Alkaline manganese battery negative electrode zinc paste additive and application thereof

An alkaline-manganese battery and additive technology, which is applied to battery electrodes, dry batteries, circuits, etc., can solve the problems of acceleration of zinc polarization at the negative electrode of discharge current density, and achieve the effects of increased current density, long service life, and strong power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

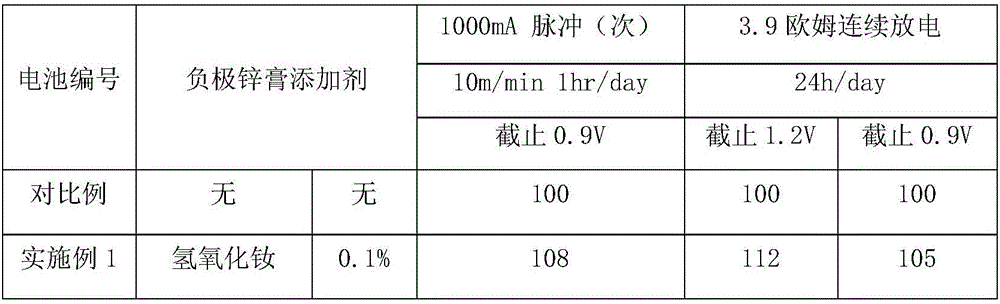

Embodiment 1

[0018] (1) Fully mix the active material manganese dioxide, conductive graphite, and HA1681 according to the weight ratio of 160:11.5:0.8, then add an alkaline electrolyte (KOH solution) with a mass of 3% of the solid material, stir evenly, and use 120kgf / cm 2 The pressure is pressed into tablets, and then granulated and sieved to form positive electrode particles with a certain particle size distribution, and then the positive electrode ring is made by compression molding.

[0019] (2) Mix zinc powder, polyacrylic acid sodium and indium compound (indium oxide and / or indium hydroxide) in a ratio of 80:1:0.05, and then add them to the alkaline electrolyte (in which the concentration of KOH is 32%, the oxidation The zinc content is 1%) for vacuum-pumping and stirring, and finally adding a negative electrode zinc paste additive (neodymium hydroxide) of 0.01% by mass of zinc powder, and stirring evenly to obtain the negative electrode zinc paste.

[0020] (3) Assemble the positive...

Embodiment 2

[0028] Compared with Example 1, this example differs in that the formula of negative electrode zinc paste is different: the mass ratio of zinc powder, sodium polyacrylate and indium compound (indium oxide) is 120:1:0.05; the concentration of KOH in the alkaline electrolyte is 42%, and the zinc oxide content is 5%; the addition amount of the negative electrode zinc paste additive (neodymium trioxide) is 2% of the zinc powder mass, and the rest are identical.

Embodiment 3

[0030] Compared with Example 1, this example differs in that the formula of negative electrode zinc paste is different: the mass ratio of zinc powder, sodium polyacrylate and indium compound (indium oxide and / or indium hydroxide) is 100:1:0.05; The concentration of KOH in the electrolyte is 40%, the content of zinc oxide is 3%; the addition amount of the negative electrode zinc paste additive (made by mixing neodymium trioxide and neodymium hydroxide at a mass ratio of 1:2) is 0.1% of the mass of zinc powder, The rest is exactly the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com