Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Achieve crystallization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of perovskite-like varistor ceramic material CaCu3Ti4O12 with high dielectric constant

ActiveCN102432062AOvercome energy consumptionOvercome granularityTitanium compoundsNitrateVaristor ceramics

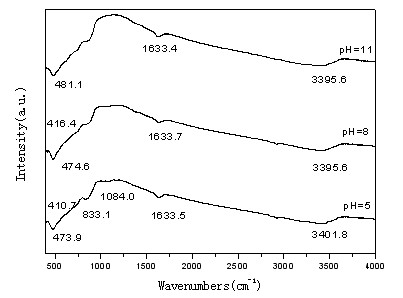

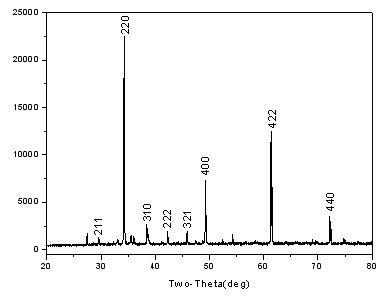

Belonging to the technical field of preparation and application of electronic ceramics, the invention relates to a preparation method of a perovskite-like varistor ceramic material CaCu3Ti4O12 (CCTO) with a high dielectric constant. With nitrates of Cu and Ca as well as Ti (OC4H9)4 as starting materials, the method of the invention combines a hydrothermal method for preparing nanometer CCTO powder so as to prepare high performance CCTO varistor ceramics, thus realizing the purposes of lowering temperature, and improving varistor as well as dielectric properties.

Owner:江苏津沂菊源生物健康产业研究院有限公司

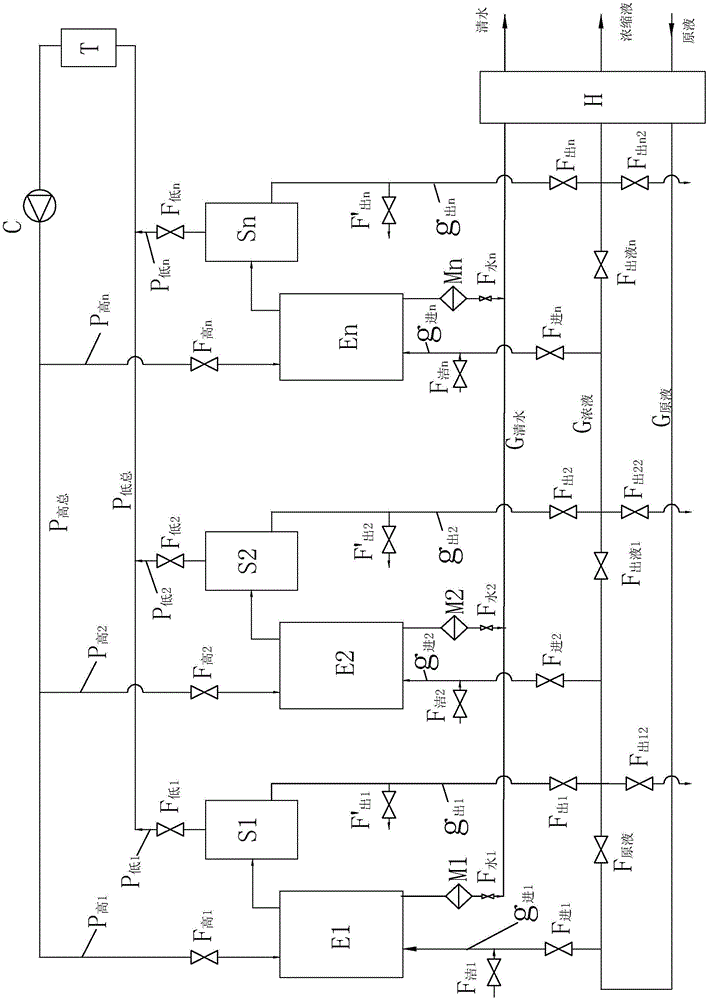

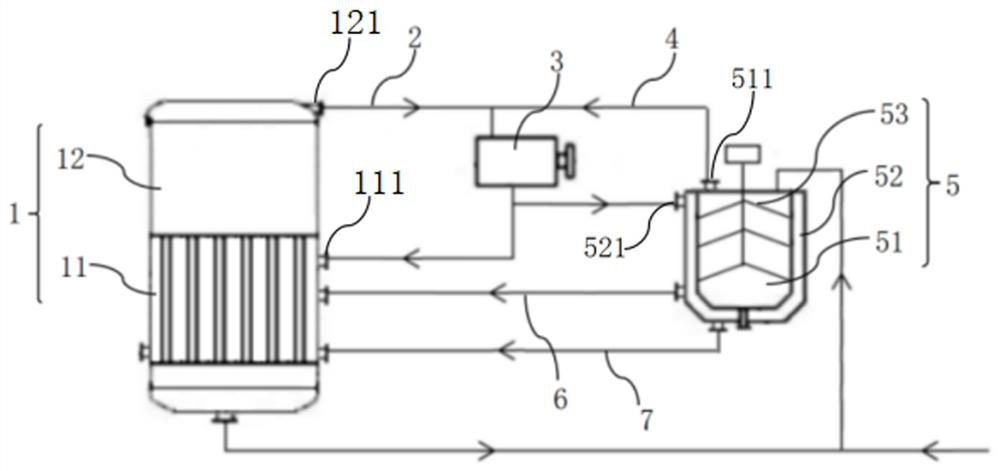

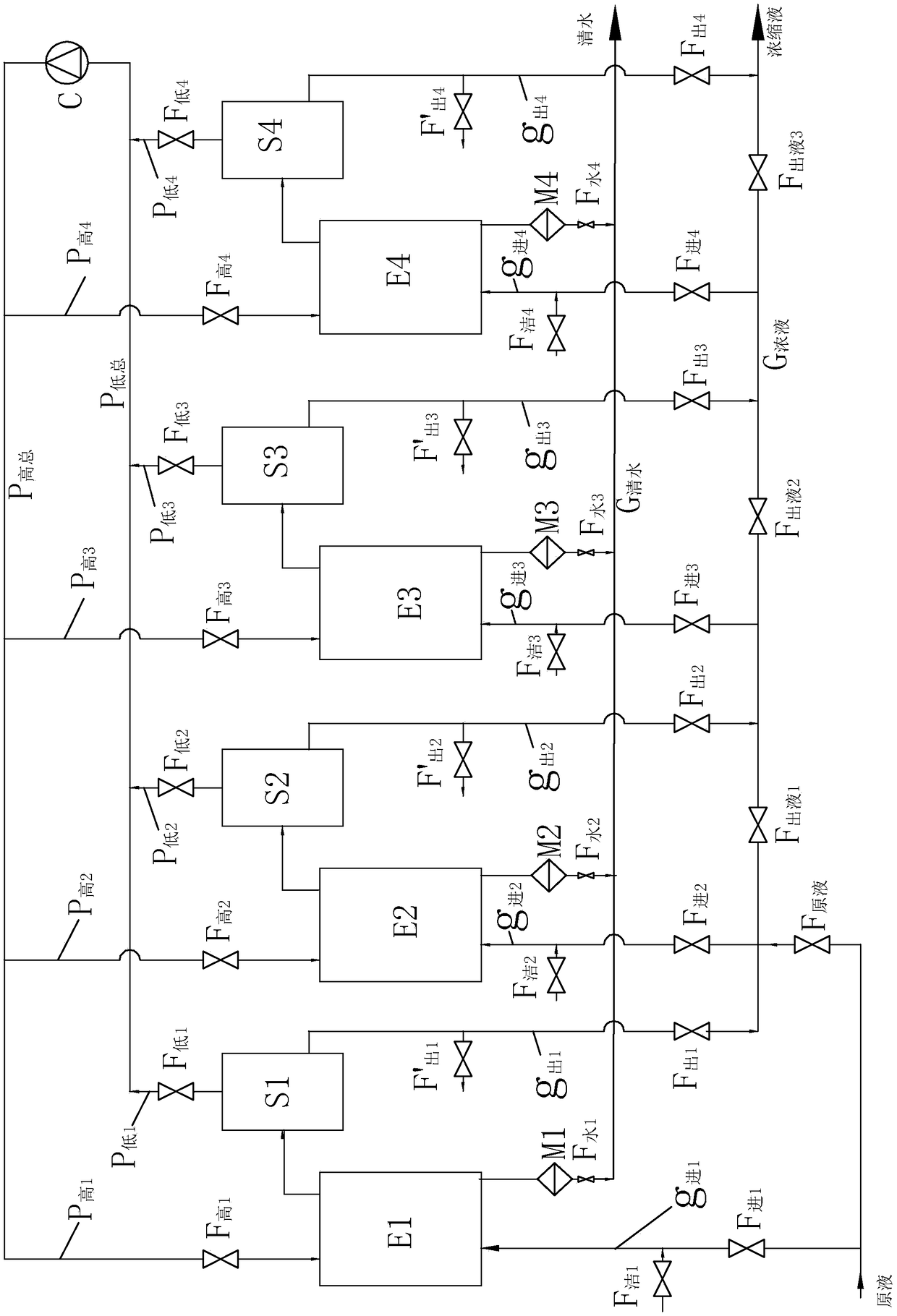

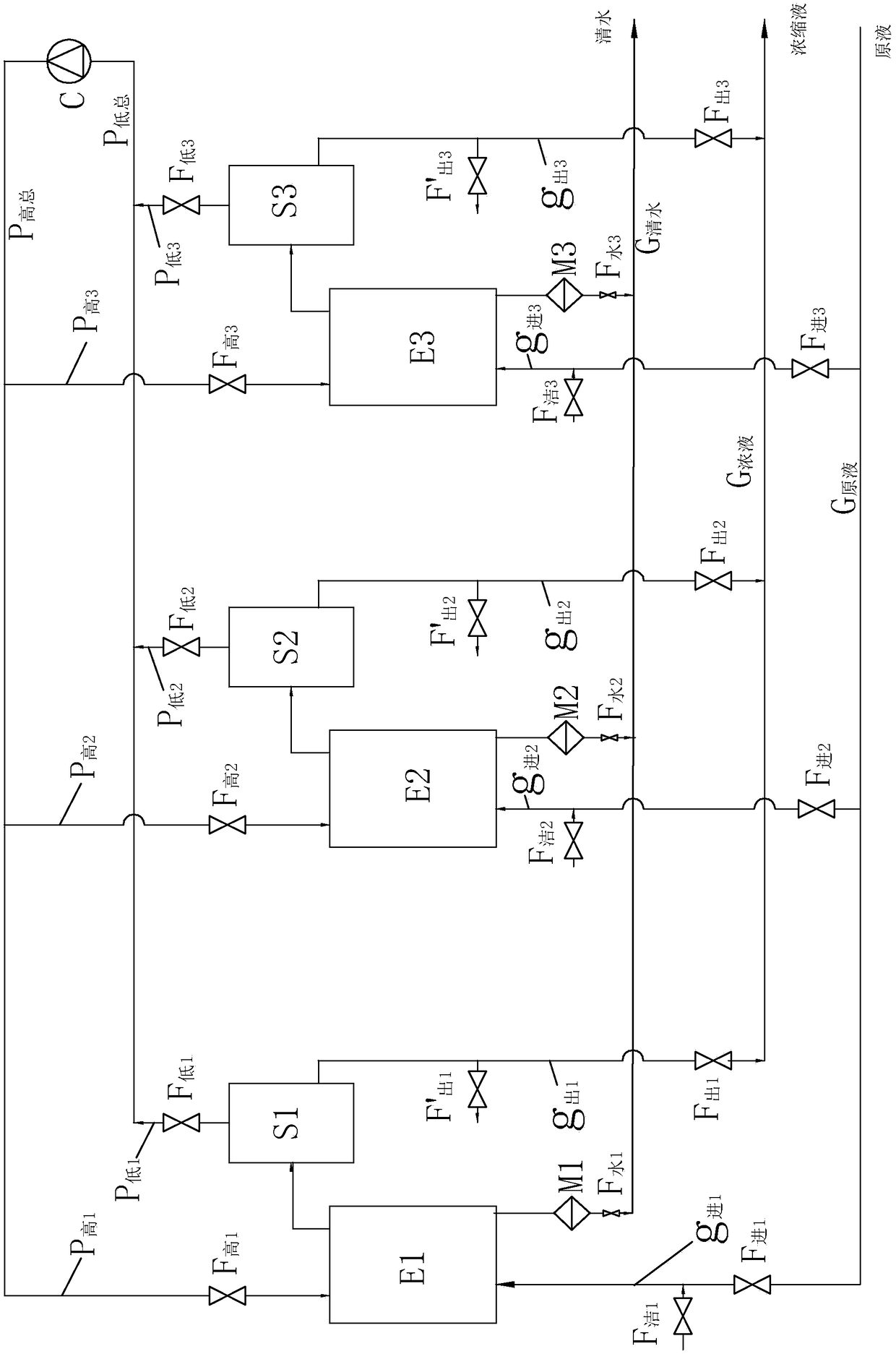

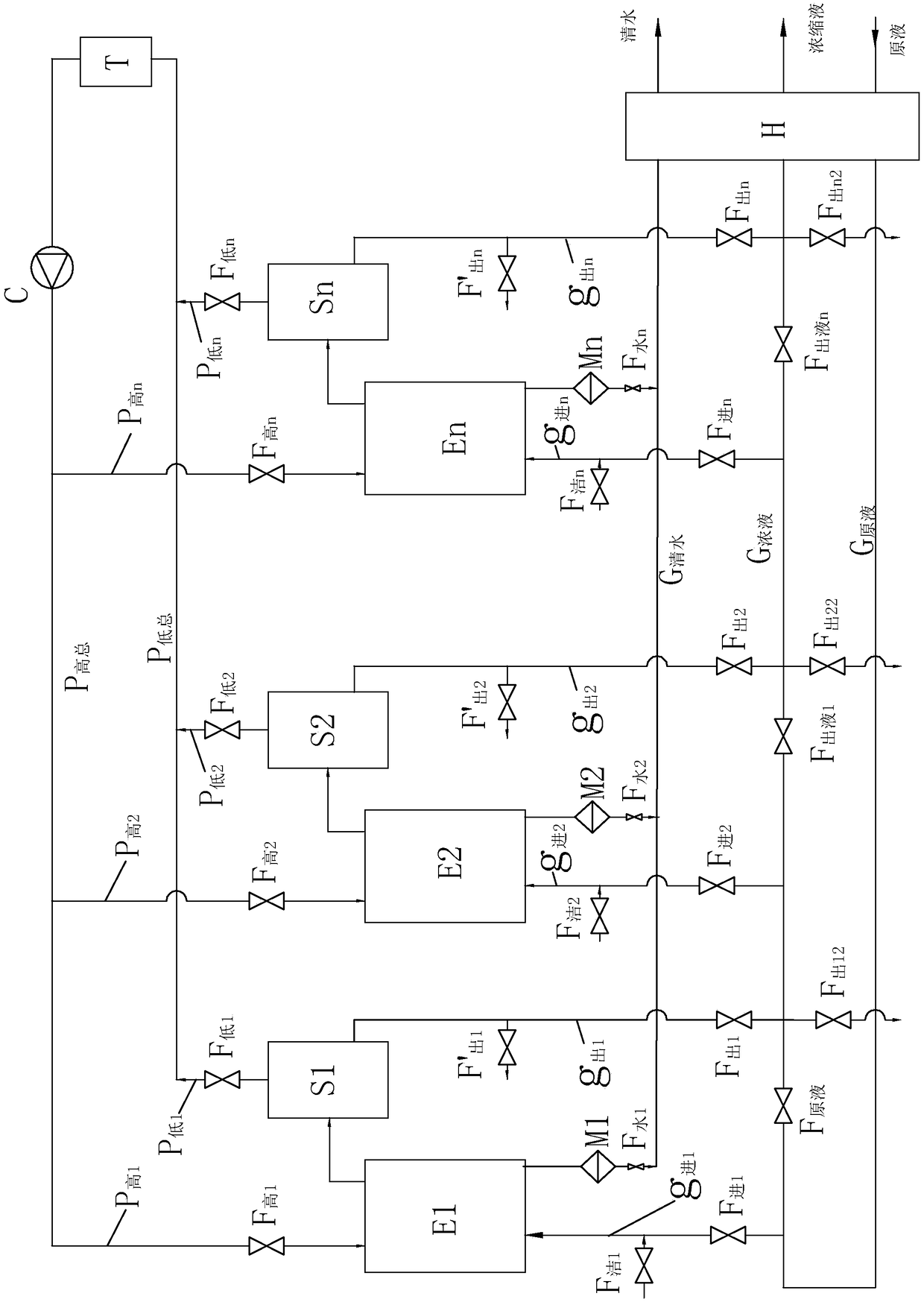

Evaporating system capable of conducting online descaling and working continuously and evaporating process

ActiveCN105999750AGuaranteed uptimeReduce the number of timesEvaporation with vapour compressionEvaporator regulation/controlEvaporationEngineering

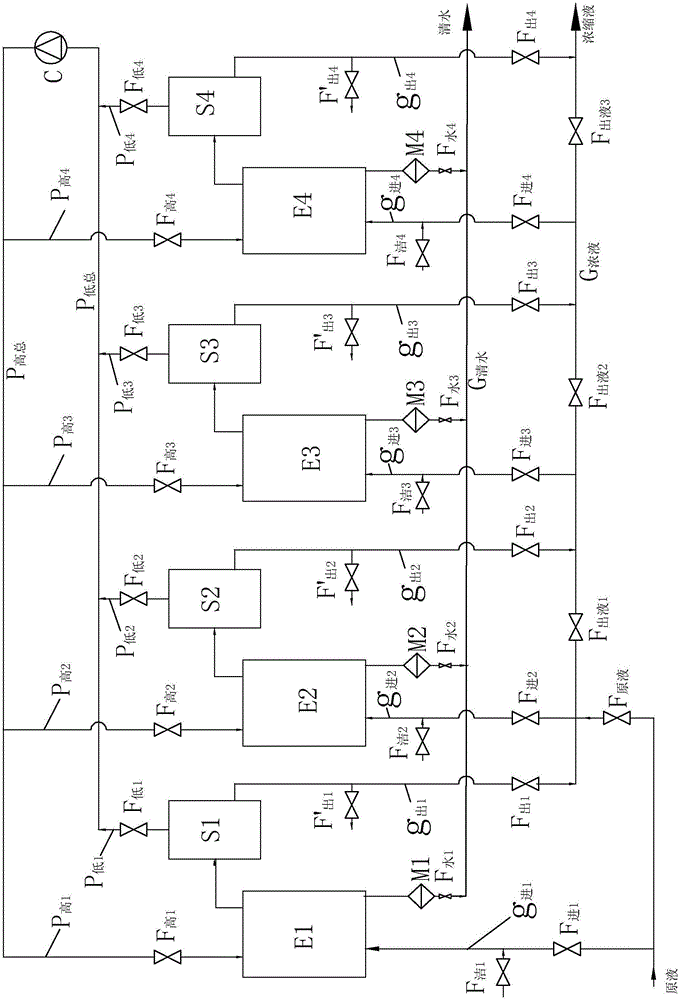

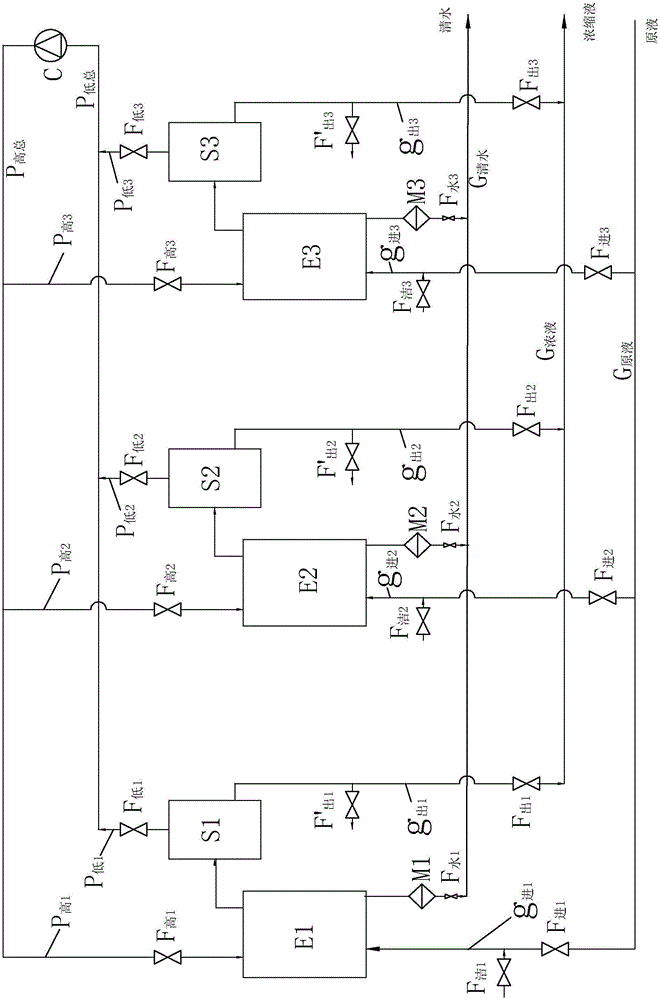

The invention discloses an evaporating system capable of conducting online descaling and working continuously and an evaporating process. The evaporating system comprises n evaporating units, each evaporating unit is composed of an evaporator E and a steam-water separation mechanism S, the n evaporating units are connected in a feed liquor series-connection or parallel-connection evaporation mode to form the complete evaporating system, secondary steam generated by the n evaporating units shares one steam compression machine for pressurization and temperature raising, and a high-temperature steam main pipe is connected out of the steam compression machine and connected to high-temperature steam inlet pipes on the evaporating units in parallel; a liquid inlet pipe of the second-level / set evaporating unit is simultaneously connected with the first-level / set concentrate outlet pipe and a stoste inlet pipe; a concentrate main pipe is arranged, all the evaporating units except the first level / set evaporating unit are connected with the concentrate main pipe, the concentrate main pipe segment between the liquid inlet pipe and the concentrate output pipe of each evaporating unit is provided with a concentrate valve, valves on related inlet pipes and outlet pipes are controlled to isolate the evaporating units to be cleaned, and evaporating work of the system is not affected.

