Environment-friendly alkaline battery production process

An alkaline battery and production process technology, applied in the field of environmentally friendly alkaline battery production technology, can solve problems such as easy leakage of electrolytes, and achieve the effects of reliable connection, prevention of leakage, and avoidance of leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The following is attached Figure 1-8 The application is described in further detail.

[0050] The embodiment of the application discloses a production process of an environment-friendly alkaline battery, comprising the following steps:

[0051] Step 1: Prepare the battery case 1, specifically through the following steps;

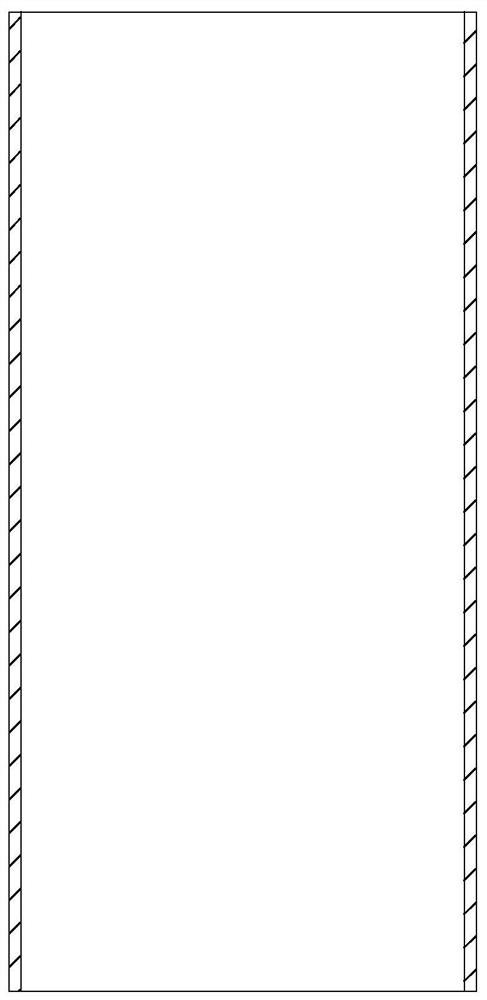

[0052] Step 101: Stretch the circular battery plate, and form the battery plate into a first green body with a preset inner diameter and a preset height, such as figure 1 shown;

