Prefabricated composite wallboard and preparation method thereof

A composite wallboard and prefabricated technology, which is applied to walls, building components, climate change adaptation, etc., can solve the problems that wallboards cannot be fireproof, thermal insulation, light and thin and load-bearing can not be integrated, low thermal conductivity, fire prevention, etc., to achieve low thermal conductivity Coefficient, energy-saving heat insulation effect, effect of reducing heat radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

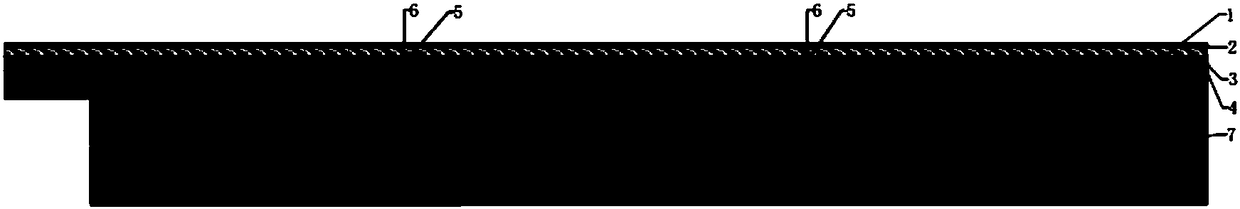

[0074] Fabrication of prefabricated composite wall panels

[0075] (1) Clean up the platform, build side molds, leave openings for doors and windows, and spray release agent.

[0076] (2) Evenly spray 12mm thick decorative mortar, pave and paste the reinforcement layer; the formula of the mortar is: cement 28kg, sand 55kg, lime 5kg, gypsum 5kg, calcium powder 8kg, titanium dioxide 0.2kg, the reinforcement layer adopts alkali-resistant glass fiber mesh cloth.

[0077] (3) Then spray 10mm thick decorative mortar on the reinforcing layer again (same formula as the second step), and vibrate the decorative protective layer to a uniform thickness, and immediately place the vacuum insulation board coated with 0.5mm thick interface agent on both sides (thickness is 15mm). The placement time should be controlled within 15-20 minutes to ensure that the decorative mortar does not reach the initial setting state.

[0078] (4) When laying vacuum insulation panels, the gap between the pa...

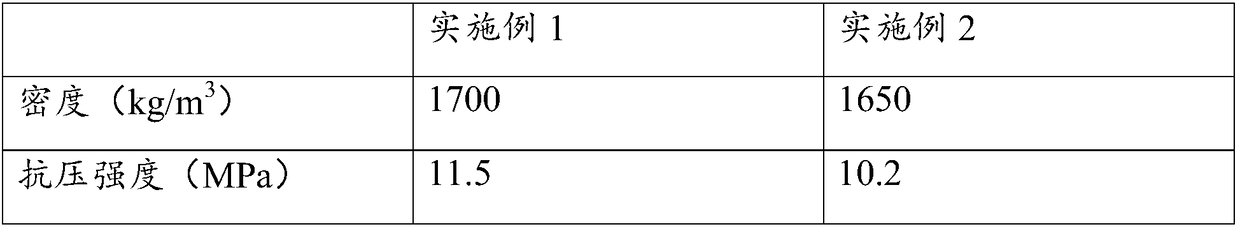

Embodiment 2

[0085] The difference with embodiment 1 is that the formula of the mortar used for the decorative protective layer is different, and the formula of the mortar used is:

[0086] 40 kg of cement, 50 kg of sand, 8 kg of lime, 3 kg of gypsum, 12 kg of calcium powder, and 0.5 kg of iron oxide yellow.

[0087] Other steps and the structure of wallboard are with embodiment 1.

Embodiment 3

[0089] The difference from Example 1 is that the formula of the ceramsite reinforced concrete used in the structural layer is different, which is:

[0090] 60 kg of cement, 3 kg of fly ash, 20 kg of slag, 60 kg of steel slag, 60 kg of ceramsite, 0.05 kg of water retaining agent, 0.2 kg of water reducing agent, and 20 kg of water; the cement is ordinary Portland cement with a strength grade of 42.5R ; The grade of fly ash is grade II; the grade of slag is grade S105; the fineness modulus of steel slag is 3.0~3.3, and the bulk density is 1020~1080kg / m 3 ; Ceramsite is fly ash ceramsite, the particle size of ceramsite is 5-15mm, and the bulk density is 840-870kg / m 3 , cylinder compressive strength ≥ 5.0MPa; water-retaining agent is hydroxypropyl methylcellulose, water-reducing agent is polycarboxylate high-efficiency water-reducing agent.

[0091] Other steps and the structure of wallboard are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com