Colored porcelain (or colored pottery)-surface light coal gangue building blocks

A technology of coal gangue and block, which is applied in the field of "color porcelain surface light coal gangue block"

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

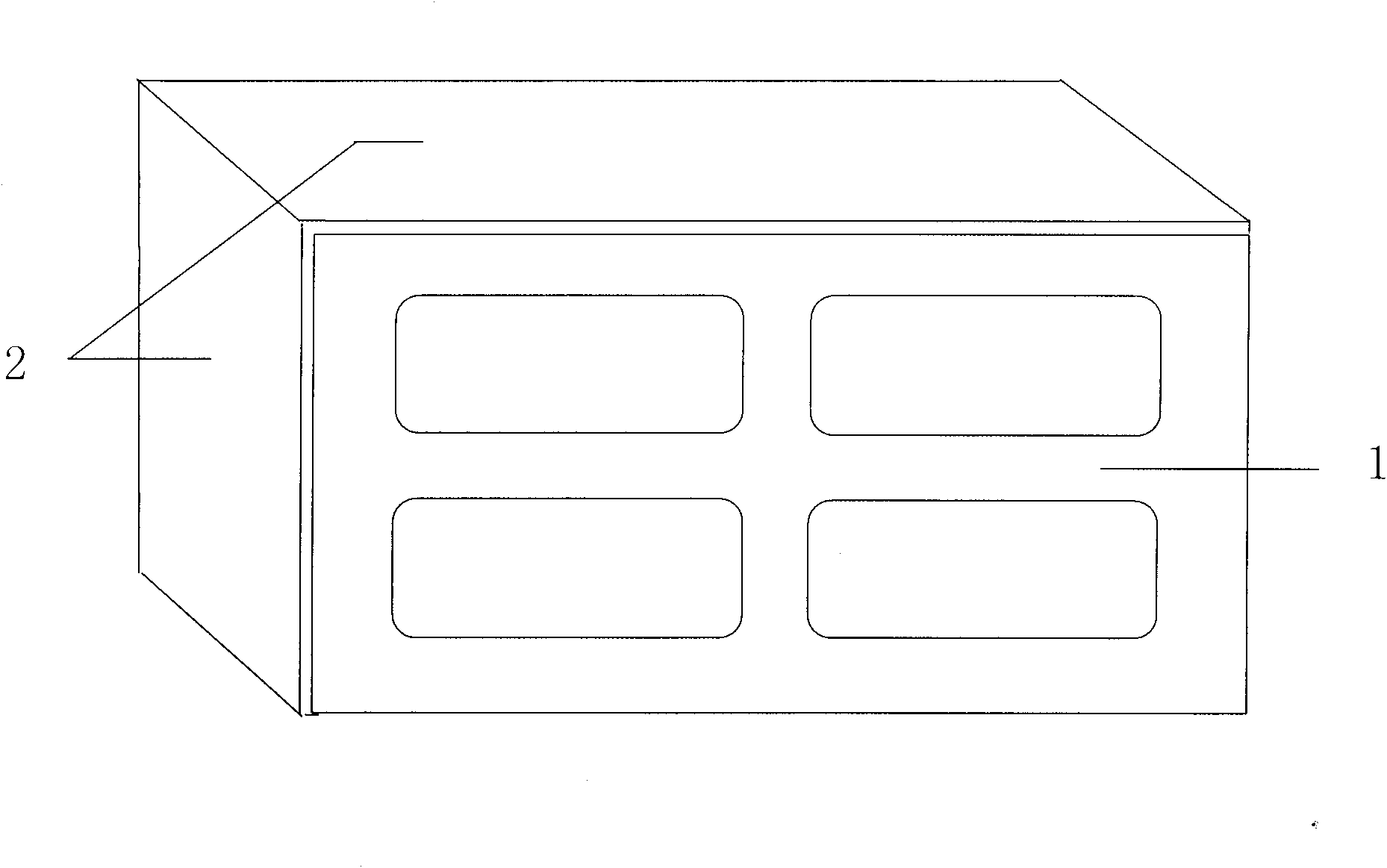

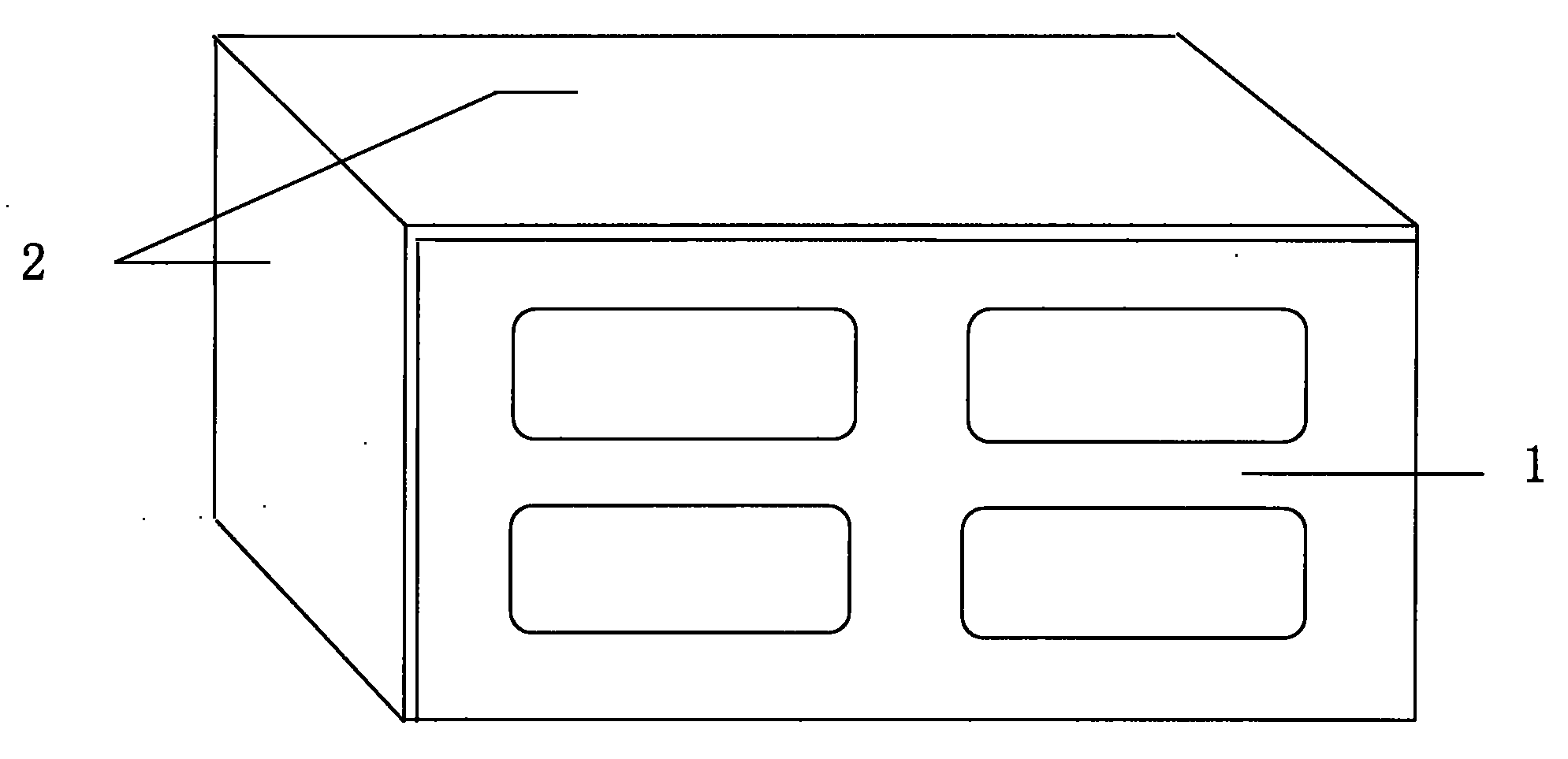

[0007] As shown in the figure, waste glass powder, clay, fly ash, and straw (or fruit shell) are added to the gangue raw material according to the proportion to make the base material of the block, which is made by a gangue vacuum block forming machine (hollow or Porous) coal gangue blocks; then kaolin, clay, feldspar, quartz, pigments, etc., are prepared according to the formula of each material to make the raw material of the block surface layer, that is, colored porcelain slurry or colored ceramic slurry, and then set up in the gangue vacuum The spraying machine at the exit of the block forming machine sprays the colored porcelain slurry or painted ceramic material on the surface of the block green body respectively, puts it on the kiln car, sends it to the drying kiln for drying, and then transfers it to the tunnel kiln for roasting. Roasting forms "colored porcelain (or painted pottery) surface light coal gangue block", the base of the block forms a sintered coal gangue mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com