Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75 results about "Vegetable oil refining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vegetable oil refining is a process to transform vegetable oil into biofuel by hydrocracking or hydrogenation. Hydrocracking breaks big molecules into smaller ones using hydrogen while hydrogenation adds hydrogen to molecules. These methods can be used for production of gasoline, diesel, propane, and other chemical feedstock. Diesel fuel produced from these sources is known as green diesel or renewable diesel.

Vegetable oil refining

InactiveUS6844458B2Risk minimizationSpeed up the processFatty oils/acids recovery from wasteOrganic compound preparationOrganic acidVegetable oil

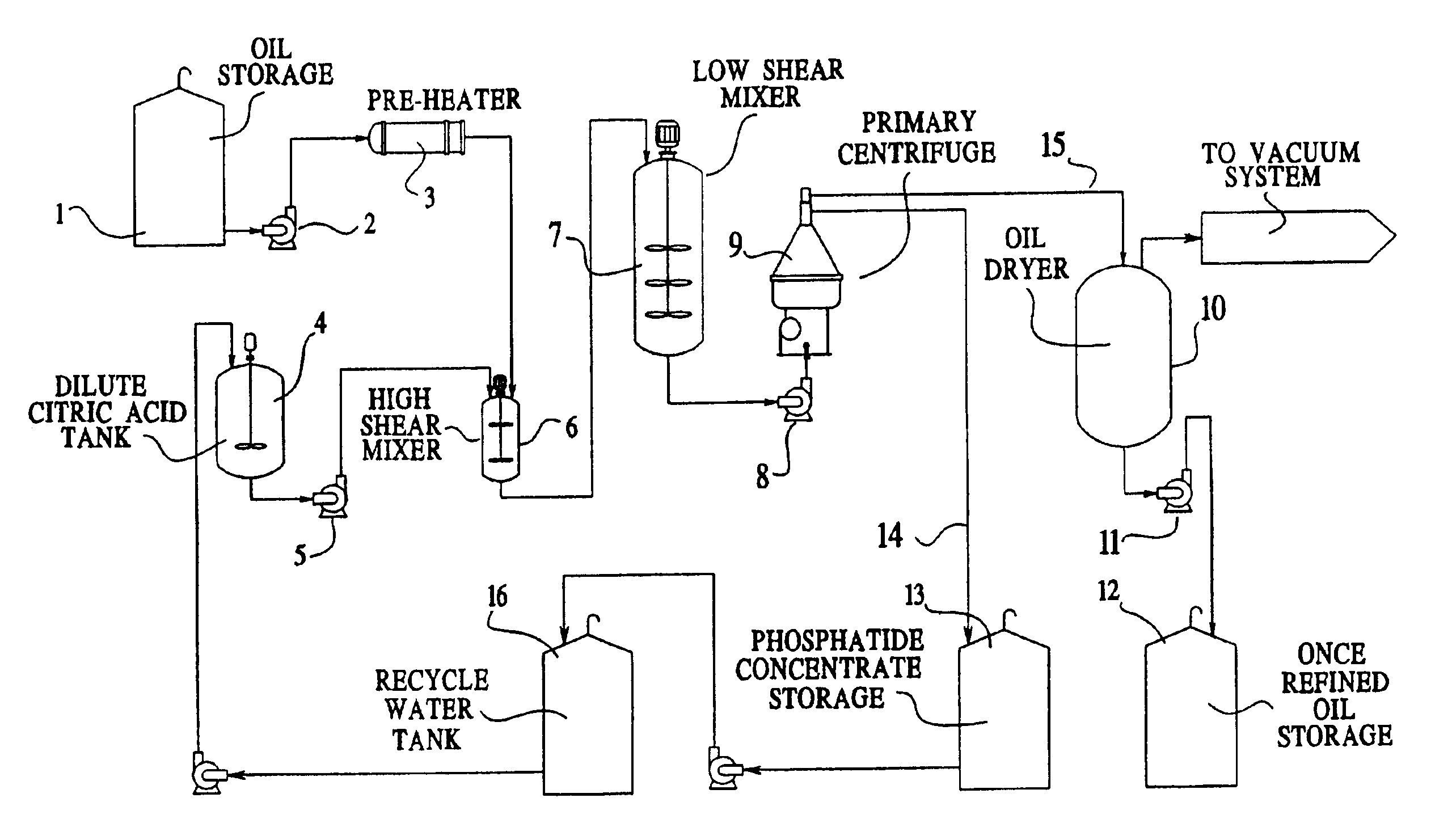

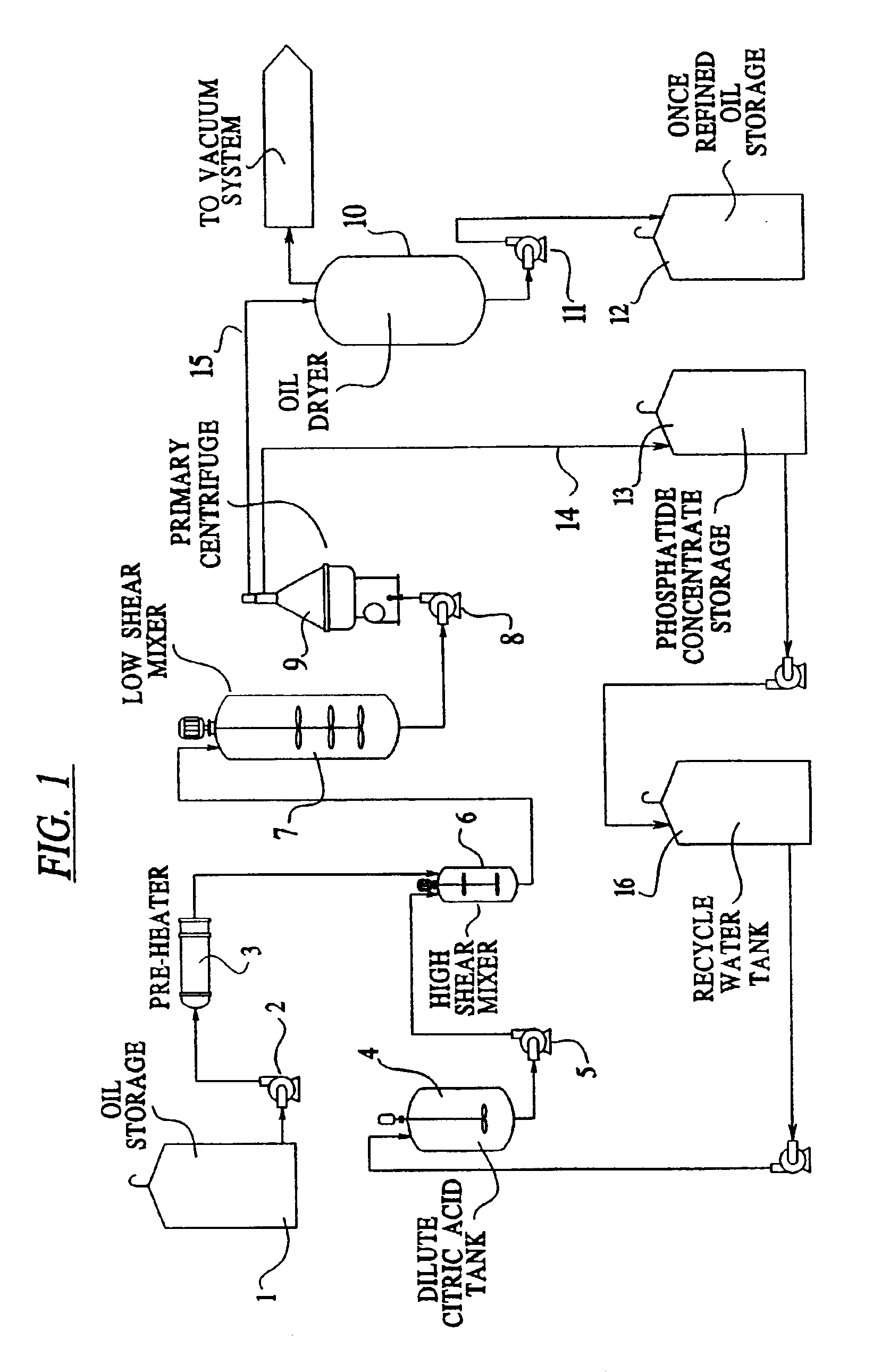

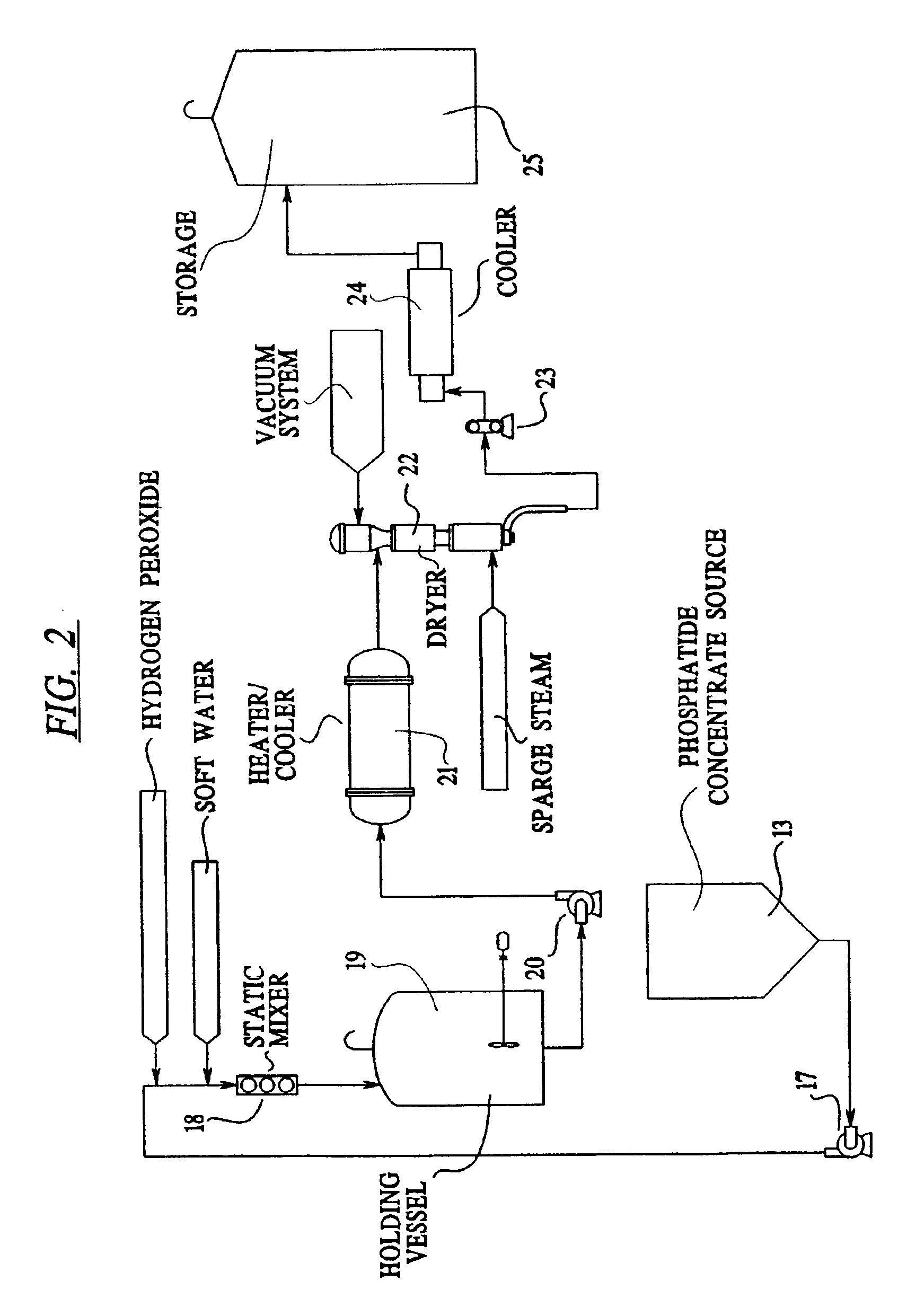

The present invention relates to improved methods for refining vegetable oils. Vegetable oil is combined with organic acid and subjected to high shear to finely disperse the acid solution in the oil. The resulting acid-and-oil mixture is mixed at low shear for a time sufficient to sequester contaminants into a hydrated impurities phase, producing a purified vegetable oil phase.

Owner:IP HLDG LLC

Process for separation of tocopherols

InactiveUS6867308B2Easy loadingHigh resolutionBiocideOrganic active ingredientsOrganic solventVegetable oil refining

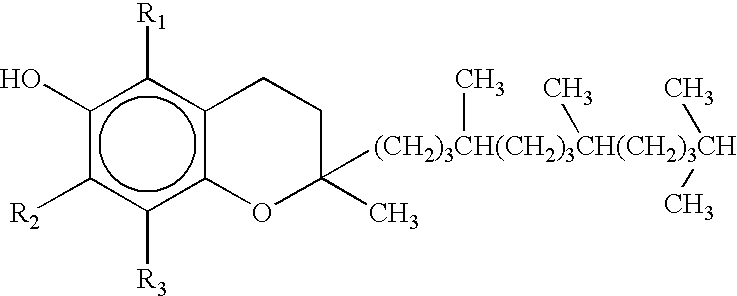

A process for separation of specific tocopherols from a mixture of tocopherols is disclosed. The process includes methods of separation of the tocopherols from residues of vegetable oil refining and other various food sources by dissolving in organic solvents and eluting over non-ionic adsorbent resins.

