Concentrated salt water zero discharge system and concentrated salt water zero discharge method based on atomization evaporation

A technology of atomization evaporation and concentrated brine, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of low evaporation efficiency, great influence of natural condition changes, and land occupation of natural evaporation ponds Large area and other problems, to achieve the effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

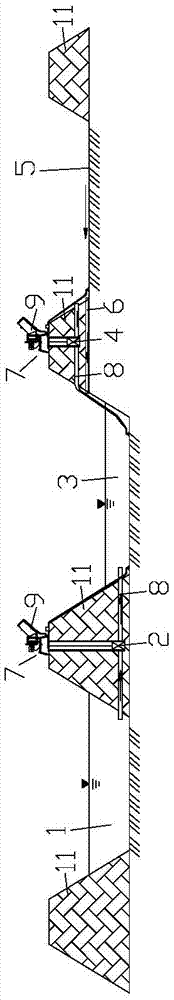

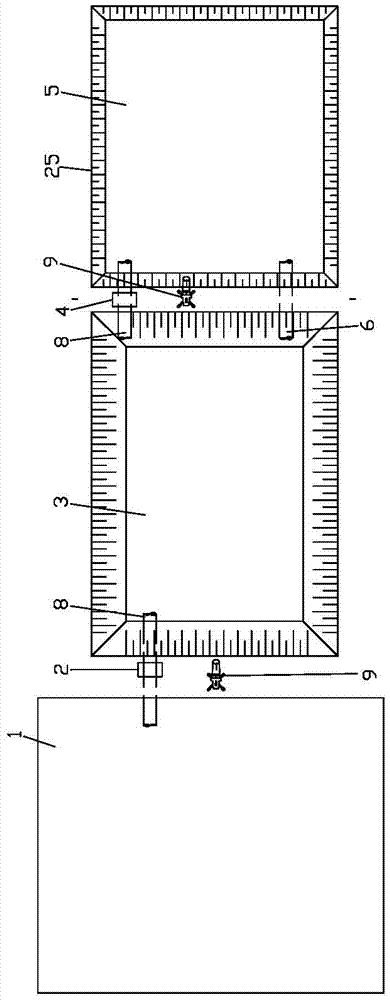

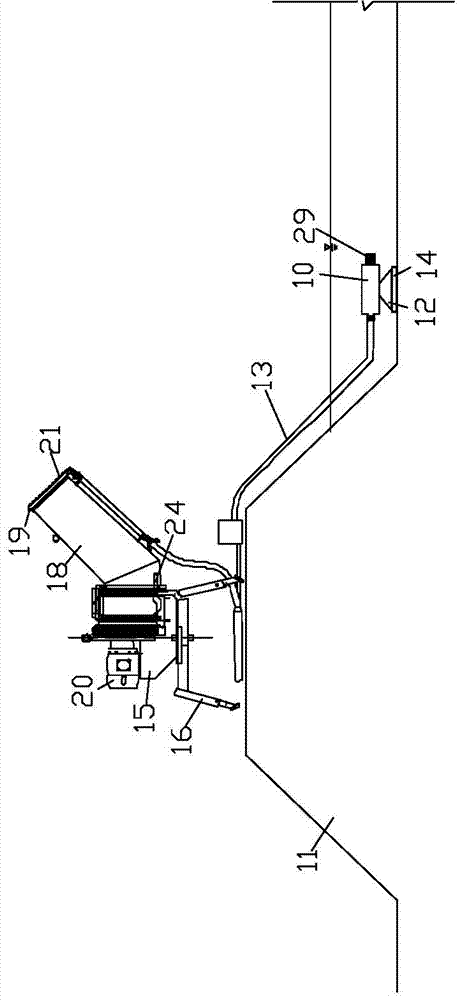

[0025] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0026] Such as Figure 1-Figure 5 Shown, the concentrated brine zero discharge method based on atomization evaporation that the present invention relates to, completes as follows::

[0027] To adjust the temporary storage, the concentrated brine first enters the adjustment pool 1; when the monthly average evaporation is less than the rainfall, the outlet control valve 2 of the adjustment pool is closed, and the adjustment pool 1 stores water; use the adjustment pool 1 to adjust the temporary concentrated brine;

[0028] Atomization and concentration, when the monthly average evaporation is greater than the rainfall, the outlet control valve 2 of the adjustment pool is opened, and the concentrated brine temporarily stored in the adjustment pool 1 and the incoming water during the period all enter the atomization evaporation cycl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com