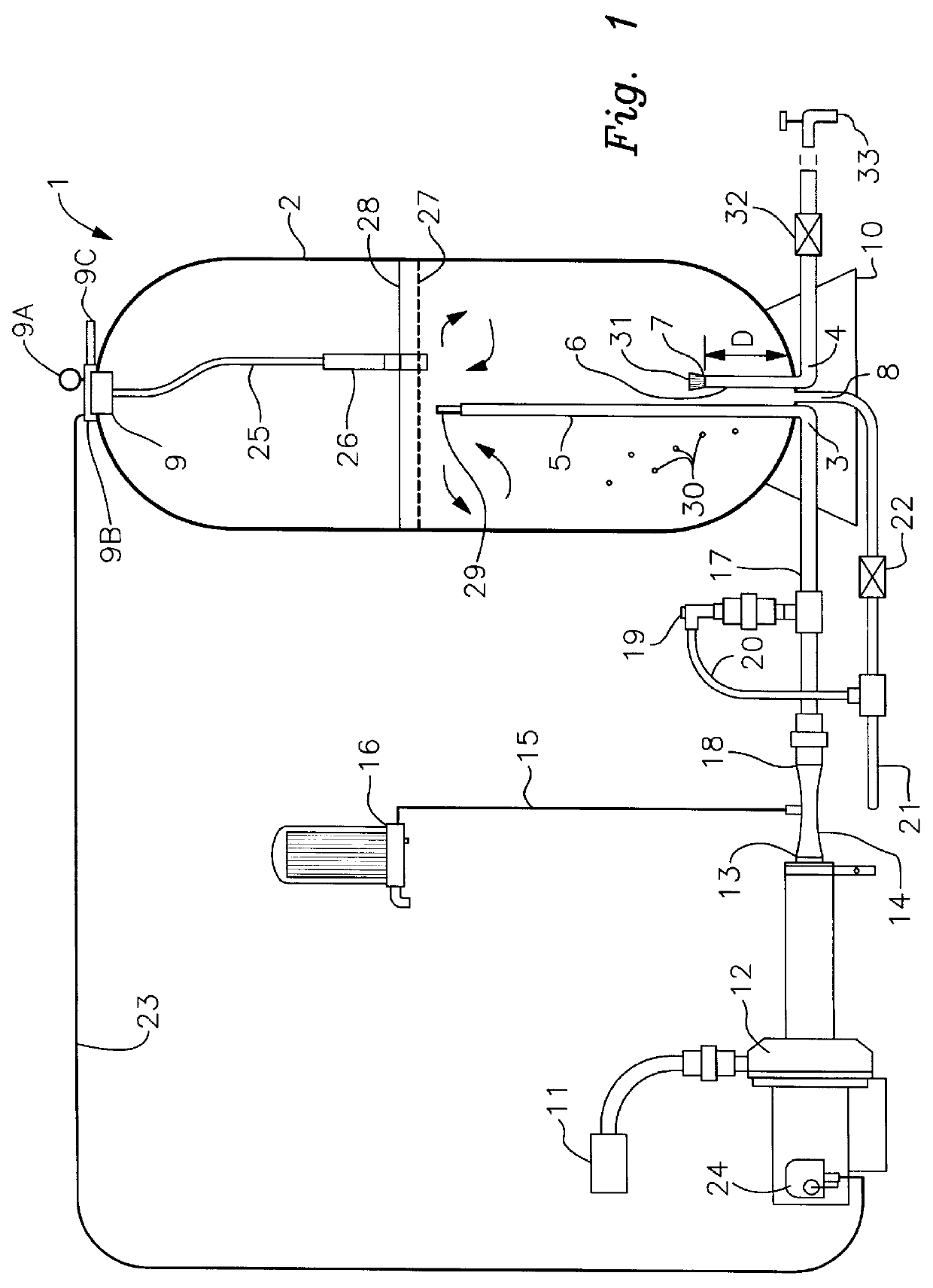

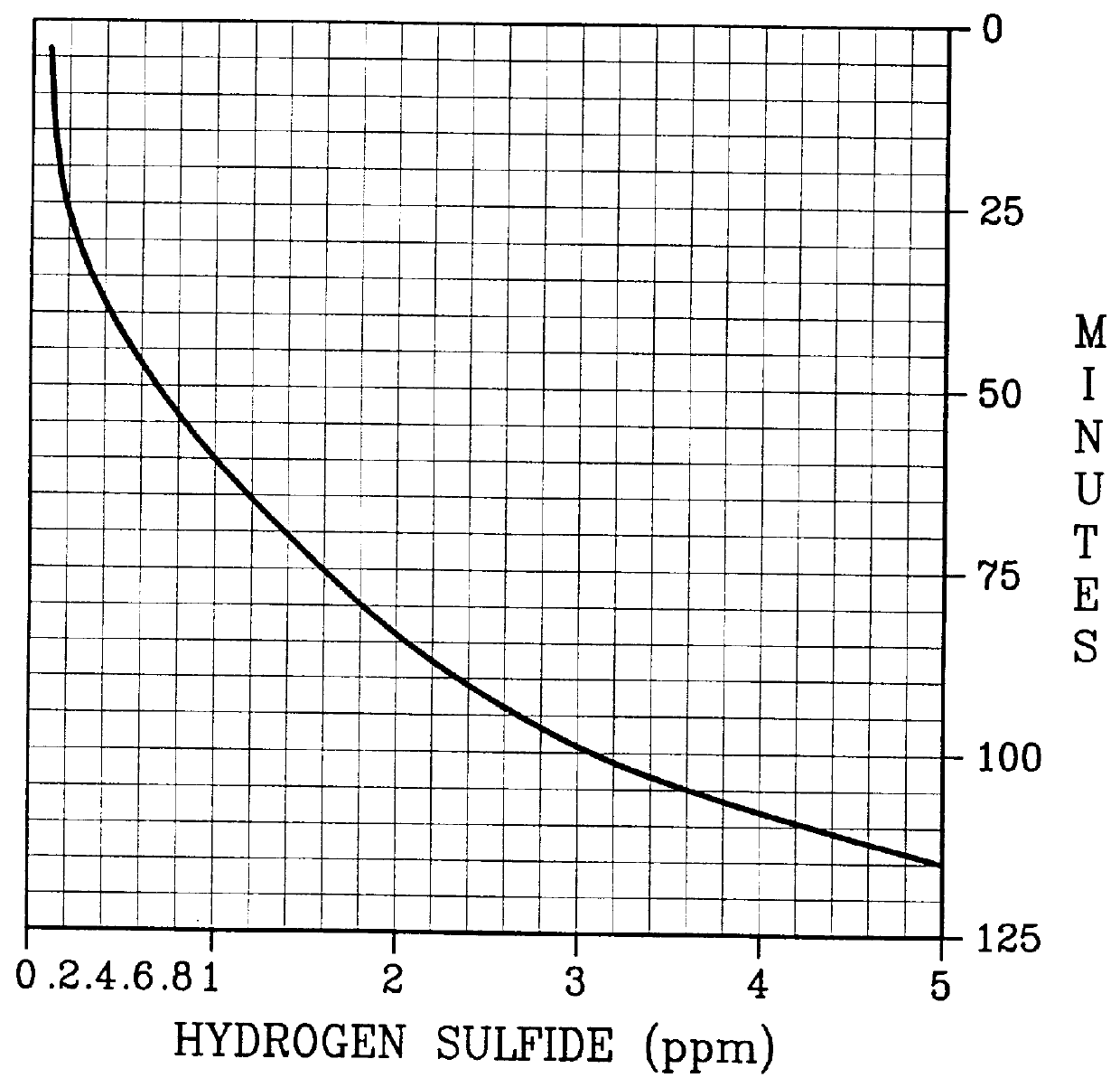

Hydrogen sulfide removal apparatus

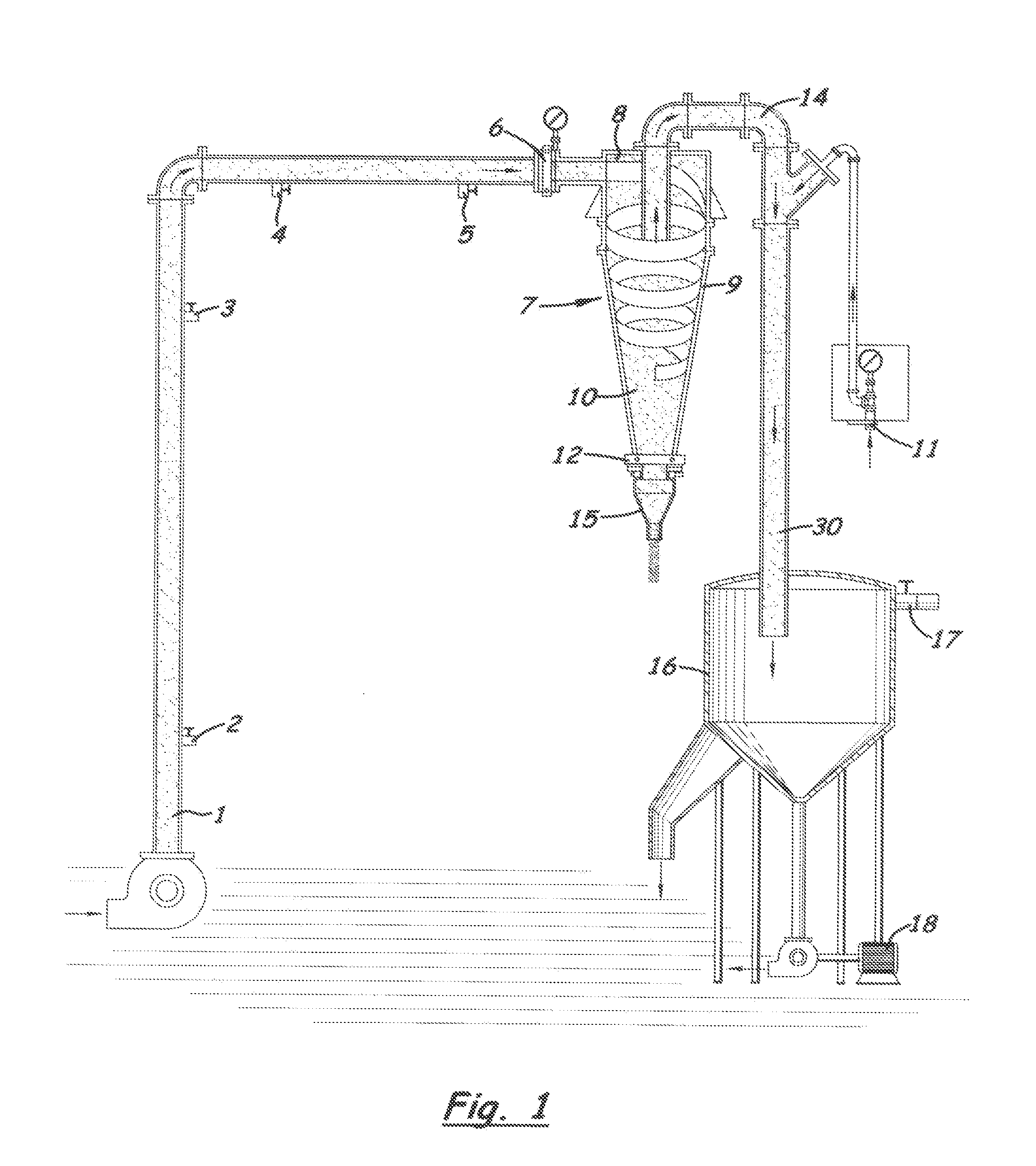

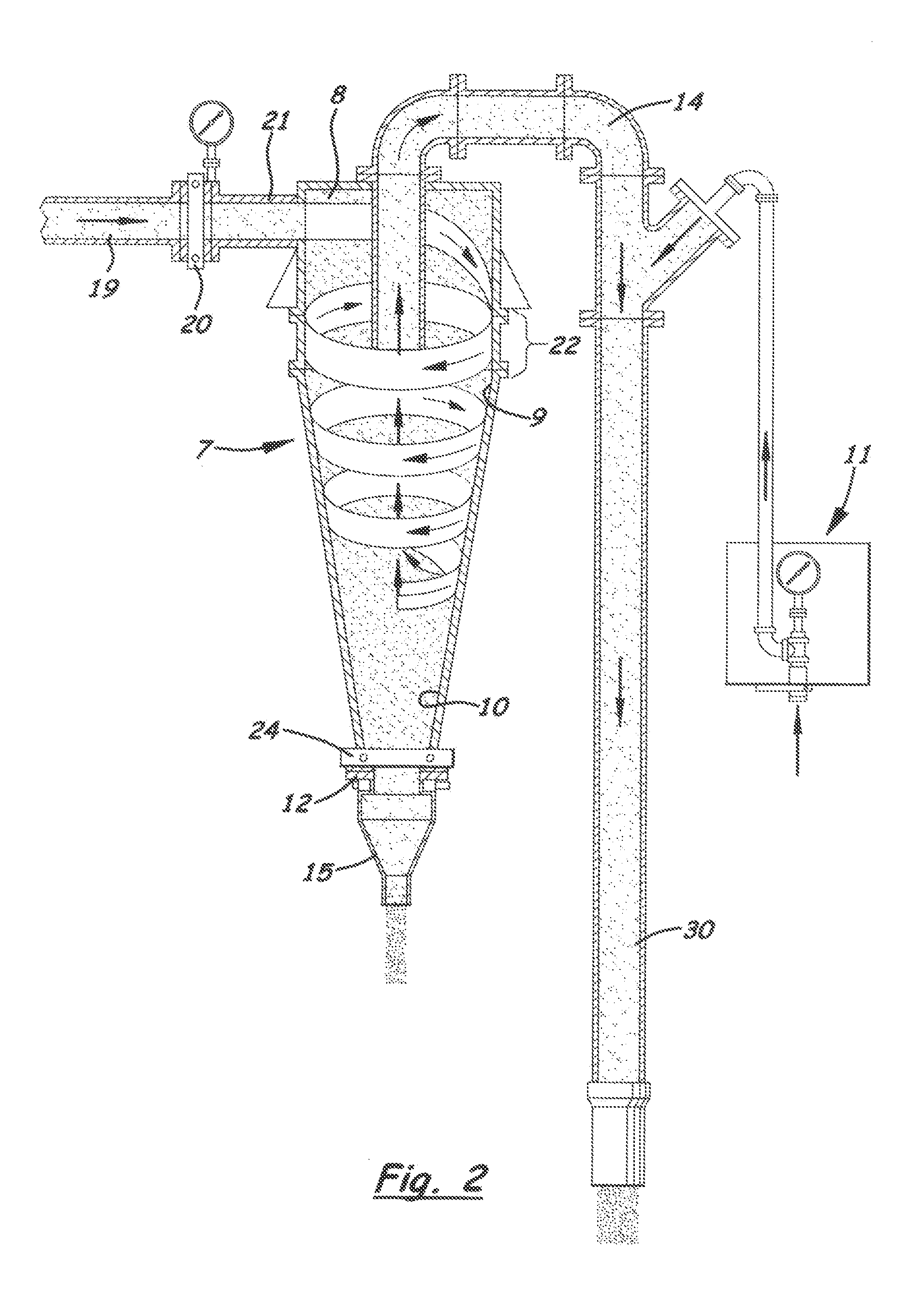

InactiveUS6080306APrevents short cyclingSafely precipitate hydrogen sulfideFlow mixersUsing liquid separation agentSufficient timeSolid particle

Owner:FALKNER KEMP E

Method for enhancing cyclonic vessel efficiency with polymeric additives

InactiveUS7153436B2Increase contactReduce particle residueWater/sewage treatment by centrifugal separationSettling tank with pumpVolumetric Mass DensityEngineering

The present invention is directed to a novel method and system for enhancing the efficiency of hydraulic centrifugal separators (cyclones) in the removal of fine size particles from a liquid carrying medium. More particularly, it is concerned with improvements in the removal efficiency of any number of cyclonic devices that rely on the use of centrifugal force to separate fine size particles of differing density from the liquid carrying medium by addition of polymeric additives, both before, and, as necessary, inside the cyclone body.

Owner:BAIR PATRICK W +1

Apparatus for and method of settling of mineral slurries

InactiveUS6936178B2Improve gravity settler designSimple designFloating sedimentation devicesSettling tank with pumpLiquid layerReciprocating motion

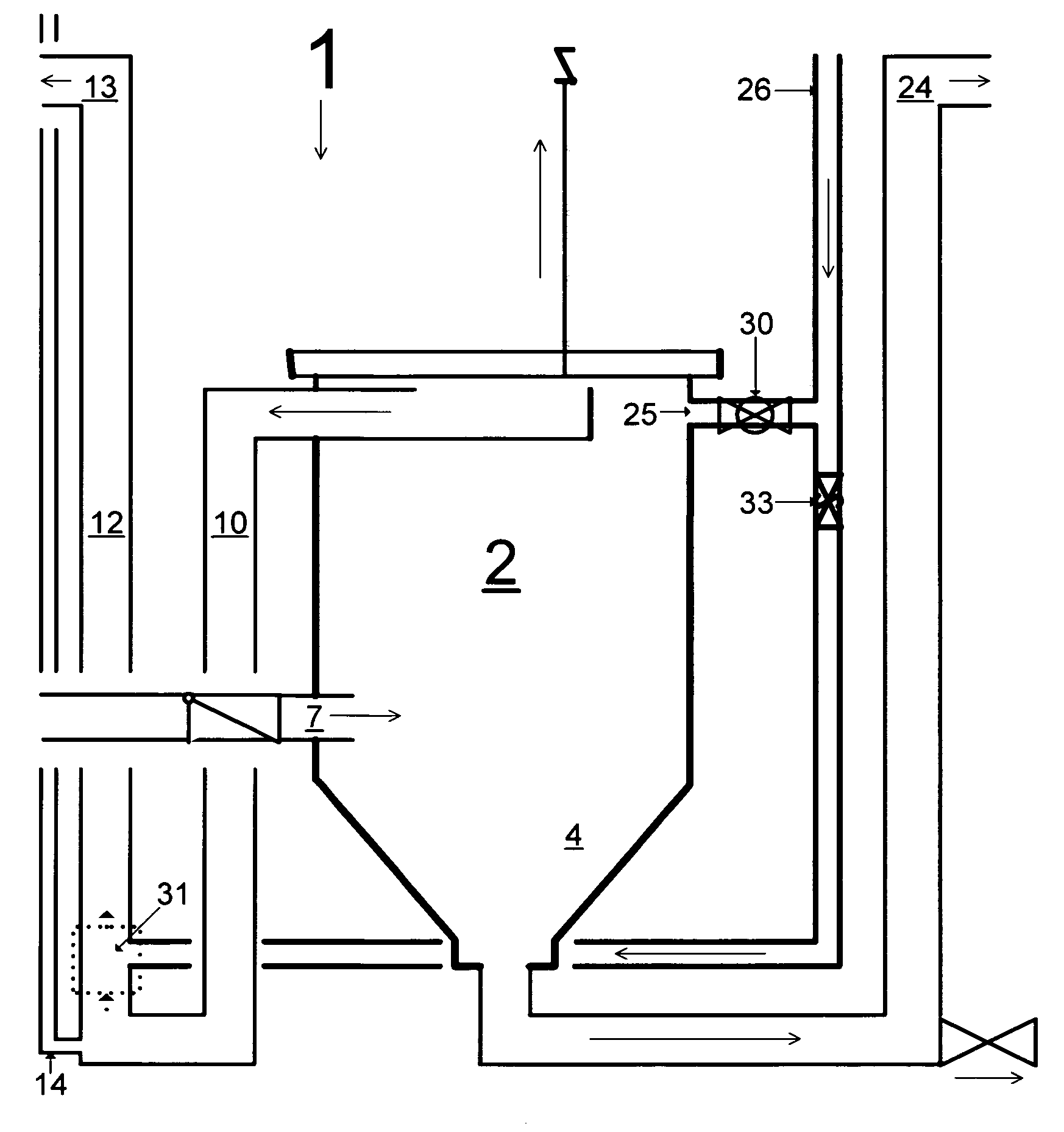

The invention relates to a settler for decanting mineral slurries and a method thereof. The settler comprises a tank for holding and decanting a body of slurry to form a thickened slurry as a lower layer and a clarified liquid as an upper layer, the tank having a side wall, a bottom and a top, an outlet for the thickened slurry at the bottom of the tank, an outlet for the clarified liquid layer near the top of the tank, a slurry inlet means near the top of the tank for introducing fresh slurry into the tank, the slurry inlet means having a slurry opening through which fresh slurry joins the body of slurry in the tank, and a stirrer having a generally vertical axis around which the stirrer rotates or reciprocates. The slurry opening is displaced laterally relative to the generally vertical axis of the stirrer and the slurry inlet means is configured to allow the fresh slurry to enter the slurry body without accumulating solids from the fresh slurry at the slurry opening.

Owner:ALCAN INT LTD

Method and apparatus for treating water or wastewater to reduce organic and hardness contamination

A method of treating liquid including mixing coagulant with the liquid, introducing mixed coagulant and liquid into a primary reaction zone, containing an agitator, of a reactor which is substantially concentrically positioned with respect to a secondary reaction zone of the reactor, introducing flocculant into the primary reaction zone at a location between the agitator and where the mixed coagulant and liquid are introduced into the primary reaction zone, mixing the mixed coagulant and liquid with the flocculant and causing the resulting mixture to flow into the secondary reaction zone, introducing an encapsulating agent into the secondary reaction zone, recirculating the liquid and encapsulated flocs through the primary and secondary reaction zone, and passing the liquid and encapsulated flocs outwardly of the reactor, and an apparatus for treating liquids including a reactor, a draft tube substantially concentrically positioned within the reactor and being positioned such that the liquids may flow inwardly and outwardly of the draft tube from opposed end portions of the draft tube, wherein space inwardly of the draft tube forms a primary mixing zone and space in the reactor, but outwardly of the draft tube forms a secondary mixing zone, an agitator positioned within the draft tube, an inlet positioned approximate one end portion of the draft tube which introduces liquid and coagulant into the primary mixing zone, an inlet connected to the draft tube and positioned between the agitator and the end portion of the draft tube through which coagulant and liquid are introduced into the primary mixing zone, an encapsulating agent inlet positioned in the secondary reaction zone between the opposed end portions of the draft tube, and an outlet downstream of the encapsulating agent inlet.

Owner:INFILCO DEGREMONT INC

Dewatering system

A system for processing drilling mud, the system including a primary separation tank having an inlet for receiving drilling waste and an outlet in fluid communication with a feed line, and an injection pump in fluid communication with a polymer tank and the feed line. The system also includes a clarifying tank in fluid communication with the feed line and a first collection tank, wherein effluent from the clarifying tank is discharged into the first collection tank, and a centrifuge in fluid communication with the clarifying tank and a second collection tank, wherein effluent from the centrifuge is discharged into the second collection tank.

Owner:MI

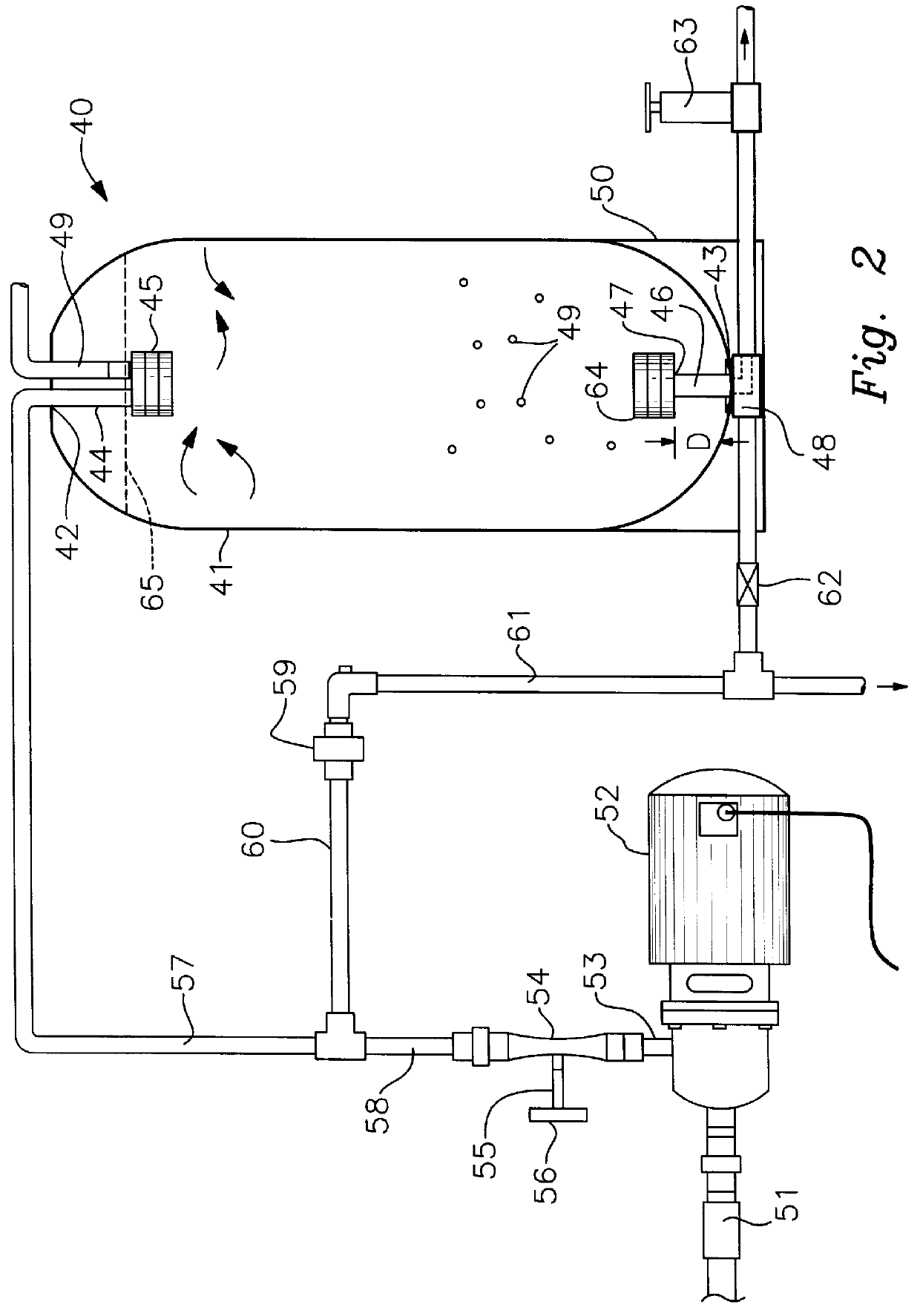

Hydrogen sulfide removal methods

InactiveUS6074562ASafely precipitateEasy to installSettling tank with pumpWater contaminantsSufficient timeSolid particle