Owner:ARCHER DANIELS MIDLAND CO

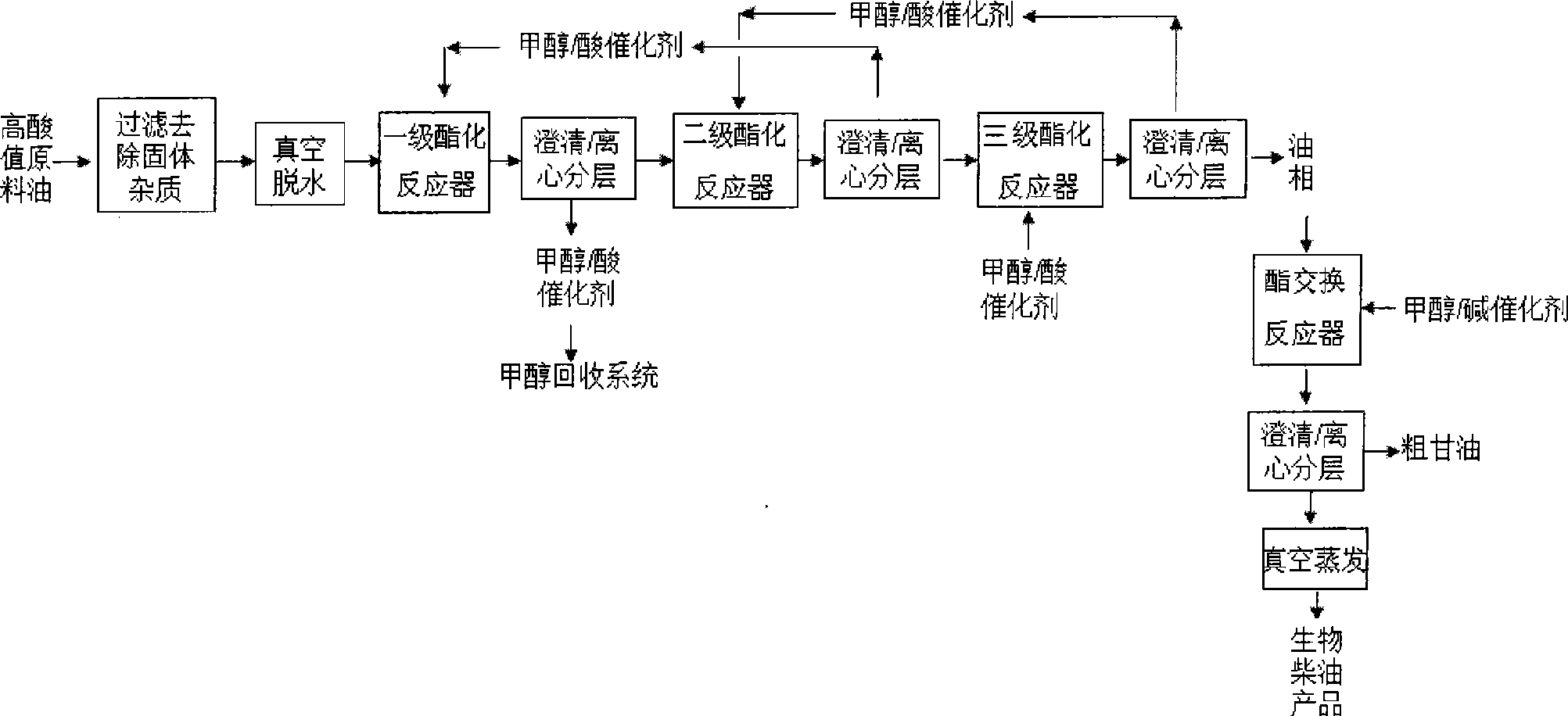

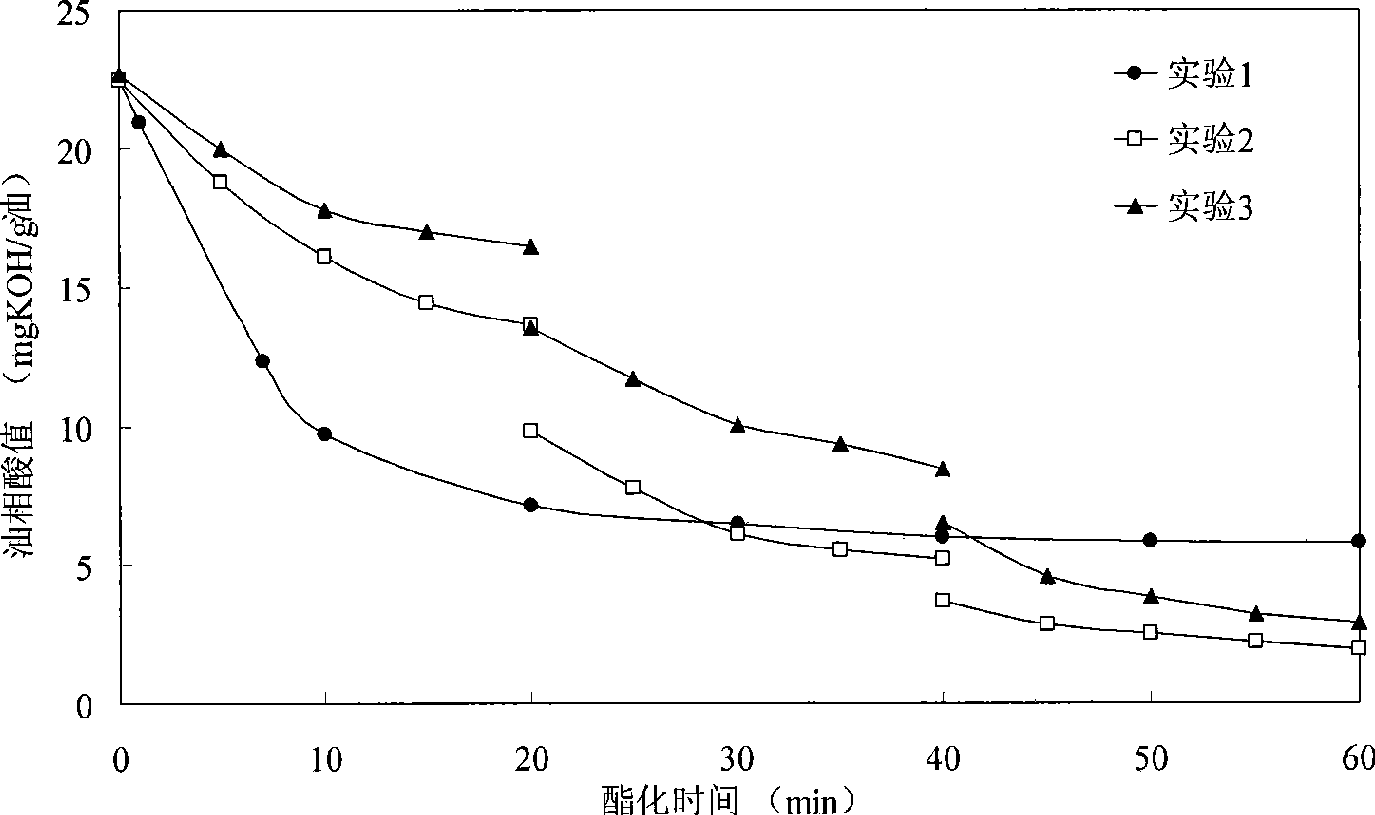

Method for preparing biodiesel by utilizing stratified and graded esterified deacidification of high acid value oil

InactiveCN101445742AHigh reaction conversion rateNot easy to carbonizeBiofuelsLiquid hydrocarbon mixture productionOil and greaseFiltration

The invention provides a method utilizing high acid value oil as raw material for preparing biodiesel. Various animal and vegetable oil, the acid value of which is larger than 3.0mg KOH / g oil, oilstock, soapstock and acidic oil in a vegetable oil refining process, various food waste oil (restaurant waste oil, hogwash oil, trench waste oil, and the like) and various waste animal oil in industrial processing (waste animal oil in leather processing, waste animal oil in slaughtering process, and the like) are used as raw materials to obtain biodiesel products by filtration for removing solid impurities, vacuum dehydration, stratified graded acid catalytic esterification, alkali catalytic transesterification and vacuum distillation. The method utilizing the high acid value oil as the raw material for preparing the biodiesel has the beneficial effect that the production process can be applied to raw materials with different acid values to produce biodiesel products with high purity by changing the operational series of the stratified graded acid catalytic esterification reaction and has the advantages of simple process, low energy consumption, high conversion rate and small device. And continuous production can be realized.

Owner:ZHEJIANG UNIV OF TECH

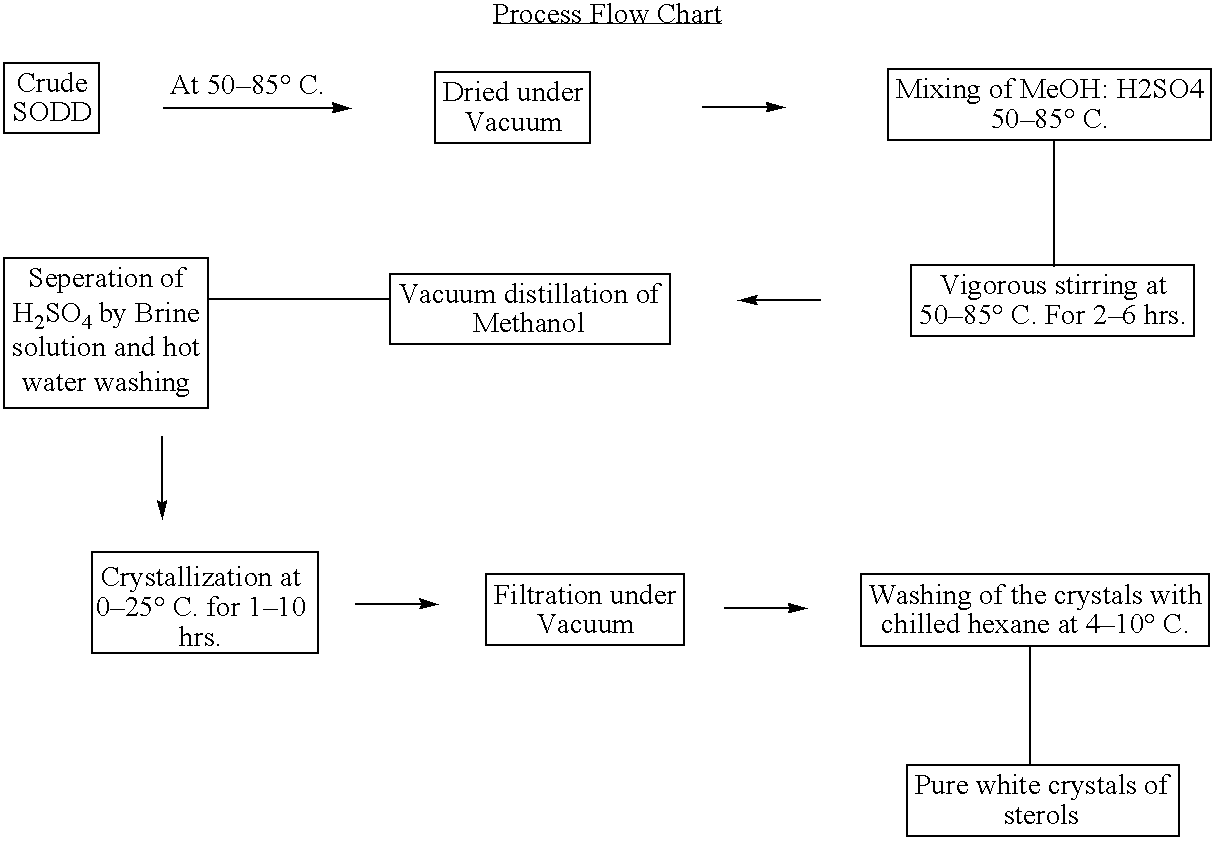

Process for the preparation of high purity phytosterols from deodourizer distillate from vegetable oils

InactiveUS20070142652A1Reduce in quantitySimple and economically more viable processFatty oils/acids recovery from wasteAlcoholic beverage preparationPlant sterolVegetable oil

The present invention provides an isolation process of the pure sterols from the SODD by simple acid catalyzed esterification and the separation of the reagents by distillation and water washing followed by the crystallization of phytosterols and purification. Soybean oil deodorizer distillate (SODD) and distillate from other vegetable oil refining contain free sterols, in addition to steryl esters, tocopherols squalene and unknown compounds. The process is also applicable to other vegetable oil distillate containing more than 1% phytosterols in the free form. Phytosterols thus obtained is of high purity (95-99%) and high yield (80-90%) and contains β-sitosterol, Stigmasterol and campesterol.

Owner:COUNCIL OF SCI & IND RES

Oil refining method

ActiveCN103740462AImprove degumming effectPrevent oxidationFatty-oils/fats refiningOil and greasePartial hydrolysis

The invention discloses an oil refining method. The oil refining method comprises a degumming process, a first refining process, a secondary refining process and a deacidification and deodorization process. The degumming effect of an enzymic degumming method is better, and the phosphorus content after the enzymic degumming can be reduced to an ideal index less than 5ppm; the oil refining can be completed under the conditions of high vacuum degree (0.1 to 10Pa) and short-time heat treatment (less than or equal to 3 seconds), and the oxidization and partial hydrolysis of the oil and generation of harmful substances (such as trans-acid, polymerized glyceride and the like) can be avoided; the core sections (refining and deacidification and deodorization) of the method belong to physical methods, no chemical additive is added in the operation process of the two sections, no waste water pollution is produced, and reference can be provided for improving an existing vegetable oil refining process.

