A kind of production method and device of pasty zinc flake pigment

A production method and technology for zinc flakes, which are applied in the directions of fibrous filler, dyeing physical treatment, dyeing low molecular organic compound treatment, etc., to achieve the effect of smoothing the surface of zinc flakes, improving dispersibility, and uniform flaky degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

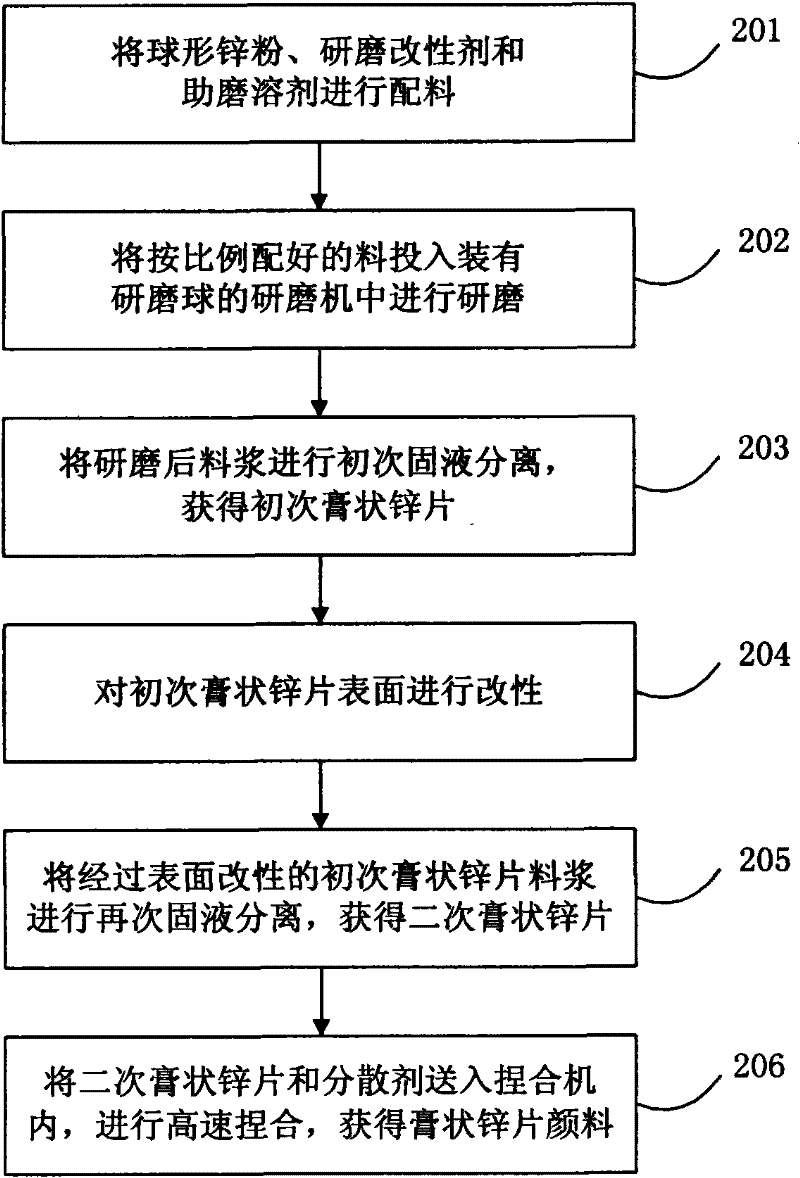

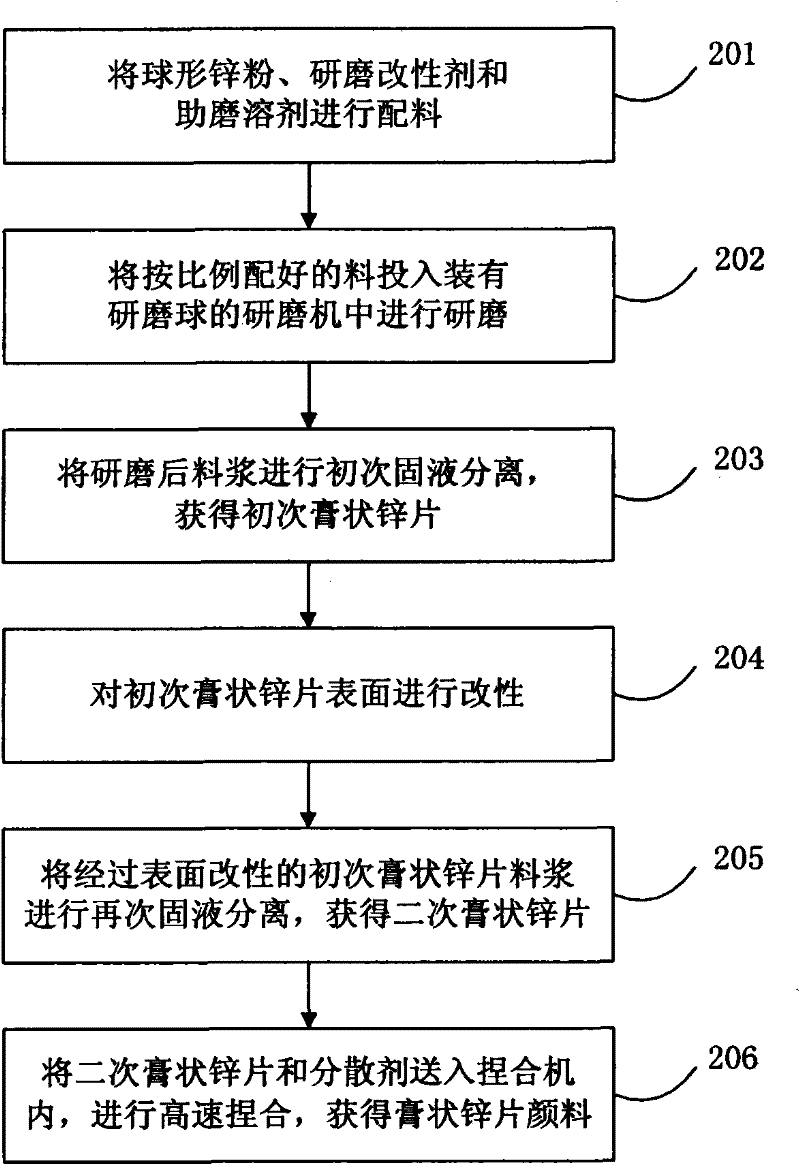

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

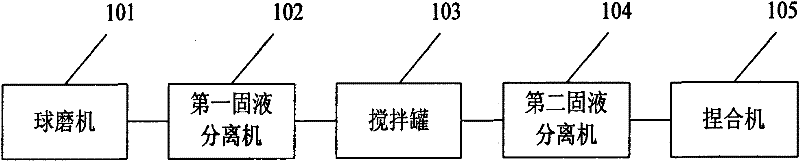

[0030] figure 1 It is a structural schematic diagram of the production device of the pasty zinc flake pigment in the specific embodiment of the present invention. Such as figure 1 As shown, the production device includes a grinder 101 , a first solid-liquid separator 102 , a stirring tank 103 , a second solid-liquid separator 104 and a kneader 105 .

[0031] The grinding machine is used to grind the material containing spherical zinc powder, grinding modifier and grinding aid solvent prepared in proportion. The grinding machine is a stirring grinding machine or a drum grinding machine, and the grinding balls are stainless steel balls, alumina balls Or zirconia balls, the diameter of the grinding balls is 1 to 15 mm, preferably 3 to 7 mm, the weight ratio of grinding balls to spherical zinc powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com