Owner:FALKNER KEMP E

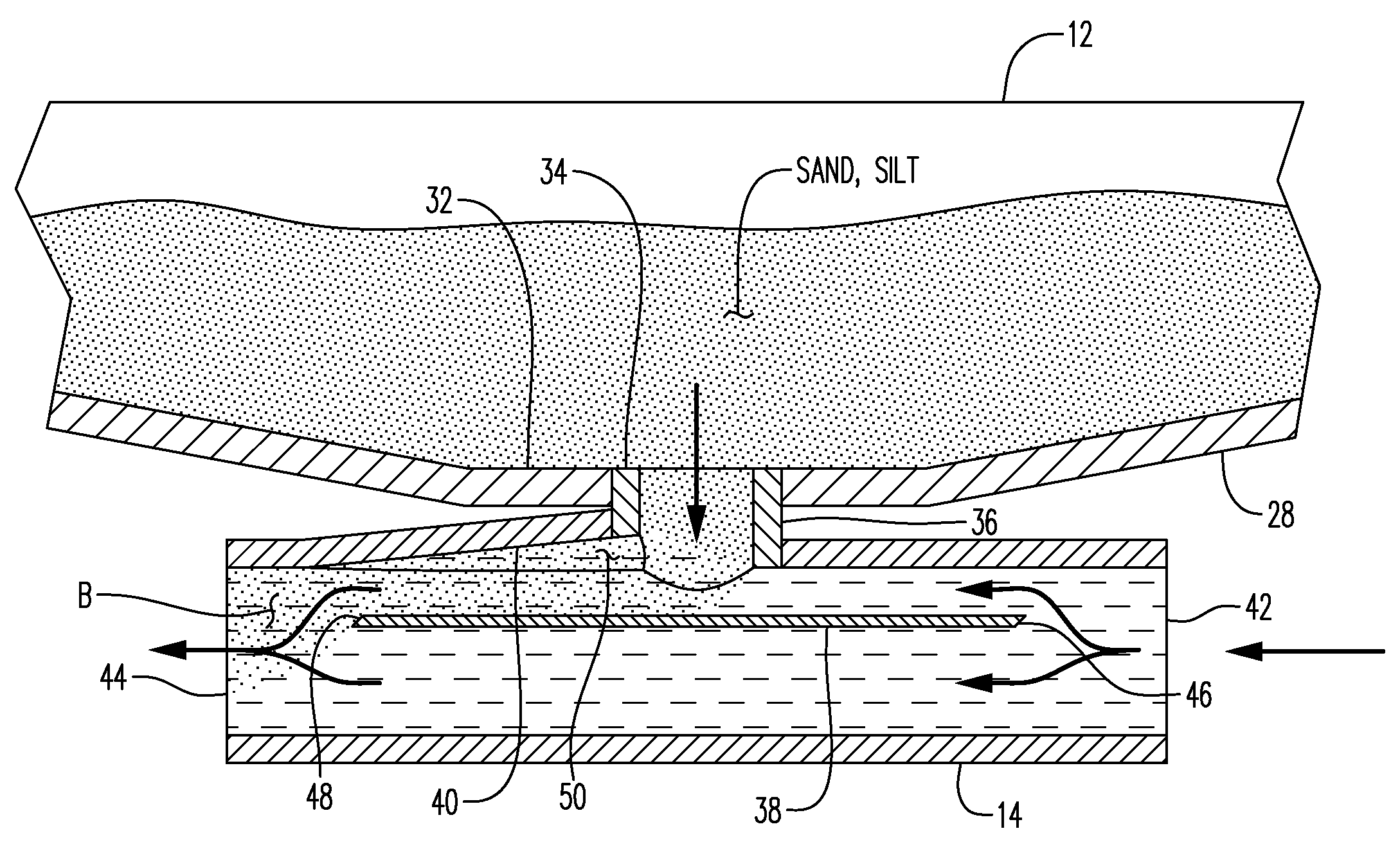

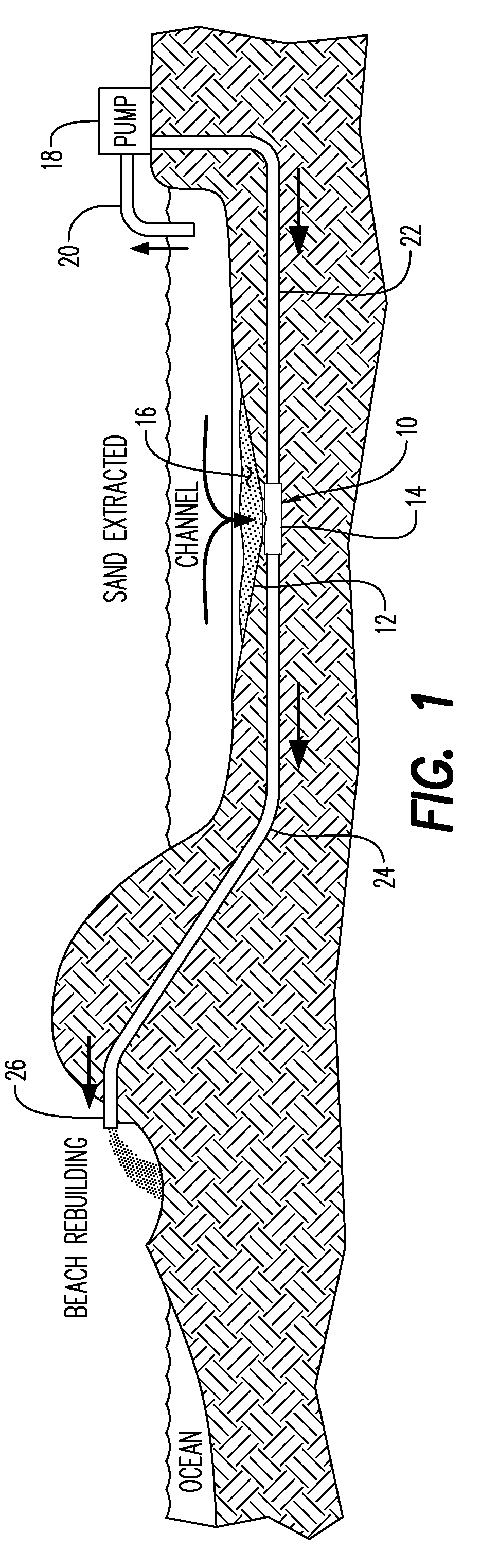

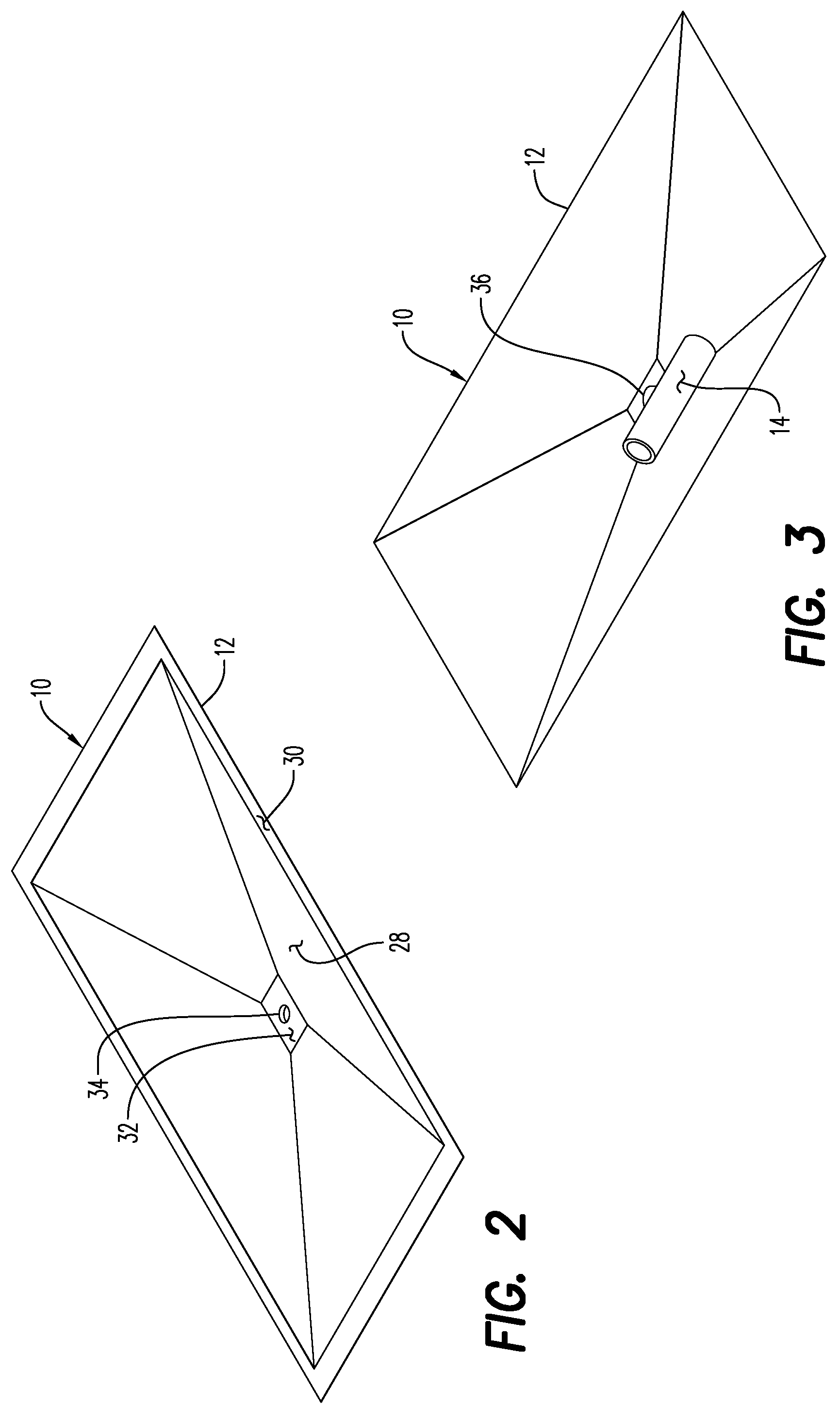

Catch basin for salt water sand

A system for collecting the flow of sand and sediment in a water current including a catch basin and a seawater pumping arrangement. The catch basin includes a basin and a transfer tube, the basin having a bottom and a plurality of angled sidewalls defining a basin. The bottom basin aperture therethrough aligned with an aperture formed in the transport tube affixed horizontally below the bottom. The transfer tube preferably includes a wedge-shaped flow-enhancing cavity immediately downstream of the aligned apertures which enhances the flow of the sand and sediment from the basin. A longitudinal catch plate extending within a midportion of the transfer tube below the apertures prevents the sand and sediment from clogging the transfer tube when water flow through the transfer tube is off.

Owner:LEBUFFE CALVIN N

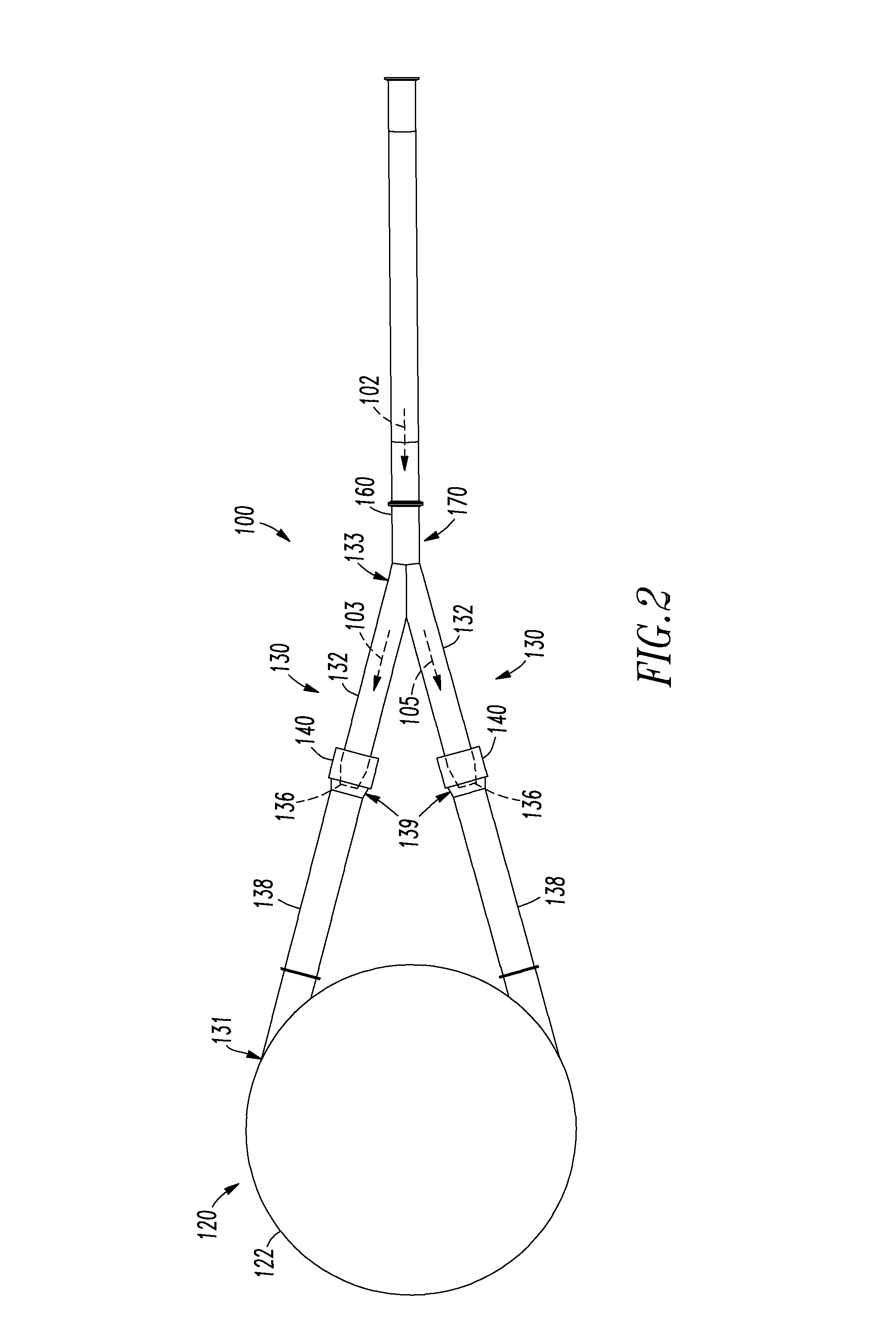

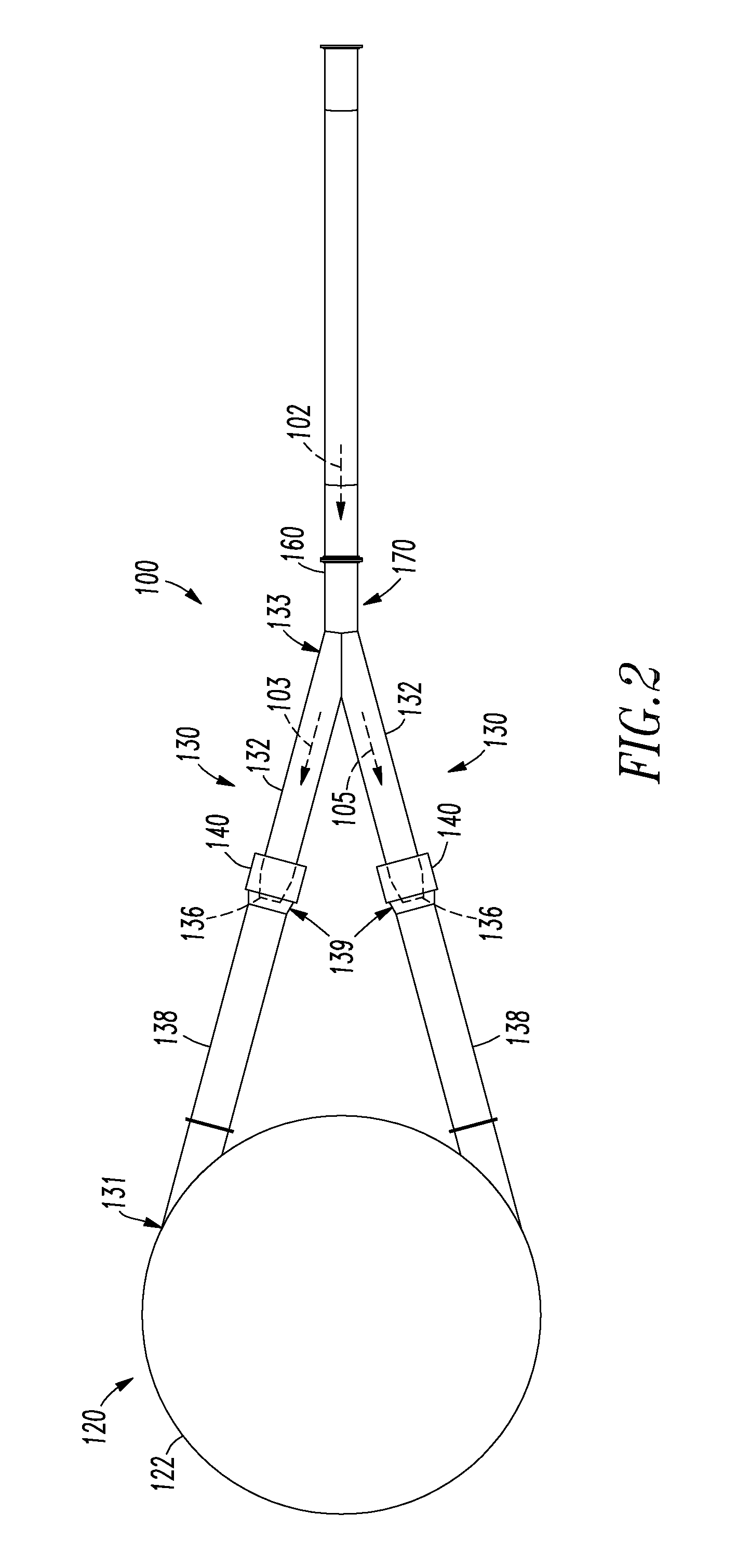

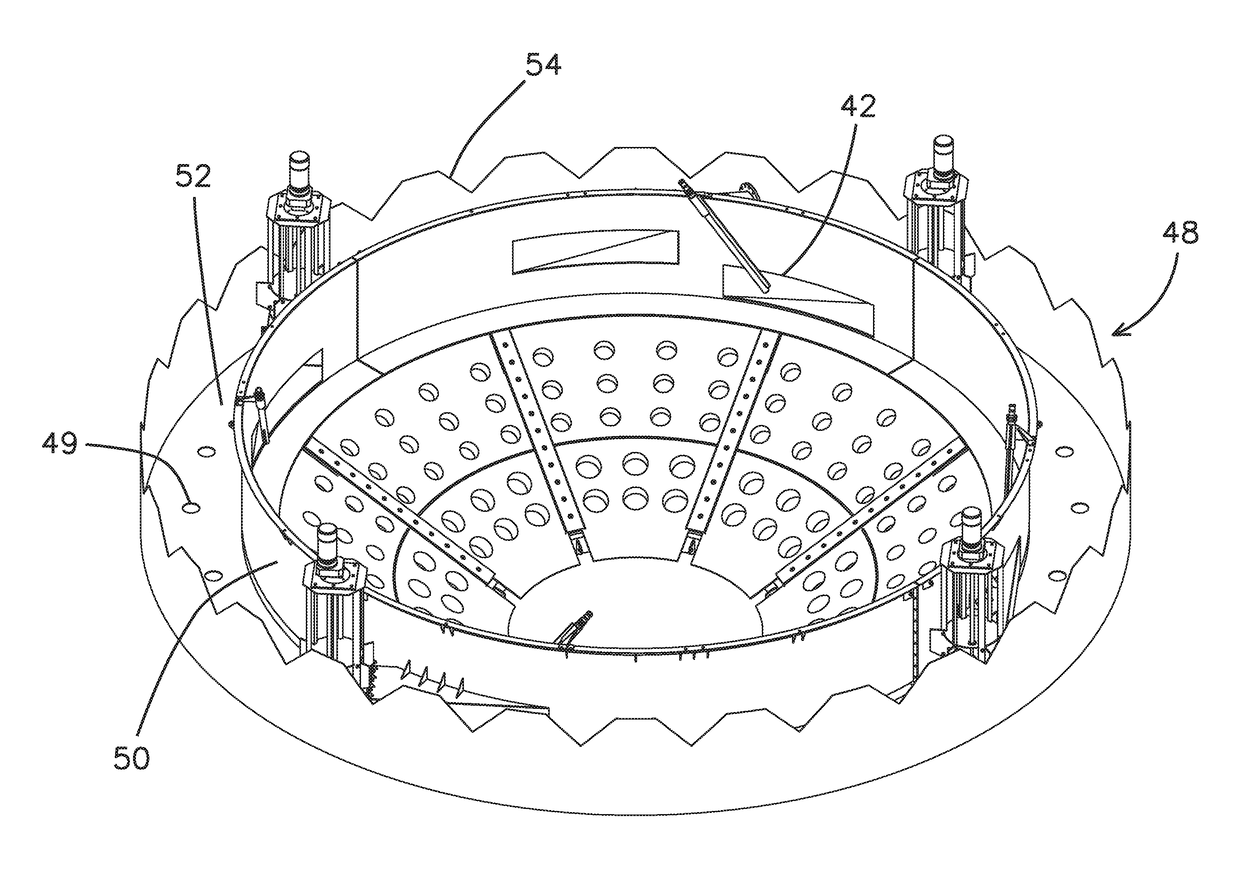

Feedwell dilution system for thickeners in oil sands

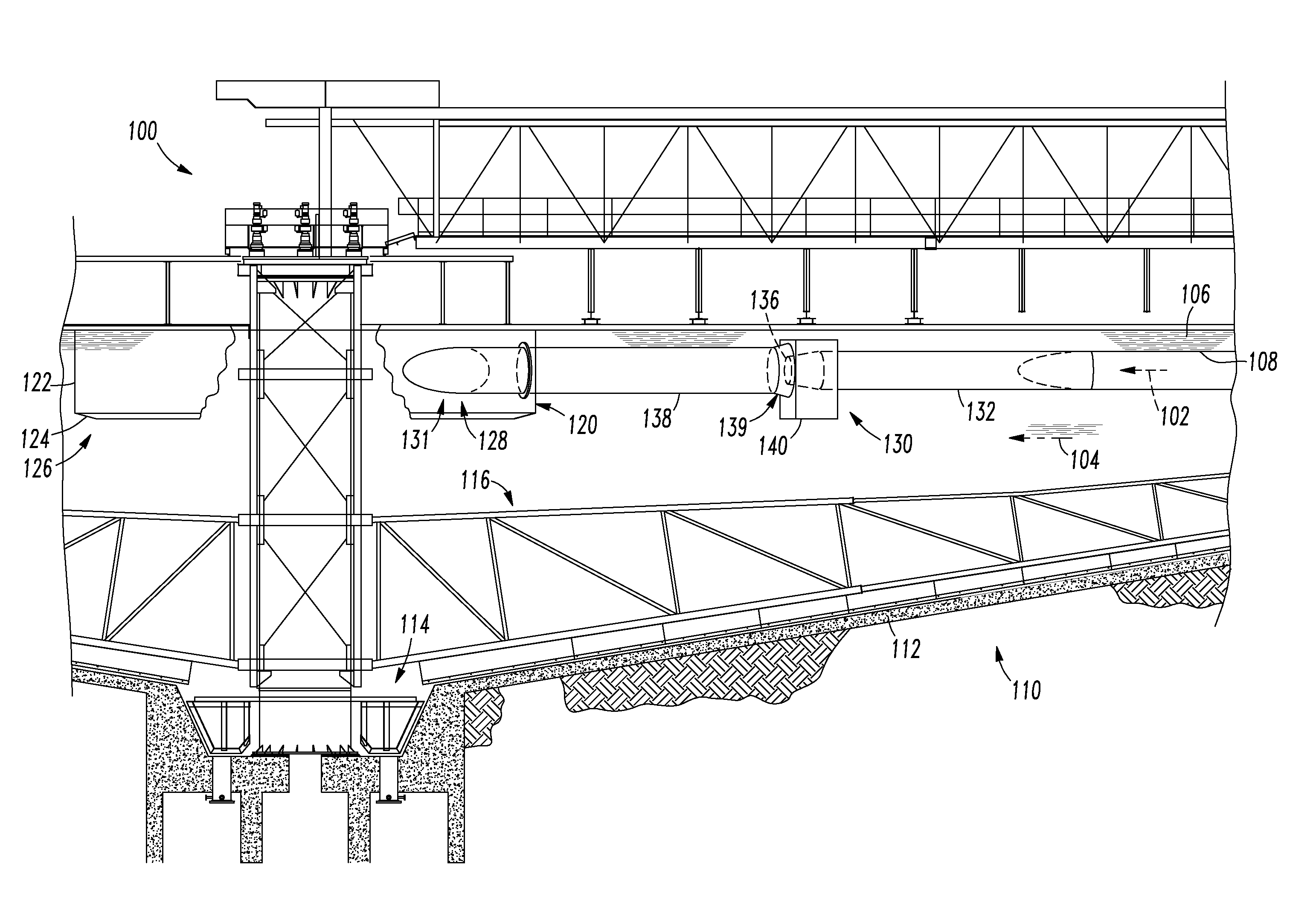

A feedwell dilution system for diluting an influent feed stream, which include at least one eductor assembly, and a feedwell assembly. The at least one eductor assembly includes a feed pipe which converges to a narrow throat portion or nozzle; a mix tube positioned downstream from the narrow throat portion that is sized and configured to provide mixing of the influent feed stream and a clarified liquid drawn from a settling tank; and an enclosure, which is installed around the narrow throat portion and an inlet portion of the mix tube and includes an open-ended portion on a bottom thereof, which is sized and configured to allow a clarified liquid to be pulled into the mix tube from below the inlet portion of the mix tube. The feedwell assembly is sized and configured to receive the mixture of the influent feed stream and the clarified liquid from the mix tube.

Owner:F L SMIDTH & CO AS

Septic tank

InactiveUS20060196827A1Prevents suspension and depositSettling tank with pumpSeparation devicesEngineeringSediment

A septic tank includes a chamber, an inlet through which waste water enters the chamber, an outlet, and an outlet pipe mounted to the outlet. At least one partitioning member is mounted in the chamber and separates the chamber into at least a first subchamber adjacent to the inlet and a second subchamber adjacent to the outlet. The partitioning member includes a plurality of through-holes allowing communication between the first subchamber and the second subchamber. The partitioning member prevents the suspensions and deposits in the first subchamber from entering the second subchamber. A submersible pump may be mounted in the first subchamber for creating recycling currents.

Owner:LIAO CHIN TUAN

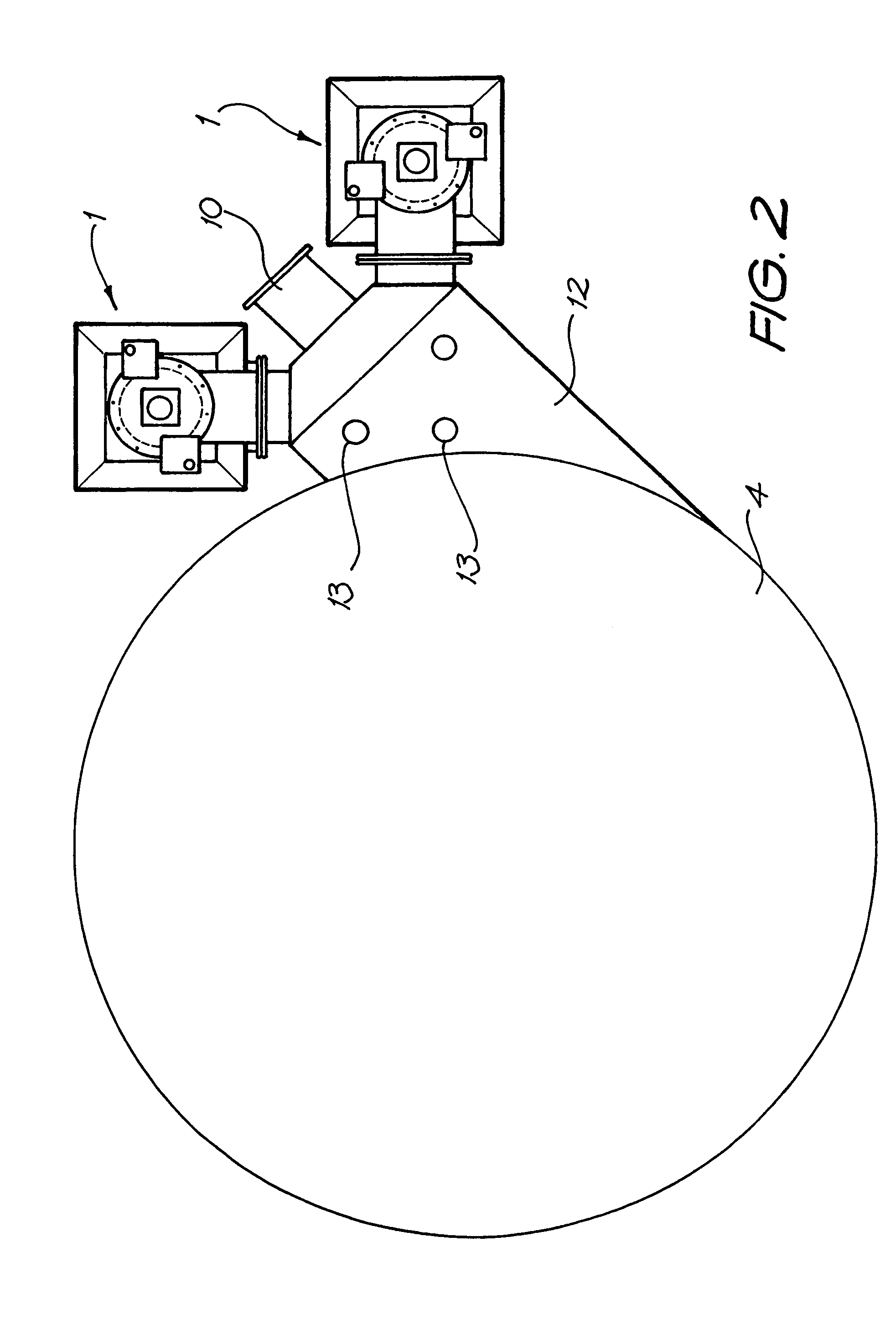

Dilution apparatus for a thickener

ActiveUS7520995B2Minimize workInorganic fibres/flakesSettling tank with pumpImpellerSystem parameters

The invention provides a dilution apparatus for a thickener of the type having a thickening tank and a feedwell disposed upstream of the tank to receive feed liquid, said dilution apparatus including: a receiving vessel adapted for at least partial submersion within the thickening tank to receive supernatant dilution liquid therefrom; and a submersible pump including an impeller adapted for at least partial submersion within the dilution liquid, the pump being adapted to transfer the dilution liquid from the thickening tank through the receiving vessel to the feed liquid for dilution thereof, before transfer of the feed liquid from the feedwell into the thickening tank. The pump is responsive to system parameters for adjusting the flow rate of the supernatant liquid.

Owner:METSO OUTOTEC (FINLAND) OY

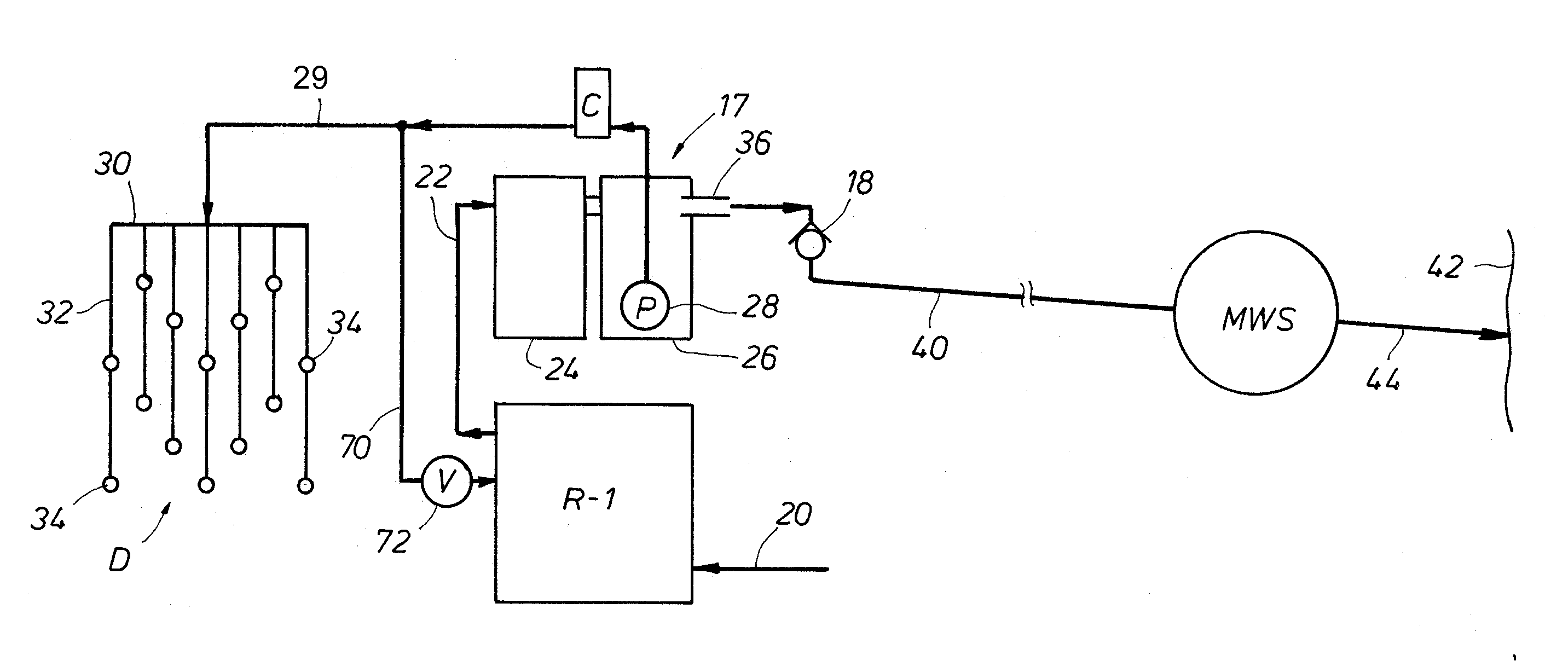

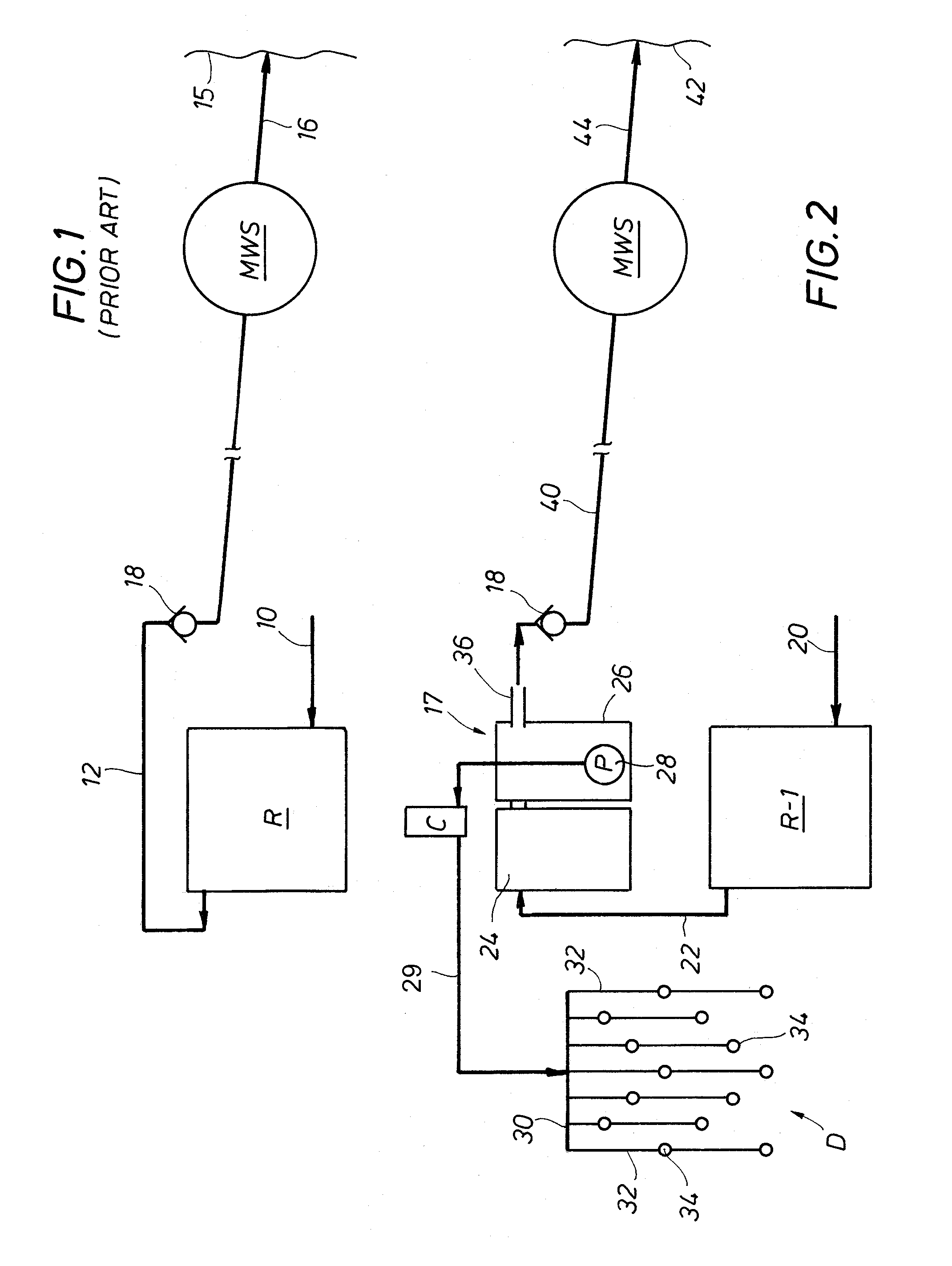

Pump system with vacuum source

InactiveUS20060110261A1Lower Reliability RequirementsIncrease distanceSpecific fluid pumpsTank vehiclesEngineeringVacuum pump