Owner:陈汉卿

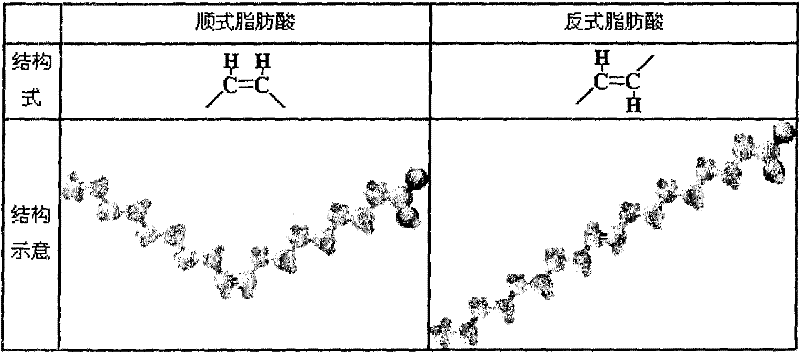

A kind of lower trans fatty acid edible vegetable oil and refining method thereof

InactiveCN102273522ALight colorHigh smoke pointFatty-oils/fats refiningEdible oils/fatsOil and greaseVegetable oil

The invention relates to fully refined edible vegetable oil with lower trans fatty acid and a refining method thereof. The vegetable oil is rapeseed oil, soybean oil, corn oil or blending oil with any ratio; the trans fatty acid content of the vegetable oil is less than or equal to 1 weight percent; and the oil smoke point is more than or equal to 210 DEG C. The refining method comprises the steps of selecting crude oil, degumming, deacidifying, removing saponin, dehydrating, decoloring, removing impurities, deoxidizing, deodorizing, cooling and obtaining finished products. The refining method is characterized in that: at the decoloring state, the removing grain size of the impurities is reduced from 25 mu m to 10 mu m; and at the deodorizing stage, the deodorizing temperature is controlled to be between 230 and 245 DEG C and the vacuum degree is controlled to be within 2 tau. Oil is refined at lower temperature and a lowest trans fat structure is realized by controlling the grain size of the impurities and the vacuum degree; after being refined, the vegetable oil has good quality, namely the trans fatty acid is reduced to be lower than 60 percent of the normal level; and the refined vegetable oil has light color, high smoke point, high purity and storage resistance and is beneficial to people's long-term health.

Owner:SHENZHEN NANSHUN GREASE

Technology for deodorizing vegetable oil with high content of unsaturated acid

ActiveCN101649250AReduce hydrolysisReduce aggregationFatty-oils/fats refiningVegetable oilAcid value

The invention relates to technology for deodorizing vegetable oil with high content of unsaturated acid, belonging to the technical field of vegetable oil refining. In the technology, two vacuum heatexchangers with the same structure are employed for heat exchanging and heating; a tray deodorization tower and a packing deodorization tower are employed to form double towers for deodorization in sequence. The obvious characteristics of adopting the vacuum heat exchangers for heat exchanging and heating are as follows: the energy is saved and the oil is slowly heated under high vacuum. By adopting the double towers for deodorization in sequence, such indexes as acid value, smoke point, color and the like of the vegetable oil with high content of unsaturated acid can be effectively improved,thus strongly ensuring that the final oil products satisfy the high standard requirements of the clients. The technology is suitable for processing the vegetable oil which has high content of unsaturated acid and is easily decomposed at high temperature, such as corn oil, and features good deodorization effect, simple operation and high comprehensive benefits.

Owner:广西北部湾粮油技术研究有限公司

Method of vegetable fat recycling from spent bleaching clay

ActiveCN106318594ASimple processShort timeFatty-oils/fats refiningFatty-oils/fats productionOil and greaseMicrowave

The invention relates to a method of vegetable fat recycling from spent bleaching clay and belongs to the field of vegetable fat processing. Based on spent bleaching clay generated in the vegetable oil refining technique as the raw material, the method comprises the steps of (1) centrifugalizing spent bleaching clay to obtain the centrifugalized spent bleaching clay and liquid I; (2) smashing the centrifugalized spent bleaching clay, adding water, performing ultrasound- microwave, then adding surface active agent, undertaking microwave demulsification after ultrasonic emulsification and recycling supernatant liquid of oil to obtain liquid II; (3) mixing and centrifugalizing liquid I and liquid II, recycling upper grease and filtering to obtain the crude oil. The method mentioned in the invention is characterized by simple technique, short time consumption, high efficiency and low cost.

Owner:SANMARK CORP

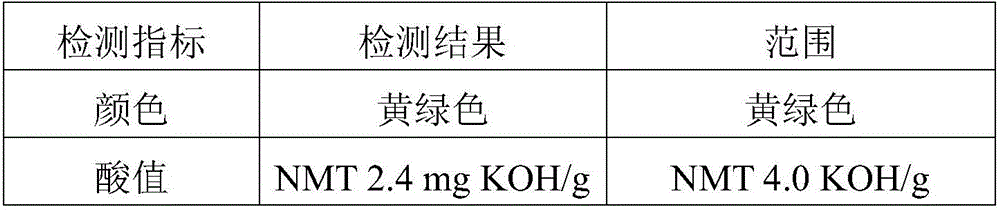

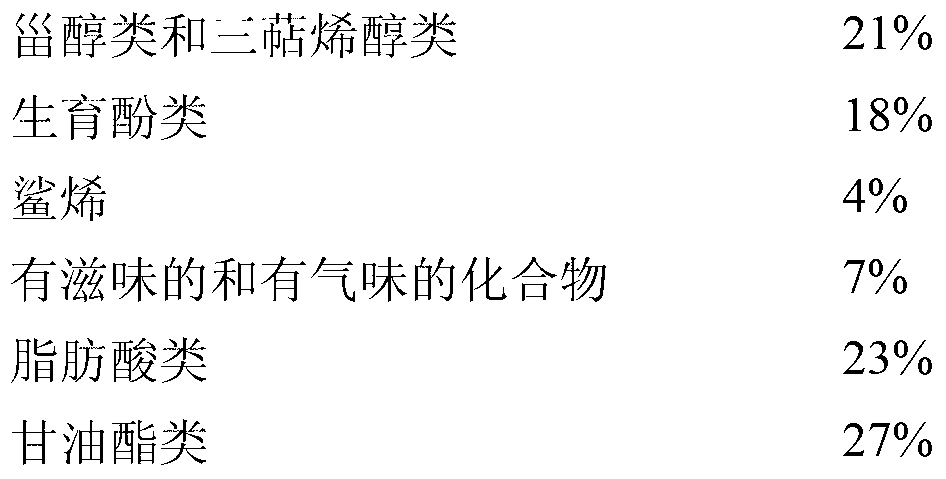

Use of at least one coproduct from the vegetable-oil refining industry for obtaining a purified total unsaponifiable vegetable oil product

ActiveCN103347990AControl evolutionControl conversionCosmetic preparationsOrganic chemistryChemical synthesisVegetable oil

The invention relates to the use of at least one coproduct of the vegetable-oil refining industry for obtaining a purified total unsaponifiable vegetable oil product which is free of the impurities initially found in said coproduct, and which is advantageously free of sapid and odorant compounds and / or of chemical compounds resulting from the breakdown and decomposition of vegetable oils. The invention also relates to a method for obtaining a purified total unsaponifiable vegetable oil product from at least one coproduct from the vegetal-oil refining industry. The invention also relates to a purified total unsaponifiable vegetable oil product that can be obtained by said method, and to compositions containing such an unsaponifiable product. The invention further relates to such unsaponifiable products or such compositions for the use thereof as a drug, medical device, dermatological agent, cosmetic agent, or nutraceutical agent for humans or animals.

Owner:LAB EXPANSCIENCE

Method for commercial preparation of conjugated linoleic acid from by-products of vegetable oil refining

InactiveUS6414171B1Increase volumeIncrease temperatureFatty acid isomerisationFatty acids production/refiningVegetable oilDouble bond

Methods for quantitative conversion of soapstock, lecithin gums, deodorizer distillate and other by-products of vegetable oil refining containing interrupted double bond systems, to products with conjugated double bonds, using a reduced amount of alkali. Less than one mole of alkali per mole of acyl group present is required, thereby greatly reducing the need for added caustic compared with methods using oils, fatty acids and esters as starting materials. The preferred starting materials are soapstocks derived from vegetable oils rich in linoleic acid.

Owner:AGRI & AGRI FOOD

Method for preparing biological diesel fuel

InactiveCN1966614AWide variety of sourcesNot affected by regionBiofuelsLiquid hydrocarbon mixture productionCost effectivenessFatty acid methyl ester

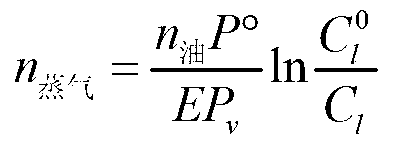

The invention disclosed a way to produce biological diesel oil which contains high pure fatty acid methyl ester. The material of the way is the physically refined and deodorized distillate of the side products in vegetable oil refining. The way includes the following steps: a) make the mentioned distillate react with methanol at 65-85DEG C with acid catalyst; b) separate the fatty acid ester from the mixed reacting products. The way to treat the physically refined and deodorized distillate is also disclosed in the invention which includes esterizing the free fatty acid in the distillate to get the fatty acid ester and extracting the phytocholesterol from the residue. The invention uses the industry by-product as the material to produce biological diesel oil and phytocholesterol so it has increased the cost efficiency.

Owner:THE CHINESE UNIVERSITY OF HONG KONG

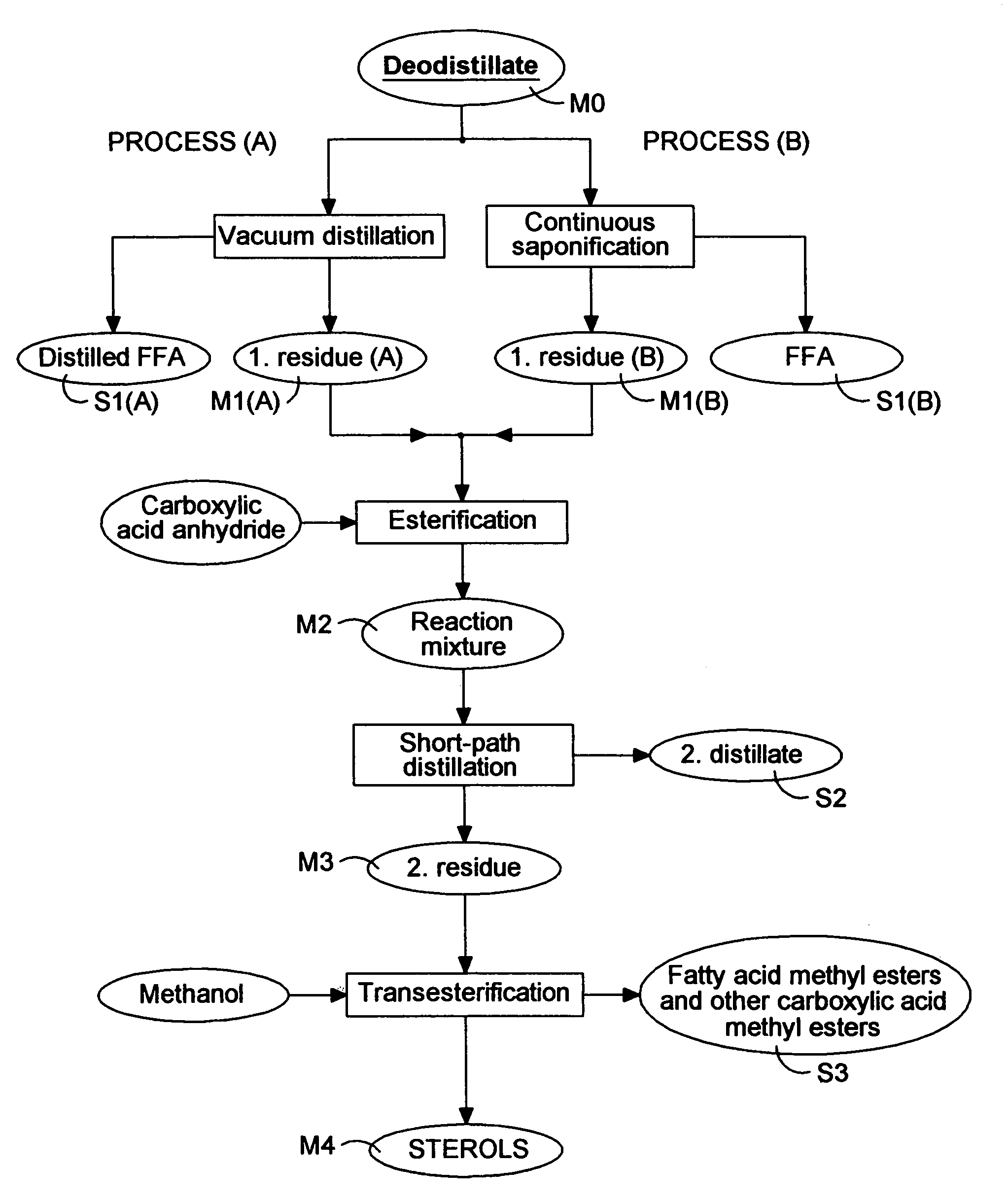

Process for recovery of plant sterols from by-product of vegetable oil refining

InactiveUS7368583B2Reduce contact timeEasy to separateCosmetic preparationsOrganic active ingredientsVegetable oilSterol ester

The process for recovery of plant sterols and tocopherols from deodorization distillates formed during chemical or physical refining of vegetable oils consists of the following steps: free fatty acids are removed from the deodorization distillate by vacuum distillation or by continuation solvent saponification, after the removal of free fatty acids, the received material is reacted with an aromatic carboxylic acid anhydride at a temperature of 50-150° C., under reduced pressure, after the treatment with anhydride, tocopherols are removed from the mixture, and crystalline free sterols are recovered from the distillation residue containing sterol esters, di- and triglycerides by transesterification.