Owner:广州中科鑫洲科技有限公司 +1

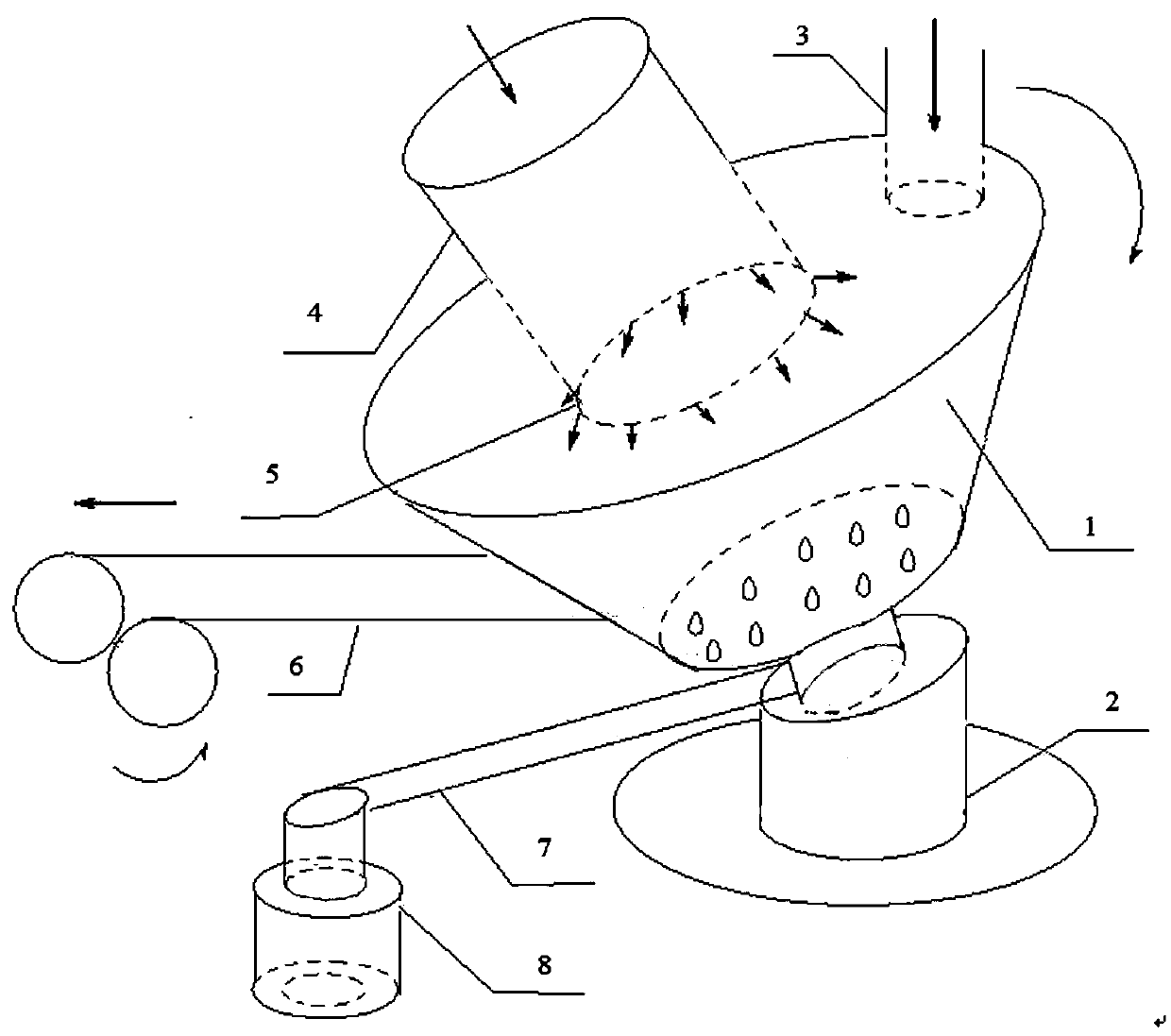

Potassium chloride aerosol generation method and potassium chloride aerosol generation device

InactiveCN102641699APerformance is easy to evaluate reasonablyControl processColloidal chemistry detailsAerosolizeEngineering

The invention provides a potassium chloride aerosol generation method and a potassium chloride aerosol generation device. The potassium chloride aerosol generation device comprises a gas storage cylinder, an atomizing chamber and potassium chloride solution. The gas storage cylinder is used for storing filtered and purified gas and connected with two pipelines. The first pipeline is connected to a nozzle arranged at the top of the atomizing chamber. The potassium chloride solution is connected to the nozzle through a solution pump. The second pipeline is provided with an air heater and is connected to a hot air outlet at the bottom of the atomizing chamber through a pipe. The gas storage cylinder is further connected with a third pipeline, and the third pipeline is connected with an air cooler and an air dryer, and is connected to the top of a condensing chamber through a pipe finally. The bottom of the atomizing chamber is connected to the top of the condensing chamber through a pipe, and an aerosol outlet is arranged at the bottom of the condensing chamber. With the potassium chloride aerosol generation device, moisture evaporation of liquid potassium chloride drops and crystallization of potassium chloride aerosol are realized respectively, the potassium chloride aerosol generation process can be controlled more accurately, and potassium chloride aerosol generated finally is guaranteed to be free of moisture.