Owner:MULTIQUIP

Mobile flocculation and fracking water treatment system

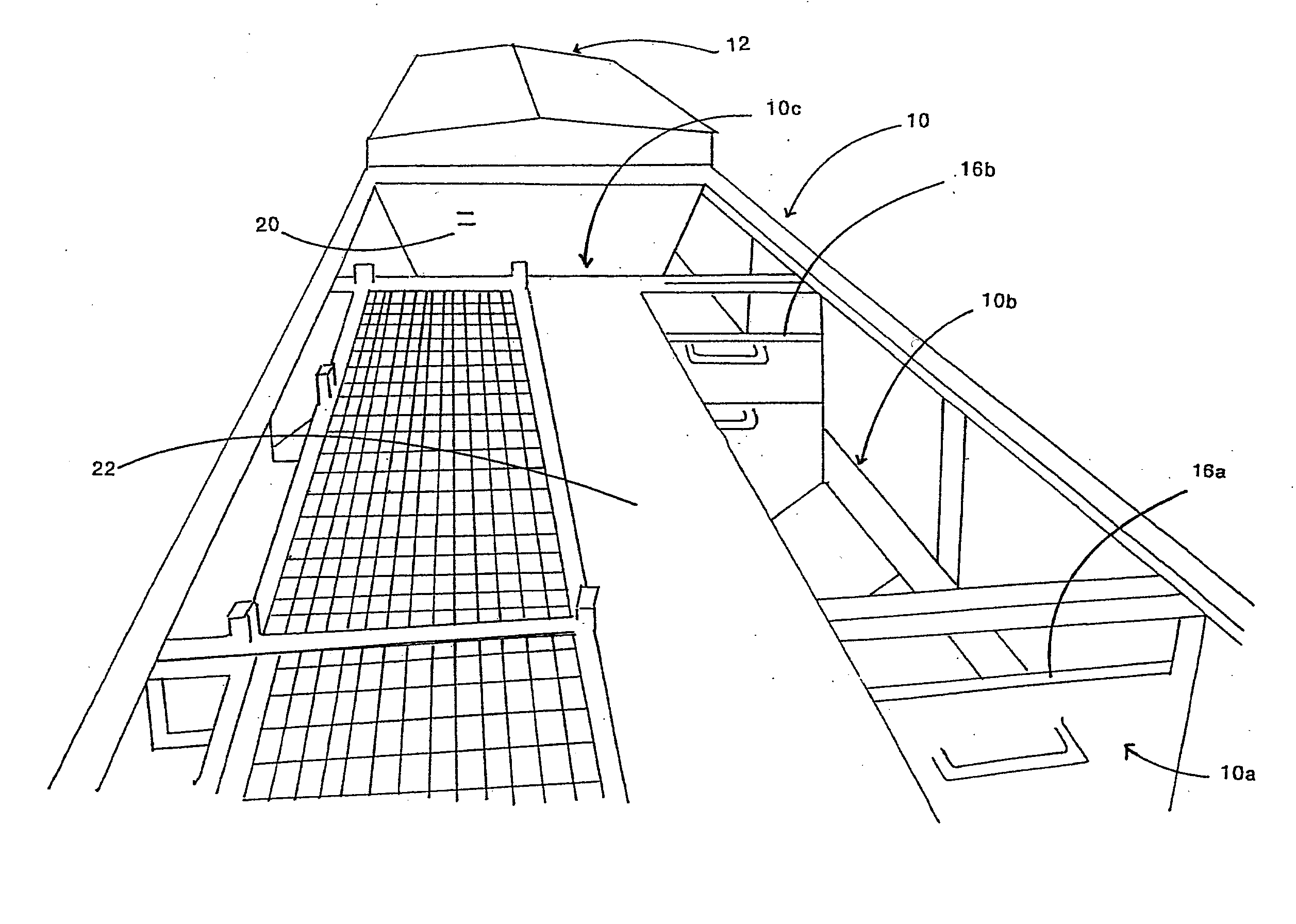

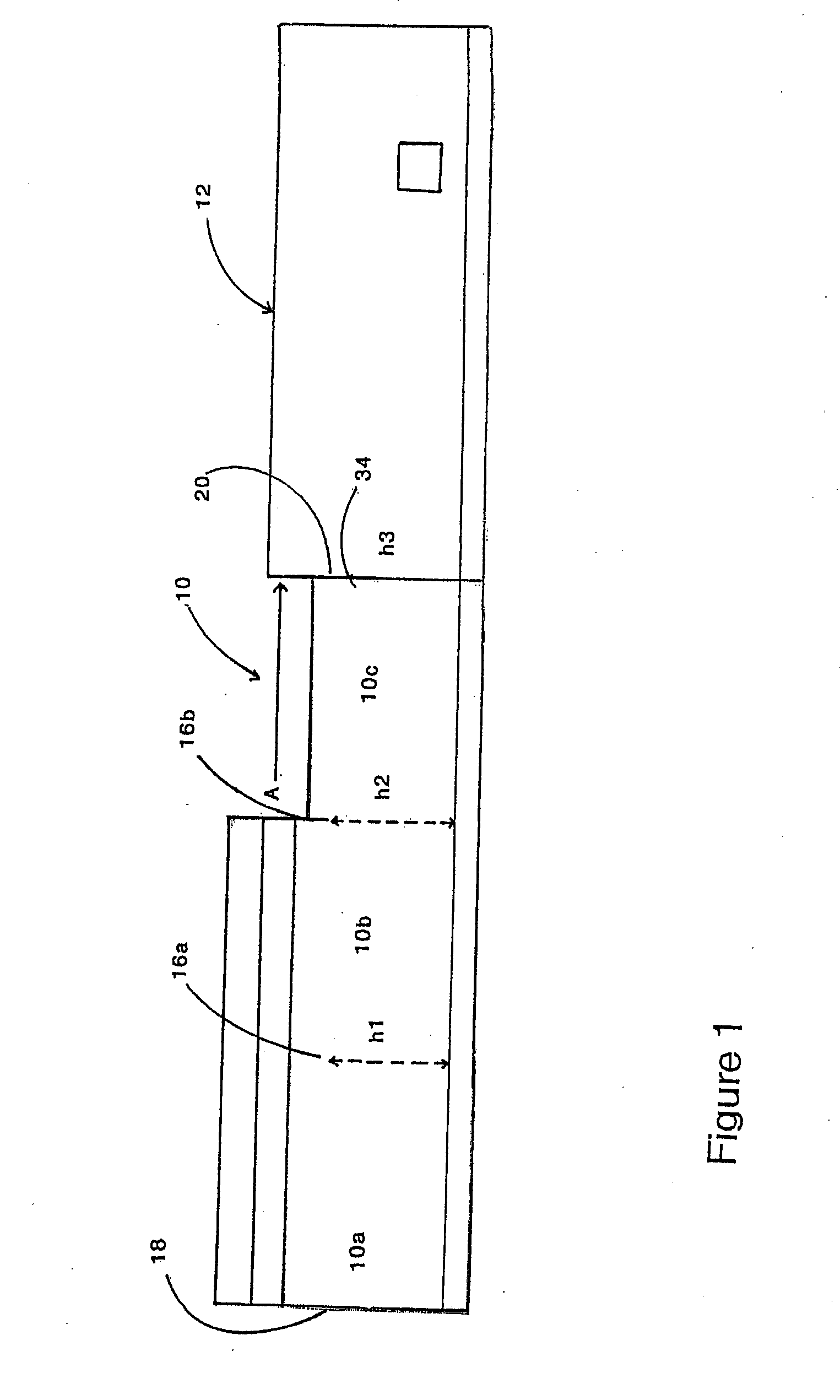

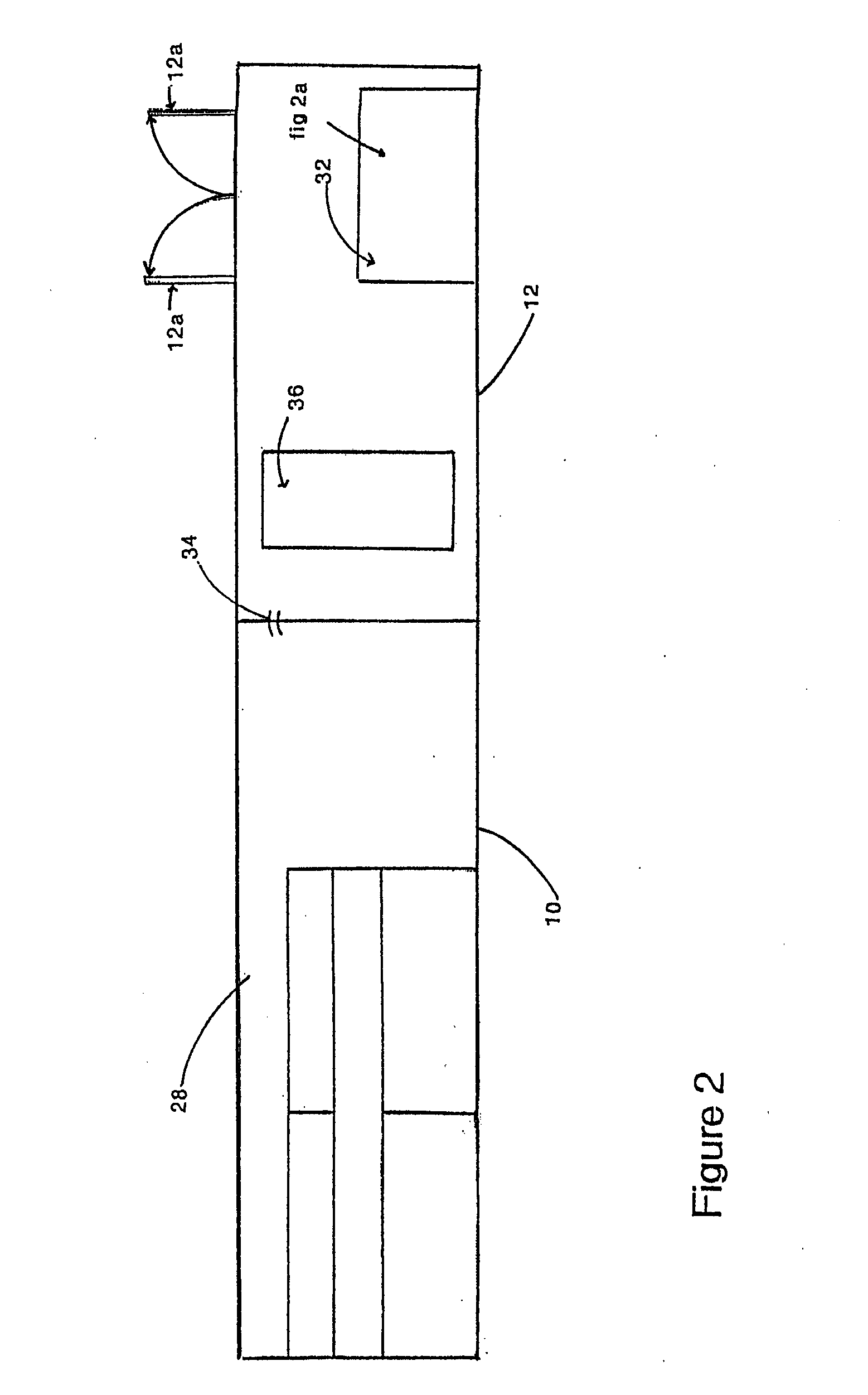

ActiveUS20140116967A1Waste water treatment from quariesSedimentation tanksFlocculationWater treatment system

A mobile flocculation and water treatment system includes at least one tank, preferably a series of adjoining tanks separated by weirs, and an adjacent pump house mounted on a mobile platform. At least one pump is mounted in the pump house. Fluid conduits run from the pumps to the tank. An overflow is mounted between the downstream tank and the pump house whereby fluid overflow from the tanks is directed into the pump house. The pump house provides a substantially water-tight reservoir zone to provide secondary containment. Water to be treated enters the upstream end of the tanks and is discharged from the downstream end.