Owner:BUNGE ZRT

Deodorization method used for lowering content of 3-chlorine-1,2-propylene glycol in vegetable oil

ActiveCN103525550AReduce generationFatty-oils/fats refiningEdible oils/fatsVegetable oilLowering plants

The invention discloses a deodorization method used for lowering the content of 3-chlorine-1,2-propylene glycol in vegetable oil. The deodorization method comprises the following steps: with discolored vegetable oil as a raw material, and heating up the discolored vegetable oil to 110 DEG C-150 DEG C by a heat exchanger; feeding the heated vegetable oil to a material distributor of a molecular distiller and uniformly distributing, and setting the temperature of a heating surface of the molecular distiller to 170 DEG C-190 DEG C, wherein the temperature of a condensing surface of an internal condenser of the molecular distiller is 5 DEG C-20 DEG C, and vacuum degree is 0.1 Pa-5 Pa; enabling a light-phase odor component to flow into a light component collecting tank after condensing through the internal condenser, and quickly cooling heavy phase to 50 DEG C or lower by the heat exchanger to obtain deodorized vegetable oil with 3-chlorine-1,2-propylene glycol content smaller than 300 mg / kg. Compared with the prior art, the deodorization method disclosed by the invention has the advantages of lowering production amount of the 3-chlorine-1,2-propylene glycol in the deodorized vegetable oil and providing references for improving an existing vegetable oil refining process.

Owner:JIANGNAN UNIV +1

Making method of sesame oil capable of reducing blood lipid

InactiveCN105145882AReduce nutrientsIncrease aromaFatty-oils/fats refiningFatty-oils/fats productionVegetable oilFiltration

The invention belongs to the field of refining of vegetable oil, and particularly relates to a making method of sesame oil capable of reducing blood lipid. The making method is characterized by comprising the following steps: (1) cleaning sesame seeds, and airing the cleaned sesame seeds for two days; (2) mixing the aired sesame seeds and traditional Chinese medicines so as to obtain a mixture, frying the mixture with a frying pan for 20 minutes at the frying temperature of 100 DEG C, and then separating the sesame seeds from the traditional Chinese medicines with a mesh sieve; (3) cleaning mulberries, pulping the cleaned mulberries into coarse mulberry juice, and filtering the coarse mulberry juice so as to obtain mulberry juice; (4) decocting the traditional Chinese medicines with water so as to obtain a traditional Chinese medicine solution; (5) mixing the mulberry juice and the traditional Chinese medicine solution so as to obtain a mixed solution, then putting the sesame seeds into the mixed solution, soaking the sesame seeds into the mixed solution for three hours, and then putting the mixed solution together with the soaked sesame seeds into a freezer for refrigeration at the refrigerating temperature of minus ten DEG C; (6) then putting the refrigerated sesame seed mixture into an oil press, and pressing the refrigerated sesame seed mixture so as to obtain a sesame oil mixture; and (7) performing filtration on the sesame oil mixture through an active carbon filter, and then performing centrifugation and oil-water separation so as to obtain the sesame oil. The sesame oil has the effect of reducing blood lipid, and the aromatic odor of the sesame oil is also enhanced.

