Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65 results about "ZINC PASTE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

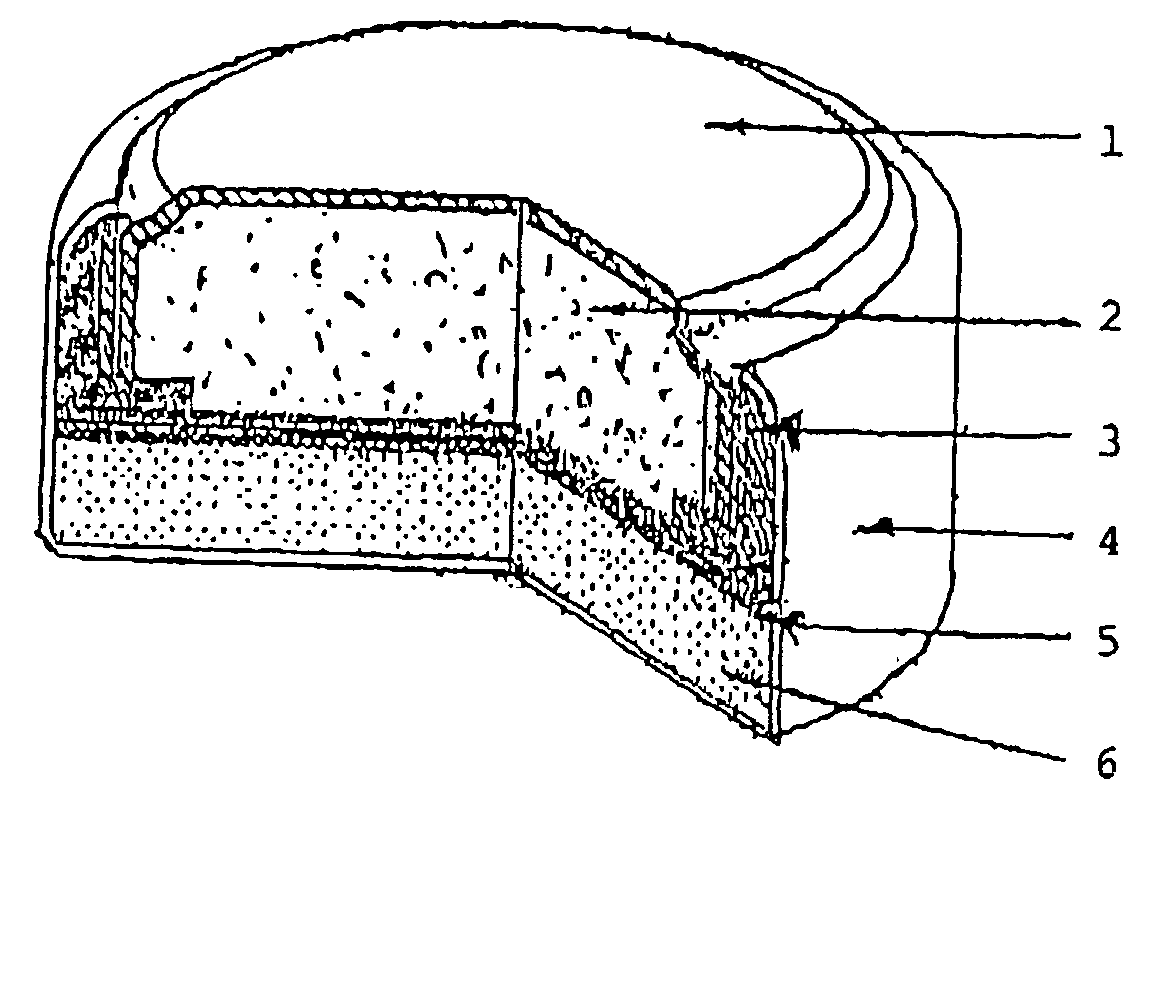

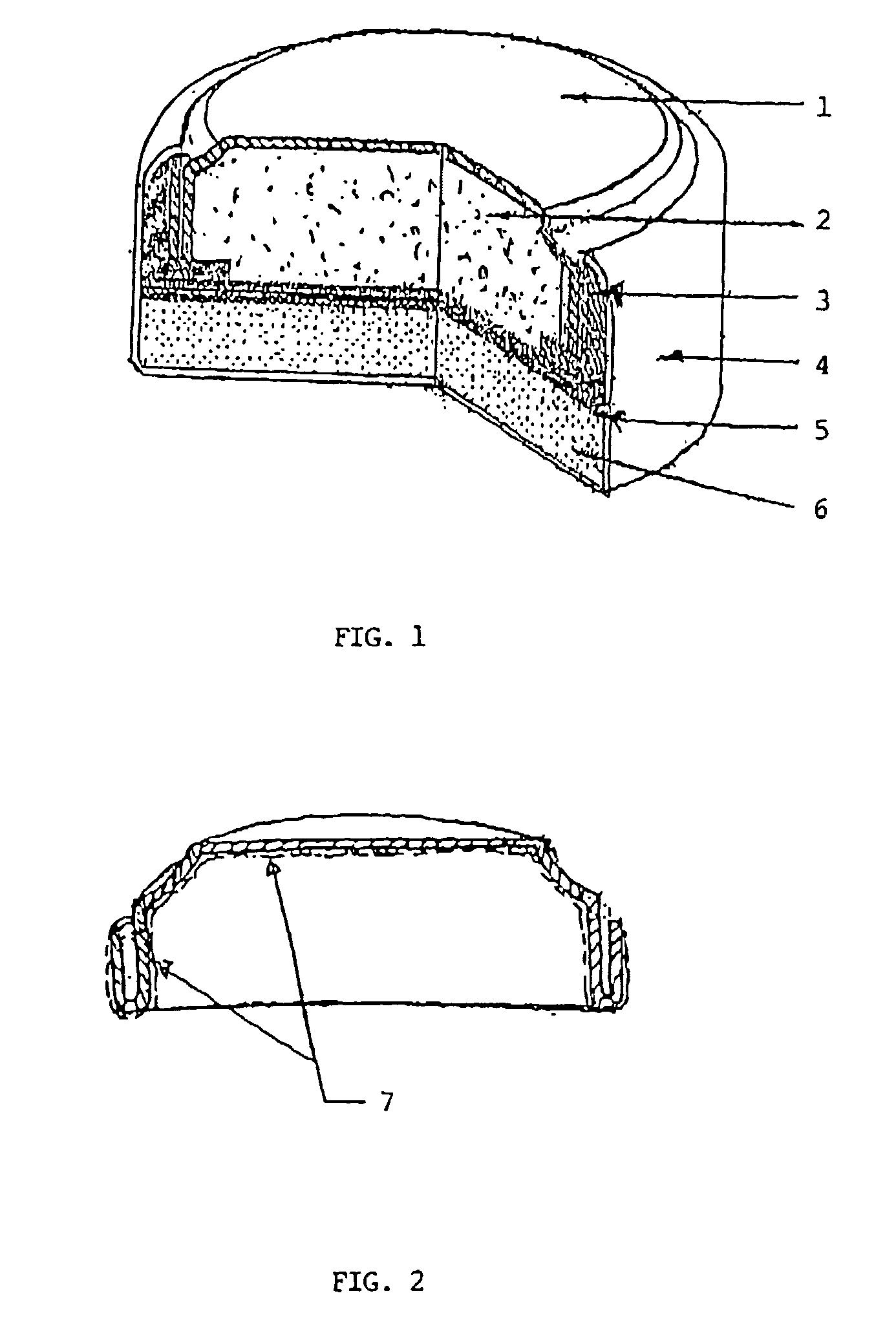

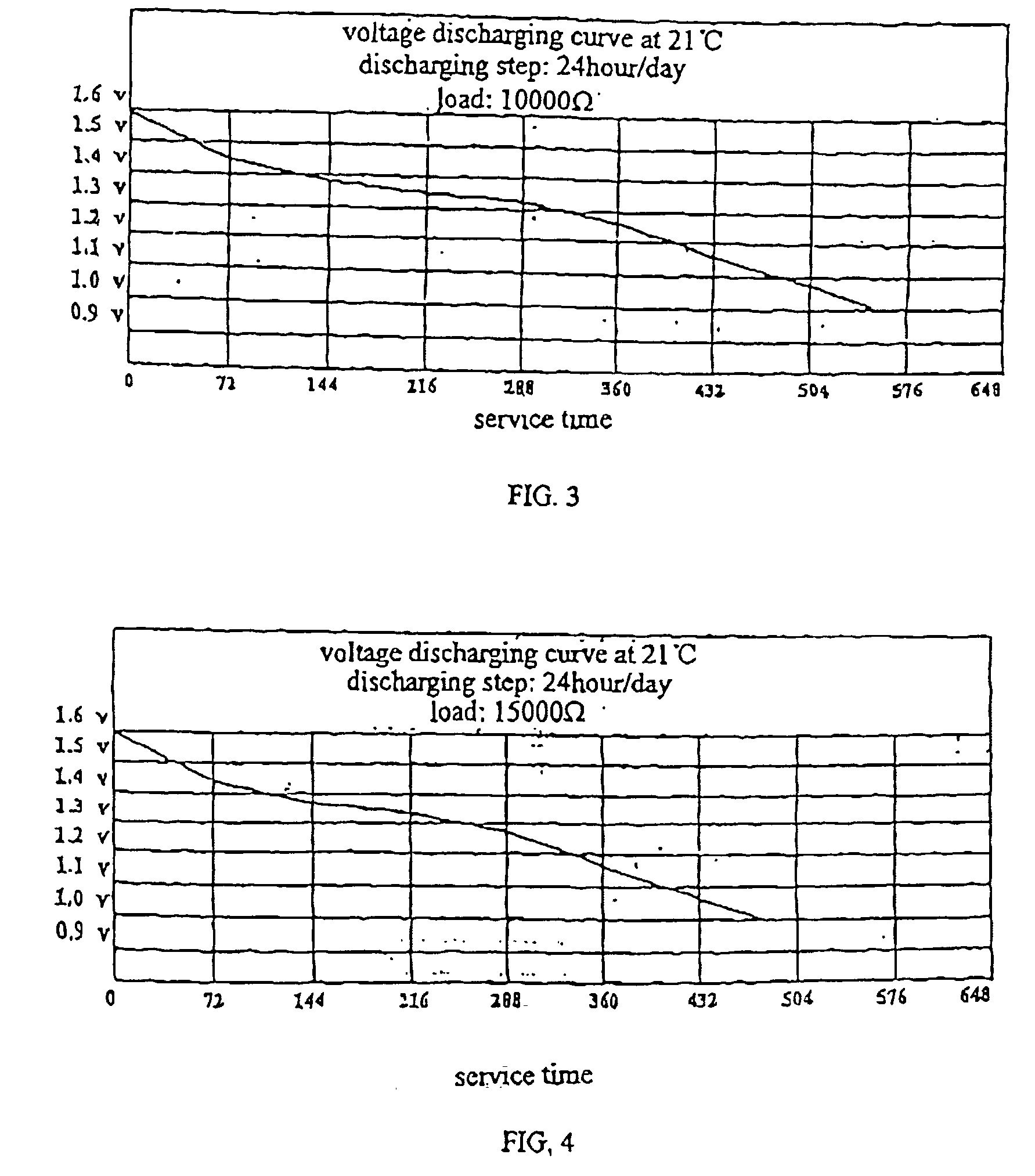

Mercury-free alkaline button cell

InactiveUS20030082456A1Easy to reachSilver accumulatorsElectrode carriers/collectorsIndiumZINC PASTE

A mercury-free alkaline button cell battery, includes an anode plate, a cathode cap, a cathode zinc paste, a seal ring, an anode case and a membrane. A layer of indium or tin is plated on the cathode plate, and indium is added into the zinc paste to replace mercury. A layer of indium or tin is plated on the cathode plate to prevent zinc in the cell from contacting other material or metal, to avoid swelling that could result in the release of gas.

Owner:HO WING KEI

Gel zinc paste for alkaline battery and preparation method thereof

InactiveCN102723471AImprove seismic performanceSmall expansion deformationElectrode manufacturing processesPrimary cell electrodesIndiumPowder mixture

The invention discloses gel zinc paste for an alkaline battery and a preparation method thereof. The gel zinc paste comprises zinc powder mixture and alkaline electrolyte which are mixed according to a mass ratio of 100 to 30-50; the zinc powder mixture comprises mercury-free zinc powder, gel, indium hydroxide or indium oxide and zinc oxide which are mixed according to a mass ratio of 100 to 0.5-5 to 0.01-0.1 to 1; the alkaline electrolyte comprises potassium hydroxide, zinc oxide, calcium oxide, sodium stannate and water which are mixed according to a mass ratio of 40 to 6-7 to 0.2-0.5 to 0.05-0.1 to 52.5-53.5. The gel comprises carboxymethyl cellulose, polyving akohol, polyacrylic acid, sodium polyacrylate, polyacrylic acid derivatives and the like. According to the gel zinc paste and the preparation method provided by the invention, the production process is simple, the product quality is easily controlled, the service life and storage period of the battery can be prolonged, and the application range of the battery can be enlarged.

Owner:BEIJING CHANGLI UNION ENERGY TECH CO

Method for producing zinc-air battery

The invention discloses a method for preparing a zinc-air battery, which comprises the following processes: a chamber is prepared on one side of an outer packing membrane of the battery; a plurality of holes are punched on the other side; an absorbing membrane, a zinc paste cathode, a diaphragm and an air anode are placed in the chamber in order; the outer packing membrane is folded so that the part having the chamber of the outer packing membrane is opposite to the part with a plurality of holes of the outer packing membrane; an anode tab and a cathode tab are respectively extracted; the edge of the diaphragm is stuck to the edge of the outer packing membrane in two sides of the diaphragm and the diaphragm as well as the outer packing membrane are sealed and bonded together by hot pressing. The invention is a method for preparing a zinc-air battery with simple technology and liquid leakage of the battery prepared by the method is not easy to happen.