Owner:WILD NORTH VAC & STEAM

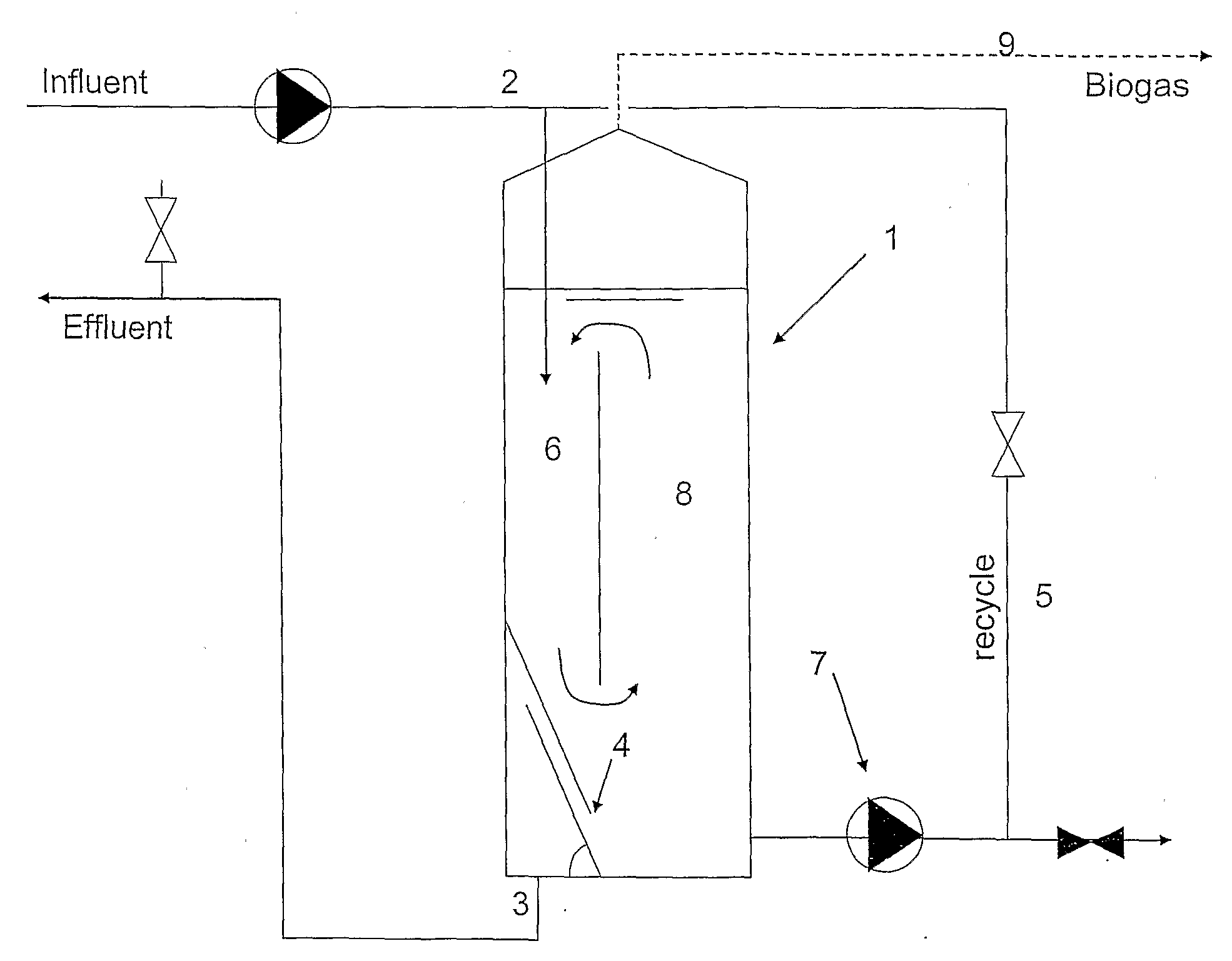

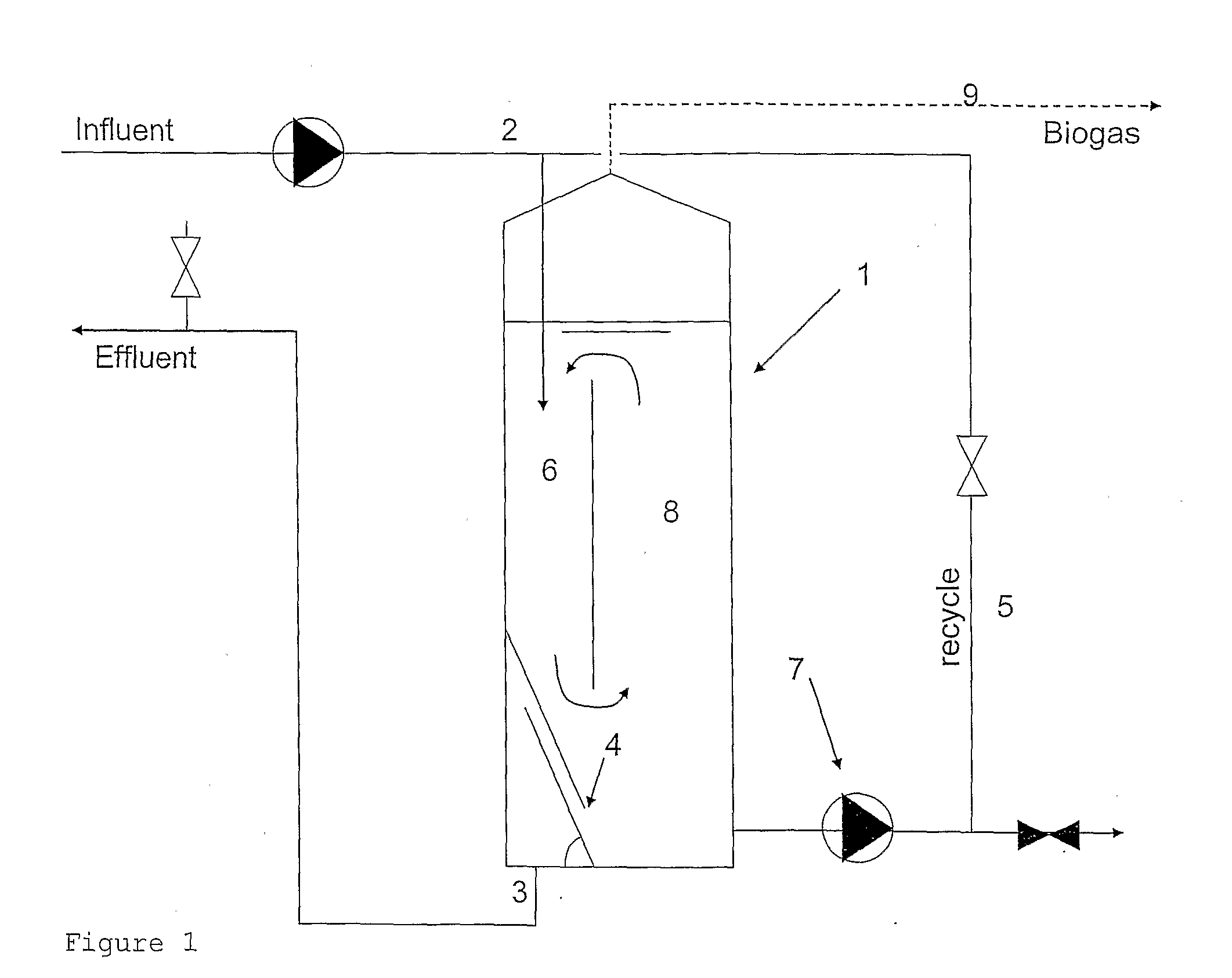

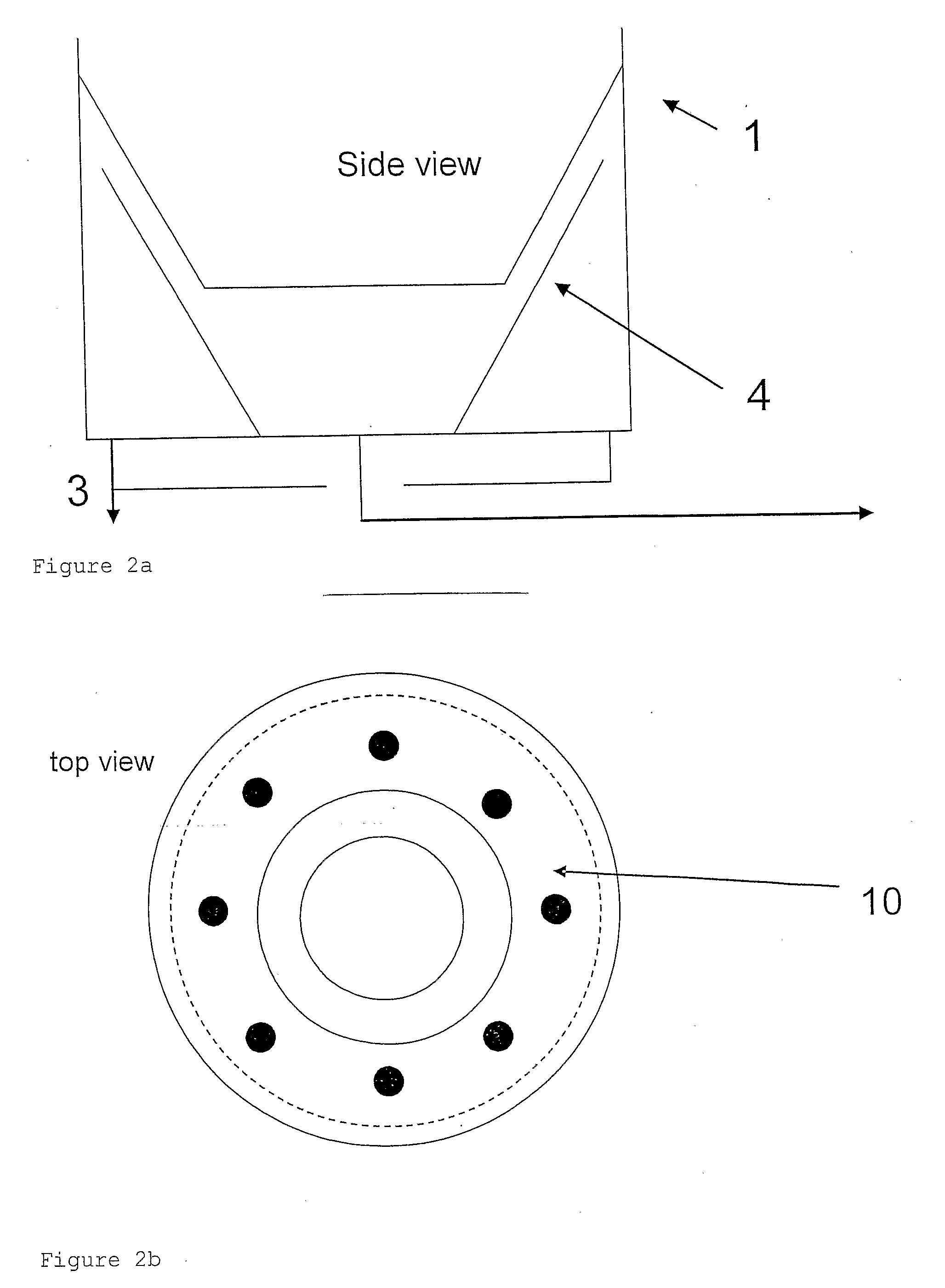

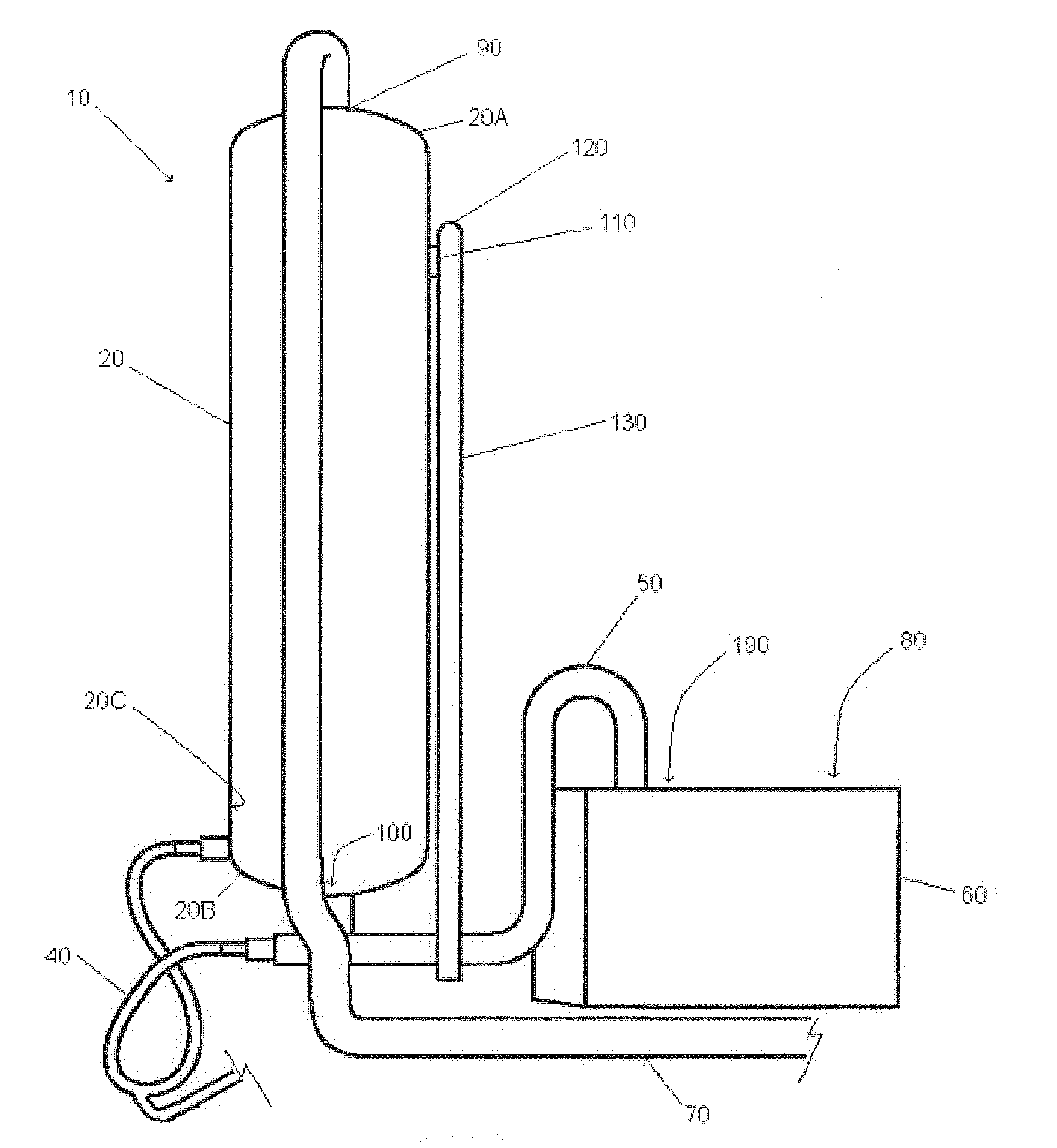

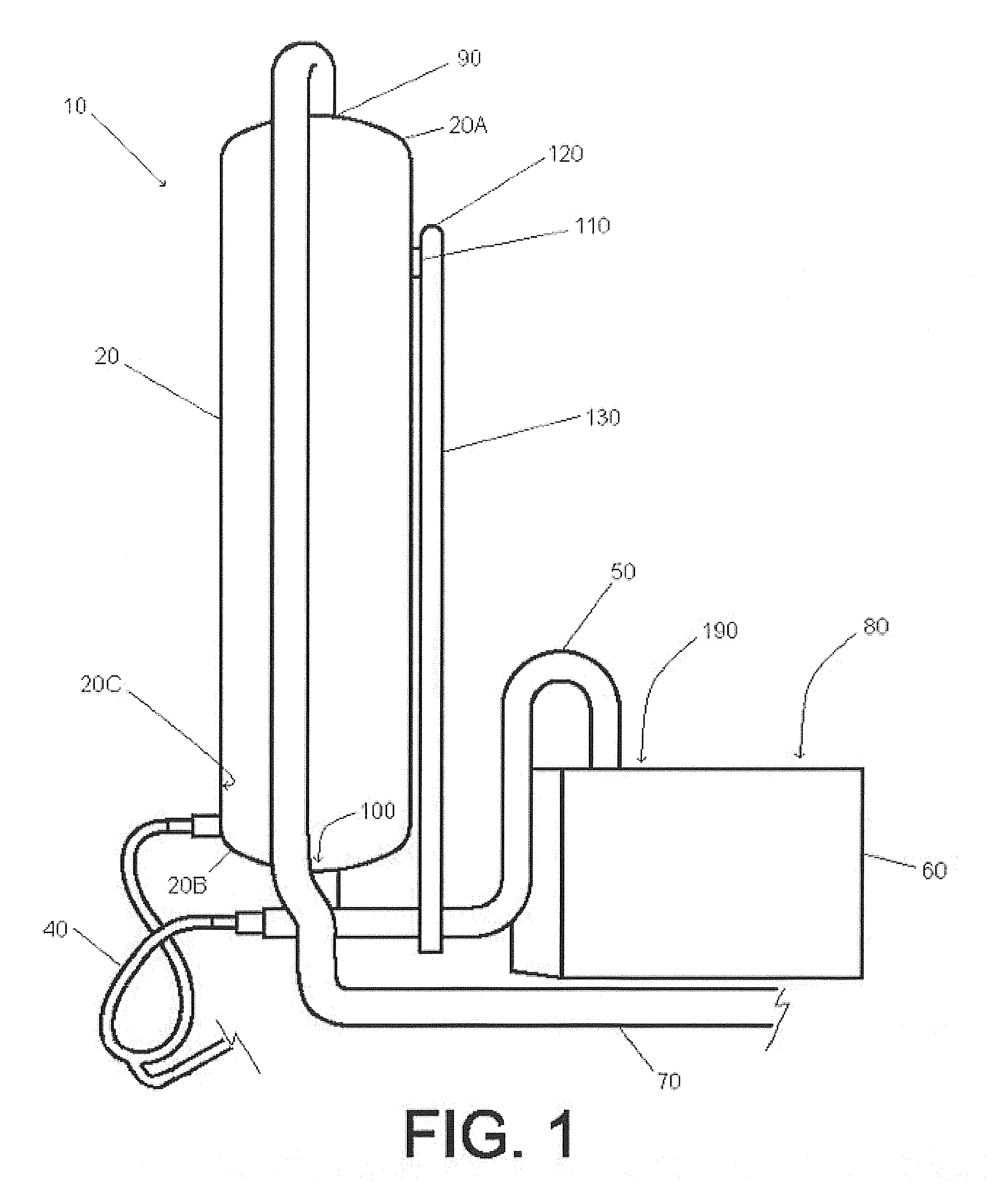

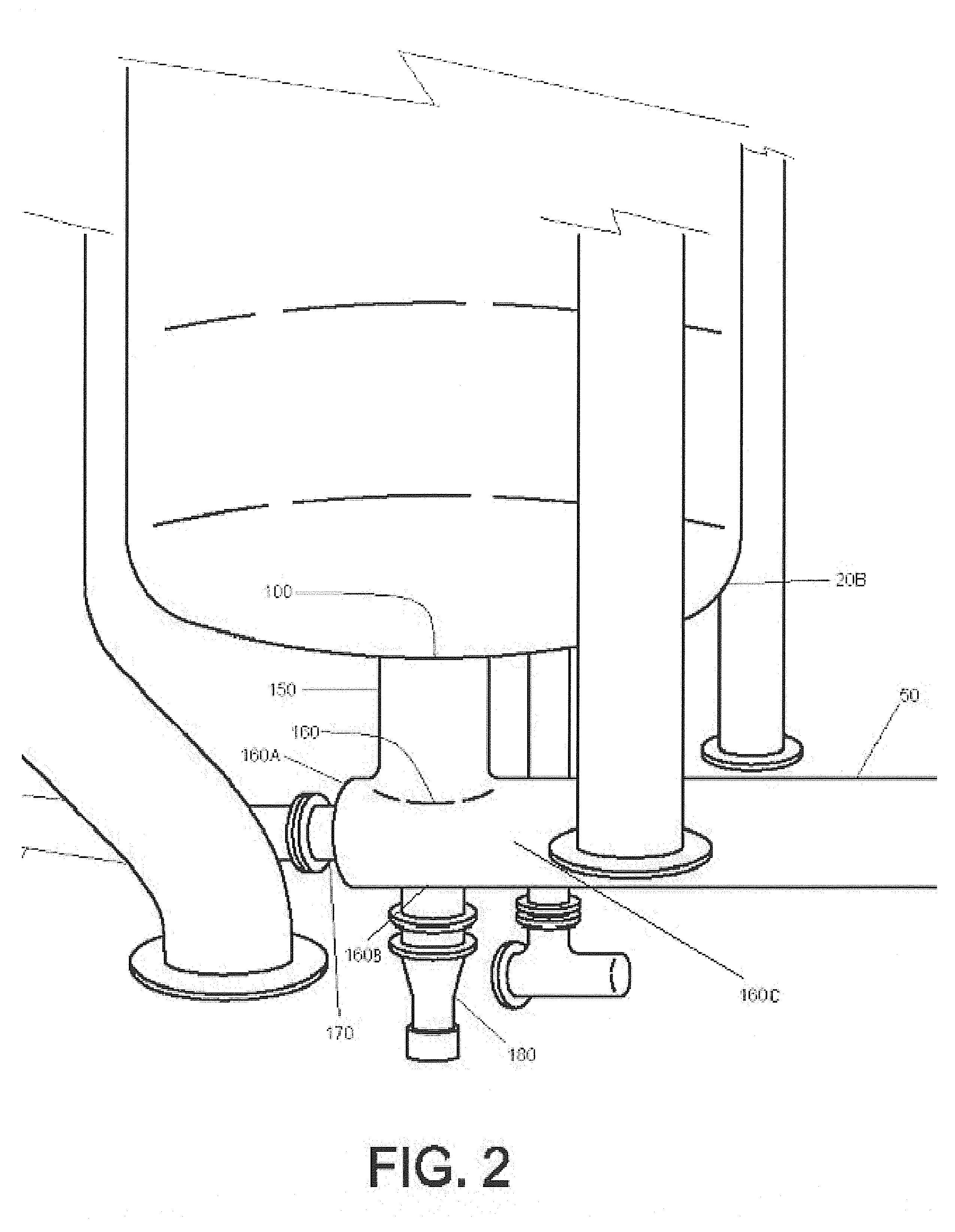

Novel anaerobic reactor for the removal of long chain fatty acids from fat containing wastewater

InactiveUS20090050560A1Liquid degasificationSettling tank with pumpLong chain fatty acidAnaerobic reactor

The invention presented is an apparatus specifically designed for the high rate anaerobic treatment of (waste)waters with relatively high concentrations of lipidic compounds, referred to as the Inverted Anaerobic Sludge Blanket (IASB) reactor. Contrary to conventional anaerobic reactors, it avoids the need of sludge with good settling properties and exploits the problem of sludge flotation due to long chain fatty acid (LCFA) or biogas adsorption onto the sludge and / or biogas encapsulation by the sludge. Furthermore, it provides an increased specific sludge surface area for better LCFA degradation. It is fed from the top and is equipped with a separation step at the bottom. Reactor contents are thoroughly mixed by the novel combined action of a gas lift loop and a liquid recycle over the reactor. The reactor can be operated in continuous and sequential mode. Although it is specifically designed for lipid degradation, its application is not limited to this.

Owner:UNIVERSITY OF MINHO

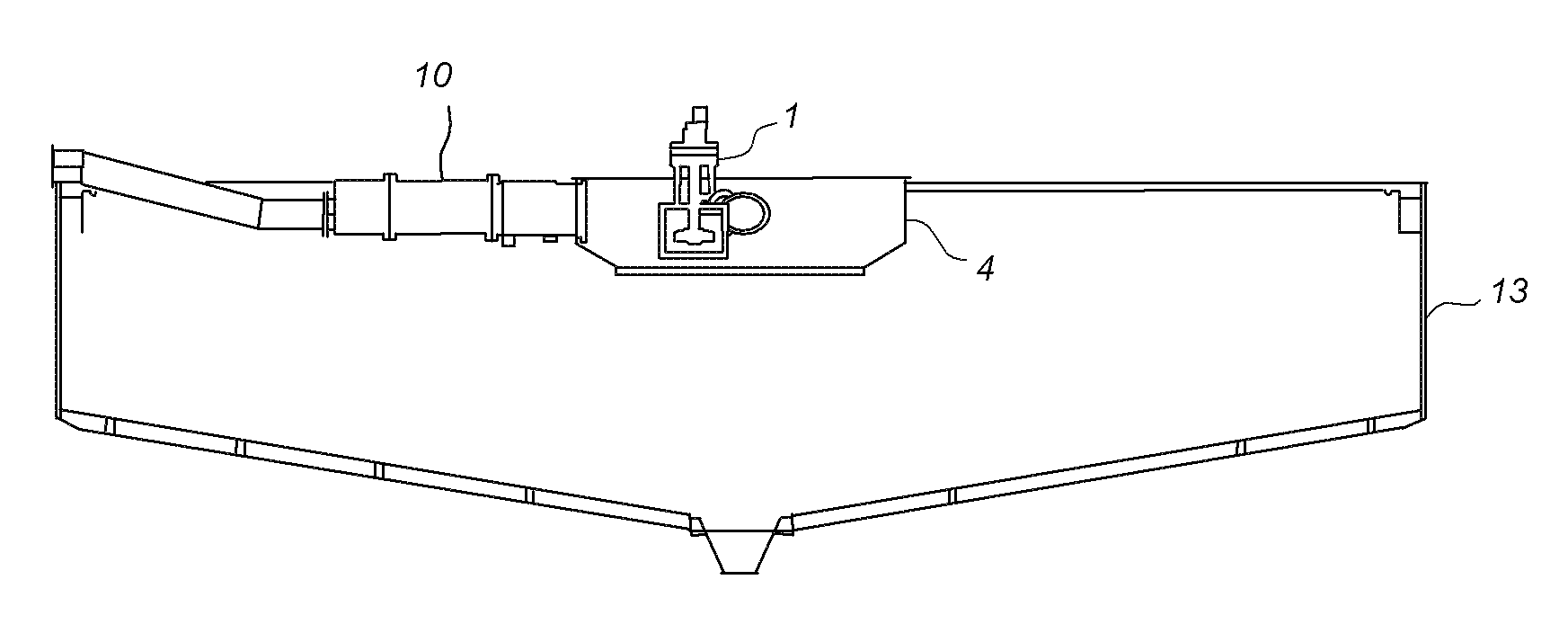

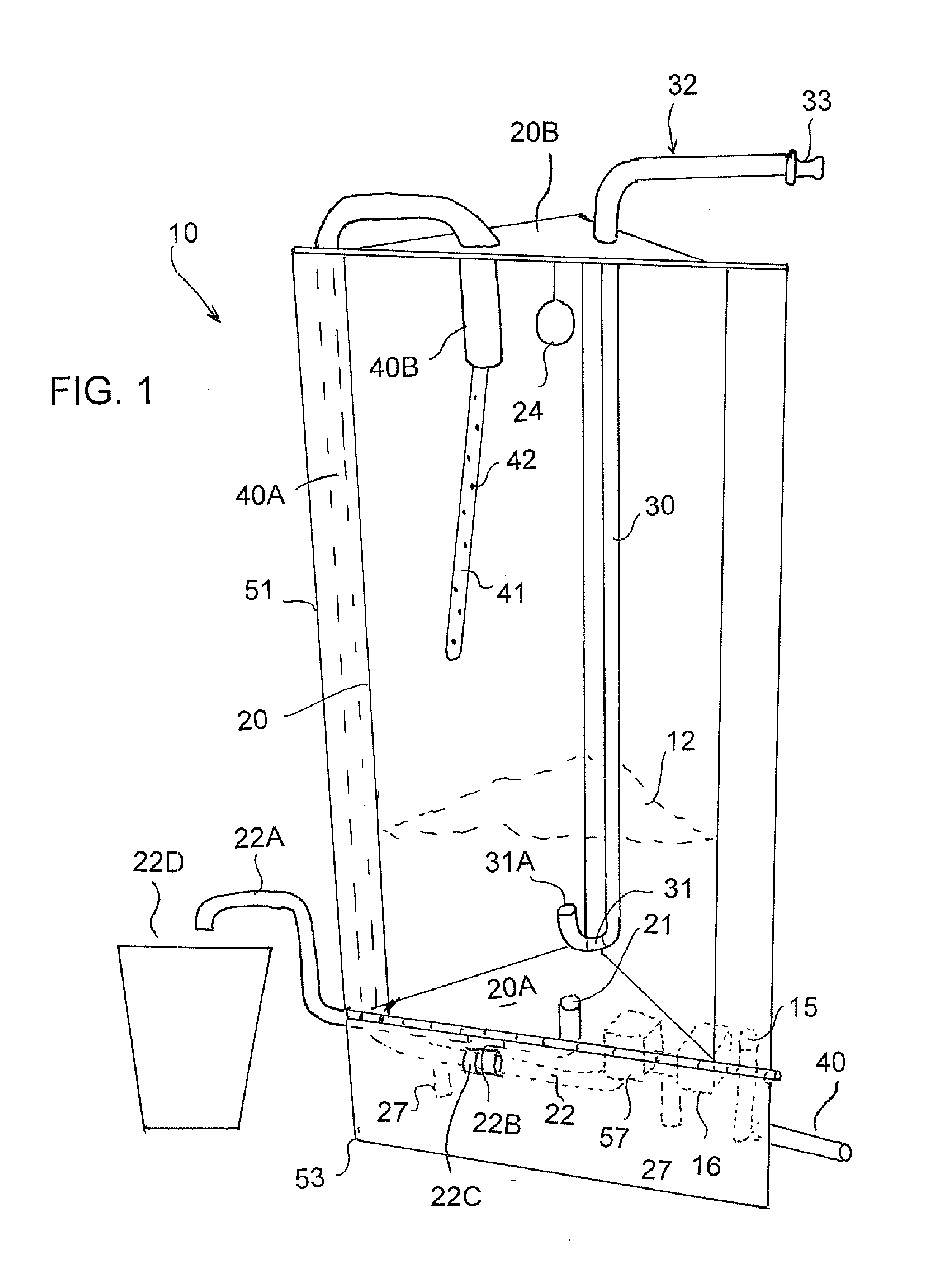

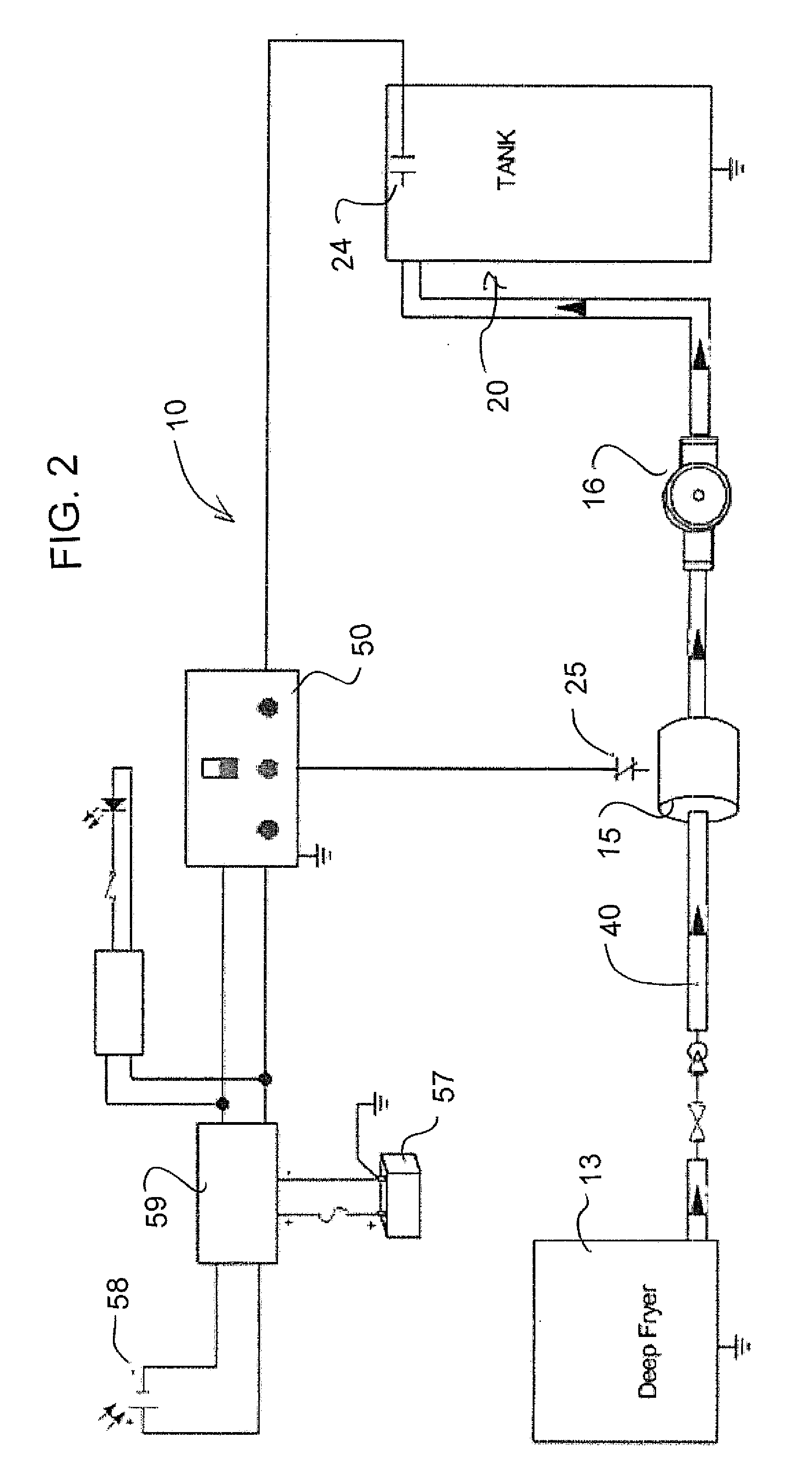

Method for Storing Used Cooking Oil

ActiveUS20130193084A1Reducing convectional agitationImpact processSettling tank with pumpCentrifugal force sediment separationSludgeEngineering

Method of collecting used cooking oil includes extracting used cooking oil from at least one deep fryer to a container, storing and separating said used cooking oil within the container which is located within the cooking area. The oil from the deep fat fryer is periodically pumped to the container and allowed to settle. The unwanted sludge is then tapped off into a portable container and the wanted oil is pumped to an exterior transportation container. The container is triangular shaped with rear walls converging into a corner of the cooking area and a diagonal front face with side flanges and a bottom flap such that it is located in the corner of an interior wall of a building and contains the pipes and plumbing.

Owner:MICHEL AGNES

Wastewater Re-Use Systems

ActiveUS20120024766A1Reduce pollutionReduce loadTreatment using aerobic processesSolid sorbent liquid separationCollection systemWastewater reuse

A wastewater reuse system has a wastewater treatment system connected to a dwelling for receiving wastewater therefrom. The wastewater treatment system has a pump tank with an outlet that can be connected to a central wastewater collection system. There can be a pump in the pump tank for pumping water from the pump tank to a use recipient of treated wastewater such as an irrigation system.

Owner:MCKINNEY JERRY L

Septic tank

A septic tank includes a chamber, an inlet through which waste water enters the chamber, an outlet, and an outlet pipe mounted to the outlet. At least one partitioning member is mounted in the chamber and separates the chamber into at least a first subchamber adjacent to the inlet and a second subchamber adjacent to the outlet. The partitioning member includes a plurality of through-holes allowing communication between the first subchamber and the second subchamber. The partitioning member prevents the suspensions and deposits in the first subchamber from entering the second subchamber. A submersible pump may be mounted in the first subchamber for creating recycling currents.

