Food evaporator

An evaporator and food technology, applied in vertical tube evaporators and other directions, can solve the problems of low evaporation efficiency and low food quality, and achieve the effects of good food quality, short residence time and fast falling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

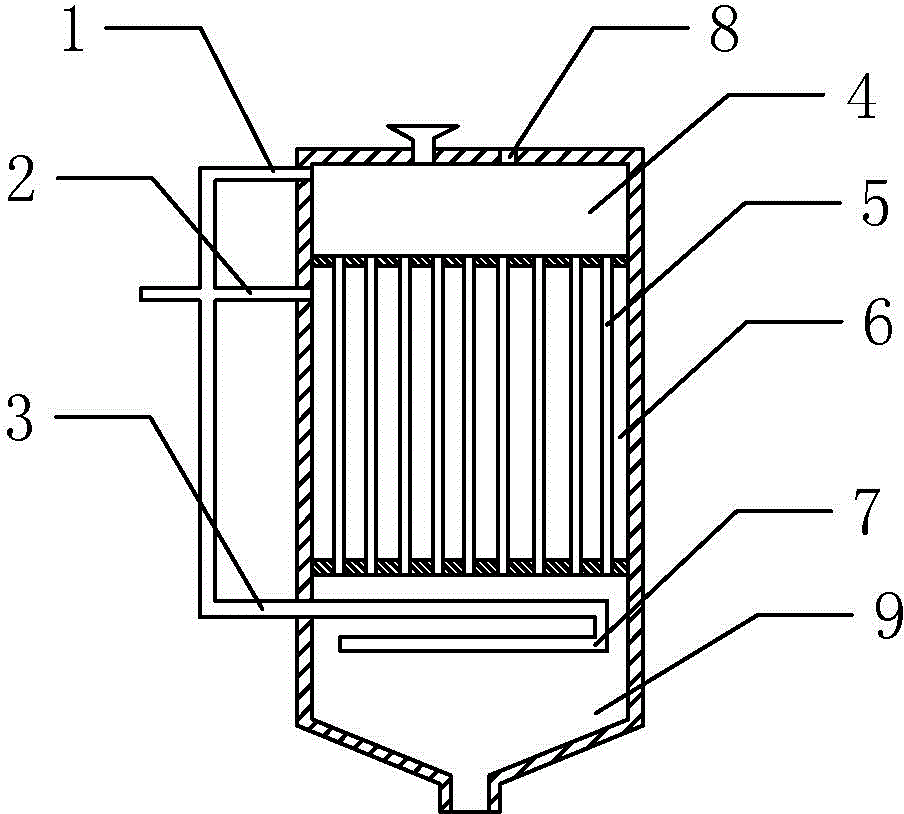

[0013] Among them: the first secondary steam pipe 1, the intake pipe 2, the second secondary steam pipe 3, the constant temperature tank 4, the evaporation pipe 5, the evaporation chamber 6, the elbow pipe 7, the ventilation hole 8, and the separation chamber 9.

[0014] Such as figure 1 As shown, the food evaporator of the present invention includes an evaporation chamber 6, and a group of vertical evaporation tubes 5 are arranged in the evaporation chamber 6. The evaporation tubes 5 are flat, and a group of evaporation tubes 5 are mutually independent. 5 The two ends respectively pass through the top and the bottom of the evaporation chamber 6, the left side wall of the evaporation chamber 6 is provided with an air intake pipe 2, and the right side wall of the evaporation chamber 6 is provided with a condensate pipe, and the condensate pipe Located on the lower side of the side wall of the evaporation chamber 6; the top of the evaporation chamber 6 is provided with a constan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com