Owner:ANHUI LONGXI FOREIGN TRADE SESAME OIL MFG

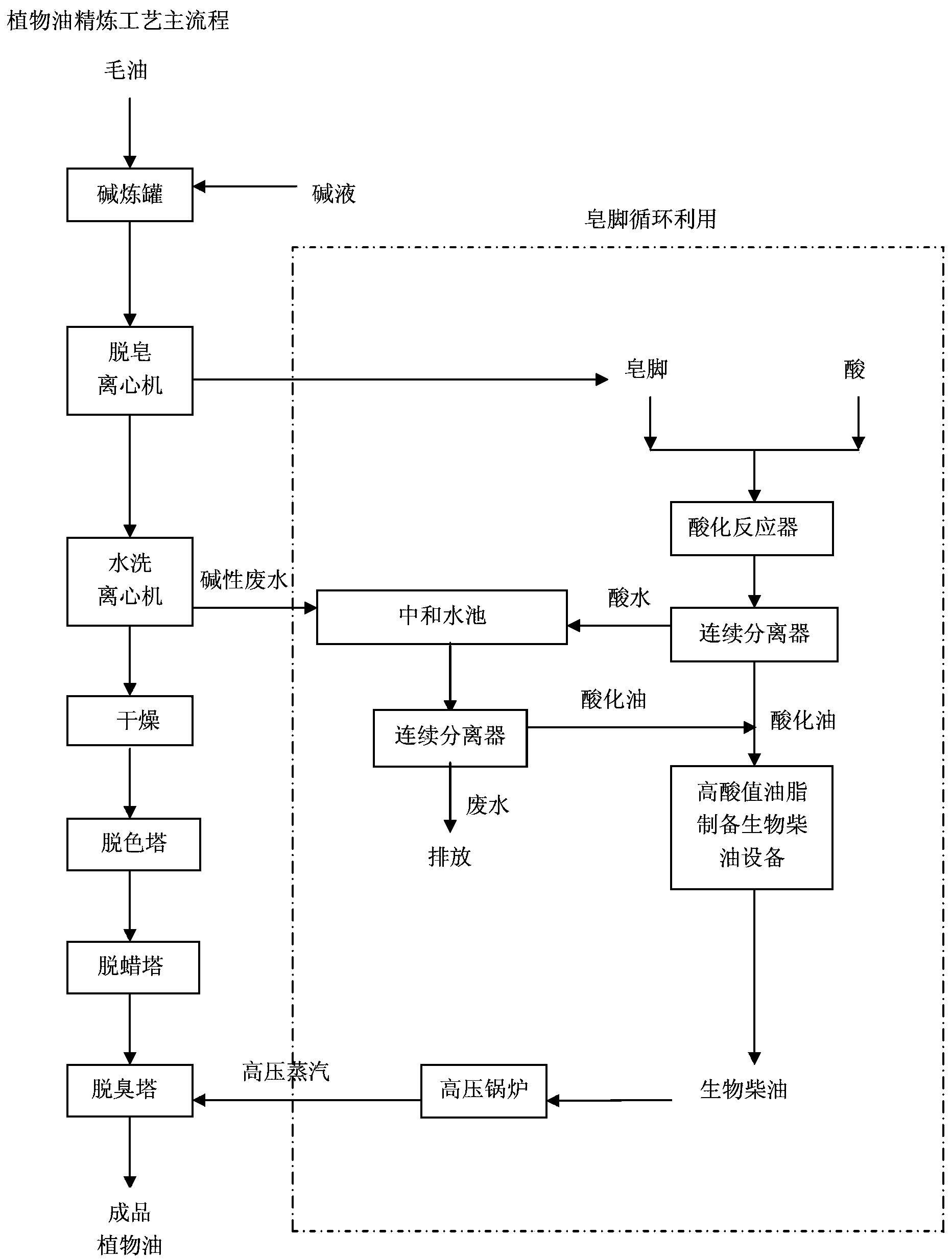

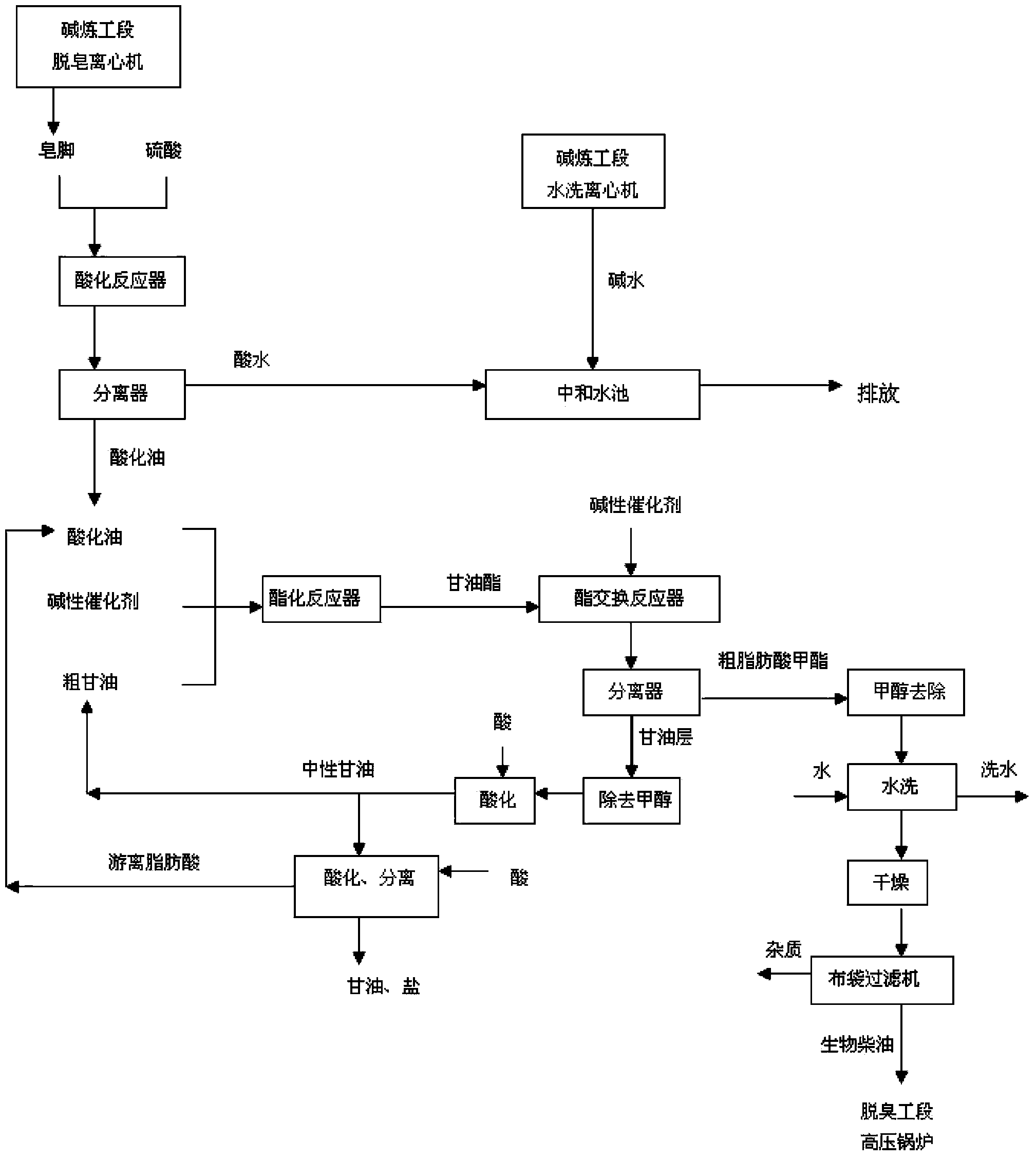

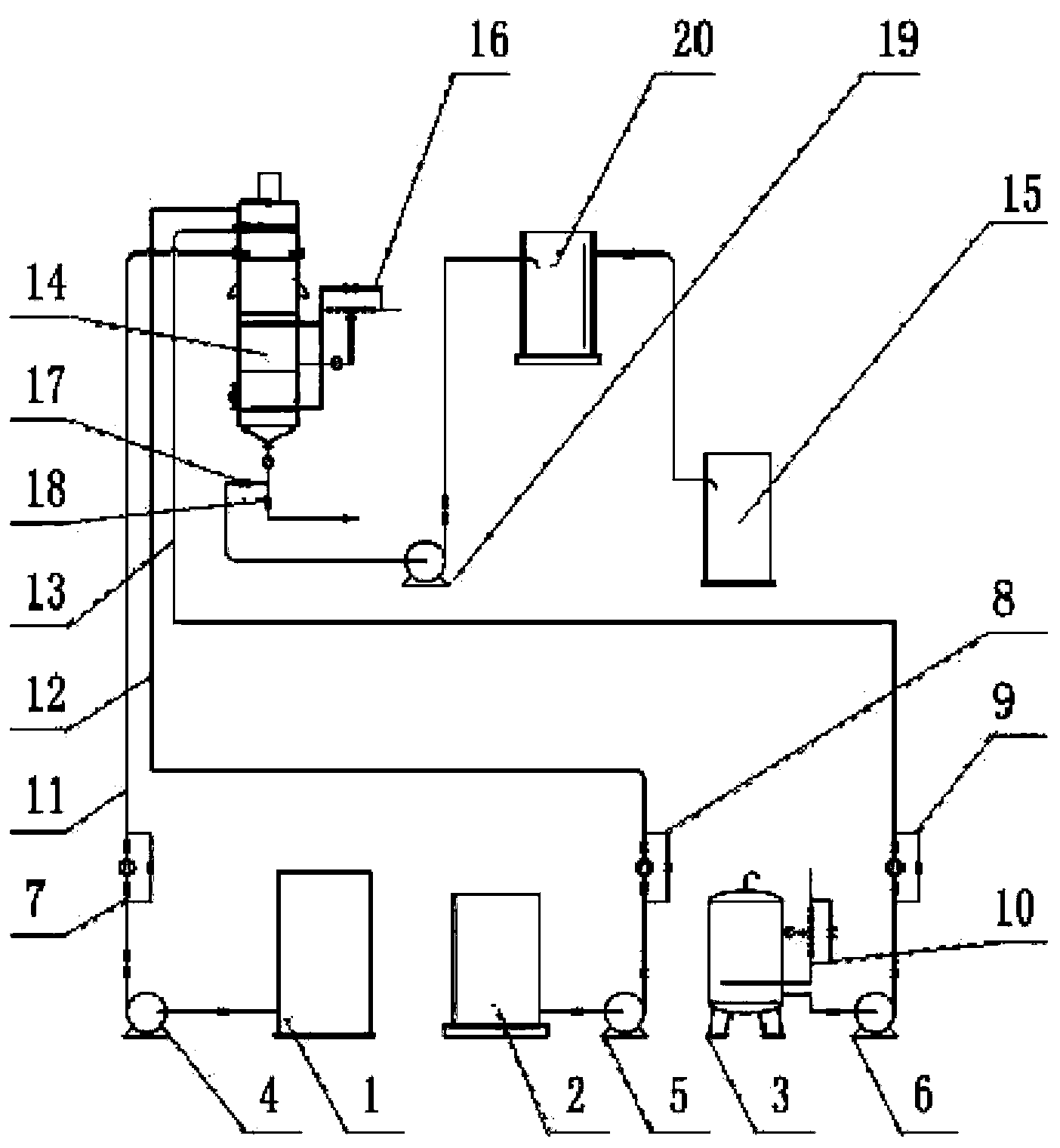

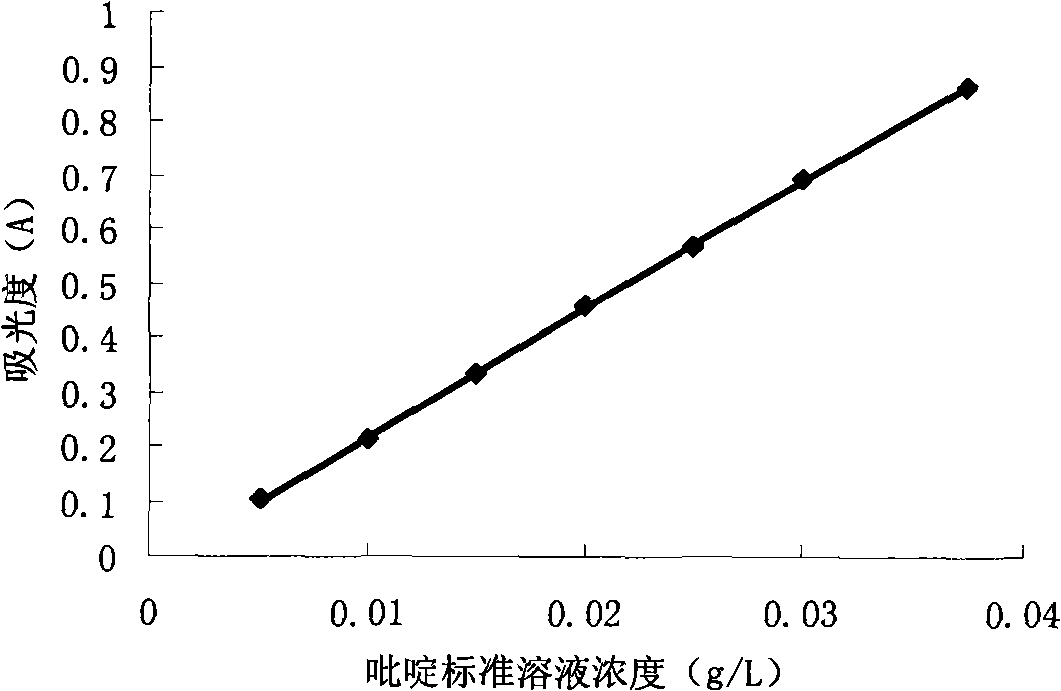

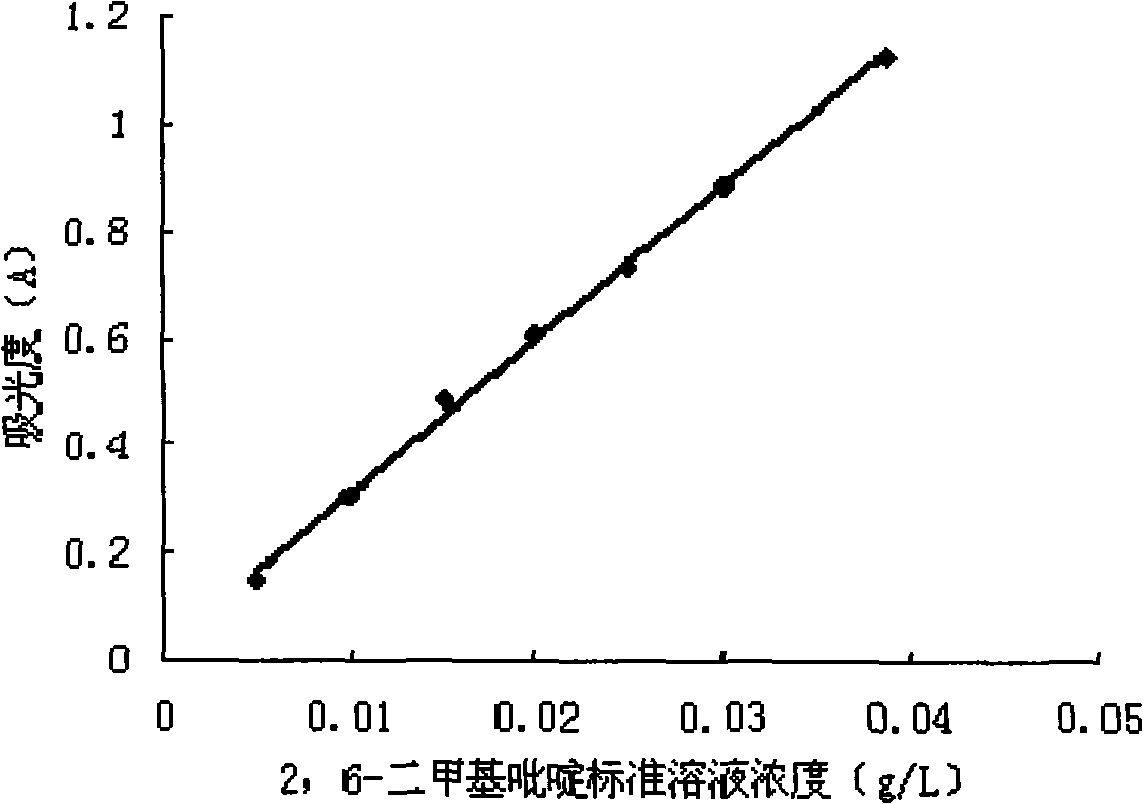

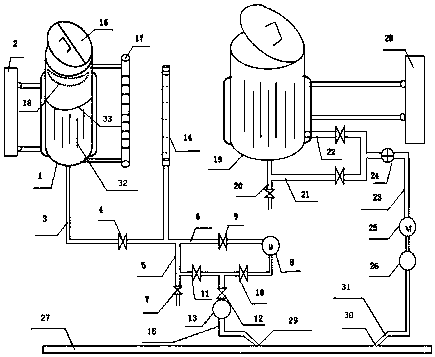

Recycling process for alkali refining by-product, namely soapstock in refining vegetable oil and reactor

InactiveCN103409242AImprove utilization efficiencyAchieve recyclingFatty oils/acids recovery from wasteFatty acid esterificationBiodieselVegetable oil

The invention discloses a recycling process for an alkali refining by-product, namely soapstock in refining vegetable oil and a reactor. The recycling process comprises the following steps: (1) acidizing the soapstock; (2), preparing a biodiesel through the acid oil; (3) neutralizing wastewater. According to the invention, a renewable energy source, namely the biodiesel is produced by directly acidizing the by-product, namely the soapstock produced in the vegetable oil refining process. Compared with the method of directly selling the soapstock, the recycling process has the advantages as follow: the problem that light diesel is needed to be purchased from the outside to be used as a fuel for the burning of a high-pressure steam generator in the deodorization working section of the same process is solved; secondary pollution after waste soapstock is sold is prevented; meanwhile, duo to acidified water after the soapstock is acidized, the discharge of high-alkalinity final washing water in the alkali refining working section is avoided; raw materials and water treatment cost are reduced. Therefore, the recycling process is an environment-friendly technology, and can bring more social and economic benefits.

Owner:广州市南洋国际工程技术服务公司 +2

Discoloring method for reducing trans-fatty acid content of vegetable oil

InactiveCN101538508ALower trans fatty acidsLow in trans fatty acidsFatty-oils/fats refiningIsomerizationVegetable oil

The invention relates to a Discoloring method for reducing trans-fatty acid content of vegetable oil, belonging to the technical field of vegetable oil refining and discoloring. In the discoloring method, activated clay and neutralized vegetable oil are used as the raw material; on the one hand, discoloring earth is selected; and on the other hand, the discoloring technology of reducing fatty acid trans-isomer is obtained by controlling the discoloring temperature, the clay usage amount, the discoloring time and the stirring rate and integrally considering the trans-isomerization of discoloring effect and fatty acid. The invention reduces the content of trans-fatty acid formed during discoloring, builds up the discoloring technology of low trans-acid, plays a role of good guiding for improving the refining processing technology of vegetable oil and lays a foundation for constructing the processing technology of healthy vegetable oil.

Owner:SHANGHAI RONGS HEALTH IND CO LTD

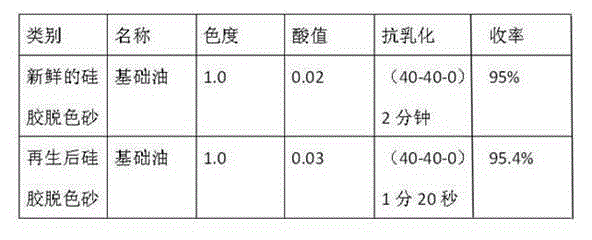

Regeneration method of silica gel bleaching sand for petroleum or animal and vegetable oil refining

ActiveCN104437446AImprove solubilityAvoid emissionsCombustible gas purificationSilicon compoundsFiltrationNitrogen pressure

The invention provides a regeneration method of silica gel bleaching sand for petroleum or animal and vegetable oil refining. The method comprises steps as follows: 1, primary extraction: (1) to-be-processed waste silica gel bleaching sand is added to an extraction reaction kettle, and the extraction reaction kettle is filled with nitrogen for replacement for three times; (2) a nonpolar solvent is added to the extraction kettle, the volume ratio of the silica gel bleaching sand to the nonpolar solvent is 1:1, and the mixture is stirred at the temperature of 30-60 DEG C for 10-20 min; (3) nitrogen pressure filtration is performed after stirring, the pressure is controlled to range from 0.1 Mpa to 0.2 Mpa, and the filtrate is an enrichment liquid; 2, secondary extraction and regeneration: (1) a mixed liquid of the nonpolar solvent and n-butyl acetate to the extraction reaction kettle, and the volume ratio of the mixed liquid to the waste silica gel bleaching sand is 1:1; (2) the mixture is stirred at the temperature of 30-60 DEG C for 30-60 min and dried after filtered, and regeneration is finished. With the adoption of the method, the silica gel bleaching sand for petroleum or animal and vegetable oil refining can be treated, and the waste silica gel bleaching sand can be regenerated.

Owner:烟台神洲能源科技有限公司

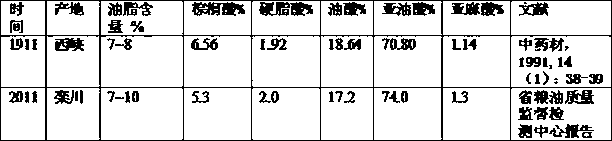

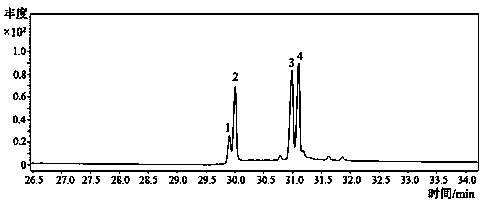

Extraction method of dogwood kernel oil

InactiveCN102703207ALow costSave solventFatty-oils/fats refiningFatty-oils/fats productionSiphonVegetable oil

The invention relates to an extraction method of dogwood kernel oil and effectively solves the problem in extracting dogwood kernel oil. The method comprises the following steps of: grinding the dogwood kernel and adding into an extractor; injecting the solvent into the extractor; adding the same solvent into a distiller; heating until boiling, and keeping the boiling state; condensing the steam into liquid by a condenser, and spraying the liquid into the extractor; percolating; enabling the liquid in the extractor to flow back to the distiller from a lower exit of the extractor through a siphon pipe, and heating by the distiller for distillation; cooling the steam into liquid by the condenser and feeding the liquid into the extractor again; when the liquid from the extractor is colorless and oil cannot be detected in the liquid, recycling the solvent, wherein when no liquid flows out of the condenser, the residual liquid in the distiller is the crude dogwood kernel oil; and treating the crude dogwood kernel oil by a conventional vegetable oil refining method to obtain the dogwood kernel oil. According to the invention, the aim of extracting crude oil from the dogwood kernel can be achieved by use of simple equipment and a set of operation procedure easy to master and by consuming little solvent and energy.

Owner:栾川县野生源生态科技开发有限公司 +1

Control method for heavy fragrant plant oil acid value

InactiveCN1616616ALow acid valueSimple refining processFatty-oils/fats refiningFatty-oils/fats productionFlavorNatural product

The present invention is control method for acid value of strong fragrant vegetable oil. The technological process includes fully moistening vegetable oil seed with composite antioxidant aqua comprising with vitamin E, tea polyphenol, carotenoid, etc.; steaming or frying and squeezing; processing obtained vegetable oil with solid processing agent for 0.5-2 hr, and filtering to obtain strong fragrant vegetable oil. The process can lower the acid value extremely, simplify the vegetable oil refining process, maintain the original flavor and color and maintain the natural product characteristic of strong fragrant vegetable oil.

Owner:GUANGXI UNIV

Selective adsorption and discoloring method for vegetable oil

InactiveCN108795572AMeet enterprise color value requirementsFatty-oils/fats refiningVegetable oilVegetable oil refining

The invention discloses a selective adsorption and discoloring method for vegetable oil, which is used for discoloring in refining of vegetable oil. The adsorption and discoloring method for the vegetable oil comprises the following steps of adding an adsorbent into to-be-discolored vegetable oil, heating, stirring, and selectively adsorbing and discoloring; filtering, and collecting filtrate, soas to obtain the discolored vegetable oil, wherein the to-be-discolored vegetable oil is deep-color crude oil of the vegetable oil which is extracted by hot pressing. The adsorption and discoloring method has the advantages that the adsorbent is added into the to-be-discolored deep-color vegetable oil which is extracted by the hot pressing, and is heated and stirred, so as to complete the selective adsorption and discoloring; then, the to-be-discolored deep-color vegetable oil is filtered, and the filtrate is collected, so as to obtain the discolored vegetable oil; the color value meets the enterprise color value requirements of the vegetable oil.