Owner:LIAO CHIN TUAN

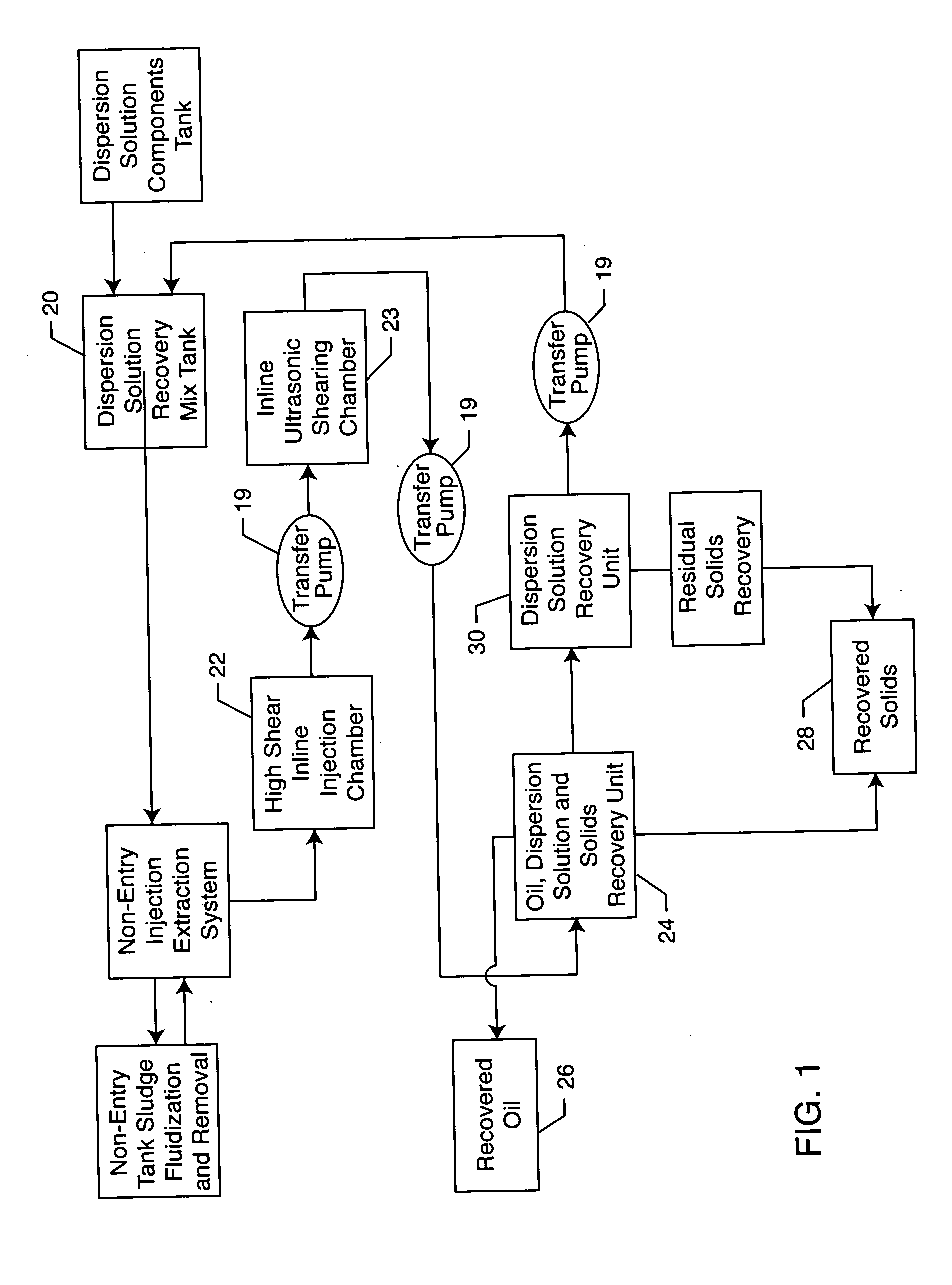

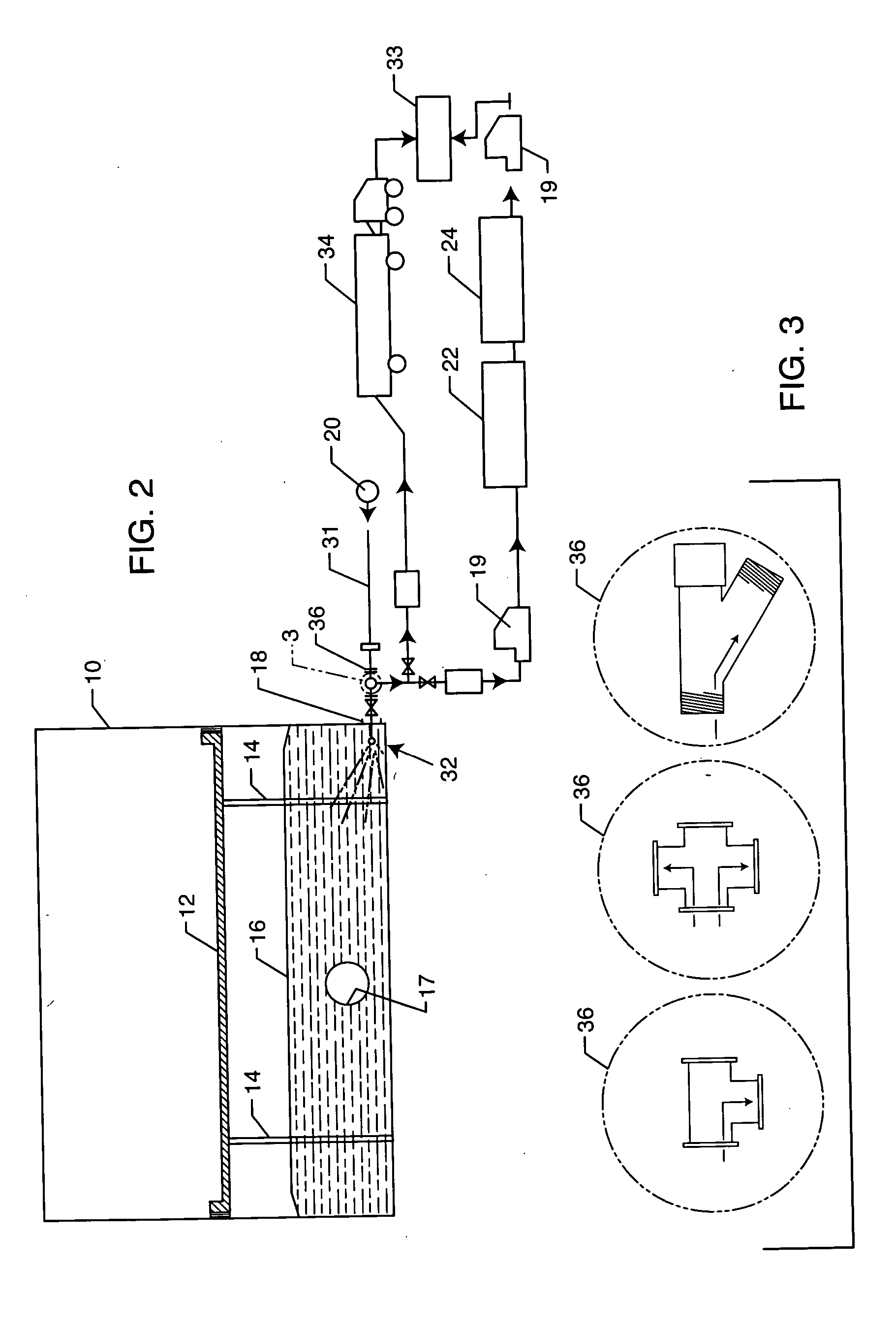

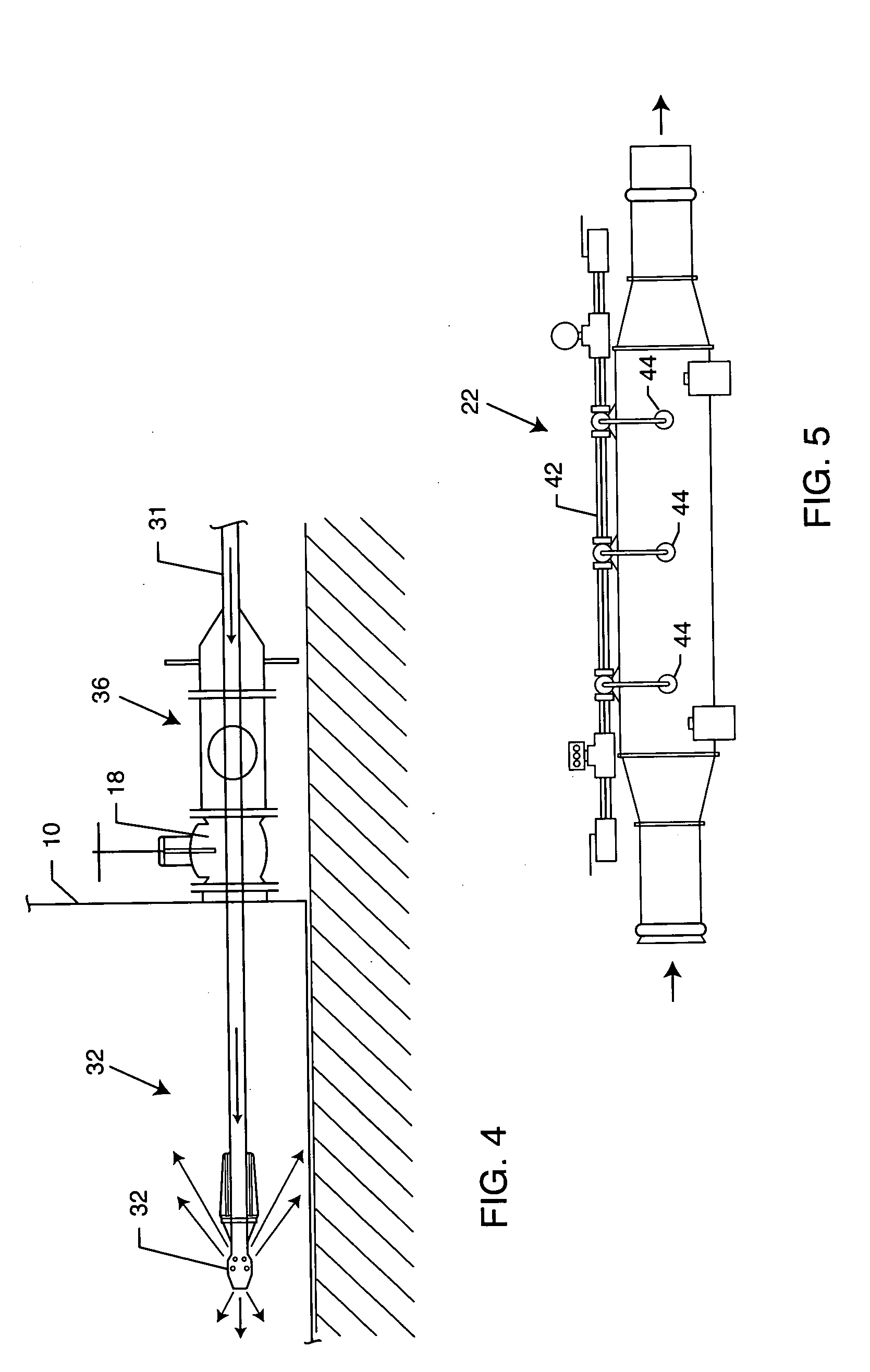

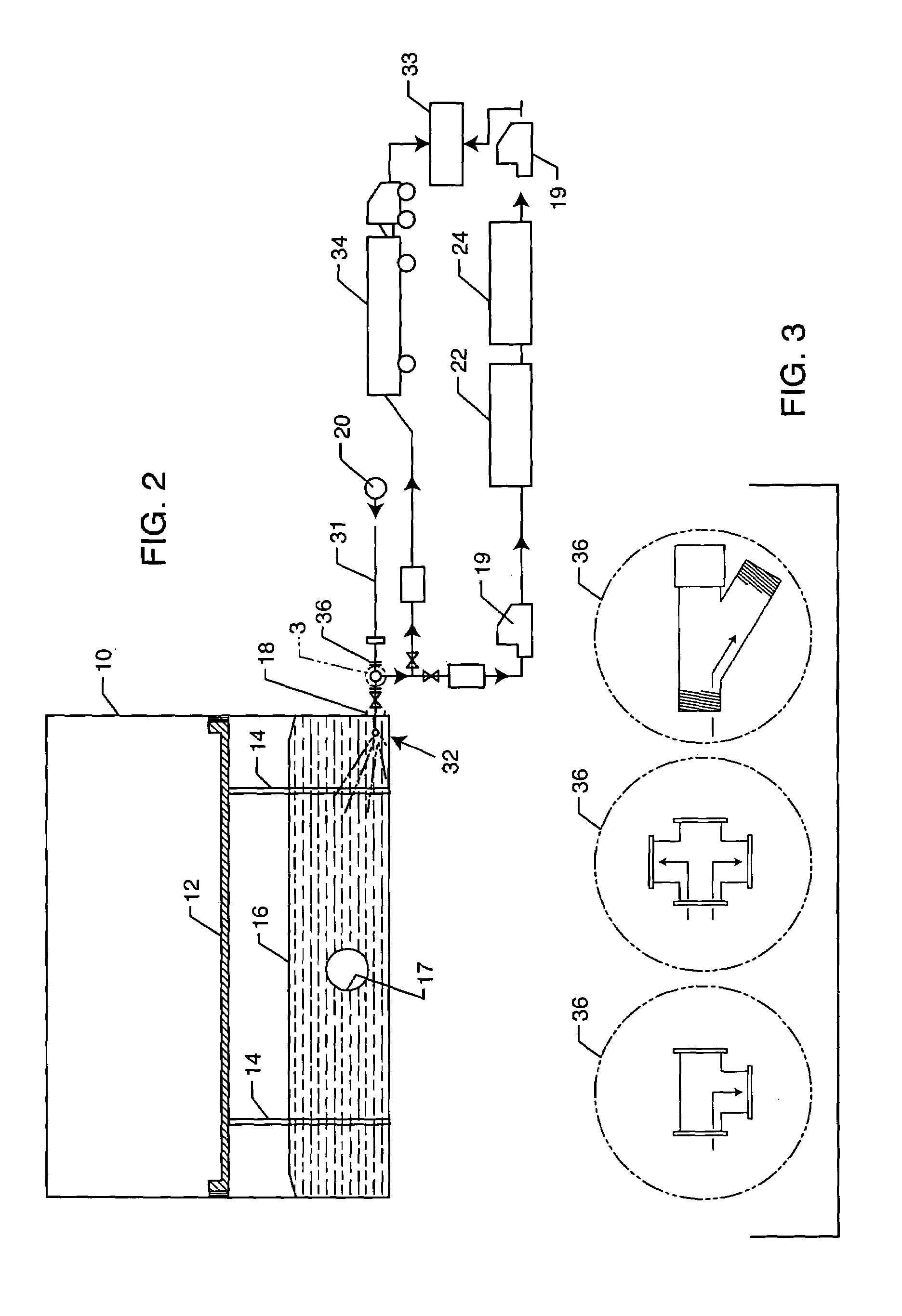

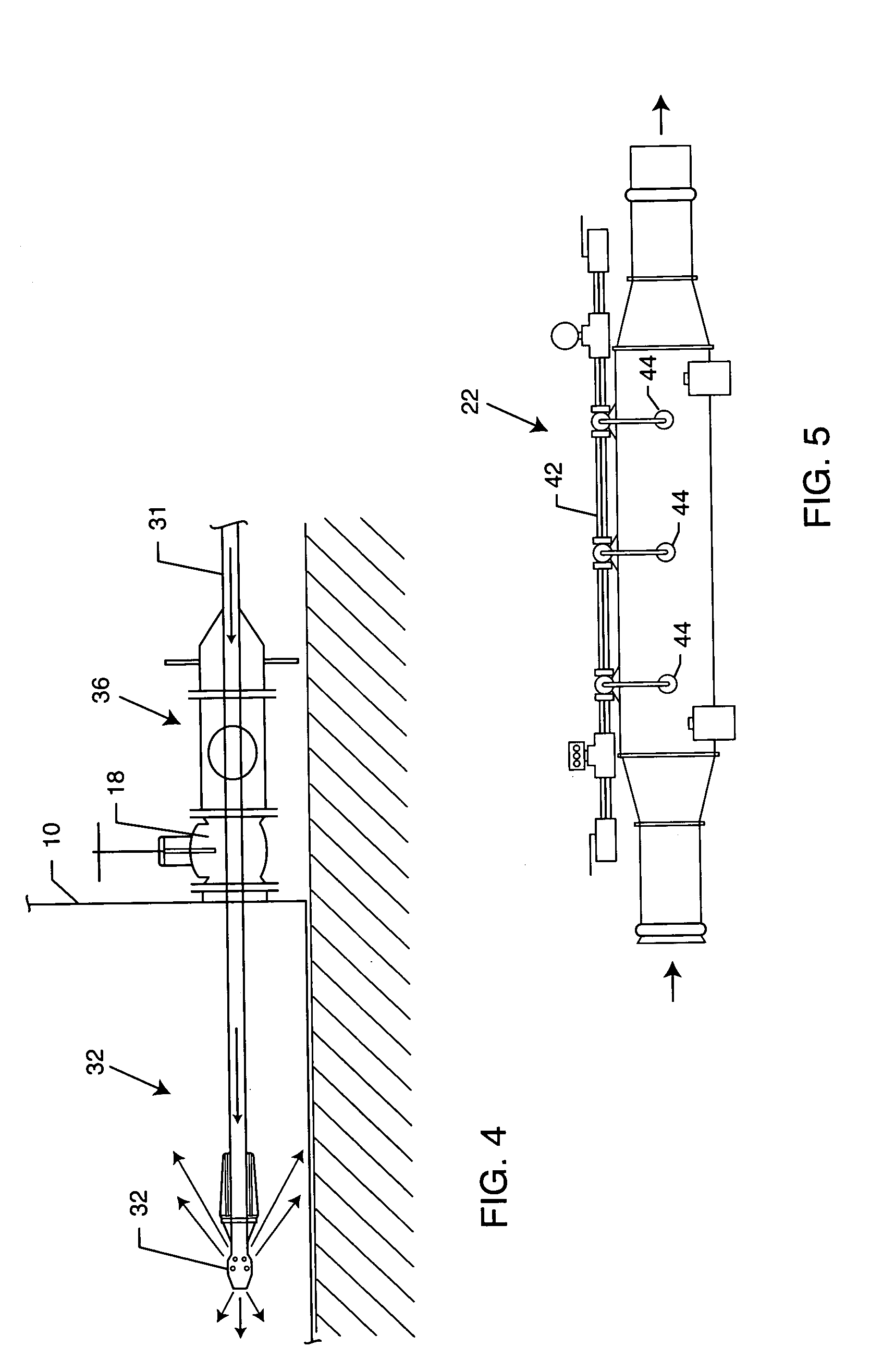

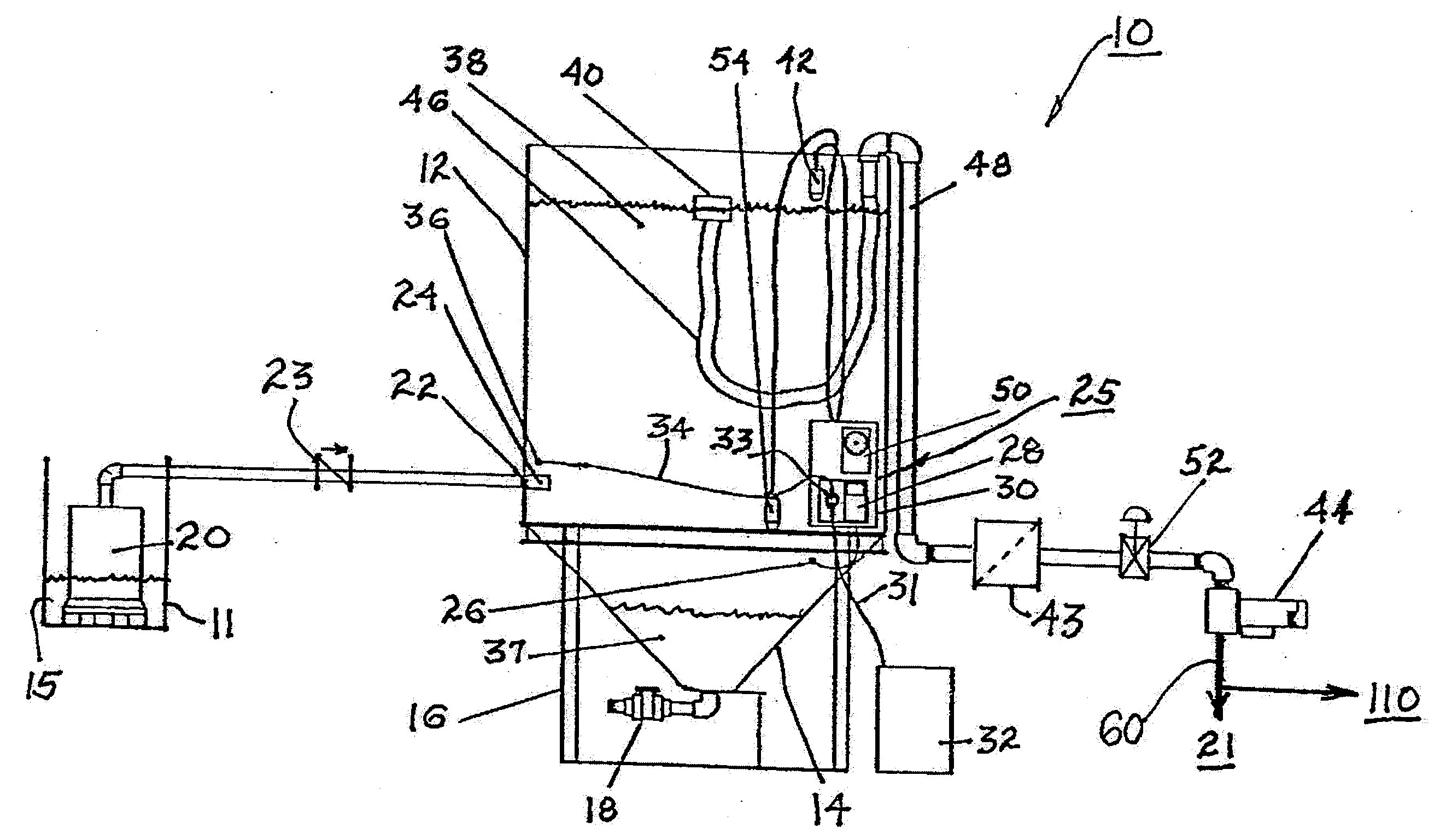

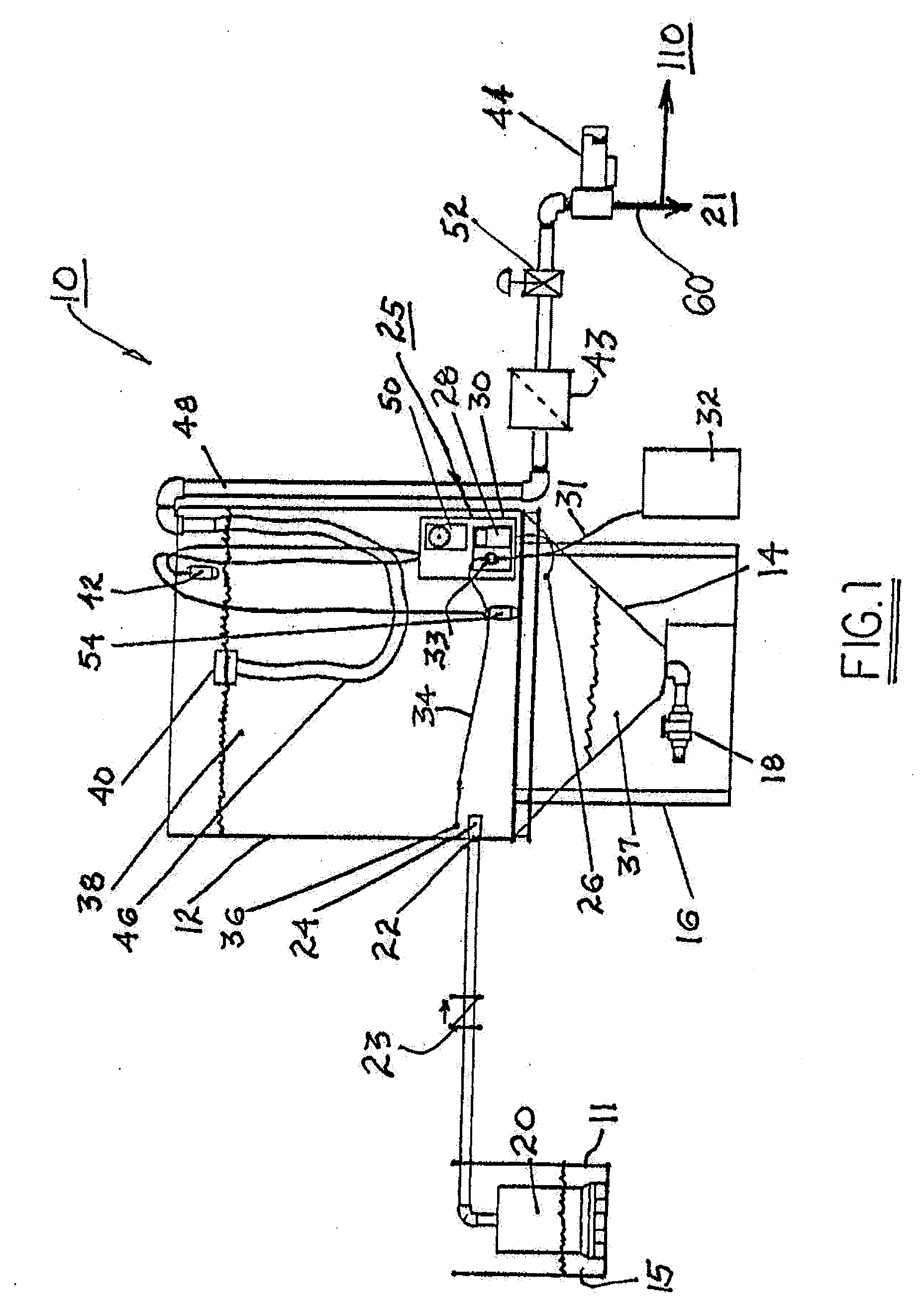

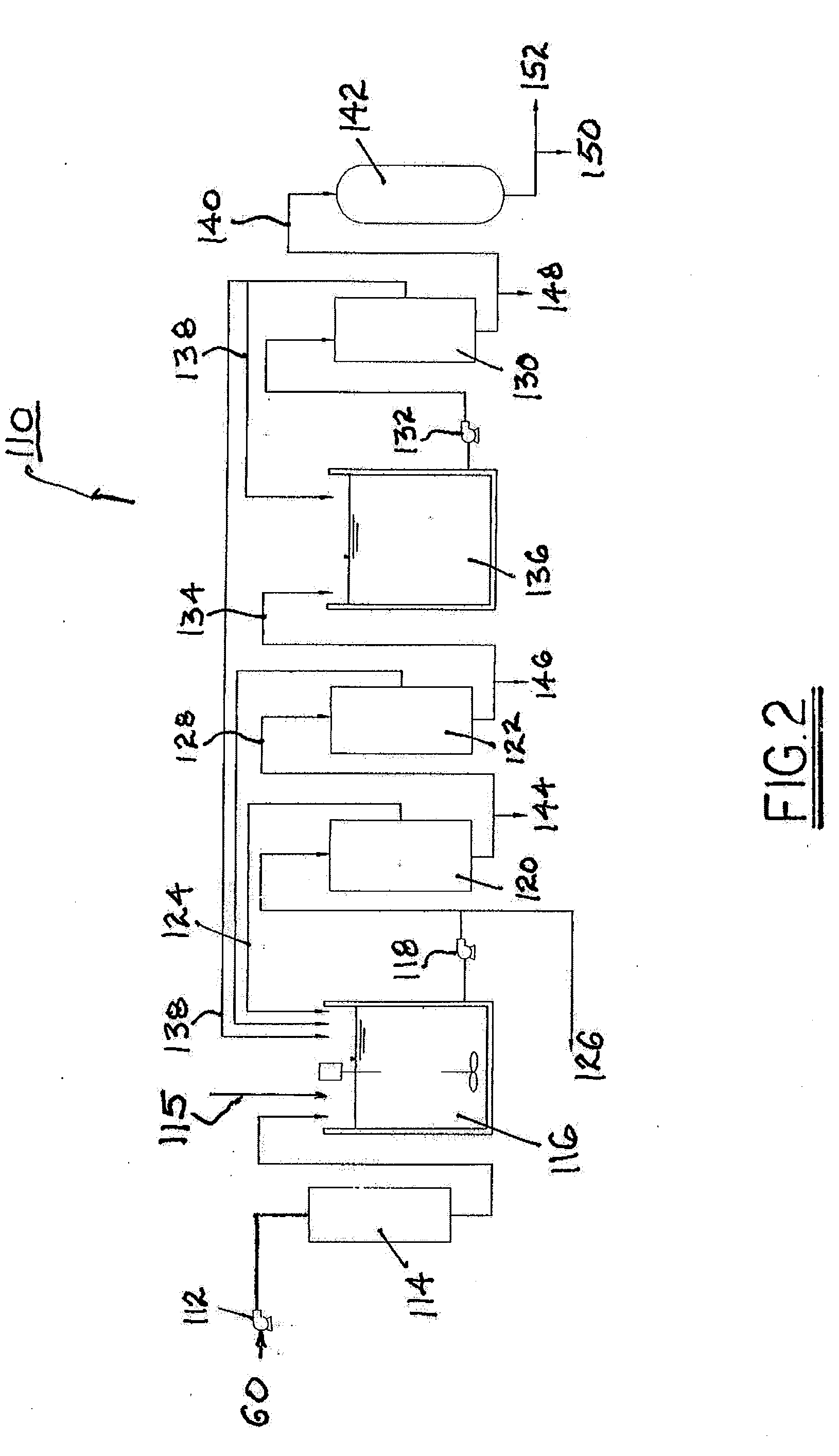

Petroleum recovery and cleaning system and process

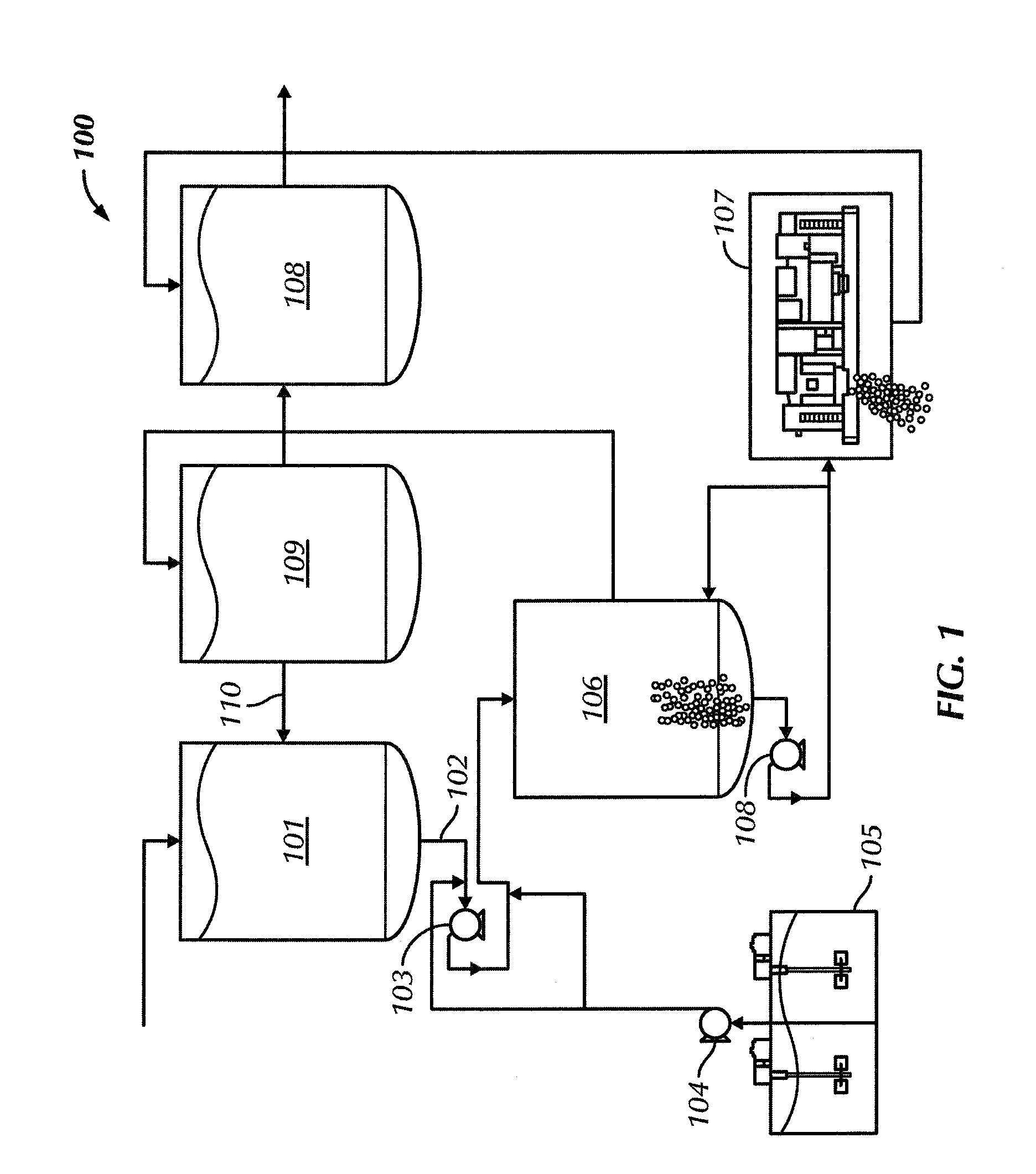

InactiveUS7594996B2Quality improvementIncrease productionInorganic/elemental detergent compounding agentsLiquid separation auxillary apparatusProcess equipmentPetroleum product

A system and process are provided for recovering and / or cleaning residual or waste petroleum products such as sludge accumulated within a storage tank or upon process equipment surfaces, or from inorganic materials such as sand or clay, and the like. The system and process include a negatively charged aqueous-based dispersion fluid, which is contacted with the petroleum product under controlled relatively high pressure and high shear conditions for fluidizing hydrocarbon molecules and for preventing such molecules from adherence to process equipment surfaces, or contaminants such as sand or clay. Additional mechanical separation as by subjecting the mixed petroleum product and dispersion fluid slurry to sonic vibration may also be employed. The thus-fluidized slurry of petroleum products, dispersion fluid, and inorganic materials can be separated by conventional techniques, as by settling and / or flotation, for further individual processing and / or re-use.

Owner:AQUA TECH LLC

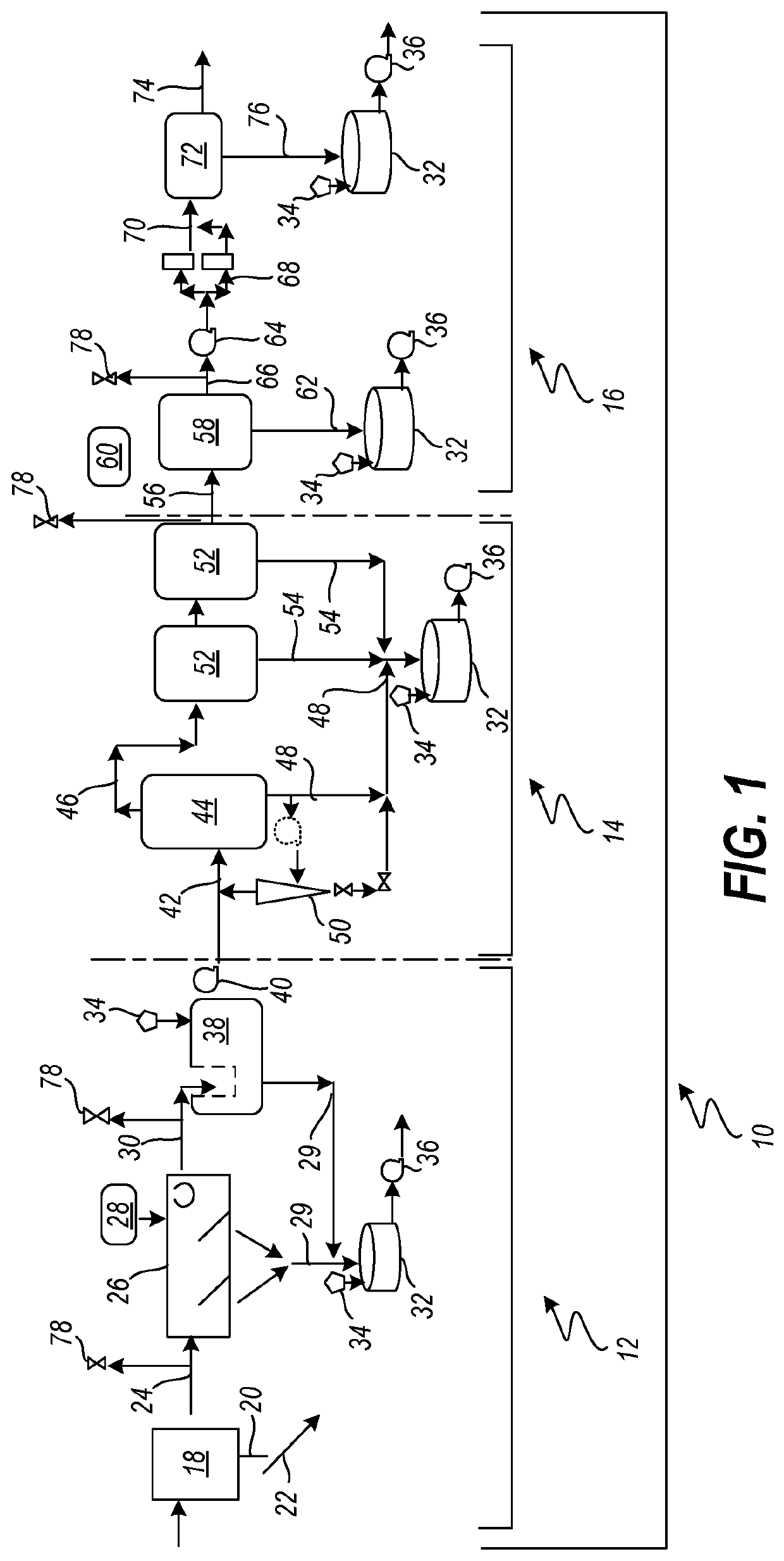

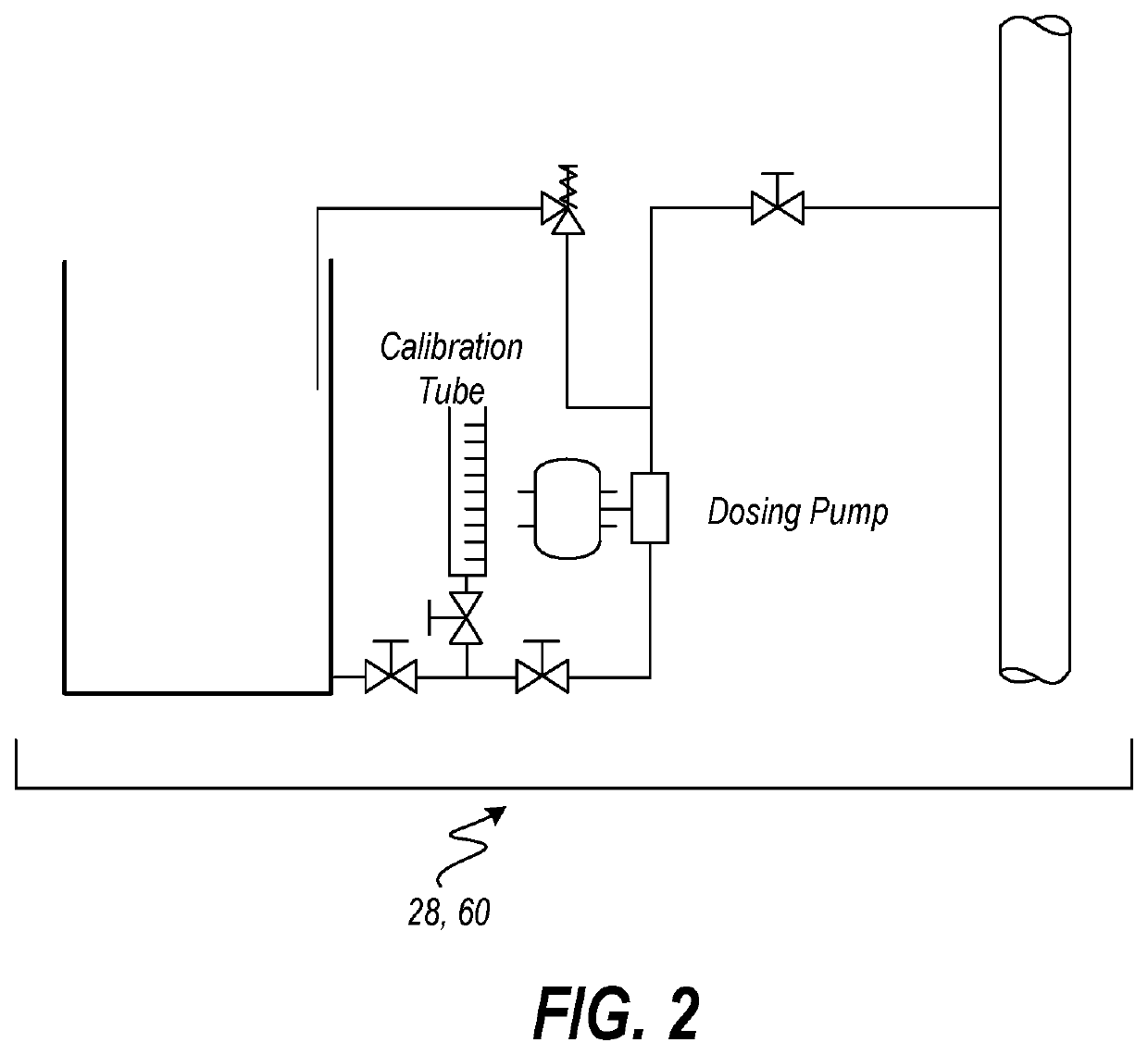

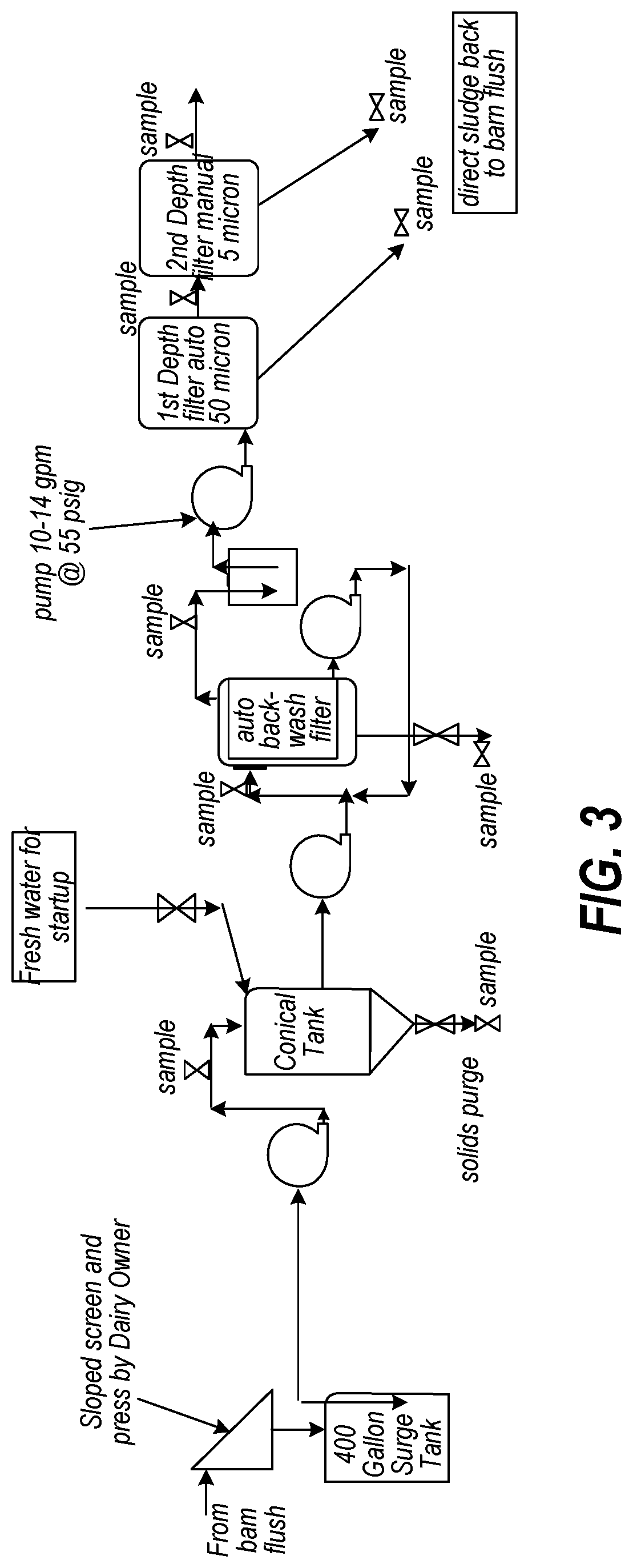

Nutrient concentration and water recovery system and associated methods

InactiveUS20200023293A1Promote recoveryIncrease volumeWaste water treatment from animal husbandryTreatment involving filtrationSludgeWaste stream

A nutrient concentration and water recovery system includes a first suspended solids settling tank configured to receive a flow stream that includes a waste stream with a sludge stream. A first centrifugal pump is coupled to the first suspended solids settling tank. The first centrifugal pump having corrosion resistant wetted parts and variable speed drives to transfer or pressurize process flow streams. A first level transmitter coupled to the first centrifugal pump that provides output signals in response to a level of a process material within the first suspended solids settling tank. The first level transmitter is mounted in the first suspended solids settling tank. A first flow transmitter coupled to the first level transmitter is configured to measure a specific volume of material transferred out of the first suspended solids settling tank. A first pump is coupled to the first flow meter and configured to transfer a flush water that includes suspended solids and inorganics. A vibrating screen is coupled to the first pump. A process tank is coupled to the submersible pump. A sedimentation removal system and a removal device coupled to the sedimentation removal system are provided and configured to remove inorganizes out of a suspension.

