Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

724 results about "Thermal energy recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

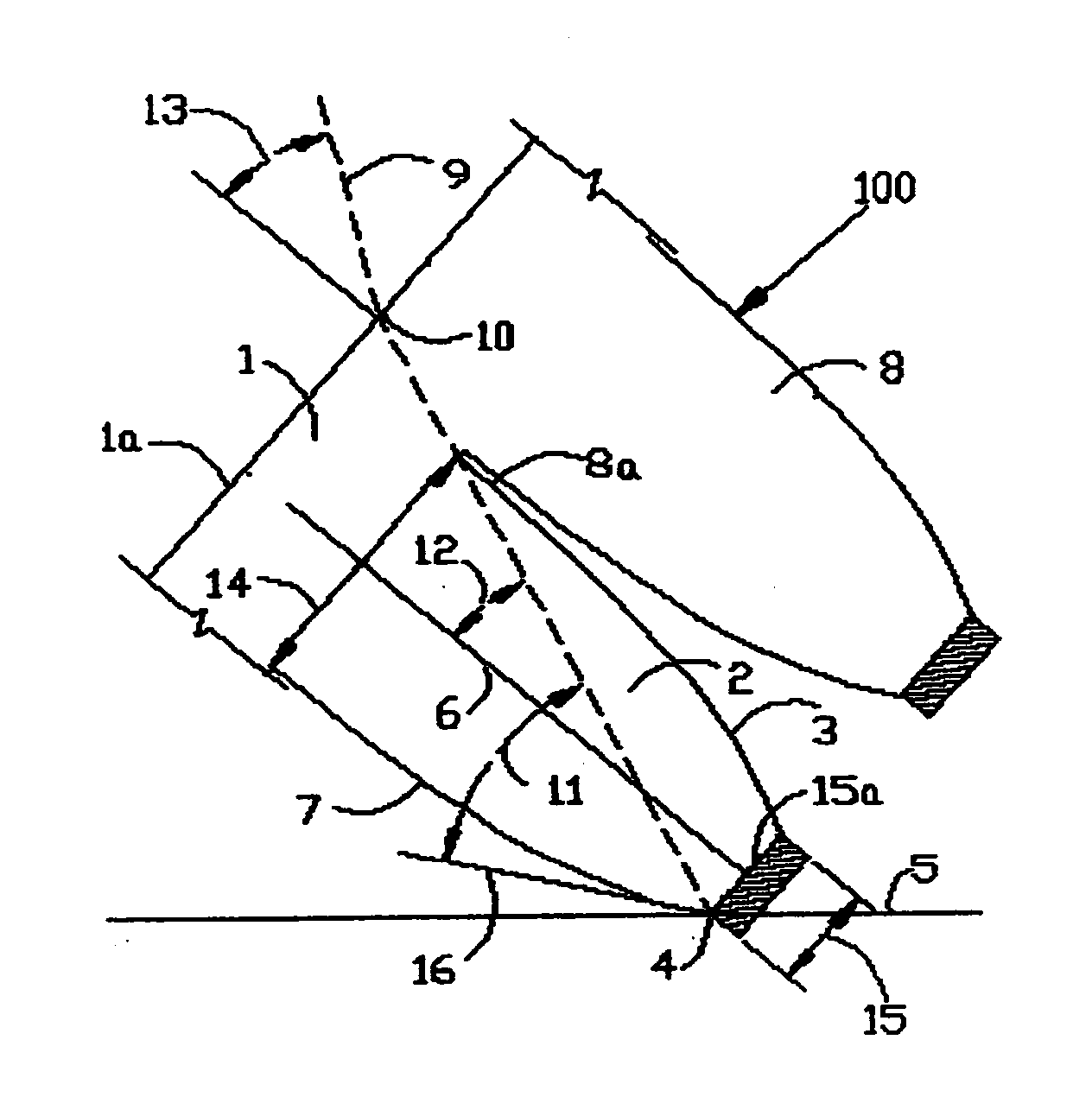

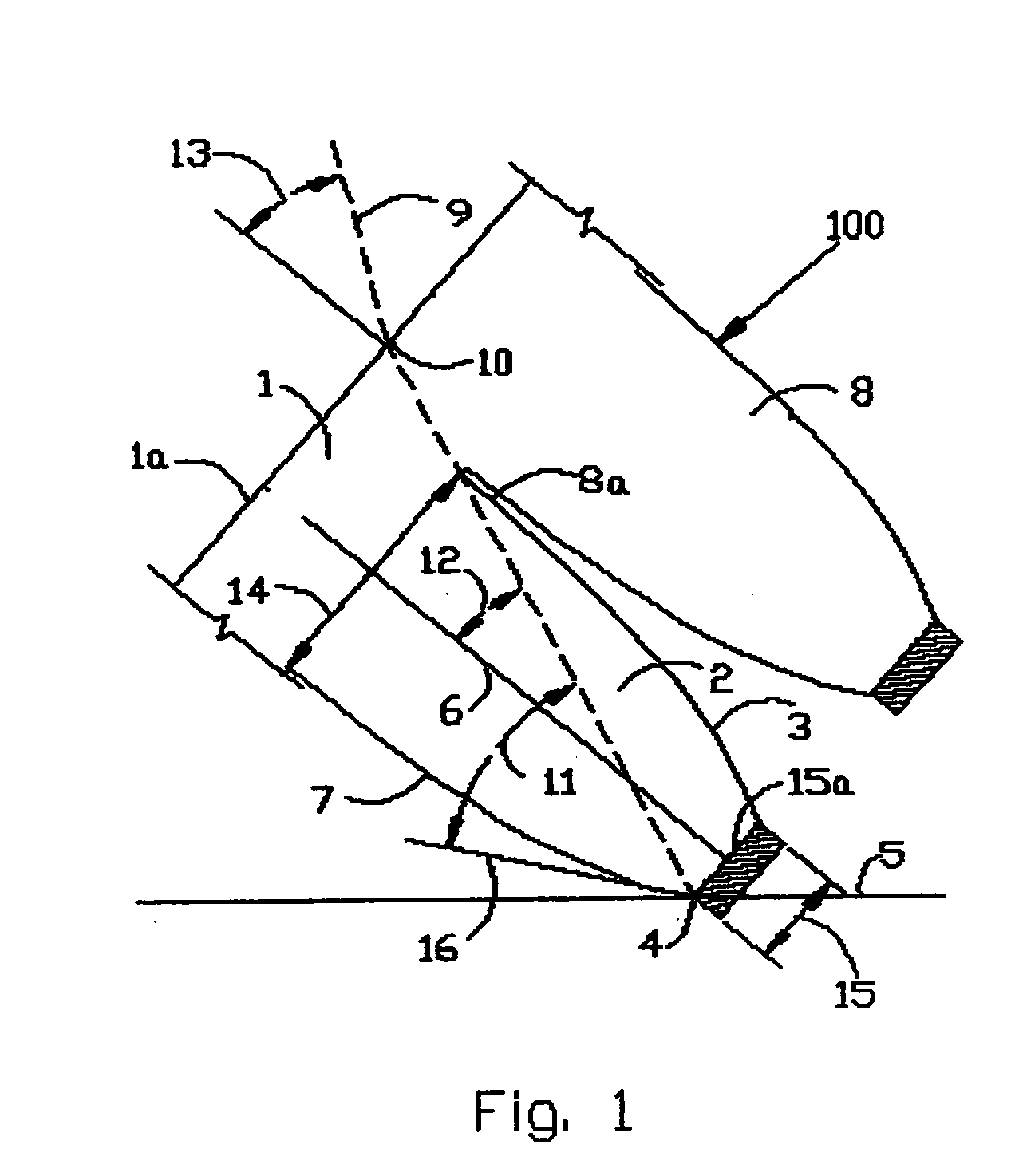

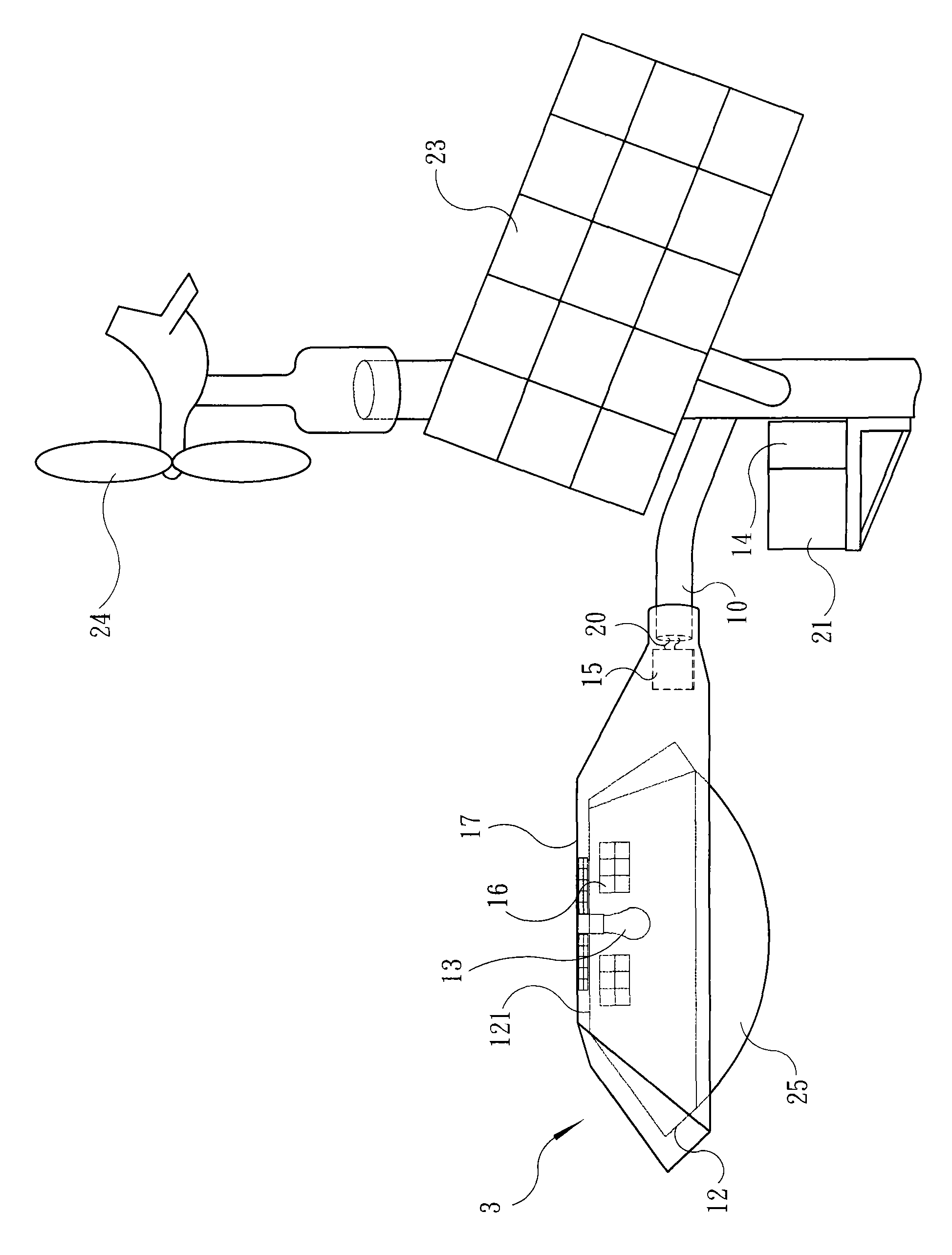

Concentrating solar roofing shingle

InactiveUS20050081909A1Reduce the amount requiredPrevent edgePhotovoltaic supportsSolar heating energyRoof tileEngineering

This invention describes a non-imaging, non-tracking, integrally-formed solar radiation concentrator that passively concentrates both diffuse and direct solar radiation onto photovoltaic cells to produce electricity, incorporating its features into a shingle-like element useful as a roofing material and in other structural applications. The substantially transparent, solar concentrating elements of the invention may also incorporate a system to remove waste energy in the form of heat that is not utilized in the generation of electricity. The invention further provides a thermal energy recovery system including a forced convection air system for removing waste heat from the concentrating shingle assembly and using it, if desired, for building space heat or domestic water heating.

Owner:STELLARIS

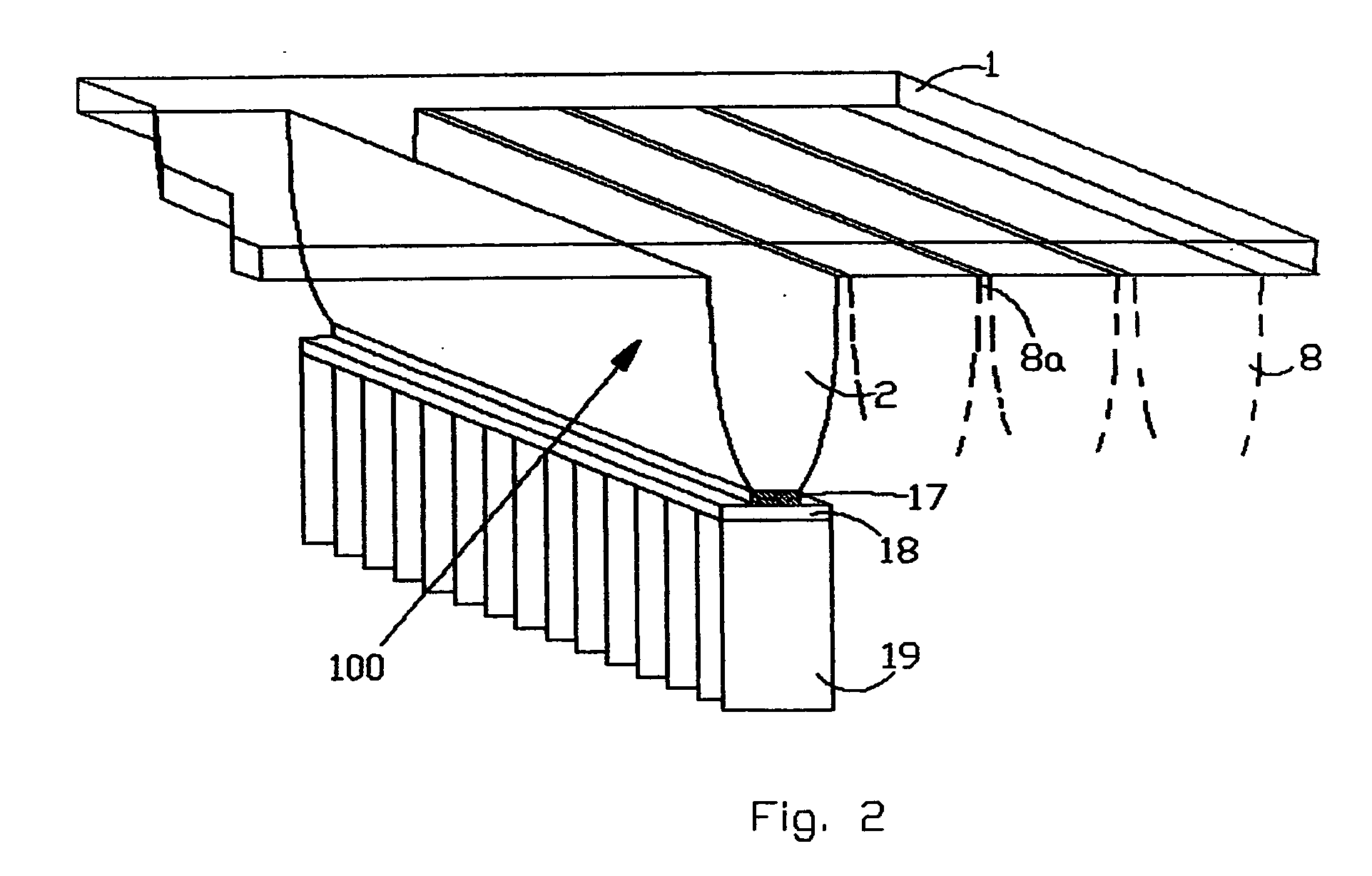

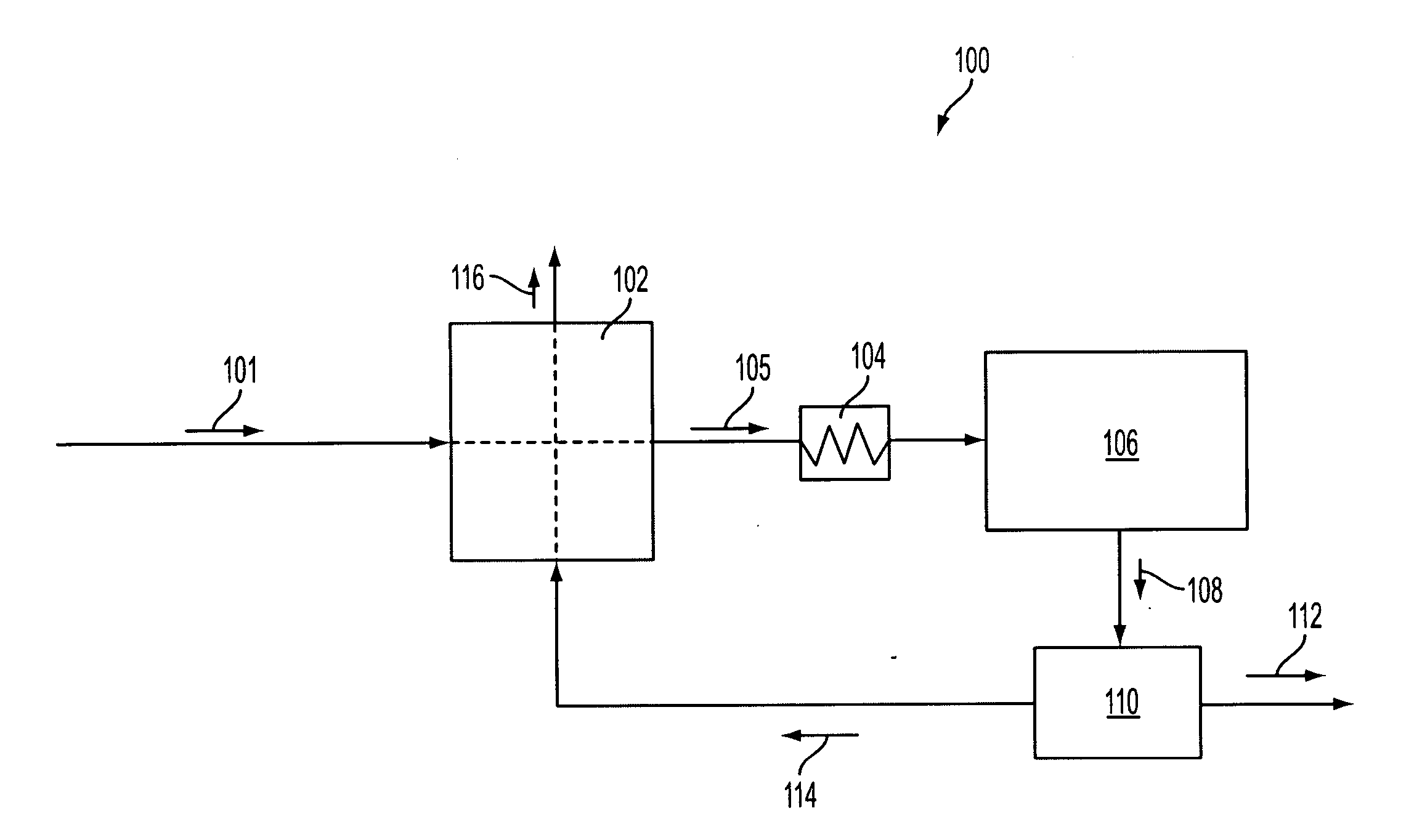

Supplementary Thermal Energy Transfer in Thermal Energy Recovery Systems

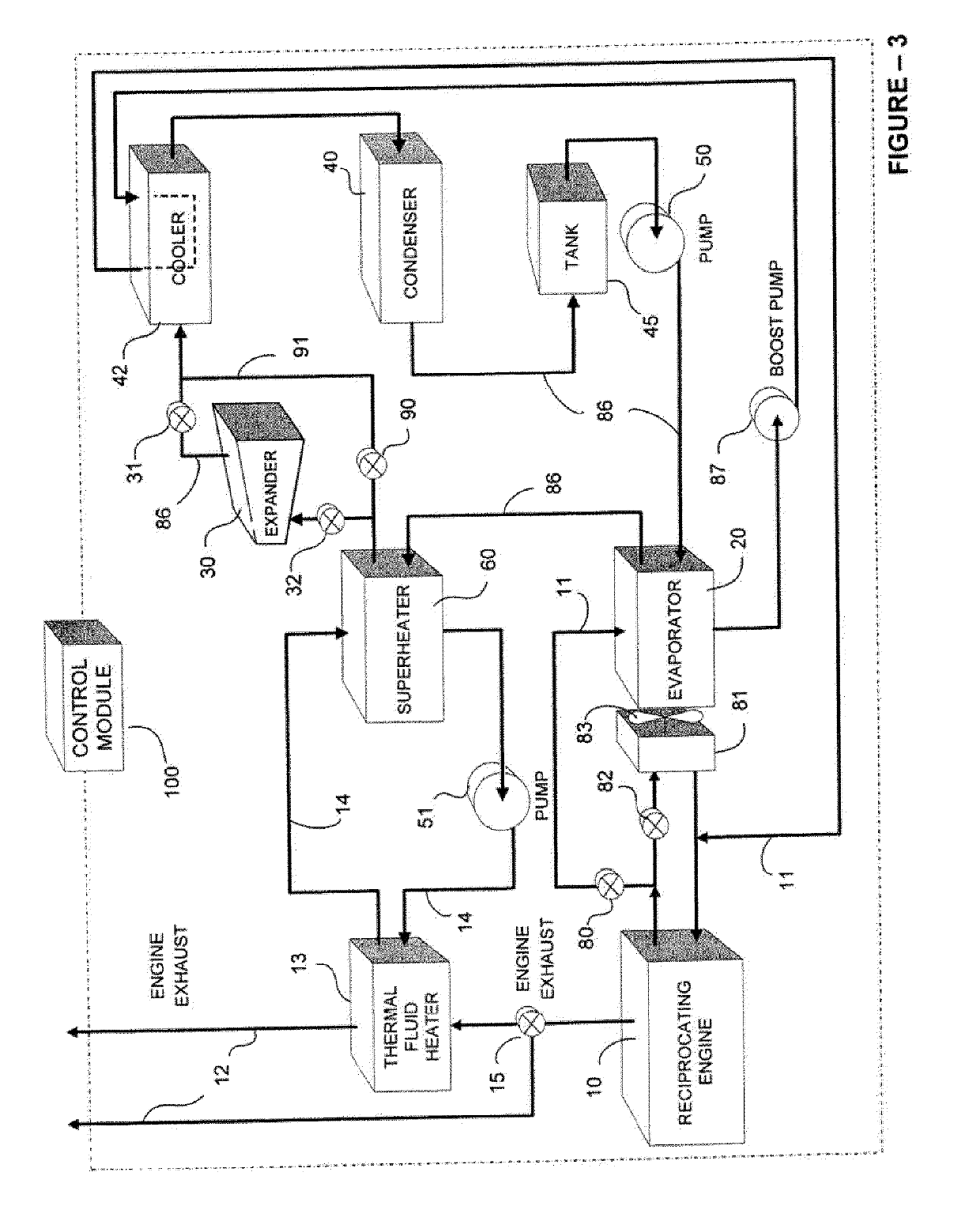

ActiveUS20090320477A1Maximize power generationIncrease energy contentSteam engine plantsMechanical energyEngineering

A system for controlled recovery of thermal energy and conversion to mechanical energy. The system collects thermal energy from a reciprocating engine (for example, from engine jacket fluid) and may also collect further thermal energy from a natural gas compressor (for example, from compressor lubricating fluid). The collected thermal energy is used to generate secondary power by evaporating an organic propellant and using the gaseous propellant to drive an expander in production of mechanical energy. Secondary power is used to power parasitic loads, improving energy efficiency of the system. A supplementary cooler may provide additional cooling capacity without compromising system energy efficiency.