Owner:周斌

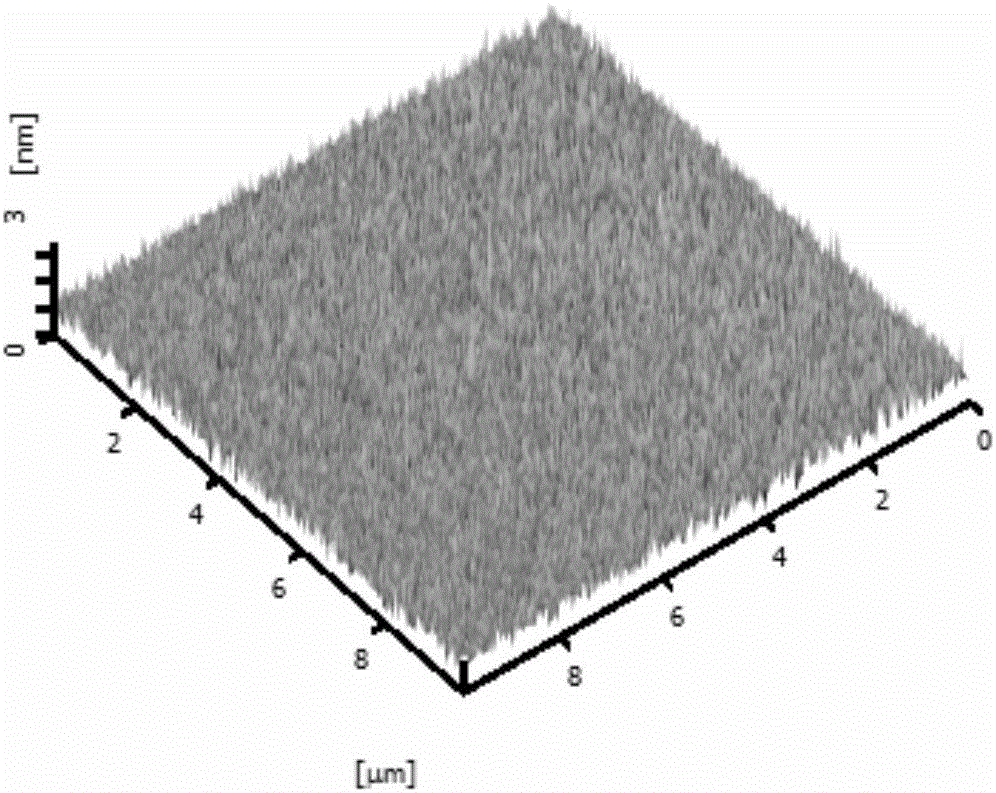

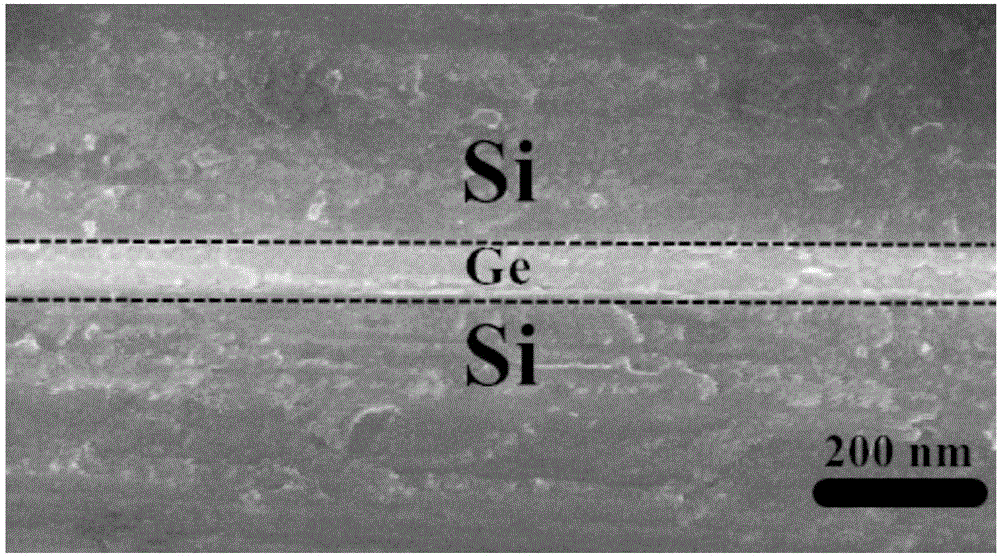

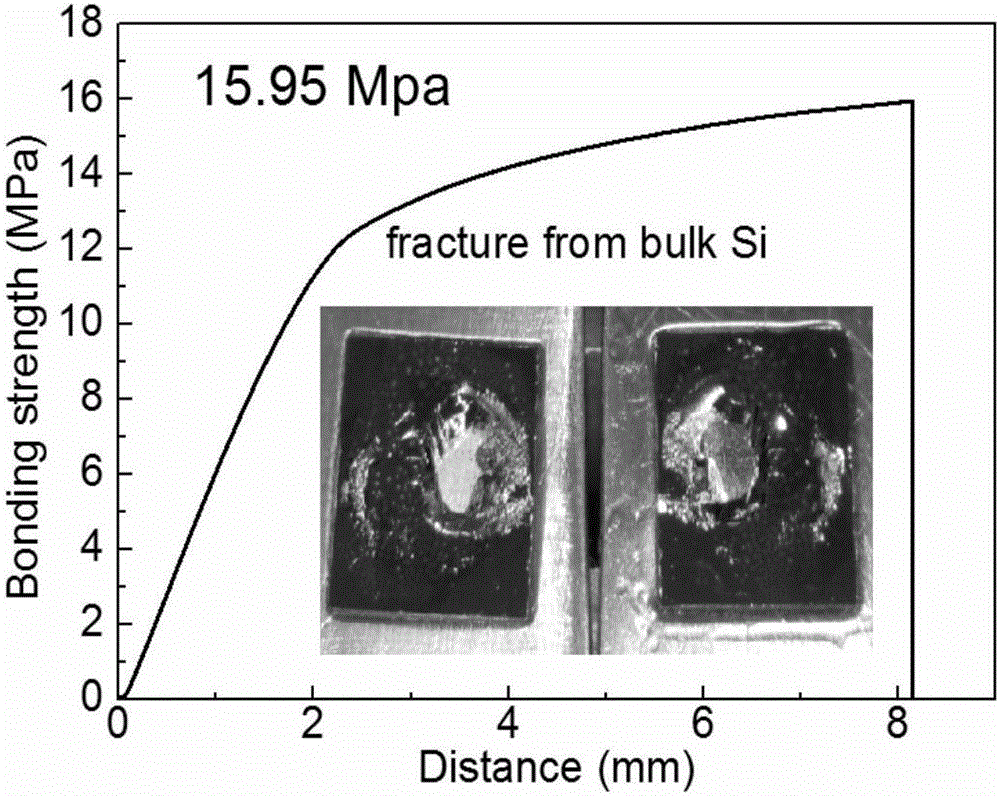

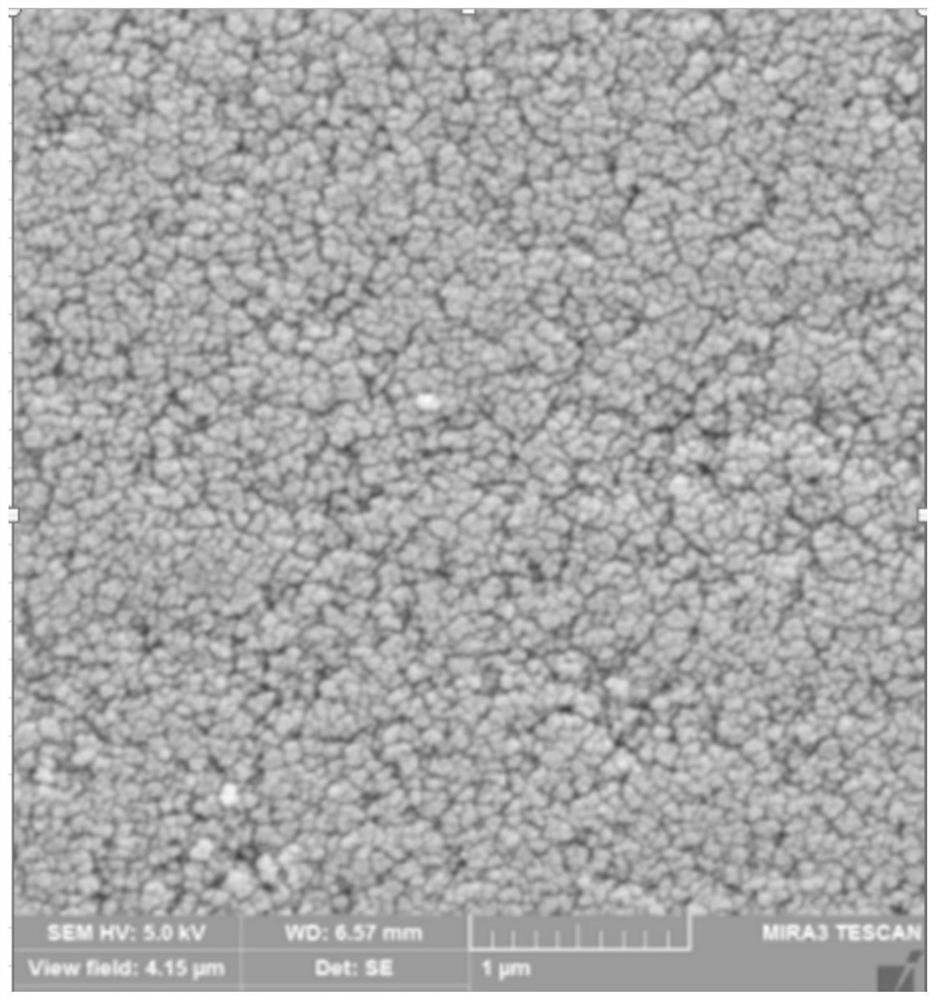

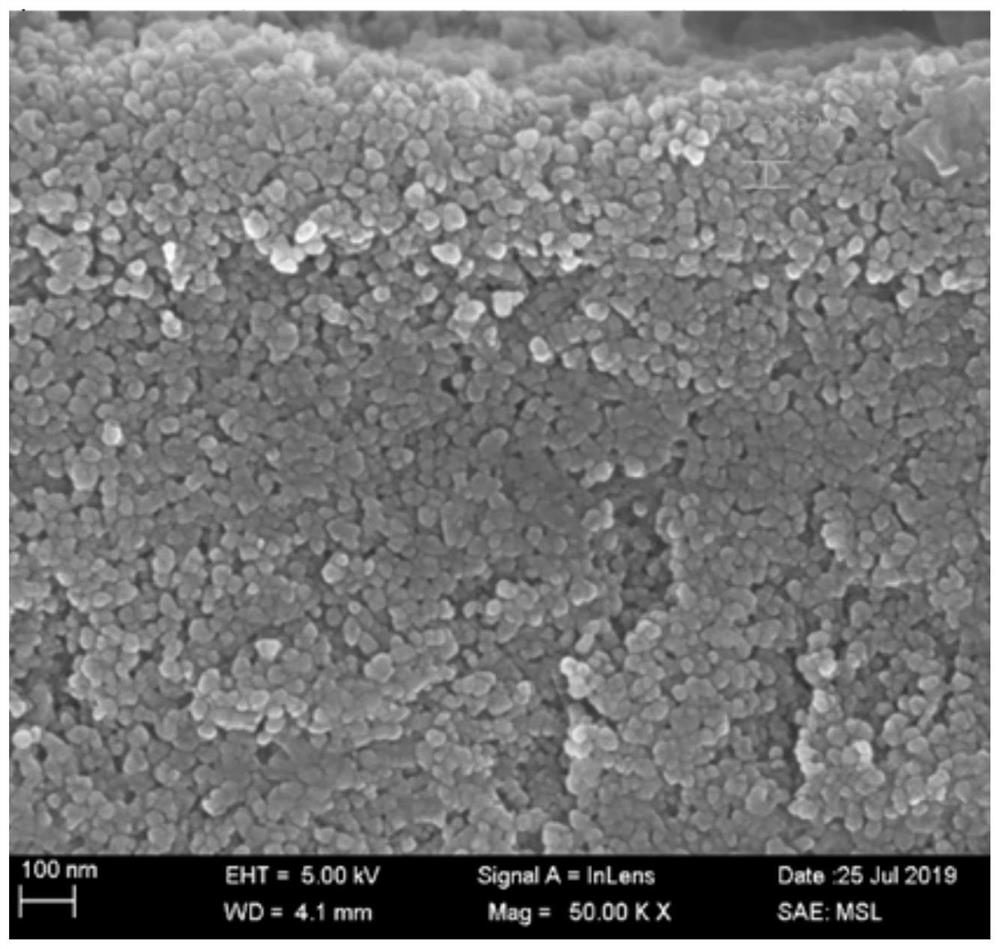

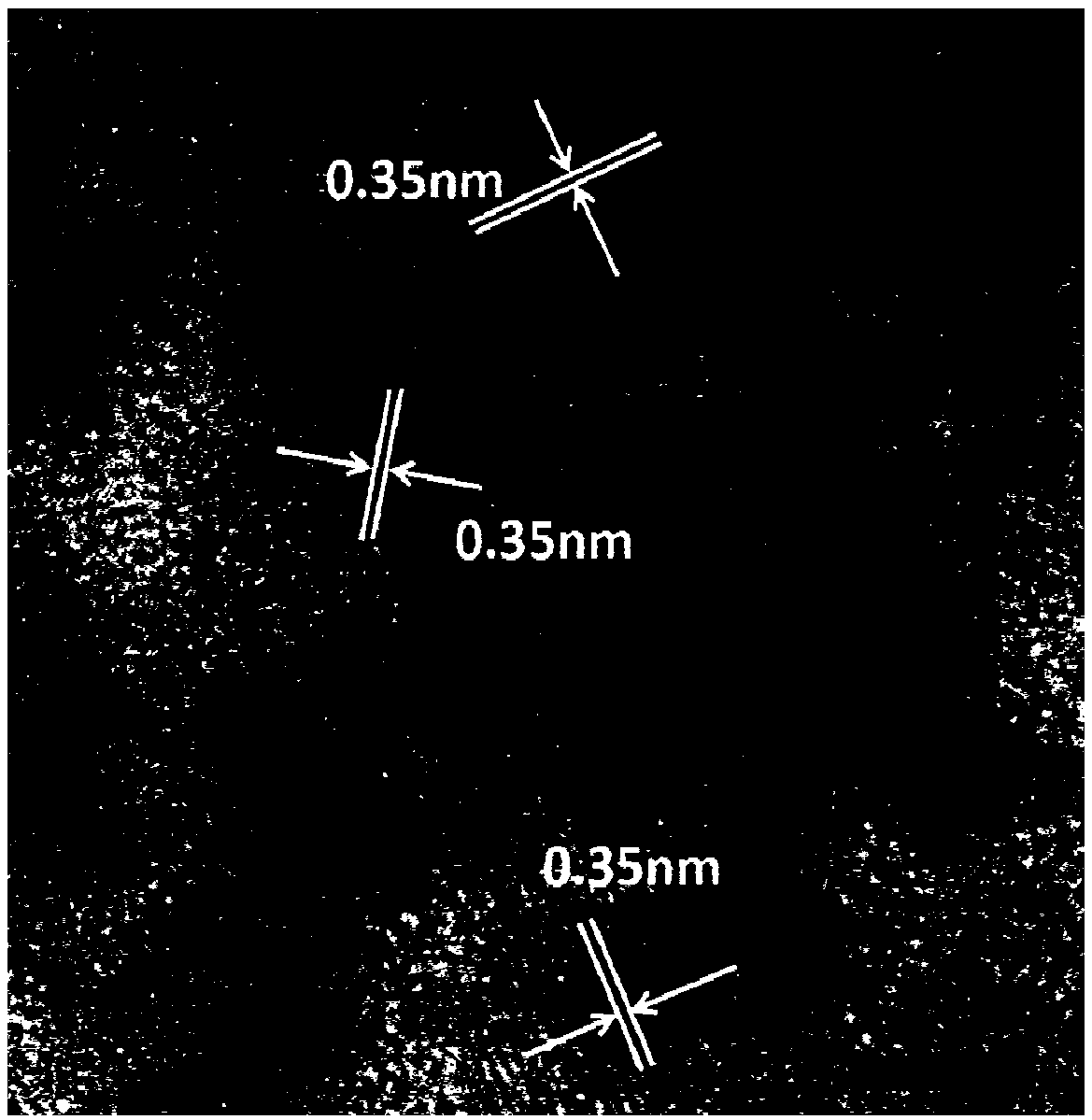

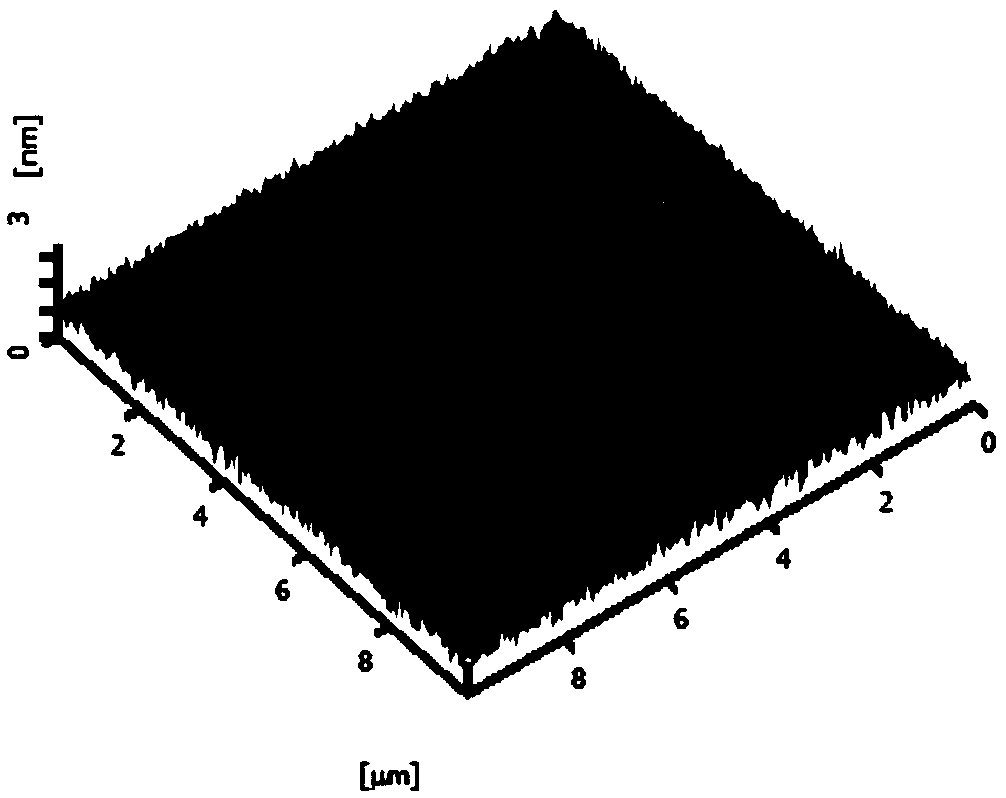

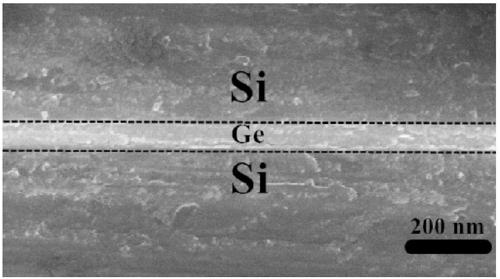

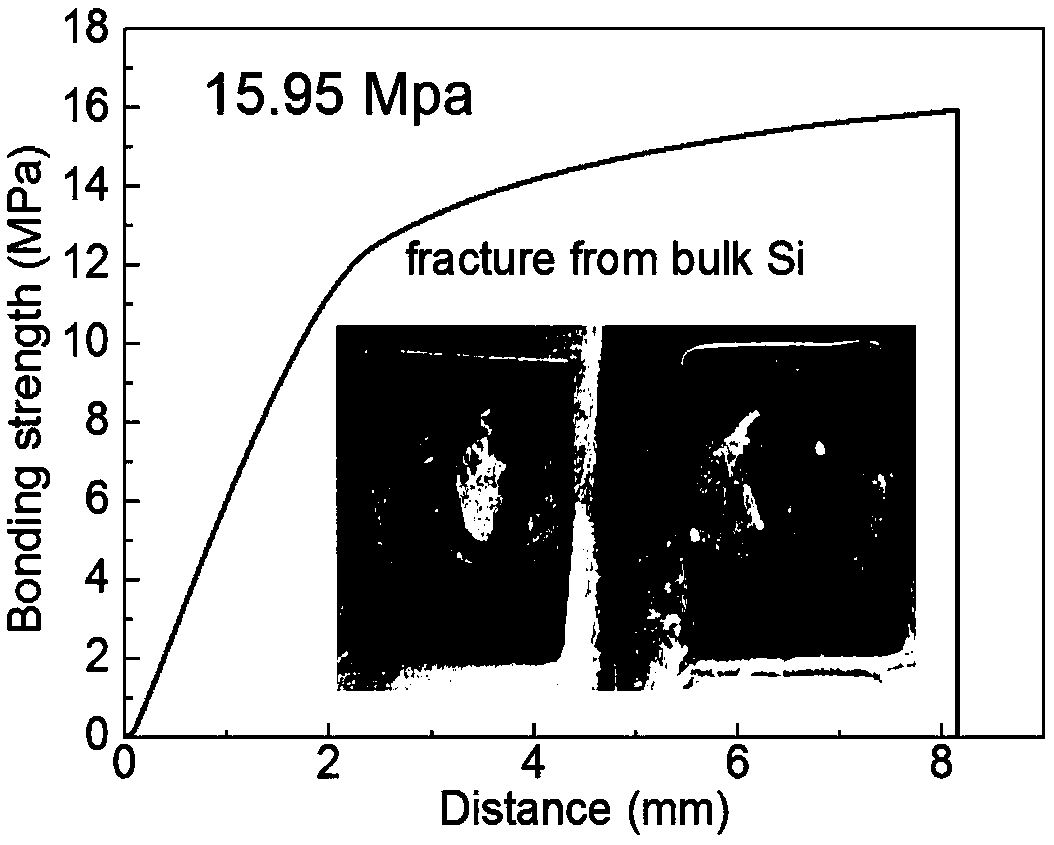

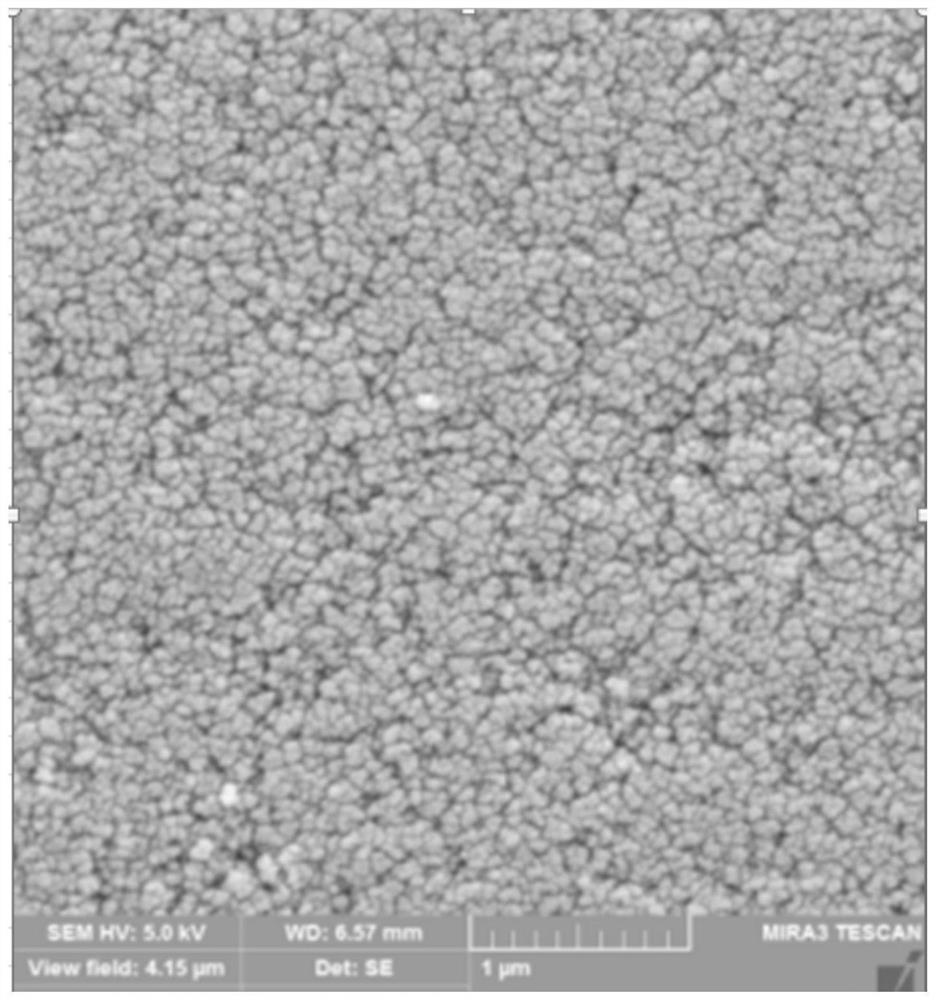

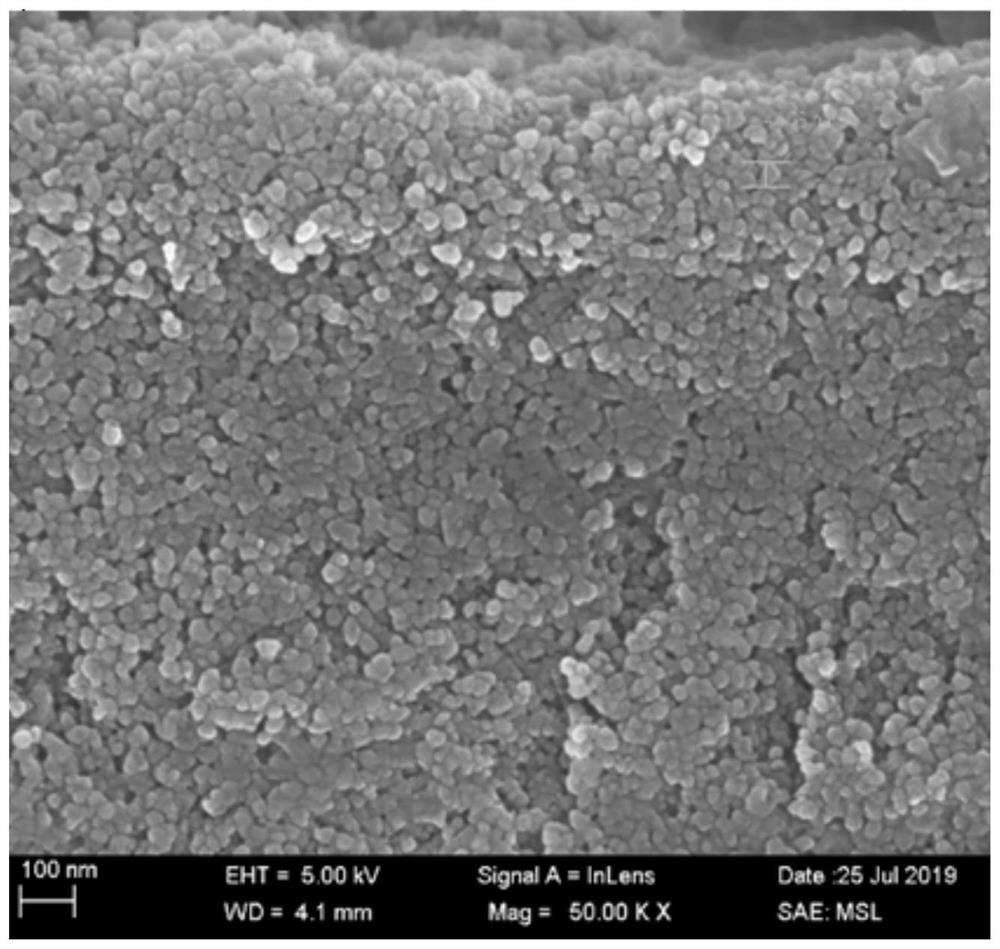

Method for realizing Si-Si bonding through adoption of amorphous germanium film

InactiveCN106847681AAchieve crystallizationAvoid incompatibilitiesVacuum evaporation coatingSolid-state devicesOptoelectronicsHigh intensity

The present invention provides a method for realizing Si-Si bonding through adoption of an amorphous germanium film, and relates to a Si wafer bonding method. The method comprises: selecting Si substrate materials with crystal direction as (100), performing cleaning; boiling the substrate materials through adoption of a mixed solution of H2SO4 and H2O2, and immersing the substrate materials in a mixed solution of HF and H2O2; boiling the processed Si wafer in a mixed solution of NH4OH, H2O2 and H2O, and immersing Si wafer in a mixed solution of HF and H2O2; boiling the processed Si wafer in a mixed solution of HCL, H2O2 and H2O, and immersing the Si wafer in a mixed solution of HF and H2O2; drying the processed Si wafer to put the Si wafer into a direct current magnetron sputtering system, filling Ar gas into a sputtering chamber when the base pressure of the sputtering chamber is smaller than 1*10<-4>Pa; sputtering a-Ge thin film through regulation of direct current sputtering current and sample holder rotation speed; and realizing high-intensity Si-Si bonding through adoption of a hydrophilic a-Ge layer.

Owner:XIAMEN UNIV

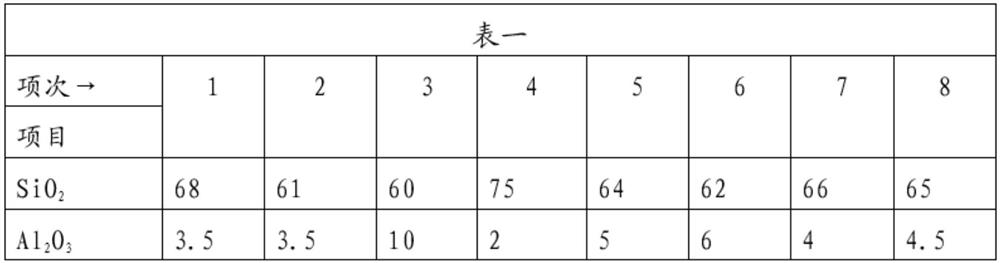

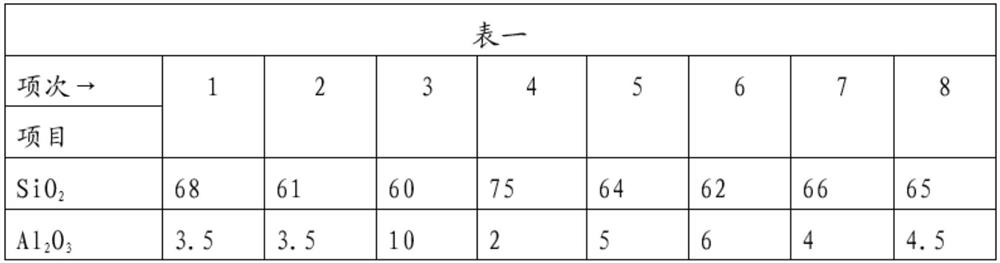

Glass ceramic with transmittance close to that of glass precursor and preparation method of glass ceramic

The invention provides a glass ceramic with transmittance close to that of a glass precursor. The glass ceramic comprises the following components in percentage by mole: 60 to 75 mol% of SiO2, 2 to 10mol% of Al2O3, 0 to 5 mol% of P2O5, 0.5 to 3 mol% of ZrO2, 0.5 to 6 mol% of Na2O, 15 to 28 mol% of Li2O, at least one of 0 to 5 mol% of B2O3, 0 to 5 mol% of MgO, and 0 to 5 mol% of ZnO, and at leastone of 0 to 2 mol% of HfO2, 0 to 2 mol% of Ta2O5, and 0 to 2 mol% of Y2O3, wherein the sum of the amounts of HfO2, Ta2O5 and Y2O3 is more than 0 and less than or equal to 2 mol%, and the difference between the visible light transmittance of the glass ceramic and the transmittance of the glass precursor for preparing the glass ceramic is 0.3-5%. According to the invention, the regulation and control difficulty of the visible light transmittance of the glass ceramic is reduced, so that the difference between the visible light transmittance of the glass ceramic and the visible light transmittanceof the glass precursor is only 0.3-5%.

Owner:CHONGQING XINJING SPECIAL GLASS CO LTD

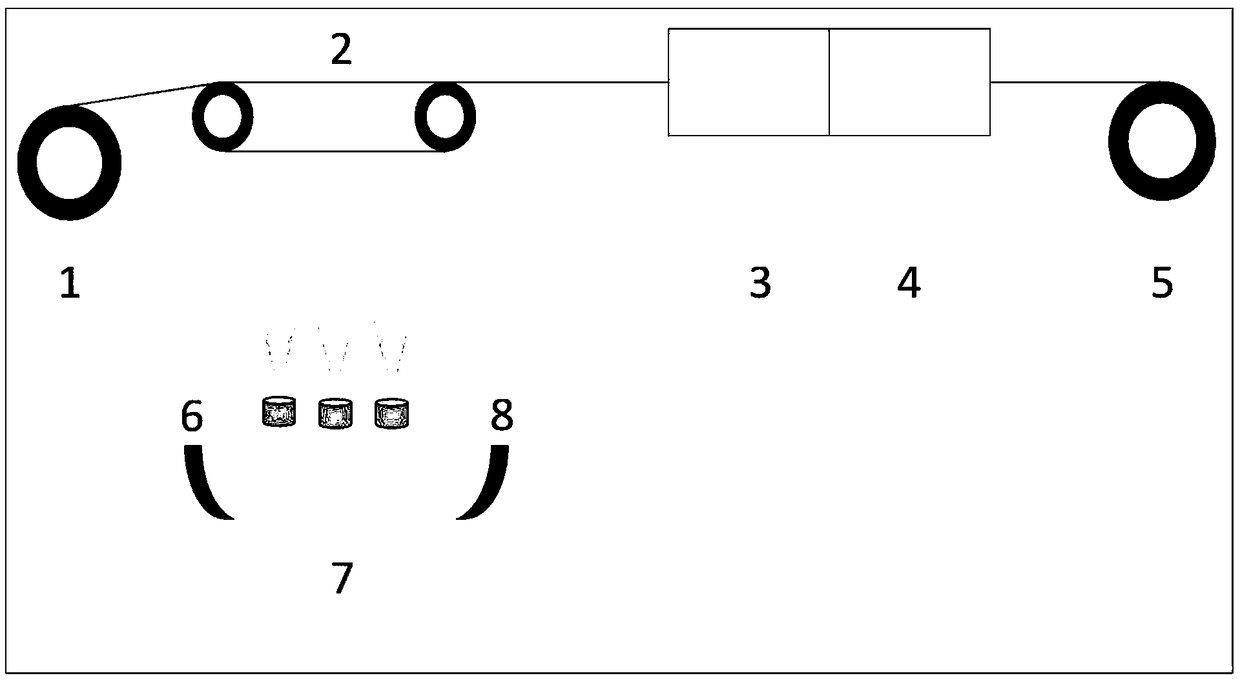

Heterotopic multi-metal oxide film epitaxial growth and continuous preparation method

InactiveCN108588648AEvenly distributedAchieve crystallizationVacuum evaporation coatingSputtering coatingEvaporationAmorphous metal

The invention provides a heterotopic multi-metal oxide film epitaxial growth and continuous preparation method. According to the characteristics of a metal target, the initial component evaporation isperformed; after nanoparticles evaporated from the target the high vacuum state reach the substrate, the nanoparticles are deposited into an amorphous metal precursor film; after deposition, the precursor film is transported to low-pressure atmospheres with different oxygen partial pressures; and at different temperatures, crystallization and epitaxial growth are performed. By the method, co-evaporation of multi-metal elements with different melting points and sublimation temperatures is realized, the evaporation technology and conditions of the elements can be selected according to characteristics of the constituent elements, and the dynamic baseband can help realize the uniformity of the precursor component; the later oxidation treatment starts with the highly-refined nano-scale precursor, nucleation centers of later crystallization growth are many, and growth is fast and density is high; and by controlling the oxygen partial pressure, the reaction heat-treatment can be realized ata lower temperature, and then crystallization and epitaxial growth can be achieved at low temperature. The preparation method is simple.