Owner:RENEWABLE ENERGY ALTERNATIVES

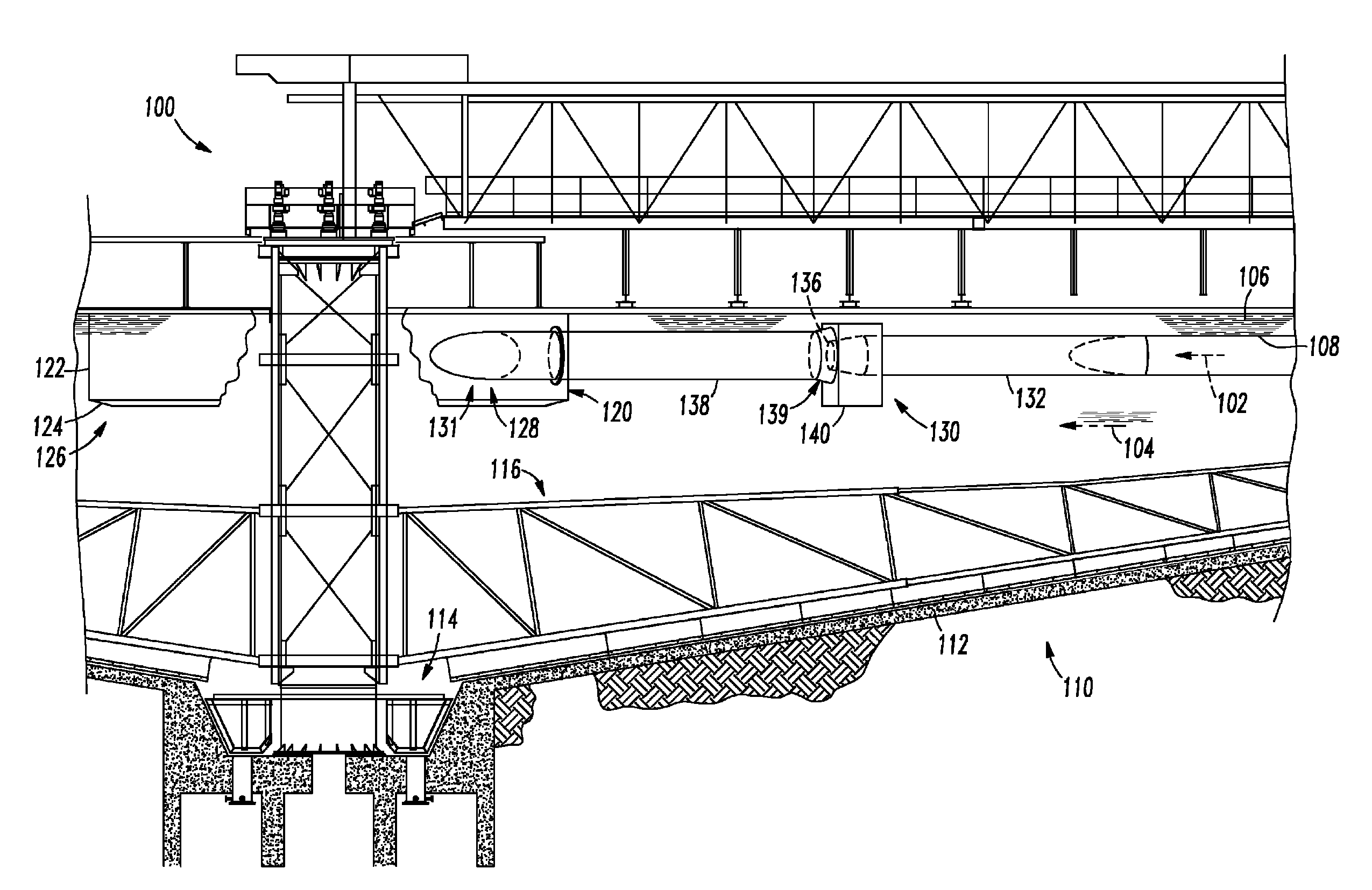

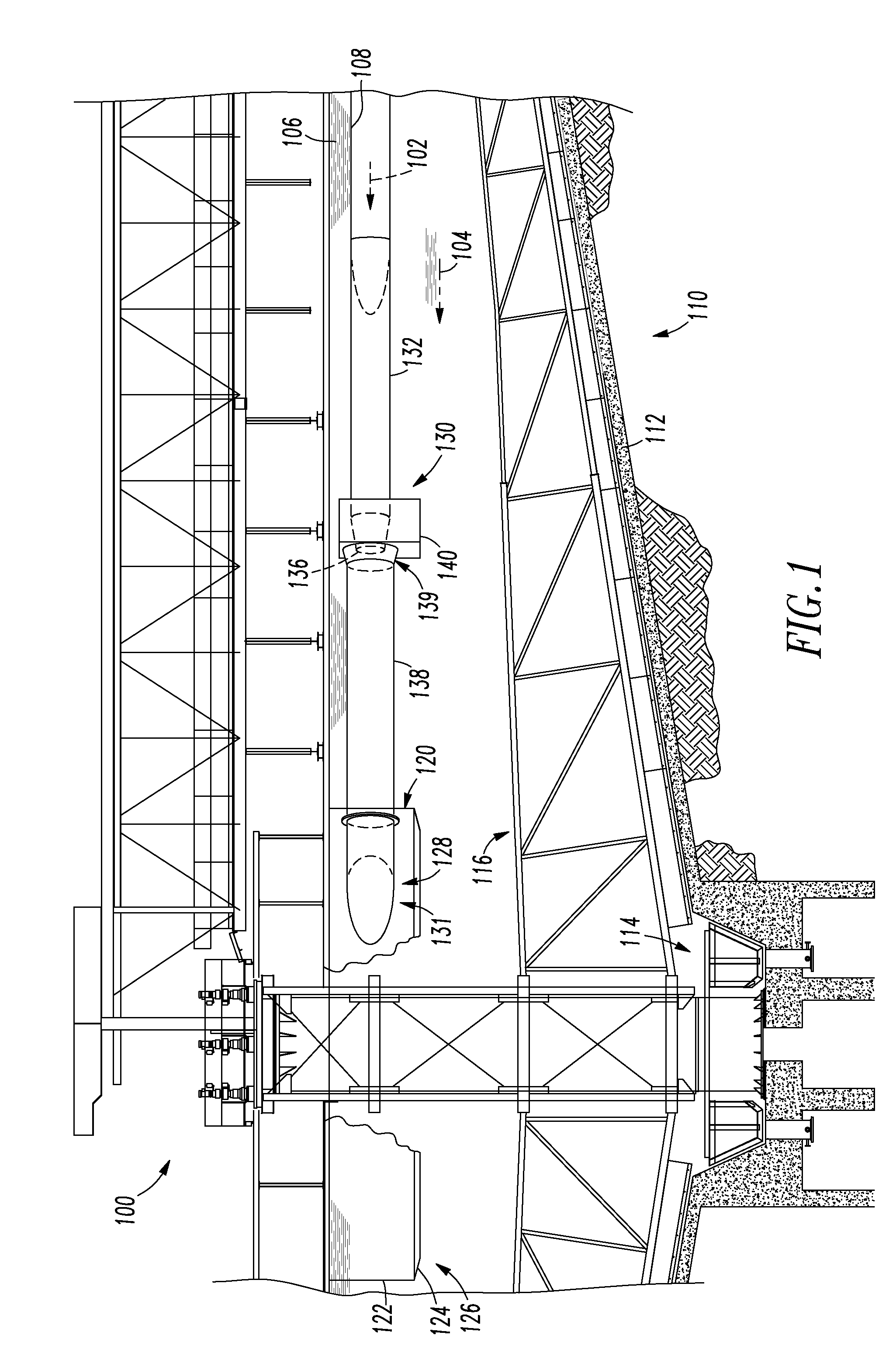

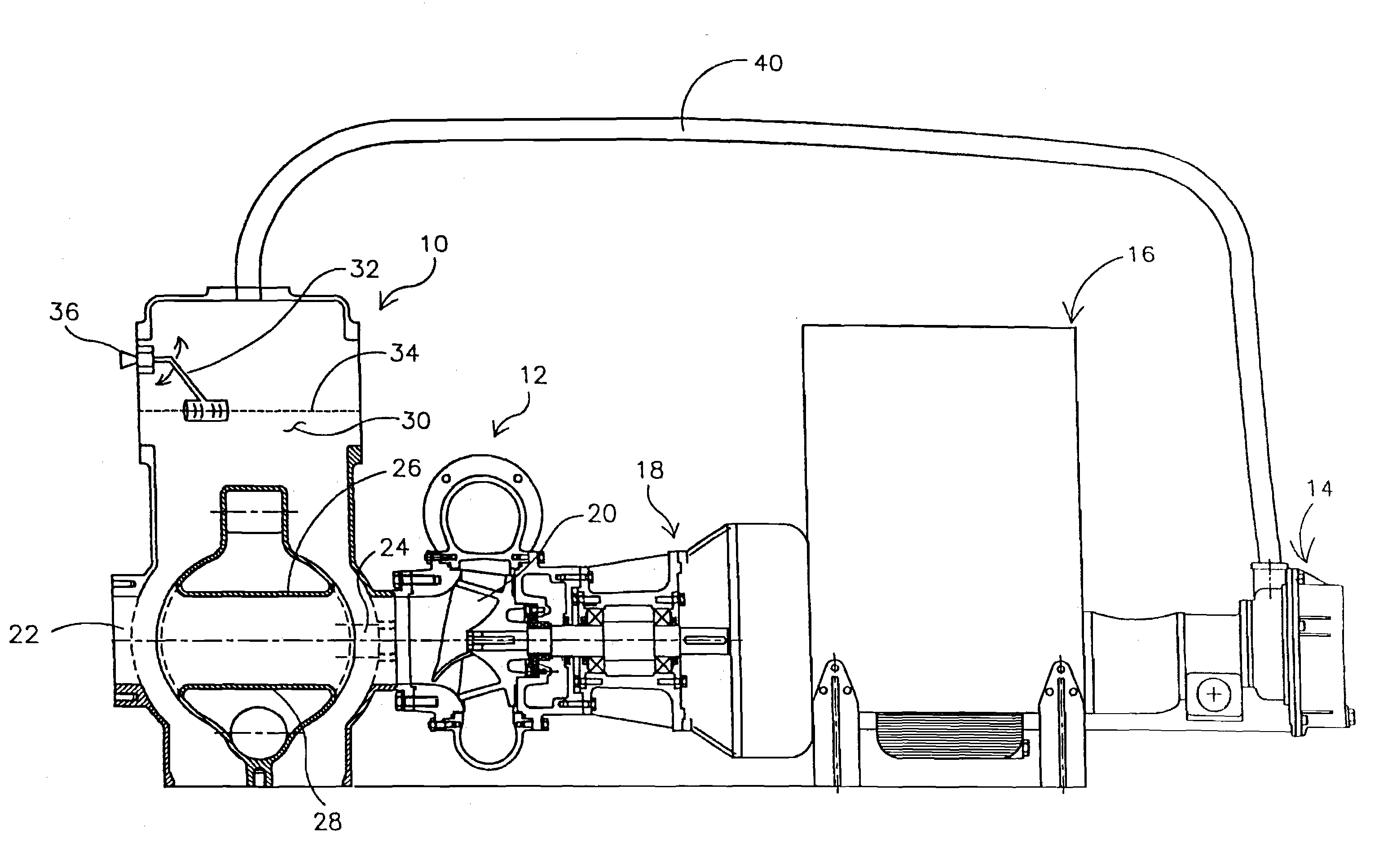

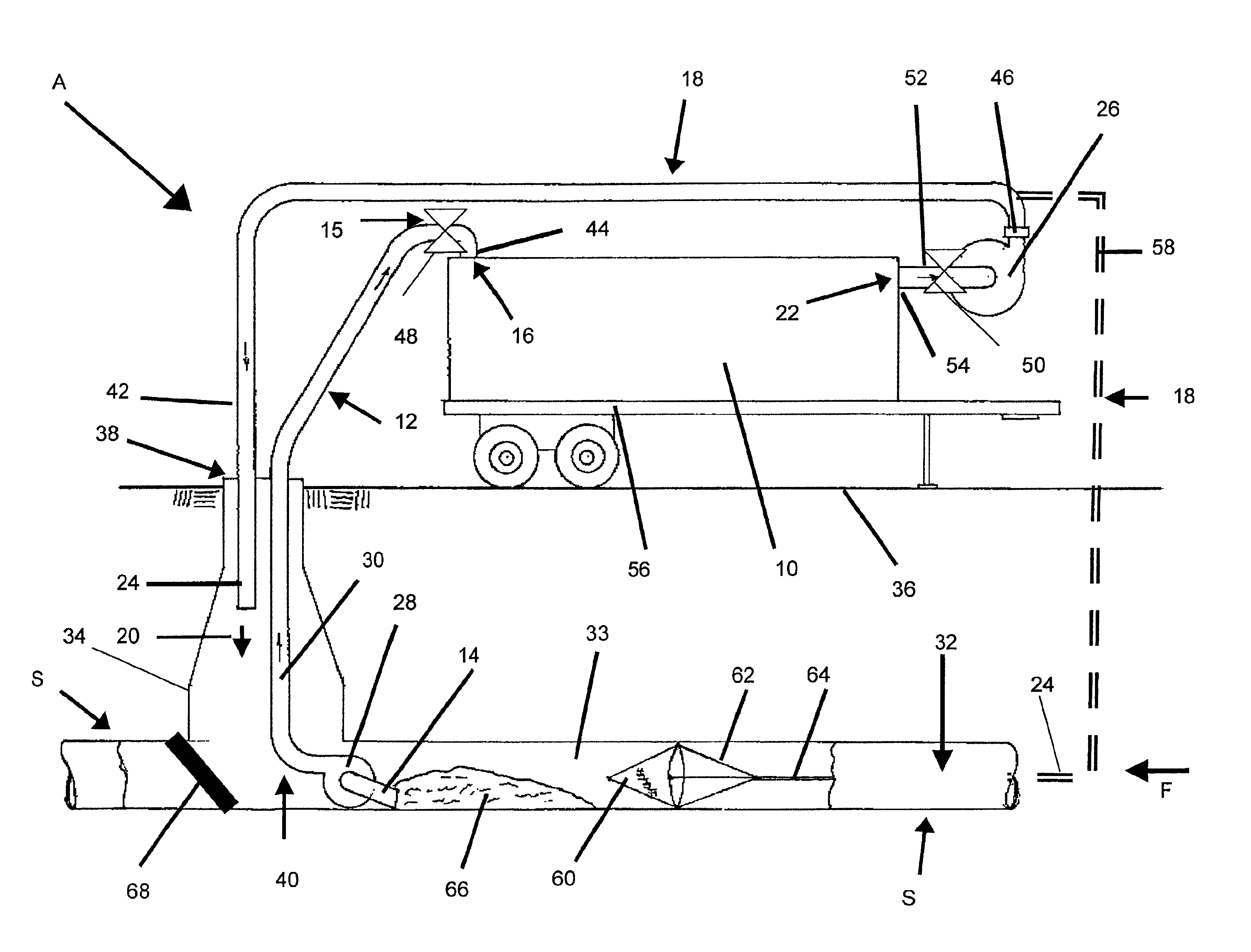

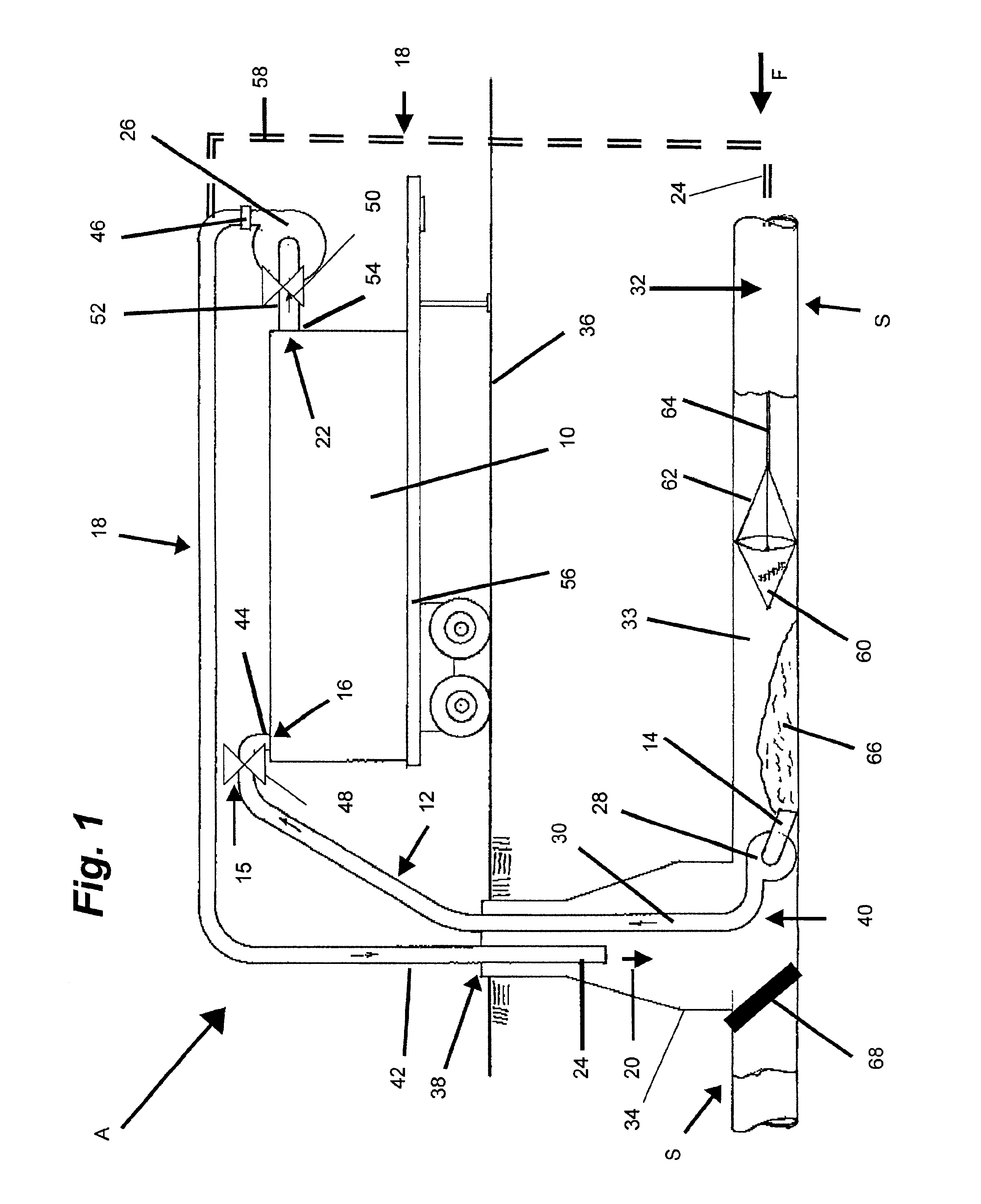

Sewer line pumping system

InactiveUS6764604B1Reduce wearLiquid separation auxillary apparatusLiquid displacementSlurryEngineering

