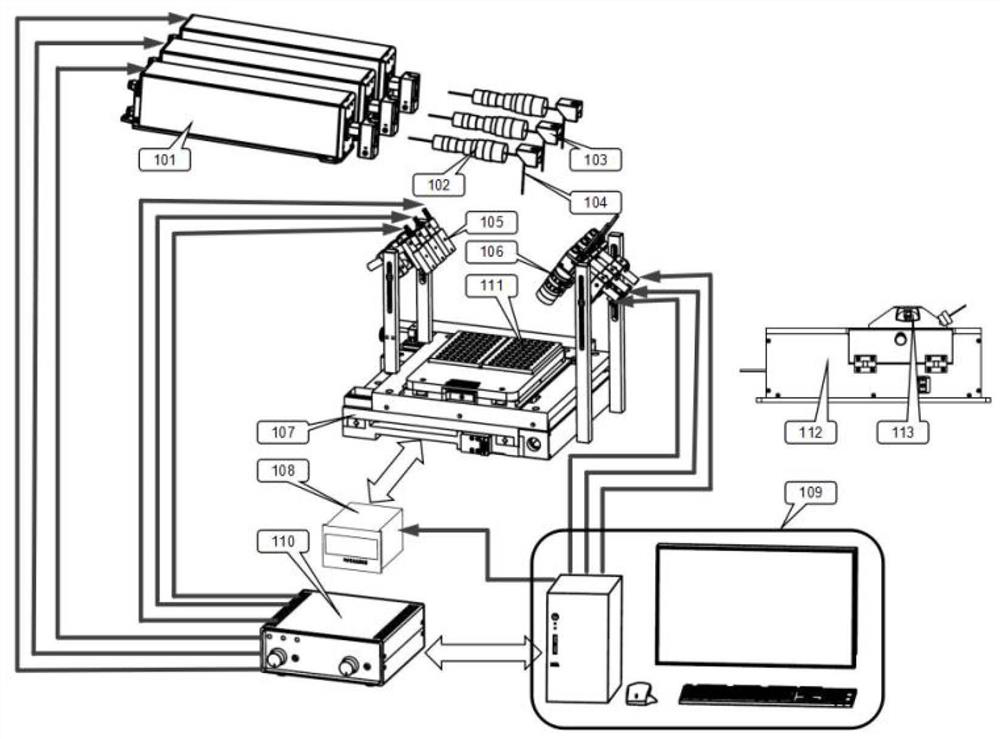

Array sample laser heating system

A laser heating and sample technology, which is applied in the field of array sample laser heating system, can solve the problem of inapplicability of rapid high-temperature heat treatment of array sample library, and achieve the effect of rapid heating, stable heating process and directional heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

