Multifunctional filler and evaporator, condenser and reactor comprising multifunctional filler

A multi-functional, container technology, applied in water shower coolers, heat exchanger types, lighting and heating equipment, etc., can solve the problems of inability to use low-temperature waste heat resources, large equipment investment, easy scaling and fouling, etc. High maintenance cost, low investment cost and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

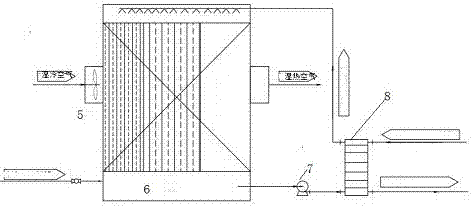

[0053] The acid waste gas containing HCl and H2S enters the reactor with filler A and filler B through the pipeline, and is fully mixed with the alkaline aqueous solution containing NaOH sprayed from the top of the reactor, and the acid-base neutralization reaction occurs on the surface of the filler to become neutral . The remaining alkaline aqueous solution that descends to the bottom of the reactor becomes thinner due to the consumption of alkali, which can be supplemented with alkali for recycling. The neutral gas from the reactor can meet the standard and be directly discharged into the atmosphere.

Embodiment 2

[0055] The concentration of concentrated sulfuric acid used for product drying becomes thinner after use. After being heated to above 50°C, it is sprayed from the top of the evaporator. The easily evaporated water evaporates on the surface of the packing and is taken out of the evaporator by the wind. The sulfuric acid returns from the top of the packing to the bottom. Department, circulation treatment, sulfuric acid concentration becomes concentrated.

Embodiment 3

[0057] The low-concentration medicinal solution dissolved and extracted is heated and controlled below 50°C to avoid deterioration of heat-sensitive drugs. It is sprayed from the top of the evaporator, and the water or solvent in the medicinal solution evaporates on the surface of the filler and enters the air, which is continuously absorbed by the air. Take away, the liquid flowing to the bottom along the filler can be concentrated, and the concentrated solution after multiple cycles can be discharged from the bottom of the evaporator to form a finished product or a semi-finished product after reaching the concentration requirement.

[0058] The evaporator is as image 3 structure shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com