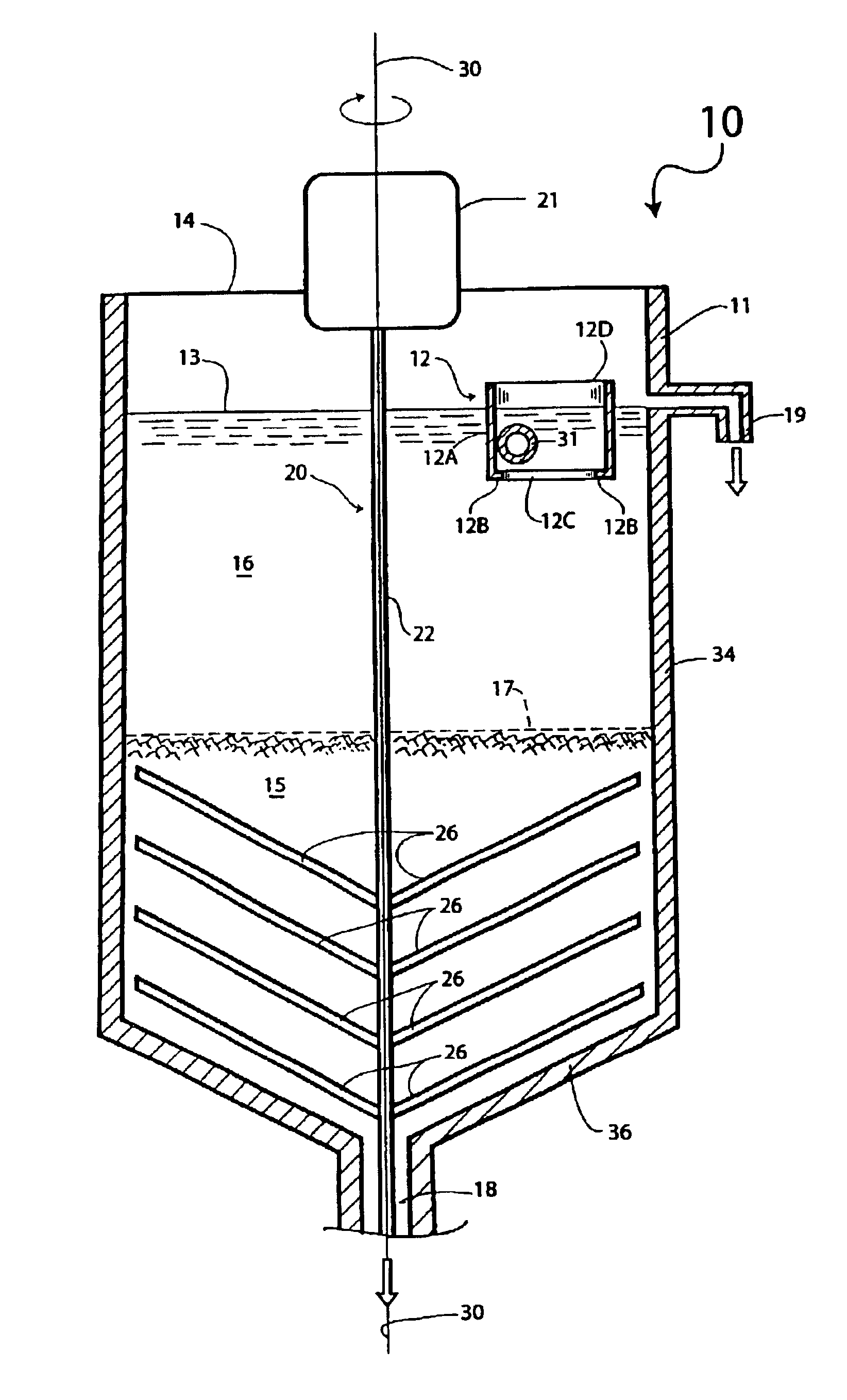

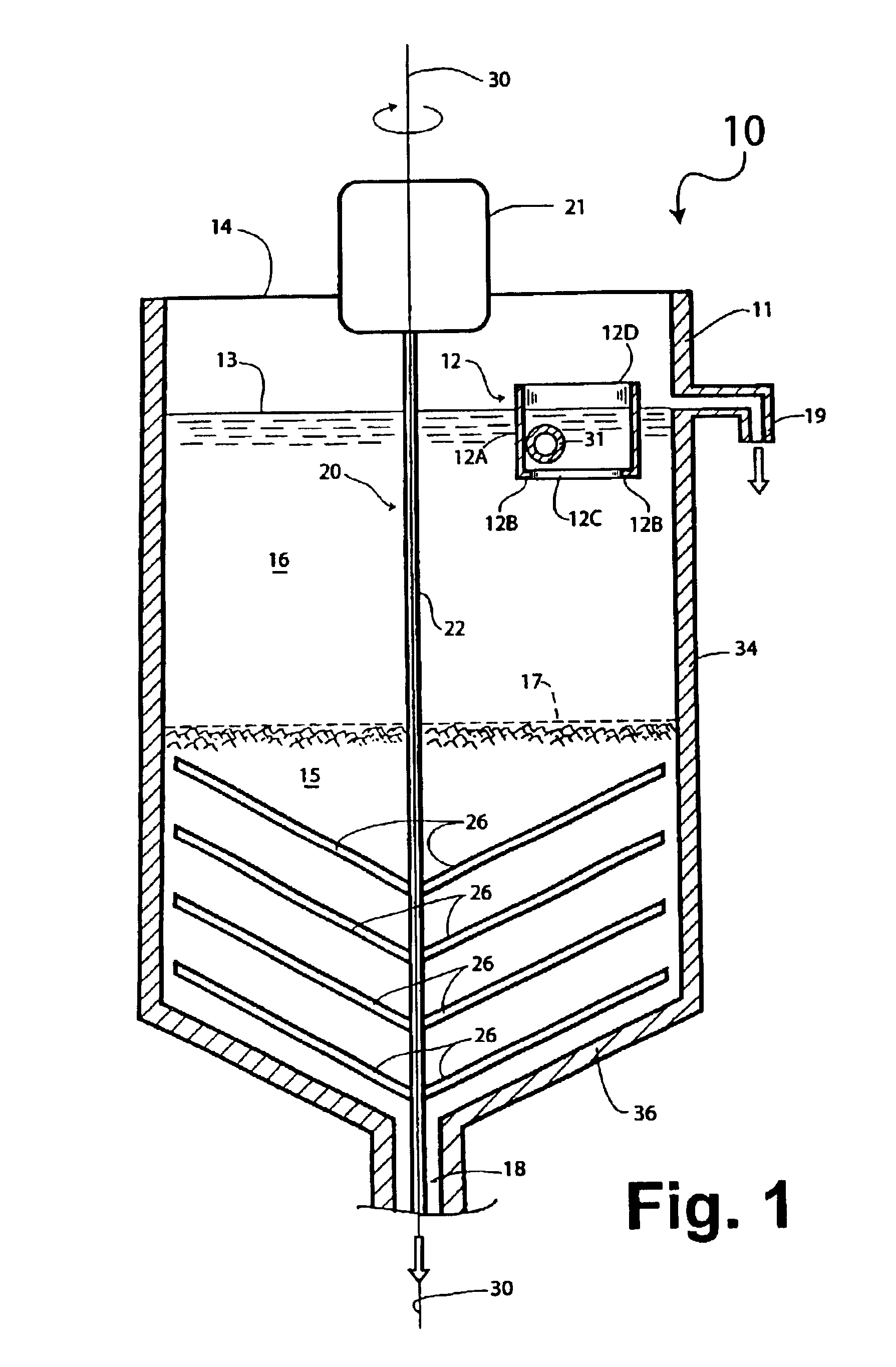

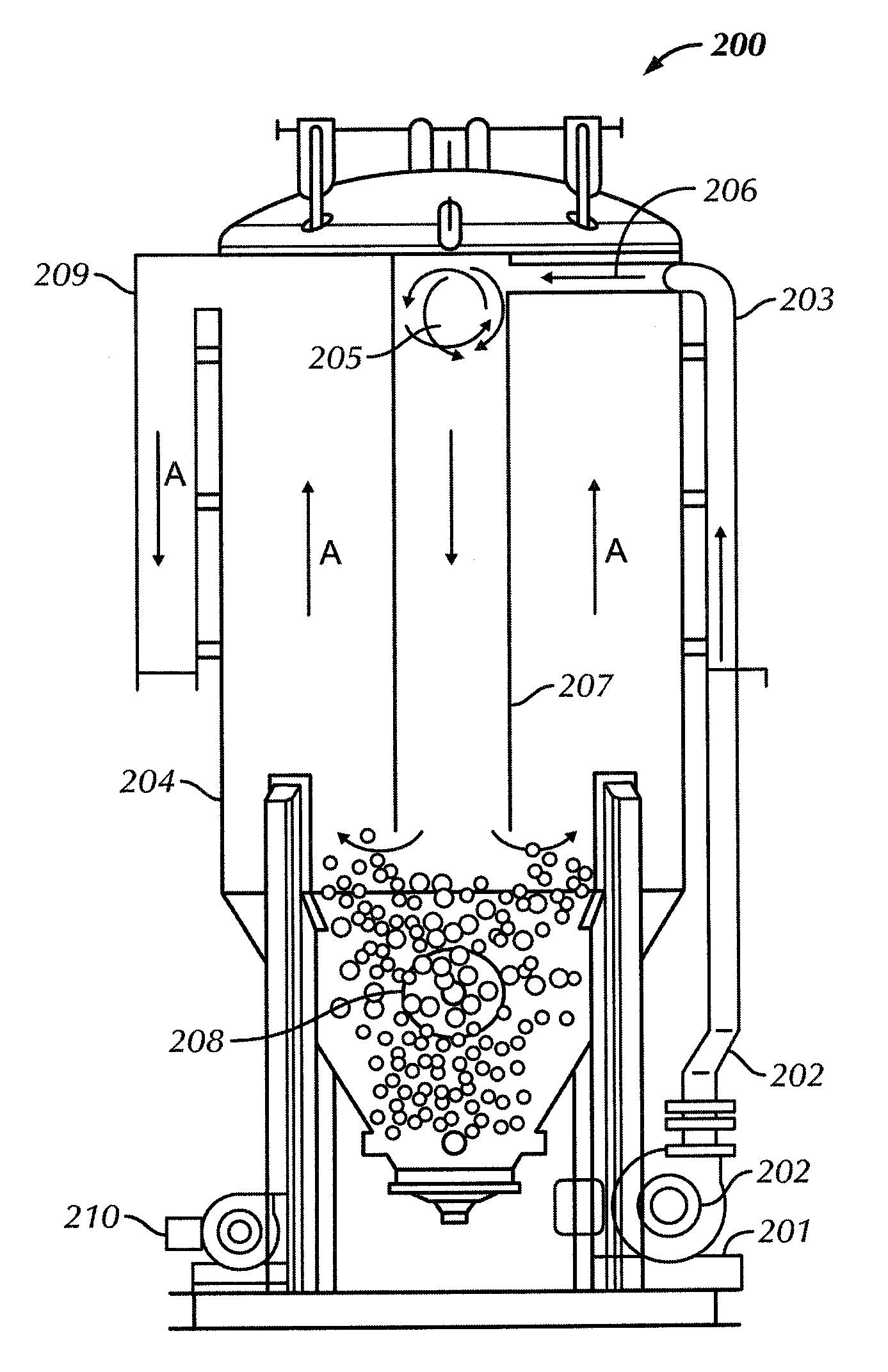

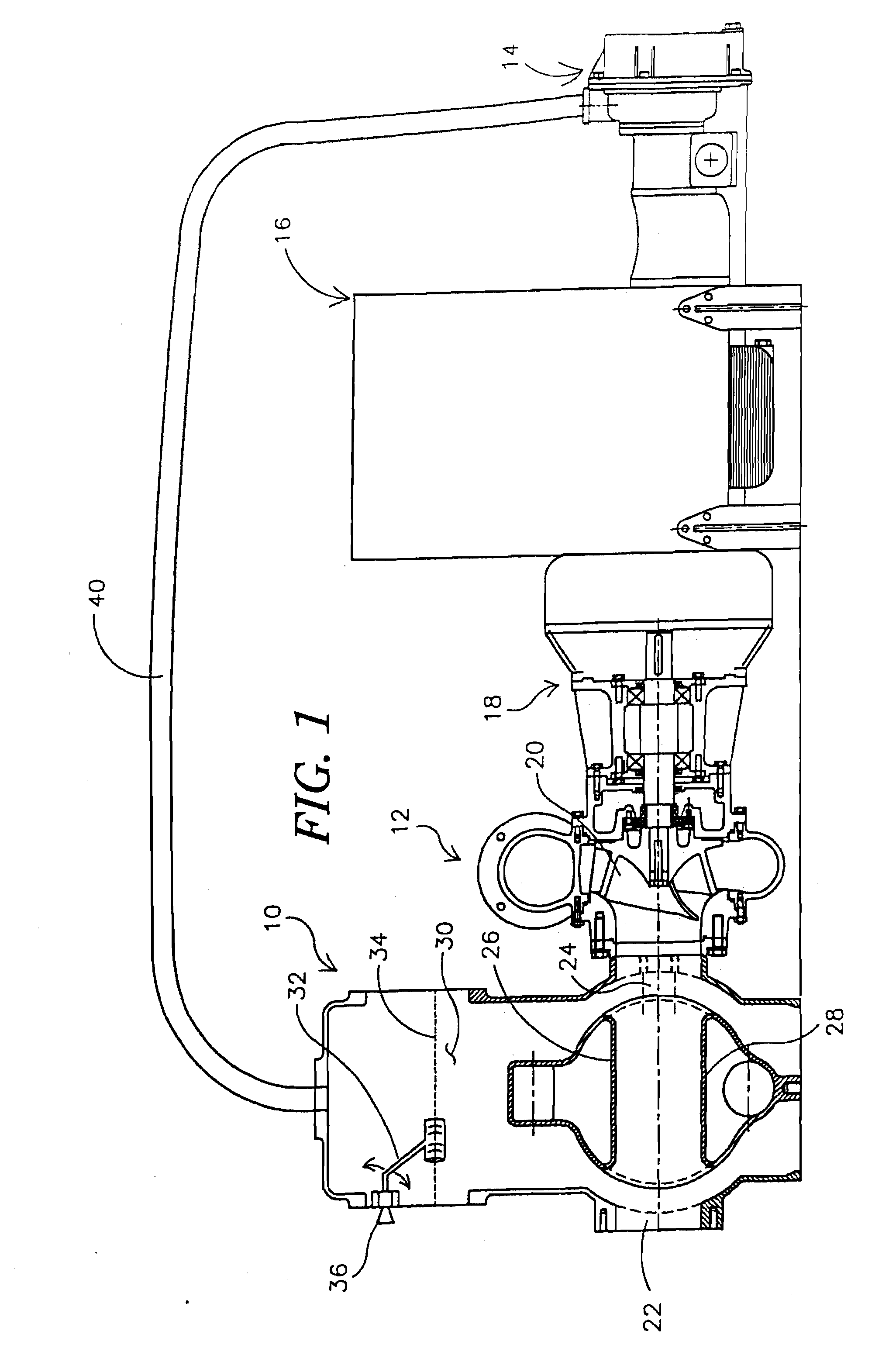

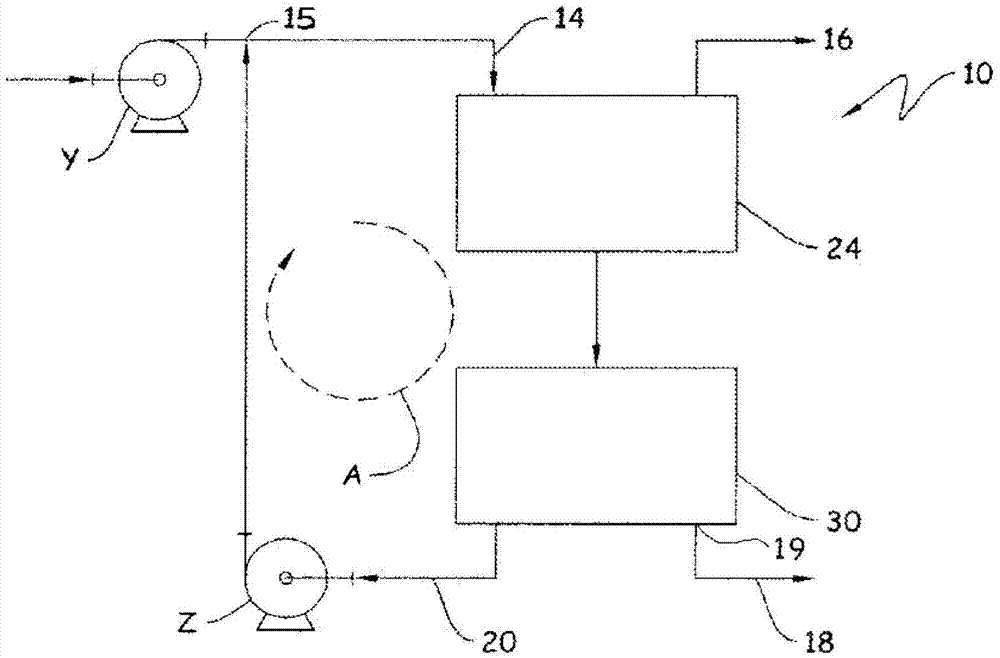

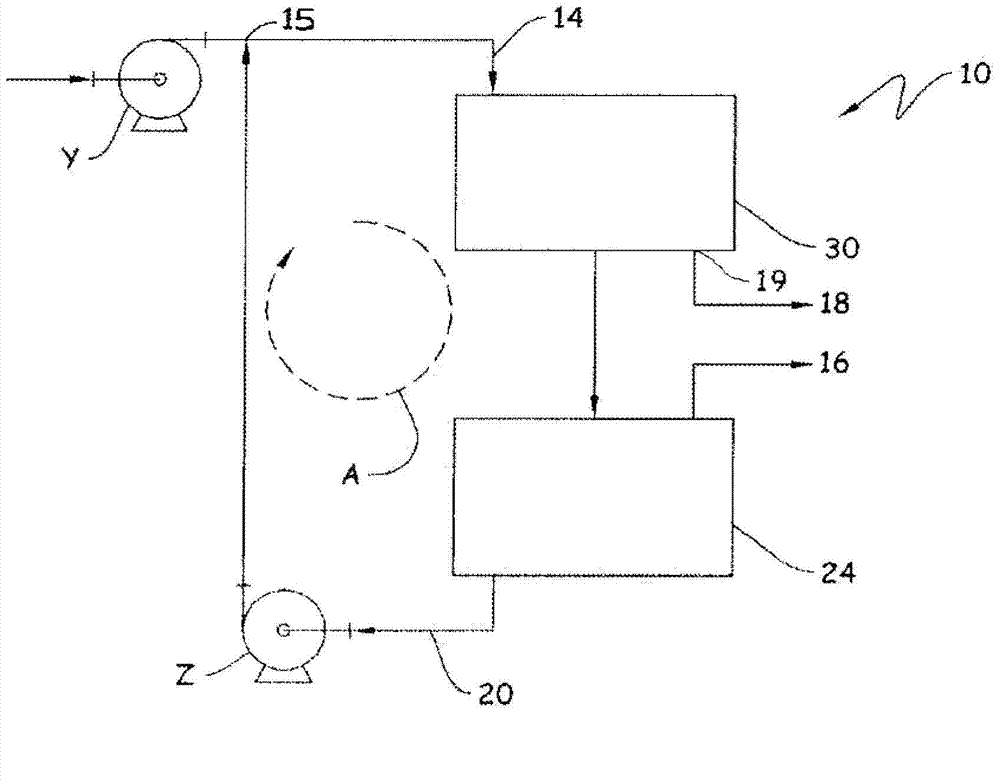

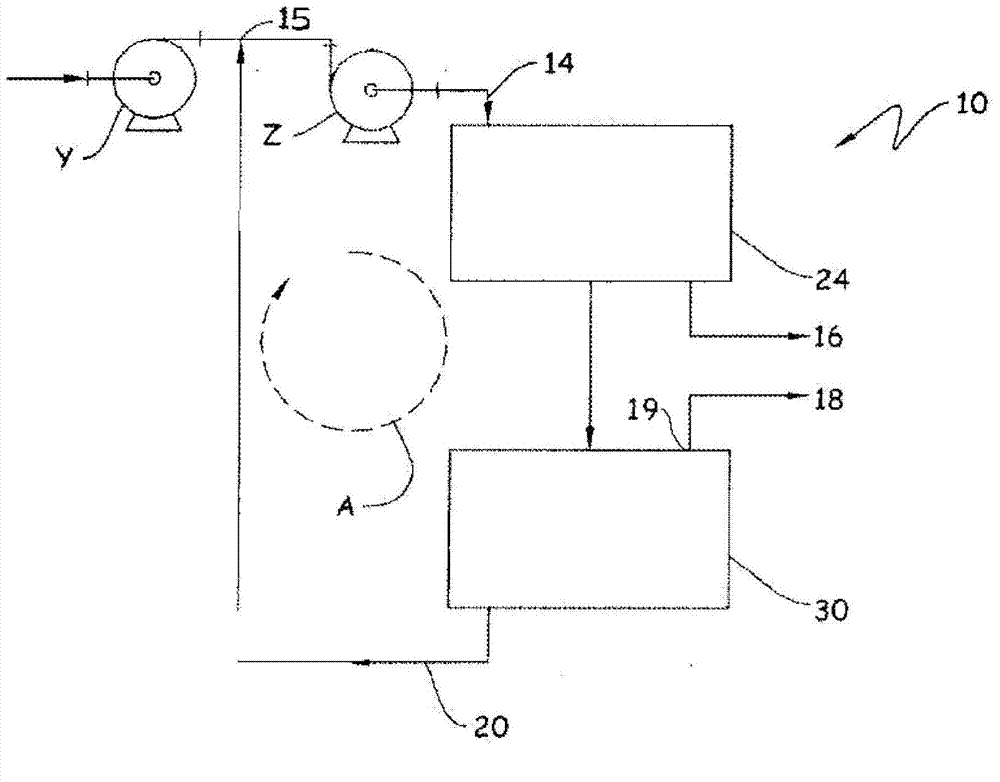

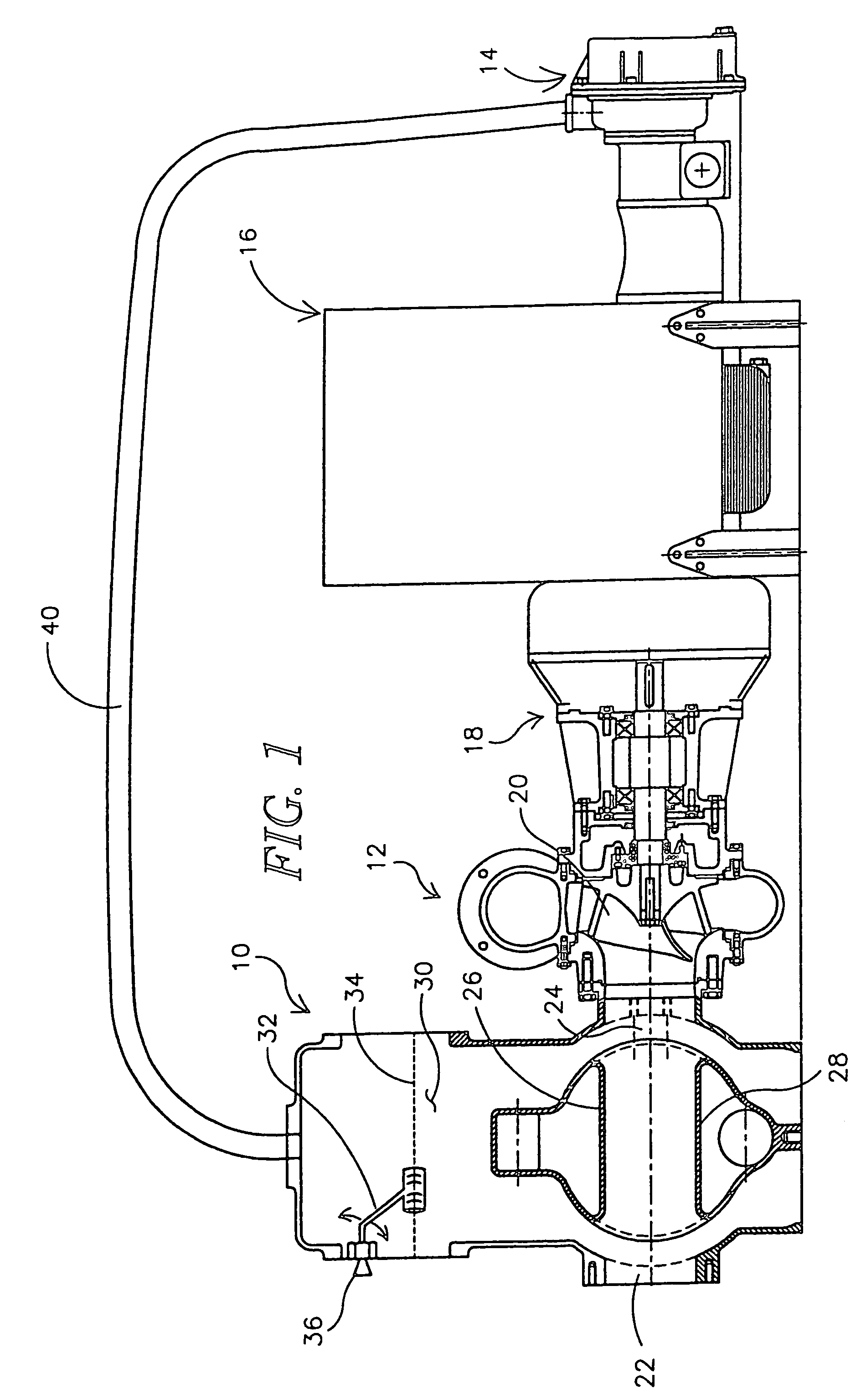

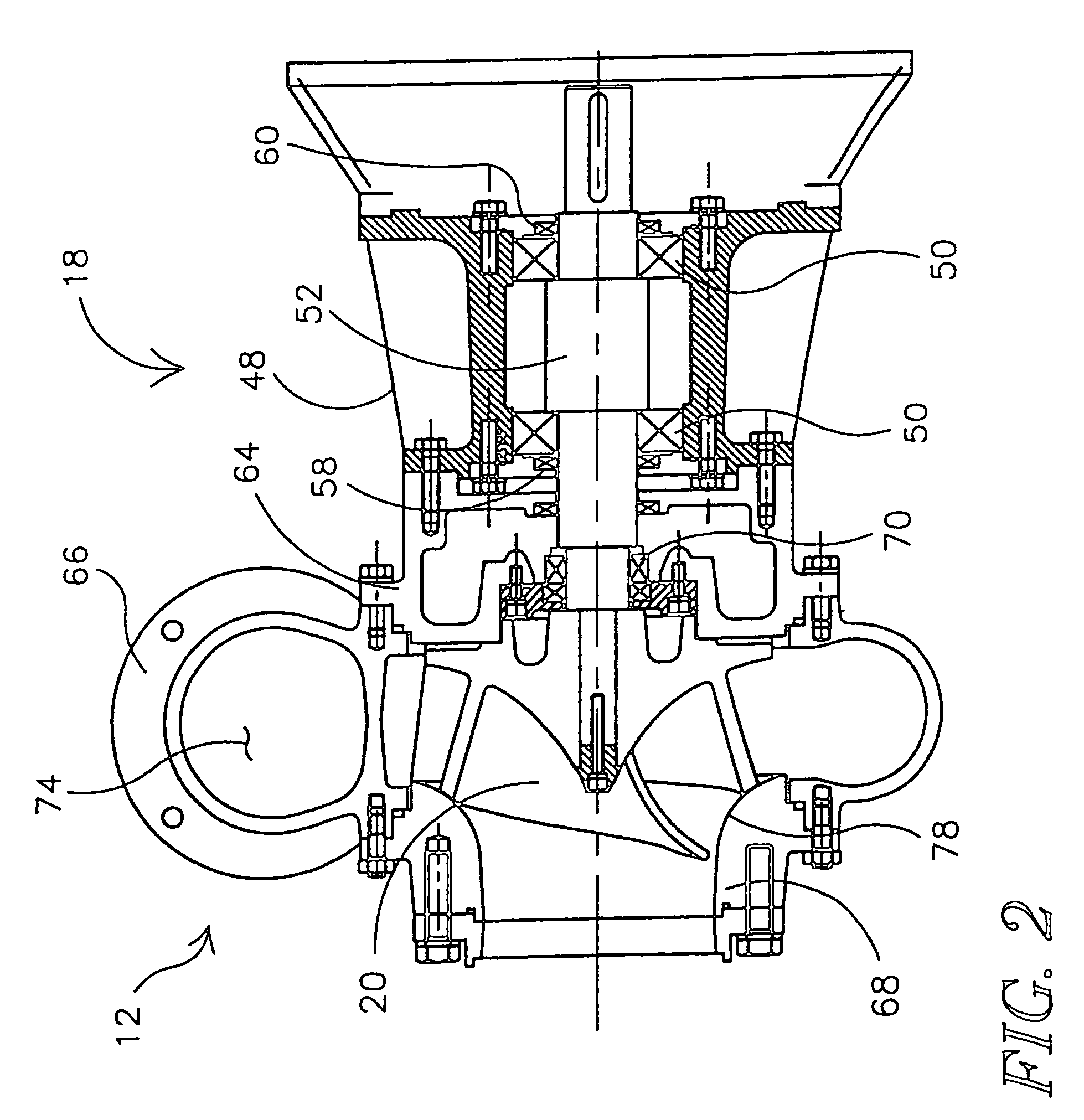

A separation apparatus (A) for separating solids from a slurry of liquid and solids includes a separation tank (10). An intake assembly (12) communicates with the separation tank (10) for conveying the slurry through an entrance end (14) into an inlet (16) formed in the tank (10). An outlet assembly (18) communicates with the separation tank (10) for conveying decanted liquid (20) through an outlet (22) formed in the tank (10) to an exit end (24) of the outlet assembly (18) positioned in a desired location. A pump (26) is adapted to convey the decanted liquid (20) from the separation tank (10) through the outlet assembly (18). The tank (10), intake assembly (12), and outlet assembly (18) form an airtight, compartmented system when the entrance end (14) of the intake assembly (12) and the exit end (24) of the outlet assembly (18) are sealed.

Owner:NEZAT II MALVIN A

Oil skimming apparatus and method for using same

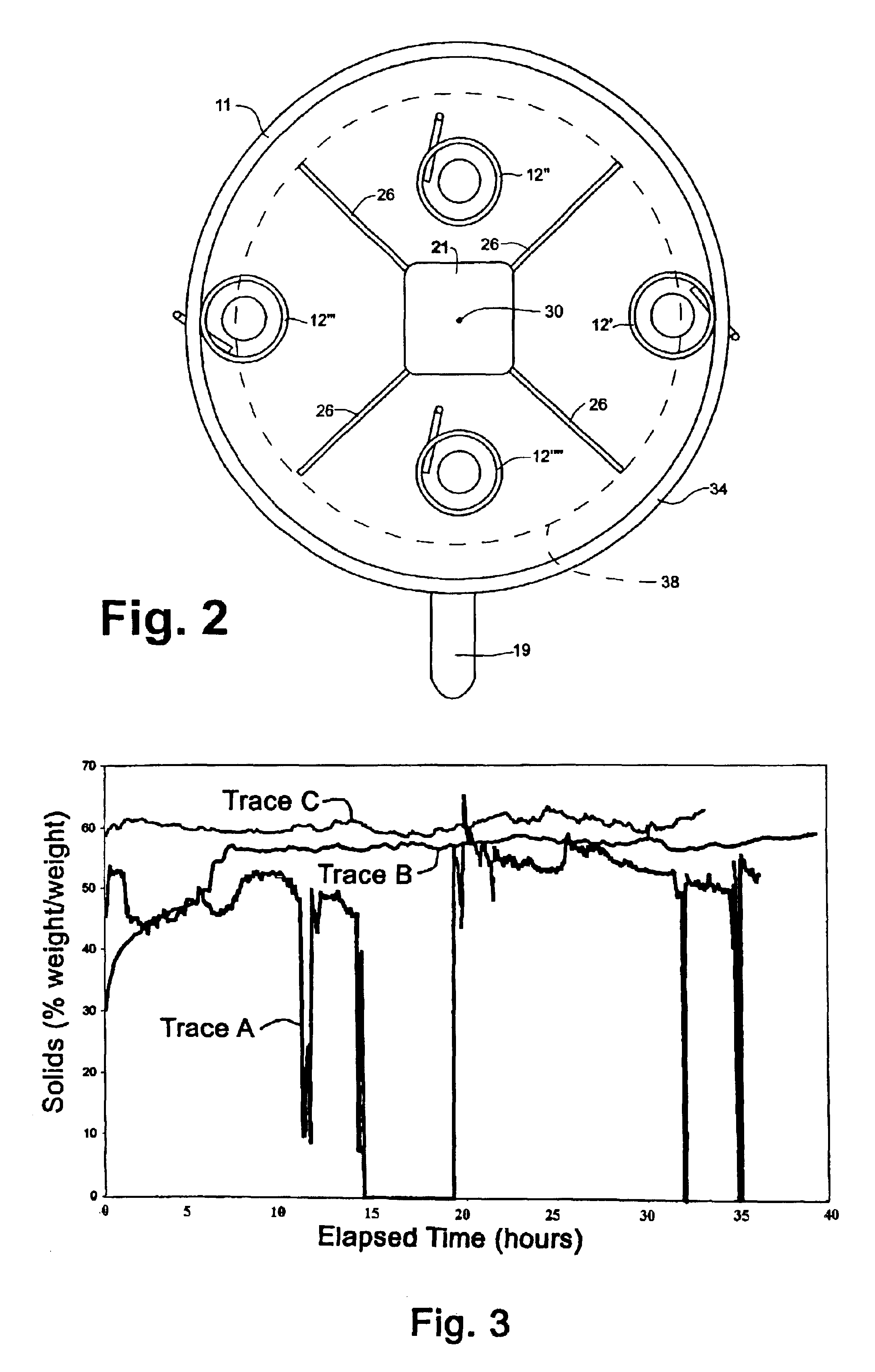

An oil separation method and apparatus for the separation of acceptable oil from contaminated oil containing solids and liquids withdrawn from an oil well. A single oil skimming unit is partitioned into compartments and provided with rotating skimming tubes. A water leg may be raised and lowered in order to maintain a constant fluid level in the first, or water, compartment. Two pump jets are incoporated into the neck of the gas separator in order to continually move the solid contaminants so that they are not as able to settle and block fluid flow in the gas separator.

Owner:HORIZONTAL RENTALS

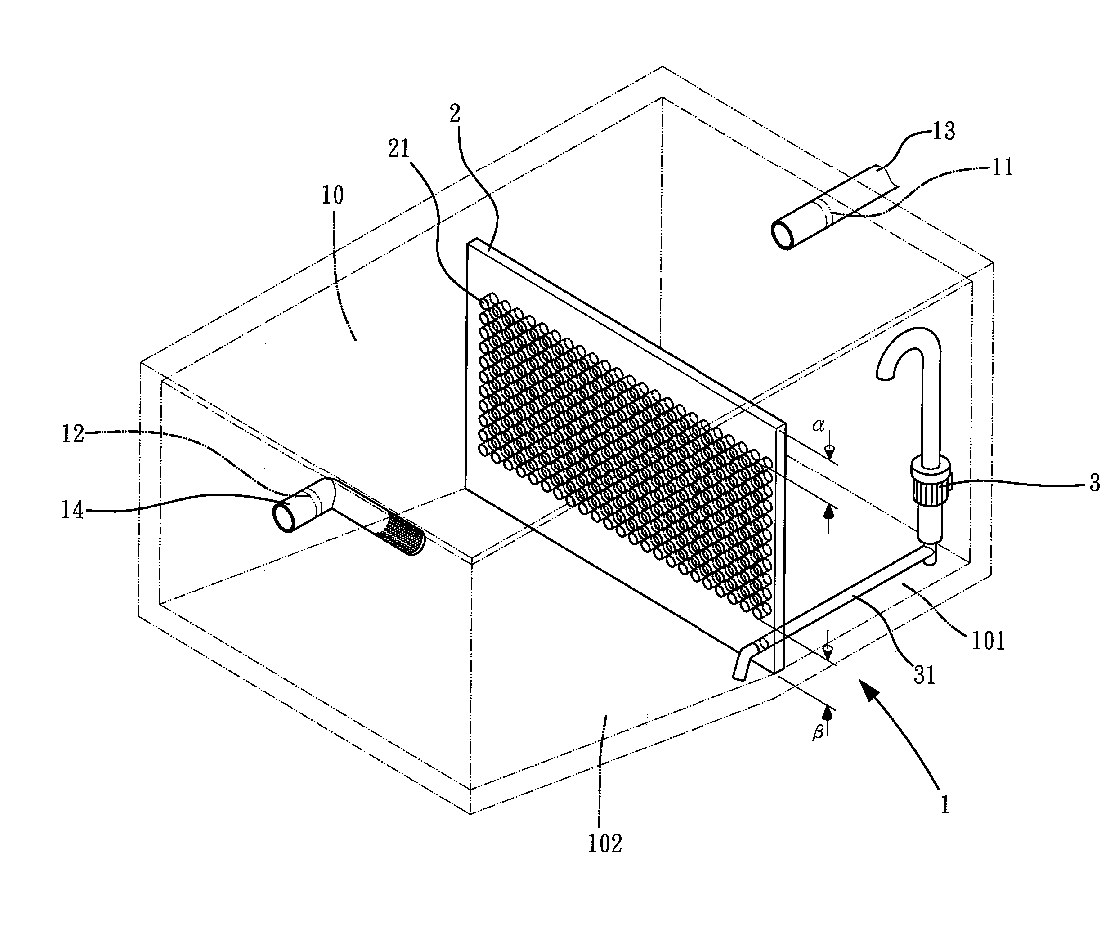

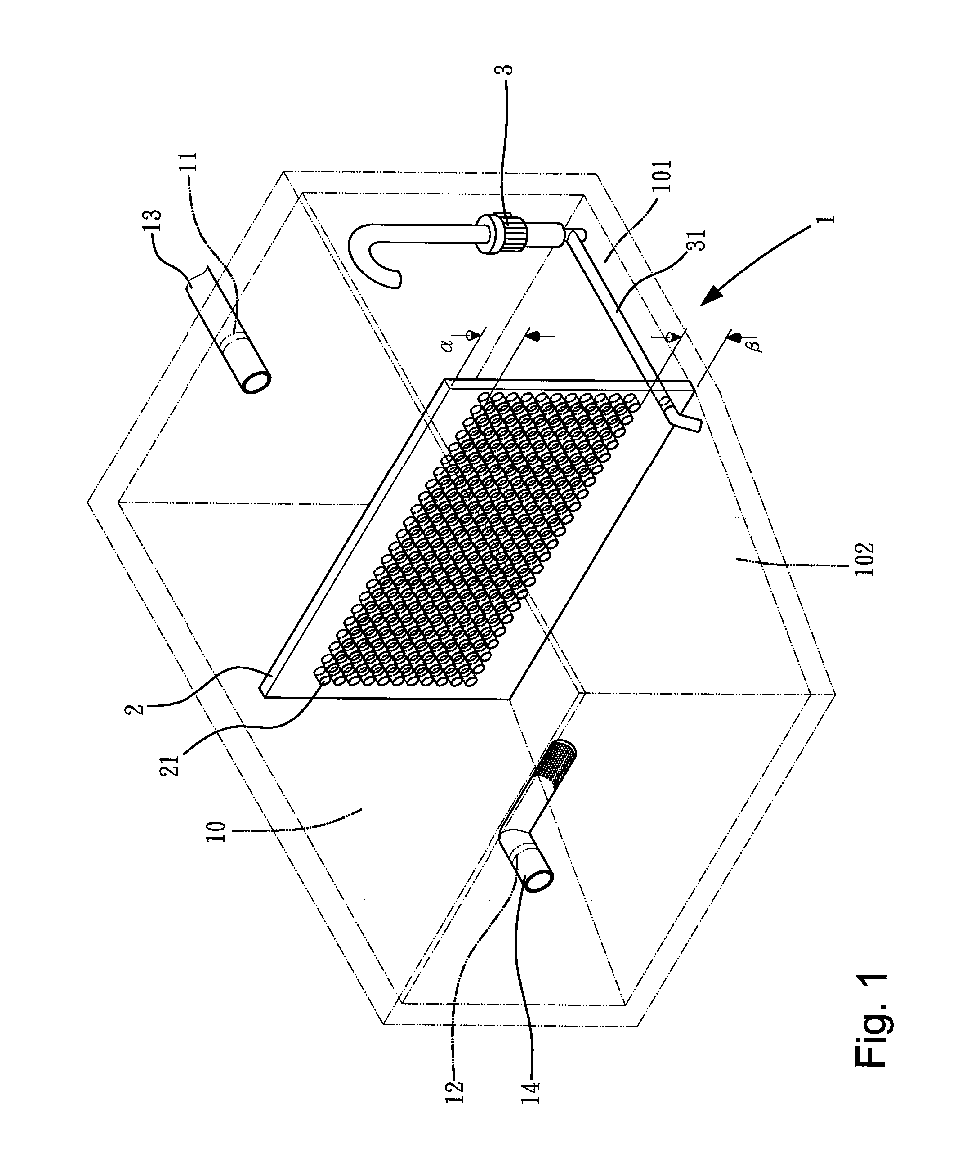

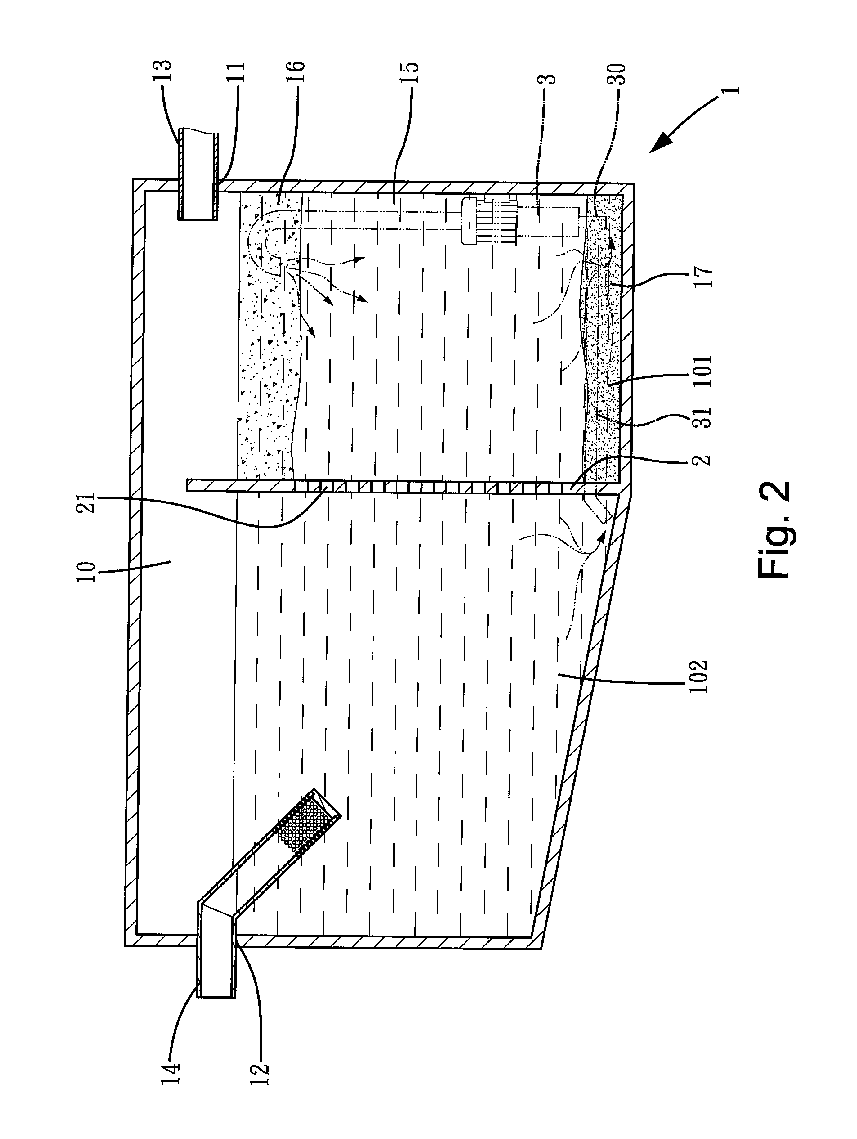

System for processing food process waste water including purification and optional recycling of purified waste water