Owner:WUHAN POLYTECHNIC UNIVERSITY

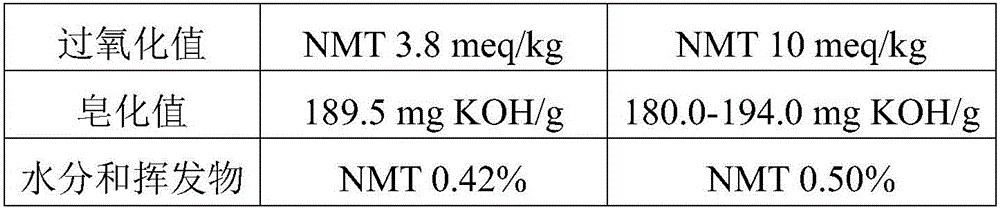

Refining technology for wheat bran oil and method for extracting phytosterol from wheat bran oil

InactiveCN108865427AHigh purityComply with the hygienic standard of edible sanitary oilFatty-oils/fats refiningSteroidsSocial benefitsVegetable oil

The invention discloses a refining technology for wheat bran oil and a method for extracting phytosterol from the wheat bran oil, and belongs to the field of the vegetable oil refinement. The method comprises the following steps: using crude oil of the wheat bran oil as a raw material, to obtain the refined wheat bran oil and the high-purity phytosterol through degumming, decoloring, dewaxing anddeacidifying successively, wherein the deacidifying is performed by using multi-level molecular distillation. The method is capable of, through a mode of the multi-level molecular distillation, respectively acquiring light component grease and heavy component grease. The heavy component grease is the refined wheat bran oil. The light component grease is extracted by using diethyl ether, and the phytosterol is obtained. Namely, the method is capable of realizing the refinement of the wheat bran oil, and acquiring the phytosterol, and remarkable in economic benefit and social benefit.

Owner:QILU UNIV OF TECH

A kind of oil refining method

ActiveCN103740462BImprove degumming effectPrevent oxidationFatty-oils/fats refiningOil and greasePartial hydrolysis

The invention discloses an oil refining method. The oil refining method comprises a degumming process, a first refining process, a secondary refining process and a deacidification and deodorization process. The degumming effect of an enzymic degumming method is better, and the phosphorus content after the enzymic degumming can be reduced to an ideal index less than 5ppm; the oil refining can be completed under the conditions of high vacuum degree (0.1 to 10Pa) and short-time heat treatment (less than or equal to 3 seconds), and the oxidization and partial hydrolysis of the oil and generation of harmful substances (such as trans-acid, polymerized glyceride and the like) can be avoided; the core sections (refining and deacidification and deodorization) of the method belong to physical methods, no chemical additive is added in the operation process of the two sections, no waste water pollution is produced, and reference can be provided for improving an existing vegetable oil refining process.

Owner:陈汉卿

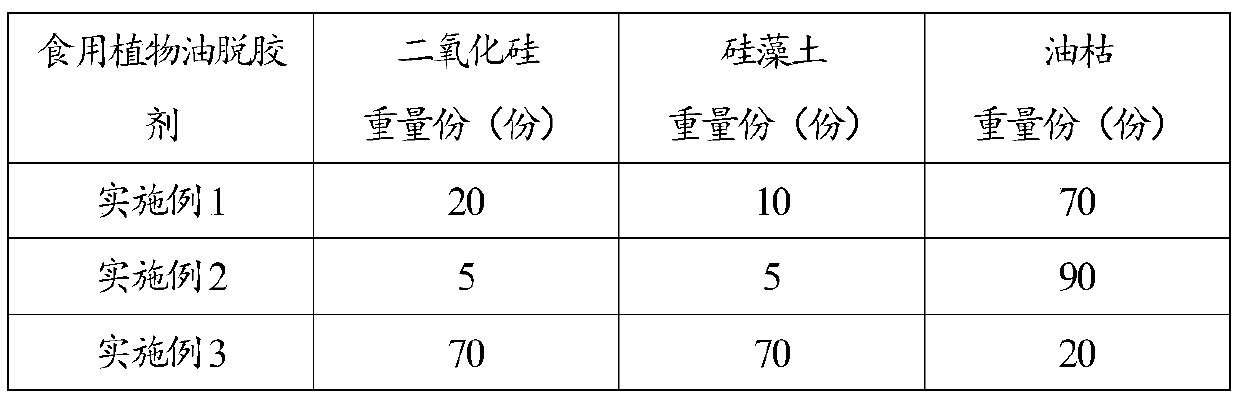

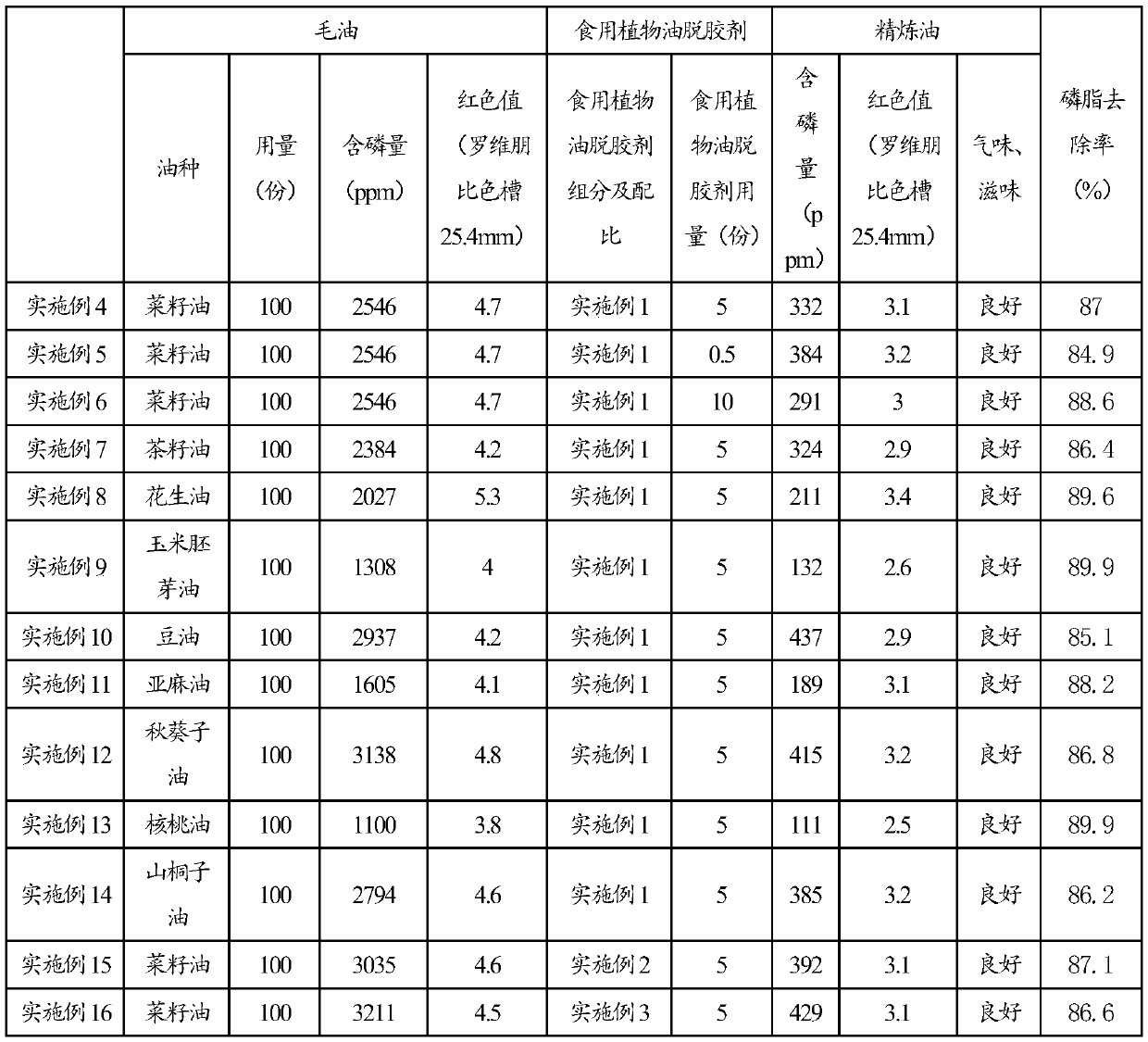

Edible vegetable oil degumming agent and production method thereof and edible vegetable oil refining method

PendingCN110016387AReduce manufacturing costLow costFatty-oils/fats refiningEdible oils/fatsOil and greaseVegetable oil

The invention discloses an edible vegetable oil degumming agent and a production method thereof and an edible vegetable oil refining method with the edible vegetable oil degumming agent adopted. The degumming agent comprises silicon dioxide, diatomite and oil cake. The refining method comprises the steps of according to weight parts, mixing 100 parts of crude oil and 0.5-10 parts of the degummingagent, and conducting stirring and filtering to obtain refined oil. The refining method has a good degumming effect, color and lustre of the oil are improved, an aroma of the vegetable oil is kept, the cost, energy consumption and time consumption can be reduced, and the problem of wastewater treatment does not exist.

Owner:INST OF AGRO PROD PROCESSING SCI & TECH SICHUAN ACAD OF AGRI SCI

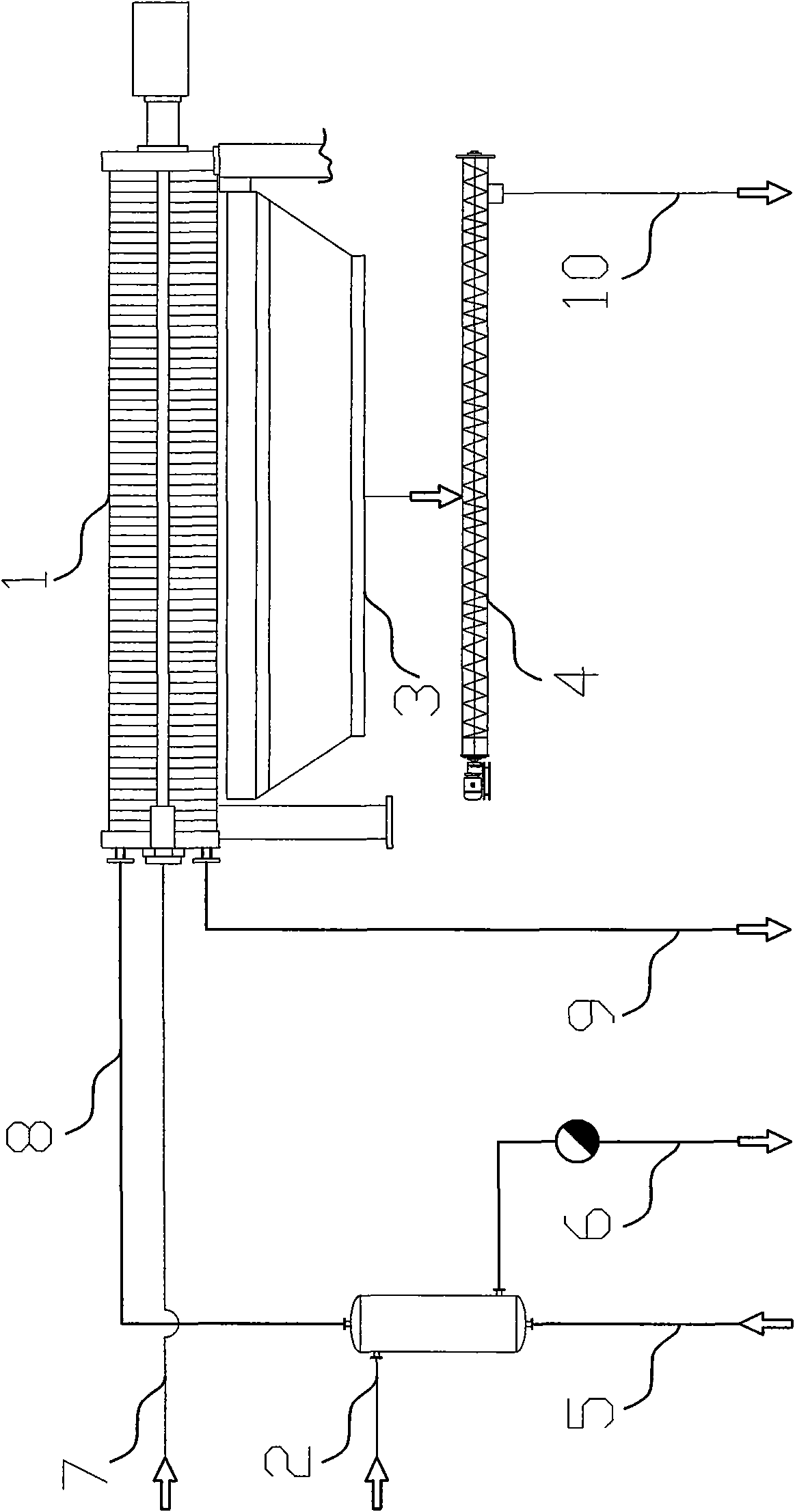

Filtering and impurity removing technology for oil with high colloid content

InactiveCN101643685AImprove efficiencyReduce processFatty-oils/fats refiningFiltration separationVegetable oilFiltration

The invention relates to a filtering and impurity removing technology for oil with high colloid content, belonging to the technical field of vegetable oil refining. The invention relates to a depositing, filtering and centrifugalizing technology which is adopted by the prior base oil impurity removal and is suitable for the filtration and the impurity removal of oil with high colloid content and the improvement of an adopted corresponding device. Crude oil is heated and then is filtered by a program-controlled film type pressure filter technically. The invention reduces procedures, increases the oil yield by filtering and impurity removing, has reasonable and compact design, good impurity removing effect, convenient operation and high comprehensive benefit, is suitable for filtering and removing impurities of various kinds of vegetable oil and especially has advantages for removing impurities of oil with high colloid content, such as corn base oil in base oil.