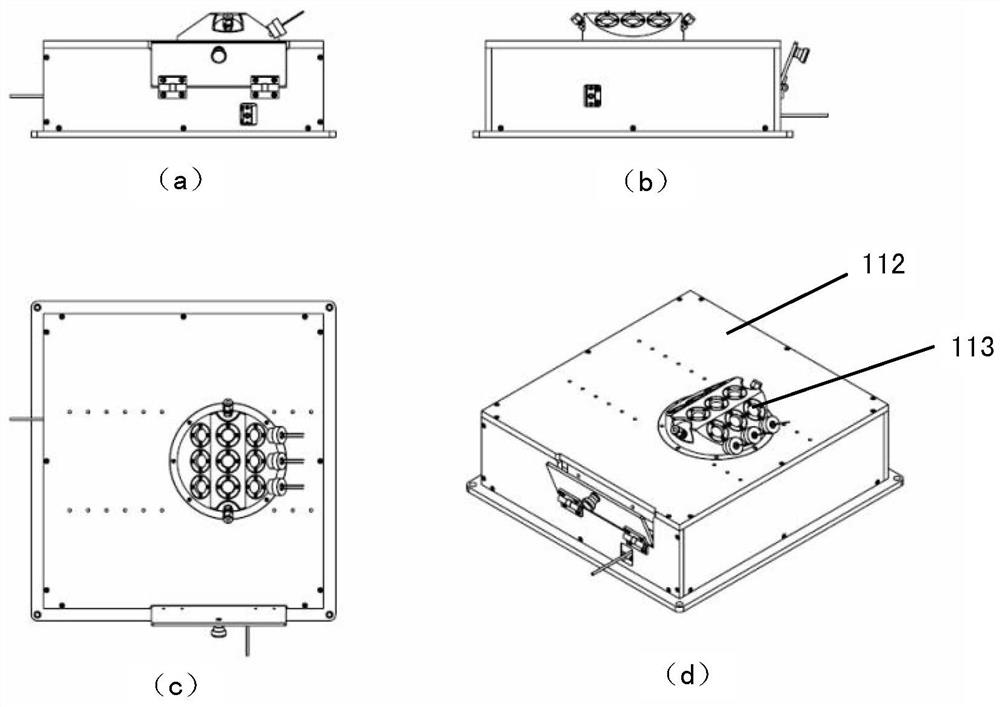

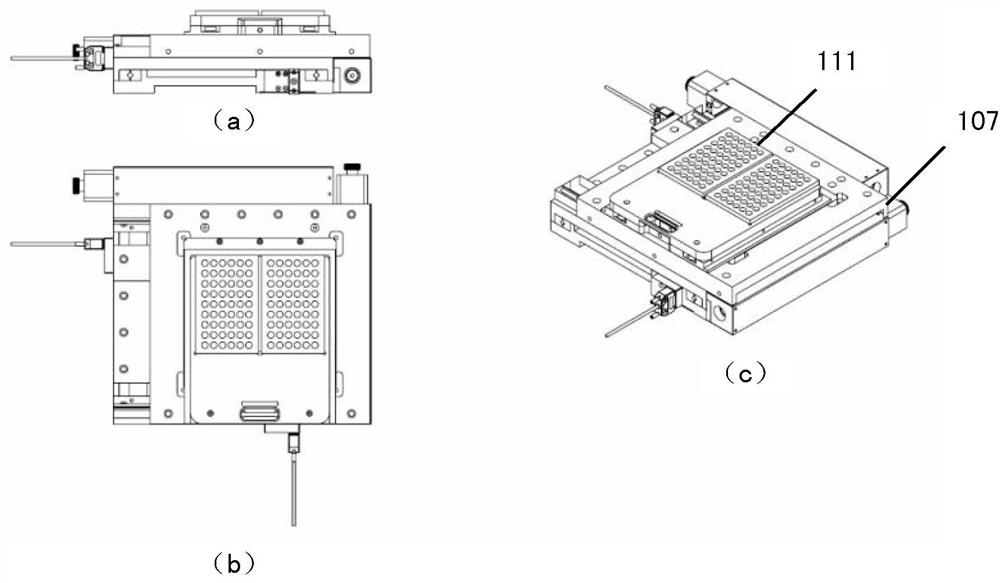

Embodiment 1

[0082] to follow figure 1 The designed and fabricated three-beam laser heating system performs laser heating experiments on a {5×5} array of yellow phosphor sample libraries. According to the requirement, use a single beam or a combination of two or three laser beams for heating. In the {5×5} array of yellow phosphor sample libraries, the spacing of each sample in the X-axis direction is 14 mm, which is consistent with the spacing of the laser beam, and the spacing of the samples in the Y-axis direction is 12 mm. The movement of the stage matches the heating position of the sample with the laser beam, realizing fixed-point heating. The laser beam passes through the window on the sealed cabin to heat the sample. The main control computer 109 adjusts the laser power, heating time and the moving position of the two-dimensional sample moving table to make the heating of each sample in the array sample reach the target setting value. The gas products released during the sample he...

Embodiment 2

[0089] Taking the heating of ceramic samples as an example, optimize the best observation parameters of the high-speed camera to achieve clear and accurate video recording. Single-beam laser heating is adopted, and the heating power adjustment range is 30-90W. Adjust the beam expander so that the diameter of the laser irradiation spot is 6 mm. According to the working distance of the lens, adjust the camera to the focus position. Selected filter models: wavelength 520 nm (green light) and 650 nm (red light); attenuation filter models: transmittance 2% and 0.1%. Sample heating image recording effect see Figure 6 shown.

[0090] The first group of heating imaging effect comparison: when the attenuation film is not used, only the filter (wavelength 520 nm and 650 nm) is added, if the laser power is heated above 60W, due to the strong radiation emitted by the sample when it is heated to high temperature The halo causes the image spot to appear as a white radial spot, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com