Owner:SHANGHAI UNIV

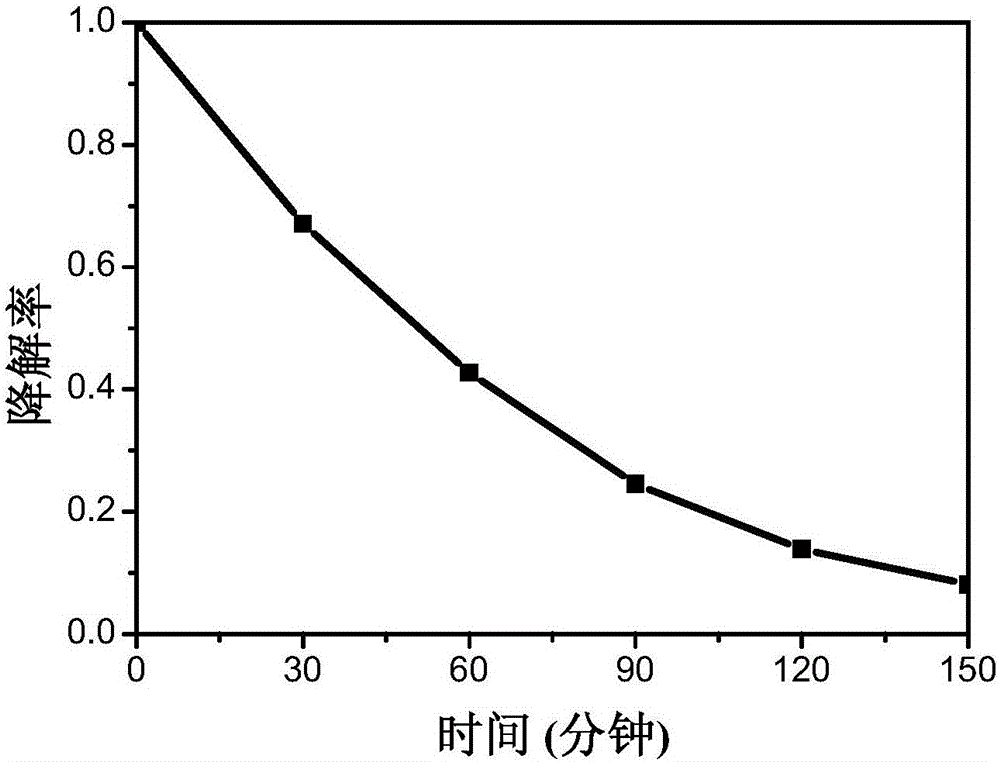

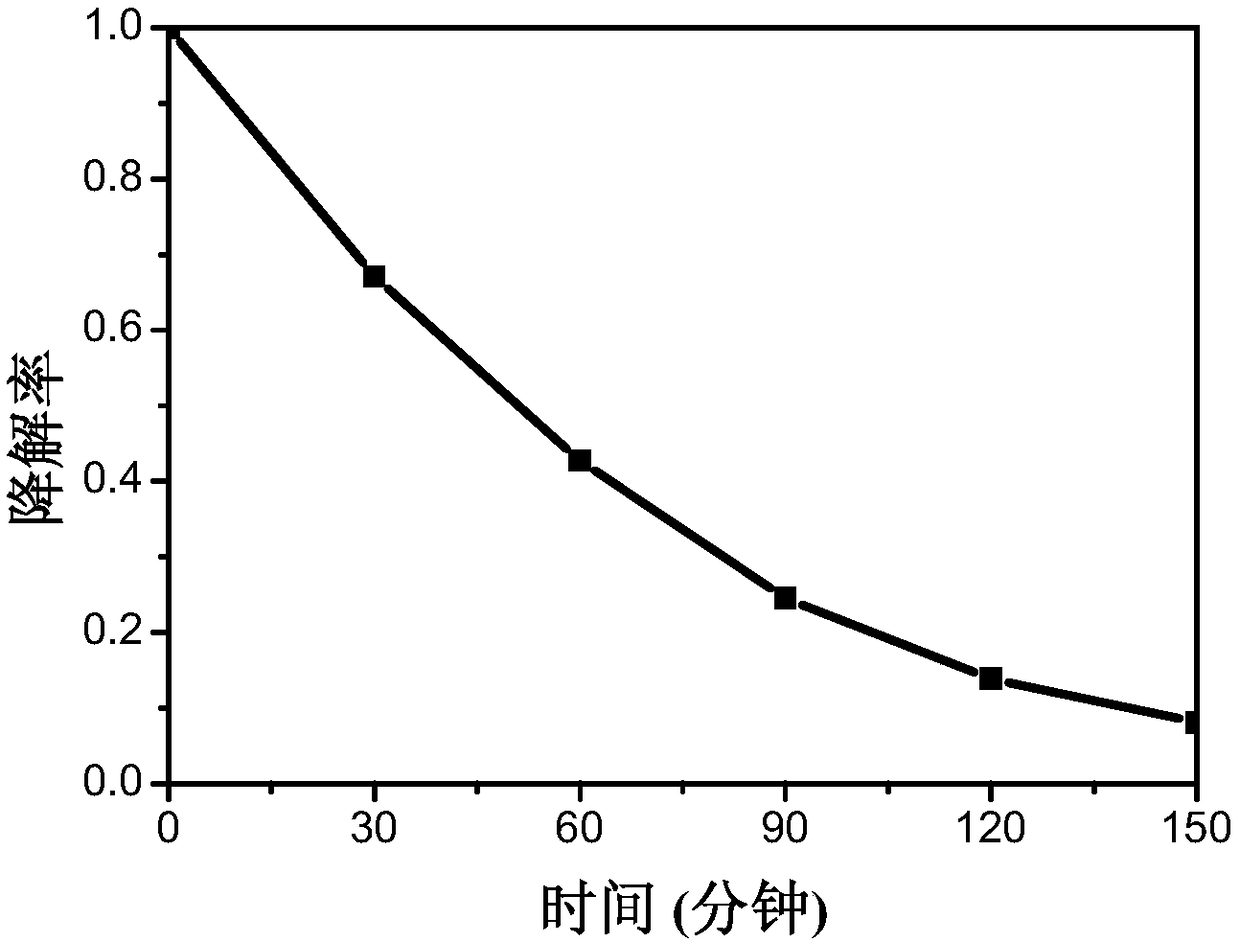

TiO2-SiO2 visible-light-driven photocatalytic composite film and preparation method thereof

ActiveCN106362784AWide variety of sourcesLow pricePhysical/chemical process catalystsLight drivenFilm-coated tablet

The invention discloses a TiO2-SiO2 visible-light-driven photocatalytic composite film and a preparation method thereof. The preparation method is characterized by comprising the following concrete steps: (1) dissolving ethyl orthosilicate in alcohol, adding an aqueous solution containing an ammonium salt, adding hydrochloric acid to adjust the pH value of the obtained solution to 1 to 3 and carrying out stirring at room temperature so as to obtain a solution A; (2) mixing tetrabutyl titanate with alcohol and carrying out stirring at room temperature so as to obtain a solution B; (3) adding the solution B into the solution A drop by drop, adding a ferric salt so as to obtain a solution C and carrying out reaction at 10 to 90 DEG C so as to obtain a transparent sol; (4) adding polyethylene glycol into the transparent sol and carrying out stirring at room temperature so as to obtain a film coating sol; and (5) allowing the film coating sol to form a film on a substrate, drying the obtained film, immediately transferring the film to water with a temperature of 55 to 100 DEG C for a reaction, and taking out the film for drying after the reaction so as to obtain the TiO2-SiO2 visible-light-driven photocatalytic composite film. The invention also discloses the TiO2-SiO2 visible-light-driven photocatalytic composite film prepared by using the method. According to the invention, crystallization of titanium dioxide and iron and nitrogen doping of TiO2-SiO2 are realized at low temperature.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

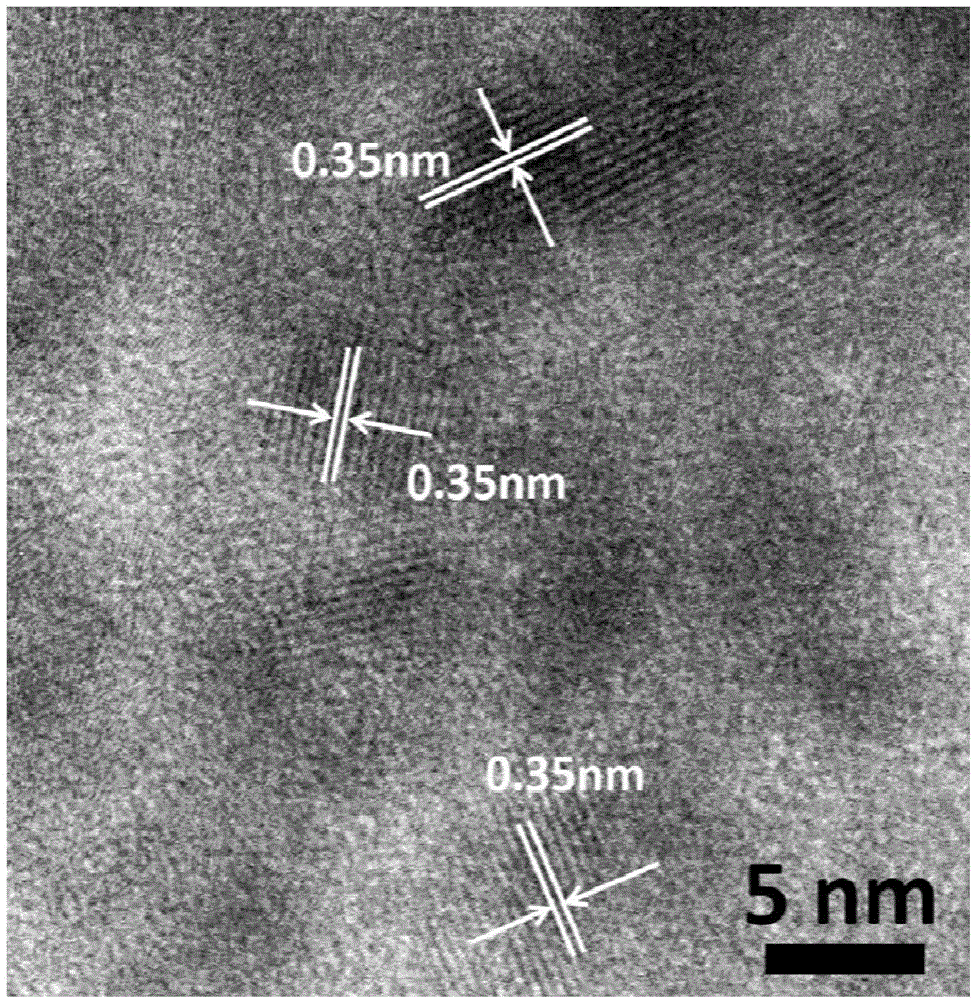

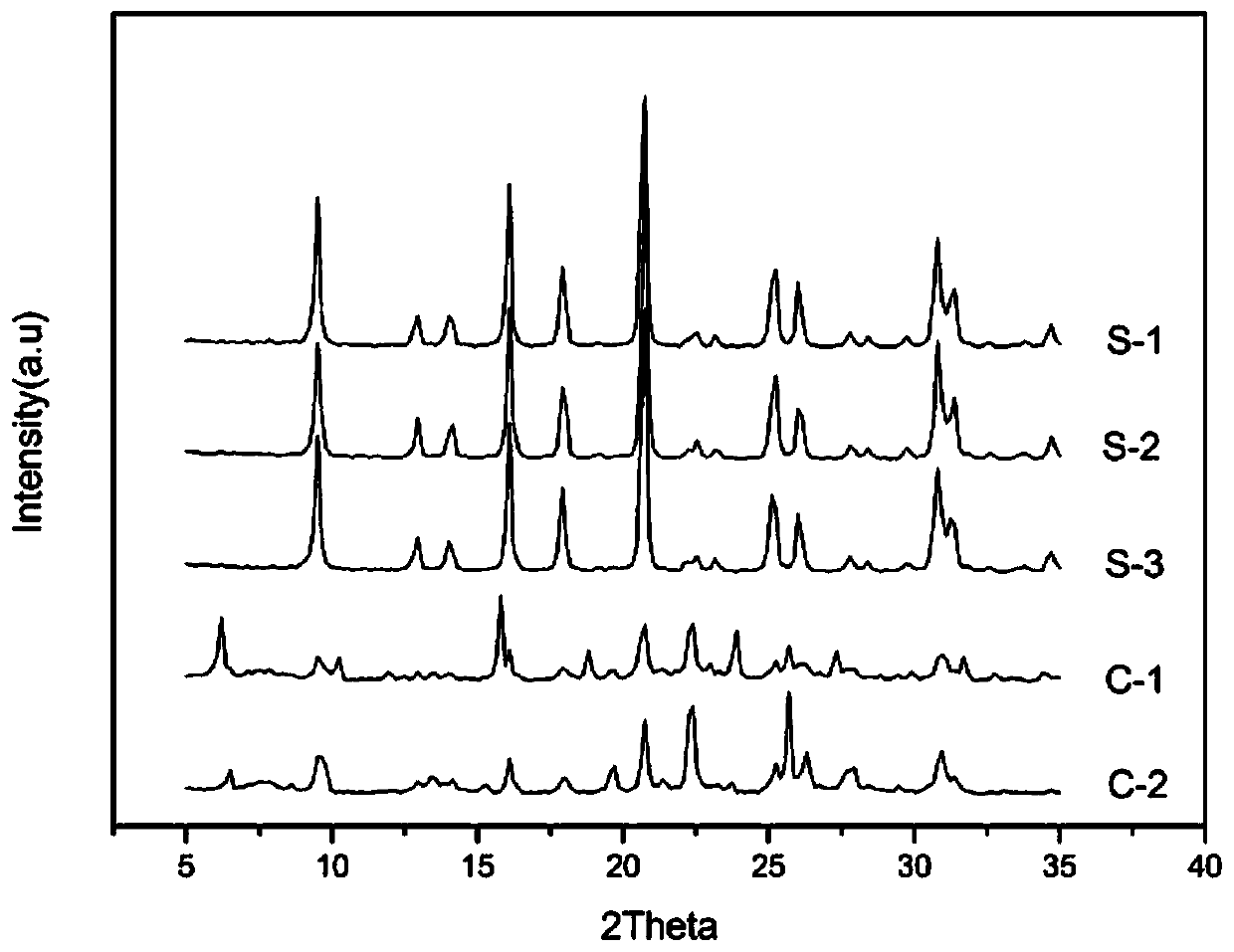

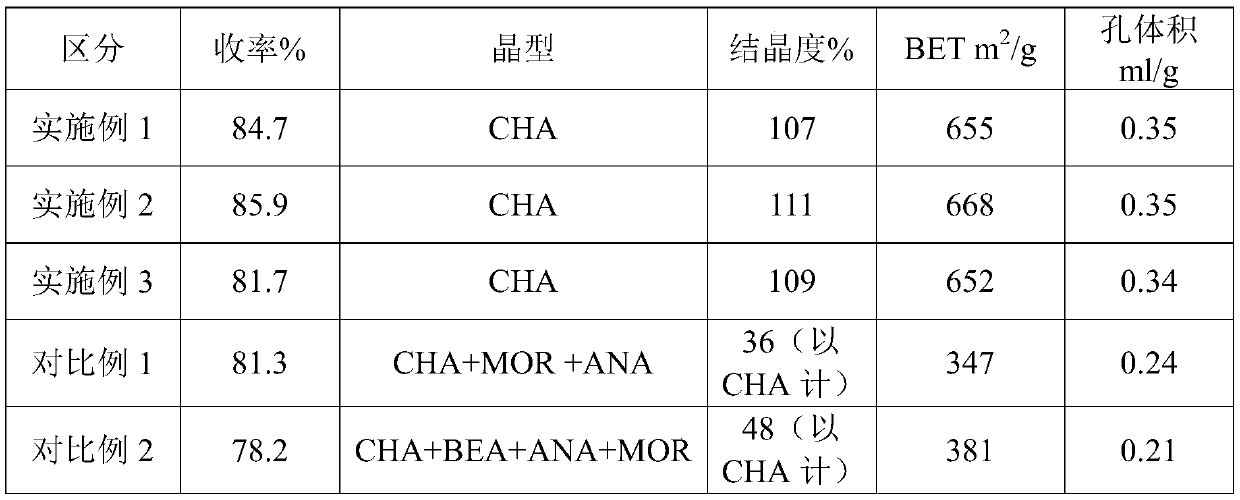

Method for preparing SSZ-13 molecular sieve from Beta molecular sieve

ActiveCN111233002AReduce manufacturing costAchieve crystallizationMolecular sieve catalystsMolecular-sieve and base-exchange compoundsMolecular sievePerylene derivatives

The invention relates to a method for preparing an SSZ-13 molecular sieve from a Beta molecular sieve, which belongs to the technical field of molecular sieve preparation. According to the method forpreparing the SSZ-13 molecular sieve from the Beta molecular sieve, the treated Beta molecular sieve is used as a silicon source and an aluminum source, an amantadine derivative is used as a first-stage template agent for dynamic crystallization, then a second-stage template agent is added for static crystallization, and the SSZ-13 molecular sieve is prepared. According to the method for preparingthe SSZ-13 molecular sieve from the Beta molecular sieve, the use amount of an expensive template agent is greatly reduced, the production cost is reduced, the process is simple, and industrial production is facilitated; the prepared SSZ-13 molecular sieve has the advantages of high yield, high specific surface area and high crystallinity, and is wide in application range.