Owner:JUCHYMENKO VICTOR

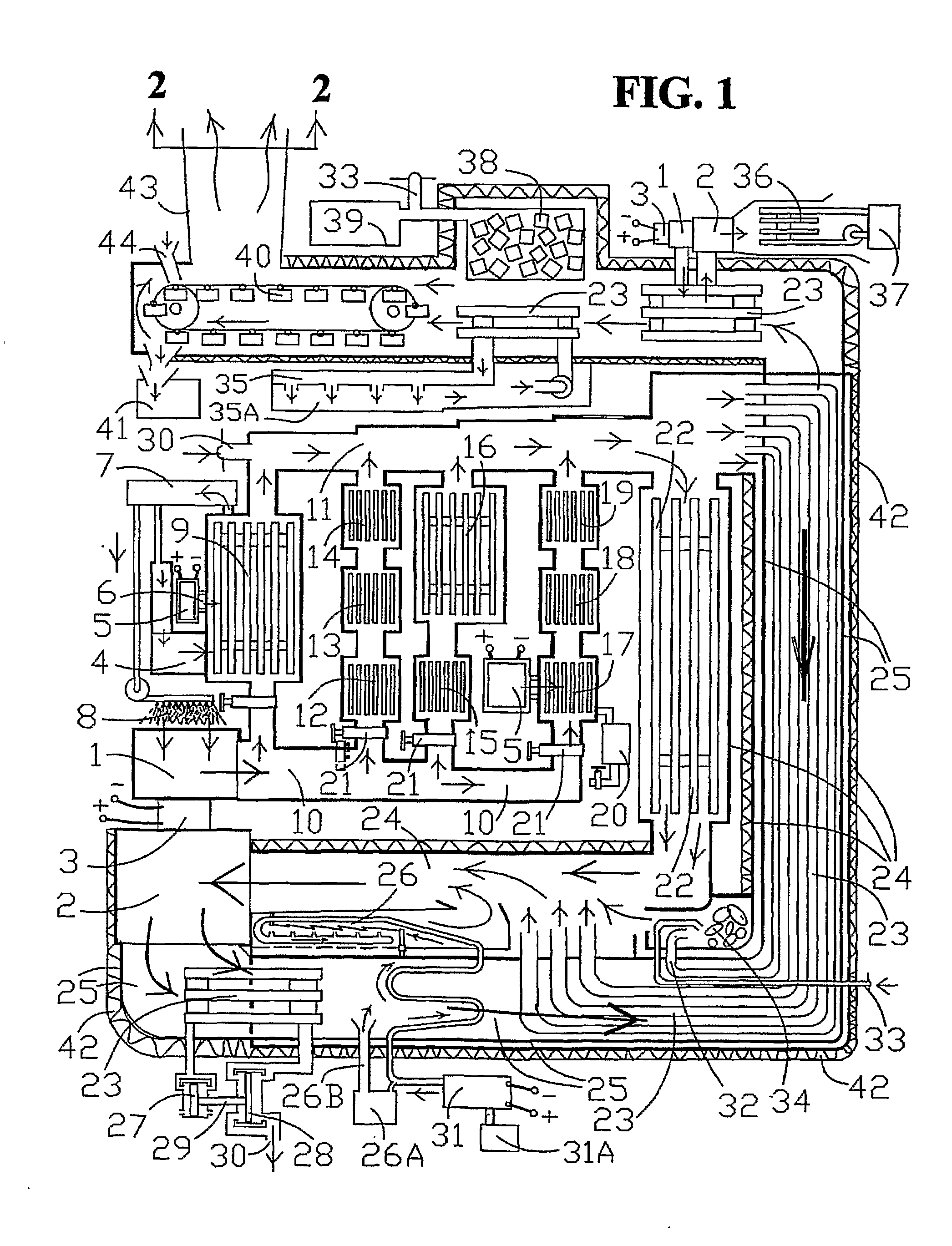

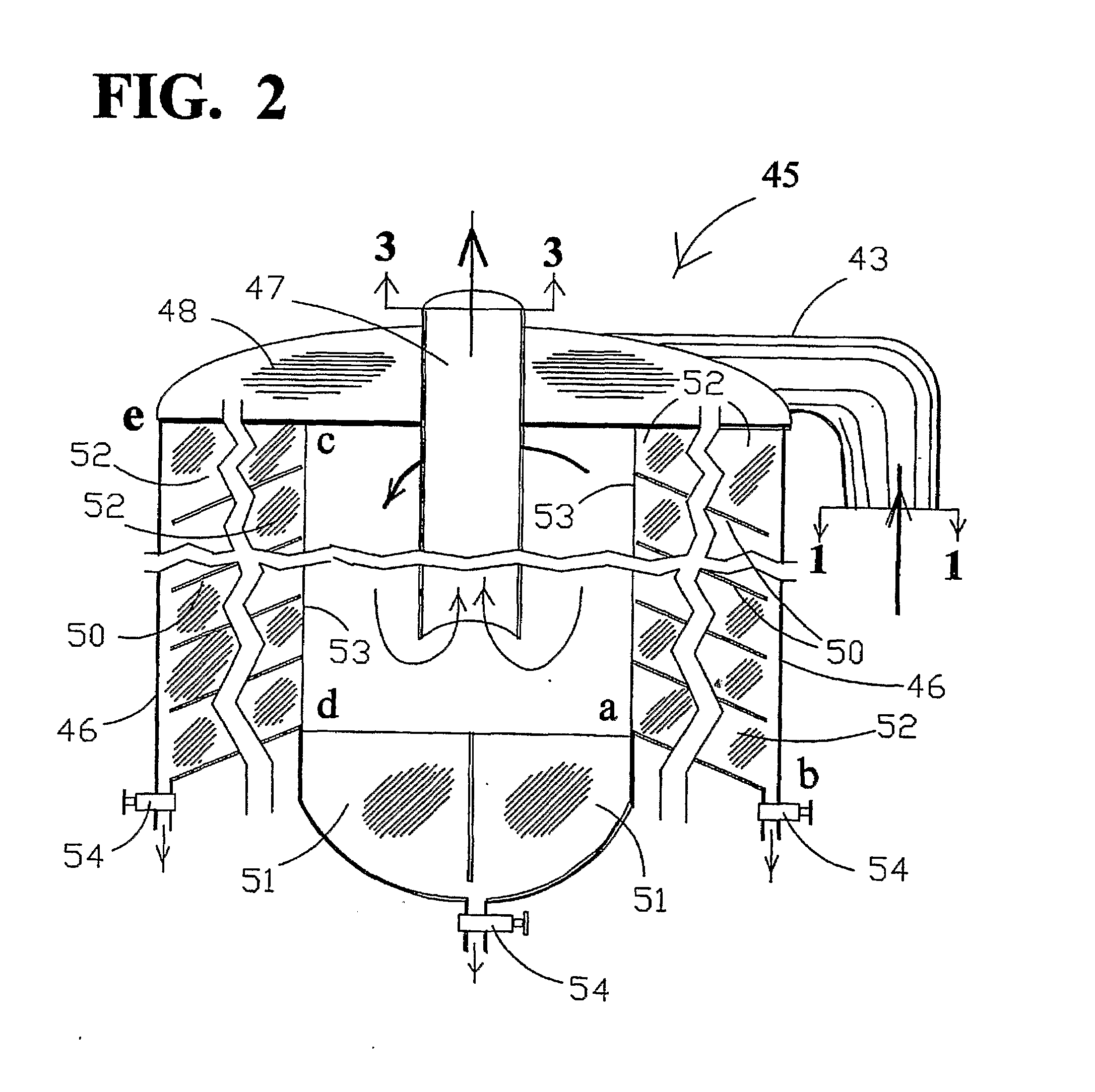

Heat Energy Recapture And Recycle And Its New Applications

InactiveUS20080155985A1Benefit maximizationReduce constructionReciprocating combination enginesEngine fuctionsFusion powerEngineering

A heat absorbing radiator and a gas turbine engine or a reciprocating piston engine are used to recapture and reconvert wasted heat energies into electric power and finally into hydrogen-deuterium fuel by having the engine's tailpipes submerged in cold compressed air inside the heat absorbing radiator pipes in reverse air flow to further drive the same engine. In order to capture fusion heat energy a hydrogen bomb is detonated in deep ocean to catch the flames by the water and the hot water energizes compressed air inside heat absorbing radiator pipes. In order to produce fusion energy an electric arc is passed thru / across liquid or gaseous deuterium by an electro-plasma torch and by a sparkplug in an internal combustion engine, or by detonating a dynamite inside liquid deuterium. Diamond is produced by placing carbon inside a hydrogen bomb which is then detonated in deepwater. Deuterium fusion flame is used first in smelting glass into large structural sizes before running an engine.

Owner:LABRADOR GAUDENCIO AQUINO

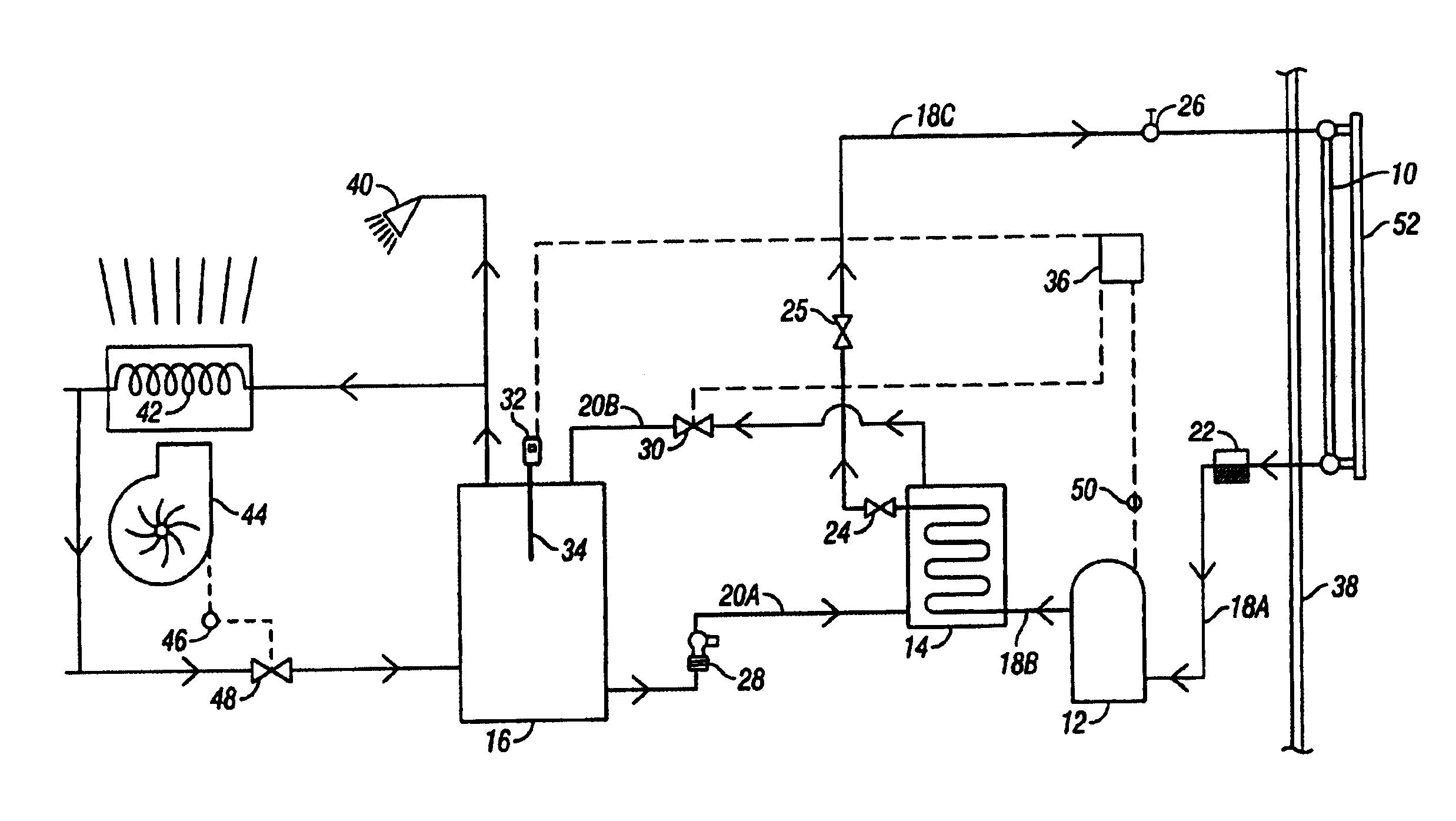

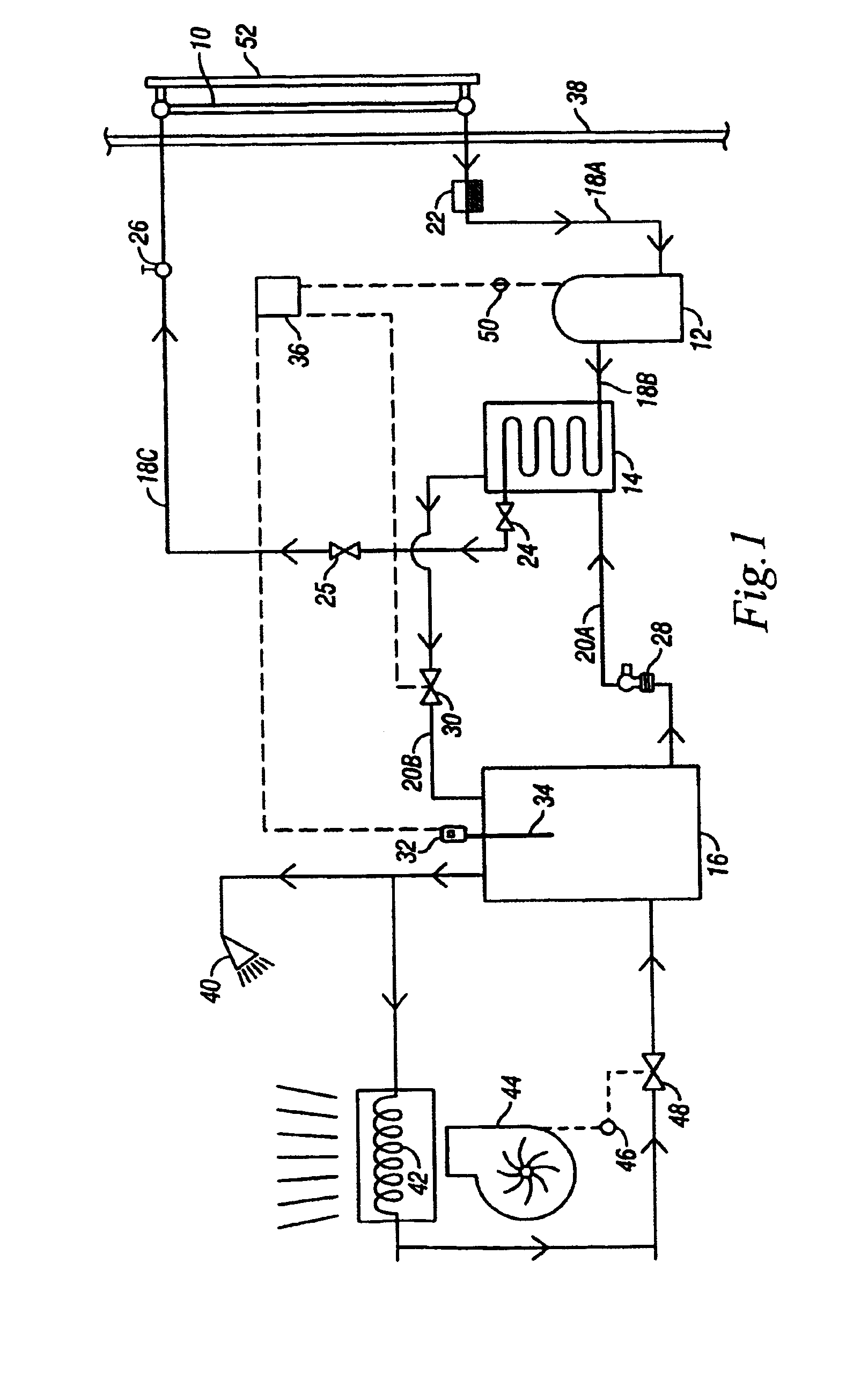

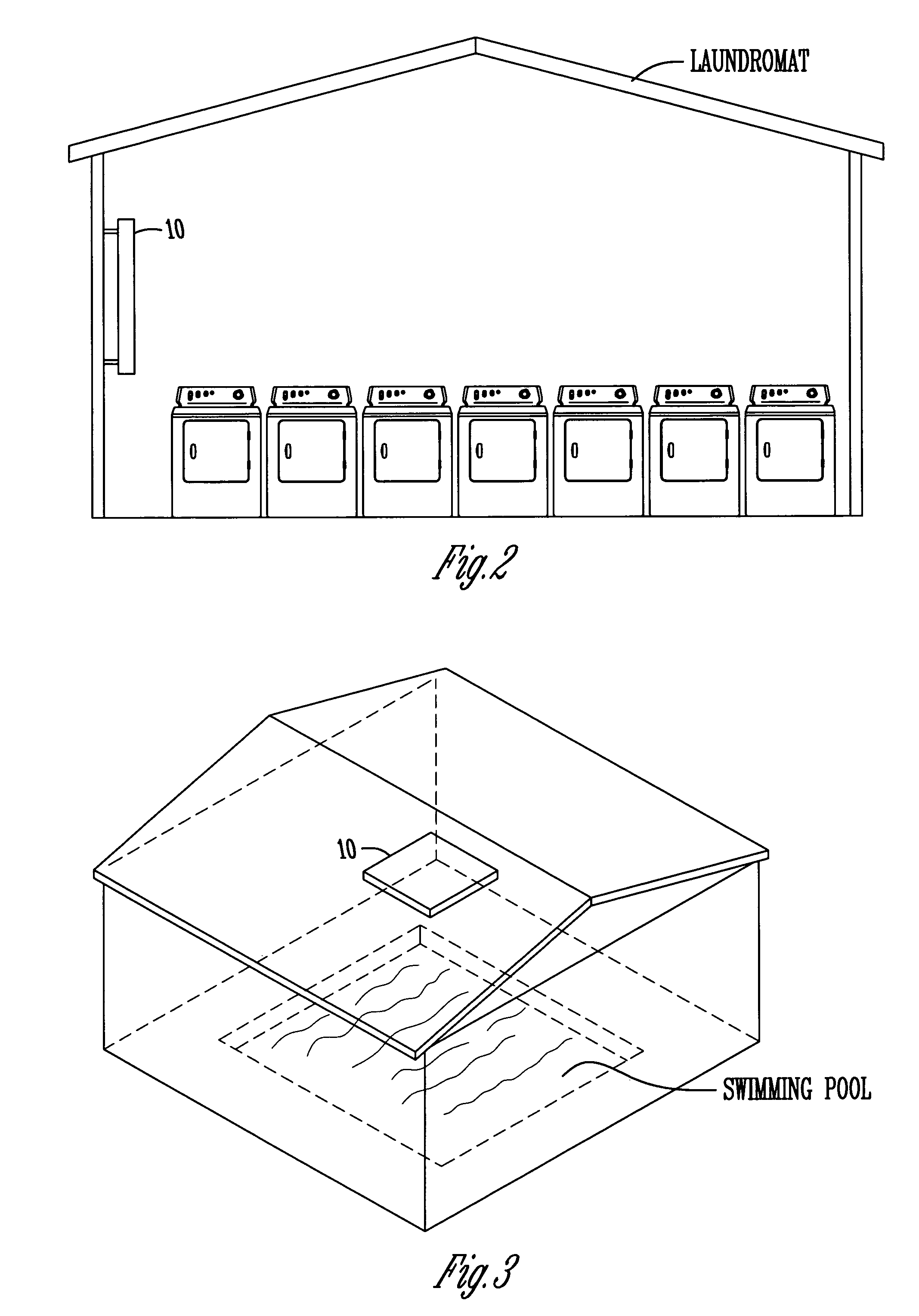

Ambient thermal energy recovery system

InactiveUS7040108B1Heat dissipationIncrease temperatureHeat pumpsCentral heating with accumulated heatWater storage tankEngineering

A method and system for recovering thermal energy from an ambient environment includes an evaporator plate assembly located in the ambient environment, such as outdoors to absorb thermal energy from air. A compressor, heat exchanger, and water storage tank are located indoors. Fluid lines provide a closed circuit between the evaporator plate assembly, the compressor, and the heat exchanger. Water lines provide a flow path between the exchanger and the hot water tank. Refrigerant fluid in the evaporator plate assembly absorbs thermal energy from the ambient environment, and the fluid is then compressed by the compressor to increase the temperature thereof. The heated fluid transfers thermal energy to water in the heat exchanger, which is then stored in the tank for use. The hot water can be circulated to furnace coils wherein air is blown over the coils to absorb heat therefrom, and used to heat one or more rooms.