Owner:BYD CO LTD

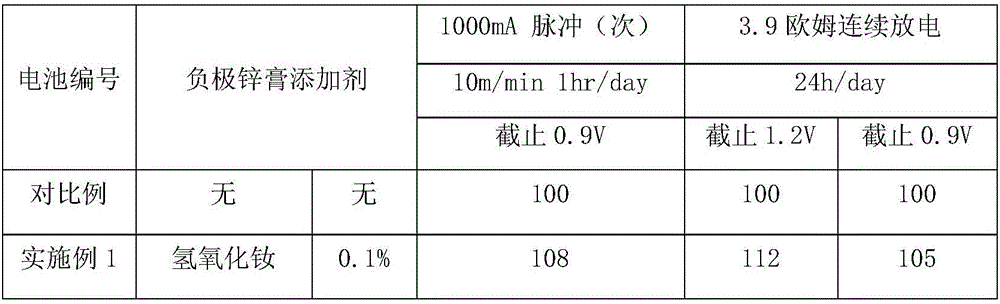

Alkaline manganese battery negative electrode zinc paste additive and application thereof

InactiveCN106159276AIncrease current densityImprove high voltage discharge timeCell electrodesDry cellsPower flowHigh pressure

The invention discloses an alkaline manganese battery negative electrode zinc paste additive. The negative electrode zinc paste additive is neodymium oxide and / or neodymium hydroxide. The negative electrode zinc paste additive is selected from one or more of neodymium, the neodymium oxide and the neodymium hydroxide, and is added into negative electrode zinc paste, so that polarization of zinc can be lowered effectively when a battery discharges; the current density of a battery reaction is increased; high-voltage discharging time is prolonged when the battery discharges; the problems of low battery discharge current density, accelerated polarization of negative electrode zinc during discharging, low constant-resistance discharge high-voltage segment and the like are solved effectively; the service life of the battery in a large-current or high-power appliance is prolonged; and higher power is achieved.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

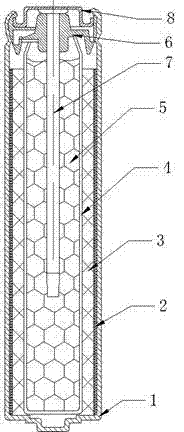

High-energy zinc-manganese battery

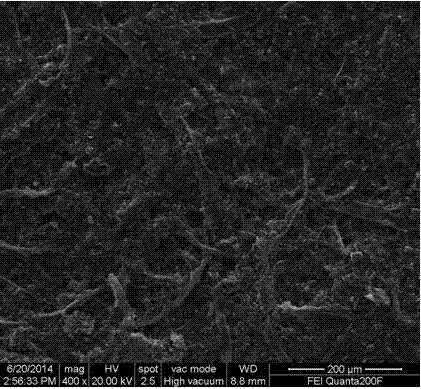

InactiveCN104269560AHigh affinityEasy to gatherElectrode carriers/collectorsDry cellsHigh energyCarbon nanotube

The invention relates to a high-energy zinc-manganese battery which comprises a steel shell, a positive pole ring, zinc paste, diaphragm paper, a sealing ring, a copper nail and a negative pole cover. The high-energy zinc-manganese battery is characterized in that a layer of carbon nanotube conductive paper is additionally arranged between the steel shell and the positive pole ring to be taken as a current collector of a positive pole. The high-energy zinc-manganese battery has the advantages that 1, the affinity between the positive material and the current collector can be improved, and the positive material is more closely contacted with the steel shell, so that electrons can be well converged together on the carbon nanotube conductive paper; 2, a carbon nanotube has a high liquid absorption property so as to be used for well storing electrolyte, so that more electrolyte can be stored in the zinc-manganese battery, and the reaction can be continuously carried out.

Owner:NANCHANG UNIV

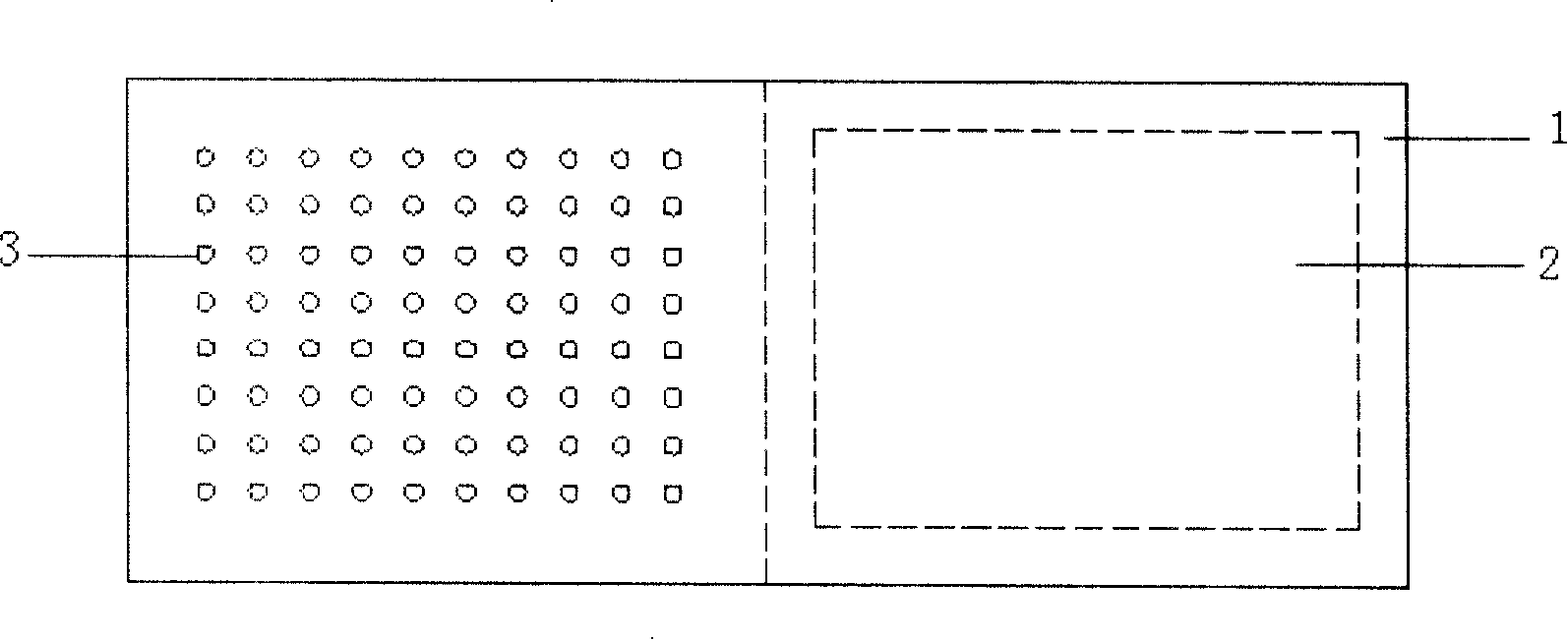

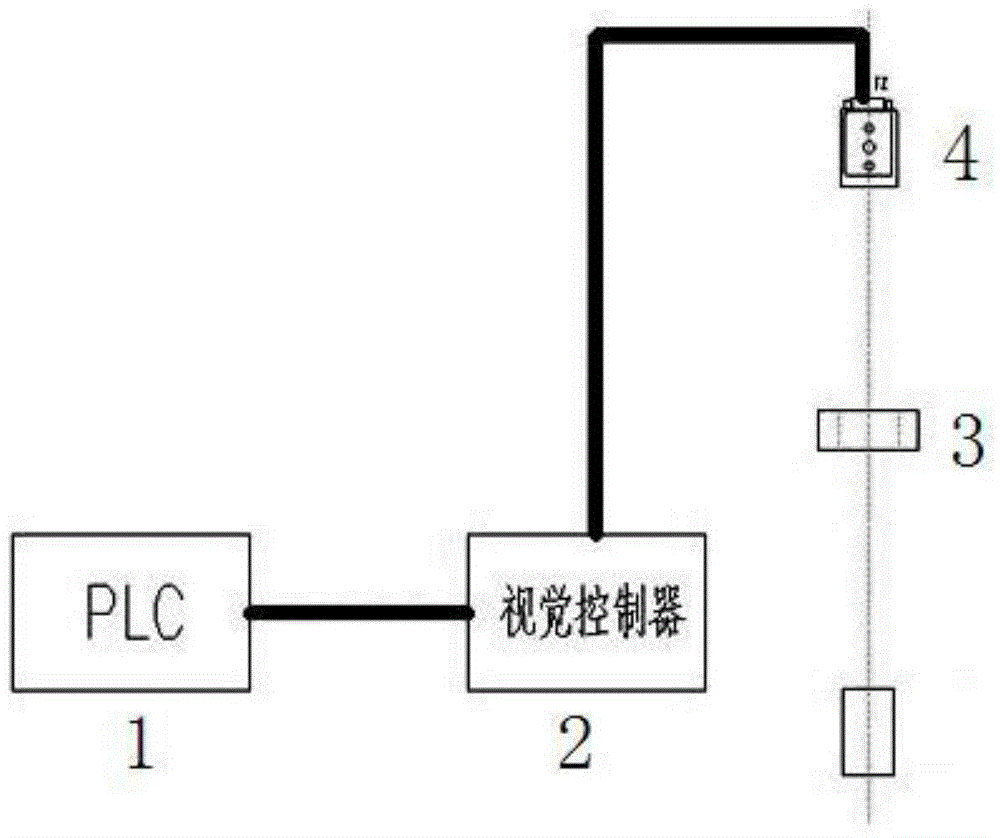

Zinc paste visual detection method and device

The invention discloses a zinc paste visual detection method and device. The device includes a PLC controller, a visual controller and a camera; the PLC controller is connected with the visual controller; the visual controller is connected with the camera; the camera is arranged at the right upper side of a to-be-detected cylindrical battery steel shell; the front end of the camera is provided with a light source, and the light source is an annular light source. The method and the device have the beneficial effects that an image processing method is utilized to realize detection of a battery zinc paste, the battery zinc paste can be detected full-automatically, and the method and the device are good in detection effect, high in detection precision, safe and reliable, simple in structure and convenient to operate, improve the work efficiency and reduce the labor intensity.

Owner:ZHENGJIANG MUSTANG BATTERY CO LTD

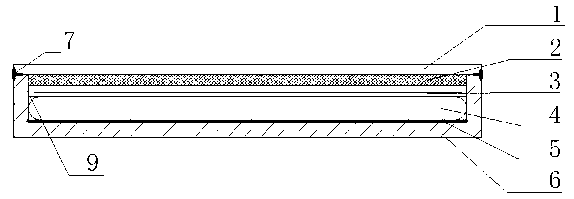

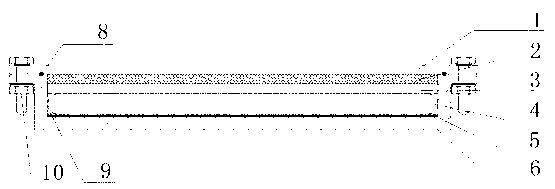

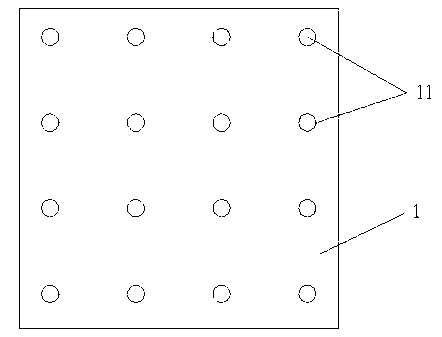

Zinc air battery with microporous membrane

InactiveCN103219563AImprove performanceExtend your lifeFuel and primary cellsCell electrodesEnvironmental engineeringZinc–air battery

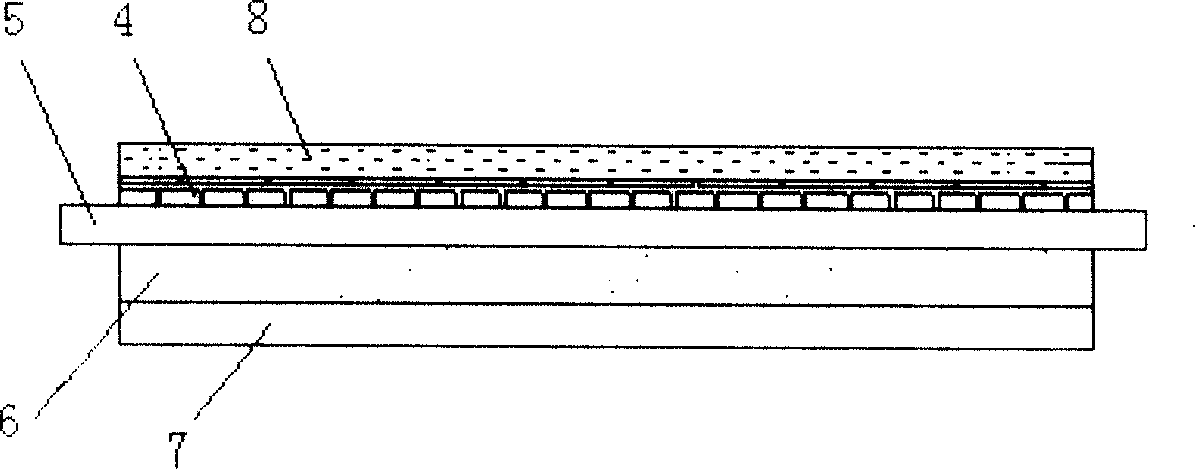

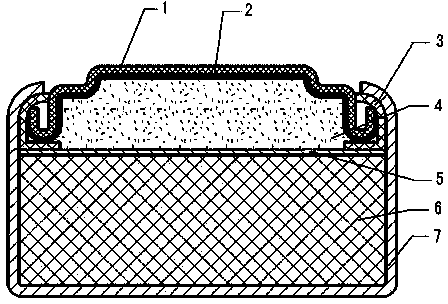

The invention discloses a zinc air battery with a miroporous membrane. Compared with the prior art, the zinc air battery overcomes the shortcoming of high water loss rate caused by the exposure to air of a gas diffusion electrode of a zinc air battery in a discharging process under environmental influence. The zinc air battery comprises a battery jar (6) and a current collector (5) on the upper part of the battery jar (6). Zinc paste (4) is laid on the current collector (5). An air electrode is arranged on the zinc paste (4) through a diaphragm, and is formed by covering the gas diffusion electrode (2) by the microporous membrane (1). The microporous membrane is a unique passage for oxygen and water vapor exchange between the zinc air battery and the outside, so that the normal passage of oxygen is ensured, water vapor is difficult to lose, the performance of the battery is improved, and the service life of the battery is prolonged.

Owner:ANHUI DEQING BATTERY TECH

Method for preparing cell zinc paste

ActiveCN102832372AImprove discharge performanceExtended service lifePrimary cell electrodesRare-earth elementPowder mixture

The invention discloses a method for preparing a sealing material of a lead-acid battery, and relates to a method for preparing a zinc paste of an alkaline zinc-manganese battery. The zinc powder mixture used in the method comprises lead-free mercury-free zinc alloy particles, polyacrylic acid, polyacrylate, sodium polyacrylate powder and indium oxide powder, wherein the lead-free mercury-free zinc alloy particles comprise the following elements: aluminum, bismuth, lanthanum, yttrium, cerium rare earth element and zinc. By tests of the battery manufacturers, compared with other zinc paste materials in the markets, the discharging capability of the zinc paste used for the alkaline zinc-manganese battery is greatly increased, and the usage life can be effectively prolonged, and the method enables environmental protection due to no lead and no mercury.