Owner:SHANDONG QILU HUAXIN HIGH TECH

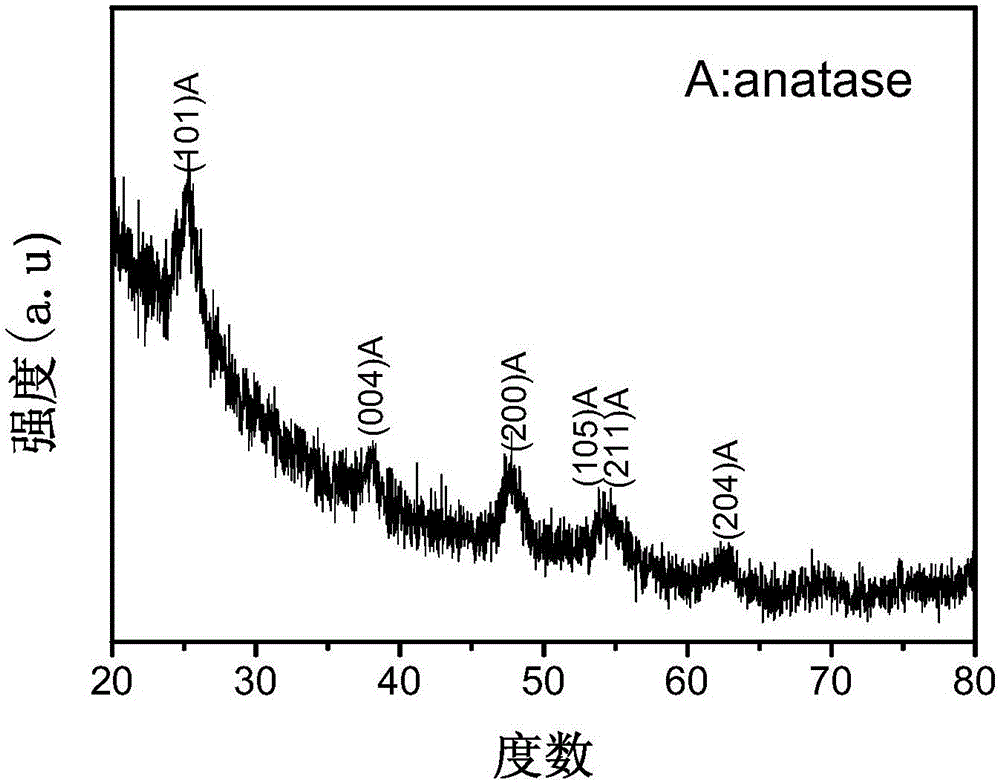

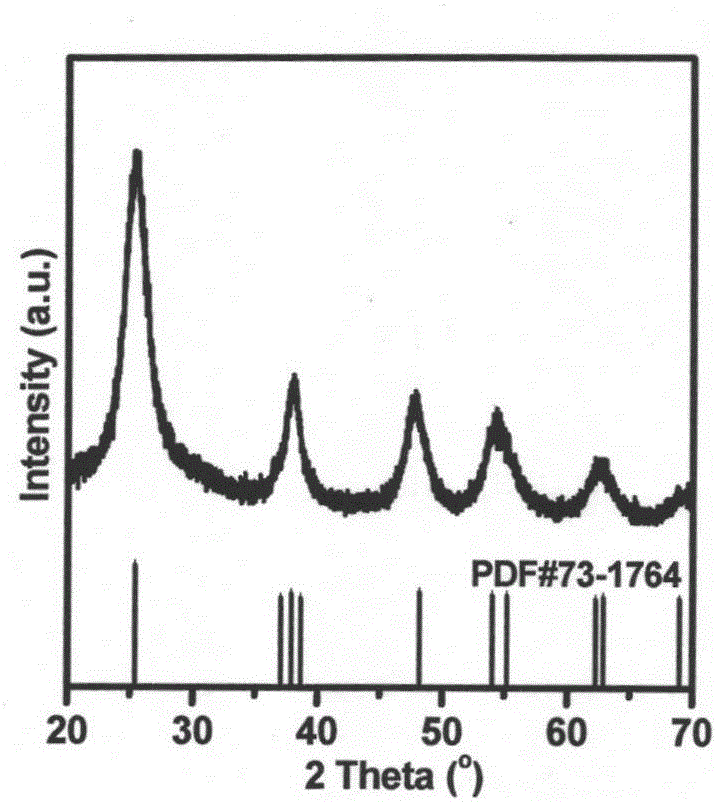

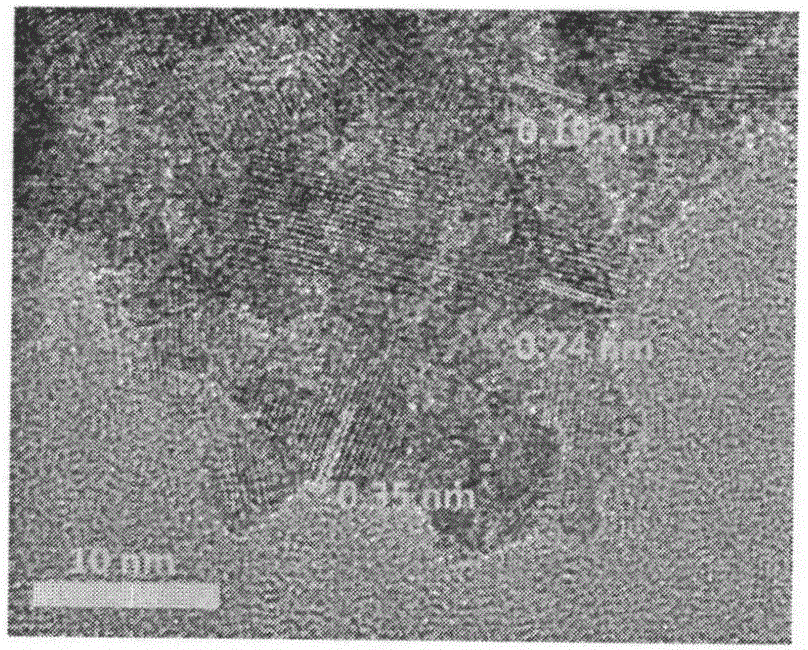

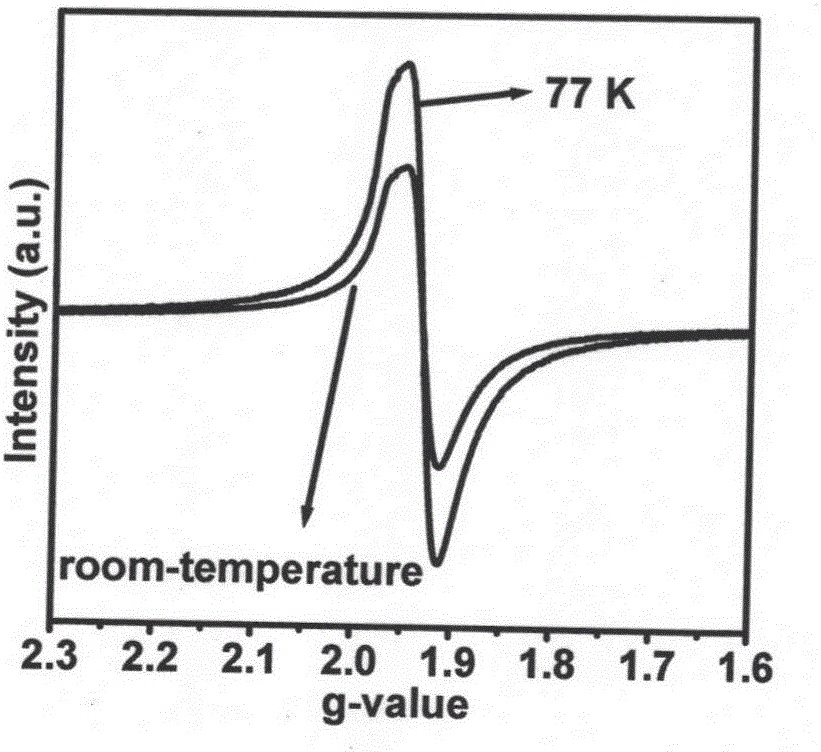

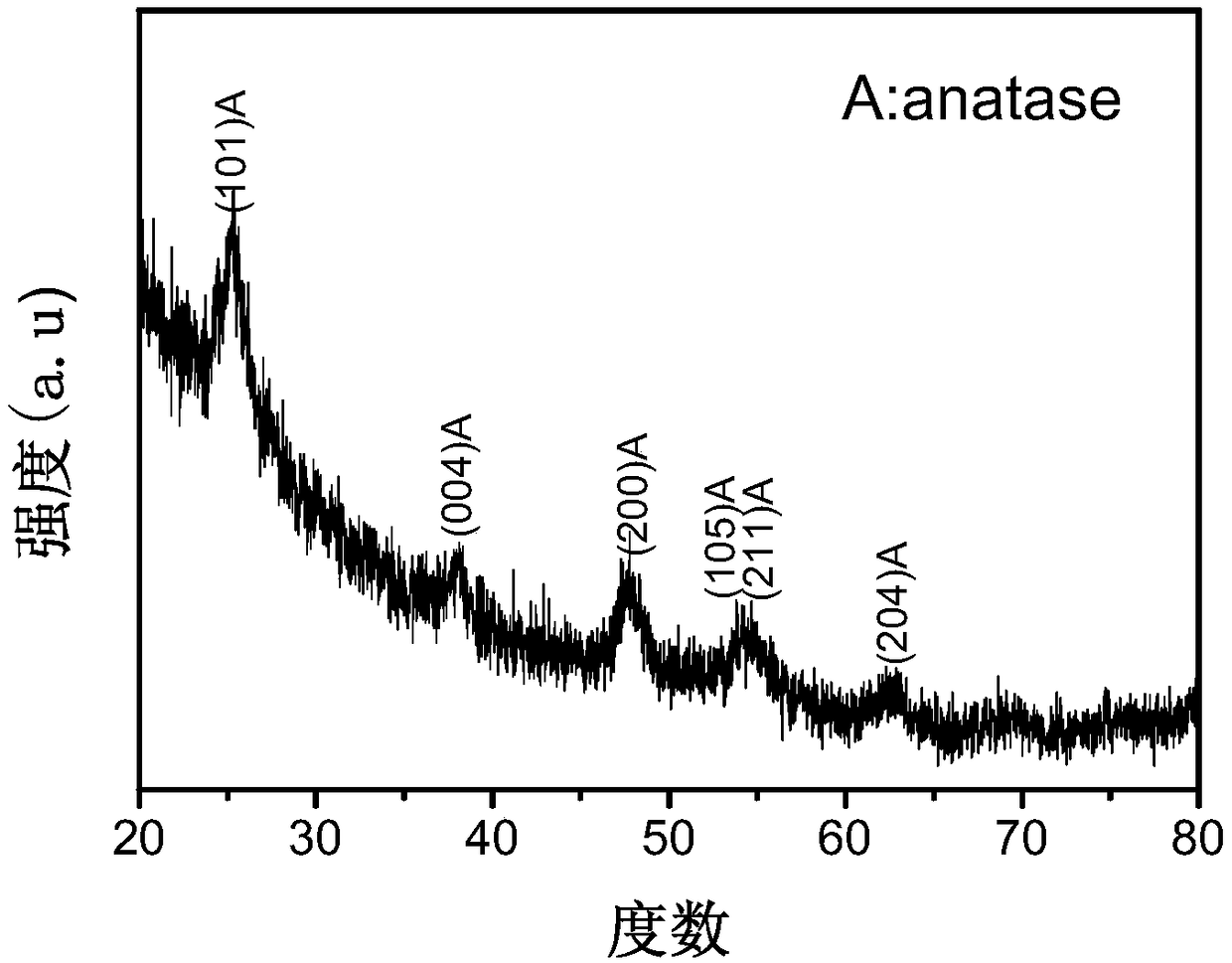

Porous reducing state titanium dioxide crystal material and preparation method thereof

InactiveCN106319626AAchieve crystallizationRealize build flawsPolycrystalline material growthSingle crystal growth detailsHigh energySynthesis methods

The invention provides a porous reducing state titanium dioxide crystal material and a preparation method thereof. The porous reducing state titanium dioxide crystal material has the anatase crystal phase; the specific surface area is 463 to 736 m<2> / g; the pore diameter is 1 to 4nm; the doping quantity of the surface Ti<3+> irons is 5.1 percent to 9.4 percent; the light absorption interval covers ultraviolet light and visible light intervals. Through an optoelectronic storage technology under the room temperature condition, the porous reducing state titanium dioxide crystal material with the large specific surface area is synthesized for the first time. The preparation method is different from a conventional synthesis method; a mild room temperature processing process is used for replacing a conventional high-energy processing process to realize the material crystallization and to overcome building defects. The porous reducing state titanium dioxide crystal material and the preparation method have the advantages that the synthesis technology is simple and green, and is suitable for large-scale production.

Owner:SHANGHAI TECH UNIV

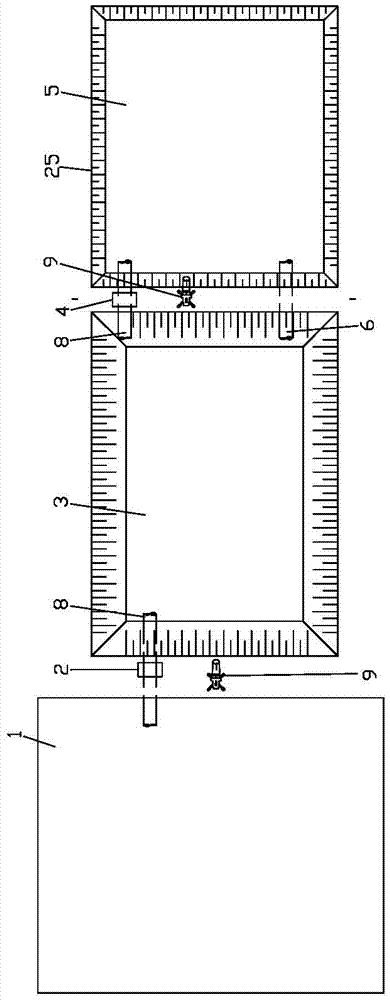

Caprolactam crystallizing device and using method

PendingCN107551598AHigh purityIncrease productivityOrganic chemistrySolution crystallizationEngineeringBreakage rate

The invention discloses a caprolactam crystallizing device and a using method. According to the crystallizing device, a crystallizing tank is respectively connected with a base and a transmission chain, and the transmission chain is connected with a motor; a vent pipe is connected with a gas distributor, and the gas distributor is arranged inside the crystallizing tank; a material pipe is arrangedon the upper part of the crystallizing tank, and the bottom of the material pipe is lower than the upper edge of the crystallizing tank; a conveyer belt is arranged on the lower part of the crystallizing tank; and one end of the conveyer belt is positioned on the inner side of the vertical lower part of the lower edge of the crystallizing tank. The using method comprises the following steps: controlling the crystallizing tank to be positioned in an inclined state; starting a motor, and enabling the crystallizing tank to rotate by virtue of the transmission chain; starting a conveyor belt button to move the conveyor belt; feeding gases into the crystallizing tank through the vent pipe; and feeding materials into the crystallizing tank by the material pipe, crystallizing and drying in the crystallizing tank so as to obtain the caprolactam crystal, and conveying the crystal to the next process by the conveyor belt. The device disclosed by the invention has the advantages of being scientific in design, reasonable in structure, high in production efficiency and the like. According to the caprolactam crystallizing device provided by the invention, the prepared product is high in purity,uniform in particle size, high in strength and low in damage rate.

Owner:SHEN MA INDUSTRY CO LTD +1

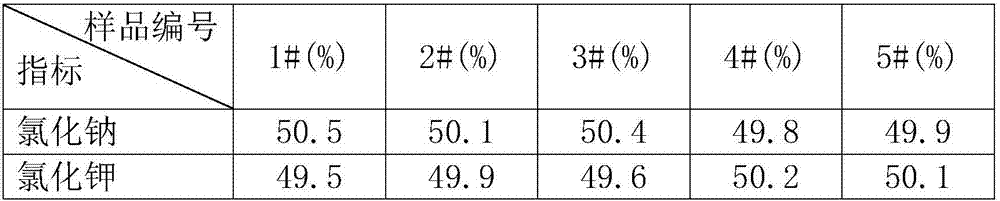

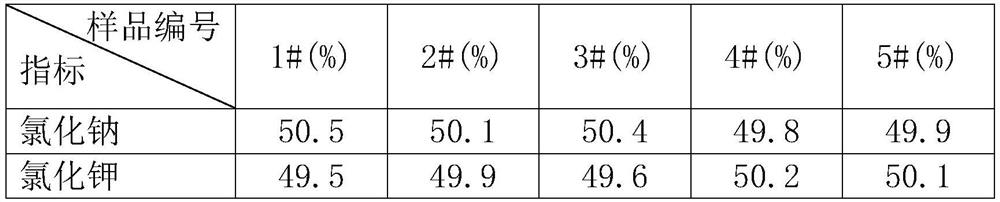

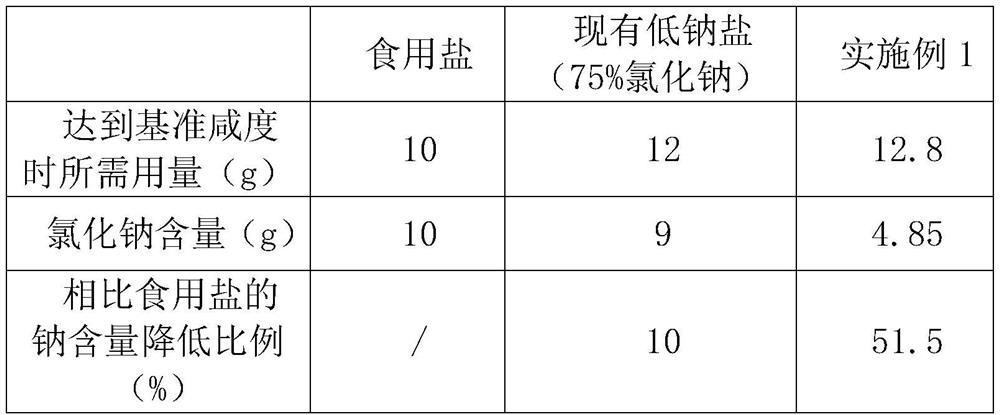

Ultra-low-sodium salt seasoning product and preparation method thereof

ActiveCN106858520AReduce intakeReduce usageAcidic food ingredientsFood ingredient as taste affecting agentDiseaseSalty taste

The invention discloses an ultra-low-sodium salt seasoning product and a preparation method thereof. The ultra-low-sodium salt seasoning product is prepared from the following ingredients in parts by weight: 25 to 45 parts of sodium chloride, 25 to 45 parts of potassium chloride, 5 to 8 parts of cellulose, 5 to 8 parts of hemicelluloses, 5 parts of starch zymolyte and 4 to 8 parts of auxiliary materials. The potassium chloride saturated solution is attached onto the surface of the sodium chloride in a spraying mode; through drying, the sodium chloride and the potassium chloride are combined into one integral particle; the mixing is more uniform; the mouthfeel is more uniform, softer and more stable. The consumption of the sodium chloride is further reduced; the salt intake quantity of people every day can be greatly reduced, so that the probability of diseases of hypertension, heart disease, cerebral apoplexy and the like can be reduced; through adding starch zymolyte and various auxiliary materials, the competition taste sense sensing mechanism is used for inhibiting hydrophobic substances and expanding an ENaC special protein signal path; therefore the foreign taste of bitter taste, metal taste and the like brought by the potassium chloride and the like can be shielded; the integral flavor and delicious taste including salty taste and fresh taste can be improved.

