Device and process for dissolving out cooling crystals of monazite alkali decomposition liquor

A technology for cooling crystallization and decomposing liquid, applied in solution crystallization, chemical industry, sustainable manufacturing/processing, etc. It can solve the problems of high energy consumption, large floor space, small output, etc., and achieve low impurity content and high cooling efficiency. , the effect of complete crystal form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

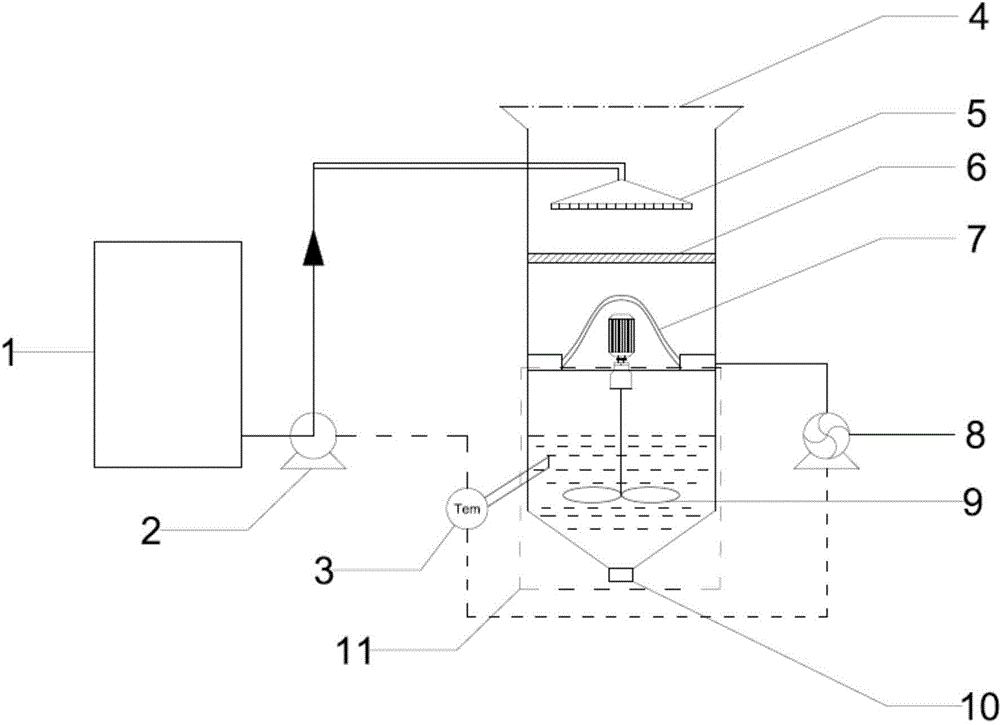

[0030] Air at 5°C is first blown into the device through the fan (8), and the 65°C decomposed lye is sprayed at the top of the device through the nozzle (5) using a high-speed centrifugal spray method, and the atomized droplets are below 0.2mm; through the air distribution plate (6 ) realizes rapid contact with the liquid droplets and takes away the heat, realizes the separation of the gas and the liquid droplets in the water vapor separation device (4), and the ratio of the flow rate of the decomposed lye liquid to the flow rate of the air is 1:4000.

[0031] The cooled droplets enter the crystallization part (11) under the action of gravity through the motor cover and the guide cover (7), and the temperature after cooling is 15°C, and they are uniformly precipitated under the stirring action of the stirring (9) Trisodium phosphate crystals are discharged through the discharge port (11). During the operation, the temperature of the decomposed liquid in the crystallization kett...

Embodiment 2

[0034] Air at 28°C is first blown into the device through the fan (8), and the 90°C decomposed lye is sprayed at the top of the device through the nozzle (5) using a high-speed centrifugal spray method, and the atomized droplets are below 0.1mm; through the air distribution plate (6 ) realizes rapid contact with the liquid droplets and takes away the heat, realizes the separation of the gas and the liquid droplets in the water vapor separation device (4), and the ratio of the flow rate of the decomposed lye liquid to the flow rate of the air is 1:2500.

[0035] The cooled droplets enter the crystallization kettle (11) under the action of gravity through the motor cover and the guide cover (7), the temperature is 34 ° C, and the phosphoric acid triphosphate is evenly precipitated under the stirring action of the stirring (9). The sodium crystal is discharged through the discharge port (11). During the operation, the temperature of the decomposed liquid in the crystallization ket...

Embodiment 3

[0038] Air at 15°C is first blown into the device through the fan (8), and the 85°C decomposed lye is sprayed at the top of the device through the nozzle (5) using a high-speed centrifugal spray method, and the atomized droplets are below 0.1mm; through the air distribution plate (6 ) realizes rapid contact with the liquid droplets and takes away the heat. In the water vapor separation device (4), by reducing the air velocity, the separation of the gas and the liquid droplets is realized, and the ratio of the flow rate of the decomposed lye liquid to the flow rate of the air is 1:1000.

[0039] The cooled droplets enter the crystallization kettle (11) under the action of gravity through the motor cover and the guide cover (7), and the temperature is 30°C. Under the agitation of the stirring (9), the triphosphate is evenly precipitated The sodium crystal is discharged through the discharge port (11). During the operation, the temperature of the decomposed liquid in the crystalli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com