Method for preparing SSZ-13 molecular sieve from Beta molecular sieve

A molecular sieve, R-1 technology, applied in the direction of molecular sieve catalysts, molecular sieves and base exchange compounds, chemical instruments and methods, etc., can solve the problems of unfavorable industrialization of SSZ-13 molecular sieves, limited cost reduction of template agents, and no substantial progress, etc. Achieve the effects of high yield, wide application range and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

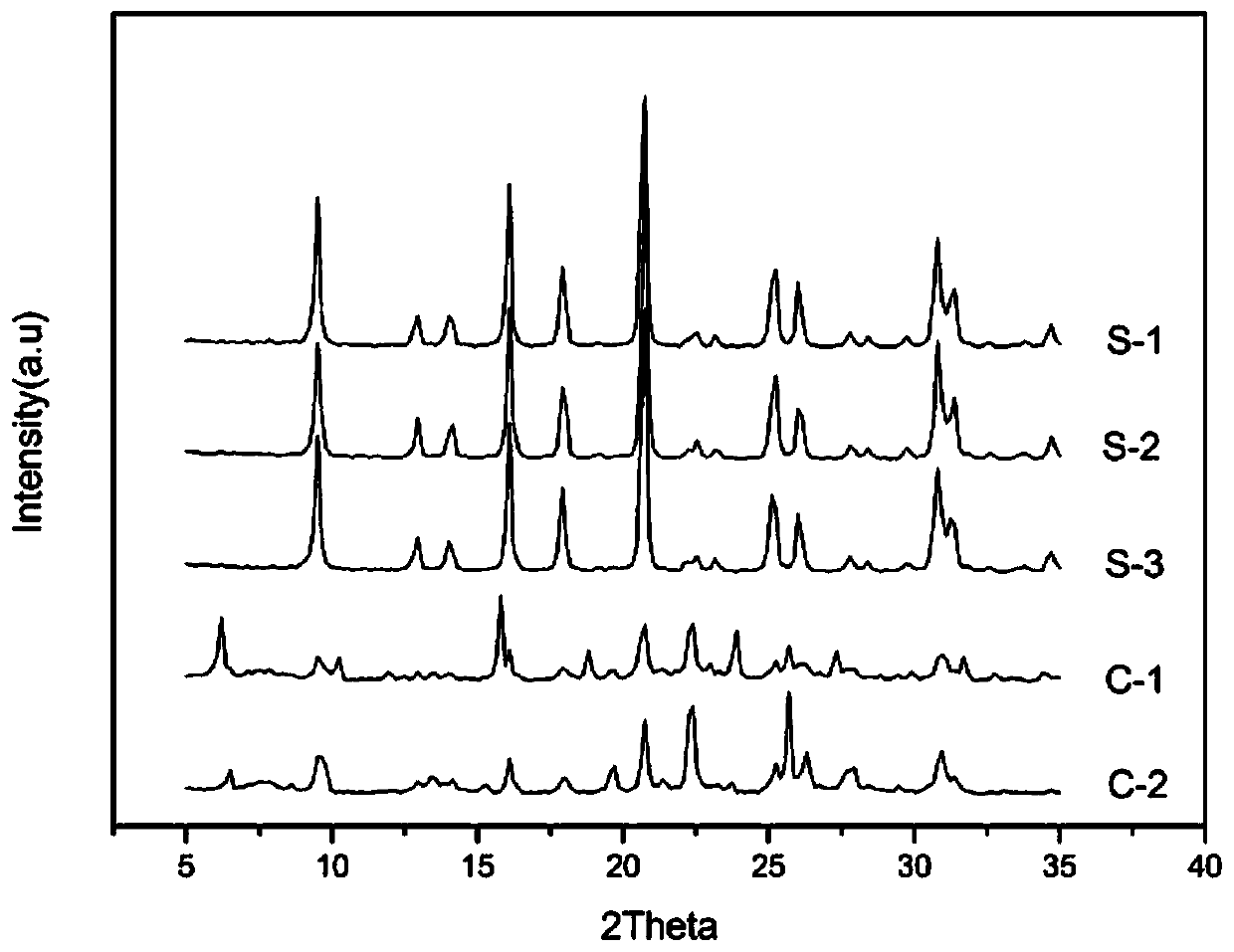

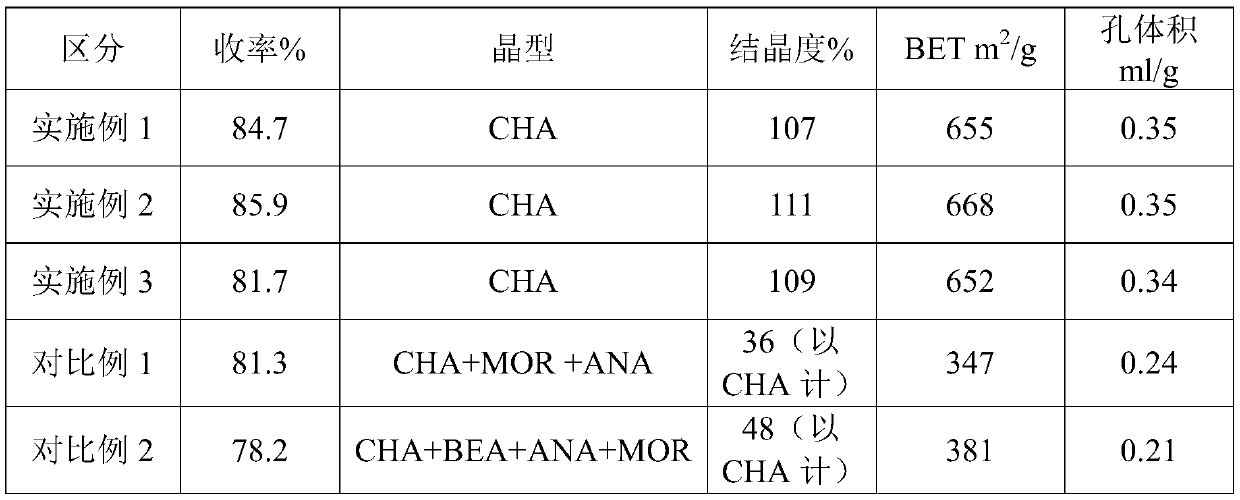

Embodiment 1

[0037] Beta molecular sieve (silicon-aluminum ratio 24) is roasted at high temperature to remove the template agent, and the roasted sample is weighed and dispersed in water evenly. Then it was transferred to a high-pressure crystallization kettle, and subjected to hydrothermal treatment at 260° C. for 5 hours, and the solid content of the slurry was 33%. After the treatment is completed, cool to room temperature to obtain a molecular sieve slurry.

[0038]Weigh a section of template agent 1-amantadine (R-1), sodium hydroxide solution and an appropriate amount of water and mix evenly to prepare a gel. The mass ratio of each component in the gel is as follows: SiO 2 :Al 2 o 3 :Na 2 O:R-1:H 2 O=1:0.042:0.12:0.012:20.

[0039] The gel was transferred into a high-pressure reactor, and stirring was started for a period of crystallization at a temperature of 120°C for 18 hours.

[0040] After the first-stage crystallization is completed, use a high-pressure pump to add the se...

Embodiment 2