Owner:世盐同达(天津)科技有限公司

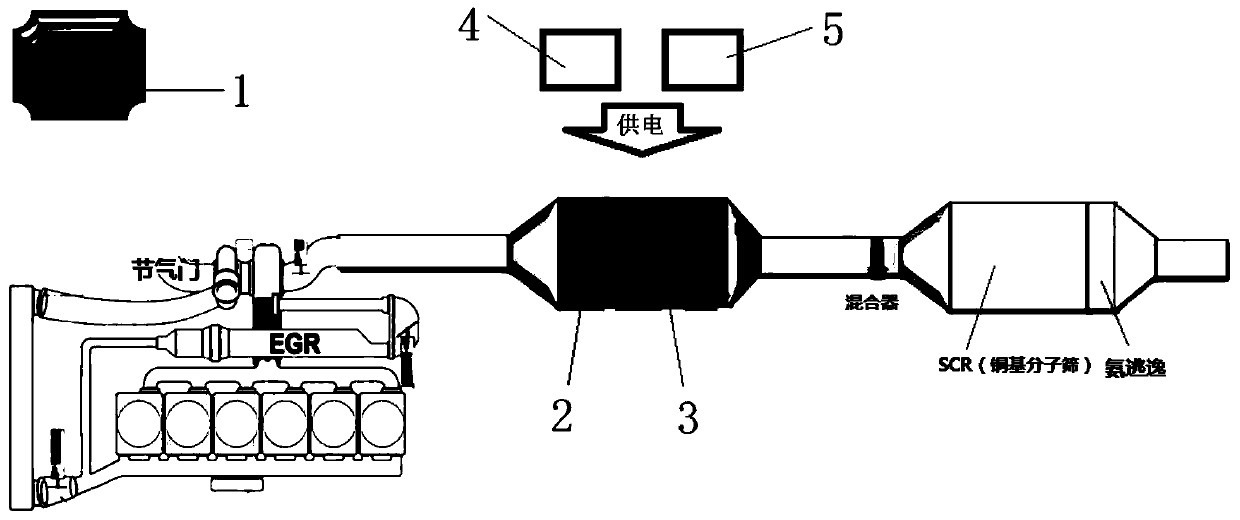

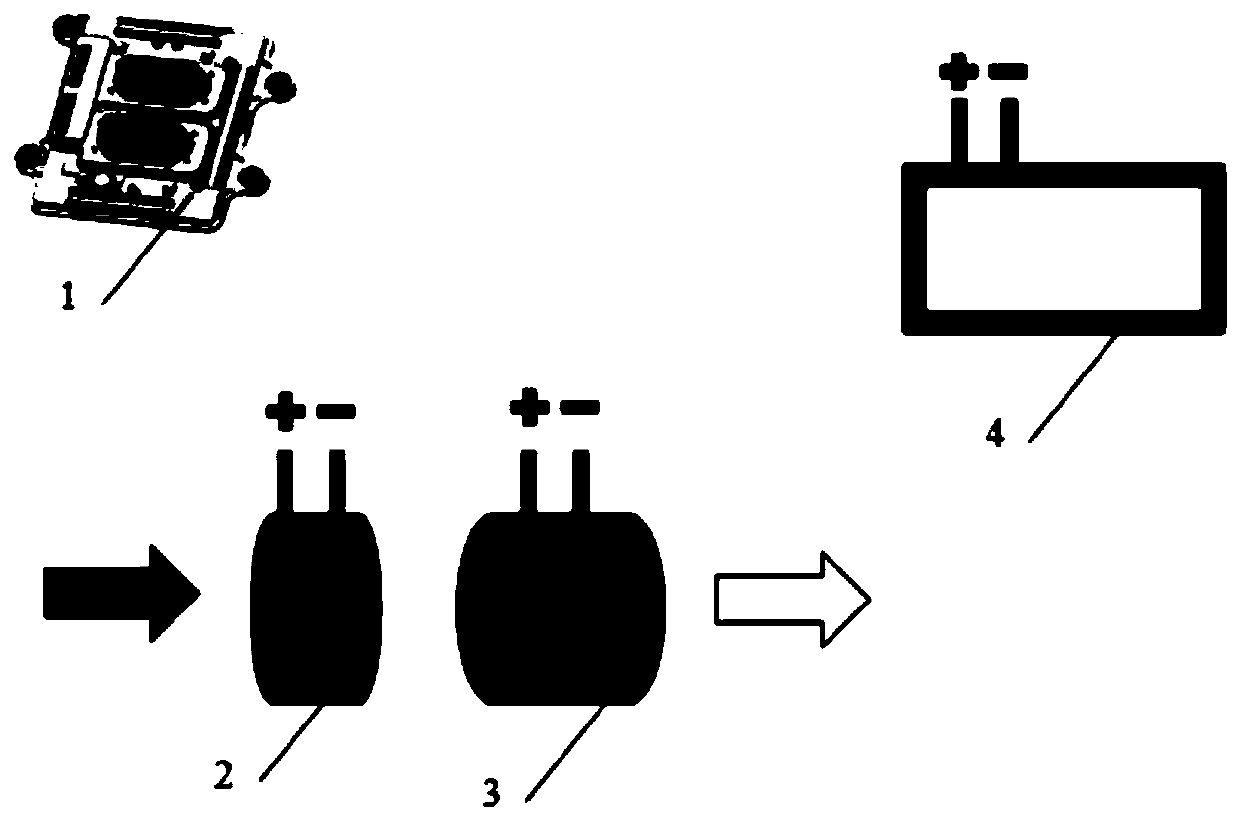

Electric heating particle catcher aftertreatment system for diesel engine

InactiveCN111365095AReduced risk of burnoutIncrease temperatureInternal combustion piston enginesExhaust apparatusDiesel engineAlternate current

The invention discloses an electric heating particle catcher aftertreatment system for a diesel engine, belongs to the technical field of diesel engine exhaust aftertreatment, and aims to improve reliability and adaptability of the particle catcher aftertreatment system. The electric heating particle catcher aftertreatment system for the diesel engine is composed of a metal electric heating DOC, an electric heating particle catcher, an engine ECU, a storage battery and an alternating current converter; ceramic carriers of the metal electric heating DOC and the electric heating particle catcherare changed into metal carriers; the metal carriers are connected with the alternating current converter and the storage battery correspondingly, can be connected with 220 V alternating current through the alternating current converter or can be directly powered by the storage battery to realize electrified heating so as to realize regeneration of the electric heating particle catcher, and meanwhile, through electrified heating of the metal electric heating DOC and the electric heating particle catcher, SCR front temperature can be increased, the functions of desulfurization and urea crystalremoval can be achieved, and normal running of a vehicle is ensured after sulfur poisoning or urea crystallization blockage of an aftertreatment device occurs.

Owner:FAW JIEFANG AUTOMOTIVE CO

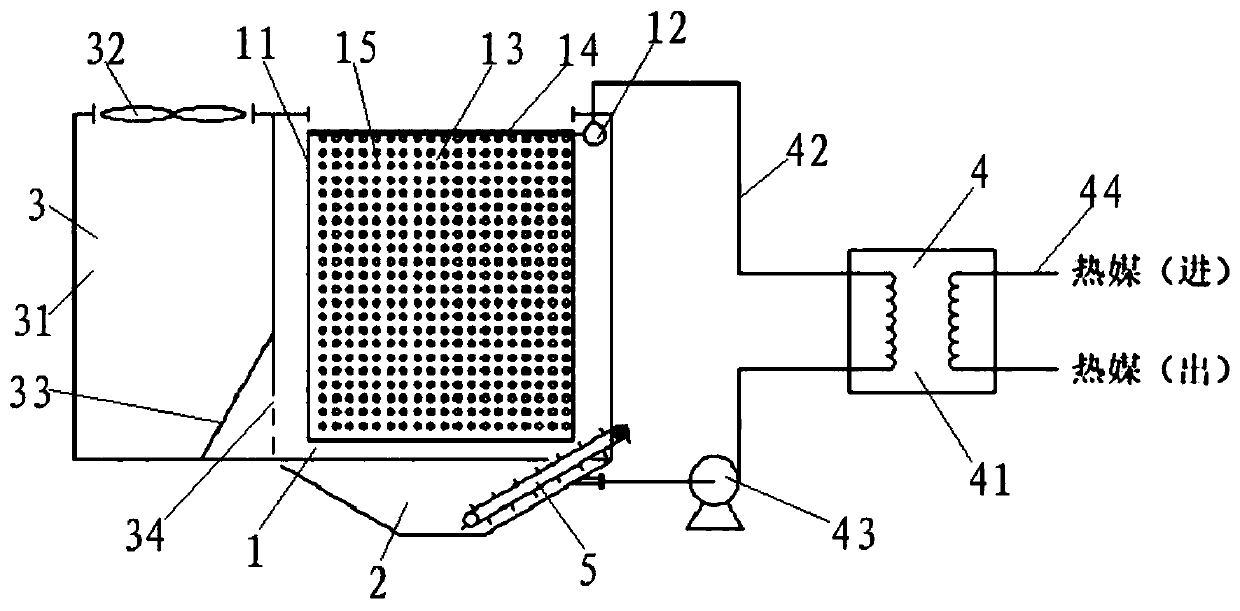

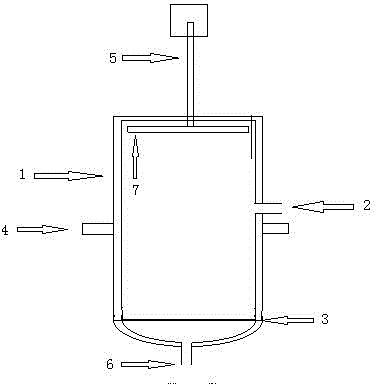

Low-temperature evaporative crystallization apparatus

InactiveCN111450567AAchieve evaporationAchieve crystallizationCrystallization by component evaporationEngineeringEvaporation chamber

The present invention discloses a low-temperature evaporative crystallization apparatus. The apparatus comprises: a curtain type evaporator, which comprises an evaporation chamber, a plurality of evaporation modules and a water distribution mother pipe, wherein each evaporation module comprises a plurality of curtain cloth assemblies arranged in parallel at an equal, and each curtain cloth assembly comprises a hydrophilic cord fabric and a water distribution branch pipe; a crystallizing pond, which is arranged at the bottom of the evaporation chamber and used for collecting materials and crystals falling from the hydrophilic cord fabric; an air exhausting mechanism, which communicates with the evaporation chamber and used for generating negative pressure to exhaust evaporated steam in theevaporation chamber; and a heating device, which is separately connected with the water distribution mother pipe and the crystallizing pond and used for heating the materials in the crystallizing pondand then conveying the materials into the water distribution mother pipe. According to the invention, evaporation and crystallization of the materials can be achieved at low temperature and natural atmospheric pressure, and the evaporative crystallization device has the advantages of low operation pressure, simple structure, convenience in operation and the like.

Owner:上海缘脉环境科技有限公司

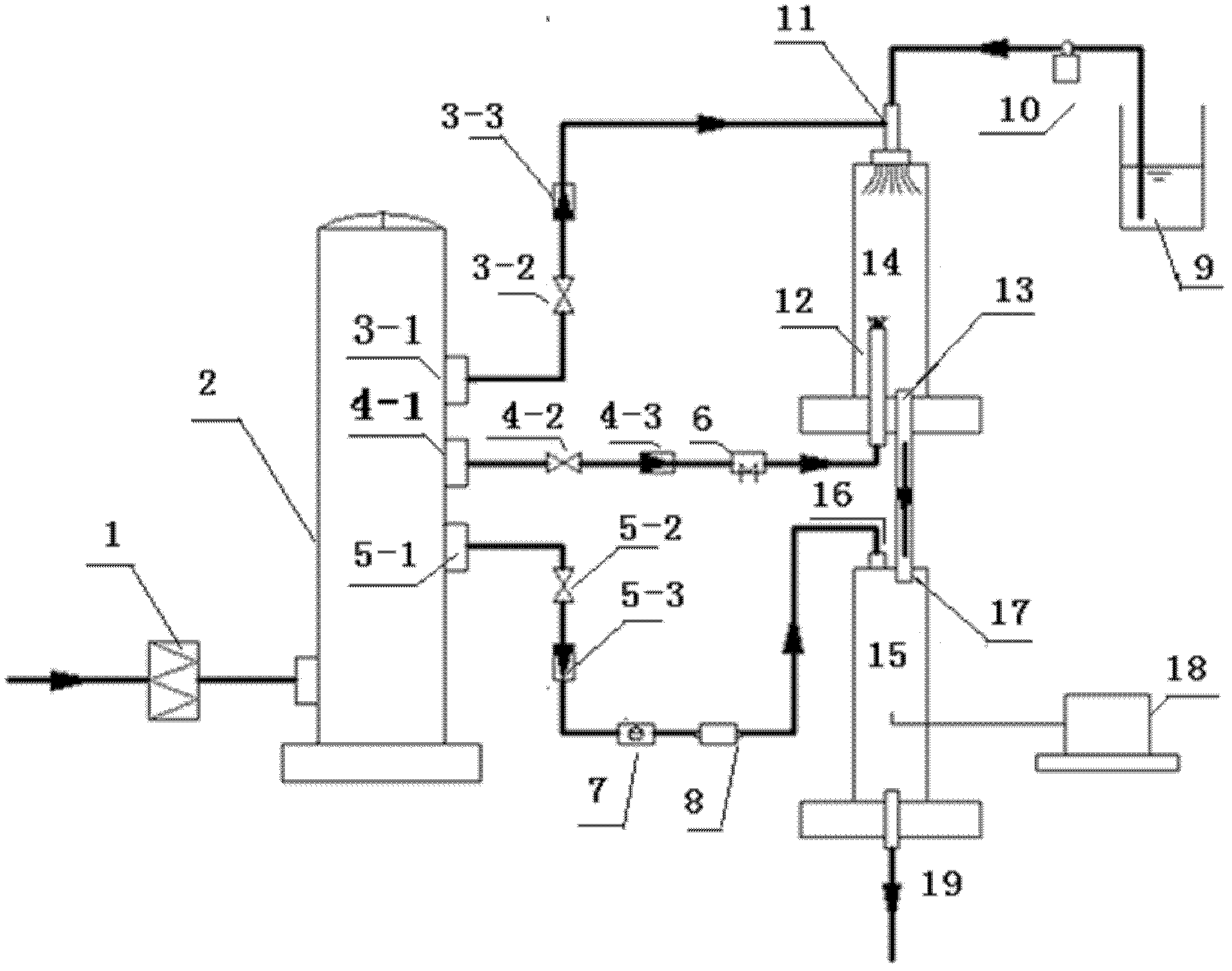

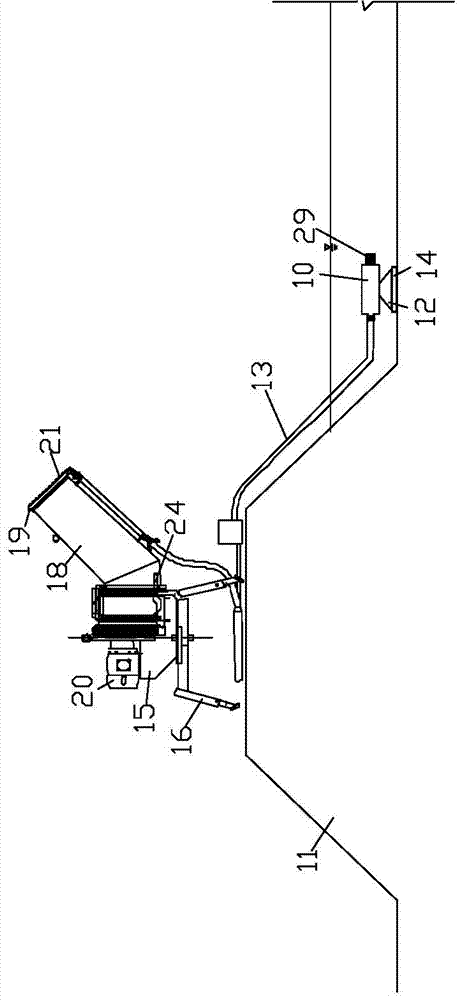

Concentrated salt water zero discharge system and concentrated salt water zero discharge method based on atomization evaporation

ActiveCN106976924AAchieve evaporative concentrationAchieve crystallizationWater/sewage treatmentRefluxSalt water

The present invention relates to a concentrated salt water zero discharge system and a concentrated salt water zero discharge method based on atomization evaporation. The concentrated salt water zero discharge method comprises adjusting and temporary storage, atomizing concentration, and atomizing crystallization. The concentrated salt water zero discharge system comprises an adjustment pool and a crystallization pool, and further comprises an atomizing evaporation circulation concentration pool, a reflux pipe, an atomizing crystallization device, an adjustment pool water outlet control valve and an atomizing evaporation circulation concentration pool water outlet control valve. With the technical scheme of the present invention, concentrated salt water is atomized into small water drips with a diameter of 100-150 [mu]m by using mechanical equipment so as to increase the heat exchange specific surface area and increase the natural evaporation efficiency by 2-5 times; by combining the atomizing evaporation device and the reasonable system control, the requirement on the land occupation is reduced by 50-80% compared to the traditional evaporation pond concentrated salt water treatment technology; and through the method comprising adjusting stored concentrated salt water by the adjustment pool, atomizing concentration, and atomizing crystallization, by combining the system control and the meteorological monitoring, the evaporation concentration and crystallization of the concentrated salt water can be achieved, and the concentrated salt water treatment zero discharging can be achieved.

Owner:BEIJING GEOENVIRON ENG & TECH

Spray drying system

ActiveCN109589625AAchieve instant dry effectNot easy to stickSludge treatment by de-watering/drying/thickeningEvaporator accessoriesReciprocating motionAgricultural engineering

The invention provides a spray drying system. The spray drying system comprises a shell, wherein a volute heating plate and a vertical cleaning brush which are vertically placed are arranged in the shell; the outer end of the volute heating plate is communicated with a steam inlet; the inner end of the volute heating plate is communicated with a hollow pipeline of the lower part of a rotating shaft arranged at the center position of the shell; the hollow pipeline is connected to a condensate outlet; the two ends of the vertical cleaning brush are connected to the rotating shaft, and the vertical cleaning brush is driven by the rotating shaft to reciprocate along the volute heating plate; a material liquid inlet pipe is arranged at the upper side of the volute heating plate; a spray head isarranged at the lower part of the material liquid inlet pipe; a horizontal drying plate is arranged at the lower side of the volute heating plate; a horizontal cleaning brush is arranged on the horizontal drying plate; one end of the horizontal cleaning brush is fixedly connected to the rotating shaft; and a discharge port is formed in the bottom of the horizontal drying plate. The spray drying system has the advantages that a crystalline material is not easy to agglomerate and harden, the material solution drying efficiency is high, and the energy saving effect is remarkable.

Owner:SHANDONG XIANGHUAN ENVIRONMENTAL TECH CO LTD

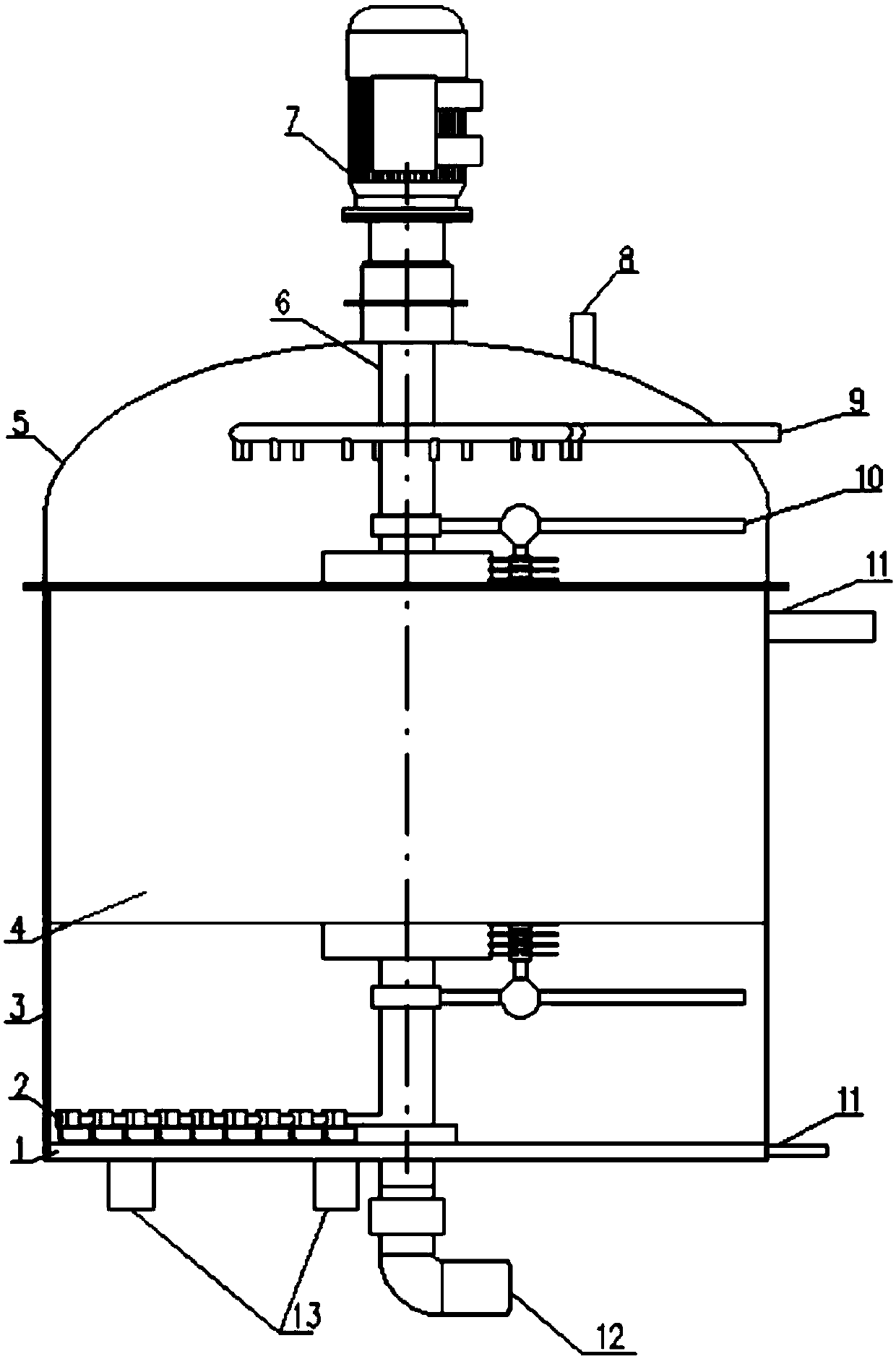

High-temperature continuous evaporative crystallization equipment and crystallization process thereof

PendingCN114504838ALarge processing capacityReduce energy consumptionGeneral water supply conservationEvaporation with vapour compressionCrystallizationHigh heat

The invention discloses high-temperature continuous evaporative crystallization equipment which comprises a high-temperature evaporator, a steam compressor connected with the high-temperature evaporator through a first pipeline and a high-temperature crystallizer connected with the steam compressor in parallel through a second pipeline. The high-temperature evaporator comprises a heat exchange cavity and an evaporation cavity. The steam compressor communicates with a first steam inlet and a first steam outlet in the heat exchange cavity and the evaporation cavity through the two ends of a first pipeline correspondingly. The high-temperature crystallizer comprises a crystallization cavity, a heating device and a stirring device; a concentrated solution formed by heating and evaporating in the heat exchange cavity is conveyed to the crystallization cavity; and the steam compressor is respectively communicated with the heating device and a second steam inlet and a second steam outlet on the crystallization cavity through two ends of a second pipeline. According to the equipment, on the basis of not changing parts of the MVR high-temperature evaporation system and not increasing new parts, the high-temperature crystallizer is connected with the MVR high-temperature evaporation system in parallel, so that the advantages of large treatment capacity and low energy consumption in the MVR high-temperature evaporation system are reserved, and meanwhile, the crystallization of a concentrated solution is realized.

