Method for producing zinc-air battery

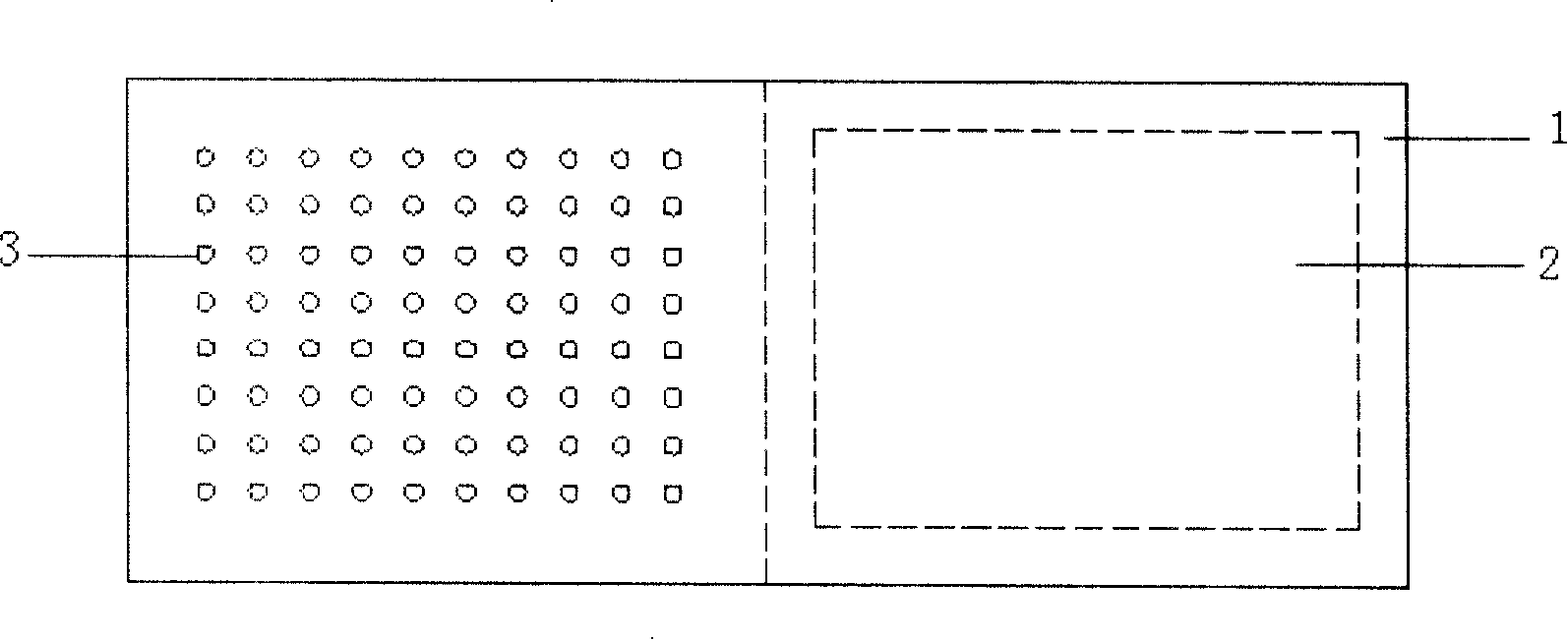

A technology of air battery and cavity preparation, which is applied in the direction of fuel cell half-cell and primary battery half-cell, etc. It can solve the problems of complex manufacturing process and easy leakage of battery, and achieve simple process, not easy to leak, Thin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

