Use of at least one coproduct from the vegetable-oil refining industry for obtaining a purified total unsaponifiable vegetable oil product

A vegetable oil and saponification technology, which is applied in the direction of fat oil/fat refining, anhydride/acid/halide active ingredients, and medical preparations containing active ingredients, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0150] Composition of Soybean Deodorized Distillate

[0151] The market for oils, more particularly soybean oil and DD, is severely constrained by the global availability of seeds and the growing need to develop vitamin E and phytosterols relevant to food, cosmetic or pharmaceutical applications.

[0152]This need has prompted the oil industry to optimize the deodorization process in order to obtain DD with a composition that is very conducive to the recovery of the unsaponifiable fraction.

[0153] Modifications made to the deodorizing plant were mainly aimed at increasing the deodorizing temperature and installing specific condensers capable of collecting a deodorizing distillate particularly rich in tocopherols and phytosterols.

[0154] It is this quality of DD that will preferably be addressed by the new invention.

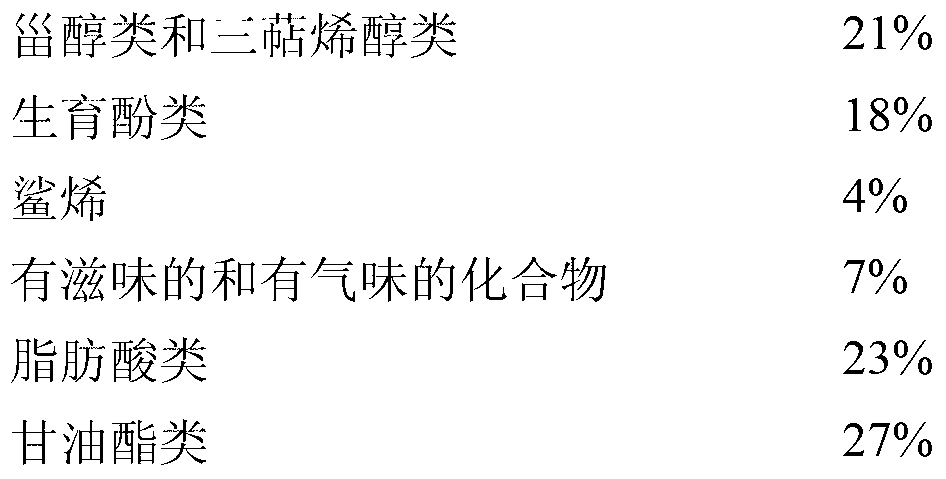

[0155] As an example, the composition of a deodorized distillate of soybean is as follows:

[0156]