Owner:FLAMMANG KEVIN E

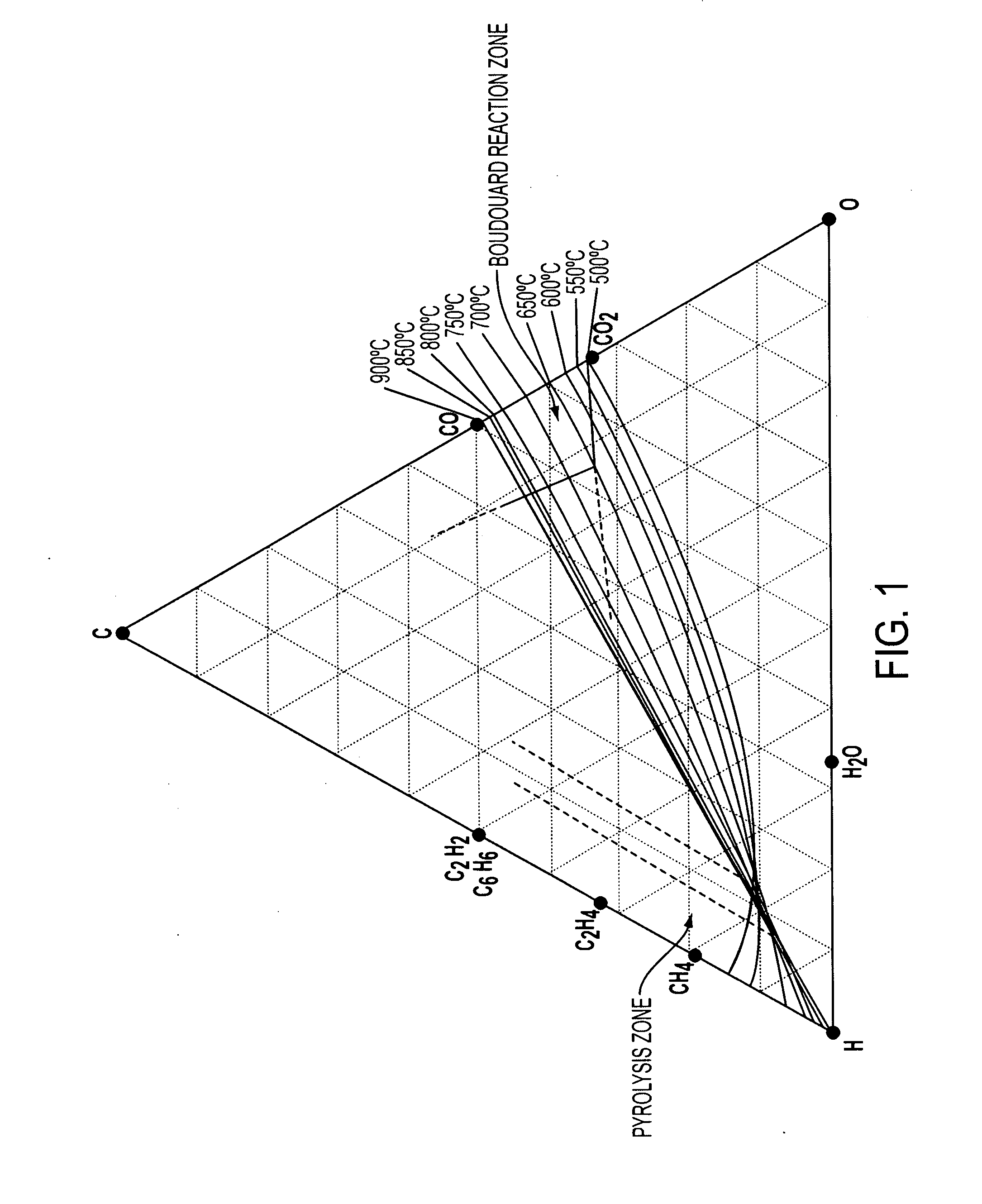

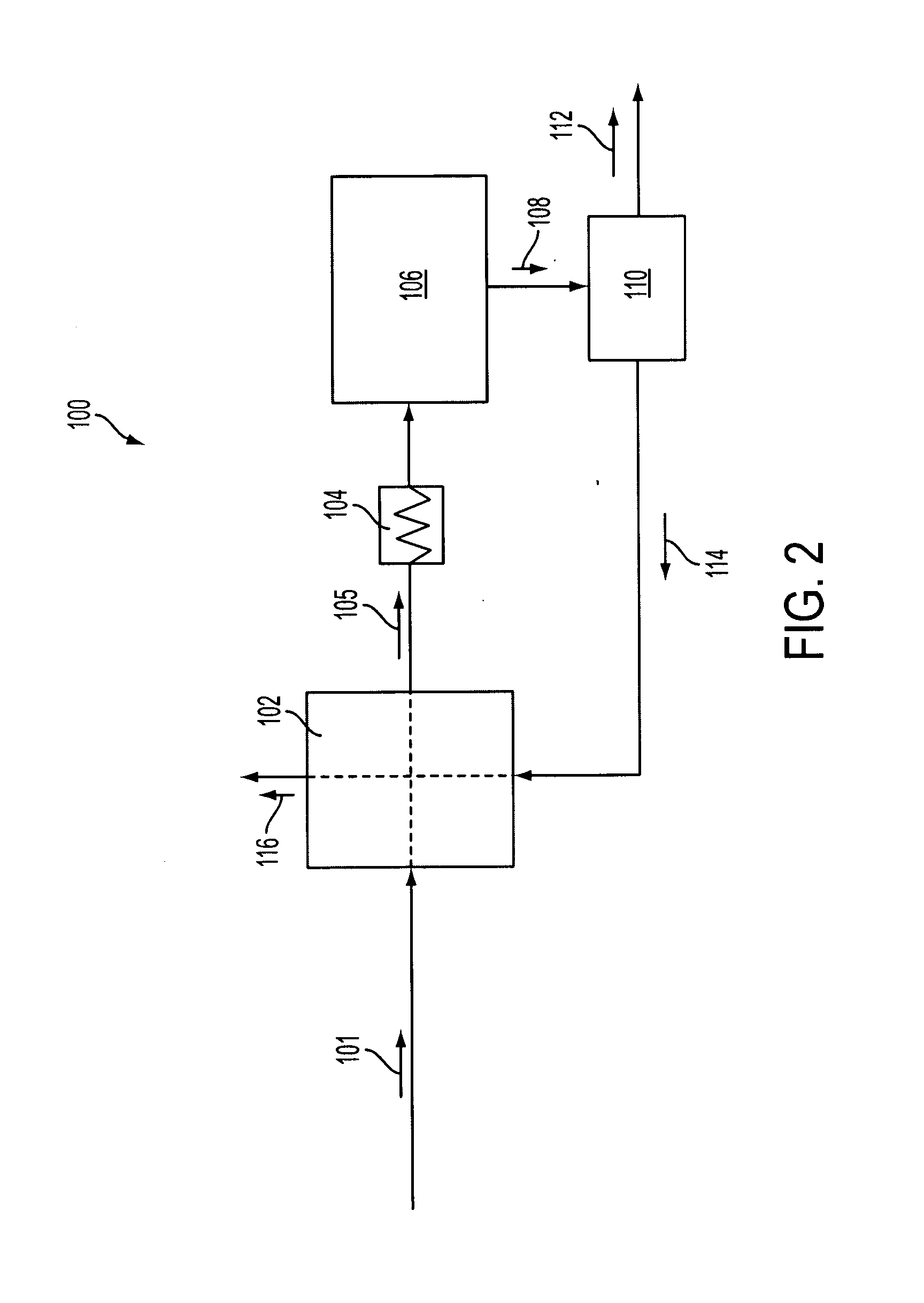

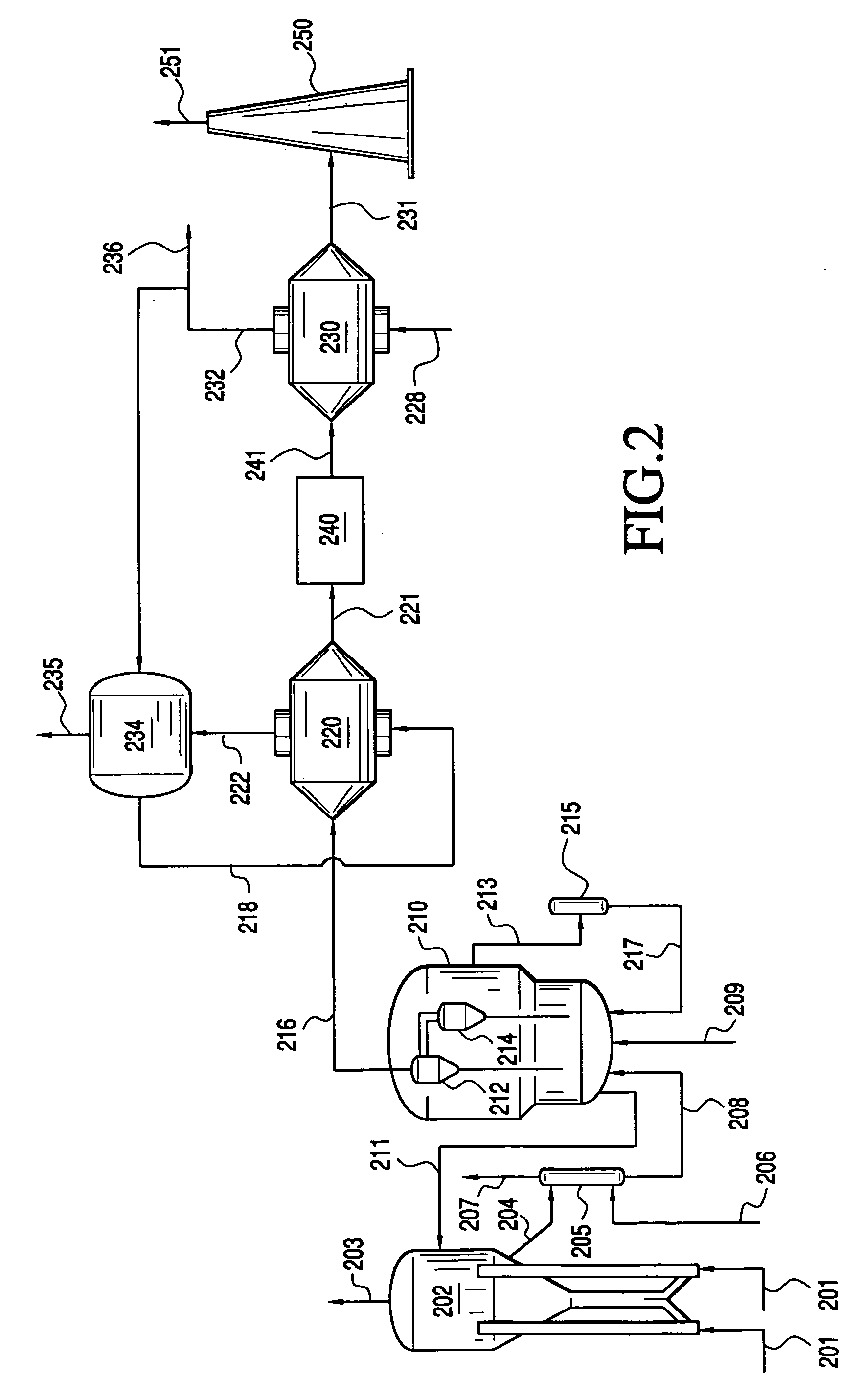

Methods and systems for thermal energy recovery from production of solid carbon materials by reducing carbon oxides

A method of thermal energy recovery from production of at least one solid carbon material comprises reacting at least one carbon oxide material and at least one gaseous reducing material at a temperature of greater than or equal to about 400° C., at a pressure greater than or equal to about 1×105 pascal, and in the presence of at least one catalyst material to produce at least one solid carbon material and a gaseous effluent stream comprising water vapor. Thermal energy is extracted from the gaseous effluent stream comprising water vapor. Other methods of generating recoverable thermal energy are disclosed, as is a solid carbon production system having thermal energy recovery.

Owner:SEERSTONE

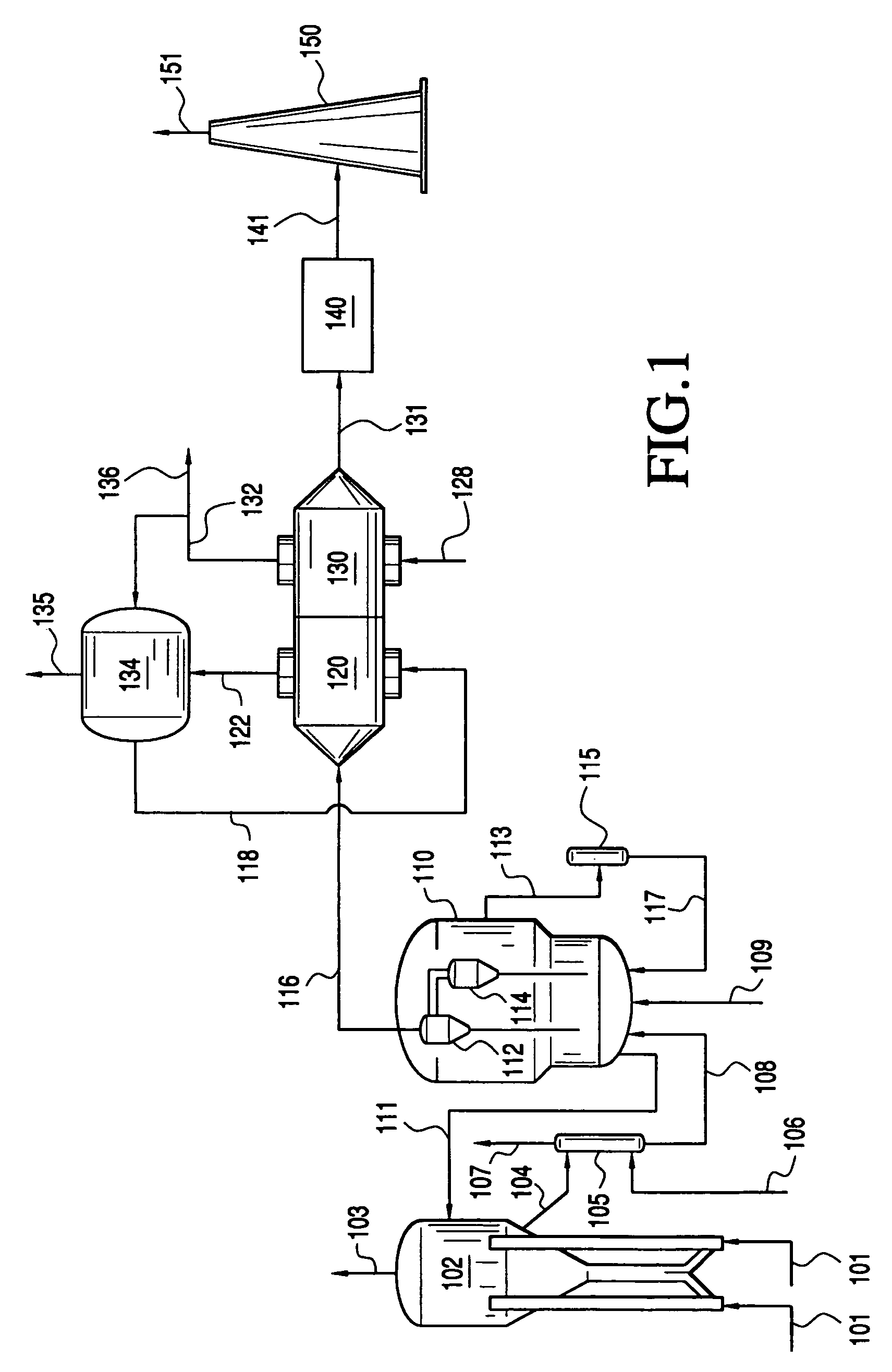

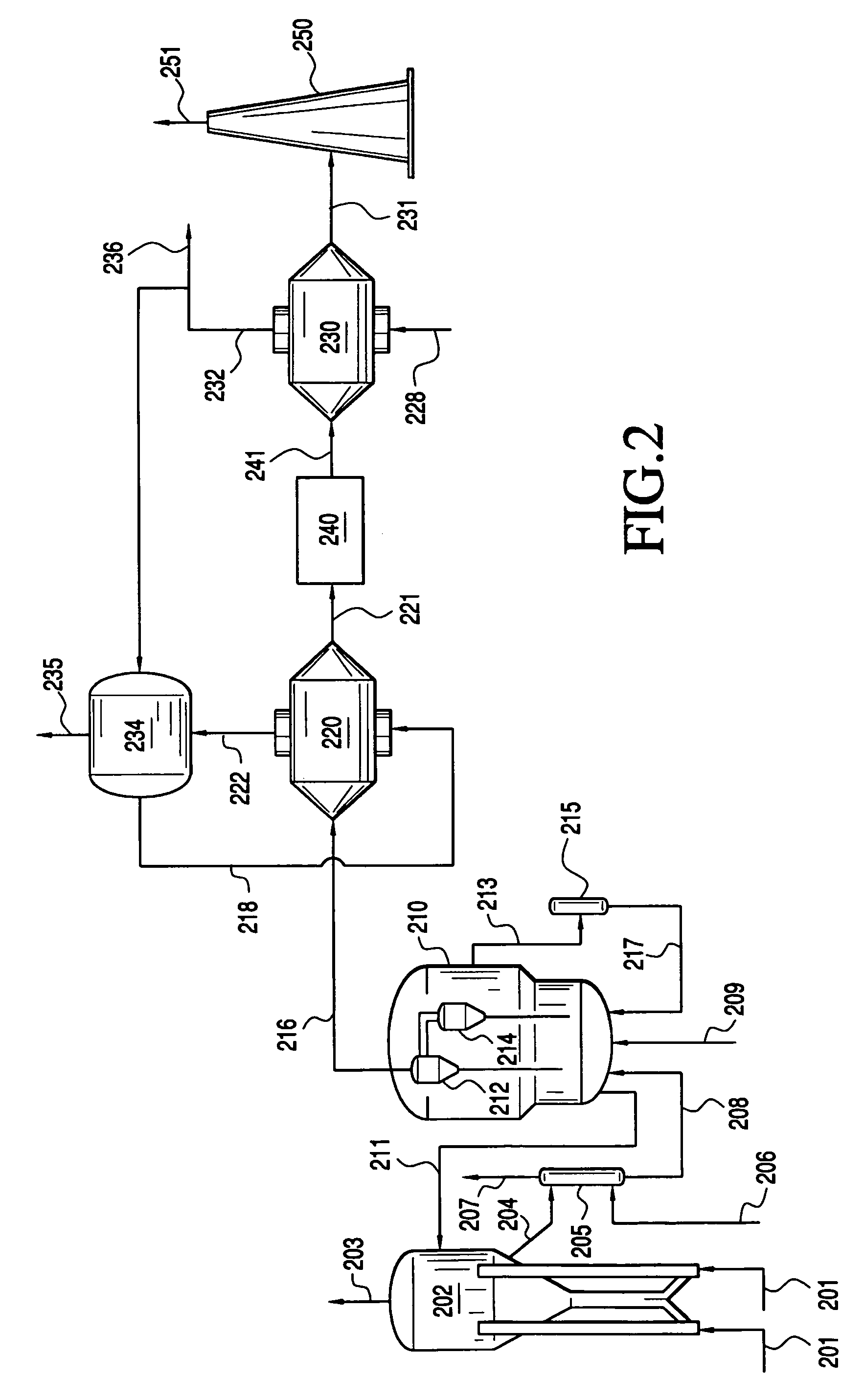

Heat recovery technique for catalyst regenerator flue gas

ActiveUS20050238548A1Effective recoveryIncrease steamThermal non-catalytic crackingCatalytic crackingFlue gasProcess engineering

A technique for recovering heat from a high temperature effluent stream from catalyst regeneration or the like, comprising processes and means for: (a) passing the effluent stream in heat exchange relationship in a steam generator with boiler feed water to produce high pressure steam and partially cool the effluent stream; (b) passing the partially cooled effluent stream from the steam regenerator in heat exchange relationship to preheat high pressure boiler feed water and further cool the effluent stream; and (c) passing the preheated boiler feed water to the steam generator. The apparatus and processes for thermal energy recovery may be used to treat hot regenerator effluent from FCC or OTO-type processes, thereby producing a cooled flue gas stream to discharge to ambient atmosphere.

