Zinc air battery with microporous membrane

A zinc-air battery, microporous membrane technology, applied in battery electrodes, fuel cell components, circuits, etc., can solve problems such as easy water loss, and achieve the effects of reducing water evaporation, improving performance, and prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to have a further understanding and understanding of the structural features of the present invention and the effects achieved, the preferred embodiments and accompanying drawings are used in conjunction with detailed descriptions, and the descriptions are as follows:

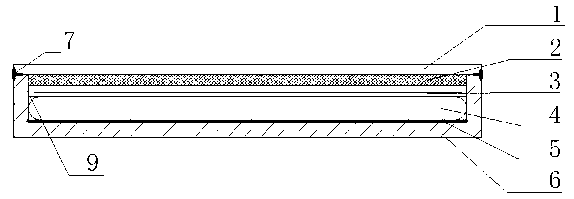

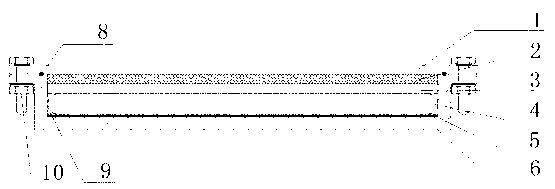

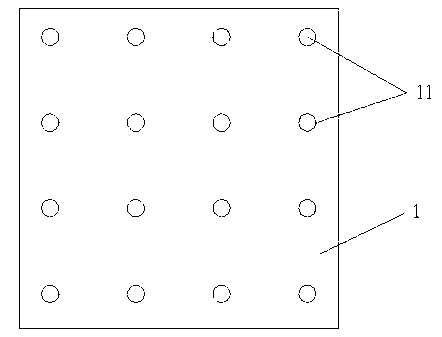

[0030] like figure 1 As shown, a zinc-air battery with a microporous membrane according to the present invention mainly includes an air electrode consisting of a microporous membrane 1 covering a gas diffusion electrode 2, a zinc electrode consisting of a current collector 5 and a zinc coating paste 4, Separator 3 and battery cell 6. The gas diffusion electrode 2 and the current collector 5 are respectively drawn out through wires as the positive and negative electrodes of the battery. The current collector 5 is placed in sequence on the battery tank 6 with the bottom sealed horizontally placed, and the zinc paste 4 is laid flat to cover the diaphragm 3 and inject a certain amount of The elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com