[0043] Beta molecular sieve (silicon-aluminum ratio 38) is roasted at high temperature to remove the template agent, and the roasted sample is weighed and dispersed in water evenly. Then it was transferred to a high-pressure crystallization kettle, and subjected to hydrothermal treatment at 220° C. for 8 hours, and the solid content of the slurry was 38%. After the treatment is completed, cool to room temperature to obtain a molecular sieve slurry.

[0044] Weigh a section of template agent N,N,N-trimethyl-1-adamantyl ammonium hydroxide (R-1), sodium hydroxide solution and an appropriate amount of water and mix evenly to prepare a gel. The mass ratio of each component in the gel is as follows: SiO 2 :Al 2 o 3 :Na 2 O:R-1:H 2 O=1:0.0263:0.14:0.014:16.

[0045] The gel was transferred into a high-pressure reactor, and stirring was started for a period of crystallization at a temperature of 125° C. for 14 hours.

[0046] After the first-stage crystallization is completed, ...

Embodiment 3

[0049] Beta molecular sieve (silicon-aluminum ratio 93) is roasted at high temperature to remove the template agent, and the roasted sample is weighed and dispersed in water evenly. Then it was transferred to a high-pressure crystallization kettle and subjected to hydrothermal treatment at 280° C. for 4 hours, and the solid content of the slurry was 26%. After the treatment is completed, cool to room temperature to obtain a molecular sieve slurry.

[0050] Weigh a section of template agent 1,3-diaminoadamantane (R-1), potassium hydroxide solution and appropriate amount of water and mix evenly to prepare a gel.

[0051] The mass ratio of each component in the gel is as follows: SiO 2 :Al 2 o 3 :K 2 O:R-1:H 2 O=1:0.0107:0.14:0.011:18. The gel was transferred into a high-pressure reactor, and stirring was started for a period of crystallization at a temperature of 135° C. for 12 hours.

[0052] After the first-stage crystallization is completed, use a high-pressure pump to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com