Owner:EXXONMOBIL CHEM PAT INC

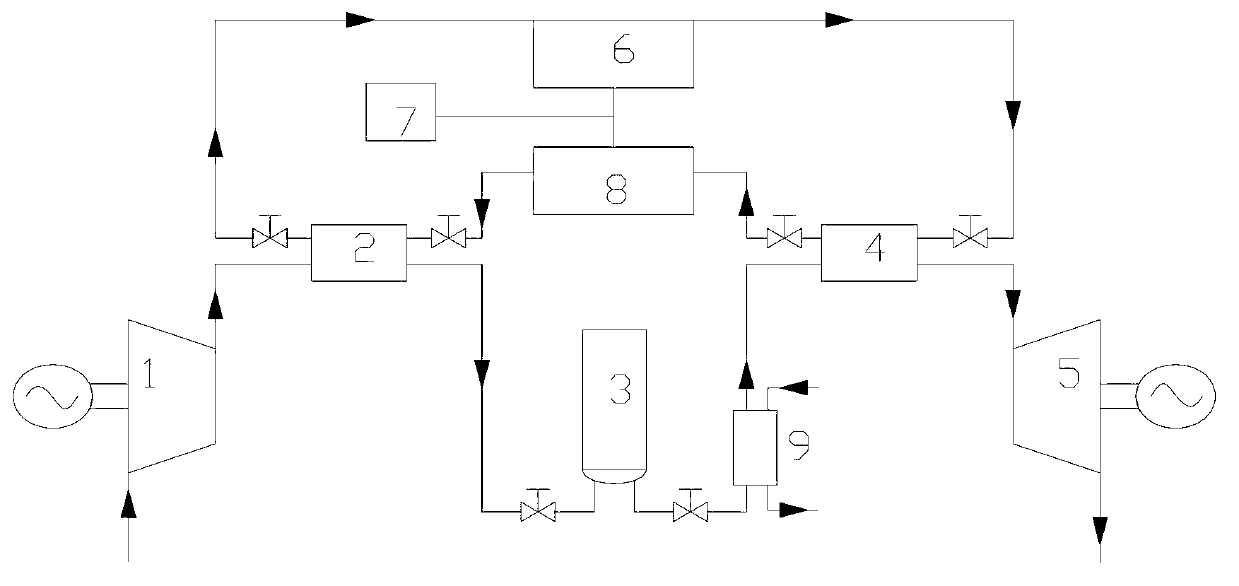

Heat-regenerated compressed air energy storage system

ActiveCN103216426AHigh boiling pointImprove heat storage capacityPositive displacement pump componentsEngine componentsHeat energyNatural gas

The invention relates to the field of electric energy storage and discloses a heat-regenerated compressed air energy storage system. During the energy storage of the system, heat energy produced during air compression is recovered and stored by a cooler and a heat storage device by using a cooling medium; and during the energy release of the system, heat stored by the heat storage device heats compressed air through a heat regenerator, and the heated compressed air is used for the power generation of a turbine generator set. The heat storage device is pressurized by adopting a pressurizing system, so that the boiling point of the cooling medium is increased; the system is simple in structure, good in heat storage effect and low in construction cost, the power generating efficiency is increased, and the electric energy conversion ratio is increased; water is selected as the cooling medium, so that the system has the advantages of easiness in material obtaining and no environmental pollution; and meanwhile, environmental residual heat, waste heat and solar energy are adopted as heat sources which are used for preheating the compressed air, and the mode of natural gas afterburning is abandoned, so that the zero emission is realized.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

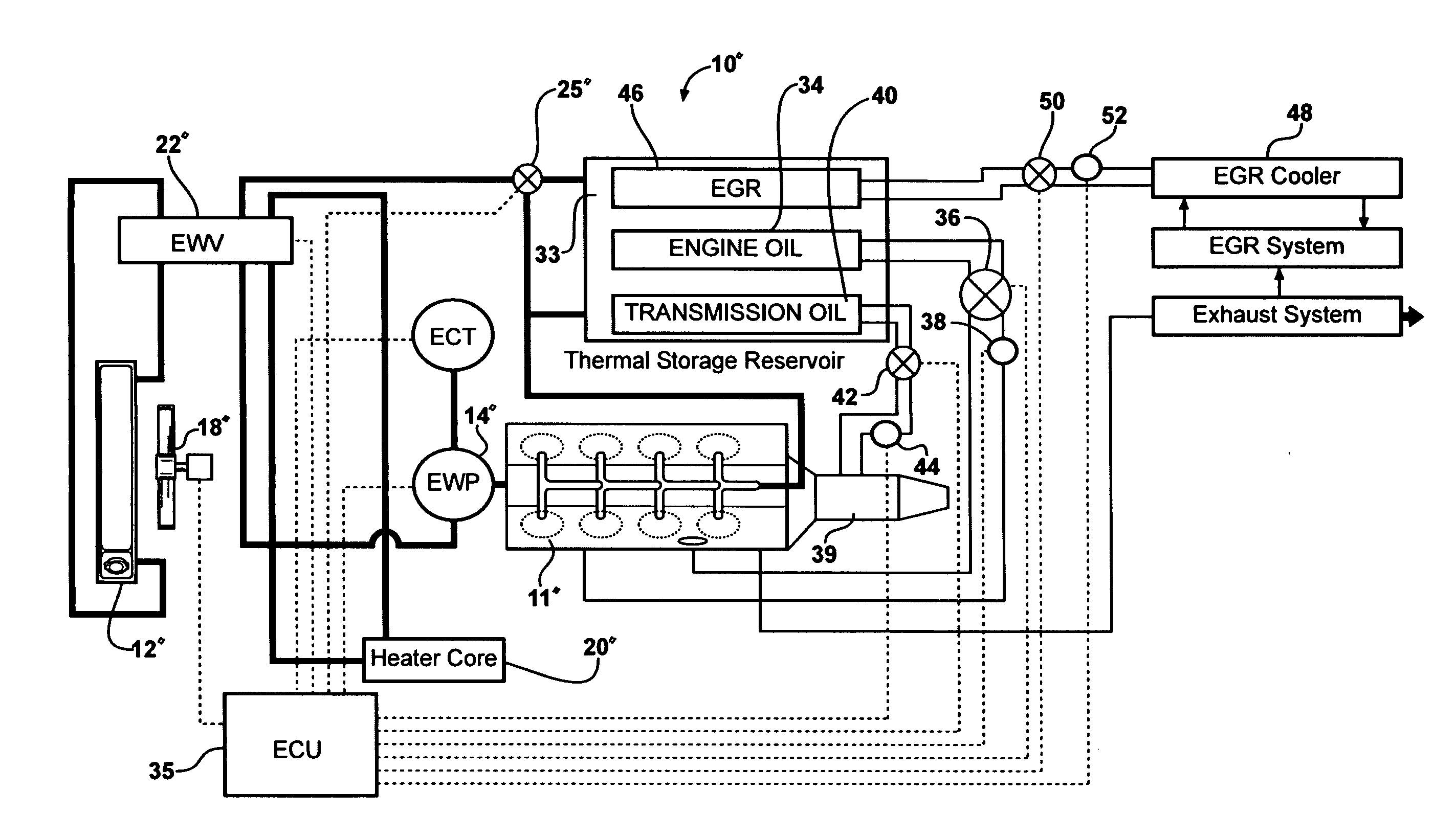

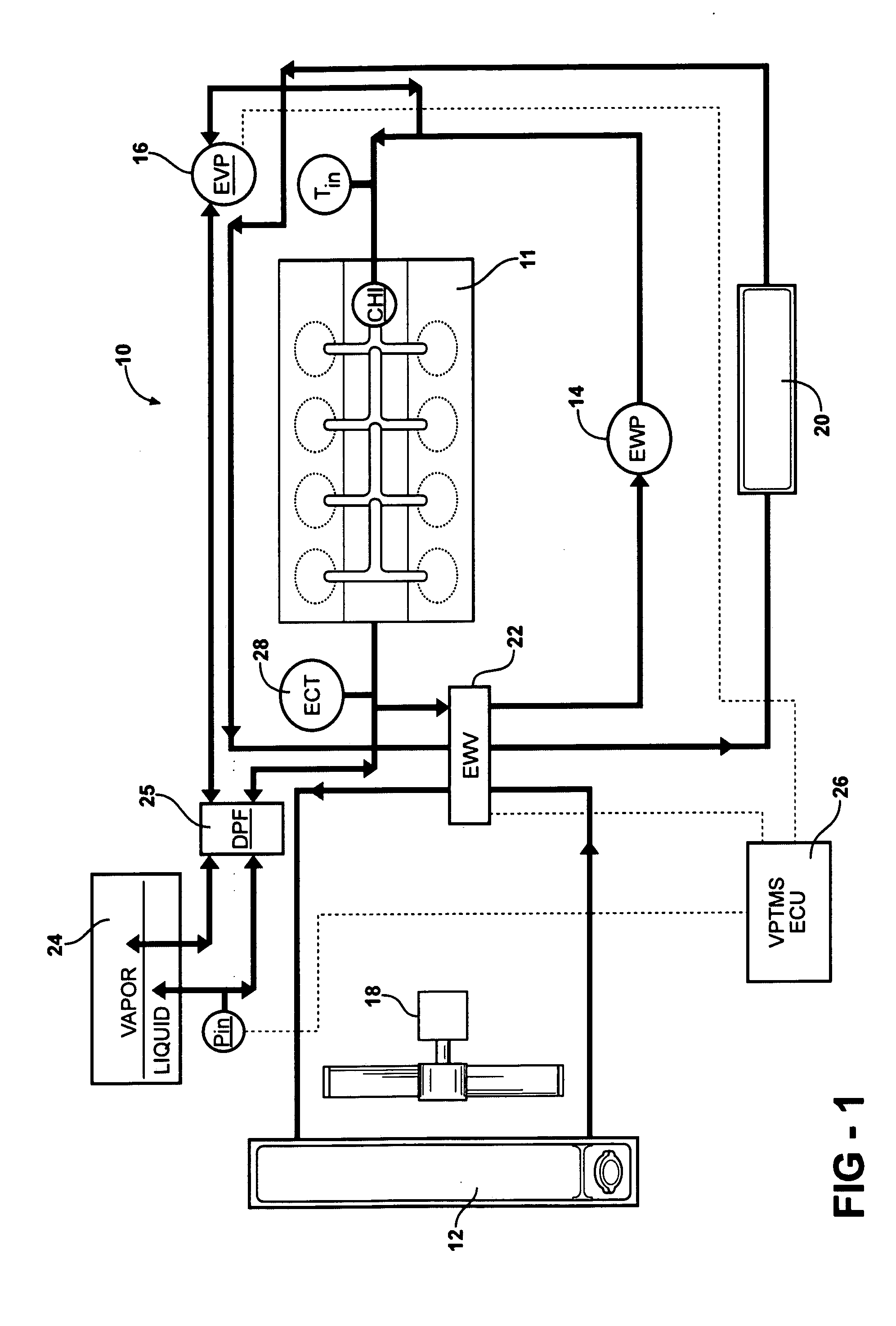

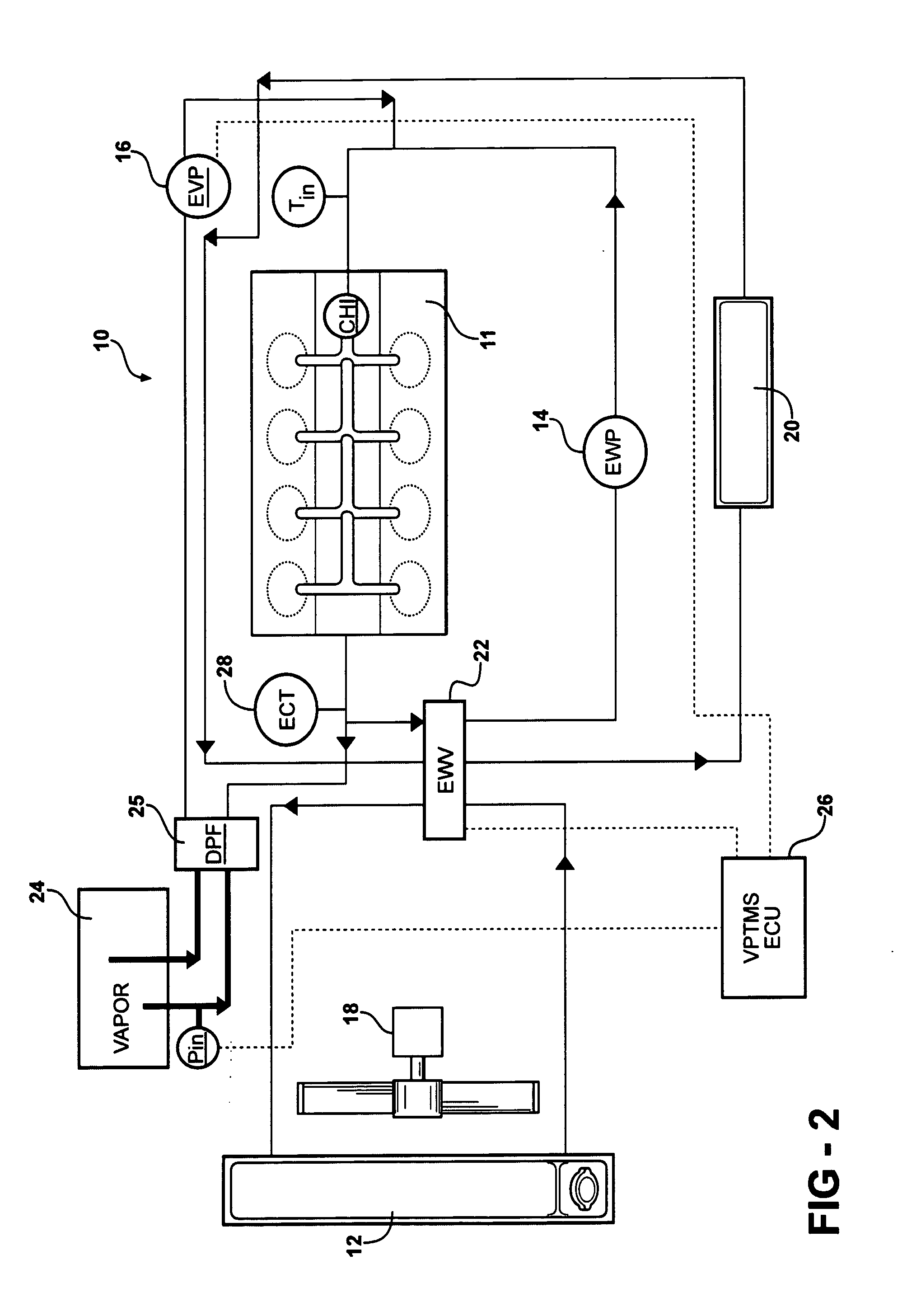

Thermal energy recovery and management system

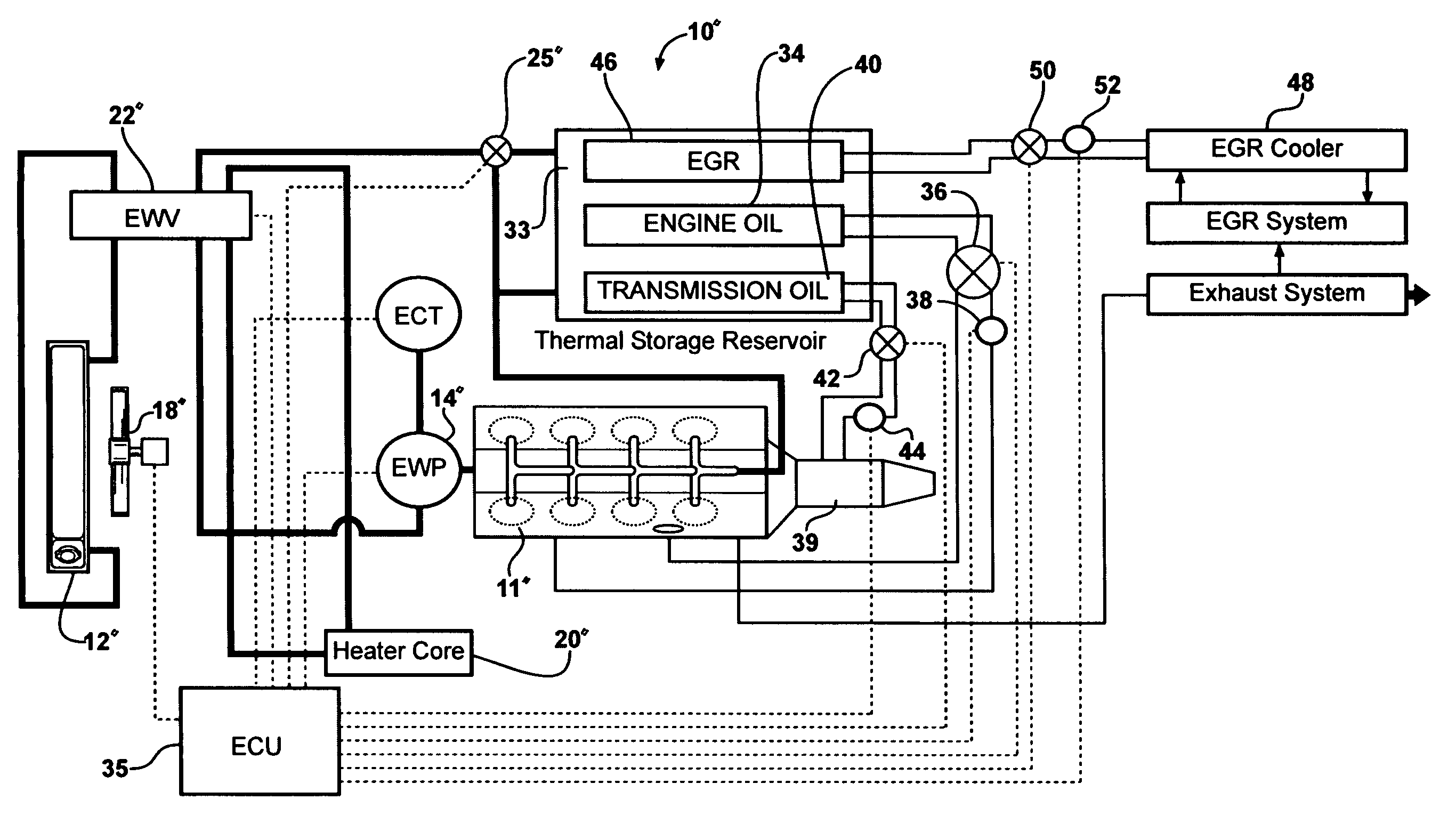

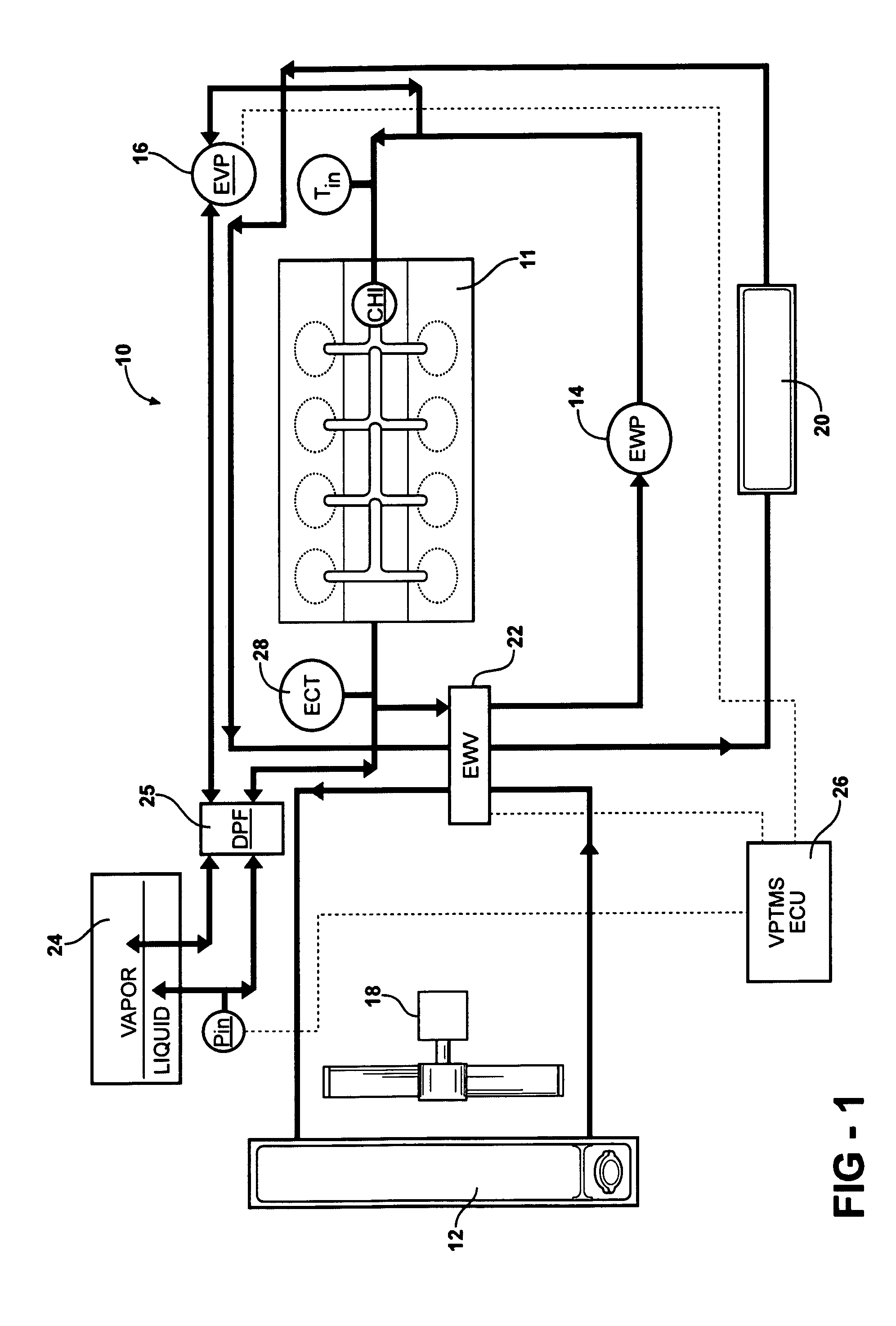

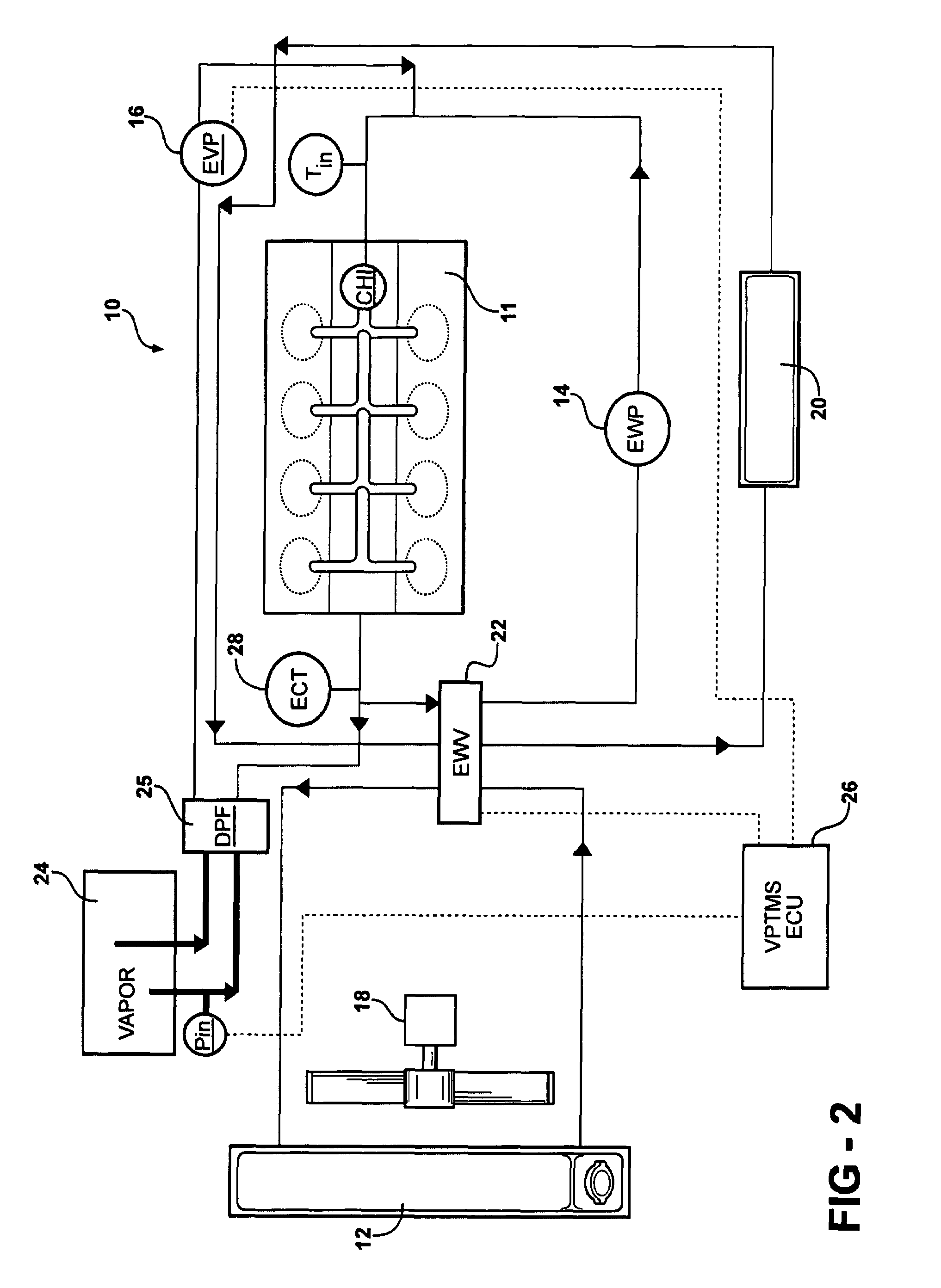

ActiveUS7467605B2Emission reductionMaximize efficiencyAir-treating devicesCoolant flow controlInternal combustion engineManagement system

A thermal energy recovery and management system for an internal combustion engine for balancing the heat energy between a primary reservoir and the engine to maximize an operating efficiency of the engine and associated engine components. The primary reservoir storing or releasing heat energy produced by the engine to achieve a balance of energy between the engine and associated components.