Owner:蚌埠中知知识产权运营有限公司

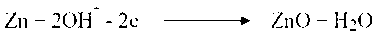

High-capacity alkaline zinc-manganese cell

ActiveCN103236552AImprove discharge performanceContinuous discharge improvementCell electrodesDry cellsManganeseBattery capacity

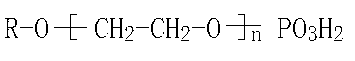

The invention discloses a high-capacity alkaline zinc-manganese cell. The high-capacity alkaline zinc-manganese cell solves the problem that the existing alkaline zinc-manganese cell has a small capacity and has a short use period under the condition of intermediate / low-current discharging. The high-capacity alkaline zinc-manganese cell comprises a steel housing, an anode ring, zinc paste, a diaphragm paper, a sealing ring, a copper nail and a cathode cover. Alkyl polyoxyethylene ether phosphate and an aluminum compound are added into the zinc paste and modify the zinc paste so that the high-capacity alkaline zinc-manganese cell is obtained. Under the condition of intermediate / low-current discharging, the high-capacity alkaline zinc-manganese cell has a long discharging period, a small self-discharging capacity, and good cell storage performances and greatly improves a cell discharging capacity.

Owner:ZHENGJIANG MUSTANG BATTERY CO LTD

Rare earth alloy doped zinc-manganese battery and preparation method thereof

ActiveCN110492092AInhibit swellingIncrease storage capacityNegative electrodesDry cellsManganeseRare earth

The invention discloses a rare earth alloy doped zinc-manganese battery. The zinc-manganese battery comprises a positive electrode ring, negative electrode zinc paste, a diaphragm and electrolyte, wherein the positive electrode ring is composed of electrolytic manganese dioxide, a conductive agent and an electrolyte, and the negative electrode zinc paste is composed of the following raw materialsin percentage by mass: 58-71 wt% of zinc powder, 1.5-6 wt% of a binder, 25-42 wt% of an electrolyte, 0.5-3 wt% of a composite additive and 100-1000 ppm of rare earth metal. The zinc-manganese batterydisclosed by the invention is not added with any lead-containing and mercury-containing material, the problems of battery expansion, liquid leakage, gassing and the like are not easily generated in the use process, and the prepared battery is environment-friendly, safe, stable in performance and long in service life. The invention further discloses a preparation method of the rare earth alloy doped zinc-manganese battery.

Owner:宁波双鹿新能源科技有限公司

Medical perfusion tube material

The invention discloses a medical perfusion tube material. The medical perfusion tube material comprises, by weight, 15-20 parts of PVC resin powder, 8-12 parts of oxidized polyethlene wax, 3-5 parts of polyamide resin, 0.5-0.7 parts of an organosilicon antifoaming agent, 4-6 parts of polyisoprene, 0.8-1 part of calcium-zinc paste, 2-4 parts of diisooctyl phenyl phosphate, 3-5 parts of glass fibers, 1.2-1.5 parts of octadecanamide, 0.4-0.6 parts of an anti-oxidant and 0.5 parts of benzyl silicone oil. The medical perfusion tube material utilizes medical PVC paste as a main raw material and other accessory materials. A medical perfusion tube prepared from the medical perfusion tube material has a low cost, is conducive to flame retardation and strength improvement, and has tensile strength of 130-135MPa, bending strength of 230-240MPa and excellent elasticity.

Owner:刘泽华

Manufacturing process of high-power environment-friendly alkaline zinc-manganese dry battery

PendingCN113764691ALower internal resistanceIncrease powerPrimary cell electrodesDry cellsElectrolytic agentElectrical battery

The invention belongs to the field of alkaline zinc-manganese dry batteries, and discloses a manufacturing process of a high-power environment-friendly alkaline zinc-manganese dry battery. The process comprises the following steps of 1, uniformly mixing a positive electrode material of the alkaline zinc-manganese dry battery with a release agent, and carrying out compression molding to obtain a positive electrode ring; 2, inserting the positive electrode ring into a steel shell, filling the bottom of the steel shell with a blocking agent to form a blocking layer, inserting a diaphragm paper, enabling the outer wall of the diaphragm paper to be in close contact with the inner wall of the positive electrode ring, enabling the bottom of the diaphragm paper to be in contact with the blocking layer, and then injecting alkaline electrolyte into the diaphragm paper; and 3, injecting a negative zinc paste containing composite conductive emulsion into the diaphragm paper, assembling a negative electrode end, a sealing ring and a negative current collector copper needle into a sealing body, inserting the sealing body into the negative zinc paste, and sealing the positive steel shell and the sealing body to prepare the alkaline zinc-manganese dry battery. According to the alkaline zinc-manganese dry battery prepared by the scheme, the internal resistance of the battery is greatly reduced and the high-power discharge performance of the battery is improved through the negative electrode zinc paste with the composite conductive emulsion.

