Zinc paste, preparation method thereof and zinc-manganese battery

A zinc-manganese battery and zinc paste technology, which is applied to battery electrodes, secondary batteries, circuits, etc., can solve problems such as obvious stratification, unsuitable batteries, and inability to fuse zinc paste, and achieve low cost, corrosion inhibition, and short process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] This embodiment provides a zinc paste, and the zinc paste is mainly composed of a zinc-containing material, an indium-containing material, a binder, a thickener and an electrolyte.

[0064] The zinc-containing material is zinc powder with a purity of 99.95%, and the indium-containing material is In(OH) 3 , the binder is pregelatinized starch, and the thickener is sodium carboxymethyl cellulose.

[0065] The electrolyte is 3mol / L ZnCl 2 solution, the solvent is deionized water, the volume of the electrolyte and the zinc powder are equal, and the pH of the electrolyte is 3.5.

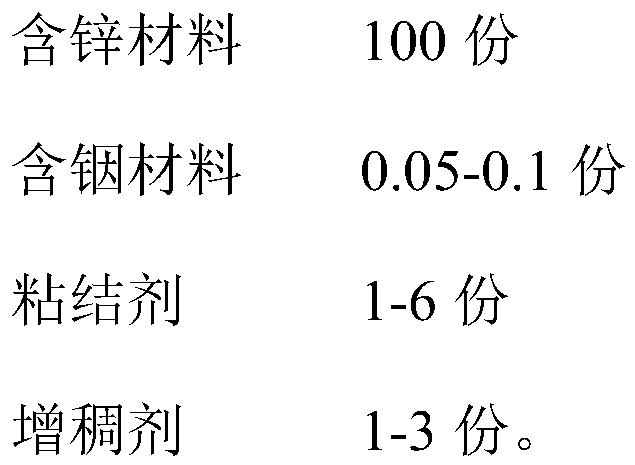

[0066] In the zinc paste, the quality of zinc-containing material, indium-containing material, binder and thickener is respectively:

[0067]

[0068] The present embodiment also provides a kind of preparation method of above-mentioned zinc paste, and its specific method is:

[0069] Preparation of zinc paste: weighed Zn powder, In(OH) 3 , pregelatinized starch, and CMC, and manually stir ev...

Embodiment 2

[0072] This embodiment provides a zinc paste, and the zinc paste is mainly composed of a zinc-containing material, an indium-containing material, a binder, a thickener and an electrolyte.

[0073] The zinc-containing material is zinc powder with a purity of 99.95%, and the indium-containing material is In(OH) 3 , the binder is pregelatinized starch, and the thickener is sodium carboxymethyl cellulose.

[0074] The electrolyte is 2mol / L ZnSO 4 solution, the solvent is deionized water, the volume of the electrolyte and the zinc powder are equal, and the pH of the electrolyte is 4.7.

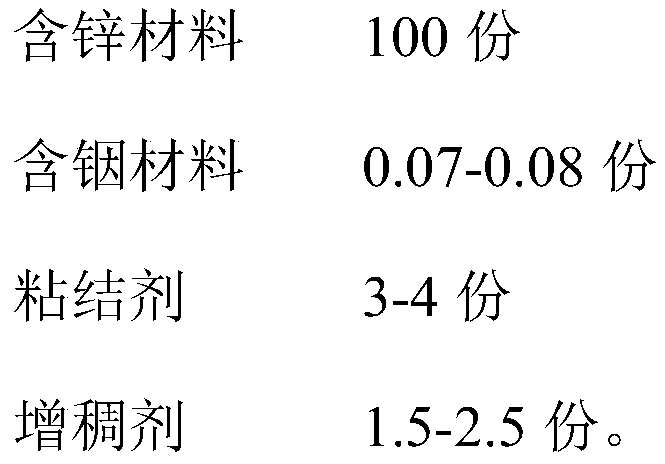

[0075] In the zinc paste, the quality of zinc-containing material, indium-containing material, binder and thickener is respectively:

[0076]

[0077] The present embodiment also provides a kind of preparation method of above-mentioned zinc paste, and its specific method is:

[0078] Preparation of zinc paste: weighed Zn powder, In(OH) 3 , pregelatinized starch, and CMC, and manually stir ev...

Embodiment 3

[0081] This embodiment provides a zinc paste, and the zinc paste is mainly composed of a zinc-containing material, an indium-containing material, a binder, a thickener and an electrolyte.

[0082] The zinc-containing material is zinc powder with a purity of 99.95%, and the indium-containing material is In(OH) 3 , the binder is pregelatinized starch, and the thickener is sodium carboxymethyl cellulose.

[0083] The electrolyte is 1mol / L ZnSO 4 +0.2mol / L MnSO 4 solution, the solvent is deionized water, the volume of the electrolyte and the zinc powder are equal, and the pH of the electrolyte is 5.2.

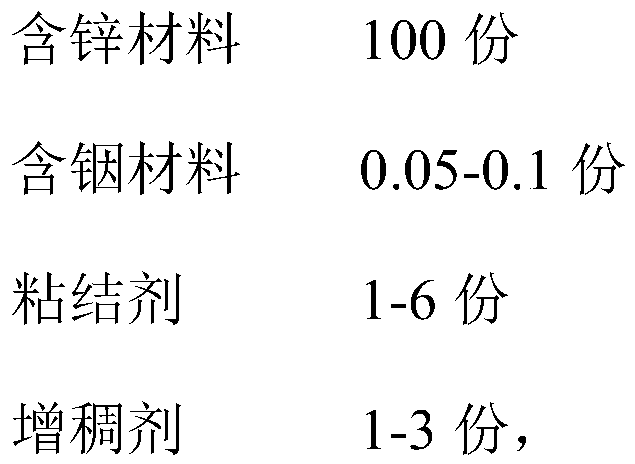

[0084] In the zinc paste, the quality of zinc-containing material, indium-containing material, binder and thickener is respectively:

[0085]

[0086] The present embodiment also provides a kind of preparation method of above-mentioned zinc paste, and its specific method is:

[0087] Preparation of zinc paste: weighed Zn powder, In(OH) 3 , pregelatinized starch, and CMC, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com