An Evaporation Concentration System Based on Thermodynamic Compression

An evaporation concentration system and thermal technology, applied in evaporation, water/sewage multi-stage treatment, separation methods, etc., can solve the problems of large equipment investment, high speed of steam compressor, high operating temperature, etc., and achieve low investment cost and equipment occupation small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

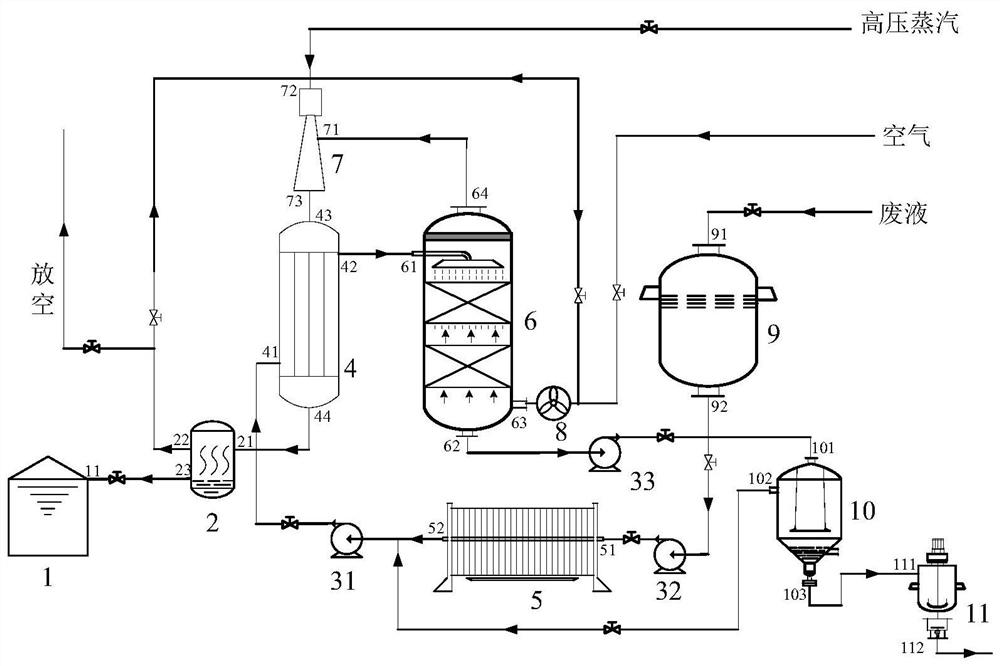

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. These drawings are all simplified schematic diagrams, and only illustrate the basic structure of the present invention in a schematic manner.

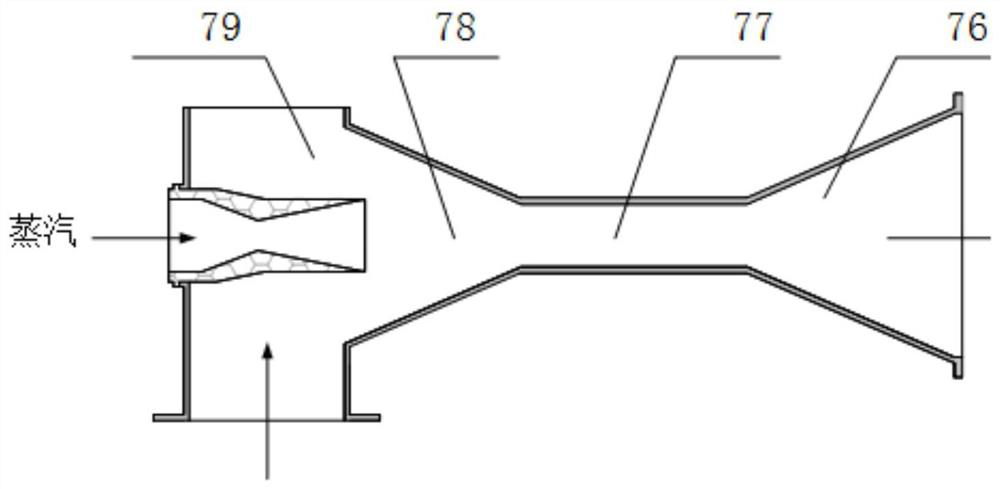

[0024]The evaporative concentration system based on thermal compression in this embodiment is based on the principle of gas humidification and dehumidification, that is, as the temperature of the gas increases, the saturated moisture content of the gas increases, and the rate of change of the saturated moisture content increases continuously with the increase of temperature. It is characterized by making full use of the huge humidity difference generated by the temperature difference of the gas. Under normal pressure conditions, the gas exchanges heat and mass with the heated material liquid. liquid concentration. At the same time, a steam jet pump based on the principle of thermal compression ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com