Single-barrel type concrete chimney structure with thermal insulation and anti-corrosion layer

A technology of thermal insulation and anti-corrosion layer and concrete, which is applied to the treatment of combustion products, combustion methods, exhaust gas devices, etc. It can solve the problems of large direct and indirect losses, damage to chimneys, etc., and achieve the effect of economical cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

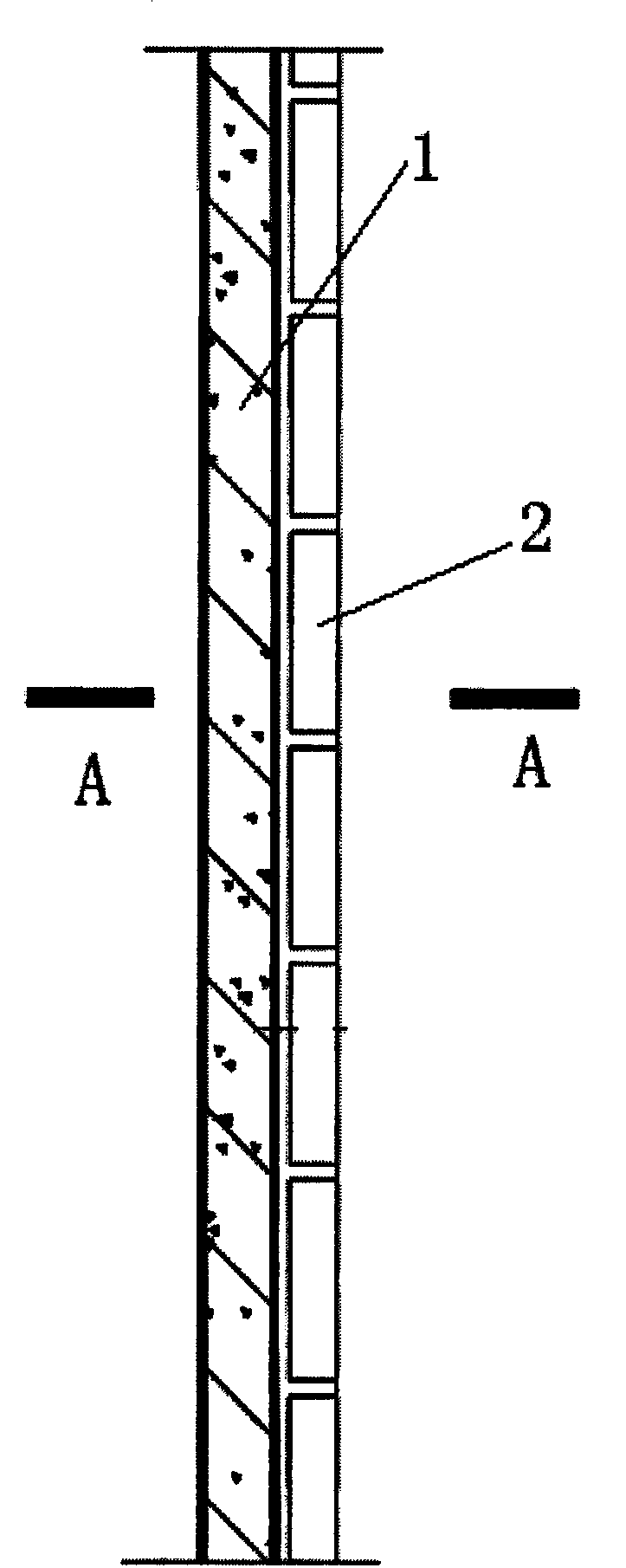

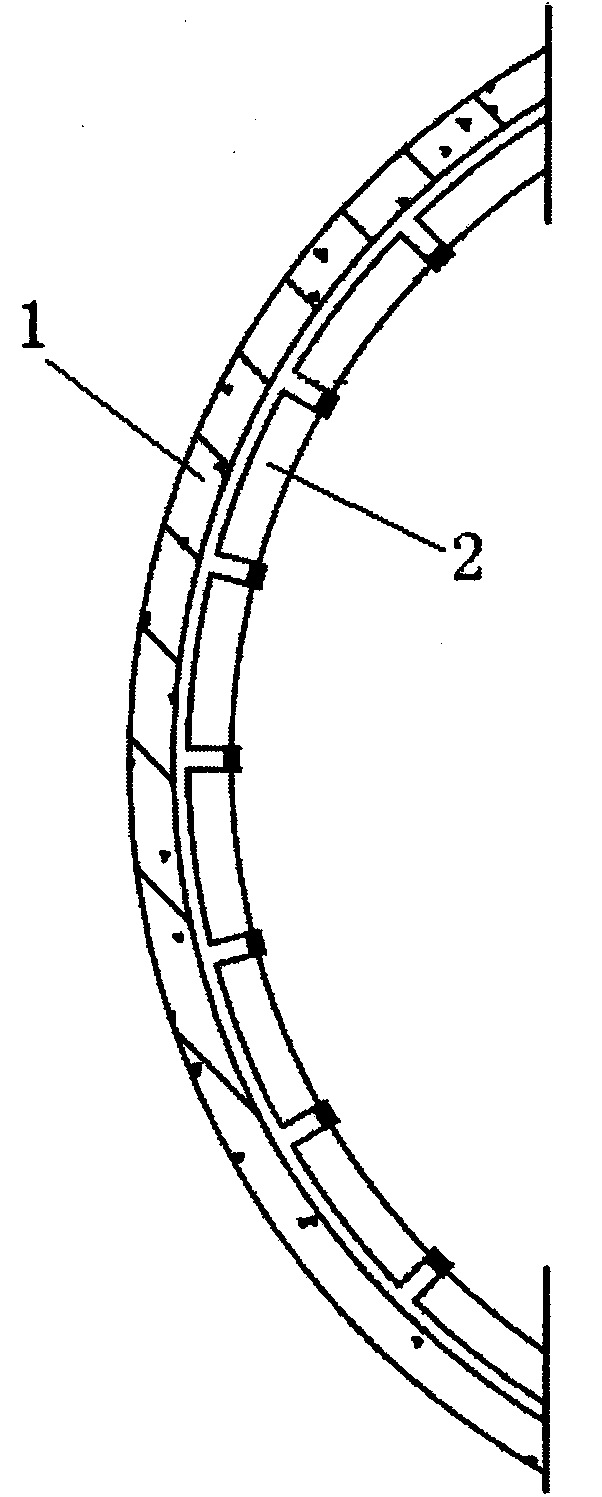

[0024] Such as figure 1 Shown is a partial cross-sectional view of a single-tube concrete chimney structure with a thermal insulation and anti-corrosion layer. The single-tube concrete chimney structure with a thermal insulation and anti-corrosion layer includes a concrete single tube 1 and also includes a thermal insulation and anti-corrosion layer. The base coat, adhesive and glass tiles are formed. The base coat is coated on the inner wall of the concrete monotube 1, and the glass tiles 2 are pasted on the base coat through the adhesive lining.

[0025] The primer is selected as a high-adhesion primer (provided by Shanghai Dehao Chemical Co., Ltd. Epoxy Primer); the adhesive is an acid-resistant elastic adhesive (provided by Shanghai Dehao Chemical Co., Ltd. Adhesive); The glass bricks are light-weight insulation glass foam bricks.

[0026] The manufacturing process of the single-tube concrete chimney structure with thermal insulation and anti-corrosion layer is as follows: aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com