Negative electrode zinc paste and alkaline battery therewith

A technology of alkaline batteries and negative electrolyte, applied in dry batteries, battery electrodes, circuits, etc., can solve the problems of battery leakage, easy over-discharge, and easy battery leakage, etc., to reduce the leakage rate, reduce the amount of gas evolution, Effect of improving discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Alkaline batteries of the control group were prepared. In the control group, the negative electrode electrolyte was prepared according to the distribution ratio of each group in Table 1, and the negative electrode zinc paste was prepared according to the ratio in Table 2 to make a control battery.

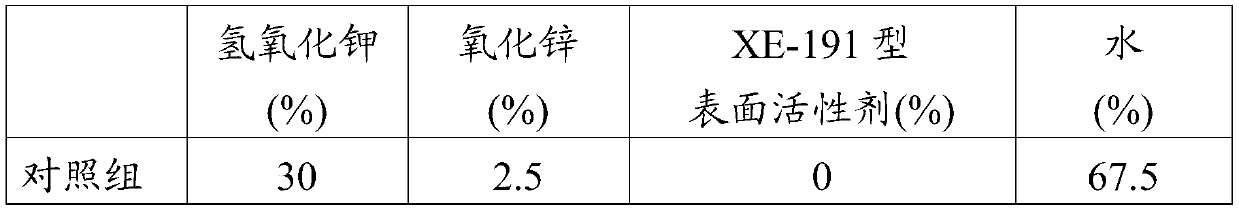

[0042] Table 1 The proportioning ratio of each component of the negative electrode electrolyte

[0043]

[0044] The negative electrode electrolyte in the above control group does not contain surfactant.

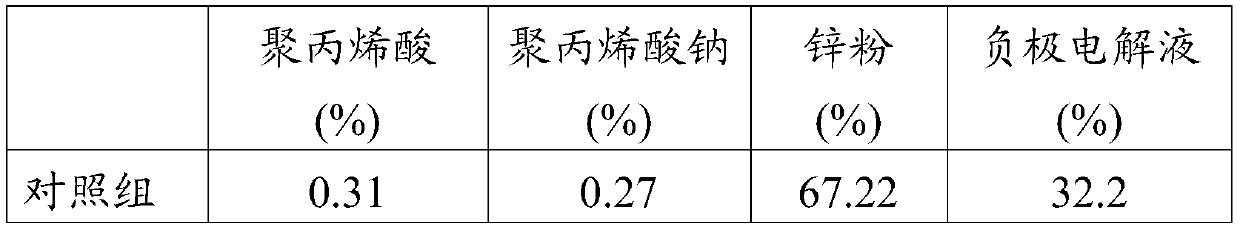

[0045] The proportioning ratio of each component of negative electrode zinc paste of table 2

[0046]

Embodiment 2

[0048] Alkaline batteries of test groups 1 to 3 were prepared. In each test group, the negative electrode electrolyte was prepared according to the proportions of each group in Table 3, and the negative electrode zinc paste was prepared according to the proportions in Table 4 to make test batteries.

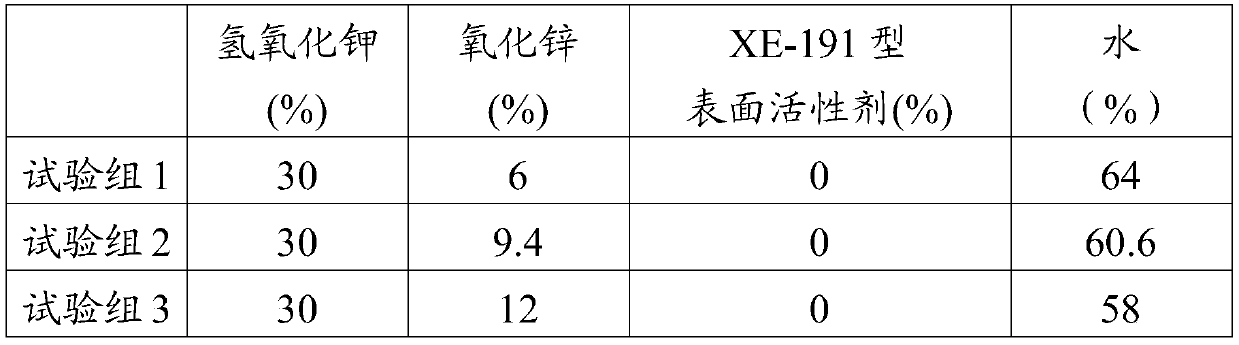

[0049] The proportioning ratio of each component of negative electrode electrolyte of table 3

[0050]

[0051] The negative electrode electrolytes in the above-mentioned test groups 1 to 3 did not contain surfactants.

[0052] The proportioning ratio of each component of negative electrode zinc paste of table 4

[0053]

Embodiment 3

[0055] Alkaline battery over-discharge test

[0056] The above-mentioned control group and test groups 1 to 3 were subjected to a 10 ohm overdischarge test and a simulated motor discharge test.

[0057] Battery over-discharge means that the battery continues to discharge after the discharge exceeds the cut-off voltage. For example, the 10-ohm discharge cut-off voltage of an LR6 battery is 0.9V. Over-discharge refers to the case where the cut-off voltage is less than 0.9V. For example, less than 0.8V, 0.6, 0V, etc. belong to the battery The case of overdischarge. Under normal circumstances, if the battery is not over-discharged, the gas volume of the battery is very small, and the battery will not leak, but once the battery is over-discharged, the gas volume of the battery will increase significantly. Leakage occurs. The discharge methods of alkaline batteries in electrical appliances are mainly divided into constant power discharge, constant current discharge, constant resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com