Owner:山东华太新能源电池有限公司

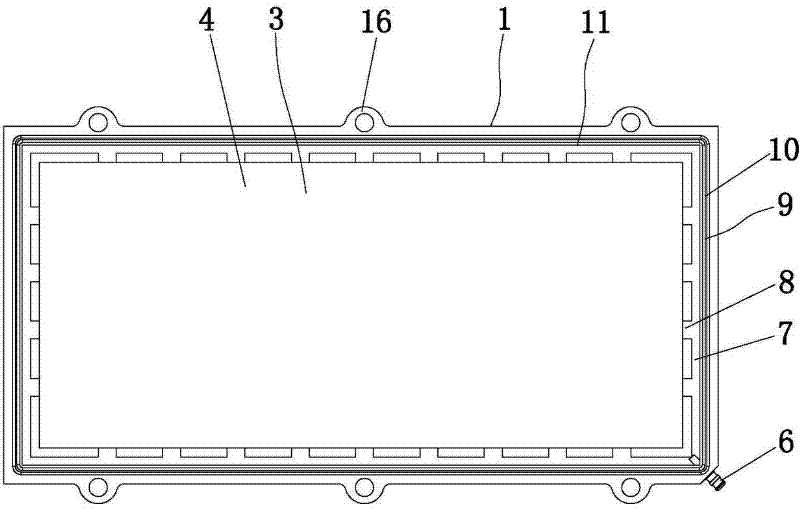

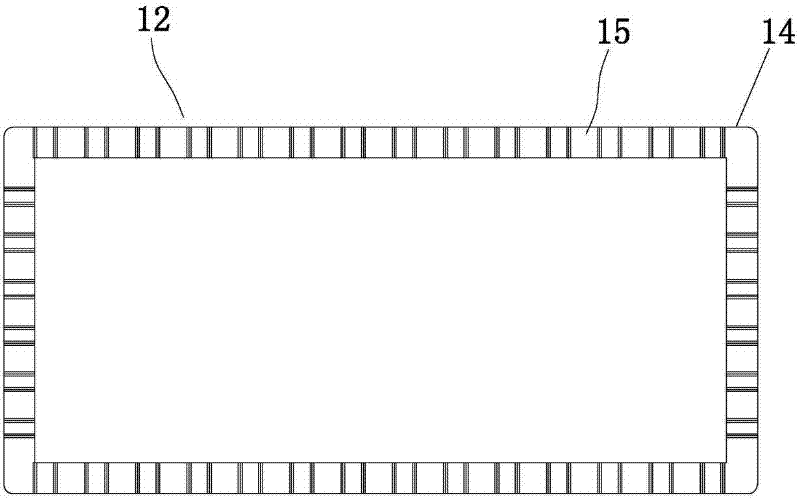

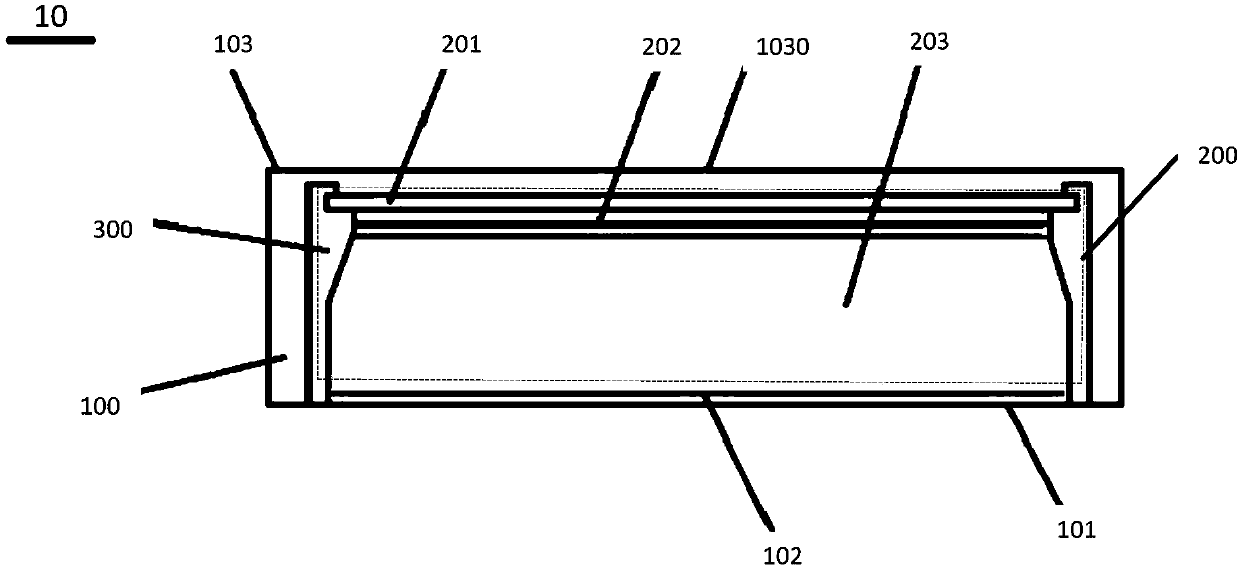

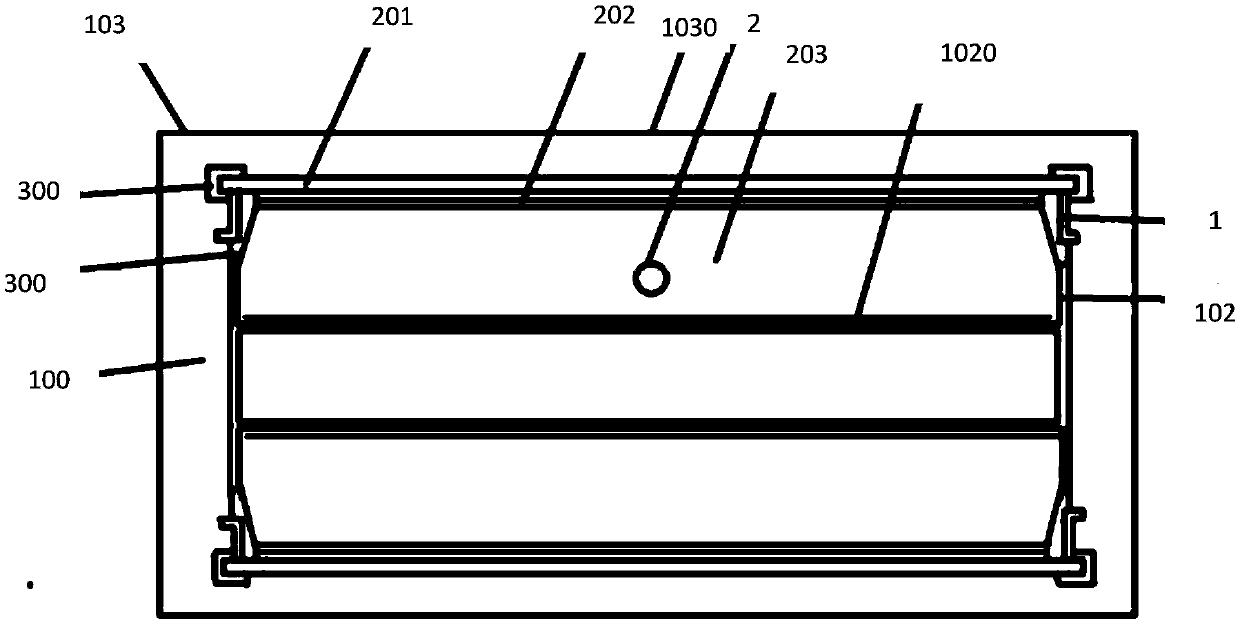

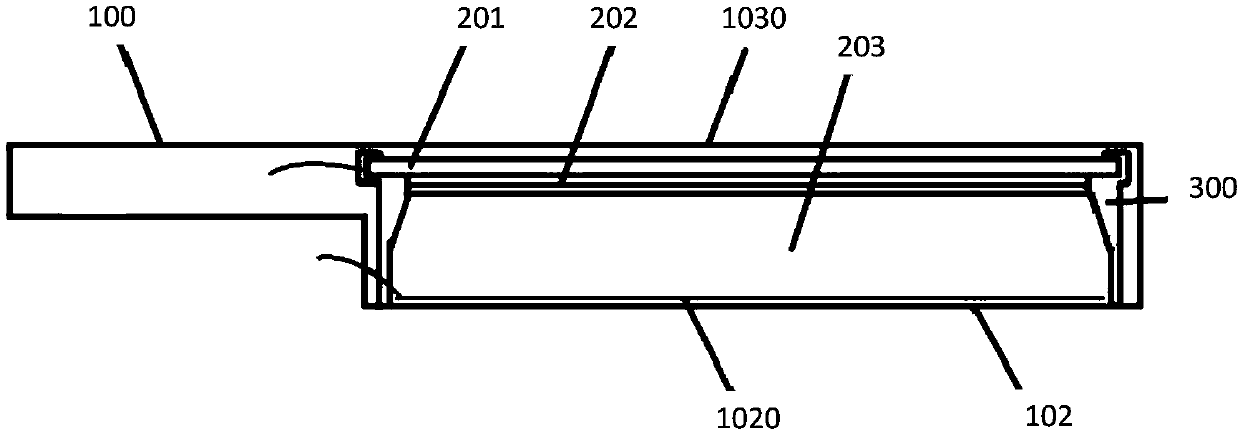

Overstocked type zinc-air cell monomer

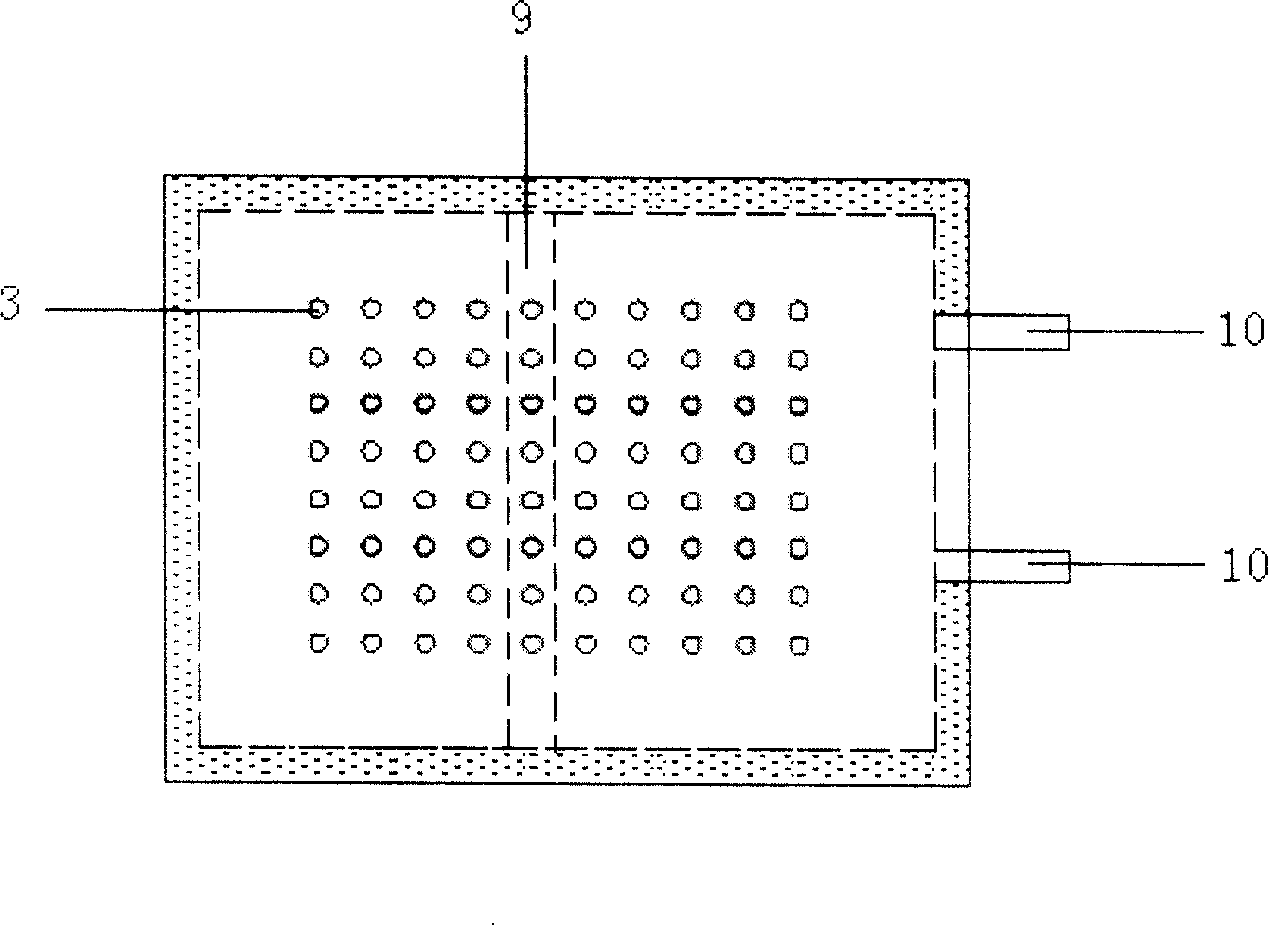

InactiveCN102412431AShorten the conductive pathIncrease the cross-sectional area of the currentFuel and primary cellsCell component detailsInternal resistanceFluid replacement

The invention provides an overstocked type zinc-air cell monomer, which comprises a pedestal frame, an alkali resistant metal negative plate is hermitically fixed at one side surface of a pedestal frame, the alkali resistant metal negative plate and the pedestal frame form an openmouthed fuel bunker, zinc paste is provided in the fuel bunker, a separator paper is hermitically provided on the fuel bunker; a fluid replacement port is provided on the pedestal frame, a fluid replacement bath communicated with the fluid replacement port is provided on the pedestal frame, a group of liquid inlet ports communicated with the fuel bunker are provided on the pedestal frame at the inner side of the fluid replacement bath, a seal groove is provided on the pedestal frame at outside of the fluid replacement bath, a sealing strip is provided in the seal groove, air electrode is provided over the sealing strip, an overstocking device is arranged on the air electrode in a compaction mode. The overstocked type zinc-air cell monomer solves the problems that the conductive path of the zinc-air cell electron is long, the recovery and regeneration waste time and labor, and the volume is large and easy to deform. The conductive path of cell pack assembled by the cell monomer can be effectively shortened, the flowing cross-sectional area of source is increased, and the internal resistance is reduced. The invention has the advantage of simple components installation and operation, and the loss of the components is reduced.

Owner:周雄杰

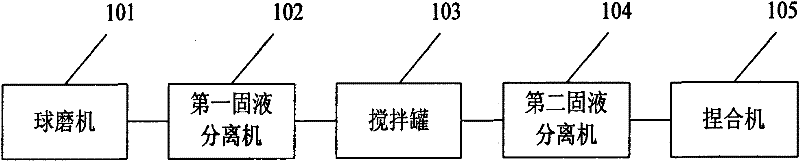

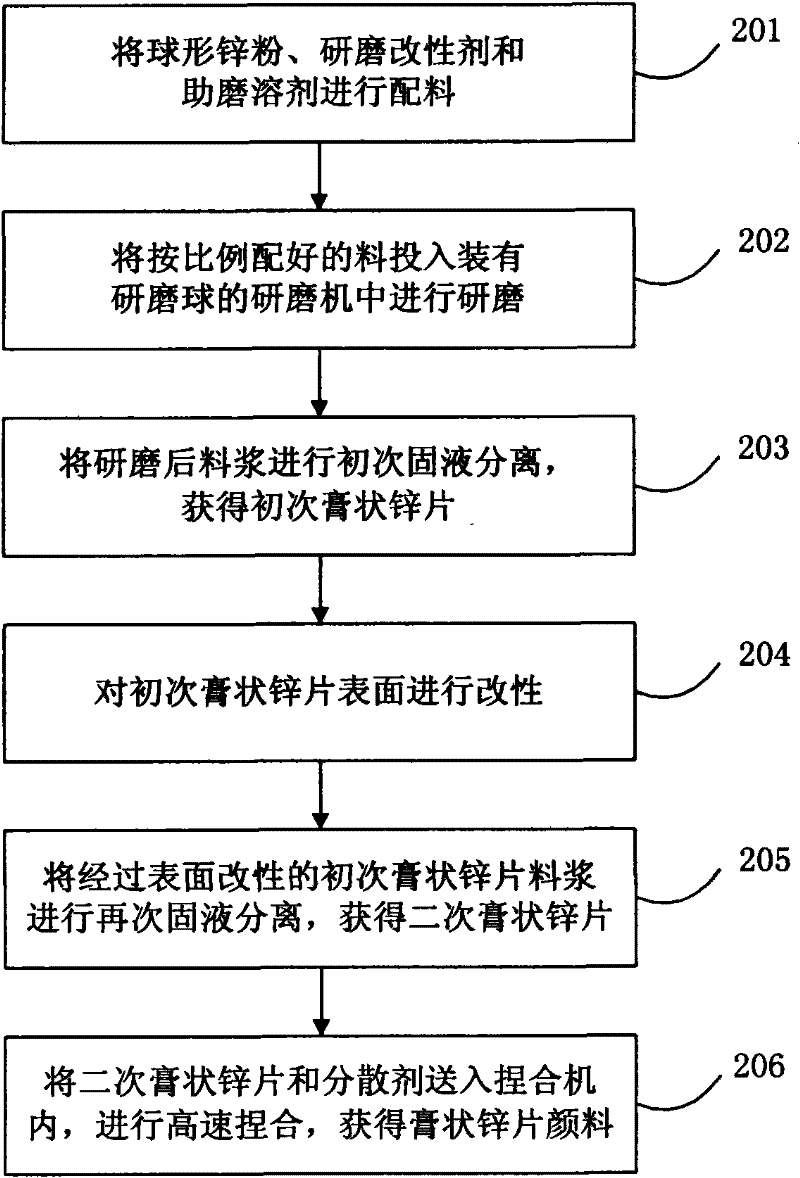

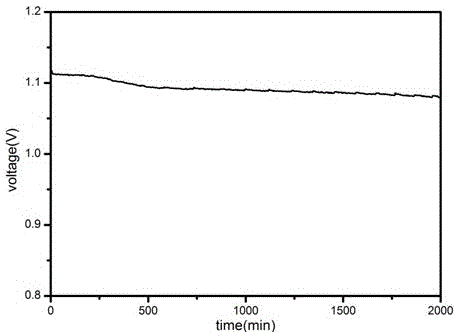

A kind of production method and device of pasty zinc flake pigment

InactiveCN102277015AHomogeneousQuality assurancePigment treatment with macromolecular organic compoundsPigment physical treatmentOrganic solventSlurry

The invention discloses a production method and device for a pasty zinc flake pigment. Spherical zinc powder, a grinding modifier and a grinding aid solvent are compounded, the compounded material is put into a grinder for grinding, and the material obtained after grinding is ground. The slurry is sent to the solid-liquid separator for the initial solid-liquid separation to obtain the initial paste zinc flakes, put the initial paste zinc flakes into the mixing tank, add an organic solvent containing a surface modifier, and treat the initial paste zinc flakes surface For modification, send the surface-modified primary paste zinc flake slurry into a solid-liquid separator for solid-liquid separation again to obtain a secondary paste zinc flake, and send the secondary paste zinc flake and dispersant into the In the kneader, high-speed kneading is carried out to obtain pasty zinc flake pigments. By adopting the technical solution of the invention, it is possible to produce paste-like zinc flakes with high metal zinc content and good quality.

Owner:BEIJING BGRIMM ZINC INDAL +1

Zinc-manganese battery containing modified nano zinc powder and preparation method thereof

InactiveCN112838213AIncrease capacityImprove Coulombic efficiencyNegative electrodesAqueous electrolyte cellsElectrolytic agentManganese

The invention relates to the technical field of zinc-manganese batteries, in particular to a zinc-manganese battery containing modified nano zinc powder and a preparation method thereof. The zinc-manganese battery comprises a shell, a positive electrode ring, negative electrode zinc paste, a diaphragm and electrolyte I; and the negative electrode zinc paste comprises the following raw materials in percentage by weight: 46-65% of modified nano zinc powder, 3-7% of a binder, 27-46% of an electrolyte II and 1-4% of an additive. The zinc-manganese battery containing the modified nano zinc powder prepared by the invention adopts a carbon quantum dot anchoring and nano zinc powder coating technology, and has the following advantages: (1) the actual capacity and coulombic efficiency of the battery are high, and the practicability is strong; (2) the cycle life of the battery is more than 1000 times, and the service life is long; (3) the battery is wide in temperature resistance and can normally work under the condition of -30 DEG C-100 DEG C; and (4) the battery is not added with any lead-containing and mercury-containing material, and is safe and environment-friendly.

Owner:GUANGZHOU ZHUOYUE ELECTRIC ENERGY TECH CO LTD

Anode of zinc air battery using zinc paste and manufacturing method thereof

InactiveCN106329031AThe preparation process is environmentally friendlyReduce energy consumptionFuel and primary cellsElectrode manufacturing processesCopper wireFreeze-drying

The invention relates to an anode of a zinc air battery using zinc paste. The anode is characterized in that the specific process comprises the following steps: 1) preparing the zinc paste according to mass ratio that the proportion of zinc powder, a binding agent, water and KOH is (10-80): (0.1-5): (10-50): (10-40), wherein the binding agent is one of hydroxymethyl cellulose, carboxymethyl cellulose sodium and sodium polyacrylate or a mixture thereof in a proportion of 1: 1: 1; 2) carrying out freeze drying treatment on the prepared zinc paste, enabling the temperature of cold hydrazine to be -10 DEG C to -200 DEG C, and carrying out vacuum drying until dehydration is completed so as to obtain an anode active substance; and 3) pressing the anode active substance and a current collector copper wire mesh by a rolling machine or a press machine so as to prepare a high-performance zinc anode capable of long-term storage. The anode solves the problem of self-discharging existing in the storage process of the zinc air battery using zinc pate, and the non-self-discharging and high-performance zinc anode capable of long-term storage is prepared.

Owner:CHINA FIRST AUTOMOBILE

Zinc-oxide-containing alkaline zinc-manganese battery and preparation method thereof

InactiveCN108172854AImprove high-current discharge performanceIncrease profitDry cellsFiberElectrolysis

The invention discloses a zinc-manganese battery, and particularly relates to a zinc-oxide-containing alkaline zinc-manganese battery and a preparation method thereof. The zinc-oxide-containing alkaline zinc-manganese battery comprises a negative electrode zinc paste, a positive electrode ring, a separation membrane, and electrolytic solutions respectively used for the positive electrode ring, thenegative electrode zinc paste and the separation membrane, wherein the negative electrode zinc paste is prepared from zinc powder, zinc oxide, sodium silicate and a binder, the positive electrode ring is prepared from electrolytic manganese dioxide and an electric conduction agent, the separation membrane is prepared from a paper pulp or fiber mixture, all the electrolytic solutions are potassiumhydroxide aqueous solutions, and the electrolytic solution for the negative electrode zinc paste contains zinc oxide. According to the present invention, the zinc-oxide-containing alkaline zinc-manganese battery is provided under the premise of the increasing demand of the market on the high-power alkaline zinc-manganese batteries, such that the utilization rate of the zinc powder is increased while the hydrogen evolution of the zinc powder is inhibited to a certain extent; and by matching the optimized battery positive electrode, the optimized battery negative electrode and the alkali liquidconcentration ratio, the alkaline zinc-manganese battery produced according to the formula has the significantly-increased high-current discharge performance.

Owner:GUANGDONG LIWANG NEW ENERGY +1

Environment-friendly alkaline battery production process

ActiveCN112421066AImprove environmental performancePrevent leakagePrimary cell manufactureDry cellsElectrical batteryEngineering

The invention relates to an environment-friendly alkaline battery production process which comprises the following steps: an annular positive electrode end clamping groove is formed in the inner wall,close to a positive electrode end, of a battery shell, and an annular negative electrode end clamping groove is formed in the inner wall, close to a negative electrode end, of the battery shell; an annular elastic spacer is pressed into the positive electrode end cover, and after one end of the positive electrode end cover is coated with glue, the positive electrode end cover is arranged on the positive electrode end of the battery shell from the negative electrode end of the battery shell; the other end of the elastic spacer is clamped into the positive electrode end clamping groove; a positive electrode ring is pressed in, and a diaphragm cylinder and zinc paste are loaded into the battery shell; and the negative current collectoris inserted into the zinc paste, the negative end cover is pressed into the negative end of the battery shell, and a sealant is coatedbetween the battery shell and the negative end cover. The battery prepared by the process is good in sealing property and not easy to leak, and the environmental protection property is improved.

