Treating and resourceful recycling system and method for scouring waste water

A waste water and smelting technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of high operating cost of waste water treatment, insufficient energy and resources to be recycled and reused , large investment in wastewater treatment facilities, etc., to achieve the effect of high cost performance, easy engineering realization, and thermal energy recovery and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below with reference to the embodiments and the accompanying drawings, but the present invention is not limited.

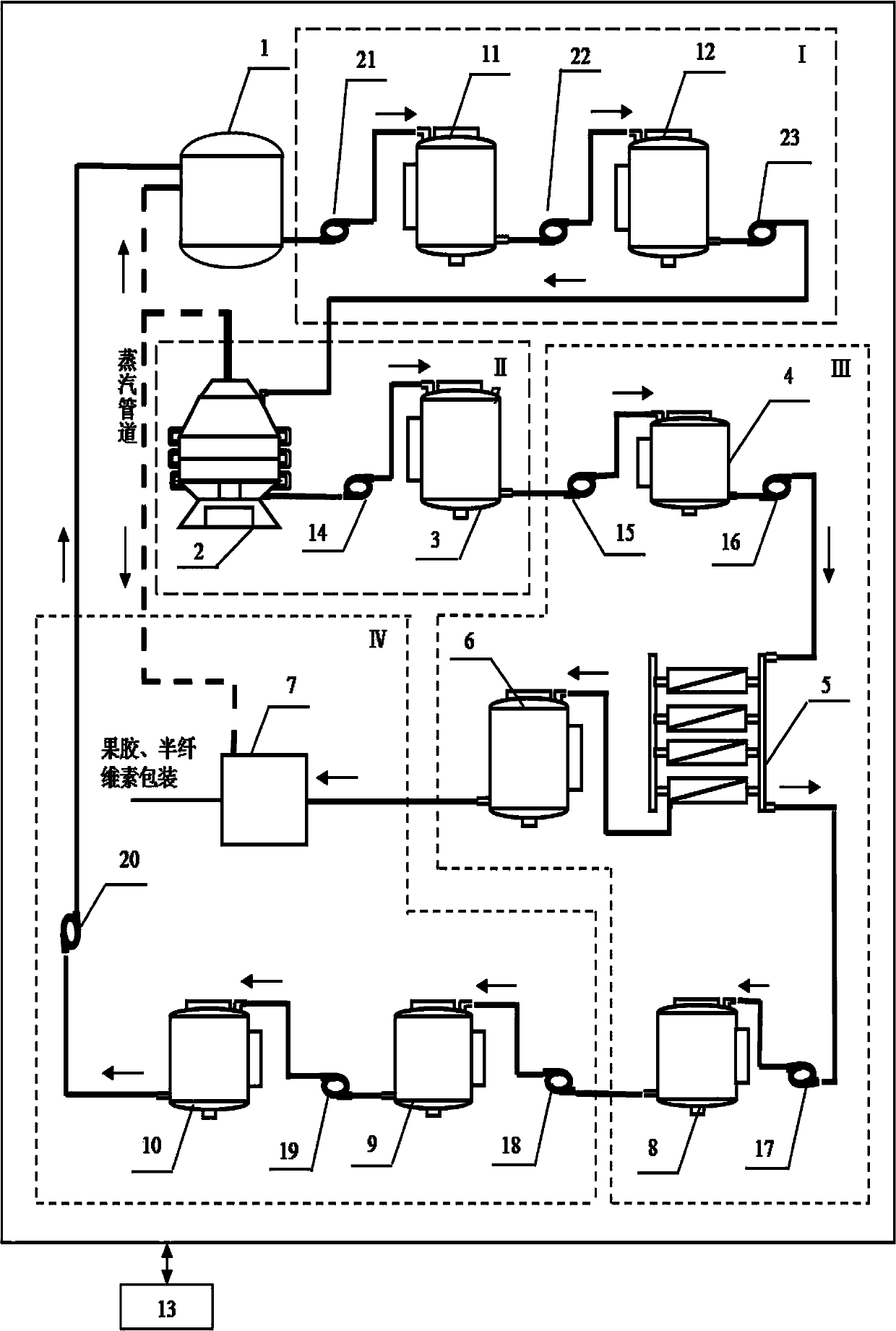

[0039] This embodiment provides a treatment and resource reuse system for smelting wastewater, which is composed of wastewater pretreatment, evaporative concentration, flocculation extraction, and recycling and reuse devices. See figure 1 ,Specifically:

[0040] Described wastewater treatment device, its composition is as follows figure 1 As shown, it consists of a waste water storage tank 11, a waste water saponification treatment device 12 and three water pumps. Wherein: the outlet of the cooking pot 1 (the liquid flowing out is the waste water in the cooking pot) is connected to the inlet of the waste water storage tank 11 through the water pump 21, and the outlet of the waste water storage tank 11 is connected to the inlet of the waste water saponification treatment device 12 through the water pump 22 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com