Owner:沃力雅环保科技上海有限公司

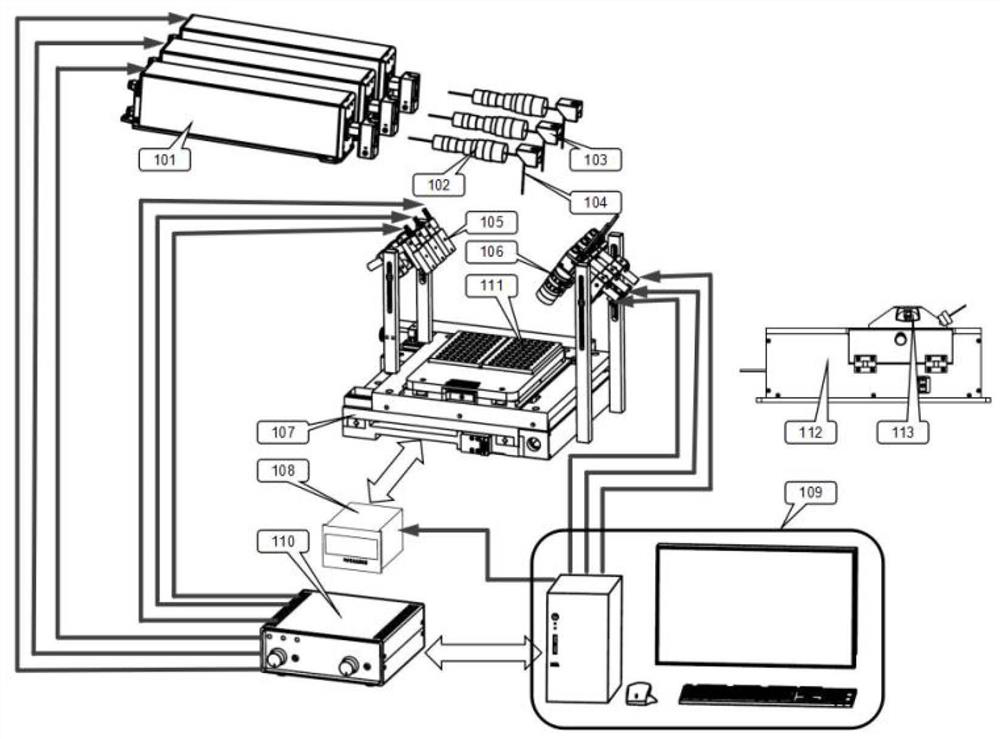

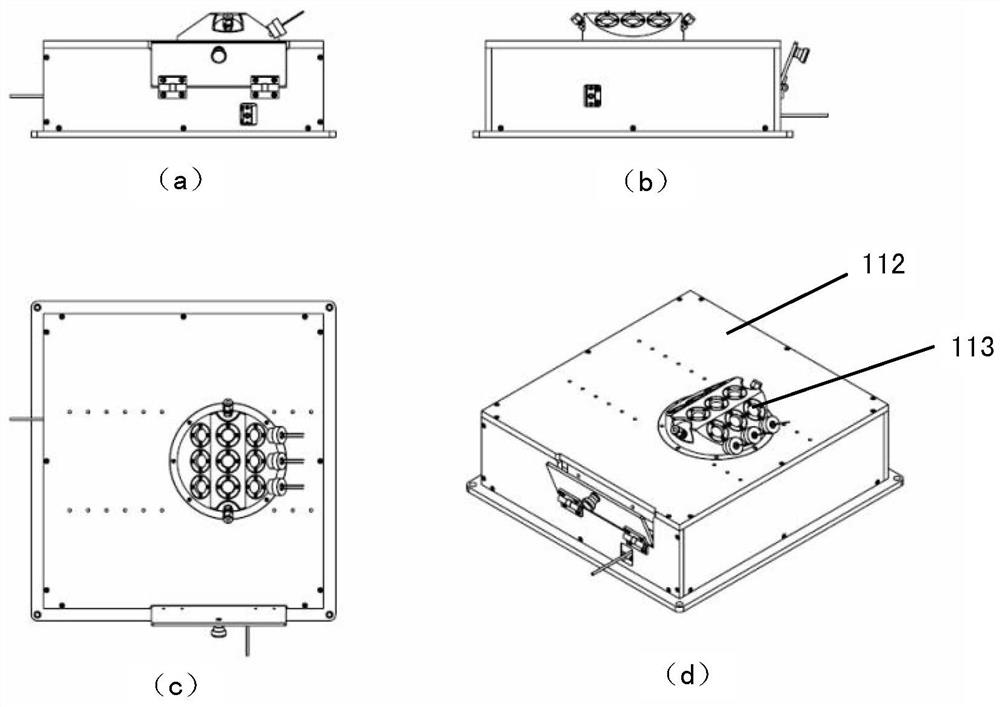

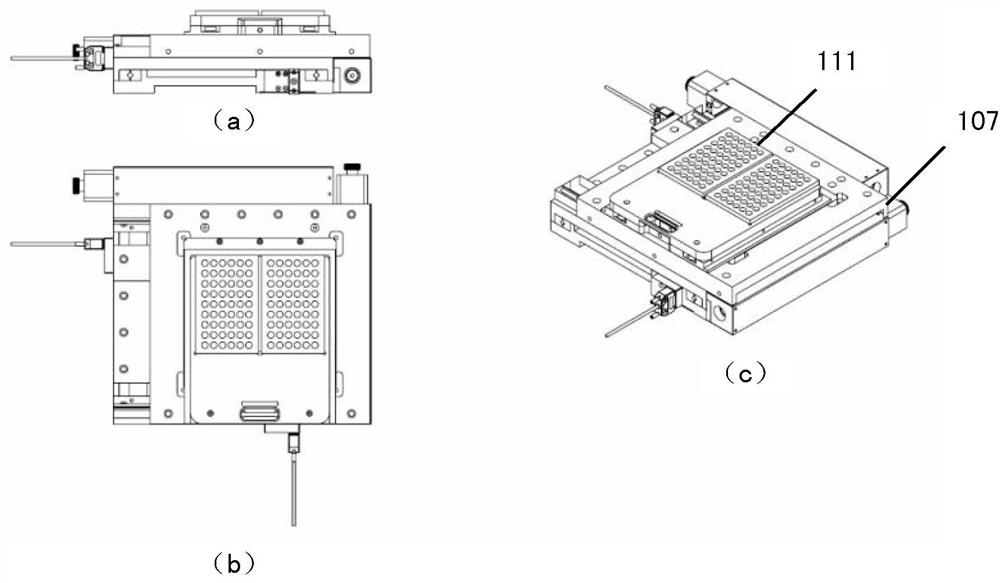

Array sample laser heating system

ActiveCN109352182BRealize in situ chemical reactionAchieve crystallizationPreparing sample for investigationLaser beam welding apparatusImage recordingLight beam

The array sample laser heating system provided by the present invention includes: a laser light source unit that outputs laser light to provide heating energy, and has a plurality of lasers arranged in parallel or in an array; a laser that is arranged downstream of the laser light source unit to change the laser spot size The beam spot adjustment unit; the sample stage for placing the array sample; the temperature measurement unit for measuring the laser heating temperature of the array sample to be heated and feeding back the heating effect; the image recording unit for recording the experimental results; and the laser light source Unit, temperature measurement unit, and image recording unit are connected to the master control unit. The invention can realize multi-beam parallel and adjustable beam spot laser heating, and is used for rapid and directional heating of material array samples required for material genetic engineering.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method for for carrying out fluidized extraction on spodumene by utilizing sulfide

PendingCN112456507AHigh purityTo achieve the purpose of removing impuritiesAluminium silicatesLithium sulphateSulfide compound

The invention discloses a method for carrying out fluidized extraction on spodumene by utilizing sulfide. The method comprises the following steps: uniformly mixing sulfide and spodumene powder, and carrying out fluidized high-temperature roasting on the mixture; and then extracting the calcined spodumene powder by using an extracting solution to obtain a leaching solution containing lithium sulfate. By roasting the mixture of sulfide and spodumene, lithium in spodumene can be extracted with low energy consumption, so that energy consumption is low, and environmental pollution is avoided; andthe extracted lithium salt has high purity and can be used in the fields of lithium batteries, nuclear power and the like.

Owner:成都大川锂电科技有限公司

Nickel-titanium shape memory alloy micro-wire surface machining process

ActiveCN111633044AImprove fatigue lifeAchieve crystallizationWire straightening devicesSolid state diffusion coatingSurface fatigueControl manner

The invention provides a nickel-titanium shape memory alloy micro-wire surface machining process and relates to the technical field of material machining. Nitriding treatment is conducted after repeated cold drawing process treatment is conducted on a preprocessed nickel-titanium shape memory alloy micro-wire, so that the nickel-titanium shape memory alloy micro-wire long in fatigue life are obtained. Cold drawing treatment is conducted on the nickel-titanium shape memory alloy micro-wire through a wire-drawing die, an amorphous layer can be formed on the surface of the micro-wire in an accurate control manner, nitriding treatment is conducted on this basis, crystallization of the amorphous layer can be achieved, and a hardening layer with the thickness being accurate and controllable is formed. The nickel-titanium shape memory alloy micro-wire surface machining process is suitable for industrially, easily and controllably machining the hardening layer on the surface of the nickel-titanium shape memory alloy micro-wire, generation of surface fatigue cracks of the nickel-titanium shape memory alloy micro-wire is effectively restrained, the fatigue life of the shape memory alloy micro-wire is greatly prolonged, and the own shape memory function of the wire cannot be damaged.

Owner:常州艾易泰合金科技有限公司 +1

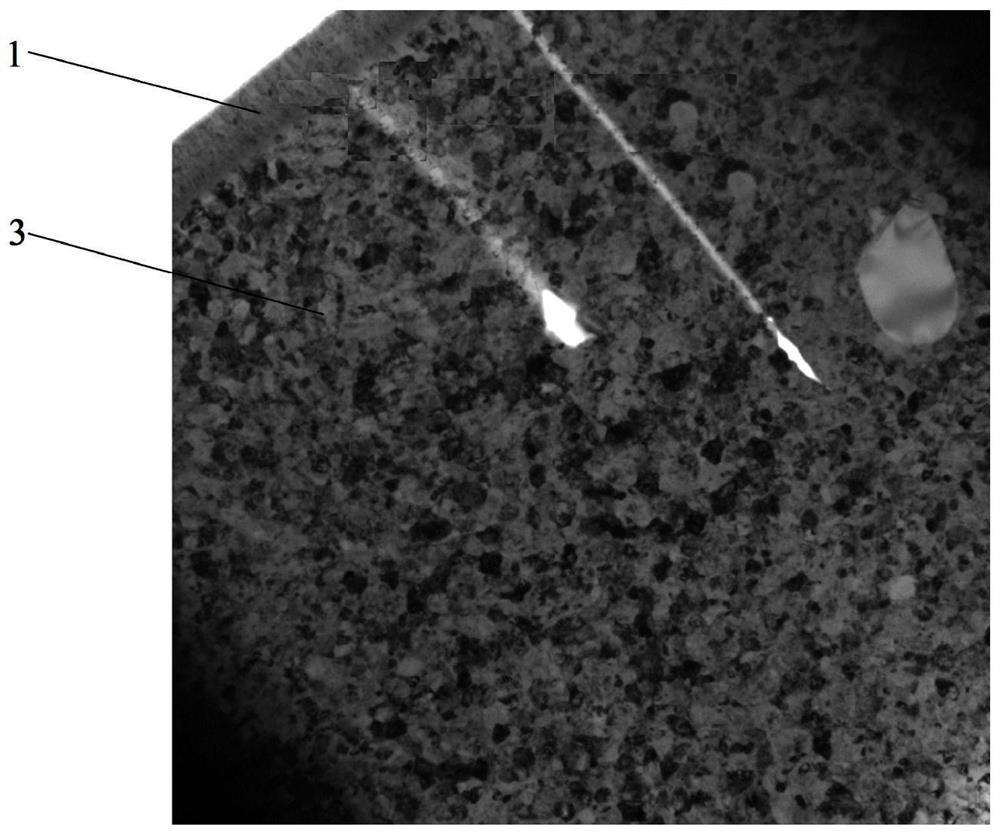

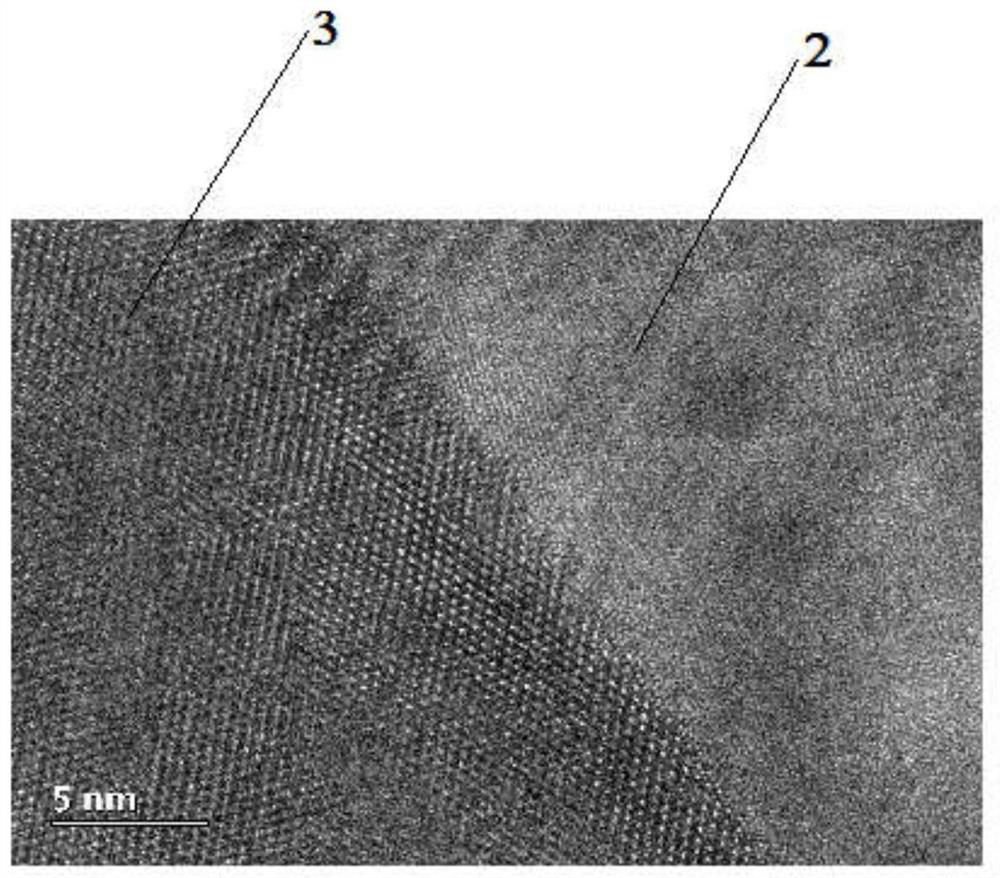

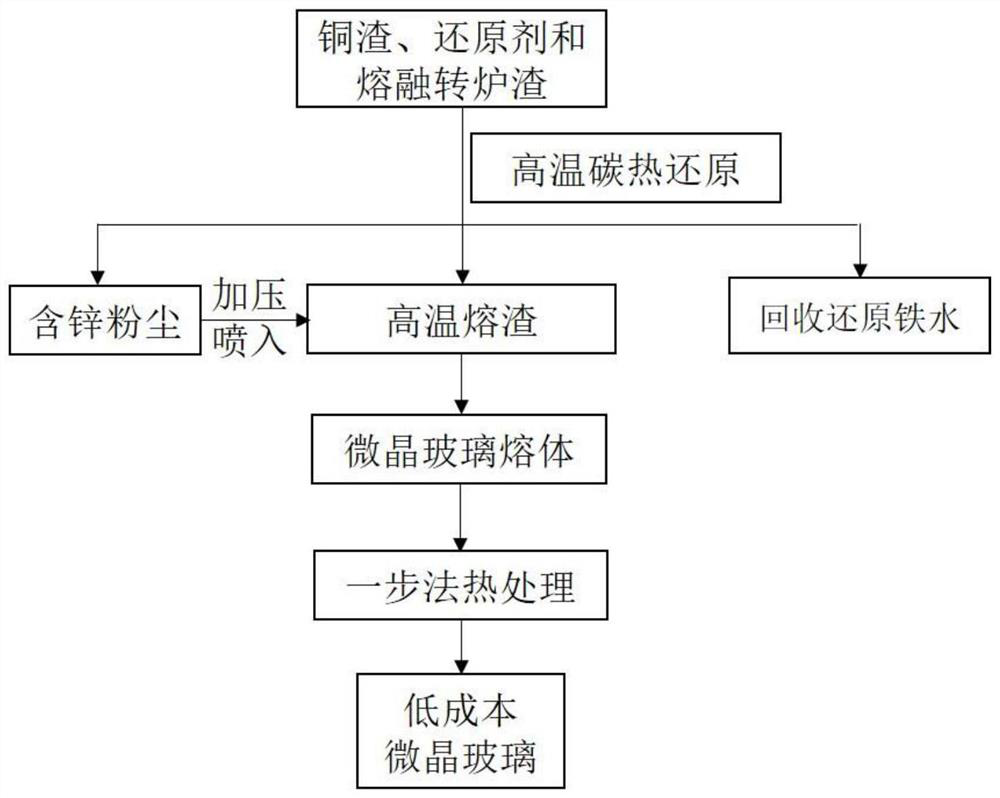

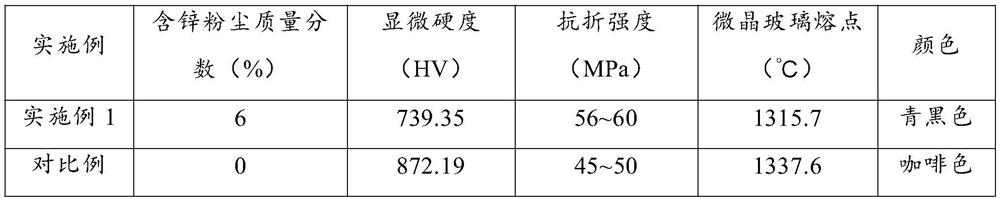

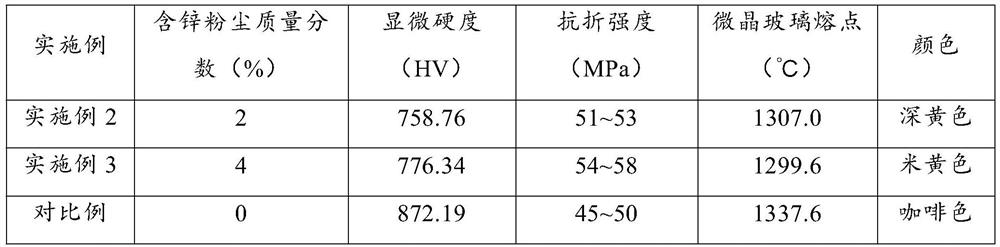

Preparation method of low-cost glass ceramic

ActiveCN113845308AReduce performanceImprove performanceGlass shaping apparatusProcess efficiency improvementGlass-ceramicNatural stone

The invention provides a preparation method of low-cost glass ceramic. Copper slag and high-temperature molten converter slag are mixed, molten reduction tailings generated after iron is reduced and recovered and zinc-containing dust serve as base materials of the low-cost glass ceramic, and a one-step heat treatment process is carried out to prepare the low-cost glass ceramic. The process can be arranged near a high-temperature converter, the solid copper slag and the reducing agent are poured into the liquid converter slag after deslagging and are heated to be completely molten, glass ceramic is prepared from generated secondary tailings, and iron in the glass ceramic is recycled. According to the method, waste of the recovery process can be completely utilized, the economic additional value of the waste is improved, solid waste is reduced, the effect of protecting the environment is achieved, and the purpose of efficiently utilizing the waste heat of the molten converter slag is achieved; and meanwhile, the technological process is simplified. The secondary tailings obtained after reduction of the copper slag and the molten converter slag are used as the base material of the glass ceramic, the preparation cost is low, the price advantage is great, the economic benefit is good, the performance of the prepared glass ceramic is superior to that of natural stone, and the application range is wide.