Owner:常州市江南电池有限公司

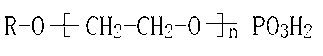

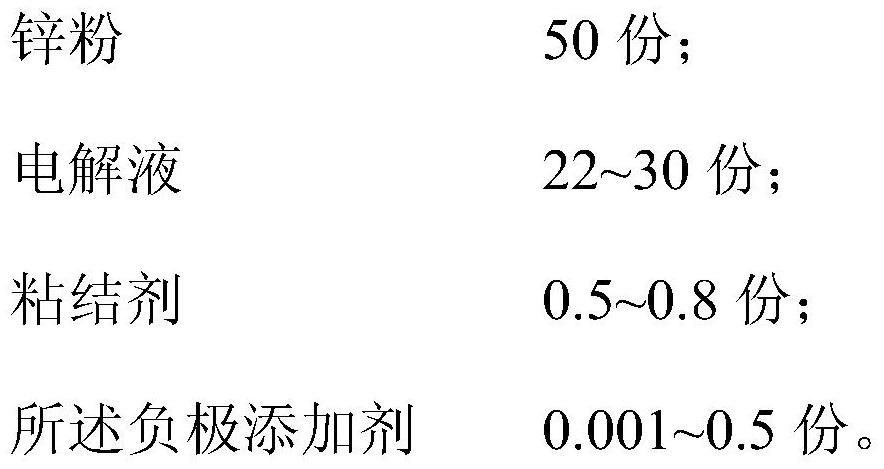

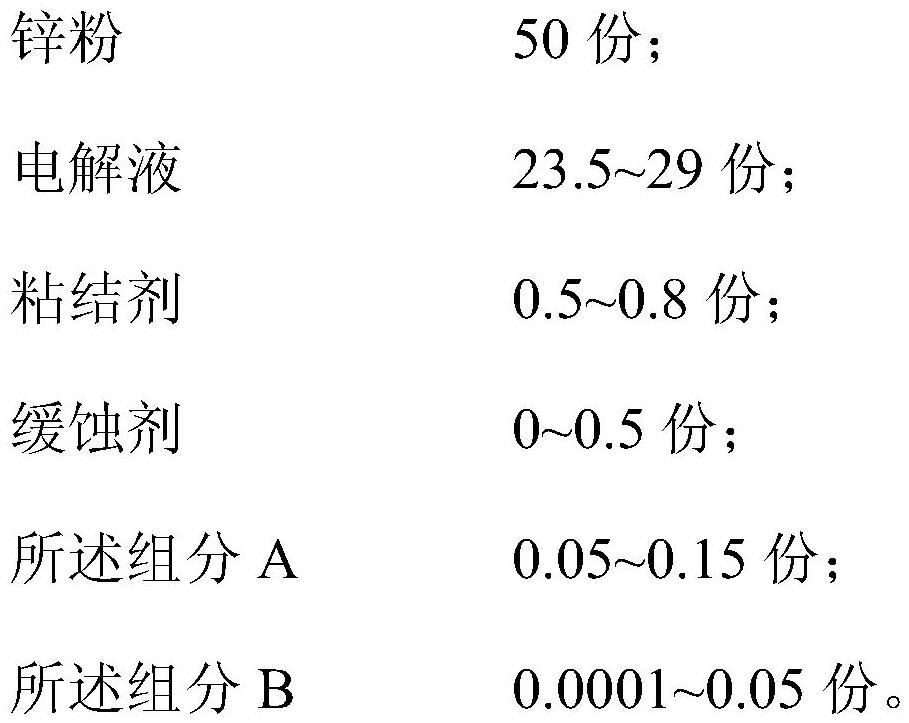

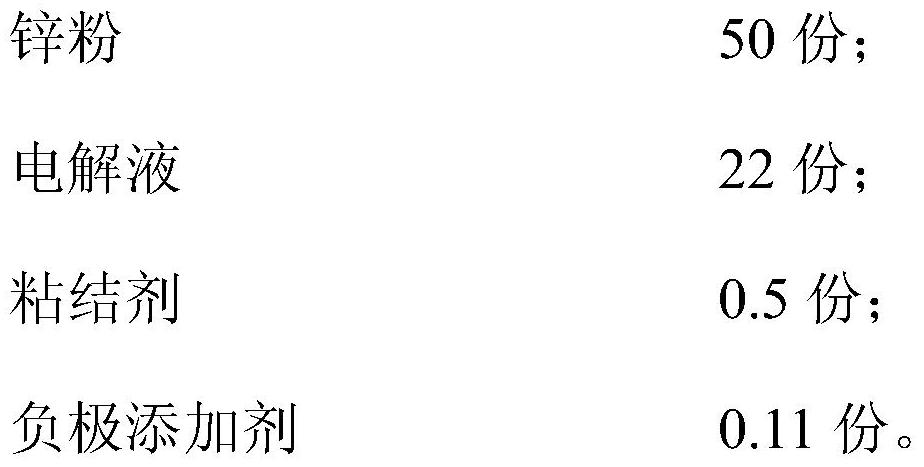

Negative electrode additive for alkaline zinc-manganese dry battery and negative electrode zinc paste containing it and alkaline zinc-manganese dry battery

ActiveCN110729482BIncrease the negative electrode reaction areaReduces electrochemical polarizationCell electrodesDry cellsElectrical batteryAlkylphenol

The invention relates to a negative electrode additive of an alkaline zinc-manganese dry battery, a negative electrode zinc paste containing the negative electrode additive and an alkaline zinc-manganese dry battery. The negative electrode additive comprises a component A and a component B, wherein the component A is a high-carbon alcohol defoaming agent, and the component B is high-carbon fatty alcohol polyoxyethylene ether and / or alkylphenol polyoxyethylene ether. On the basis of a battery negative electrode reaction mechanism, the high-carbon alcohol defoaming agent and the high-carbon fatty alcohol polyoxyethylene ether and / or alkylphenol polyoxyethylene ether are added into a negative electrode formula, and therefore, electrochemical polarization is reduced, the passivation of a zincsurface under a high-power discharge condition is avoided, and the high-power discharge performance of the alkaline manganese battery is greatly improved.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

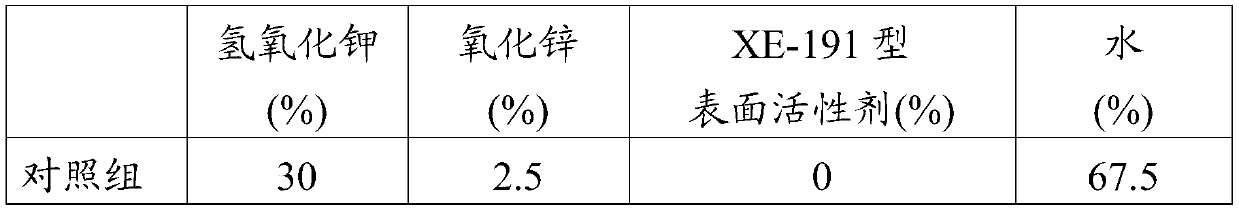

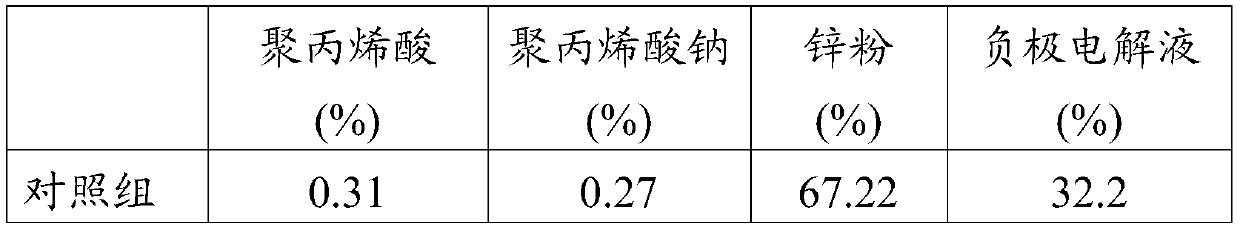

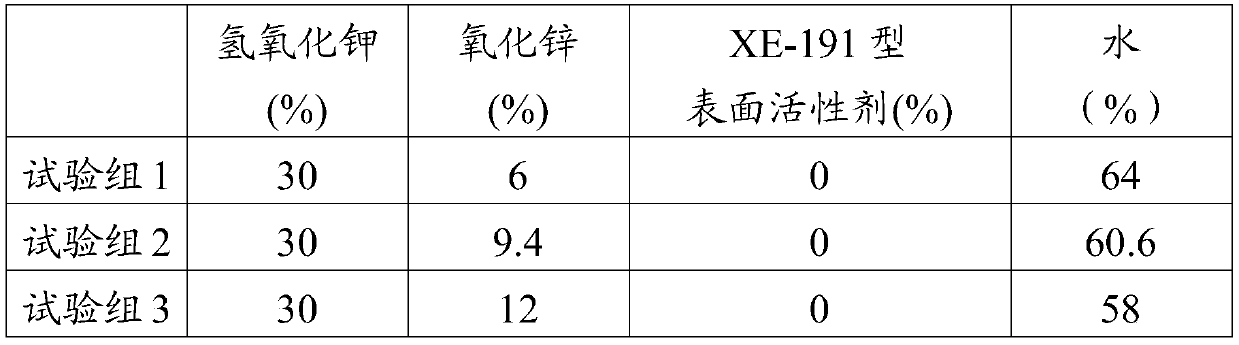

Negative electrode zinc paste and alkaline battery therewith

InactiveCN110289413AReduce outgassingReduce leak rateCell electrodesDry cellsZINC PASTESURFACTANT BLEND

The invention provides a negative electrode zinc paste and an alkaline battery therewith. The negative electrode zinc paste comprises a zinc powder, a negative electrode binder and a negative electrode electrolyte. The negative electrode electrolyte contains a predetermined content of alkali metal hydroxide, a surfactant, and zinc oxide, wherein the surfactant accounts for 0.005% to 0.1% by mass of the negative electrode electrolyte. The alkaline battery of the invention uses a negative electrode prepared by the negative zinc paste, so that the continuous discharge performance of the analog motor of the battery can be greatly improved, the amount of evolved gases during the over-discharge of the battery can be greatly reduced, and the liquid leakage rate in the over-discharge process of the battery can be reduced.

Owner:FUJIAN NANPING NANFU BATTERY

Zinc air battery charge pal

InactiveCN108172703AReduce volumeEasy to carryFuel and primary cellsBatteries circuit arrangementsEngineeringZinc–air battery

Owner:合肥伏雷科技有限公司

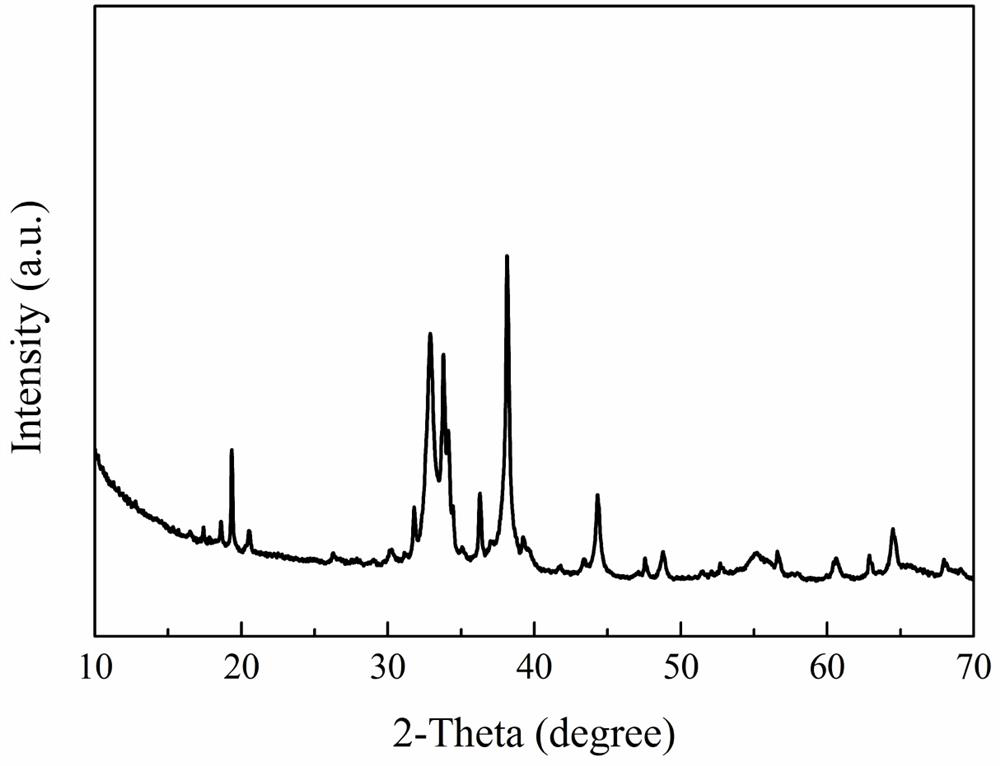

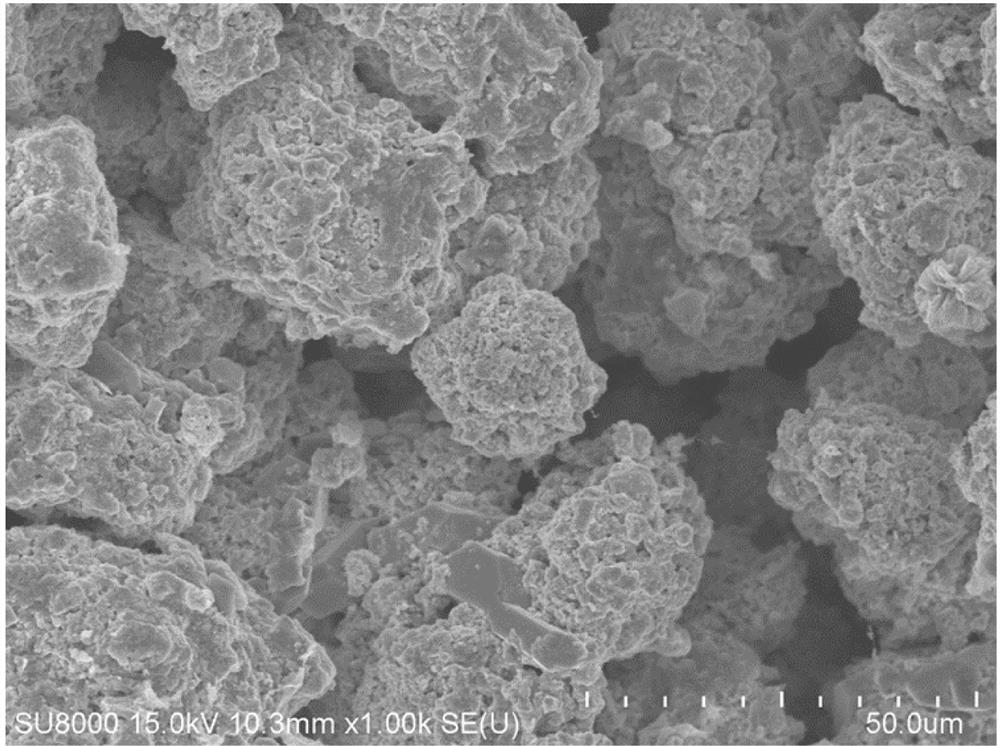

Method for preparing zinc ferrite from waste batteries and application of zinc ferrite in degradation of bisphenol A

