Anode of zinc air battery using zinc paste and manufacturing method thereof

A zinc-air battery and zinc paste technology, applied in electrode manufacturing, battery electrodes, fuel cell-type half-cells and primary battery-type half-cells, etc., can solve problems such as self-discharge, and achieve environmental protection and low energy consumption in the production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Step 1: Make zinc paste according to the conventional method, which is composed of zinc powder: sodium polyacrylate: water: KOH with a mass ratio of 65g: 1g: 21g: 14g, and mix the above materials evenly to make zinc paste.

[0012] Step 2: Freeze-dry the prepared zinc paste at -80°C in cold hydrazine, and vacuum-dry until the dehydration is complete to obtain the anode active material.

[0013] Step 3: Press the anode active material and the current collector copper mesh through a roller machine or a press to make a high-performance zinc anode that can be stored for a long time.

[0014] Step 4: Assemble into a zinc-air battery, and let it stand for 5 months under vacuum.

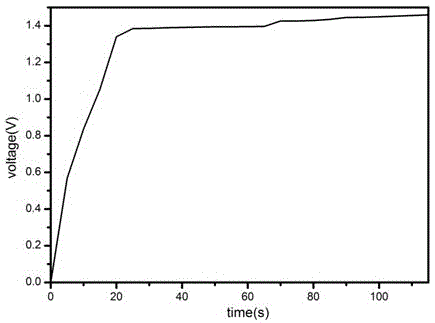

[0015] Step 5: Add water into the water inlet until the battery is fully filled, and let it stand for 10 minutes.

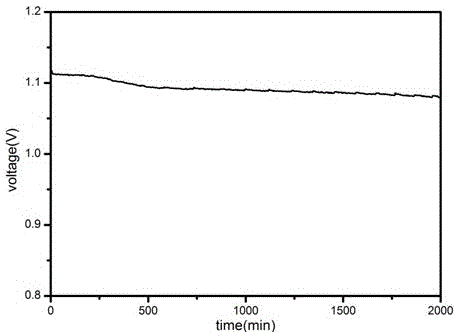

[0016] Step 6: Test its discharge curve under the charge and discharge tester.

[0017] The result is that the zinc-air battery has better discharge performance, and the discharge can...

Embodiment 2

[0019] Step 1: Make zinc paste according to the conventional method, which is composed of zinc powder: sodium hydroxymethylcellulose: water: KOH with a mass ratio of 75g: 1.2g: 28g: 20g, and mix the above materials evenly to make zinc paste .

[0020] Step 2: Freeze-dry the prepared zinc paste at -80°C in cold hydrazine, and vacuum-dry until the dehydration is complete to obtain the anode active material.

[0021] Step 3: Press the anode active material and the current collector copper mesh through a roller machine or a press to make a high-performance zinc anode that can be stored for a long time.

[0022] Step 4: Assemble into a zinc-air battery, and let it stand for 5 months under vacuum.

[0023] Step 5: Add water into the water inlet until the battery is fully filled, and let it stand for 10 minutes.

[0024] Step 6: Test its discharge curve under the charge and discharge tester.

[0025] The result is that the zinc-air battery has better discharge performance, and the...

Embodiment 3

[0027] Step 1: Make zinc paste according to the conventional method, which is composed of zinc powder: sodium hydroxymethylcellulose: sodium polyacrylate: water: KOH, the mass ratio is 65g: 0.2g: 0.8: 28g: 20g, mix the above materials Evenly make zinc paste.

[0028] Step 2: Freeze-dry the prepared zinc paste at -80°C in cold hydrazine, and vacuum-dry until the dehydration is complete to obtain the anode active material.

[0029] Step 3: Press the anode active material and the current collector copper mesh through a roller machine or a press to make a high-performance zinc anode that can be stored for a long time.

[0030] Step 4: Assemble into a zinc-air battery, and let it stand for 5 months under vacuum.

[0031] Step 5: Add water into the water inlet until the battery is fully filled, and let it stand for 10 minutes.

[0032] Step 6: Test its discharge curve under the charge and discharge tester.

[0033] The result is that the zinc-air battery has better discharge perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com