High-energy zinc-manganese battery

A zinc-manganese battery, high-energy technology, used in dry batteries, battery electrodes, aqueous electrolyte batteries, etc., can solve the problems of short battery life, low specific energy, and insufficient combination of positive electrode materials and steel shell current collectors. The effect of affinity and strong liquid absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will further illustrate the technical solution of the invention through the following embodiments in conjunction with the accompanying drawings.

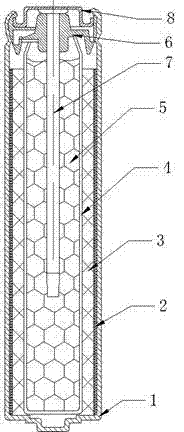

[0030] Such as figure 1 As shown, a high-energy zinc-manganese battery includes a steel shell 1, a carbon nanotube conductive paper 2, a positive electrode ring 3, a zinc paste 4, a separator paper 5, a sealing ring 6, a copper nail 7 and a negative electrode cover 8.

[0031] The present invention adds a layer of carbon nanotube conductive paper 2 between the steel shell 1 and the positive electrode ring 3 as the current collector of the positive electrode, thereby improving the utilization rate of the battery positive electrode material and greatly increasing the discharge time of the zinc-manganese battery.

[0032] The production of carbon nanotube conductive paper:

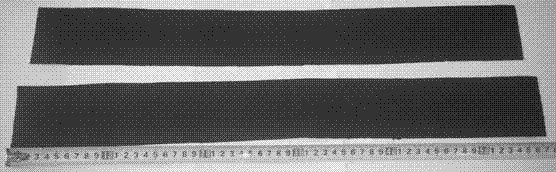

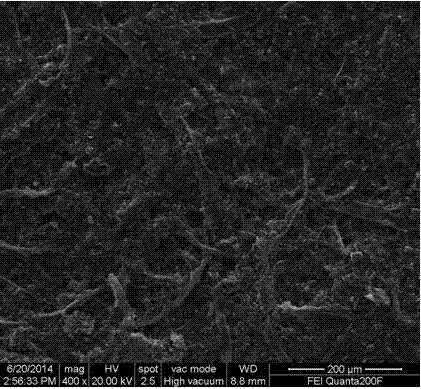

[0033] Take 2g of carbon nanotubes and heat them in a microwave oven for 5 minutes. After chemical purification and surface modification, the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com