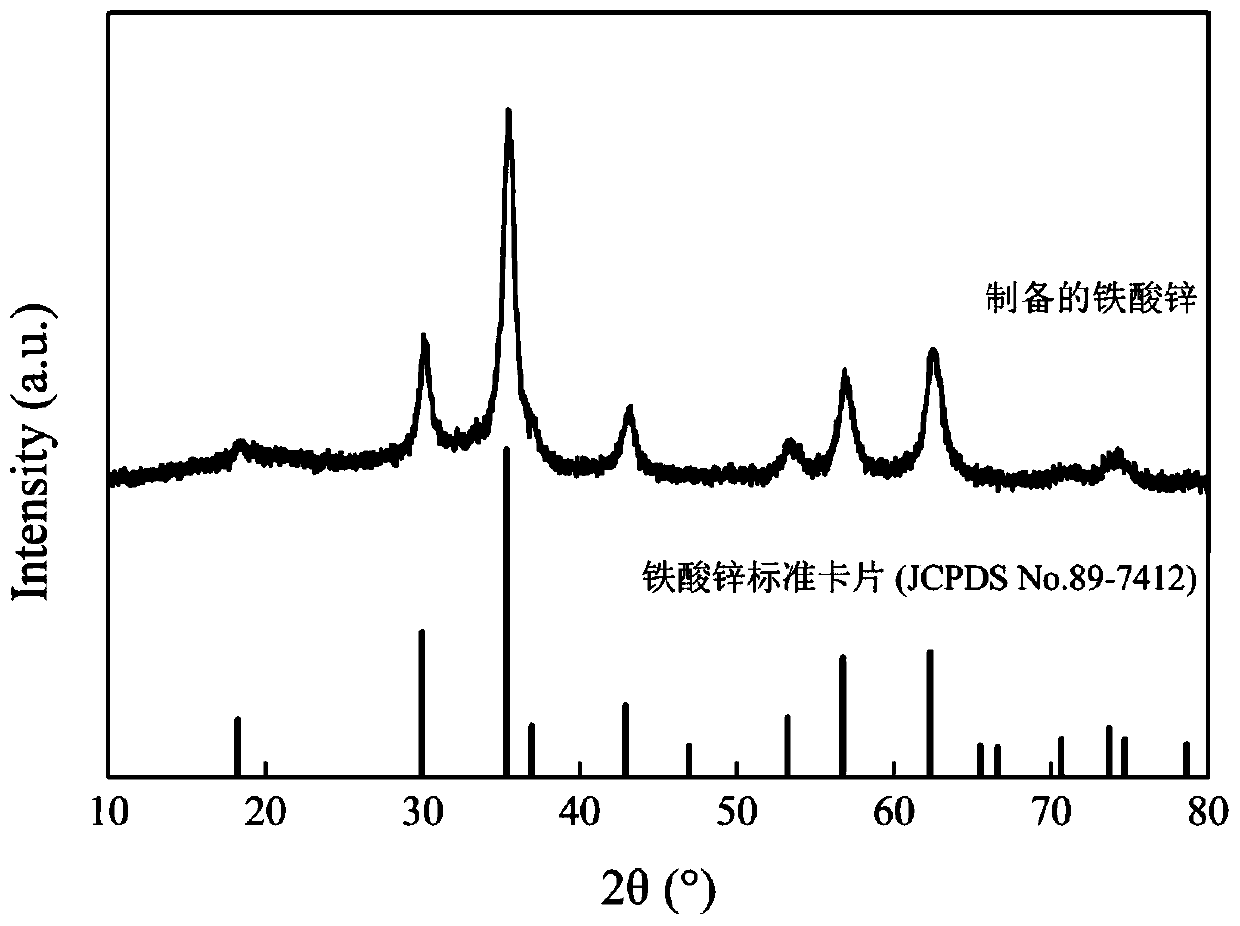

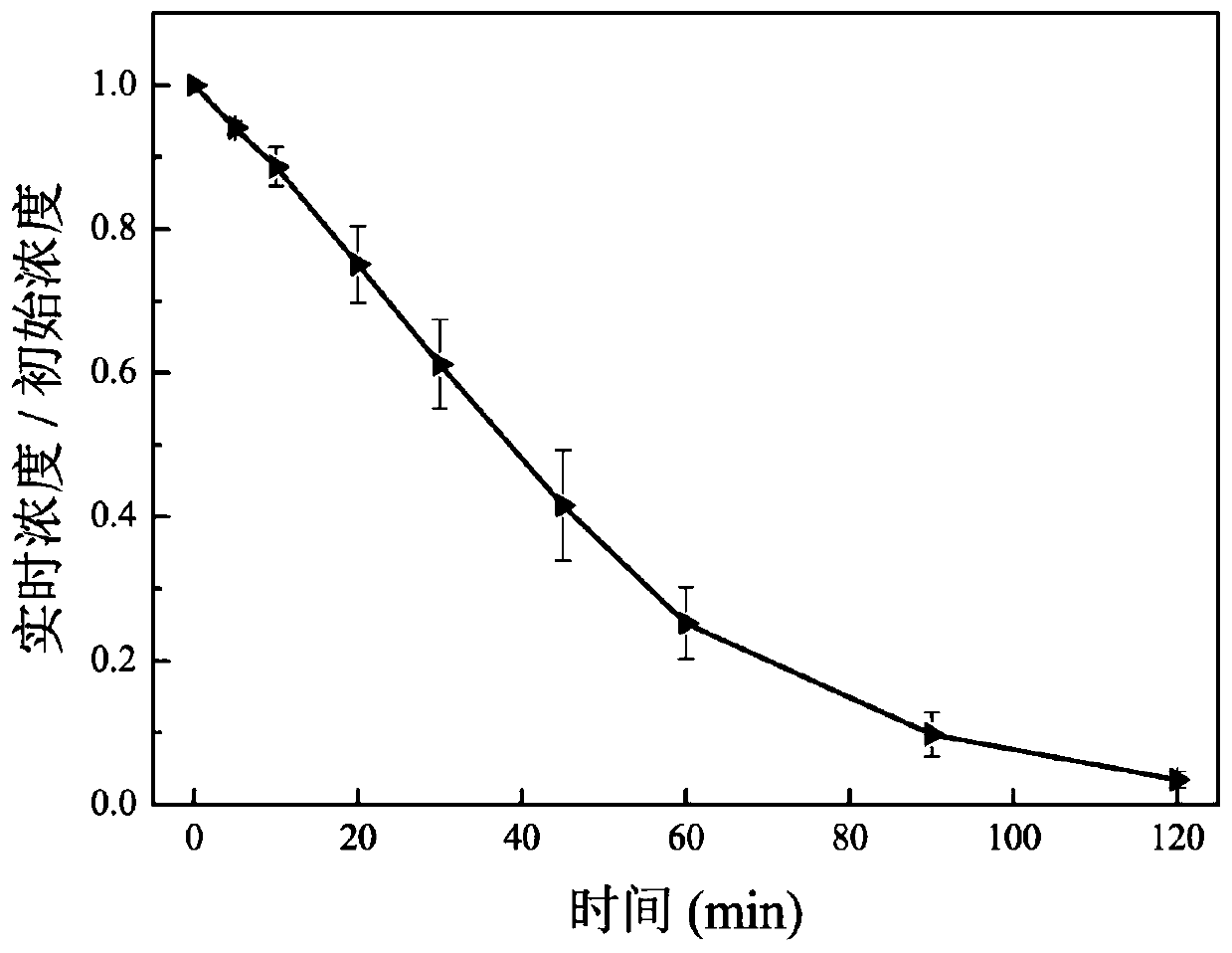

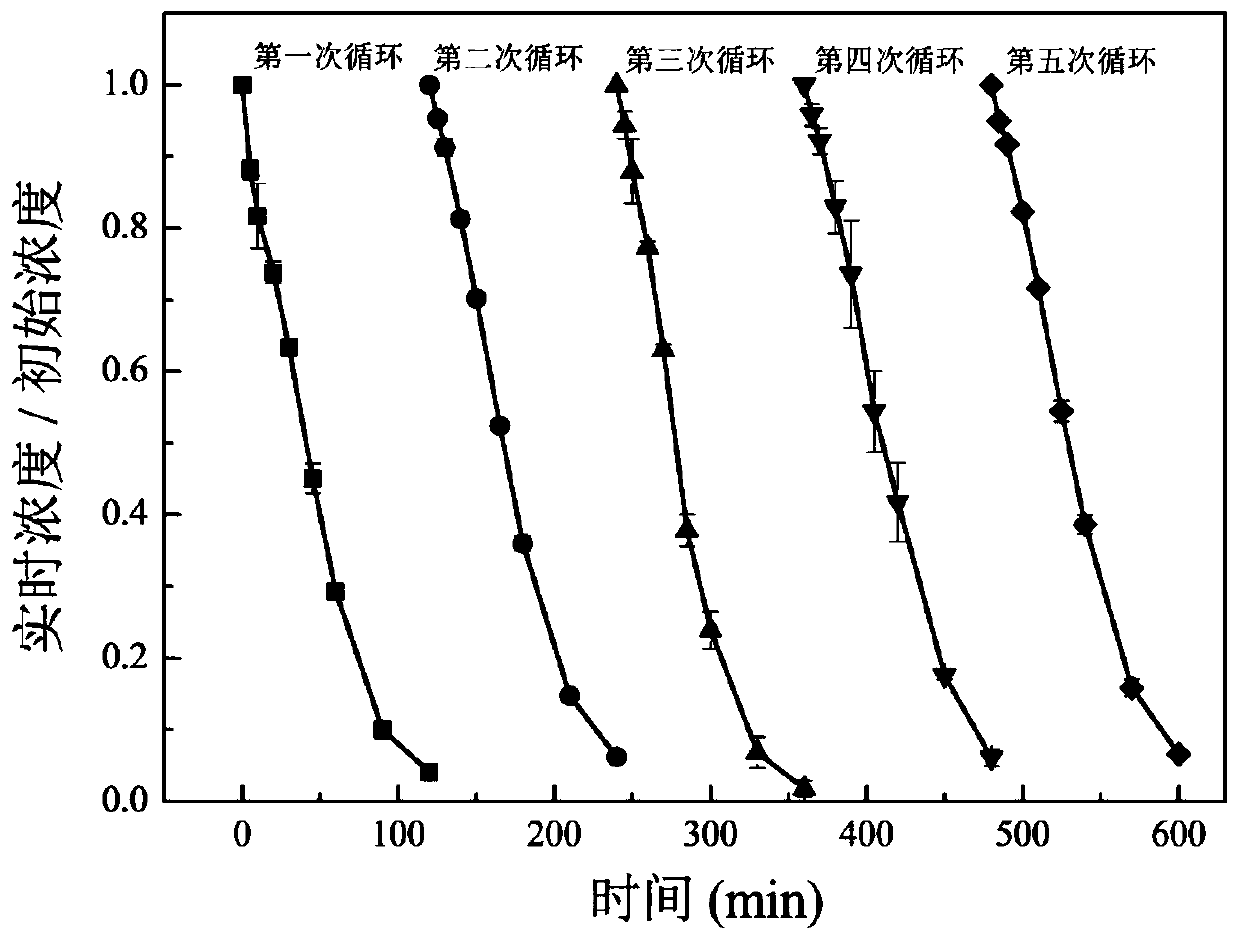

ActiveCN110950388AHigh crystallinityStable structureWater/sewage treatment by irradiationWater treatment compoundsElectrical batteryManganese

The invention relates to a method for preparing zinc ferrite from waste batteries and application of the zinc ferrite in the degradation of bisphenol A. The preparation method comprises the followingsteps of adding acid to dissolve an outer steel shell and cathode zinc paste of a waste alkaline zinc-manganese battery under heating reflux to obtain an iron-containing filtrate and a zinc-containingfiltrate, dissolving and mixing the iron-containing filtrate and the zinc-containing filtrate with citric acid monohydrate, adding alkali to adjust the pH value of the mixed solution to 2.9-3.1, andcarrying out a reaction in three steps: firstly, stirring and reacting at room temperature for 3.5-4.5 hours; secondly, stirring and reacting for 1.5 to 2.5 hours at the temperature of 55 to 65 DEG C;and finally, stirring at the temperature of 85-95 DEG C for 1-3 hours to obtain a gelatinous solid, drying, grinding, calcining, washing with water to be neutral, and drying to obtain the zinc ferrite. According to the method, the waste alkaline zinc-manganese battery is used as a raw material, exogenous metal elements do not need to be supplemented, and the prepared zinc ferrite is good in crystallinity, stable in structure, high in catalytic activity, low in metal ion dissolution rate, recyclable, simple in process, easy in raw material obtainment, convenient to operate and low in cost.

Owner:WUHAN UNIV

Mercury-free lead-free alkaline button battery

InactiveCN104377321ASolve pollutionSolve resource problemsCell component detailsPrimary cell detailsRubber ringIndium

The invention relates to a mercury-free lead-free alkaline button battery. The battery comprises a negative electrode cover, a negative electrode current collector, a sealing rubber ring, negative electrode zinc paste, a separator, a positive electrode material and a positive electrode housing, wherein the negative electrode current collector is arranged on the inner side of the negative electrode cover, the shape and size of the outer side of the negative electrode current collector are the same as those of the inner side of the negative electrode cover, the outer surface of the negative electrode current collector is in close fit with the inner surface of the negative electrode cover, and the inner surface of the negative electrode current collector is in contact with the negative electrode zinc paste. Aluminum, copper, aluminum alloy or copper alloy sheet with good conductive properties are utilized for manufacturing the negative electrode current collector, the surface of the aluminum, copper, aluminum alloy or copper alloy sheet is coated with indium, tin, indium alloy or tin alloy plating, and the collector is made by stamping. According to the invention, the negative electrode current collector is capable of effectively preventing the self-discharge hydrogen evolution of the battery, and also effectively avoiding phenomena such as gaseous distention, liquid leakage, cover blasting and even an explosion of the battery, which are caused by contact between the negative electrode zinc paste and the negative electrode cover, so that the safety performance and storage performance of the battery are improved. According to the invention, no deplating is needed, so that resources are saved, and the battery achieves environment-friendly and pollution-free effects.