Owner:MYANDE GRP CO LTD

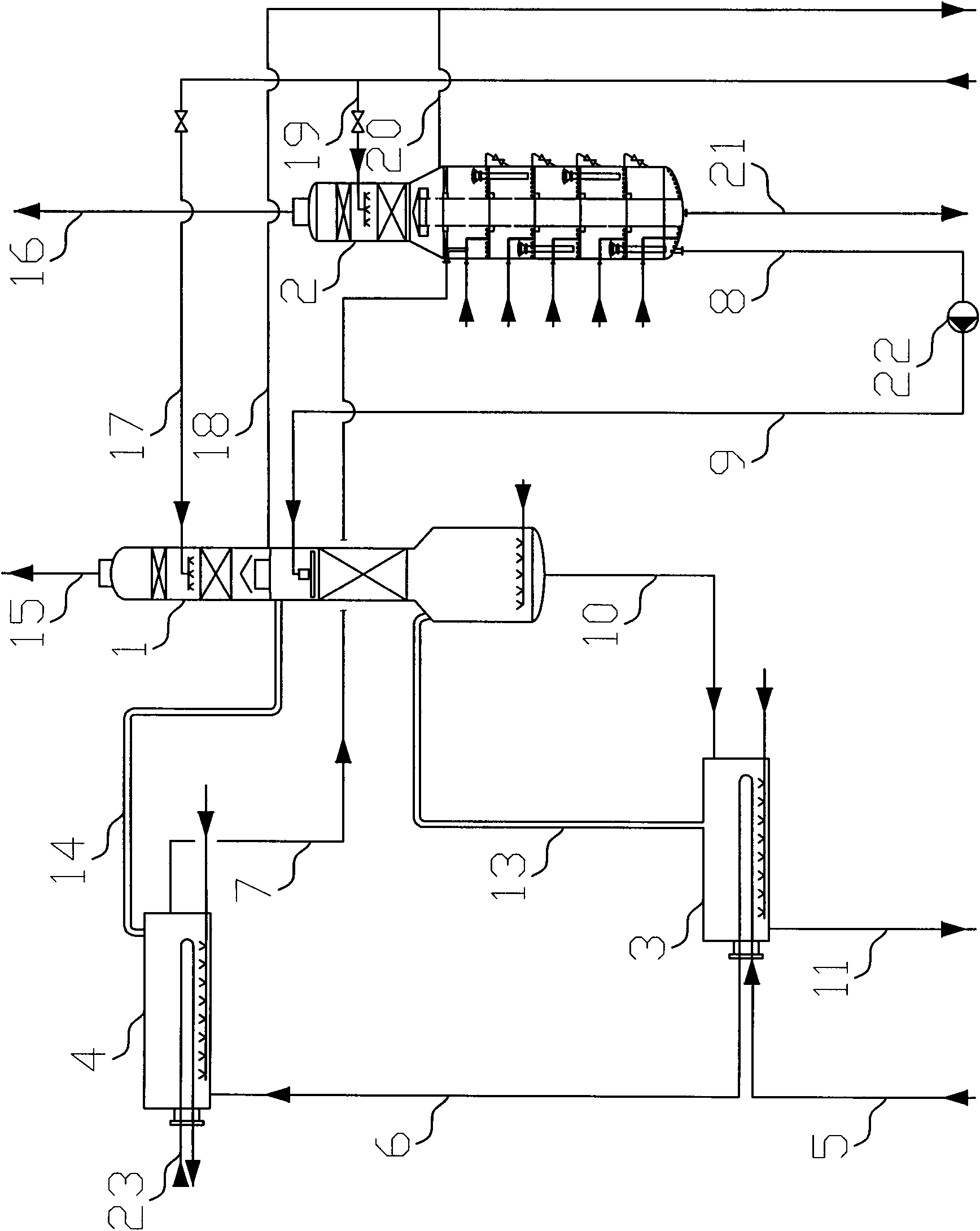

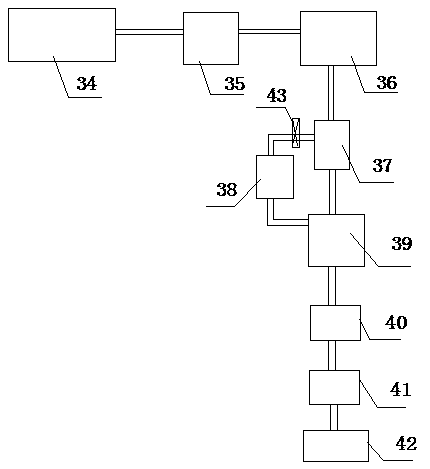

Vegetable oil physical refining device and vegetable oil physical refining method

PendingCN107574015ARealize remote metering automatic controlGuaranteed antibacterial environmentFatty-oils/fats refiningOil and greaseOil processing

The invention belongs to the field of vegetable oil refining and oil processing as well as industrial application equipment thereof, and in particular relates to a vegetable oil physical refining device and a vegetable oil physical refining method. All system devices in the vegetable oil physical refining device cooperate with one another, thus forming an organically coordinated whole. An enzyme preparation applied in the device and the method is free from pollution and meets the requirements of clean production; the best activity of the enzyme preparation can be kept and excited from storageto production, so that the enzyme preparation can be utilized efficiently; the using process is finer and more efficient, and the production process is flexibly and steadily controlled. By using the system to keep the activity of the enzyme preparation, the efficient and fine utilization of enzyme and the stable control of the production process are realized, so that the stability and consistencyof quality of products can be effectively guaranteed in a mass production process.

Owner:SHANDONG XIWANG FOOD

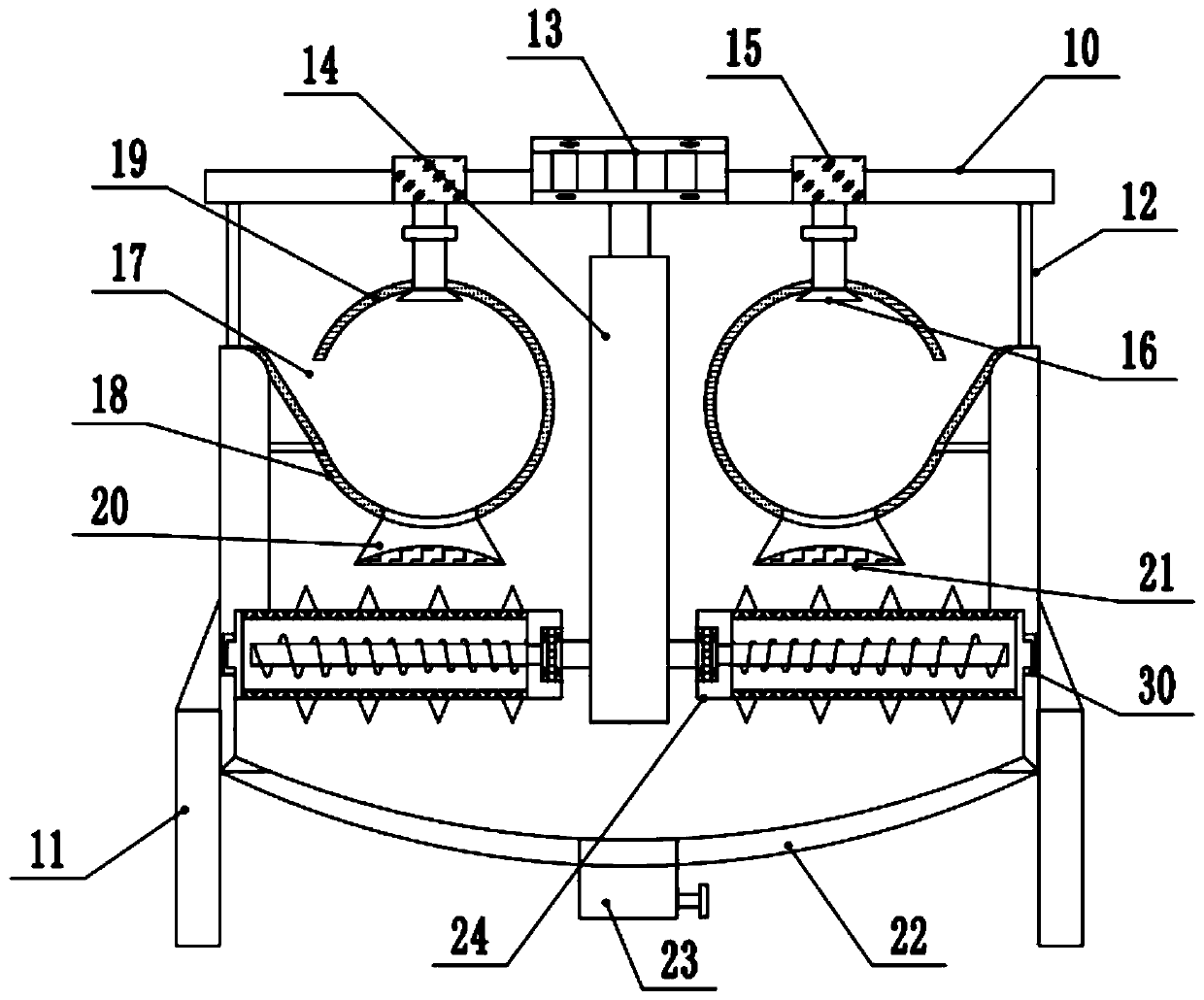

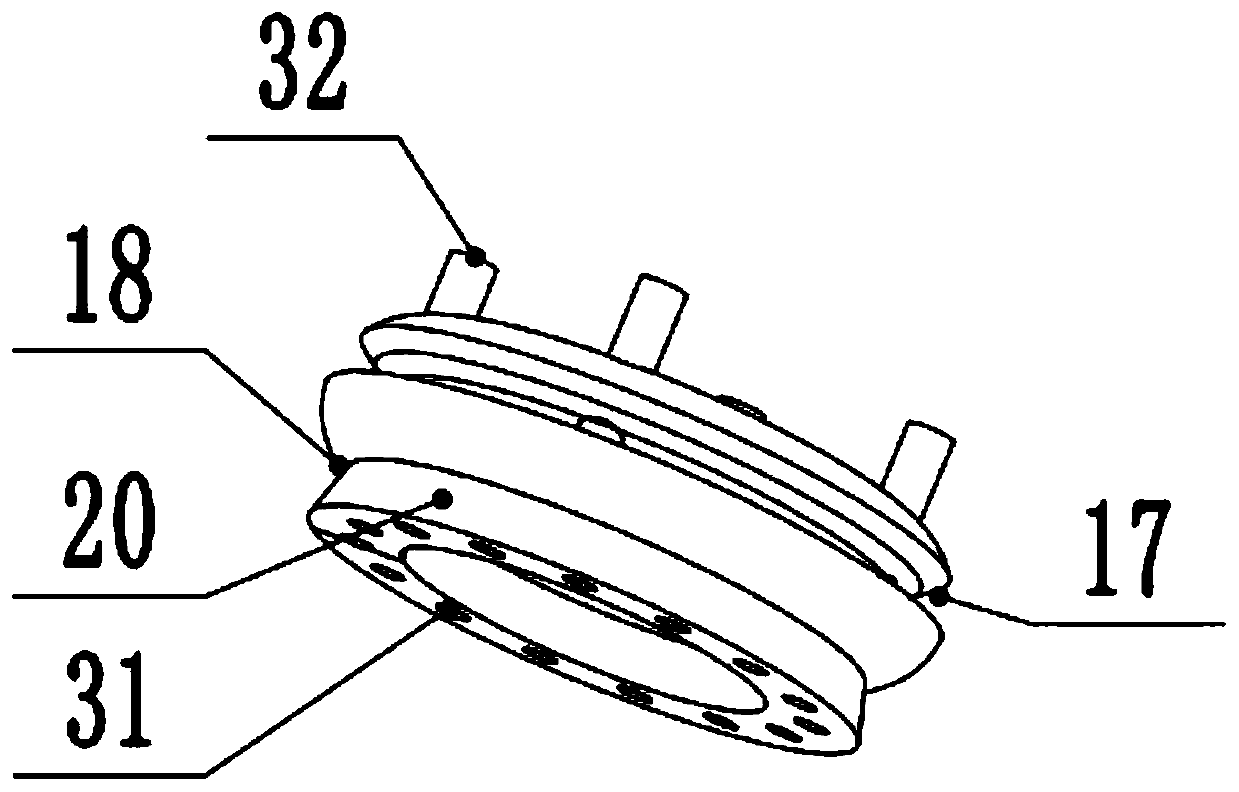

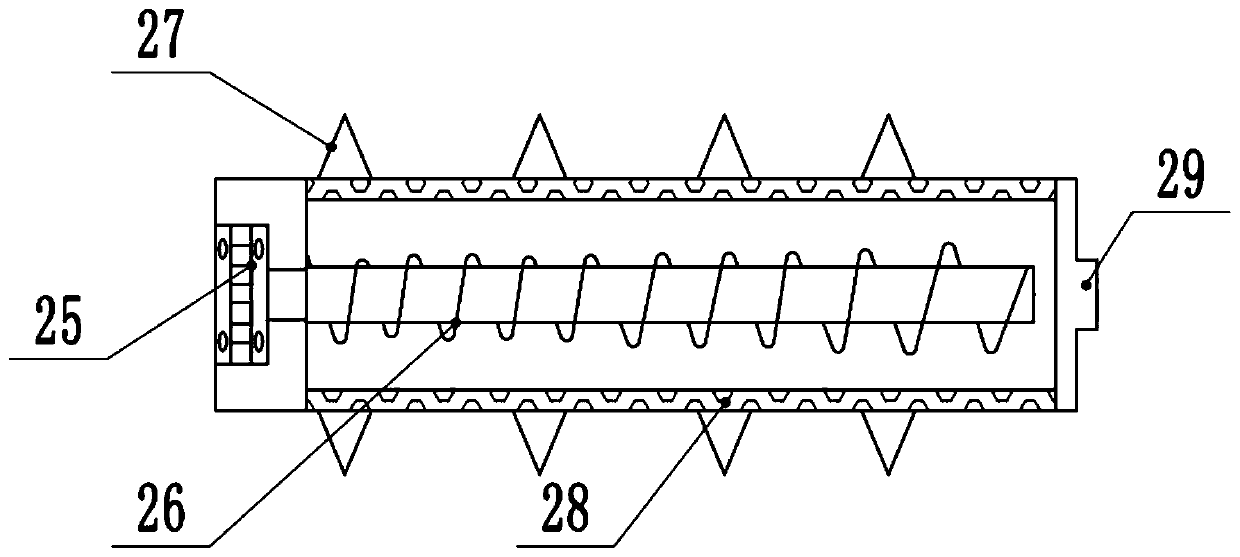

Raw material crushing device for pure vegetable oil refining

ActiveCN110801920AIncrease contact areaHigh precisionRotary stirring mixersTransportation and packagingRotational axisVegetable oil