Owner:HANON SYST

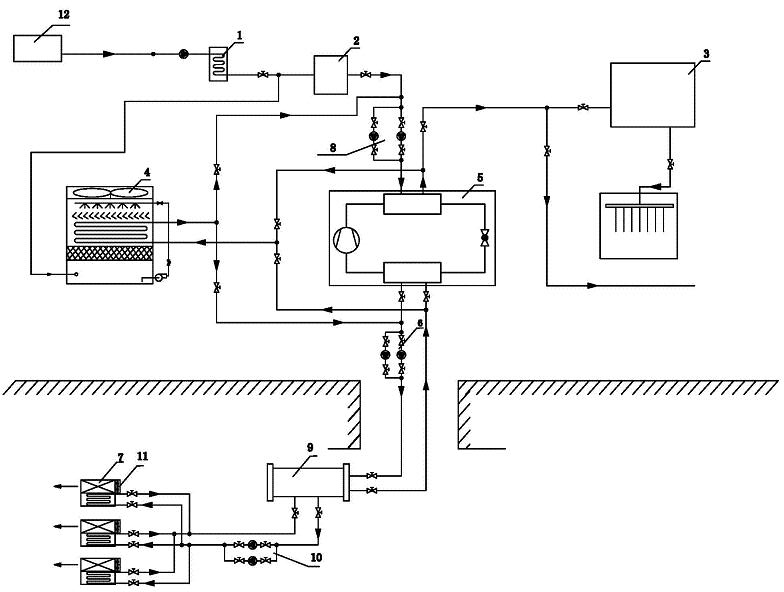

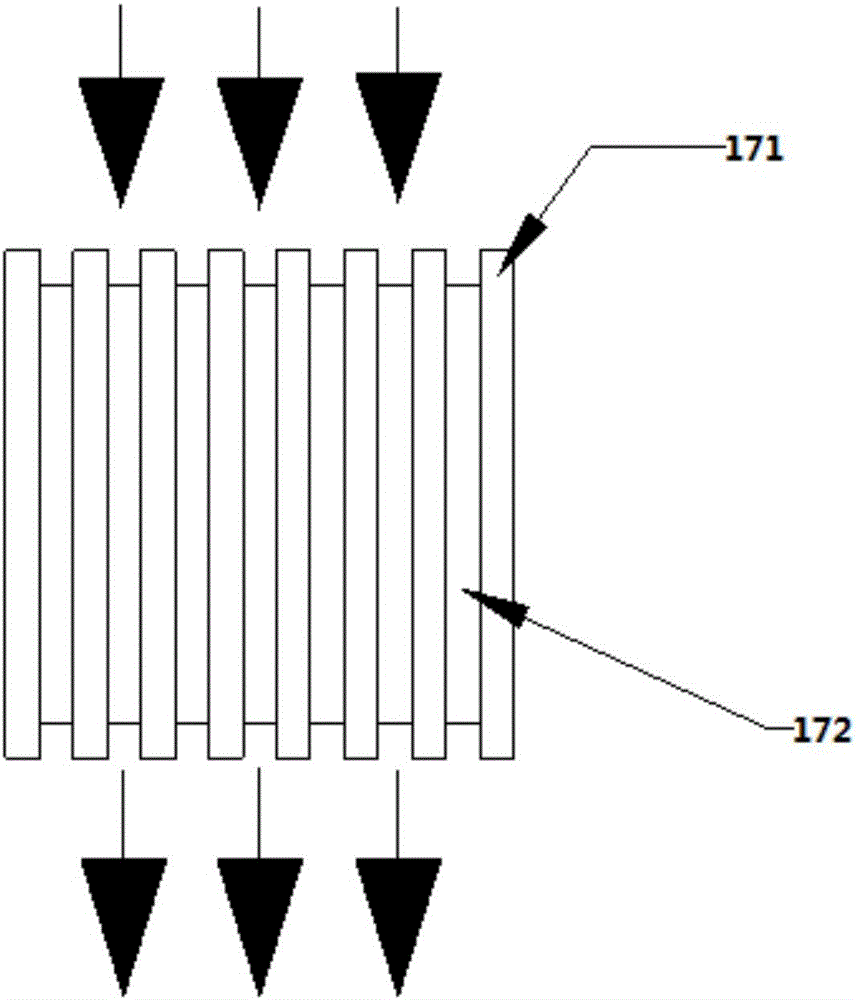

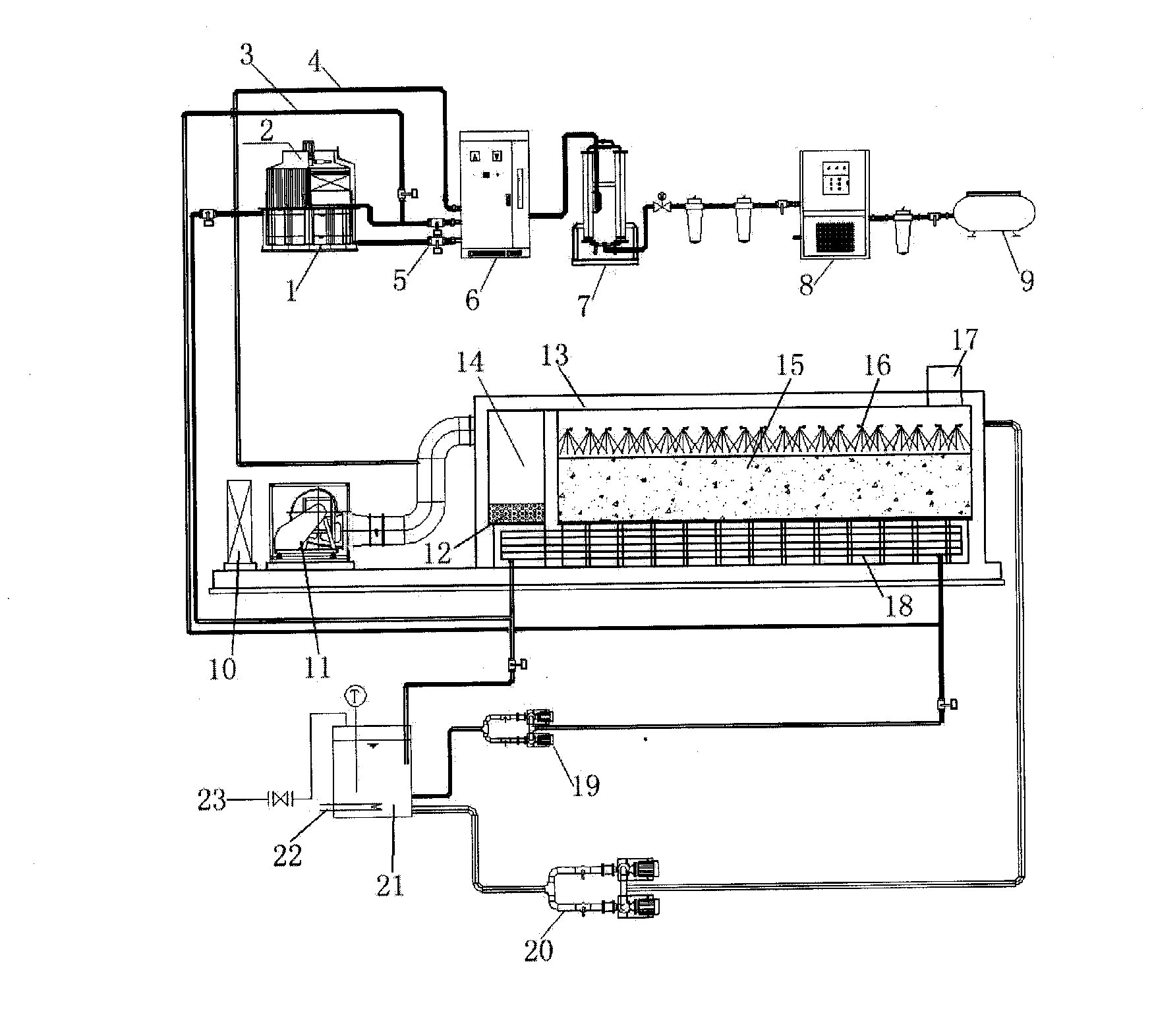

Heat-radiating, recovering and cooling system for mine

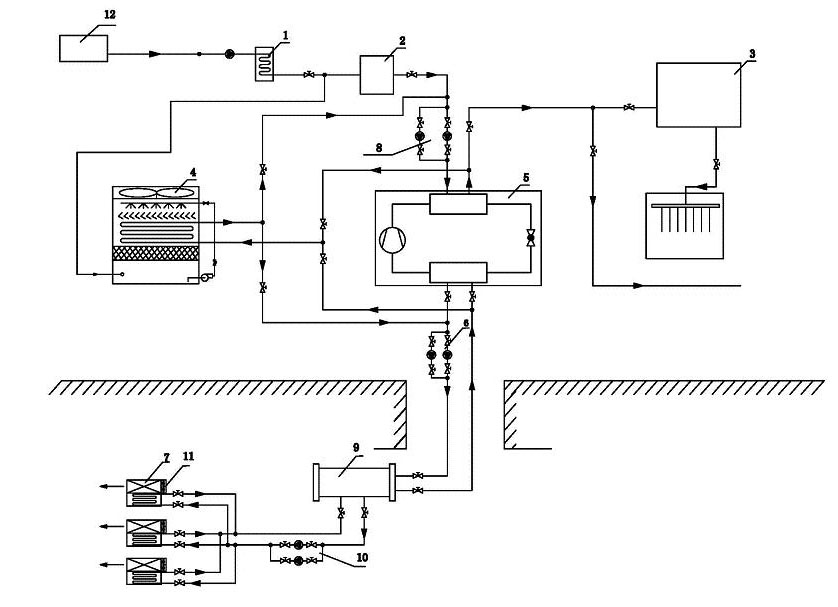

ActiveCN102121392AMeet the requirements of energy saving and environmental protectionGood well cooling effectTunnel/mines ventillationCooling towerSoftened water

The invention discloses a heat-radiating, recovering and cooling system for a mine. The system comprises an enclosed cooling tower, a thermal energy recovering device, a thermal energy recovering device water circulating pump, a pressure exchanger, a pressure exchanger water circulating pump, a refrigerating and cooling device, a fan and an underground cooling unit water circulating pump, whereinall components adopt modular designs. The system integrates the advantages of centralized refrigeration and distributed refrigeration, so that a good underground cooling effect can be achieved. Meanwhile, a thermal energy recovery technology is adopted, so that all thermal energy produced by a refrigerator is recovered and utilized, the recovered thermal energy can be used for supplying hot waterfor bathing to the ground as well as heat in office areas in winter, and a boiler can be fully eliminated. A water treatment system of the system can be used for producing purified water or softened water by using waste water drained by a sewage treatment plant, and the produced water can be recycled by the system, so that the requirements for energy conservation and environmental protection are met.

Owner:DALIAN EAST REFRIGERATION EQUIP

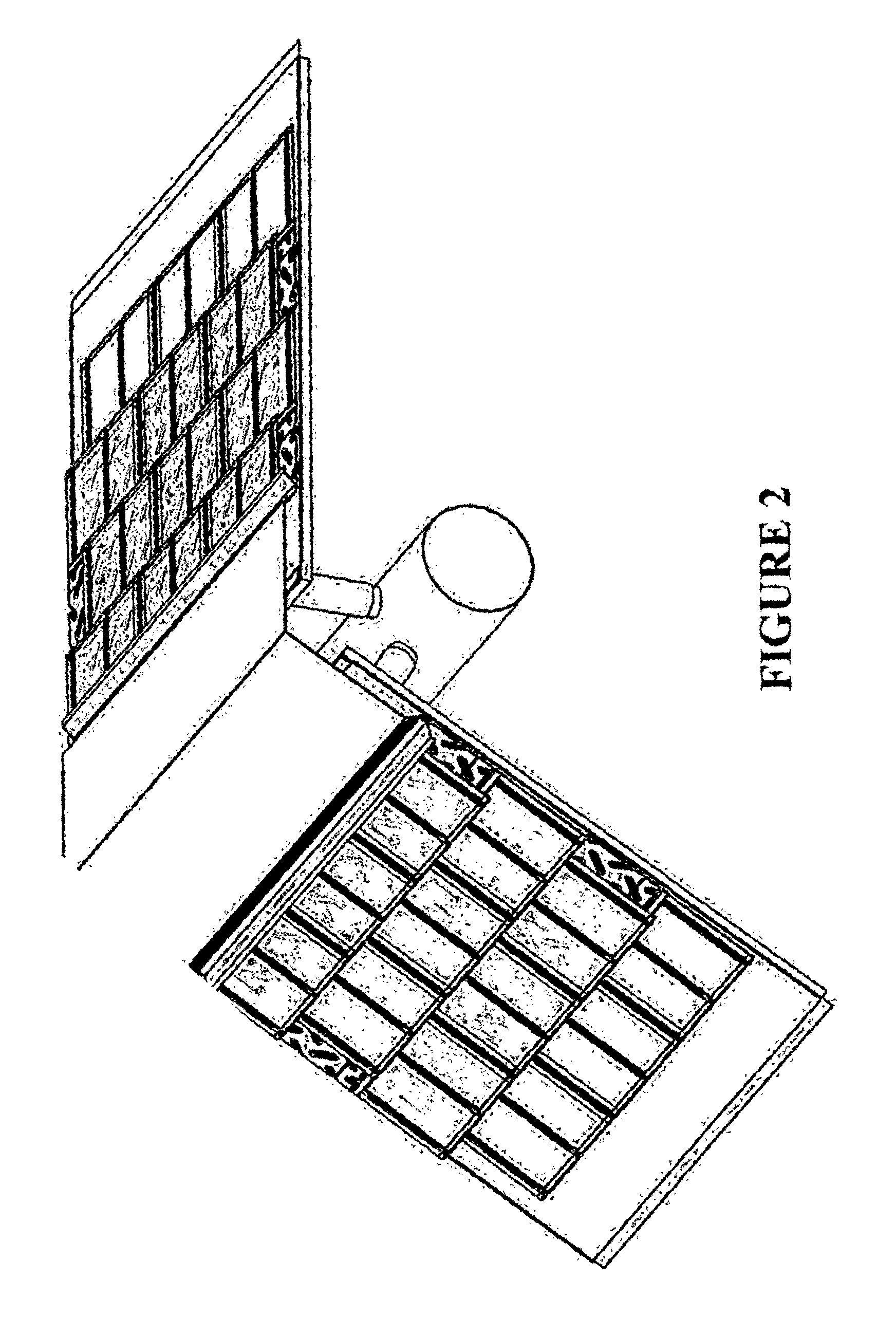

Roofing, cladding or siding product, its manufacture and its use as part of a solar energy recovery system

ActiveUS9518391B2Light weightEasy to installPhotovoltaic supportsSolar heating energyElectrical batteryStructural engineering

This disclosure provides a roofing, cladding or siding product which is light weight, easy to install, durable and resistant to environmental wear. One embodiment relates to a module that can be used to form a weatherproof covering over top of a building surface. Another embodiment is a module which can, in additional to forming a weatherproof covering, be used as part of a thermal energy recovery or removal system. Yet another embodiment is a module which can, in addition to forming a weatherproof covering, and optionally in addition to being useful as part of a thermal energy recovery system, bears an array of solar cells to generate electrical energy. Assemblies, systems, uses, and methods of manufacture are also described.