Owner:肖秀华

Mercury-free zinc paste of button alkaline zinc-manganese dioxide cell and preparation method for mercury-free zinc paste

InactiveCN102569760APrevent sedimentation and coagulationImprove discharge performanceCell electrodesIndiumButton battery

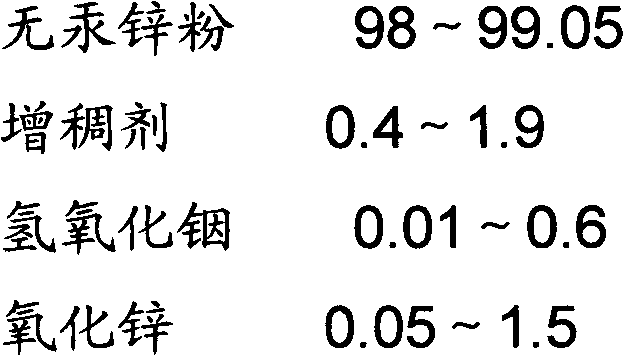

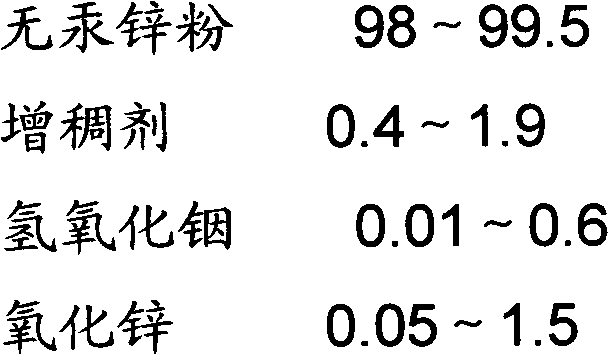

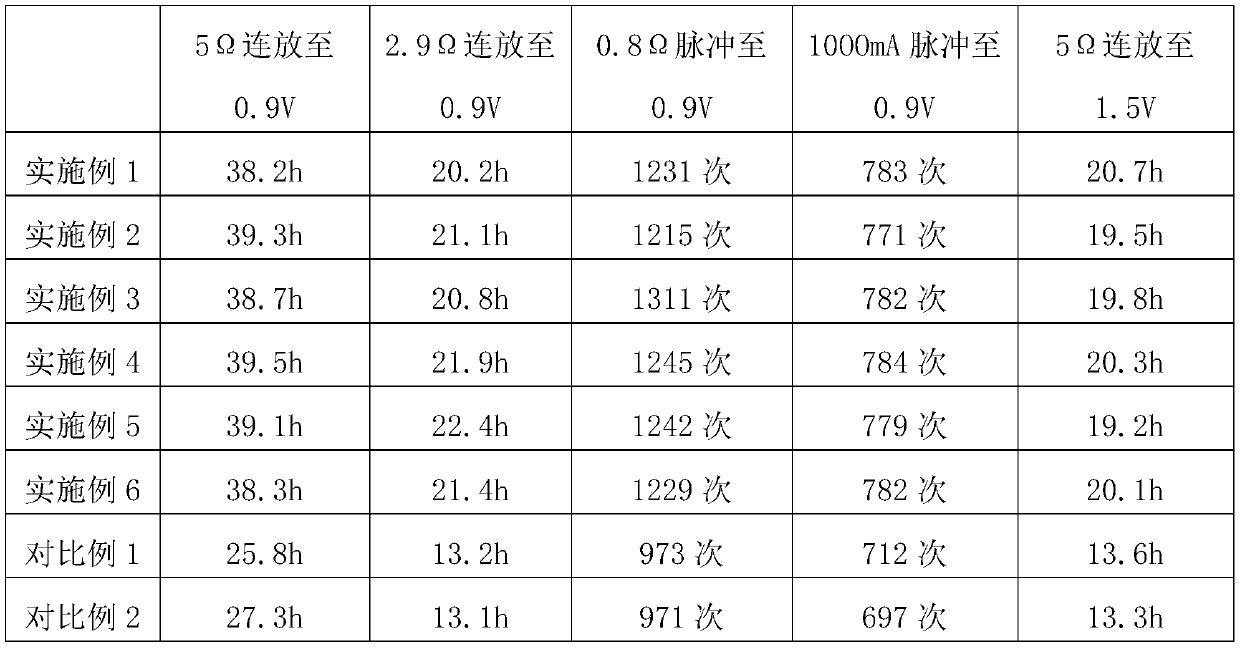

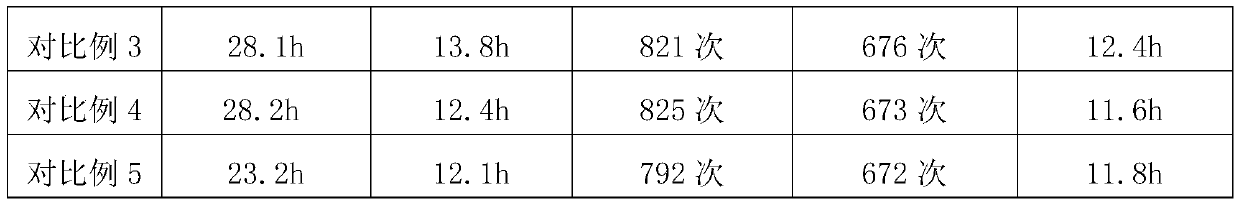

The invention provides a mercury-free zinc paste of a button alkaline zinc-manganese dioxide cell and a preparation method for the mercury-free zinc paste. The preparation method comprises the following steps of: preparing the following raw materials in percentage by mass: 98 to 99.05 percent of mercury-free zinc powder, 0.4 to 1.9 percent of an adhesion agent, 0.01 to 0.6 percent of indium hydroxide and 0.05 to 1.5 percent of zinc oxide, wherein the adhesion agent comprises sodium carboxymethylcellulose and sodium polyacrylate, and the mass ratio of the sodium carboxymethylcellulose to the sodium polyacrylate is 0.1 to 10; grinding the raw materials in three-dimensional nonmetal ball milling mixing equipment for 5 to 100 minutes; adding electrolyte of which the mass is 38 to 43 percent of that of the mixture into the ball milling mixing equipment; vacuumizing the ball milling mixing equipment to be below 0.01 MPa; and mixing for 10 to 100 minutes to obtain the zinc paste. According to the preparation method, the used substances are mixed into a paste and treated under a vacuum condition, gases generated during the preparation of the zinc paste are exhausted, and the indium hydroxide is added to replace mercury so as to prevent the generation of gases, so that the environment is not polluted. Moreover, the sodium carboxymethylcellulose is added to prevent dispersed zinc powder from sedimentation and agglomeration because the viscosity of a zinc electrode is reduced, and the sodium carboxymethylcellulose acts together with the indium hydroxide to ensure that the cell shows high discharge performance. Therefore, the cell cannot deform by swelling, so that the cell can be conveniently stored, and the environment is not polluted because the indium hydroxide is added into the zinc paste to replace the mercury so as to prevent the generation of gases. The zinc paste prepared by the preparation method can be applied to mercury-free button cells.

Owner:无锡耐克赛尔电池有限公司

Alkali zinc-manganese battery containing modified nano zinc powder and preparation method thereof

ActiveCN110783560ADistributeImprove uniformityCell electrodesDry cellsElectrolytic agentZinc nanoparticles

The invention discloses an alkaline zinc-manganese battery containing modified nano zinc powder. The alkaline zinc-manganese battery includes a positive electrode ring, negative electrode zinc paste,a separator, and an electrolyte. The positive electrode ring is made of electrolytic manganese dioxide, a conductive agent and an electrolyte. The negative electrode zinc paste is composed of, by mass, 52 to 68 wt% of modified nano zinc powder, 2 to 5 wt% of binder, 27 to 45 wt% of electrolyte, and 1 to 2.5 wt% of compound additive. According to the invention, the zinc-manganese battery does not contain any lead-containing and mercury-containing materials, and prevents problems such as battery expansion, leakage, and gas evolution during use; and the prepared battery is environmentally safe and stable in performance, and has a long service life. The invention further discloses a preparation method of the alkaline zinc-manganese battery containing modified nano zinc powder.

Owner:JIAXING HUARONG BATTERY

Zinc paste, preparation method thereof and zinc-manganese battery

InactiveCN111490245AGuaranteed charge and discharge performanceHigh capacity retentionElectrode manufacturing processesSecondary cellsElectrolytic agentPhysical chemistry

The invention provides a zinc paste, a preparation method thereof and a zinc-manganese battery. The zinc paste comprises a zinc-containing material, an indium-containing material, a binder and a thickener, and the binder is a pre-gelatinized material. The preparation method comprises the following steps: stirring and mixing the zinc-containing material, the indium-containing material, the binder and the thickener according to a formula ratio, adding an electrolyte, and continuously stirring and mixing to obtain the zinc paste, and the binder is the pre-gelatinized material. The zinc paste provided by the invention can be used for a weakly acidic electrolyte, the charging and discharging capacity of the battery can be guaranteed, the capacity retention ratio of the zinc-manganese battery isimproved, and the cost is low.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