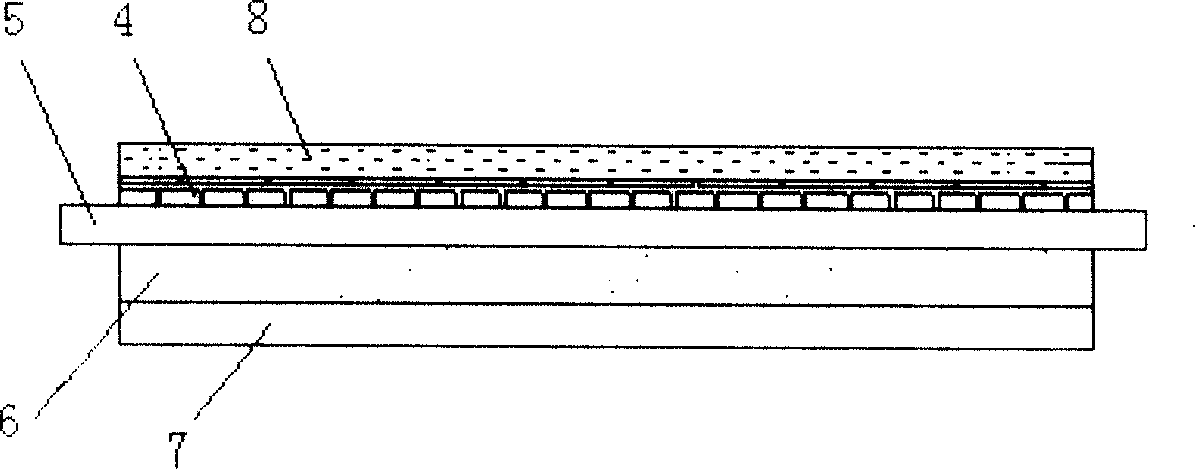

[0027] Wherein the preparation of air positive electrode is well known to those skilled in the art, for example, can adopt the catalyst (catalyst can be MnO 2 or MnO 2 -Co), activated carbon, acetylene black, and anhydrous sodium sulfate were added to a ball mill for ball milling for 30 minutes, then deionized water was added, and the quality of deionized water was 5 times that of the total mass of the solid, and after stirring evenly, adding a PTFE emulsion with a concentration of 60% , wherein the mass of the solids in the PTFE emulsion accounts for 15% of the total mass of the solids in the slurry. After stirring evenly with a glass rod, a homogeneously dispersed catalytic layer slurry is obtained, which is coated on the foamed nickel, and then together with the PTFE waterproof and breathable membrane to form an air electrode.

[0028] The preparation of colloidal zinc paste negative electrode is well known to those skilled in the art. For example, alloy zinc powder can be...