Owner:WUHAN UNIV OF SCI & TECH

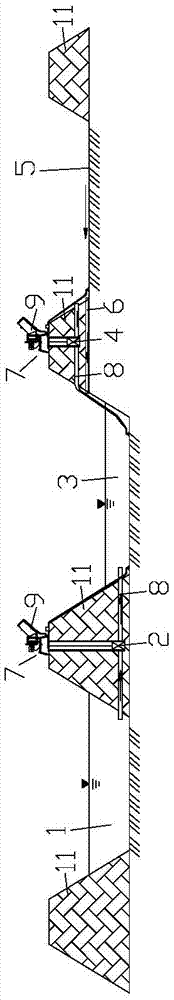

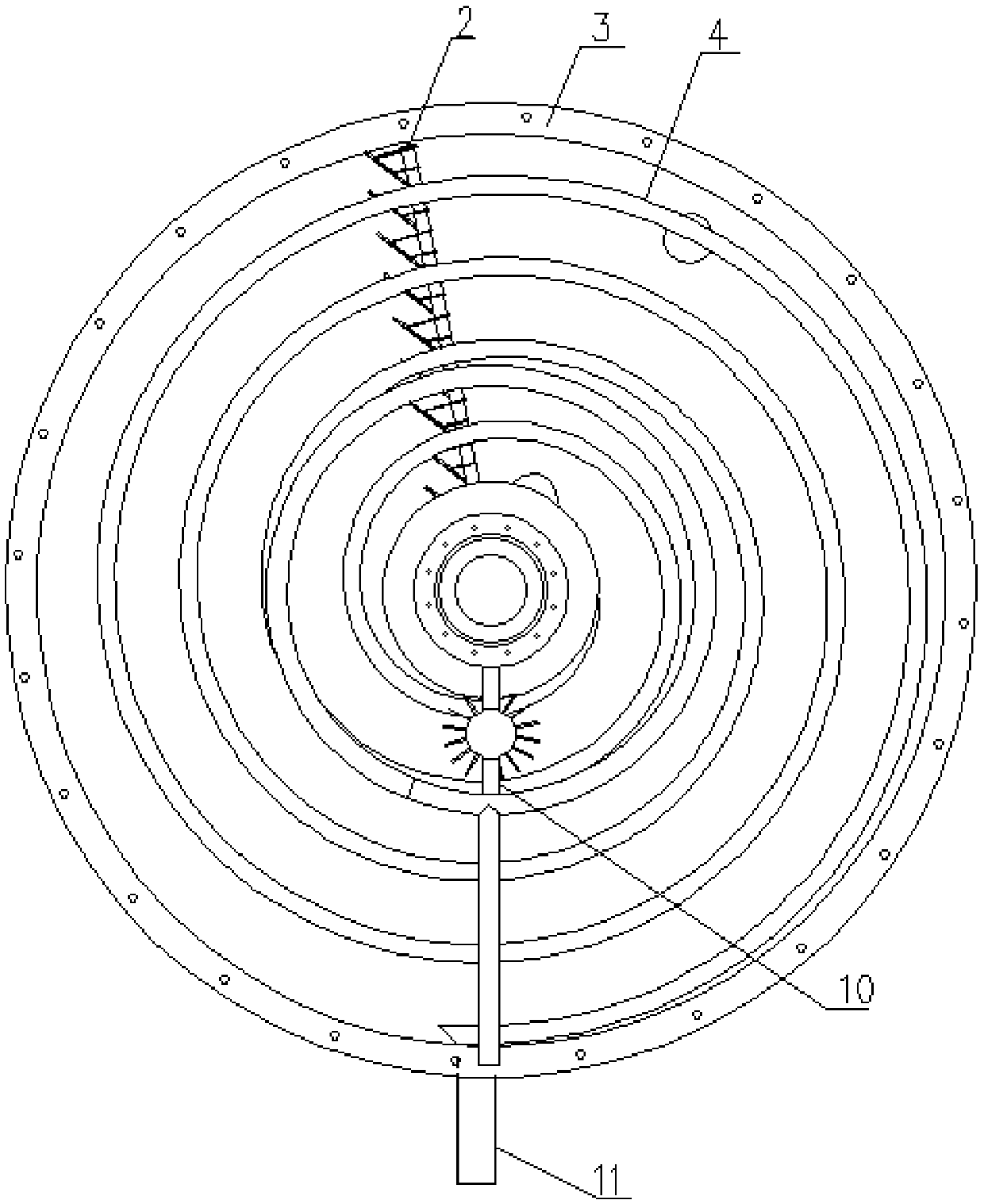

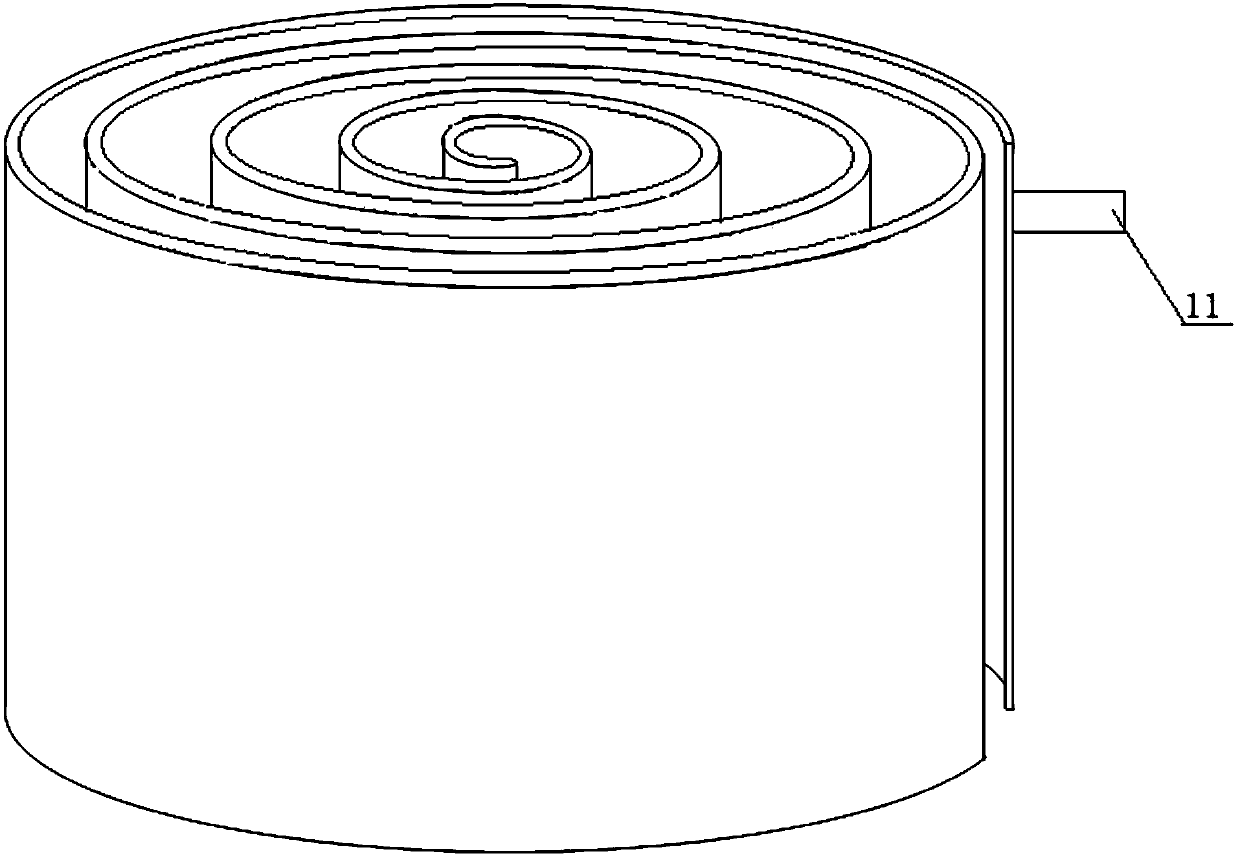

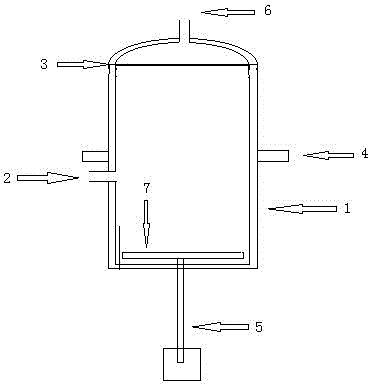

A reversible crystallization filter device

ActiveCN103752031BAchieve crystallizationImplement filteringSolution crystallizationStationary filtering element filtersFiltrationEngineering

The invention relates to turnover crystallization equipment which comprises a kettle body (1), a mother solution feed port (2), a filtering plate (3) which is arranged in the kettle body (1) and can perpendicularly divide the kettle body (1) into two parts, a rotating shaft (4) arranged in a horizontal direction outside the kettle body (1), a rotating rod (5) extending from the outside of the kettle body (1) to the inside of the kettle body (1), and a discharge port (6). The equipment is characterized in that the mother solution feed port (2) and the rotating rod (5) are located on one side of the filtering plate (3); the discharge port (6) is located on the other side of the filtering plate (3); the rotating rod (5) is perpendicular to the filtering plate (3) and can move relative to the filtering plate (3); and a cross rod (7) parallel to the filtering plate is mounted at the front end of the rotating rod (5). The equipment has the advantages that the equipment can achieve crystallization and filtering in a totally-enclosed environment, and is suitable for a crystallization product which has a pungent smell, cannot contact air, is easy to oxidize, is not suitable for open operation and has a melting point below 180 DEG C.

Owner:SHANDONG KEXIN BIOCHEM +1

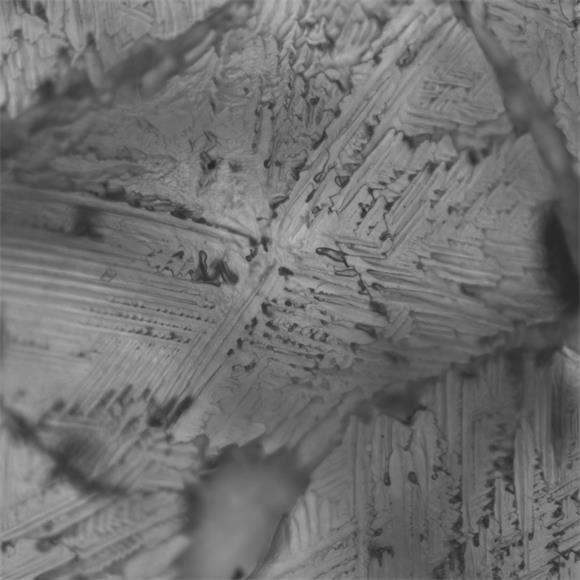

A kind of method for preparing jadeite glass-ceramic

The invention discloses a method for preparing jadeite glass-ceramics, and belongs to the technical field of material synthesis. The main points of the technical solution of the present invention are: using aluminum silicate fiber, silicic acid and sodium carbonate as raw materials, according to the jade NaAlSi 2 O 6 The theoretical mass fraction ratio of each element in the molecular formula is formulated, and the target product is sintered twice at high temperature and normal pressure through the initial treatment of the ingredients. The raw material of the present invention uses aluminum silicate fibers not only to provide Al, Si, O element sources, but also as a skeleton for forming crystals, silicic acid and sodium carbonate react around them, resulting in the formation of spherical dendrites, realizing NaAlSi under normal pressure. 2 O 6 Crystallization; preparation under normal pressure conditions solves the traditional method of realizing jadeite crystallization at high temperature and high pressure, and reduces preparation conditions and costs. The obtained product has a uniform and translucent structure, and contains a jadeite glass-ceramic mixed with an amorphous glass body and a crystallized jadeite crystal.

Owner:XINXIANG UNIV

Evaporation system and evaporation process capable of online descaling and continuous operation

ActiveCN105999750BImprove work efficiencyReduce processing costsEvaporation with vapour compressionEvaporator regulation/controlThermodynamicsEngineering

The invention discloses an evaporating system capable of conducting online descaling and working continuously and an evaporating process. The evaporating system comprises n evaporating units, each evaporating unit is composed of an evaporator E and a steam-water separation mechanism S, the n evaporating units are connected in a feed liquor series-connection or parallel-connection evaporation mode to form the complete evaporating system, secondary steam generated by the n evaporating units shares one steam compression machine for pressurization and temperature raising, and a high-temperature steam main pipe is connected out of the steam compression machine and connected to high-temperature steam inlet pipes on the evaporating units in parallel; a liquid inlet pipe of the second-level / set evaporating unit is simultaneously connected with the first-level / set concentrate outlet pipe and a stoste inlet pipe; a concentrate main pipe is arranged, all the evaporating units except the first level / set evaporating unit are connected with the concentrate main pipe, the concentrate main pipe segment between the liquid inlet pipe and the concentrate output pipe of each evaporating unit is provided with a concentrate valve, valves on related inlet pipes and outlet pipes are controlled to isolate the evaporating units to be cleaned, and evaporating work of the system is not affected.

Owner:广州中科鑫洲科技有限公司 +1

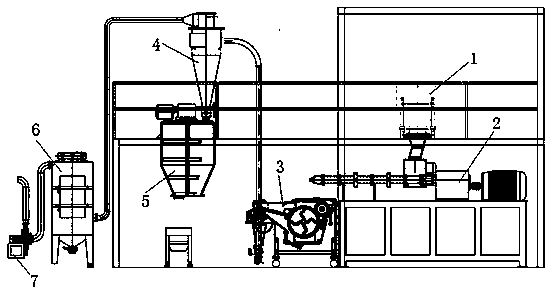

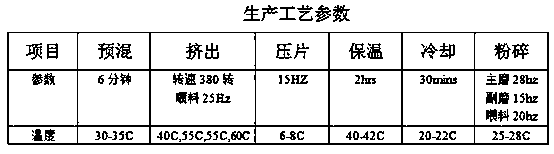

Low-temperature solidified powder production line system and production process thereof

PendingCN111266054AAdjustable and controllable temperatureEasy to shapeTransportation and packagingMixer accessoriesProduction lineLow temperature curing

The invention relates to a low-temperature solidified powder production line system and a production process thereof. The production line system comprises a mixer, an extruder, a roller type tablet press, a cyclone separator and a stirring tank which are sequentially arranged according to a production process route. The production process comprises the following steps: S1, low-temperature mixing;S2, low-temperature extrusion; S3, tabletting at low temperature; S4, separation; S5, stirring; and S6, low-temperature grinding. Transformation is carried out on the basis of existing powder coatingproduction line equipment, so that the material temperature in each process node is controllable and adjustable, and the powder coating production line equipment can be suitable for the production characteristic of low-temperature solidified powder. In the technological process, different temperature parameters are set for mixing, extrusion and tabletting respectively, so that the materials alwayskeep good properties on the technological route, and finally, the materials meet the grinding requirements through the quenching process of heating and cooling in sequence in the stirring tank.

Owner:烟台凌宇粉末机械有限公司

A kind of tio2-sio2 visible light photocatalytic composite thin film and preparation method thereof

ActiveCN106362784BWide variety of sourcesLow pricePhysical/chemical process catalystsComposite filmPolyethylene glycol

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

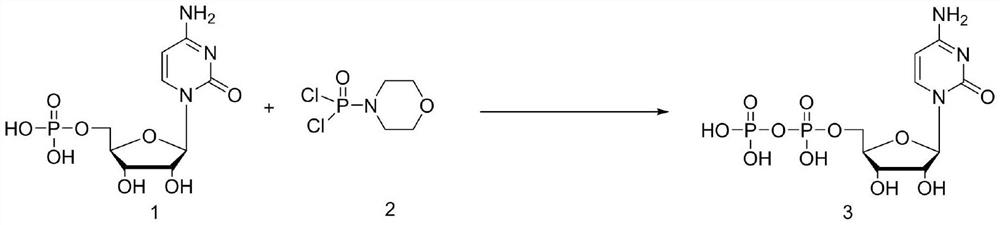

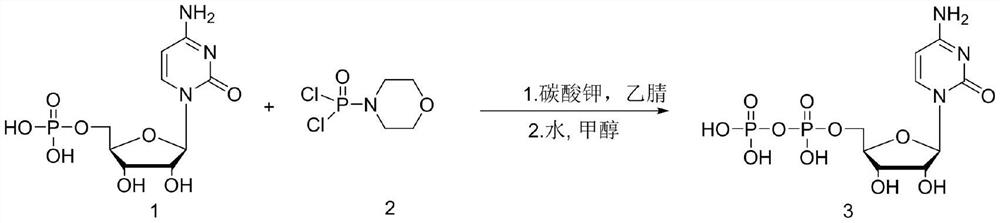

Method for synthesizing cytidine diphosphate

ActiveCN113999270AReduce usageReduce generationSugar derivativesSugar derivatives preparationAlcoholMorpholine

The invention discloses a method for synthesizing cytidine diphosphate, and belongs to the field of nucleoside synthesis in organic chemistry. The method comprises the following reaction steps that cytidine monophosphate and dichlorophosphoryl morpholine serve as raw materials, condensation is conducted under the base catalysis effect, then a crude product cytidine diphosphate is obtained through acyl chloride hydrolysis, recrystallization is conducted through an alcohol / water mixed system, and a finished cytidine diphosphate product with the HPLC purity larger than 95% is obtained. The whole reaction only comprises two steps, reaction operation is simple, and the total yield reaches 70% or above.

Owner:TUOXIN GROUP +1

A Method for Realizing Low Temperature Si-Si Bonding Using Amorphous Germanium Thin Films

InactiveCN106847681BAchieve crystallizationAvoid incompatibilitiesVacuum evaporation coatingSolid-state devicesHigh intensityOptoelectronics

The present invention provides a method for realizing Si-Si bonding through adoption of an amorphous germanium film, and relates to a Si wafer bonding method. The method comprises: selecting Si substrate materials with crystal direction as (100), performing cleaning; boiling the substrate materials through adoption of a mixed solution of H2SO4 and H2O2, and immersing the substrate materials in a mixed solution of HF and H2O2; boiling the processed Si wafer in a mixed solution of NH4OH, H2O2 and H2O, and immersing Si wafer in a mixed solution of HF and H2O2; boiling the processed Si wafer in a mixed solution of HCL, H2O2 and H2O, and immersing the Si wafer in a mixed solution of HF and H2O2; drying the processed Si wafer to put the Si wafer into a direct current magnetron sputtering system, filling Ar gas into a sputtering chamber when the base pressure of the sputtering chamber is smaller than 1*10<-4>Pa; sputtering a-Ge thin film through regulation of direct current sputtering current and sample holder rotation speed; and realizing high-intensity Si-Si bonding through adoption of a hydrophilic a-Ge layer.

Owner:XIAMEN UNIV

A kind of glass ceramics with transmittance close to glass precursor and preparation method thereof

The present invention provides a glass ceramic with a transmittance close to that of a glass precursor, which includes SiO in mole percent 2 : 60‑75mol%, Al 2 o 3 : 2‑10mol%, P 2 o 5 : 0‑5mol%, ZrO 2 : 0.5‑3mol%, Na 2 O: 0.5‑6mol%, Li 2 O: 15‑28 mol%, and B 2 o 3 : at least one of 0‑5mol%, MgO: 0‑5mol%, ZnO: 0‑5mol%, and HfO 2 : 0‑2mol%, Ta 2 o 5 : 0‑2mol%, Y 2 o 3 : at least one of 0‑2mol%, and satisfy 0<HfO 2 +Ta 2 o 5 +Y 2 o 3 ≤2mol%, the visible light transmittance of the glass ceramic is 0.3-5% different from the transmittance of the glass precursor for preparing the glass ceramic. The invention reduces the difficulty of regulating the visible light transmittance of the glass ceramics, so that the visible light transmittance of the glass ceramics is only 0.3-5% different from the visible light transmittance of the glass precursor.

Owner:CHONGQING XINJING SPECIAL GLASS CO LTD

Method for preparing jadeite microcrystalline glass

The invention discloses a method for preparing jadeite microcrystalline glass, and belongs to the technical field of material synthesis. According to the technical scheme, the main points are that aluminum silicate fiber, silicic acid and sodium carbonate are used as raw materials, proportioning is conducted according to the theoretical mass fraction ratio of all elements in the molecular formulaof jadeite NaAlSi2O6, preliminary treatment is conducted on proportioning, and then sintering is conducted twice at the high temperature and the normal pressure to obtain the target product. The aluminum silicate fibers are used as raw materials, provide Al, Si and O element sources and serve as a framework for forming crystals, silicic acid and sodium carbonate react around the aluminum silicatefibers to form spherical dendrites, and NaAlSi2O6 crystallization under normal pressure is achieved; the preparation under the normal pressure condition solves the problem of the traditional method for realizing jadeite crystallization at high temperature and high pressure, and reduces the preparation conditions and cost. The product is uniform in structure and semitransparent, and contains jadeite glass ceramics formed by mixing amorphous glass bodies and crystallized jadeite crystals.

Owner:XINXIANG UNIV

Ultra-low sodium salt substitute condiment and preparation method thereof

Owner:世盐同达(天津)科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com