Owner:ZINNIATEK

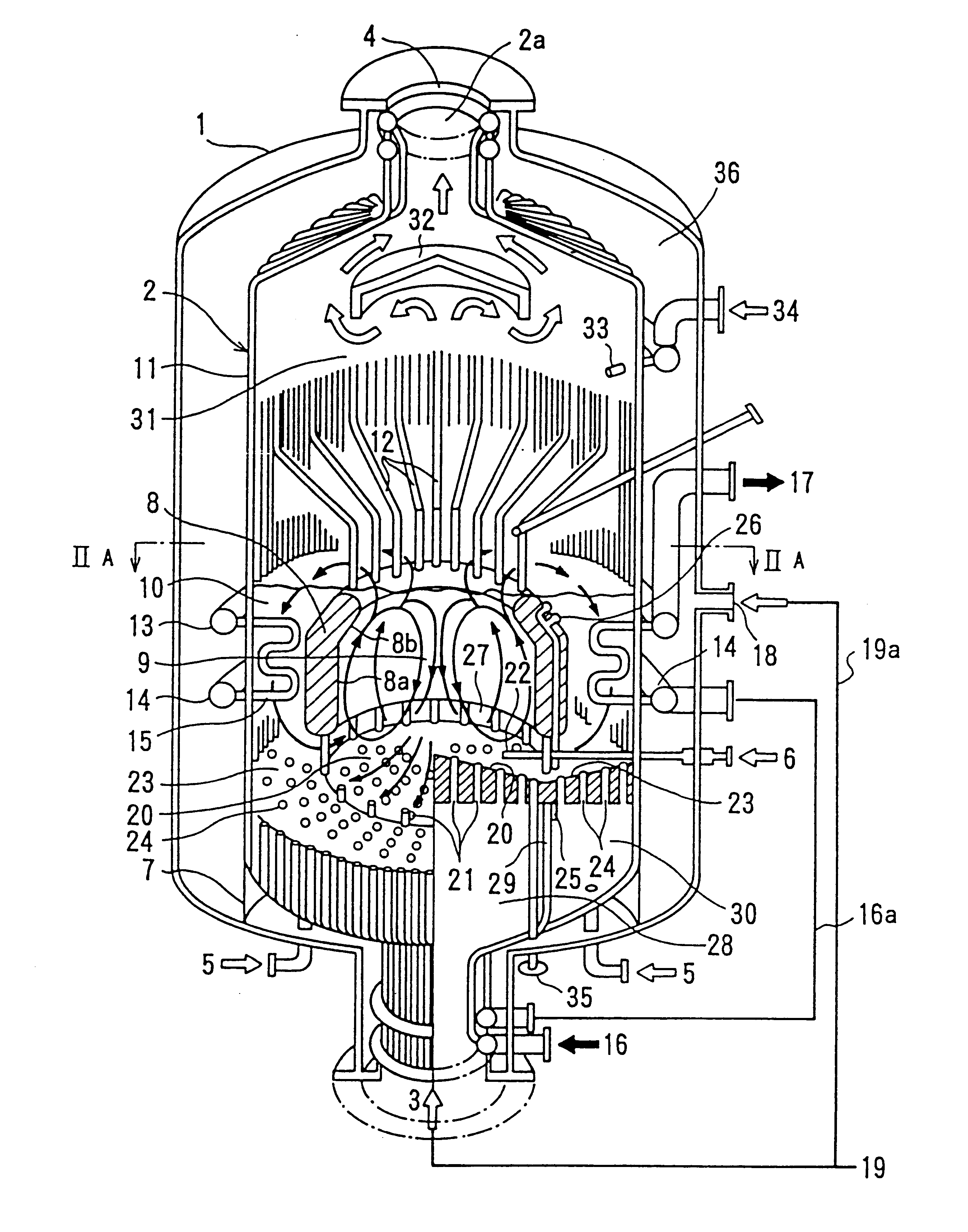

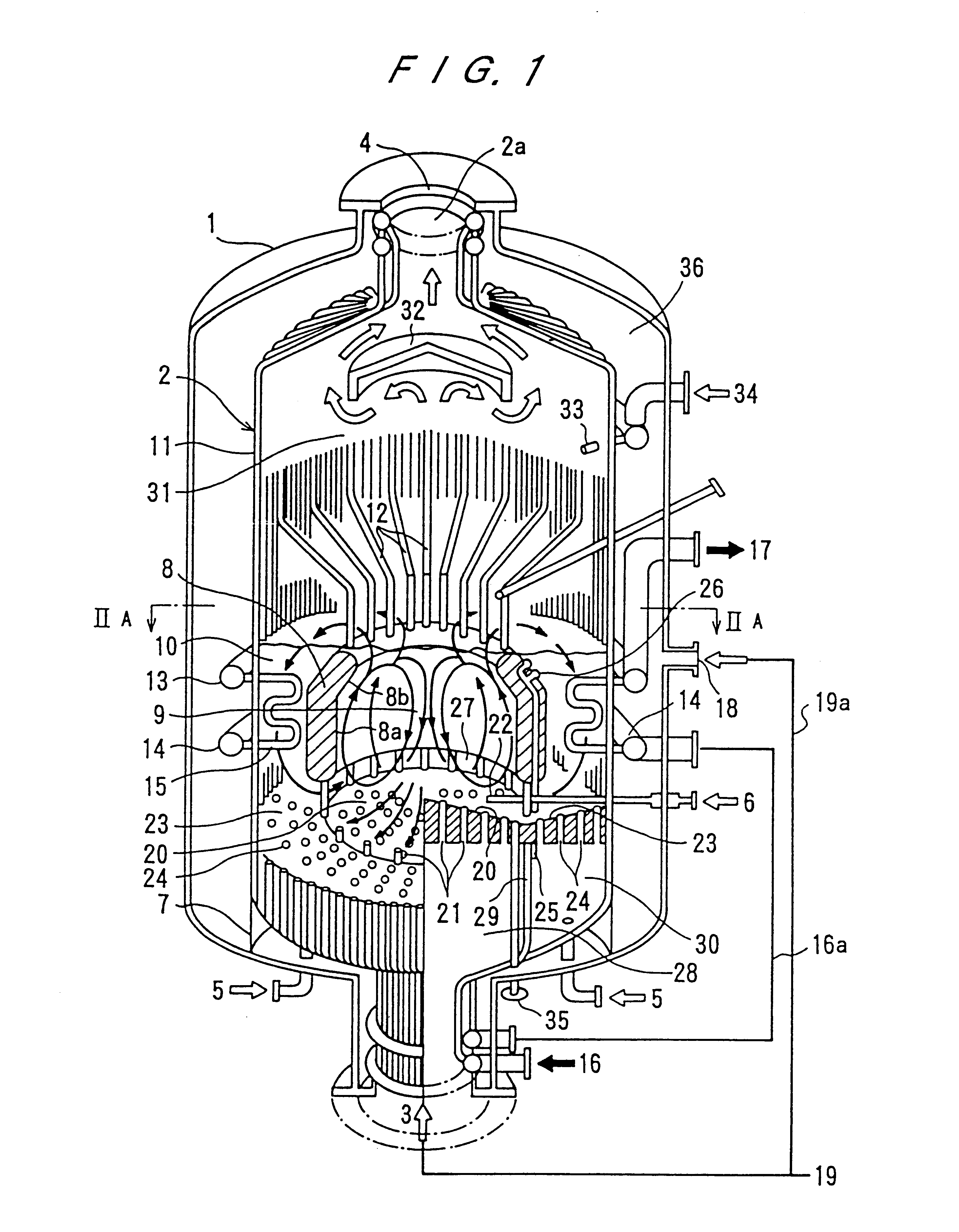

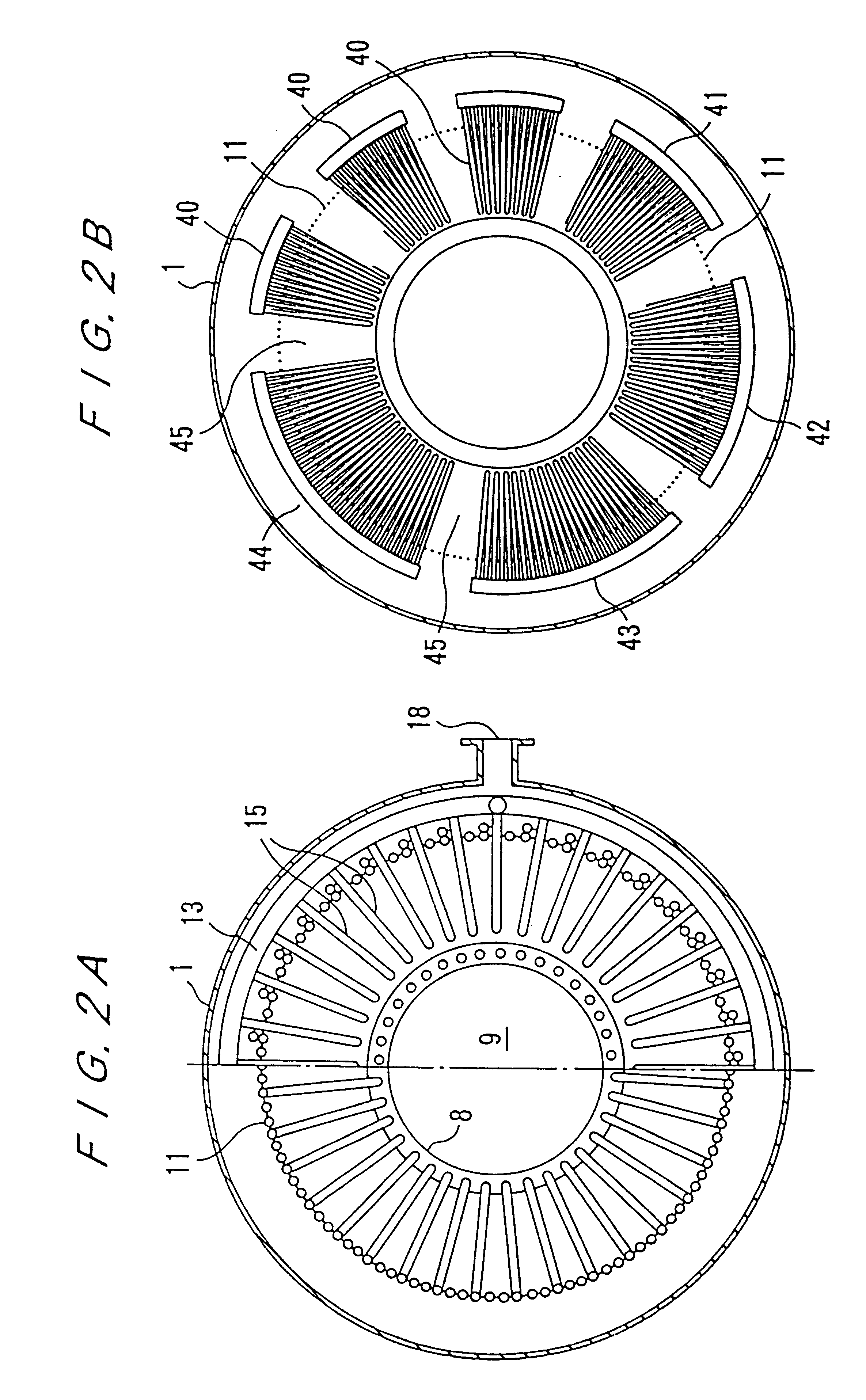

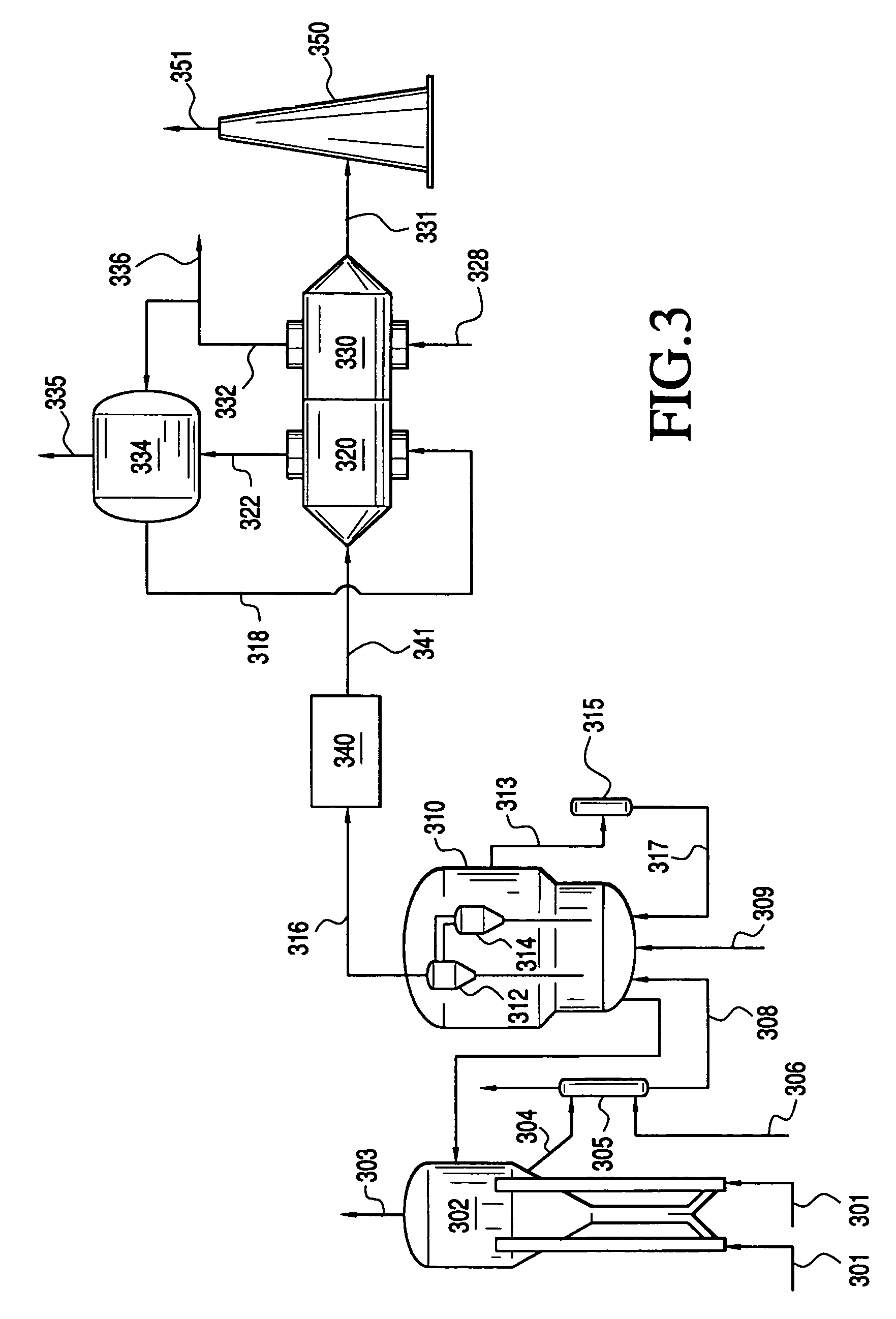

Pressurized internal circulating fluidized-bed boiler

InactiveUSRE37300E1Reduce output energyReduction factorFluidized bed combustionGasifier feeding meansCombustion chamberCombustor

A pressurized internal circulating fluidized-bed boiler is incorporated in a combined-cycle electric generating system in which a fuel such as coal, petro coke or the like is combusted in a pressurized fluidized bed and an exhaust gas produced by the combusted fuel is introduced into a gas turbine. The pressurized internal circulating fluidized-bed boiler includes a pressure vessel, a combustor disposed in the pressure vessel and a main fluidized bed combustion chamber provided with an air diffusion device. A thermal energy recovery chamber is partitioned from the main combustion chamber by an inclined partition wall. A fluidized medium flows into and out of the main combustion chamber and the thermal energy recovery chamber. A free board is provided integrally above the main combustion chamber and the thermal energy recovery chamber so that combustion gas from the main combustion chamber and the thermal energy recovery chamber is mixed in the free board.

Owner:EBARA CORP

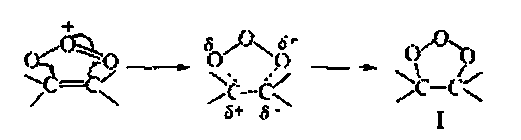

Phase-change heat-exchange type secondary steam heat recovery utilization method, apparatus and use thereof

ActiveCN101476825ASave heatReduce heat pollutionDrying gas arrangementsEvaporationBoiling pointThermal energy

The invention discloses a method and a device for phase-change heat exchange type secondary steam heat energy recovery utilization and application thereof, which aim to solve the technical problems that the prior secondary steam heat energy can or cannot be utilized, or the utilization rate of the heat energy is low, or the secondary steam heat energy can be efficiently utilized, but has low application range. A adopted technical proposal comprises: water for evaporation is injected into a water supply tank of a phase-change heat exchanger; a starting heat pump pumps a steam-water separator, the phase-change heat exchanger, and various evaporation connection pipes and tanks into negative pressure; secondary steam is continuously aerated into a heat exchange tube box of the phase-change heat exchanger; the water for evaporation is heated through heat conduction of a heat exchange tube to ensure that the water for evaporation is increased to a boiling point and absorbs a large amount of vaporization heat to be evaporated into clean steam; and the steam is pumped by a heat pump and is compressed to steam with heat supply network quality for supply or heat consumption equipment to use. The method and the device have the advantages of high utilization rate of the heat energy, and wide application range.

Owner:DONGFANG ELECTRIC MACHINERY

Heat recovery technique for catalyst regenerator flue gas

ActiveUS7404891B2Effective recoveryIncrease heightThermal non-catalytic crackingCatalytic crackingFlue gasProcess engineering

A technique for recovering heat from a high temperature effluent stream from catalyst regeneration or the like, comprising processes and means for: (a) passing the effluent stream in heat exchange relationship in a steam generator with boiler feed water to produce high pressure steam and partially cool the effluent stream; (b) passing the partially cooled effluent stream from the steam regenerator in heat exchange relationship to preheat high pressure boiler feed water and further cool the effluent stream; and (c) passing the preheated boiler feed water to the steam generator. The apparatus and processes for thermal energy recovery may be used to treat hot regenerator effluent from FCC or OTO-type processes, thereby producing a cooled flue gas stream to discharge to ambient atmosphere.

Owner:EXXONMOBIL CHEM PAT INC

Thermal energy recovery and management system

ActiveUS20070272174A1Emission reductionMaximize fuel efficiencyAir coolingMachines/enginesInternal combustion engineHeat energy

A thermal energy recovery and management system for an internal combustion engine for balancing the heat energy between a primary reservoir and the engine to maximize an operating efficiency of the engine and associated engine components. The primary reservoir storing or releasing heat energy produced by the engine to achieve a balance of energy between the engine and associated components.

Owner:HANON SYST

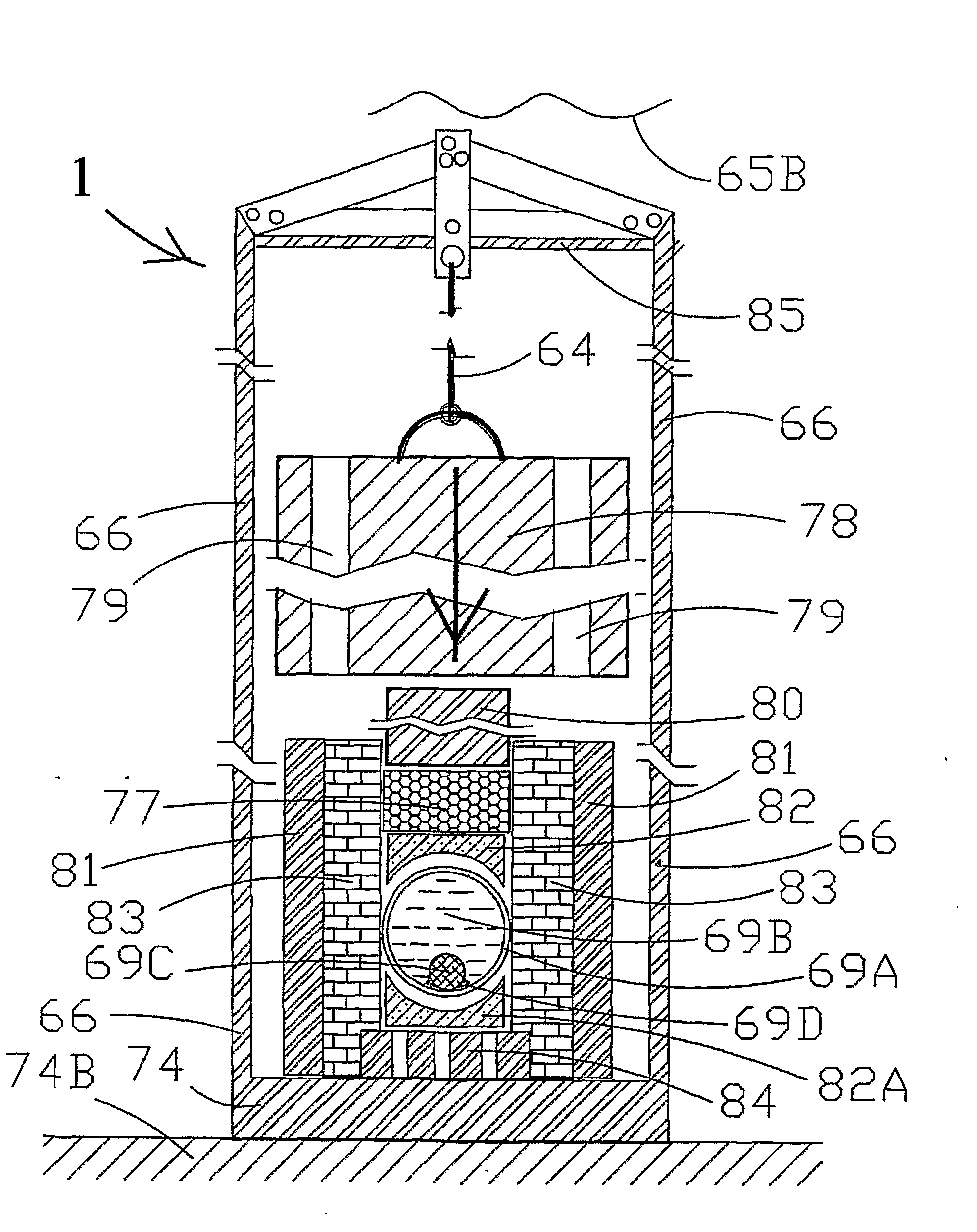

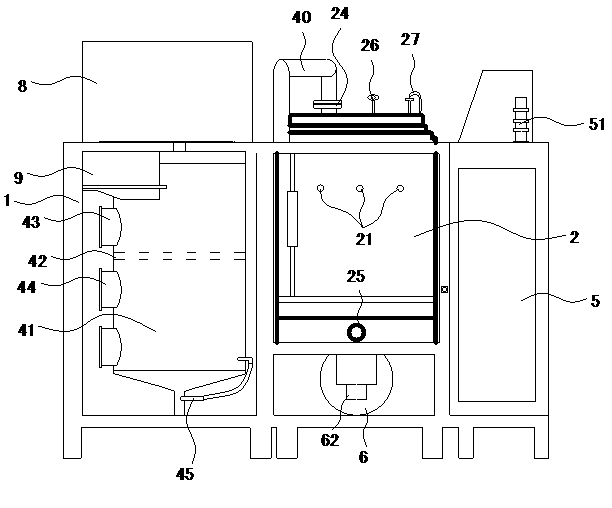

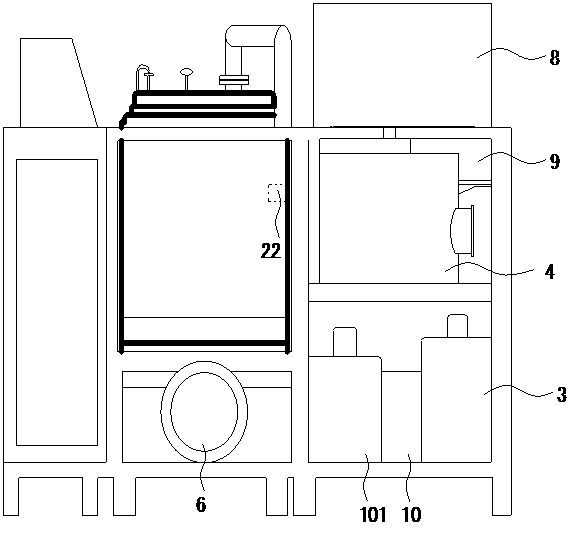

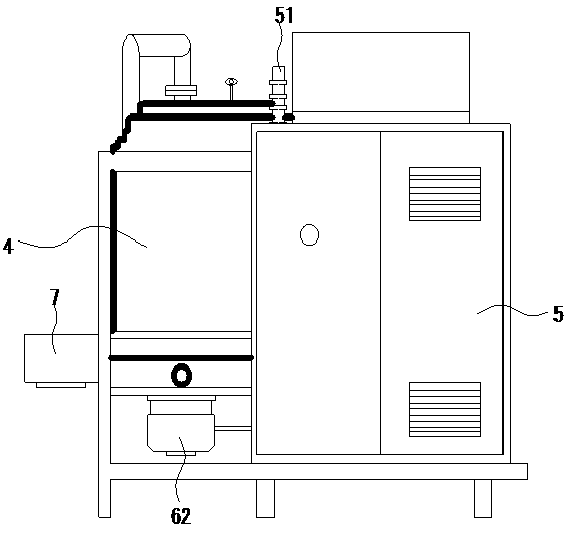

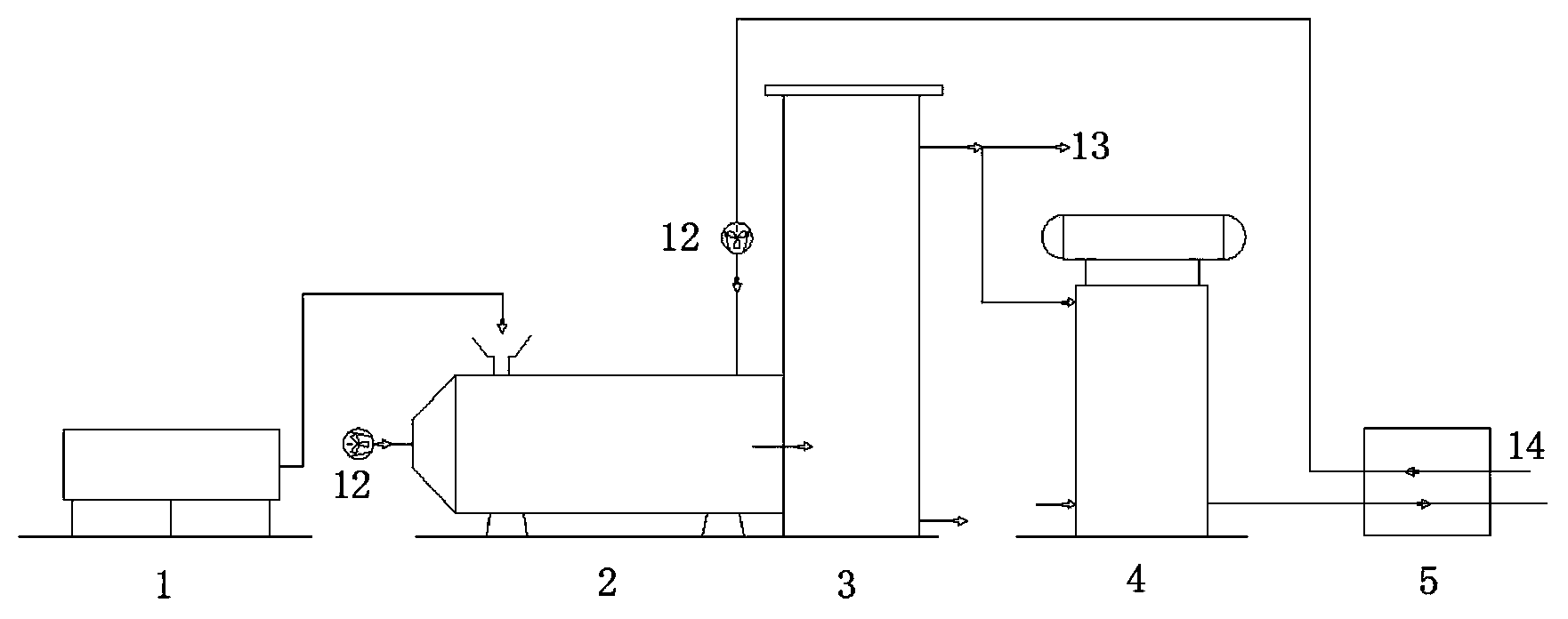

Medical waste high temperature rotary-cut treatment process and treatment equipment

ActiveCN103341201AHigh temperature rotary cutting process steps are simpleReduce volumeMedical waste disposalControl systemElectric machine

The invention relates to a medical waste high temperature rotary-cut treatment process and medical waste high temperature rotary-cut treatment equipment. The medical waste high temperature rotary-cut treatment process comprises the following steps of: loading medical waste into a disinfection cabin; driving a rotating blade at the bottom of the disinfection cabin to cut waste in a rotating manner by virtue of a motor, and injecting a disinfector into the disinfection cabin from a disinfector nozzle on the inner wall of the disinfection cabin; increasing rotating speed of the rotating blade at the bottom of the disinfection cabin, so that waste can produce heat energy under vigorous agitation and friction and the waste can be heated to a procedure preset temperature; and injecting clear water into the disinfection cabin, directly converting the clear water into steam after the clear water is fully contacted with the surface of an object treated at a high temperature, killing bacteria, dehydrating the waste and unloading. The invention also relates to medical waste high temperature rotary-cut treatment equipment. The medical waste high temperature rotary-cut treatment equipment comprises a rack, a disinfection cabin, a disinfector storage bin, a steam circulating device, an electronic cabinet, a power device and an electrical control system. Safety and reliability can be achieved when the medical waste high temperature rotary-cut treatment process and the medical waste high temperature rotary-cut treatment equipment are adopted for treating the medical waste, a sterilizing effect is good, and the treated waste residue can serve as green fuel, so that heat energy is recycled.