Embodiment 1

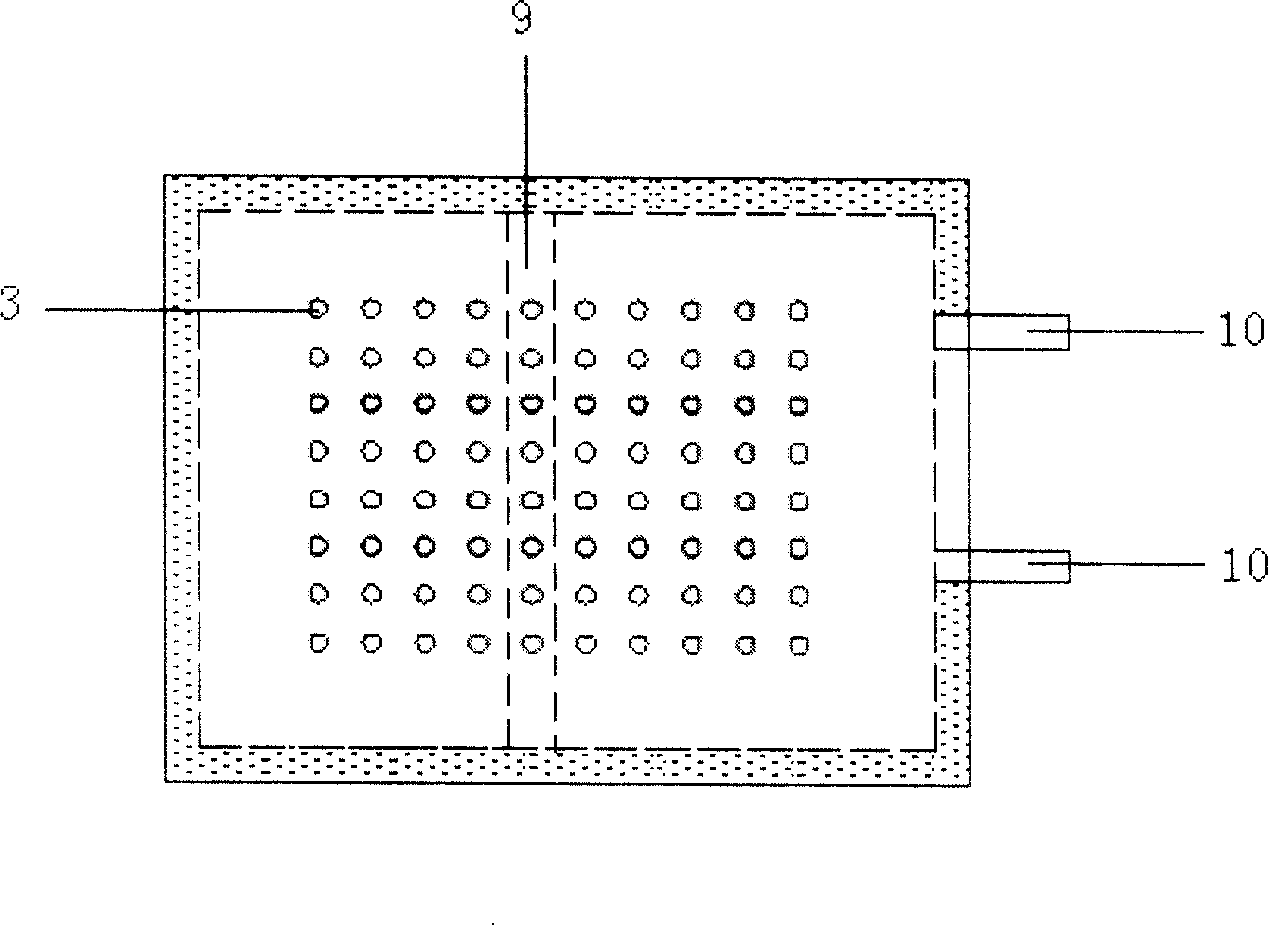

[0031] This example is used to illustrate the preparation method of the zinc-air battery provided by the present invention and the zinc-air battery produced is not easy to leak.

[0032] (1) Preparation of air cathode

[0033] Catalyst MnO with a mass ratio of 3:2:2:1.5 2 , gac, acetylene black, sodium sulfate anhydrous join in the ball mill and ball mill for 30 minutes, add deionized water, the quality of deionized water is 5 times of solid total mass, after stirring, adding concentration is 60% polytetrafluoroethylene ( PTFE) emulsion, wherein the quality of the solid in the polytetrafluoroethylene (PTFE) emulsion accounts for 15% of the solid total mass in the slurry, after being stirred evenly with a glass rod, the catalytic layer slurry that is dispersed is obtained, and coated on the nickel foam, Then cover polytetrafluoroethylene (PTFE) waterproof and breathable membrane, and finally cut into small pieces of 6 × 4 square centimeters to obtain air positive electrodes, e...

Embodiment 2

[0040] This example is used to illustrate that the zinc-air battery produced by the zinc-air battery preparation method provided by the present invention is not easy to leak.

[0041] The 100 zinc-air batteries produced in Example 1 were sealed and placed for 24 hours before discharge, and no liquid seeped out was observed. Use the BS9300 battery tester to continuously discharge the battery at a constant current of 200 mA, the discharge capacity is 1000 mA hours, the open circuit voltage of the battery is 1.4 volts, and the average operating voltage is 1.2 volts. During the discharge process, it was observed that no liquid seeped out, and after the discharge was completed and placed for 24 hours, there was still no liquid seeped out through observation.

[0042] Through the measurement, it is shown that the zinc-air battery prepared by the method provided by the invention is not easy to leak.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com