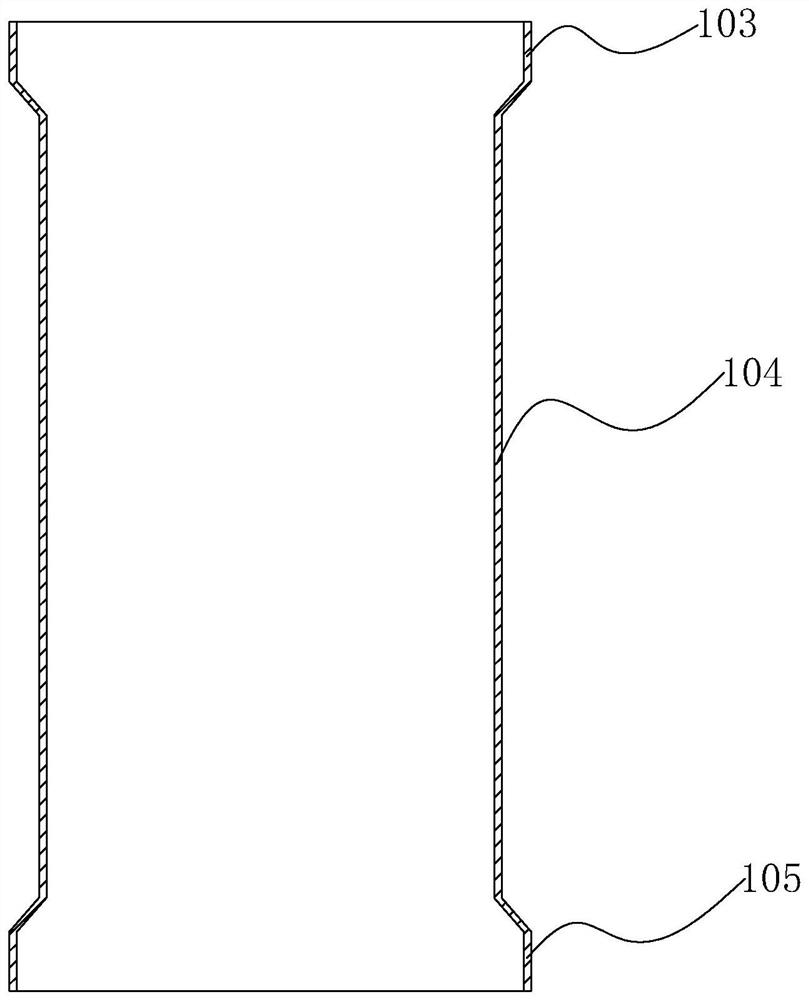

[0053] Step 102, using a flaring die to expand the inner diameter of the upper section 103 and the lower section 105 of the first blank to form a second blank with a larger inner diameter of the upper section 103 and lower section 105 and a smaller inner diameter of the middle section 104, such as figure 2 shown;

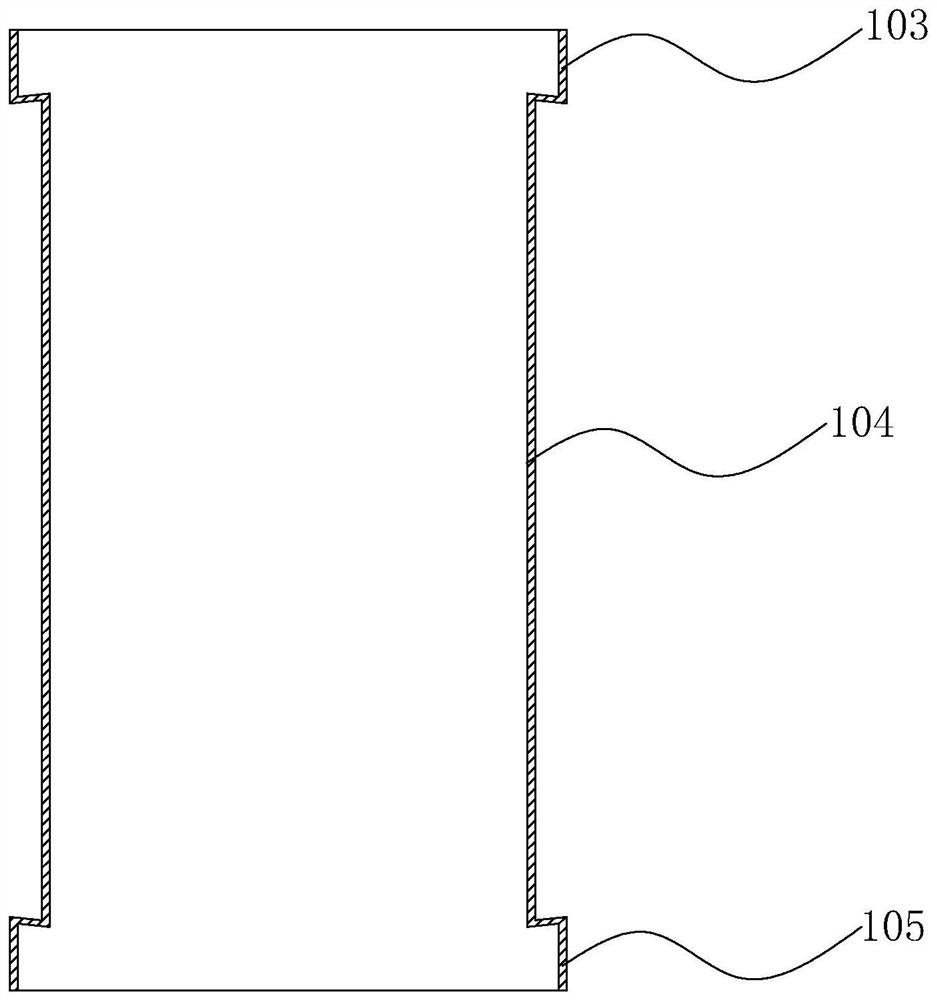

[0054] Step 103, extruding the upper section 103 and the lower section 105 of the second green body toward the direction of the middle section 104 to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com