Owner:OUERDONG CHAOYANG ENVIRONMENTAL PROTECTION EQUIP CO LTD

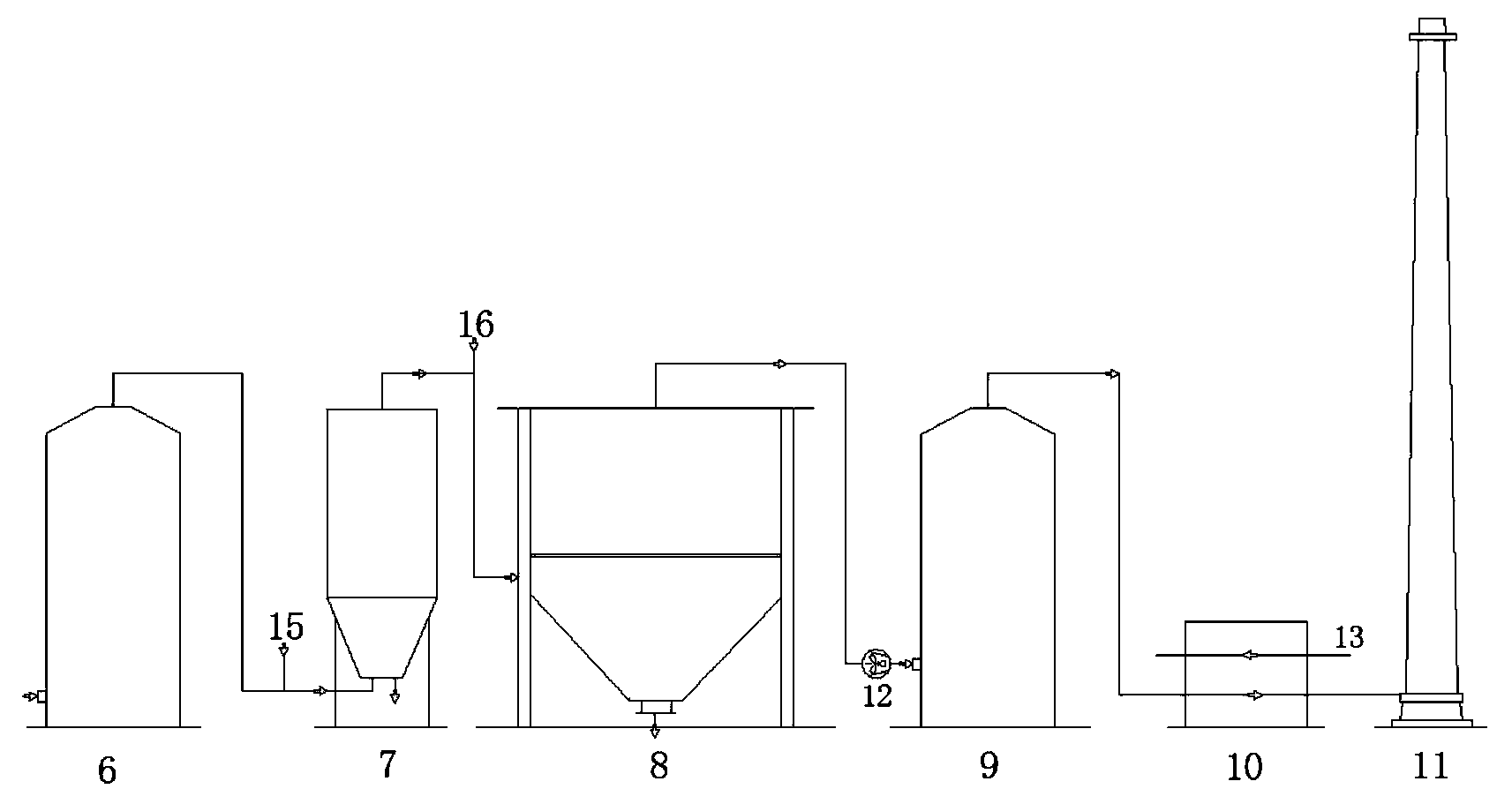

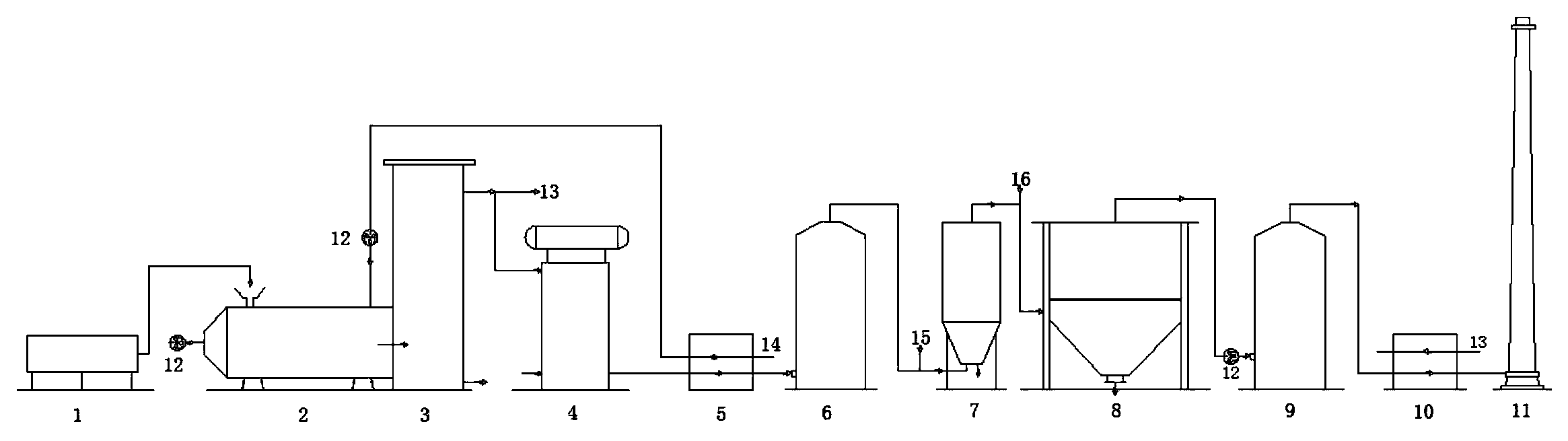

Gas, solid and liquid integrated combustion system

The invention relates to a gas, solid and liquid integrated combustion system, and belongs to the technical field of the environment. The system is composed of a waste gas collection system, a granulation system, a feeding system, a rotating furnace, a combustion furnace, a waste heat boiler, a heat exchanger, a rapid quenching tower, a smoke dry type washing system, a cloth bag dust removal device, a spray tower, a reheater and a chimney. Coal, solid waste and liquid waste are evenly mixed according to the mass ratio (1-12):(2-30):(1-16) in the granulation system for granulation; after collected waste gas is preheated, part of the waste gas enters the rotating furnace, and the other part of the waste gas enters the combustion furnace to be processed through high temperature combustion; high temperature tail gas of the combustion furnace enters the rapid quenching tower, the dry type washing system, the cloth bag dust removal device and the spray tower after heat energy recovery, and is sent to the chimney by a draught fan after the tail gas is cooled and fly ash, dioxin and acid gas are removed, so that emission reaching the standard is completed. Liquid waste produced in the running process of the system is recycled in the granulation system, solid waste such as activated carbon is fed into the rotating furnace to be combusted, and therefore harmless treatment is achieved while running cost of the system is reduced.

Owner:JIANGSU ANQIER WASTE GAS PURIFICATION

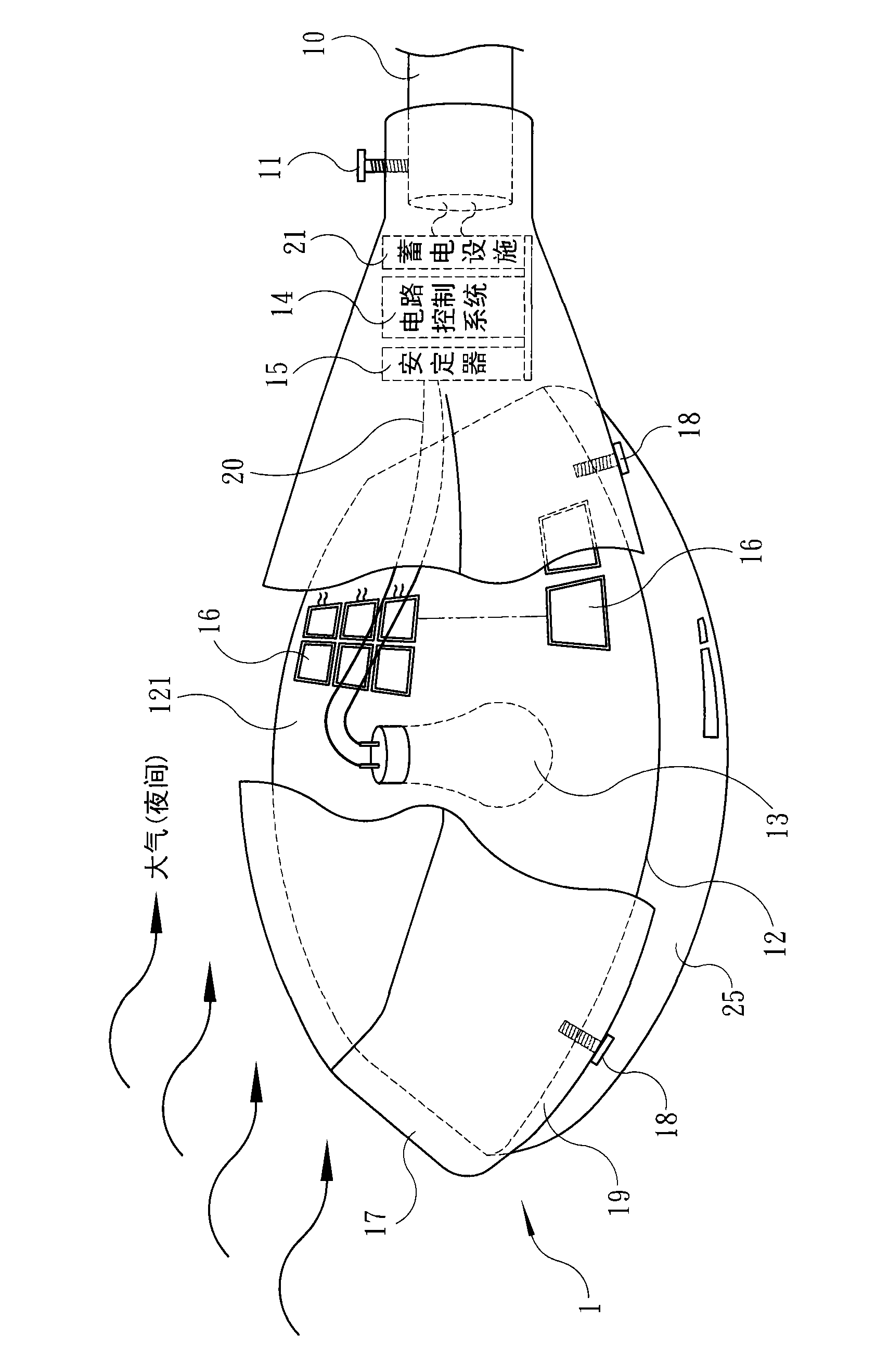

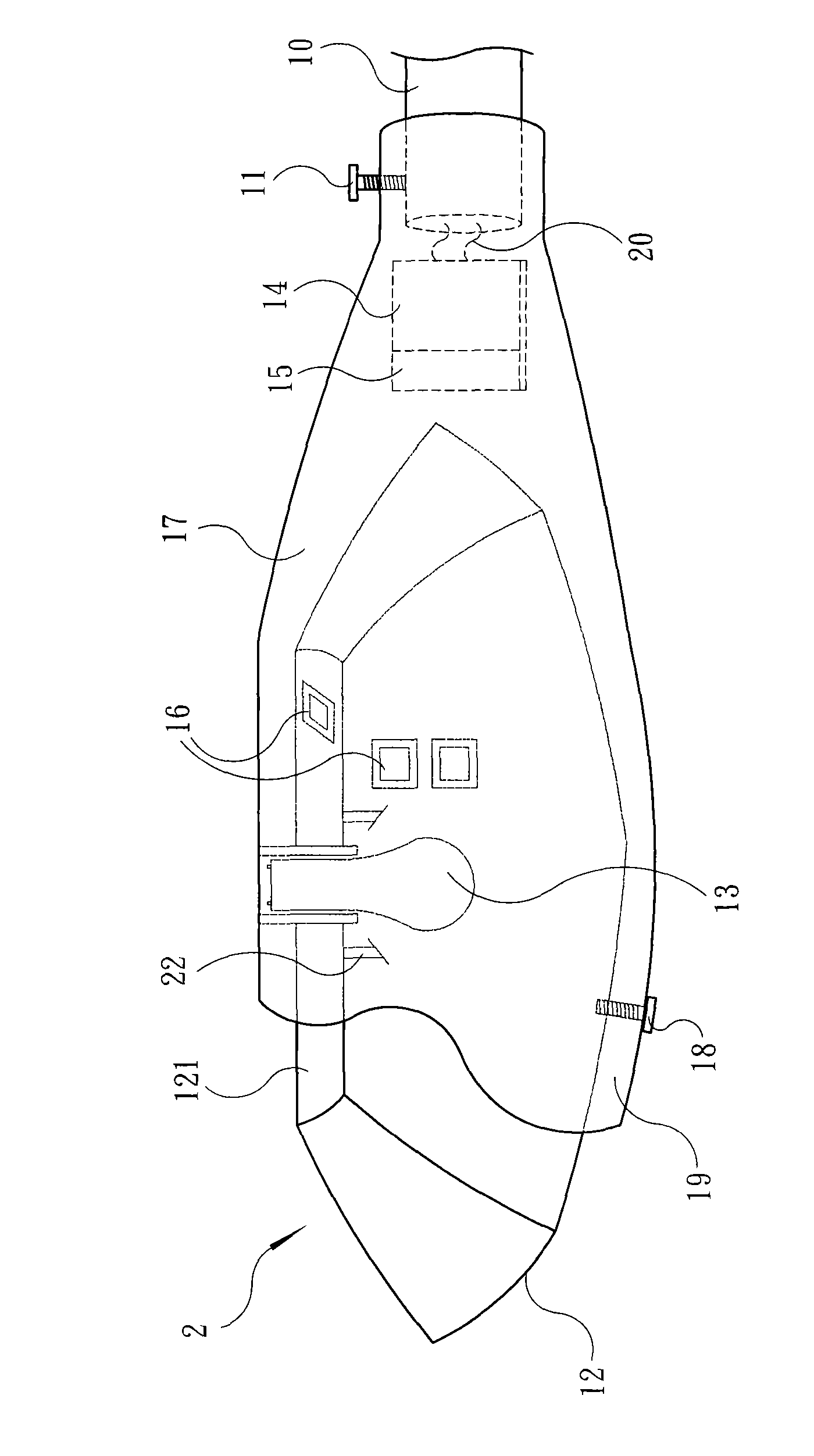

Method and device for recycling and reusing heat energy of lighting facilities

InactiveCN102570918ABatteries circuit arrangementsLighting heating/cooling arrangementsElectricityControl system

The invention discloses a method and device for recycling and reusing heat energy of lighting facilities. The device mainly comprises a thermoelectric chip module, a reflecting cover, a lamp shell, a circuit control system, an electricity-storage facility and other necessary electronic components, wherein the thermoelectric chip module is used for converting heat energy into electrical energy. Through taking heat energy (generated by a light source) as a hot end and taking the lamp shell in contact with the atmosphere as a cold end, the upper and lower ends of the thermoelectric chip module distributed between the reflecting cover and the lamp shell are respectively heated or cooled, and thus a stable temperature difference is formed so as to generate electrical energy, then the obtained electrical energy is stored in the electricity-storage facility through voltage and current control chips and circuit modules and the like in the circuit control system or directly inputted into a power supply circuit; therefore, the purpose of effectively recycling and reusing the heat energy generated by the light source and then further saving electrical energy can be achieved.

Owner:E SWEET TECH CORP

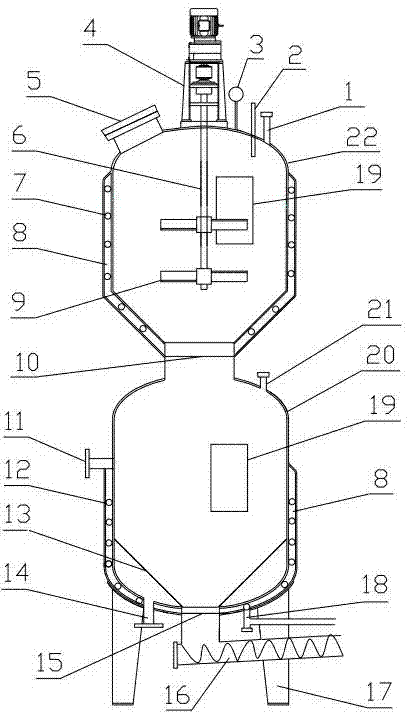

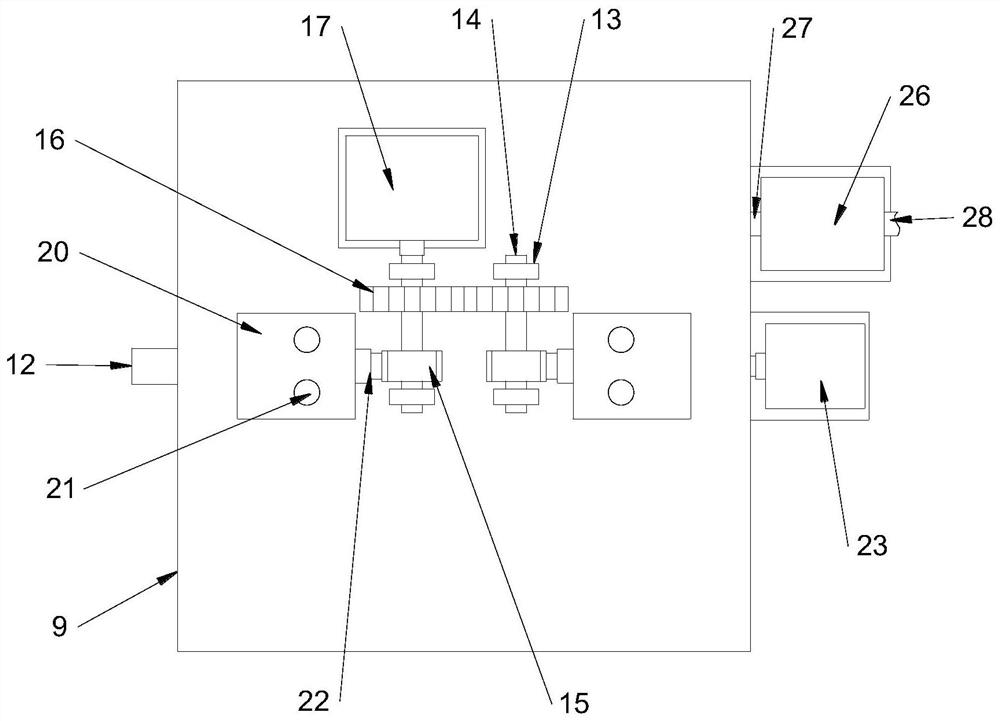

Kitchen waste hydrothermal three-phase separation system

ActiveCN103480632AFully realize hydrolysisEvenly heatedWaste processingSolid waste disposalThree-phaseVaporization

The invention relates to the technical field of treatment of kitchen waste, in particular to a kitchen waste hydrothermal three-phase separation system. In the kitchen waste hydrothermal three-phase separation system, a heating device is arranged on the outer wall of a hydrothermal reactor tank body and is a conduction oil coil pipe; the conduction oil coil pipe is clung to the side wall of a hydrothermal reactor to provide thermal energy for the kitchen waste, and the interior of the hydrothermal reactor is heated evenly; a thermal energy recovery device is arranged on a three-phase separator, and comprises a thermal energy recovery coil pipe arranged on the outer wall of a three-phase separator tank body, and a thermal energy recovery guide pipe connected with the thermal energy recovery coil pipe. According to the invention, the kitchen waste is heated by the conduction oil, so that the energy can be saved and the cost can be reduced; the kitchen waste is heated under a water condition to realize full hydrolyzation, and is discharged through jet explosion, so that the hydrolyzation is performed more thoroughly, and the subsequent utilization is facilitated. The three-phase separator integrates the functions of explosion bearing, flash vaporization and three-phase separation, and an outer water coil pipe is arranged for recovery of the thermal energy, so that the recycling of the thermal energy is realized, and the kitchen waste cannot be blocked at the same time.