Embodiment 2

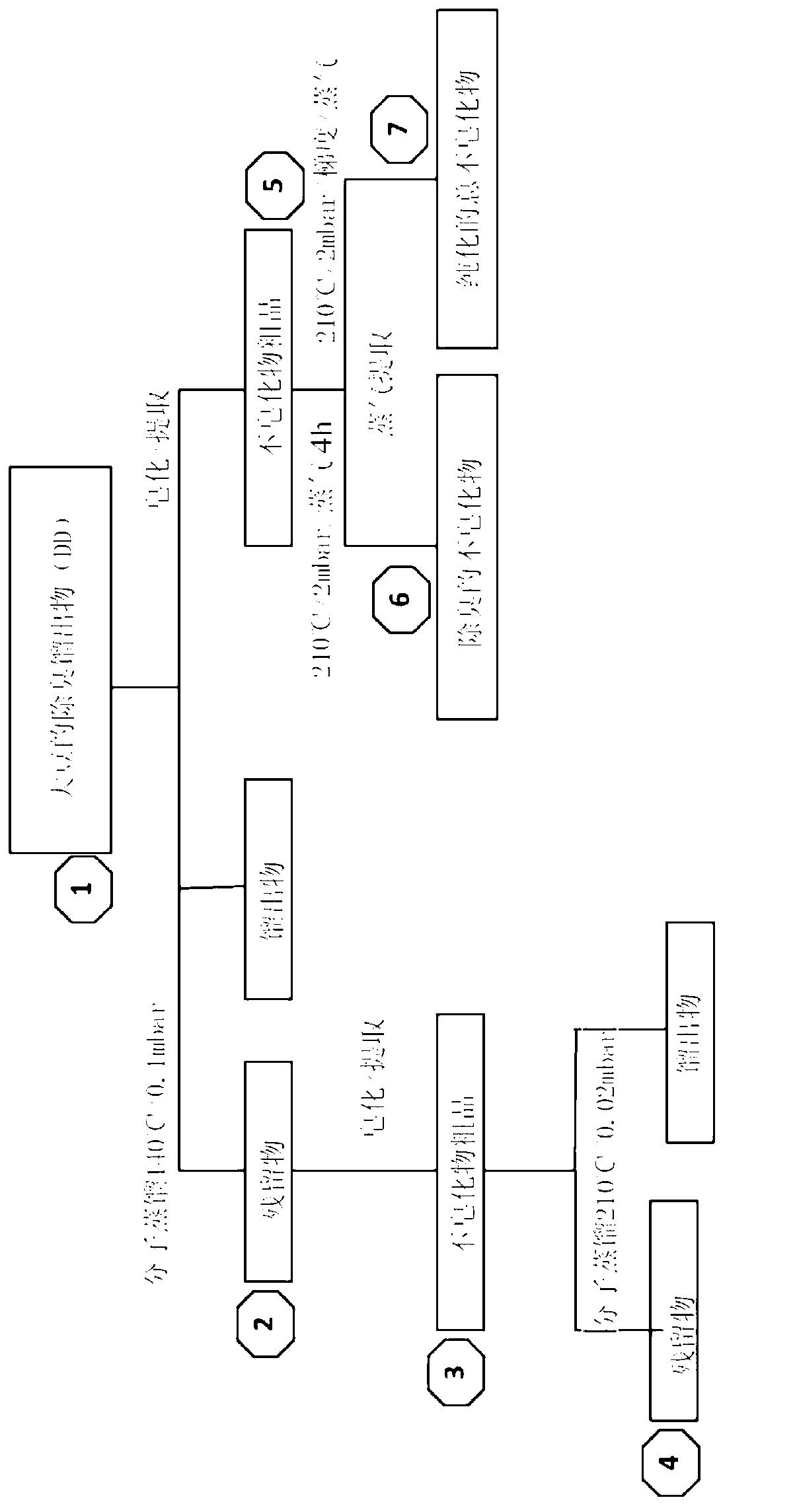

[0158] Distillation of deodorized distillates from soybeans

[0159] In the case of DD with a reduced concentration of unsaponifiables, the process of the invention can advantageously comprise a pretreatment by molecular distillation. It is applied to eliminate a portion of the light fraction of DD, mainly composed of fatty acids, in order to obtain the unsaponifiable-rich feedstock used in the process.

[0160] The test was carried out on a centrifugal molecular still with a maximum capacity of 25 kg / hour. The device consists of the following elements:

[0161] A conical circulating rotor with a diameter of 38 cm,

[0162] A water circulation coil (condenser),

[0163] Two recovery tanks for residue and distillate,

[0164] An induction heating system.

[0165] The vacuum unit consists of a vane pump (low vacuum) and an oil diffusion pump (molecular vacuum).

[0166] The product to be treated is first pumped into a continuous degasser consisting of a thin film, falling ...

Embodiment 3

[0175] Distillation of the deodorized distillate of sunflower

[0176] The test was carried out on the same apparatus as in Example 2.

[0177] The parameters used for this operation are as follows:

[0178] Feeding rate: 18.5kg / h

[0179] Vacuum degree: 10 -2 mmHg

[0180] Distillation temperature: 100°C

[0181] Distillation rate: 82.5%

[0182] Composition of the product:

[0183] Compound in g per 100g

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com