InactiveUS20160288021A1Easy to disassembleFiner treatment levelUltrafiltrationTreatment involving filtrationFiltrationWastewater

An apparatus and method for treatment of food process waste water, comprising a tank for receiving a food process waste water influent via an influent pump and discharging a treated food process waste water effluent via an effluent pump; a floating decanter disposed in the tank; a valved outlet formed in the bottom of the tank; an upper level float switch operationally connected to the floating decanter; a lower level float switch operationally connected to the floating decanter and to the effluent pump; and a timer operationally connected to the floating decanter and the effluent pump. Solids are settled from the waste water and drawn off through the tank bottom after a supernatant fluid is drawn off through the floating decanter. The supernatant fluid is passed through a filtration and membrane water purification apparatus to generate purified water.

Owner:CLEARCOVE SYST

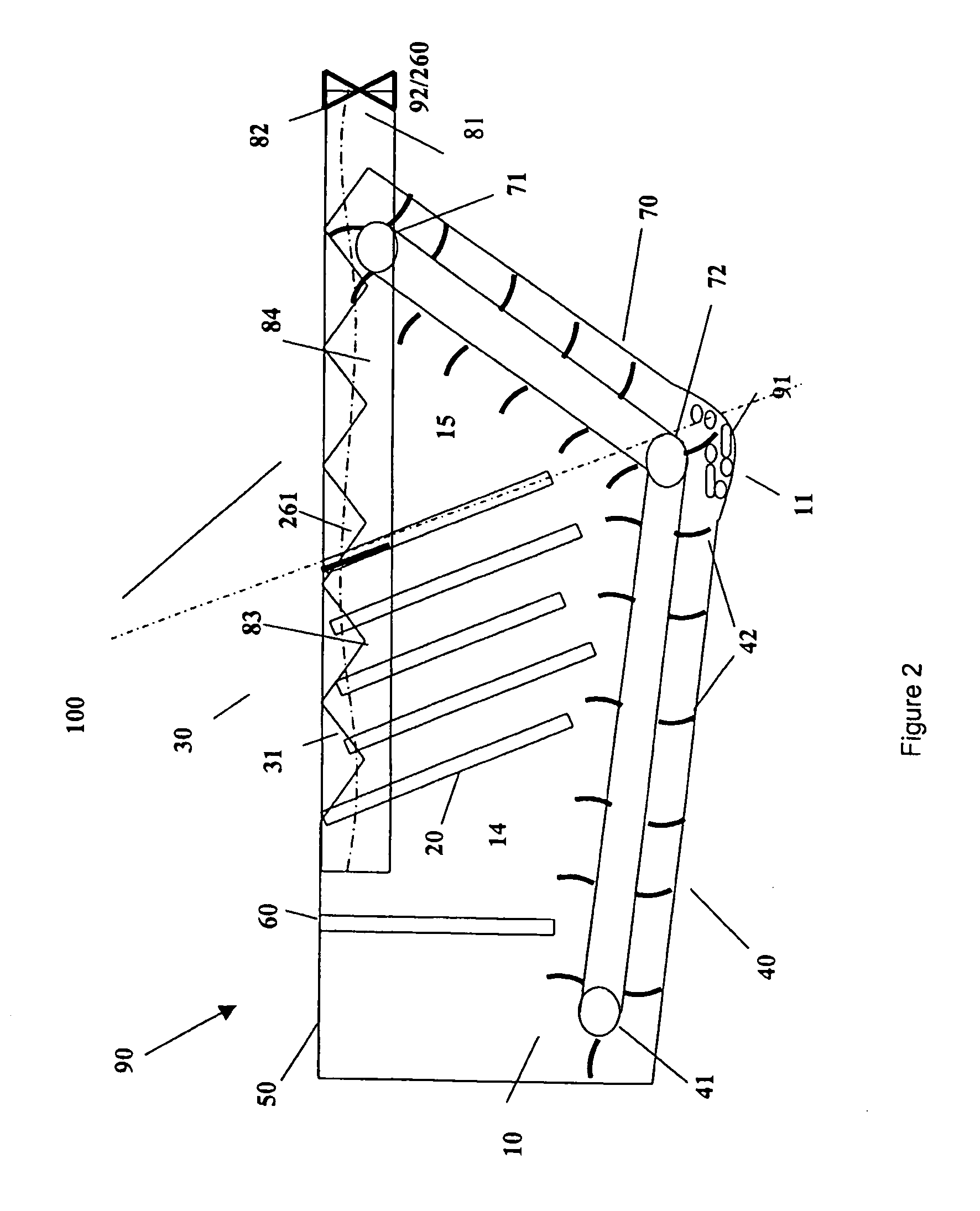

Cross-flow filtration system including particulate settling zone

Cross-flow filtration systems and corresponding methods for separation particulate matter from liquids. A representative system includes a cross-flow filtration zone (24) in fluid communication with a particulate settling zone (30) and further includes a fluid inlet (14) in fluid communication with one of the zones and a process fluid outlet (20) and in fluid communication with the other zone. A fluid treatment pathway (28) extends from the fluid inlet (14), through the cross-flow filtration and particulate settling zones (24, 30) to the process fluid outlet (20). A filter assembly (26) is located within the cross-flow filtration zone (24) and comprises a membrane surface (44) that isolates a filtrate chamber (46) from the fluid treatment pathway (28), and the filtrate chamber (46) is in fluid communication with a filtered fluid outlet (16). A recirculation pump (Z) in fluid communication with the process fluid outlet (20) and fluid inlet (14). A pressurizable recirculation loop (A) comprises the fluid treatment pathway (28) and recirculation pump (Z) and the recirculation pump (Z) is adapted for driving pressurized through the recirculation loop (A). A feed pump (Y) is adapted to introduce feed liquid into the system (10); and an effluent outlet (18) in fluid communication with the particulate settling zone (30). The feed pump (Y), effluent outlet (18) and filtered fluid outlet (16) reside outside of the recirculation loop (A).

Owner:DOW GLOBAL TECH LLC

Pump system with vacuum source

InactiveUS7011505B2Reduces system reliabilityIncrease distanceSpecific fluid pumpsPipe elementsEngineeringVacuum pump

A self priming pump system that includes a motor coupled to a centrifugal pump for driving the centrifugal pump. A separator having a reservoir is provided for storing a limited amount of pumped fluid in advance of the centrifugal pump. A vacuum source provides a vacuum suction to the reservoir to draw pumped fluid into the reservoir to prime the pump. To increase the reliability of the vacuum pump system, a deflector and / or extension may be provided in the reservoir to help prevent pumped fluid from entering the vacuum pump input. Also, the configuration of a tank used to store liquid for the vacuum pump system may be configured to separate and collect sediments near a drain port, which then can be easily drained. For positive head pressures, one or more valves may be used to prevent pumped fluid from escaping the reservoir, if desired.

Owner:MULTIQUIP

Feedwell dilution system for thickeners in oil sands

ActiveUS20110132846A1Promote formationLiquid separation auxillary apparatusSettling tank with pumpEngineeringOil sands

A feedwell dilution system for diluting an influent feed stream, which include at least one eductor assembly, and a feedwell assembly. The at least one eductor assembly includes a feed pipe which converges to a narrow throat portion or nozzle; a mix tube positioned downstream from the narrow throat portion that is sized and configured to provide mixing of the influent feed stream and a clarified liquid drawn from a settling tank; and an enclosure, which is installed around the narrow throat portion and an inlet portion of the mix tube and includes an open-ended portion on a bottom thereof, which is sized and configured to allow a clarified liquid to be pulled into the mix tube from below the inlet portion of the mix tube. The feedwell assembly is sized and configured to receive the mixture of the influent feed stream and the clarified liquid from the mix tube.

Owner:F L SMIDTH & CO AS

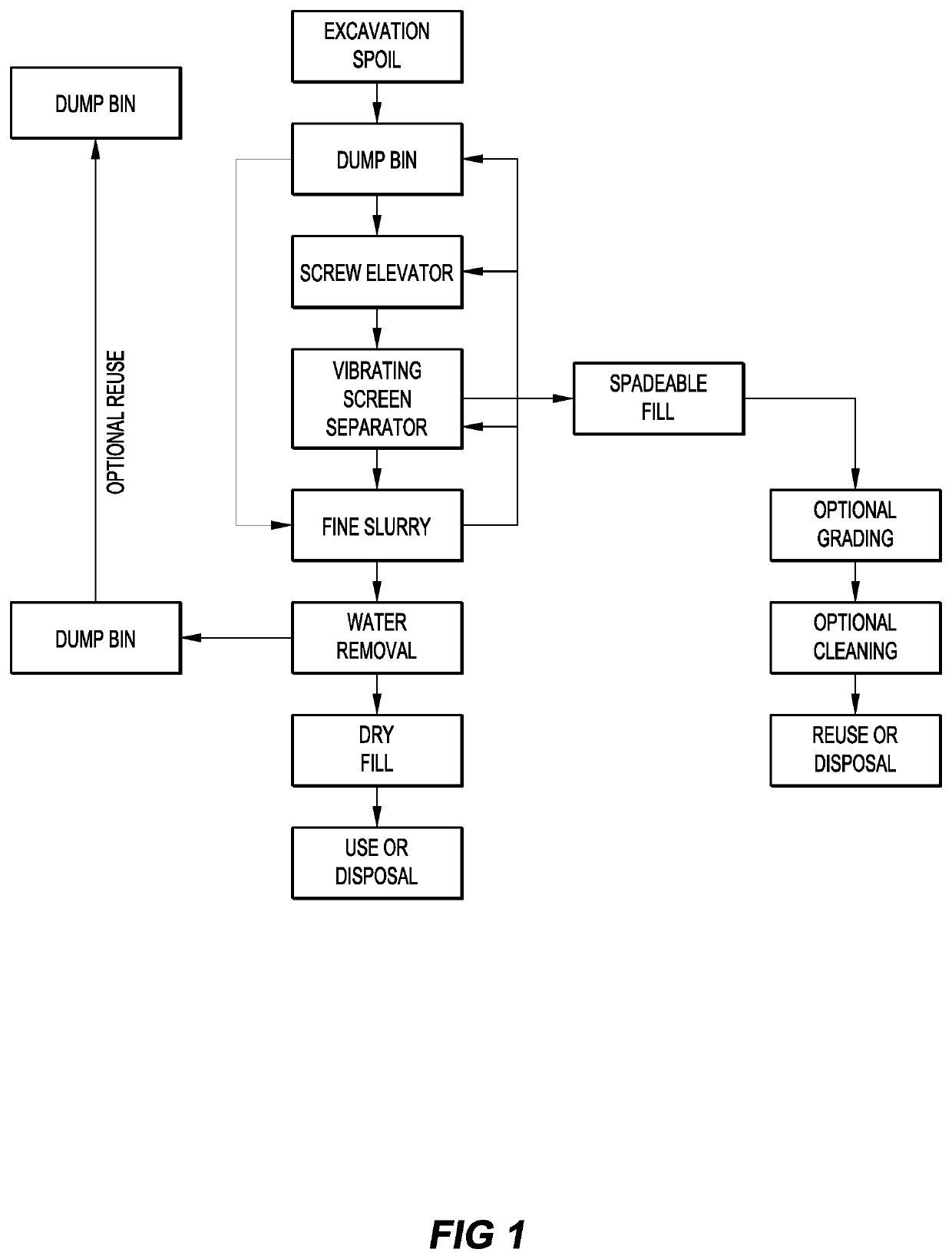

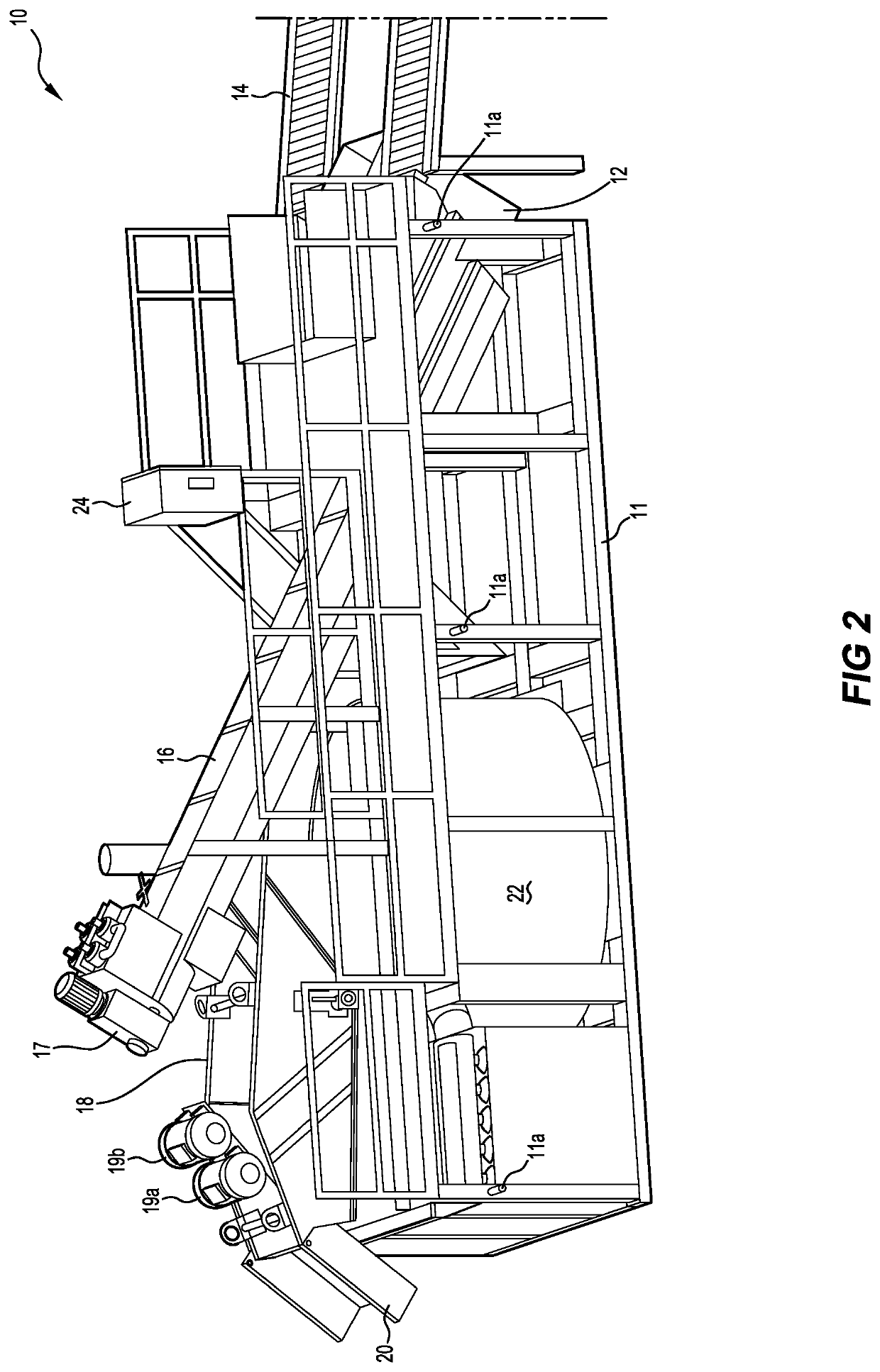

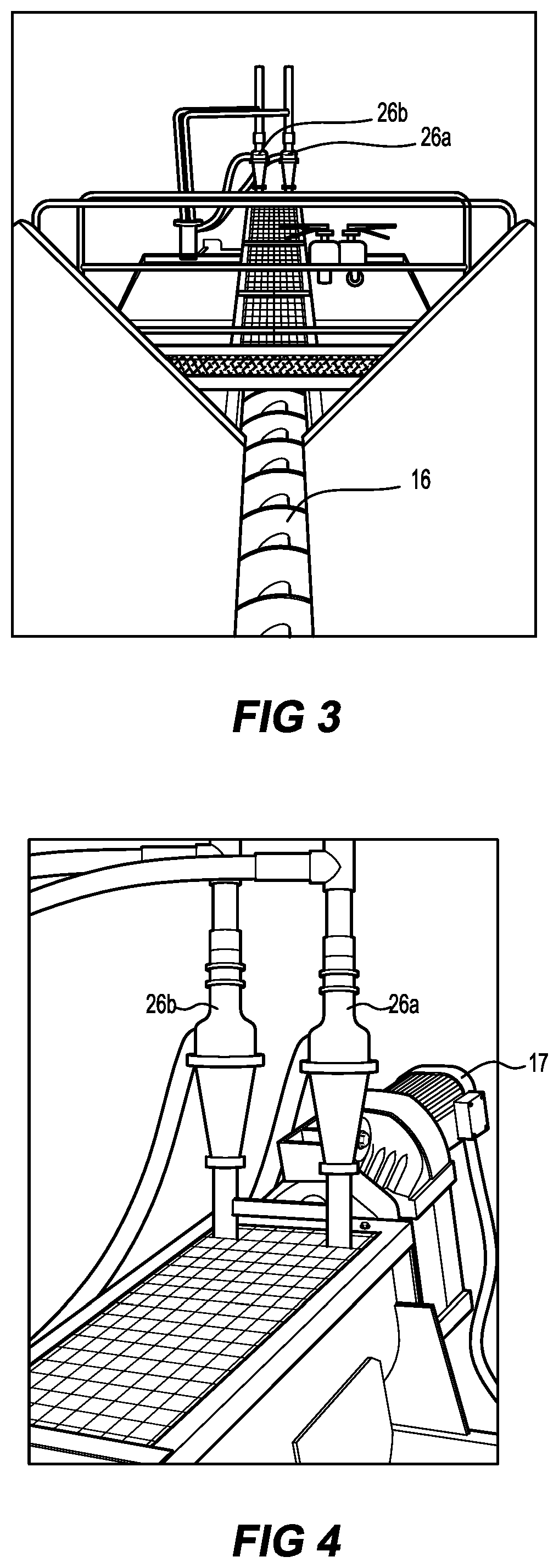

Spoil treatment plant

Owner:VHS IP PTY LTD

Thickener Feed Dilution System

InactiveUS20180133622A1Settling tank with pumpSedimentation regulating devicesEngineeringCheck valve

Dilution check valves, pumps, systems, and methods of use, useful for dilution of incoming feed into a feedwell or feed system that can be easily installed and removed on solid / liquid separation units. The feed dilution apparatuses or systems can be installed in a single location or in multiple locations around a feedwell, transferring supernatant drawn from single or multiple locations within a solid / liquid separation tank. Optionally, an in-line turbine style pump and / or downward draft configuration can be used to provide efficient pumping and accurate adjustment of volume by increasing or decreasing rotation speed. The feed dilution pumps can optionally be installed using a quick fit system that allows removal and replacement during operation without the need for mobile cranes or heavy lifting equipment.

Owner:PATERSON & COOKE IDEAS LTD

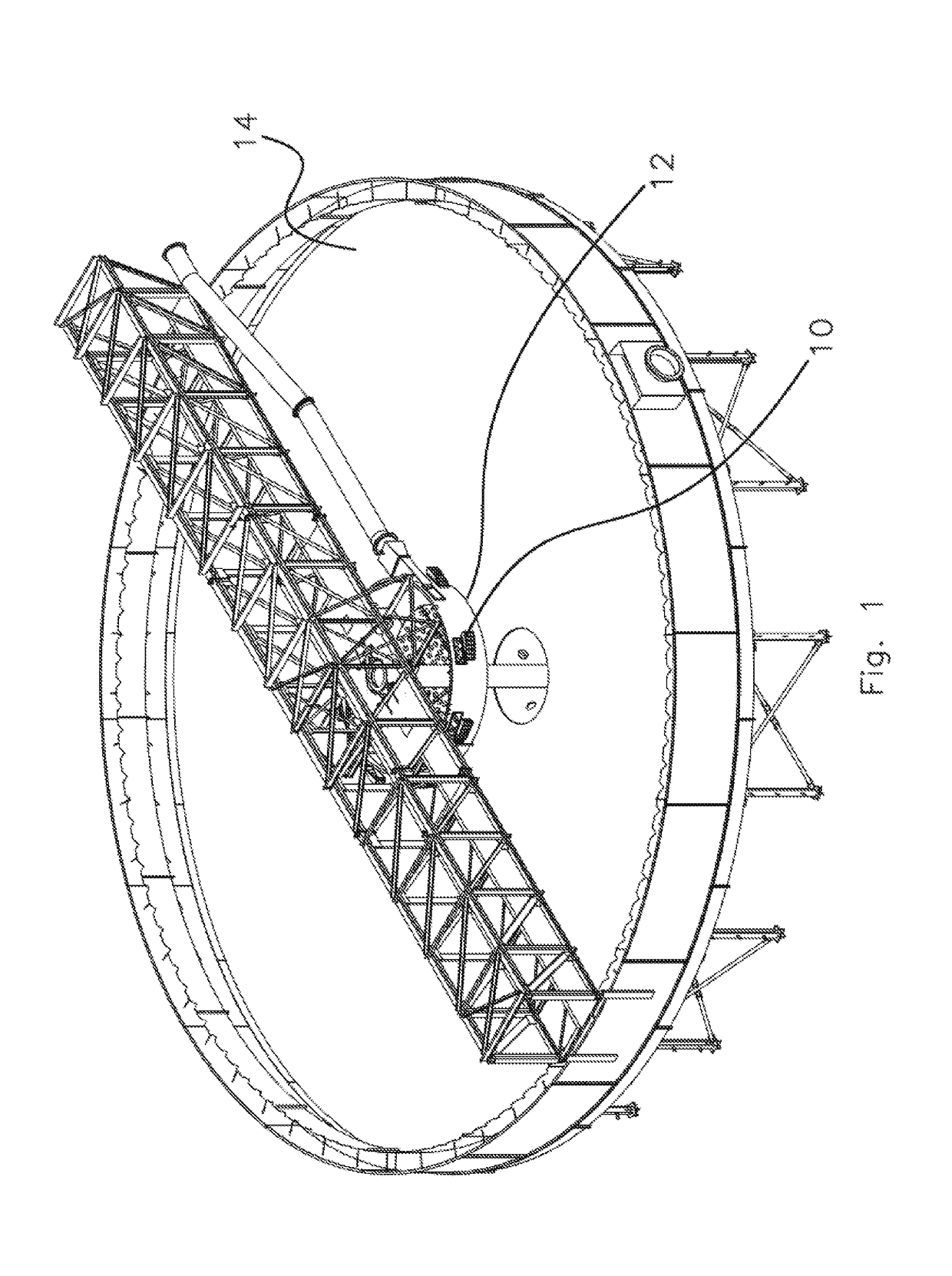

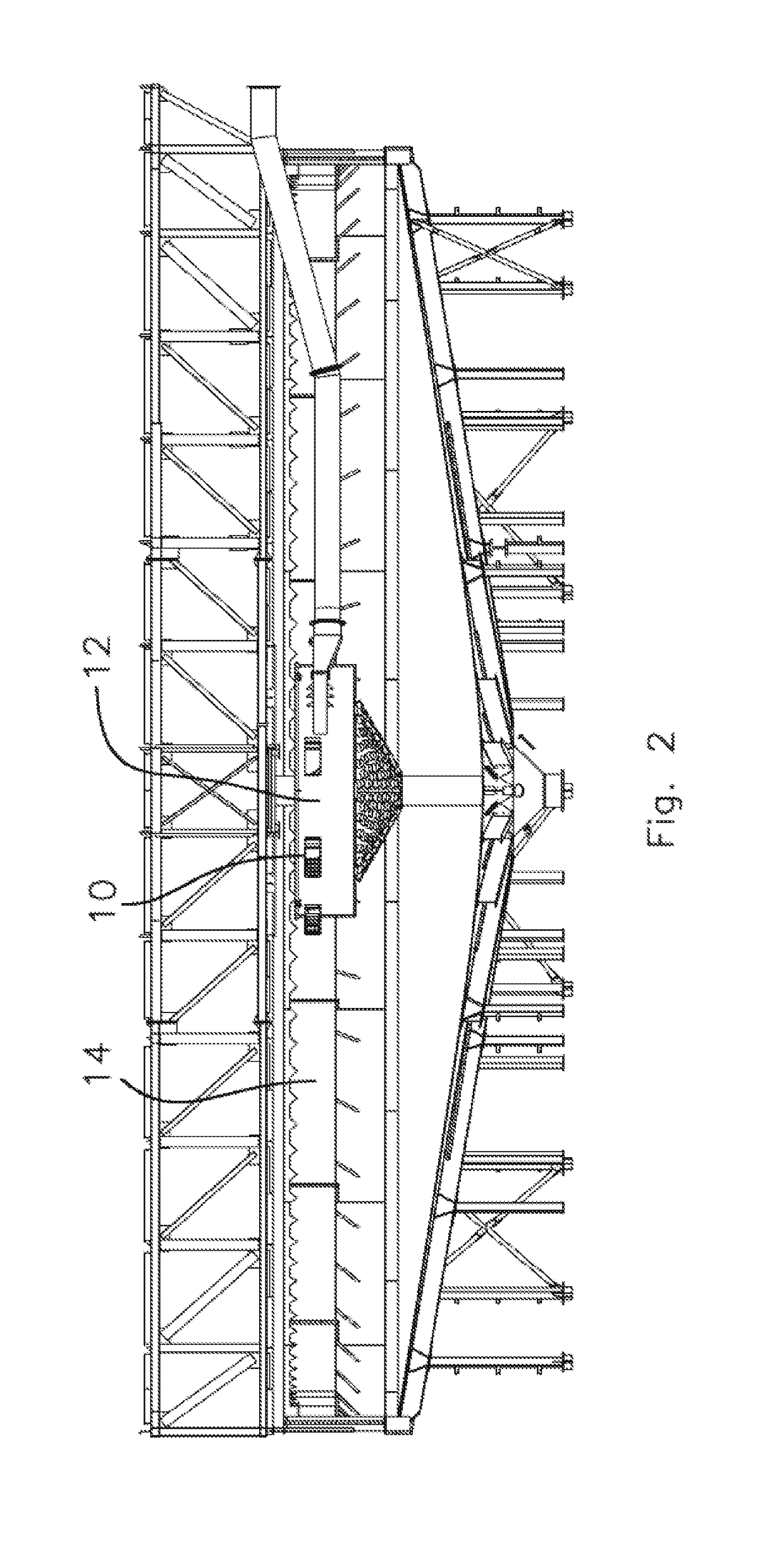

Waste concrete and aggregate reclaimer

InactiveUS8168073B2Easy to separateEfficient flotationSettling tank with pumpLiquid displacementSlurryReclaimer

A reclaimer, for the separation of heavier solids from slurry water, including an inlet means (50) to allow loading of a flow of the solid laden slurry water (90), a reclaiming tank (10) to contain the input from the inlet means (50), a plurality of lamella plates (20) to increase the effective separation surface area to improve the separation process, said lamella plates (20) provided at an angle, an agitation mechanism (40) for loosening up the slurry water from the heavier solids, an outlet means (82) to allow the separated slurry water to exit the tank (10), wherein the agitation mechanism (40) is a conveyor, with a plurality of protrusions (42).

Owner:SP ZICOM PTE LTD

Popular searches

Organic detergent compounding agents Transportation and packaging Detergent mixture composition preparation Contaminated soil reclamation Liquid hydrocarbon mixture production PH-change processes Hydrocarbon oils refining Cleaning using liquids Non-miscible liquid separation Other chemical processes

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com