Mercury-free lead-free alkaline button battery

A technology of lead-free alkaline and button batteries, which is applied to battery pack parts, secondary battery parts, primary battery parts, etc., can solve the problems of battery negative cover plating damage, waste of resources, environmental pollution, etc., to achieve Improve safety performance and storage performance, solve a large amount of heavy metal emissions, and avoid the effect of chemical reaction hydrogen evolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

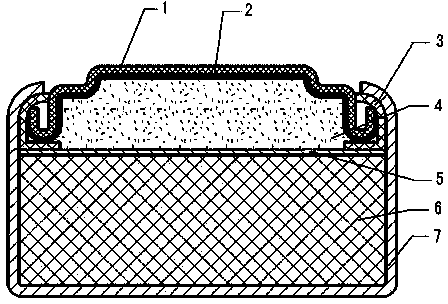

[0012] Such as figure 1 As shown, the mercury-free lead-free alkaline button battery according to the embodiment of the present invention includes a negative electrode cover 1 , a negative electrode current collector 2 , a sealing rubber ring 3 , a negative electrode zinc paste 4 , a diaphragm 5 , a positive electrode material 6 and a positive electrode case 7 . The negative electrode zinc paste 4 is mercury-free and lead-free zinc paste, the positive electrode material 6 is silver oxide or manganese dioxide, and the base material of the negative electrode current collector 2 is aluminum or copper or aluminum alloy or copper alloy sheet. The surface of the aluminum alloy or copper alloy sheet is plated with indium or tin or indium alloy or tin alloy layer, which is combined with the negative electrode cover 1 after stamping and forming. The base material of the negative electrode current collector 2 is the surface of a copper-tin alloy or a multi-component copper-tin alloy, wh...

Embodiment approach 2

[0015] Such as figure 2 As shown, the mercury-free lead-free alkaline button battery according to the embodiment of the present invention includes a negative electrode cover 1 , a negative electrode current collector 2 , a sealing rubber ring 3 , a negative electrode zinc paste 4 , a diaphragm 5 , a positive electrode material 6 and a positive electrode case 7 . The negative electrode zinc paste 4 is mercury-free and lead-free zinc paste, and the positive electrode material 6 is silver oxide or manganese dioxide. Or stainless steel sheet, the other side is a special metal sheet of aluminum or copper or aluminum alloy or copper alloy sheet coated with indium or tin or indium alloy or tin alloy layer, the surface coated with indium or tin or indium alloy or tin alloy layer Facing inward, nickel-plated or tin-plated cold-rolled steel or stainless steel faces outward, and is punched to form an integrated negative electrode cover 1 and negative electrode current collector 2 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com