A reversible crystallization filter device

A technology of crystallization equipment and filter plate, which is applied in the field of equipment with both filtration function in crystallization process, can solve the problems of inability to contact with air, no solvent, and inappropriate addition of crystallization solvent, etc., and achieve the effect of not easy to operate in open air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Purification of 2-chloro-5-chloromethylthiazole (melting point 29-30°C)

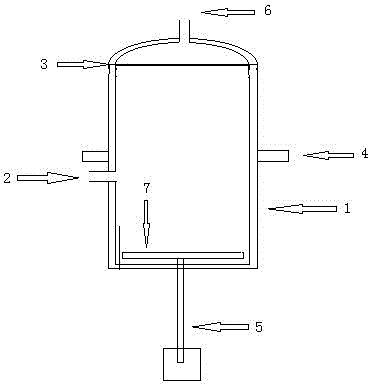

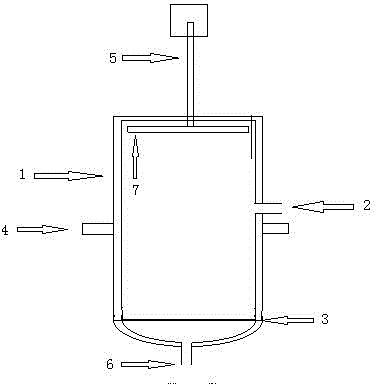

[0018] Add 20kg of methanol to 180kg of 2-chloro-5-chloromethylthiazole (content 90-94%), control the temperature at about 38°C, and enter the kettle body 1 of the reversible crystallization equipment through the feed port, and the jacket of kettle body 1 Slowly pour cold water at 5°C to lower the temperature in the kettle to 10°C for 6 hours, and crystallize slowly. After the crystallization is completed, water at 25-32°C is slowly introduced into the jacket of kettle body 1, and "sweats" for 4 hours. Slowly turn on the rotating device, so that the whole kettle body 1 starts to rotate with the rotating shaft 4 as the rotating shaft until 180°, and the material is slowly poured onto the filter plate 3. Turn on the rotating rod 5, which rotates on its own and moves to the filter plate 3, and the cross bar 7 at the front end pushes the materials accumulated on the surface of the filt...

Embodiment 2

[0019] Example 2: Purification of cyhalothrin (melting point 49.2°C)

[0020] Add 50kg of absolute ethanol to 200kg of cyhalothrin (content 90-95%), the temperature is about 50°C, and enter the reactor body 1 of the reversible crystallization equipment through the feed port, and the jacket of the kettle body 1 is slowly introduced -10°C salt water, let the temperature in the kettle drop to -5°C for 6 hours, and crystallize slowly. After the crystallization is completed, water at 45-48°C is slowly introduced into the jacket of kettle body 1 and kept for 5 hours. Slowly turn on the rotating device, so that the whole kettle body 1 starts to rotate with the rotating shaft 4 as the rotating shaft until 180°, and the material is slowly poured onto the filter plate 3. Turn on the rotating rod 5, which rotates on its own and moves to the filter plate 3, and the cross bar 7 at the front end pushes the materials accumulated on the surface of the filter plate 3 to level. Turn on the va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com