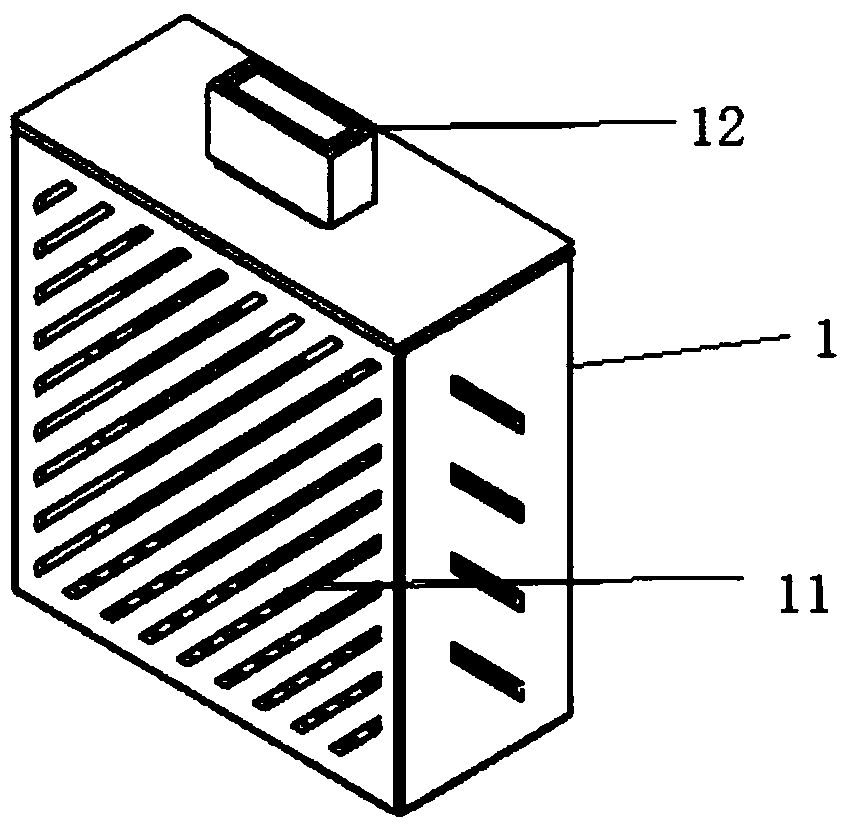

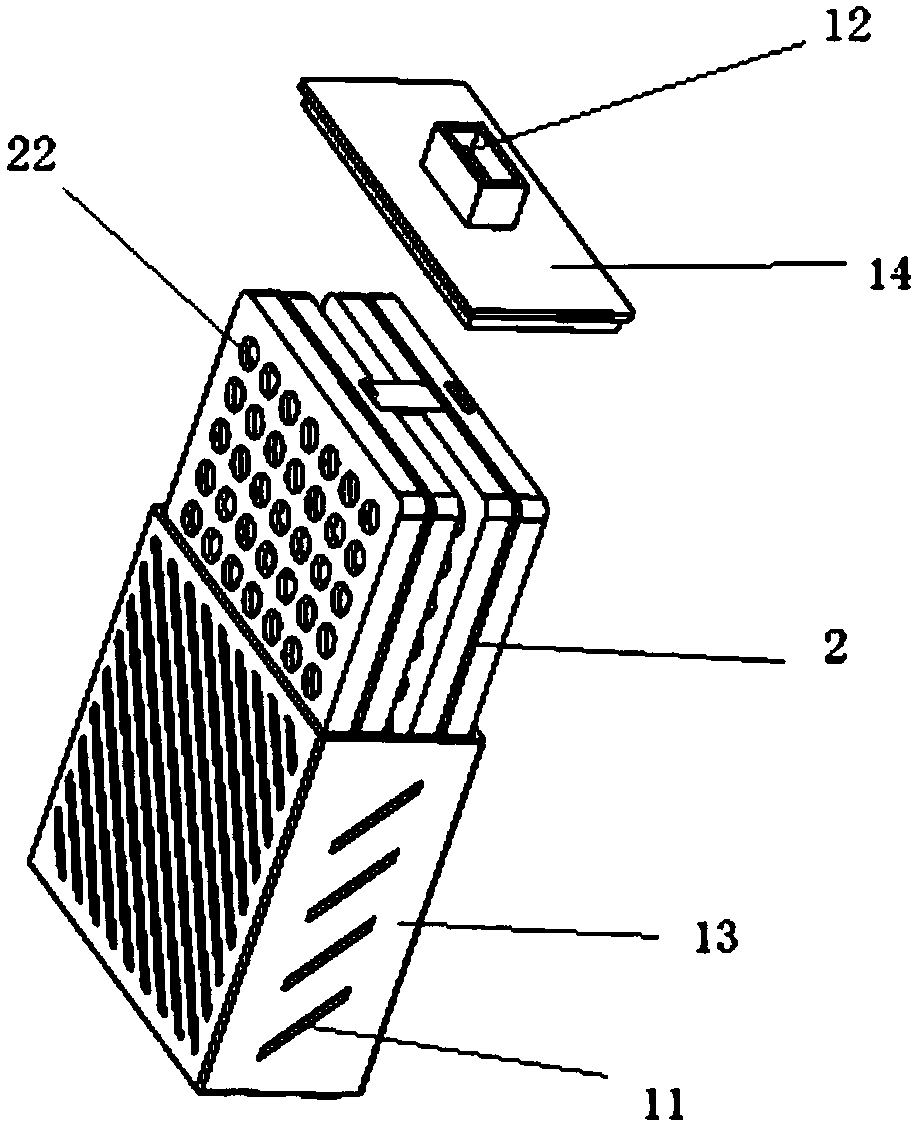

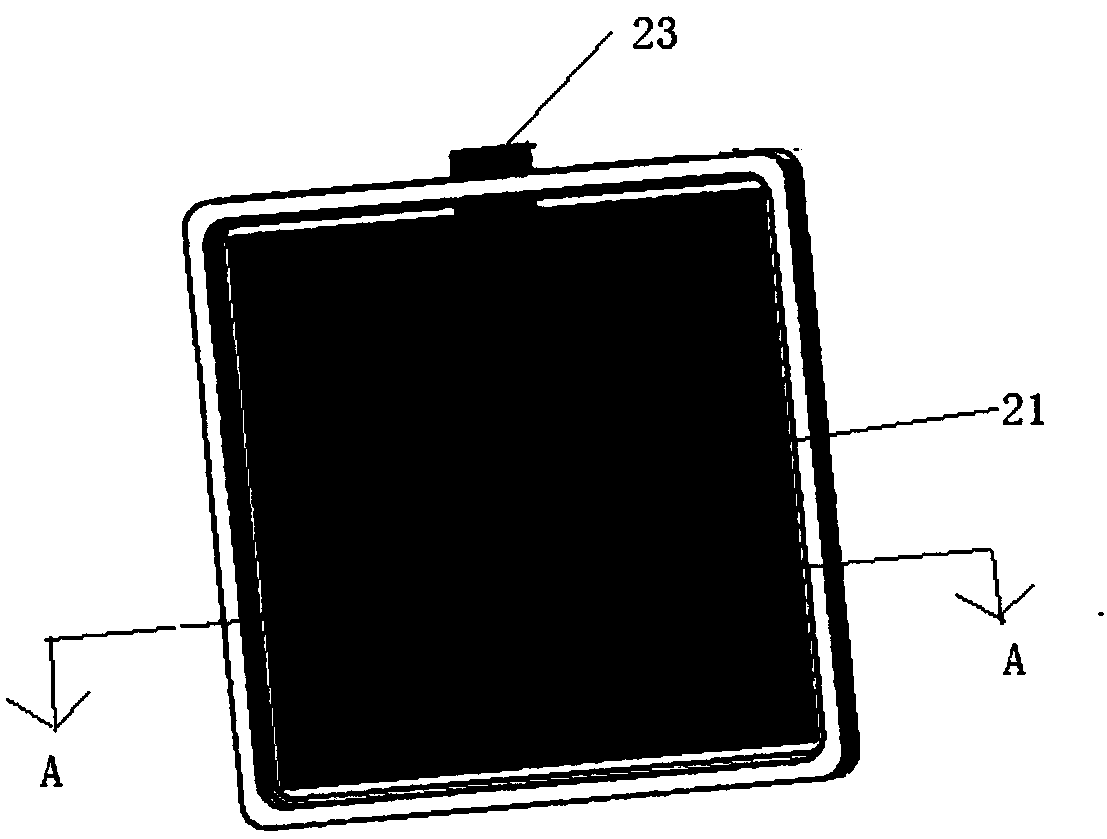

Portable mechanical rechargeable zinc-air secondary battery

PendingCN107910618AImprove efficiencyImprove charging efficiencyFuel and primary cellsReactant parameters controlElectrical batteryEngineering

The invention discloses a portable mechanical rechargeable zinc-air secondary battery, which comprises a battery shell and a battery reaction component arranged in the battery shell, wherein the battery shell comprises a bottom shell, a zinc paste box and a head cover; the zinc paste box is movably arranged between the bottom shell and the head cover; the battery reaction component comprises an air electrode, a membrane and zinc paste; a catalyst layer of the air electrode is close to the membrane; a hydrophobic breathable side of the air electrode is toward a breathable mesh of the head cover; the zinc paste is arranged in the zinc paste box; and an open surface of the zinc paste box is clung to the membrane, so that the zinc paste box is mechanically recharged into the battery as a negative electrode. According to the portable mechanical rechargeable zinc-air secondary battery, secondary use of the battery can be achieved through mechanical replacement of a negative electrode material, so that the service efficiency of the battery is improved, the security of the battery is improved and the energy is saved.

Owner:TSINGHUA UNIV

Anticorrosion component for cable sheath

InactiveCN103680729AImprove anti-corrosion performanceInsulated cablesInsulated conductorsState of artBenzoic acid

The invention provides an anticorrosion component for a cable sheath. According to the technical scheme, the anticorrosion component for the cable sheath comprises water and benzoic acid, and is characterized by further comprising, by mass, 7-17 parts of potassium dichromate, 2-7 parts of silica sol, 1.5-7 parts of cured zinc paste and 0.4-1.4 parts of nitroglycerin. Compared with the prior art, the anticorrosion component for the cable sheath has the advantages that due to the fact that the potassium dichromate, the silica sol, the cured zinc paste and the nitroglycerin are added, the anticorrosion component can have good cable sheath corrosion prevention capacity.

Owner:王刚

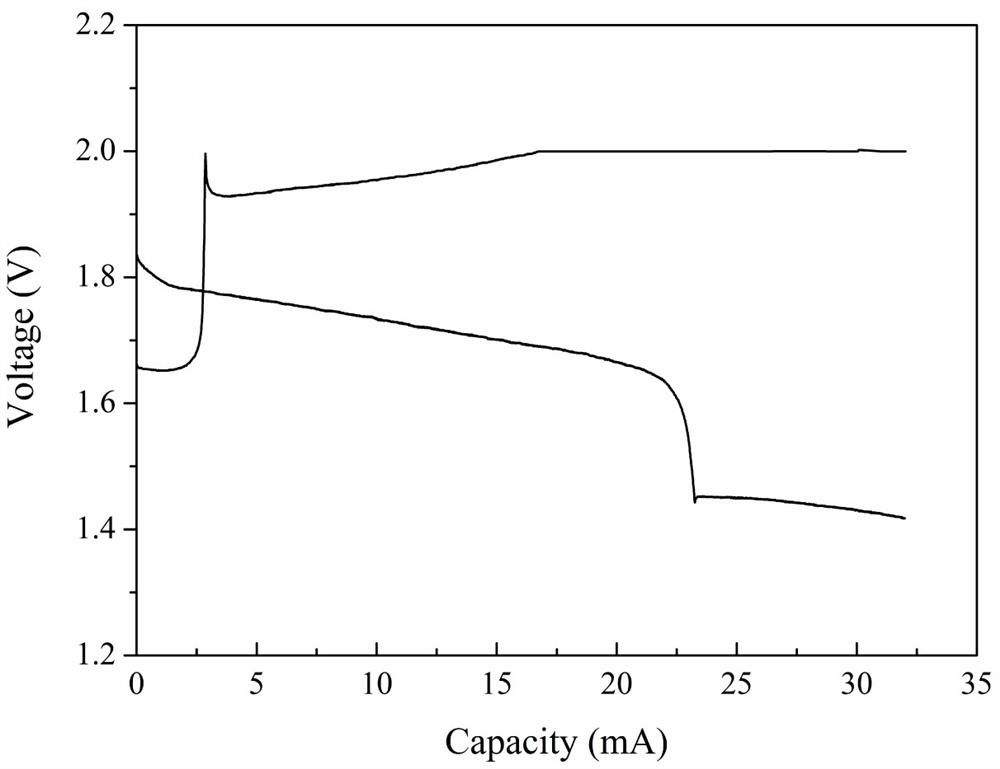

Preparation method of high-specific-energy Zn/AgO small button type secondary battery

PendingCN114597512AImprove stabilityGood compatibilitySilver accumulatorsCell electrodesElectrolytic agentElectrical battery

The invention discloses a preparation method of a high-specific-energy Zn / AgO small button secondary battery, which comprises the following steps: synthesizing a positive electrode material by adopting a chemical method, preparing an alkaline electrolyte with low hydrogen evolution amount, finally using a mercury-free corrosion inhibitor zinc paste negative electrode, and assembling an AG3 type zinc-silver button battery by using the positive electrode, the zinc paste negative electrode, the alkaline electrolyte and a diaphragm, thereby obtaining the high-specific-energy Zn / AgO small button secondary battery. The Zn / AgO small button secondary battery prepared by the method provided by the invention has the advantages of high specific energy, long cycle life and simple preparation process.

Owner:WUHAN MARINE ELECTRIC PROPULSION RES INST CHINA SHIPBUILDING IND CORP NO 712 INST

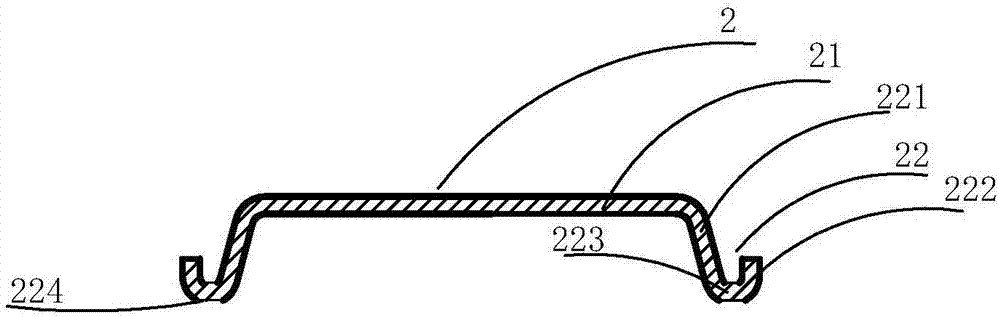

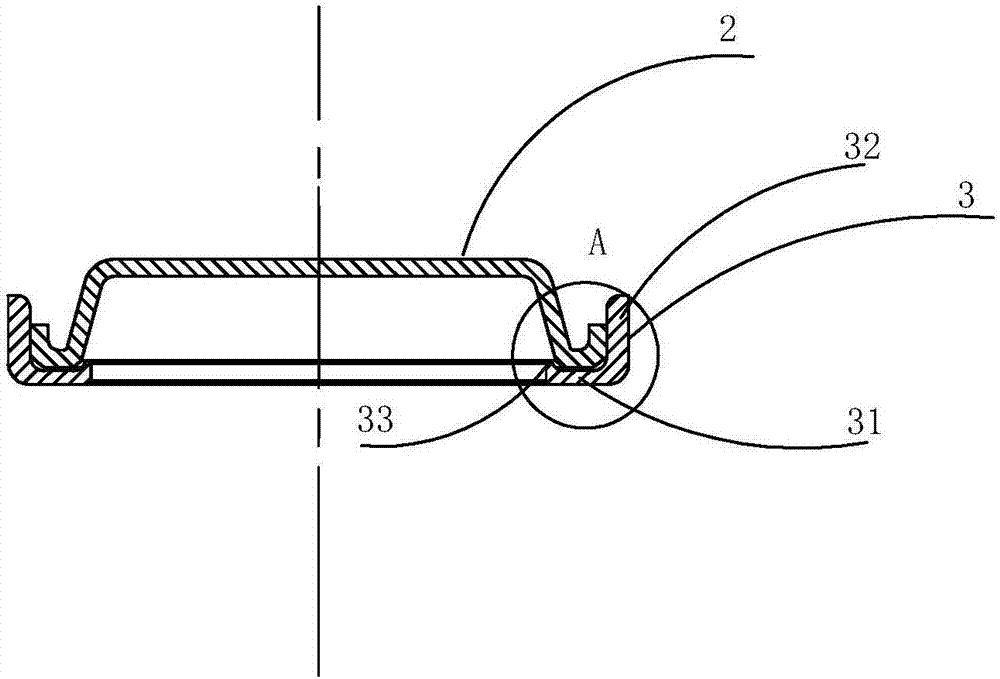

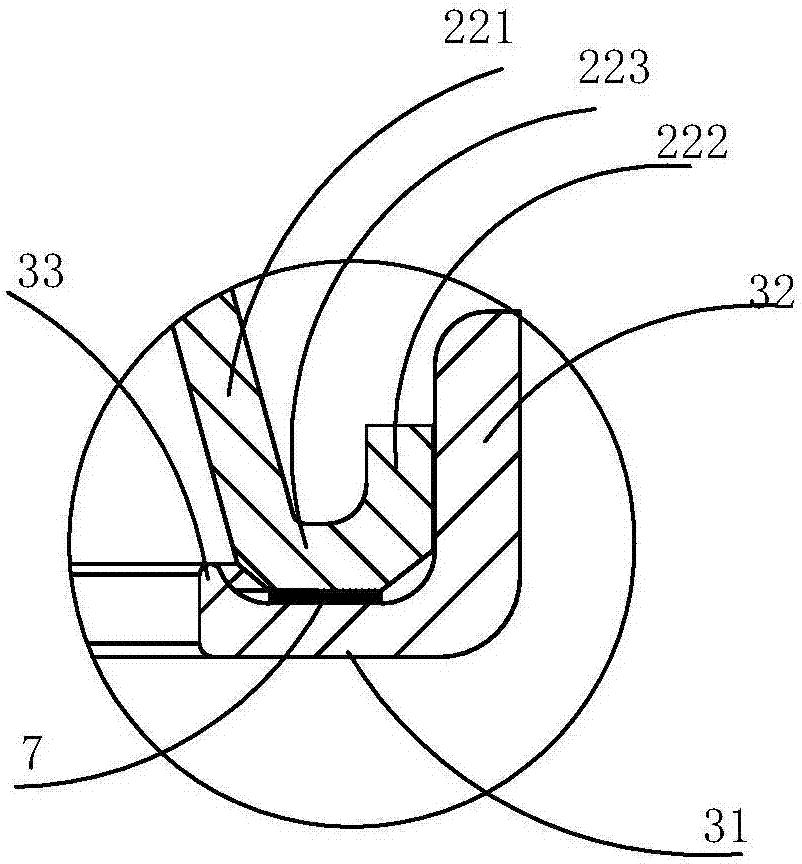

Button cell negative electrode top and negative electrode combination, and alkali button cell

InactiveCN106960946AImprove adhesionImprove leak-proof effectFinal product manufactureAlkaline accumulator electrodesButton batteryEngineering

The invention discloses an alkali button cell and a negative electrode combination. The alkali button cell comprises a positive electrode cup, a negative electrode top, an annular sealing ring, a positive electrode cake, a diaphragm and zinc paste, wherein the positive electrode cup and the negative electrode top are insulated through the annular sealing ring; the positive electrode cake and the zinc plate are isolated through the diaphragm; the negative electrode top comprises an integrally-formed central region, and an annular bending part on the periphery of the central region; the annular bending part comprises an annular inner wall, an annular outer wall and an annular connecting part between the annular inner wall and the annular outer wall; the lower end plane of the annular connecting part is an annular plane which is 0.2-0.4mm in width; and the lower end plane of the annular connecting part is immersed with glue and then fixed with the annular sealing ring through gluing. The alkali button cell has the advantages as follows: the lower end plane of the annular connecting part of the negative electrode top is the annular plane which is 0.2-0.4mm in width; and by designing the circular-arc-shaped lower end of the negative electrode top into the planar shape, when the lower end plane of the negative electrode top is immersed with glue, the planar-shaped contact part can be glued with more glue, so that the gluing effect between the negative electrode top and the sealing ring can be better.

Owner:宁波必霸能源有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com