The invention relates to the technical field of pure vegetable oil refining, and discloses a raw material crushing device for pure vegetable oil refining. The device comprises a top plate, supportinglegs, a first motor, a crushing cavity and crushing mechanisms, wherein the four corners of the upper surface of the top of the crushing cavity are fixedly supported with the horizontal top plate through four support rods, the first motor is arranged at the center of the top plate, the output end of the lower side of the first motor penetrates through the top plate to be rotatably connected with arotating shaft, the four crushing mechanisms are mounted on the periphery of the bottom of the rotating shaft at equal intervals, the middle part of the outer side of a drying cavity is fixed to theinner wall of the crushing cavity through a connecting rod, four exhaust holes are formed in the inner top part of the drying cavity at equal intervals in an annual mode, the outer ring walls of the crushing mechanisms are provided with screening nets uniformly distributed, the inner ends of crushing rods are rotationally connected with second motors fixed at the inner end parts of the crushing mechanisms, and the surfaces of the crushing rods are fixedly provided with stirring frames of spiral structures. The device has the advantages of a pre-drying function, comprehensive crushing, high speed, high precision and high efficiency.

Owner:含山县正隆油脂有限公司

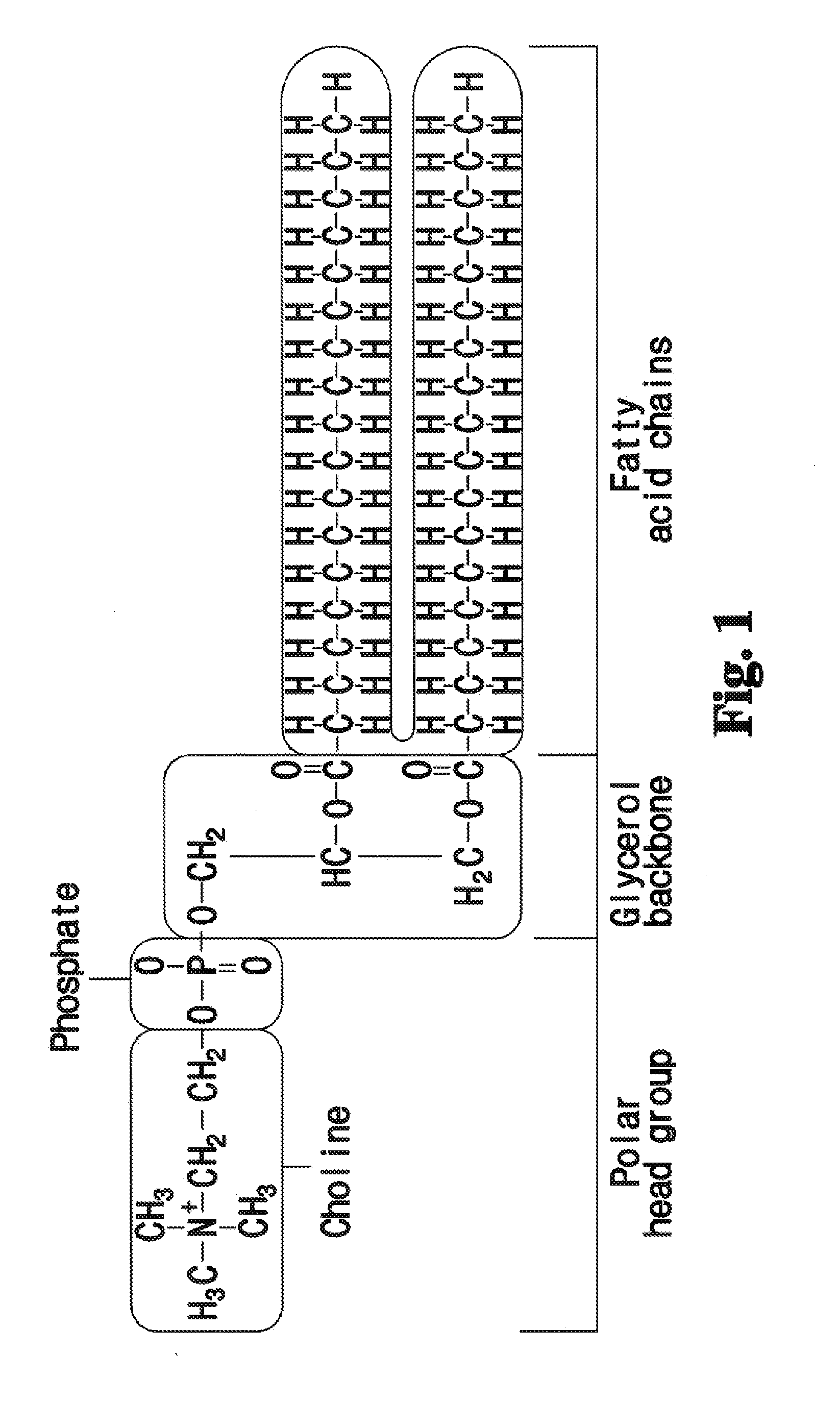

Method of processing phospholipid based lipid materials

ActiveUS20160229793A1High fatty acid contentHigh yieldFatty oils/acids recovery from wasteFatty substance recovery/refiningLipid formationOil phase

The present invention provides methods of processing lipid materials such as soapstock, wet gums and dry gums. Enzymes are utilized to catalyze hydrolysis of the lipids materials to recover fatty acids. Addition of organic acids and / or polyols improved yield of fatty acids and reduced formation of emulsion. Lipid materials can be formulated with other agricultural products as new value-added animal feed products. Further, a process for concentrating nitrogenous compounds such as choline, inositol, ethanolamine and serine from phospholipid materials obtained as byproducts from vegetable oil refining is provided. The process involves performing hydrolysis of the gum based products in the presence of an alcoholic solvent and acid catalyst. Post hydrolysis, gums breakdown to oil and water phases which are further separated and concentrated. These concentrated products may be further fractionated to concentrate individual nitrogenous compounds.

Owner:RRIP

Method for refining tea seed soil

InactiveCN107686772ASolid content reductionQuality improvementFatty-oils/fats refiningSalting outEvaporation

The invention discloses a method for refining tea seed soil, and relates to the technical field of vegetable oil refining. The method comprises the steps of heating a crude product of the tea seed soil, then mixing the heated tea seed soil with an inorganic acid solution, carrying out centrifugal separation, evaporation, alkali refining and salting-out, and filtering. According to the method, thesolid content of the tea seed soil is reduced by means of the step of salting-out; in a refining process, a ceramic membrane filter is used for filtering, so that colloid, pigment and other impuritiesare removed. The refining method provided by the invention does not involve the steps of high temperature treatment, thus avoiding the damage of high temperature to the nutrients in tea seed oil andimproving the quality of the refined tea seed oil. After the method is adopted, the refined tea seed oil is light in color.

Owner:三江县善茶轩工艺品有限公司

Ruminant feed additive and preparation method thereof

ActiveCN108056258AGood thickeningIncrease nutritionAnimal feeding stuffAccessory food factorsVegetable oilPhospholipid

The invention provides a ruminant feed additive which is characterized by comprising the following components: (1) hydrated phospholipids and other jellies discharged in a hydration step in a refiningprocess of vegetable oil; (2) soap bases (fatty acid sodium and a small amount of neutral oil) and the like discharged in an alkali refining process of the vegetable oil; (3) waste clay containing oil and pigment, discharged in a process of discoloring the vegetable oil by using activated clay and clay; and (4) vegetable wax cream removed in a wax removal process of the vegetable oil. The invention also provides a preparation method of the ruminant feed additive. Leftovers discharged in the refining process of the vegetable oil are used for preparing the ruminant feed additive, ruminant feedand blocks are further prepared, and all wastes produced in the refining process of the vegetable oil can be used for realizing very beneficial effects on nutrition and health of ruminants.

Owner:苏志刚

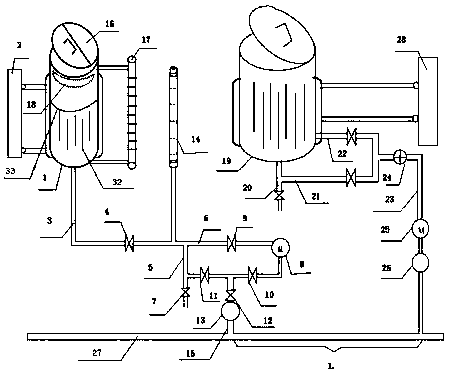

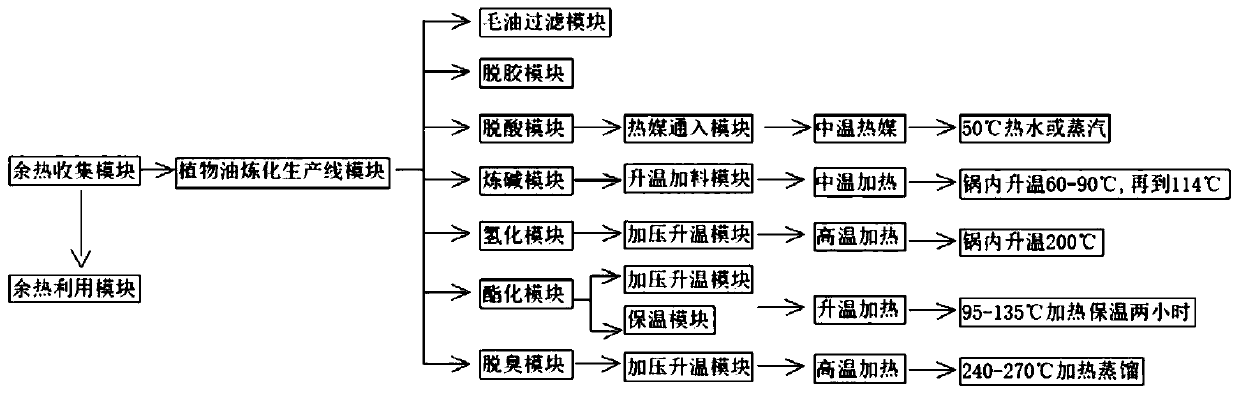

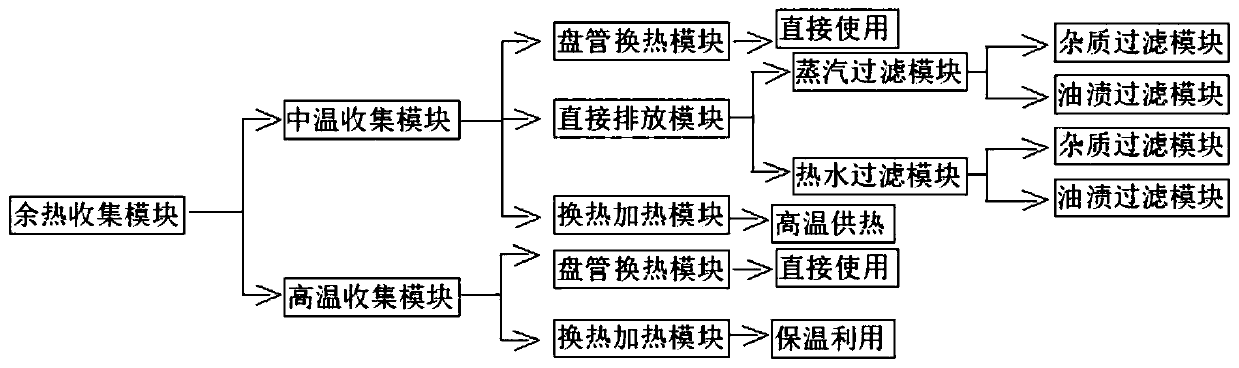

Waste heat recycling system of vegetable oil refining production line

InactiveCN110846127AAccurate analysis of temperatureAvoid wastingFatty acid chemical modificationFatty-oils/fats refiningThermodynamicsVegetable oil

The invention discloses a waste heat recycling system of a vegetable oil refining production line, and relates to the field of vegetable oil refining. The waste heat recycling system comprises a wasteheat collecting module used for collecting heat energy generated by a heating module on the vegetable oil refining production line; a vegetable oil refining production line module used for accuratelyanalyzing a specific heat consumption link, a specific heating temperature and a specific medium on the production line; and a waste heat utilization module used for carrying out secondary utilization on collected waste heat. According to the invention, the waste heat collecting module is arranged; heat exchange can be carried out on a heating link on the vegetable oil refining production line module; the system comprises a deacidification module, an alkali refining module, a hydrogenation module, an esterification module and a deodorization module, the temperature of each heating link is accurately analyzed, then a heat exchange module performs heat exchange utilization according to the specific temperature of different heating links, waste heat on the production line is used for production and living, and heat energy waste is avoided.

Owner:衡阳县共兴油脂有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com