Owner:SOUTH CHINA AGRI UNIV

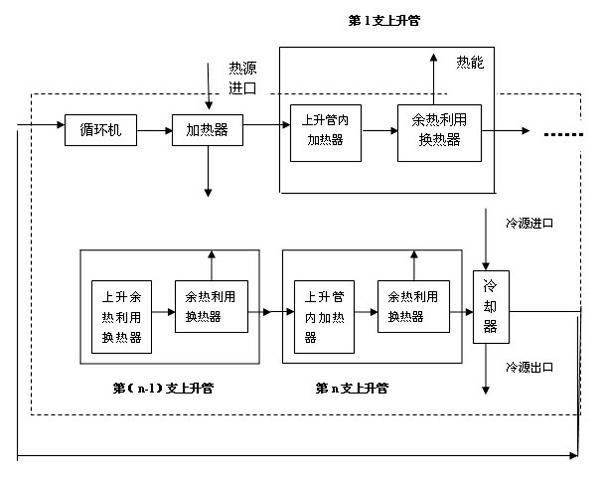

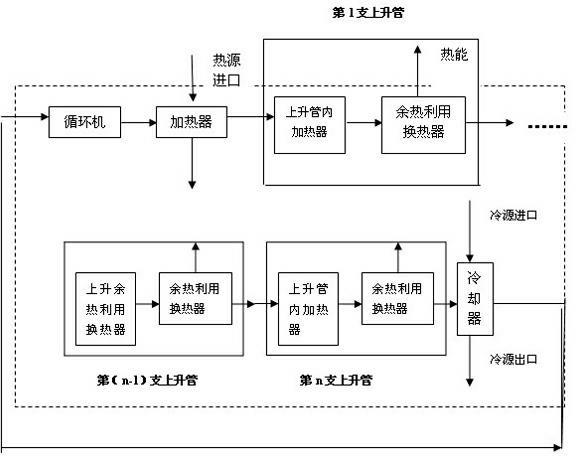

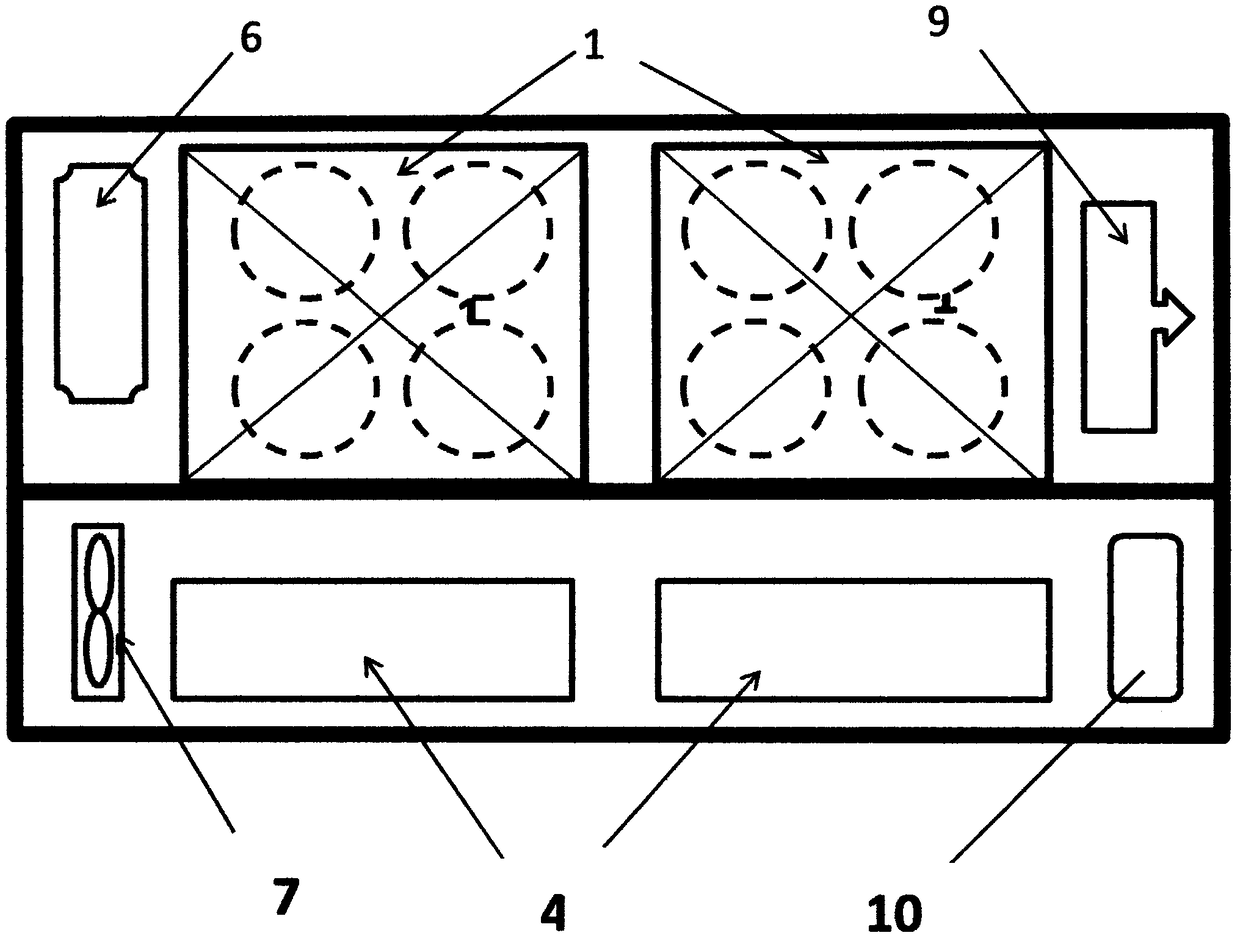

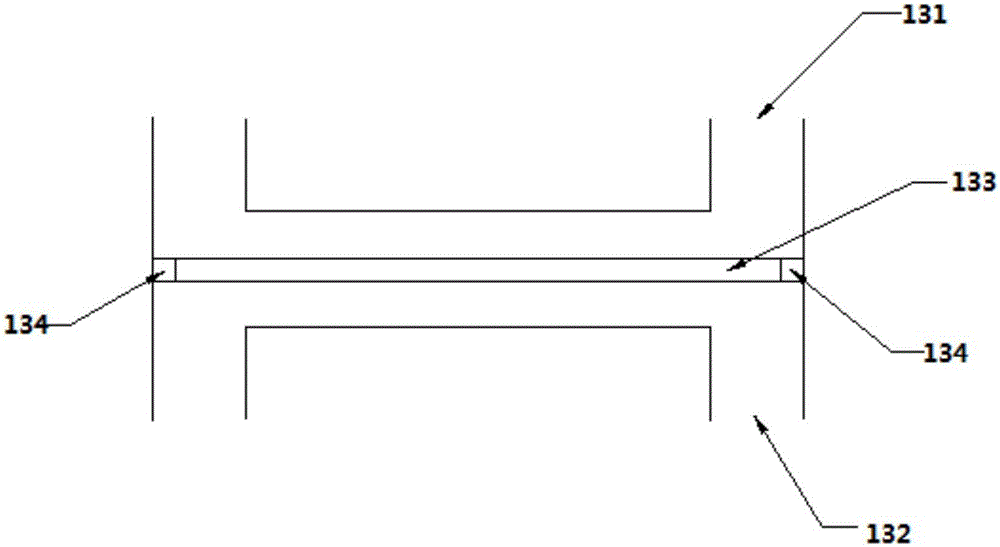

Coke oven crude gas waste heat recycling method and dedicated heat exchange type ascending tube

ActiveCN102329627AImprove energy savingGuaranteed uptimeEnergy inputStationary tubular conduit assembliesTarCoke oven

The invention relates to a coke oven crude gas waste heat recycling method and a dedicated heat exchange type ascending tube, belonging to the technical field of coke oven heat energy recycle. In the technical scheme, gas as a heat exchange medium enters into a heat exchanger in the ascending tube through a gas outlet after being pressurized by a circulator; in the heat exchanger in the ascending tube, the gas is heated by high-temperature gas which flows out of the ascending tube after being cooled by the gas; the heated gas enters into a waste heat utilization heat exchanger after flowing out of the heat exchanger in the ascending tube, enters into the circulator to be pressurized after discharging heat energy and then enters the next circulation, and by such a circulation, the heat energy of the gas in the ascending tube of a coke oven is continuously taken out of the ascending tube by the gas and is utilized by the waste heat utilization heat exchanger. By using the coke oven crude gas waste heat recycling method and the dedicated heat exchange type ascending tube, tar bonding or floccule plugging can not be generated on a heat exchange surface, and in addition, heat exchange devices in the ascending tube are excellent without damage and can be started up for working at any time, and other parts can be put into work at any time, thus, the technical problem expected to be solved for a long term in the field is solved.

Owner:董洪峰

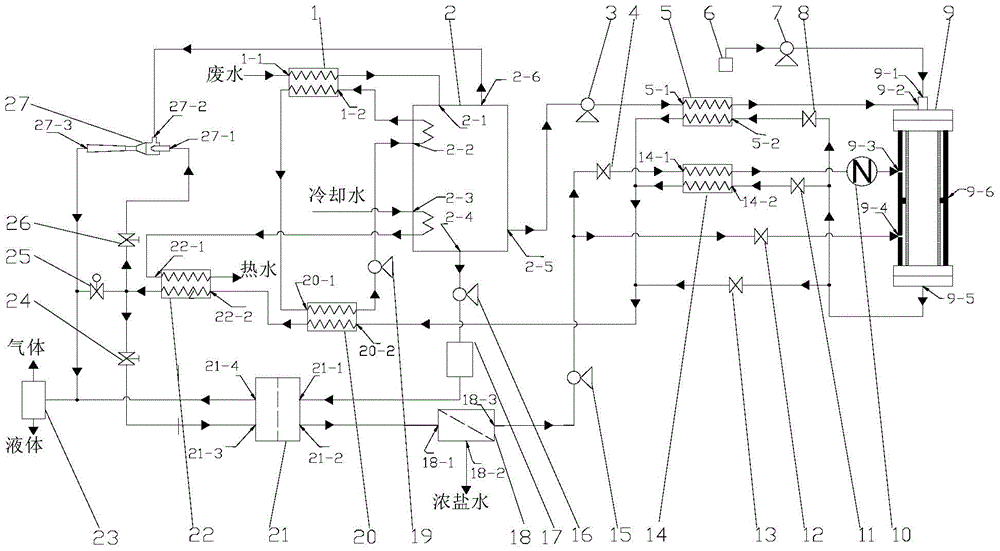

System and method for treating organic wastewater with high volatility by supercritical water oxidation

ActiveCN105130080ASolve the blockageReduce consumptionGeneral water supply conservationWater contaminantsLiquid wasteHigh concentration

The invention relates to the technical fields of energies and environments, and particularly discloses a system and a method for treating organic wastewater with high volatility by supercritical water oxidation. Concentrated saliferous wastewater and organic liquid with high concentration are produced by low temperature multi-effect distillation, scale formation of inorganic salt is avoided in a concentration process, the organic liquid with high concentration can be injected into a transpiring water reactor at low temperature, even at normal temperature, the stability of the supercritical water oxidation is guaranteed, and the blocking problem of wastewater in a preheating section can be avoided; the concentrated saliferous wastewater is subjected to ultrafiltration and reverse osmosis to produce fresh water, the fresh water is injected into the transpiring water reactor as evaporable water so as to protect the reactor, and the operation cost of the system is reduced. The reaction fluid is subjected to thermal energy recovery and is reduced to normal temperature, and then the pressure of high-pressure fluid can used as a power source of a pressure energy recovery device and an ejector, preparation of fresh water through desalting of concentrated solution and condition of negative pressure of a low temperature multi-effect distillation apparatus can be realized, and energy consumption in the step can be greatly lowered.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI +1

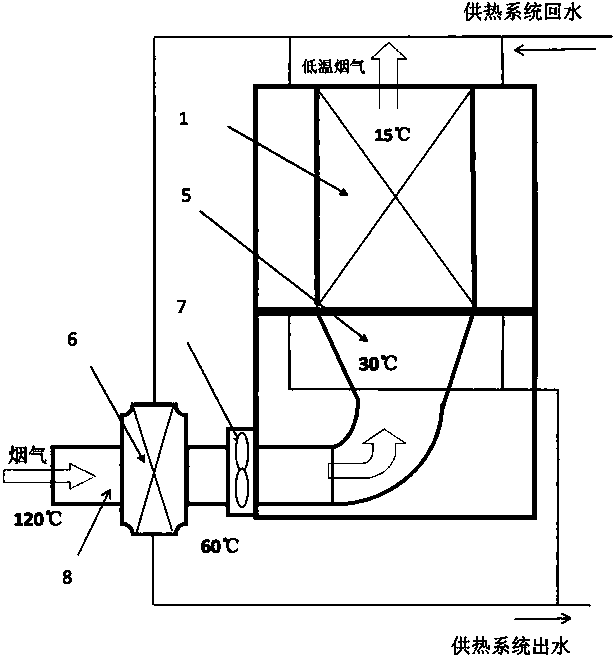

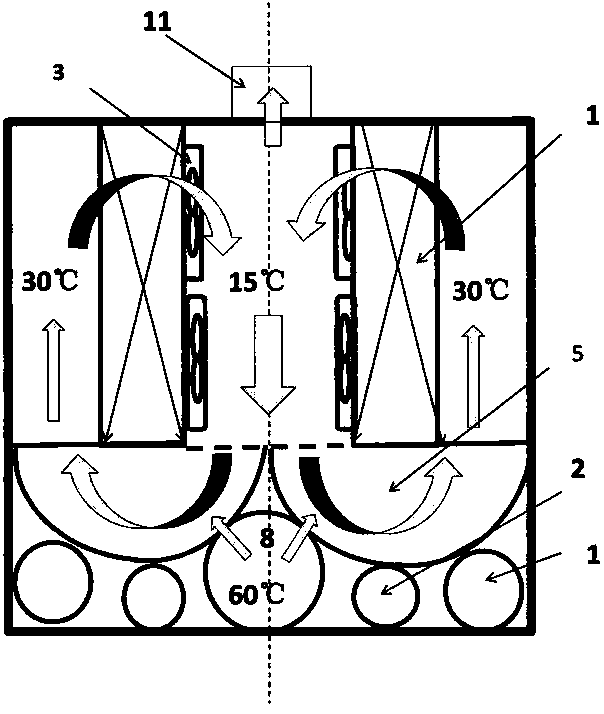

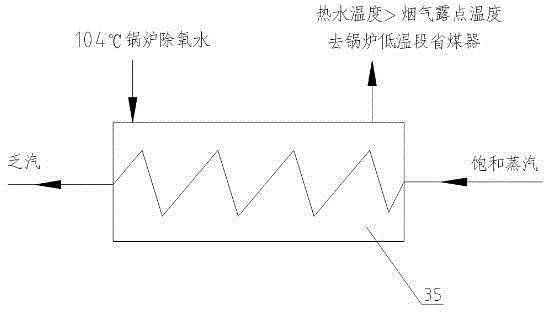

Natural gas smoke waste heat complete heat recovery device

PendingCN108131867AAchieve recyclingReduce consumptionHeat pumpsFeed water supplyCogenerationEngineering

The invention provides a natural gas smoke waste heat complete heat recovery device, belongs to the technical field of energy, and particularly relates to a technology for completely recovering smokewaste heat emitted by fuel gas burning devices (boilers, direct-fired machines, gas engines, gas turbines and the like). Aiming at the status-quo that the heat energy utilization rate of a current natural gas boiler is low, a three-grade cooling two-grade heat exchanging technological process is adopted, cascaded cooling is conducted on smoke through a heat exchanger and a heat pump, particularlylatent heat for vaporization in the smoke is recovered and reused, the smoke emission temperature of a natural gas boiler is decreased to be the temperature the same as the natural gas entering the boiler, and complete utilization of the heat energy of the natural gas is truly achieved. In the processes of smoke cooling and heat energy recovering, a great deal of condensed water is recovered, partof sulfide and nitric oxide in the smoke is dissolved in the water, and thus emission of pollutants is reduced. When the natural gas smoke and waste heat complete heat recovery device is applied to combined heat and power generation power plants, less electric energy can be consumed in the heating period, the heating area can be increased by 30% or above, and the consumption amount of heating fuel gas can be reduced by 10-15%.

Owner:苏桐梅

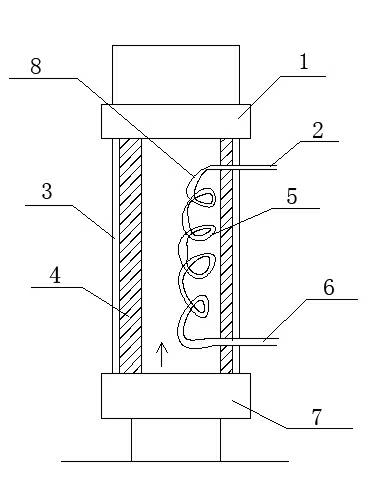

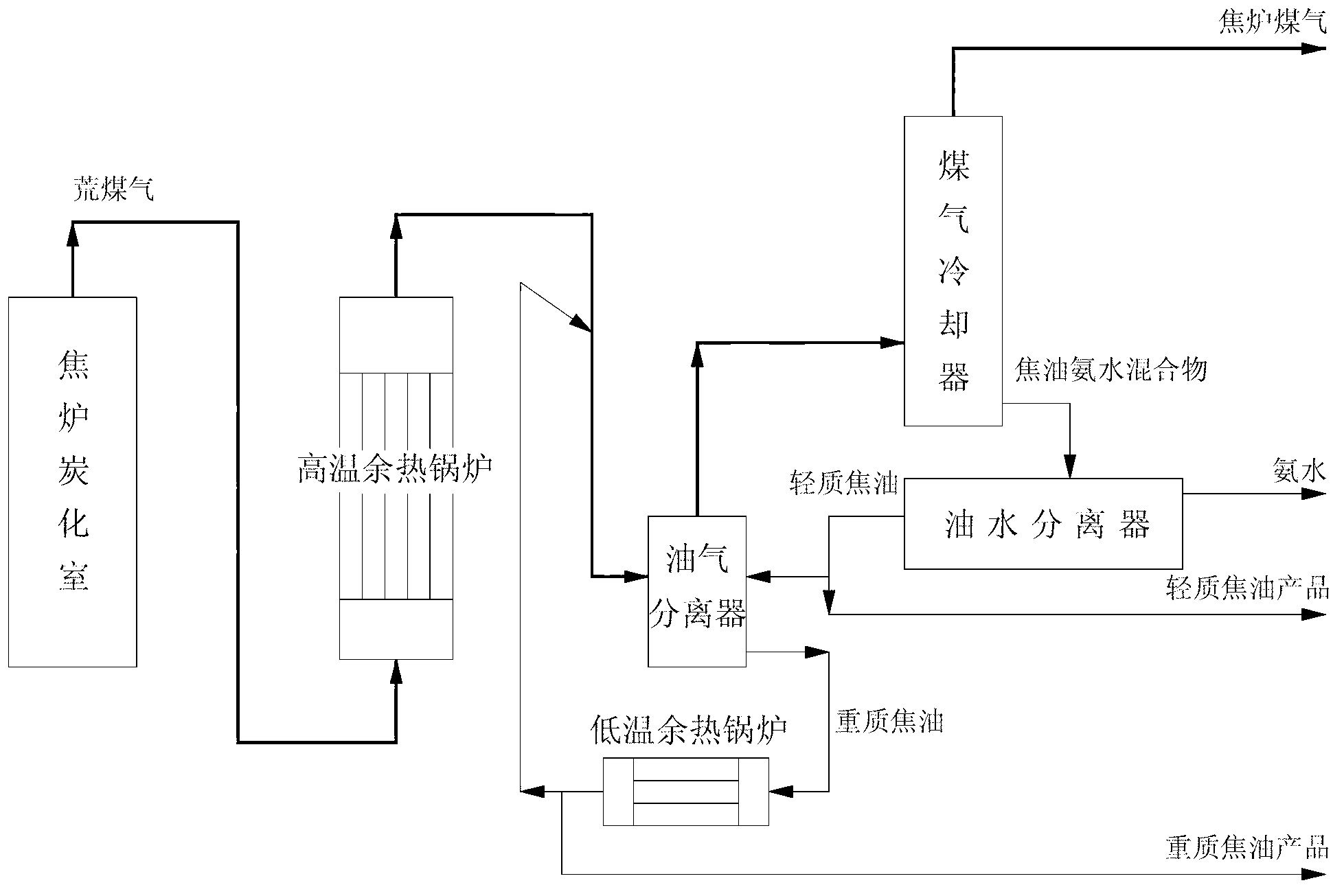

Coke oven gas afterheat recovering method and device

ActiveCN103194274AAvoid cloggingHigh recovery rateEnergy inputGas purification by non-gaseous materials condensationCarbonizationGas cooler

The invention belongs to the field of afterheat recovering of coke oven gas, and in particular relates to a coke oven gas afterheat recovering method and a coke oven gas afterheat recovering device. Coke oven gas recovery and tar recovery are integrated, high-temperature heat energy and low-temperature heat energy in the gas are respectively recovered by using a segmental recovery mode; and the gas is cooled by using a mode of spraying tar during recovering. The device comprises a high-temperature afterheat boiler, an oil-gas separator, a gas cooler, an oil-water separator and a low-temperature afterheat boiler, wherein a gas inlet of the high-temperature afterheat boiler is connected with a gas outlet of a coke oven carbonization chamber raw coke oven gas; and a gas outlet of the oil-gas separator is connected with the gas cooler. Compared with the prior art, the method and the device have the advantages that high-temperature heat energy can be recovered and low-temperature heat energy also can be recovered in a segmental afterheat recovery mode that the high-temperature afterheat of the gas is recovered by the high-temperature afterheat boiler and the low-temperature afterheat is recovered by spraying the gas by using tar, so that the heat energy recovery rate is high, the double aims of energy conservation and improvement on economic benefit are fulfilled, and the phenomenon that an afterheat boiler is blocked by the tar and dust in the gas also can be avoided.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

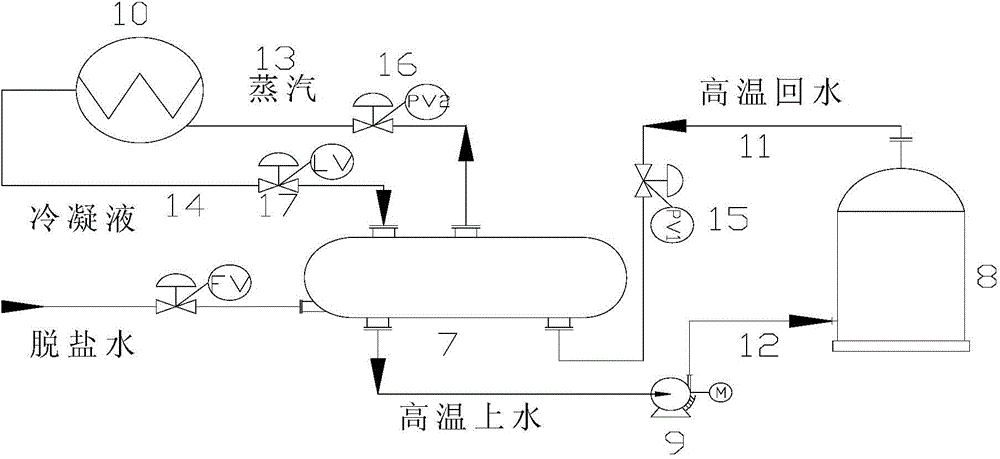

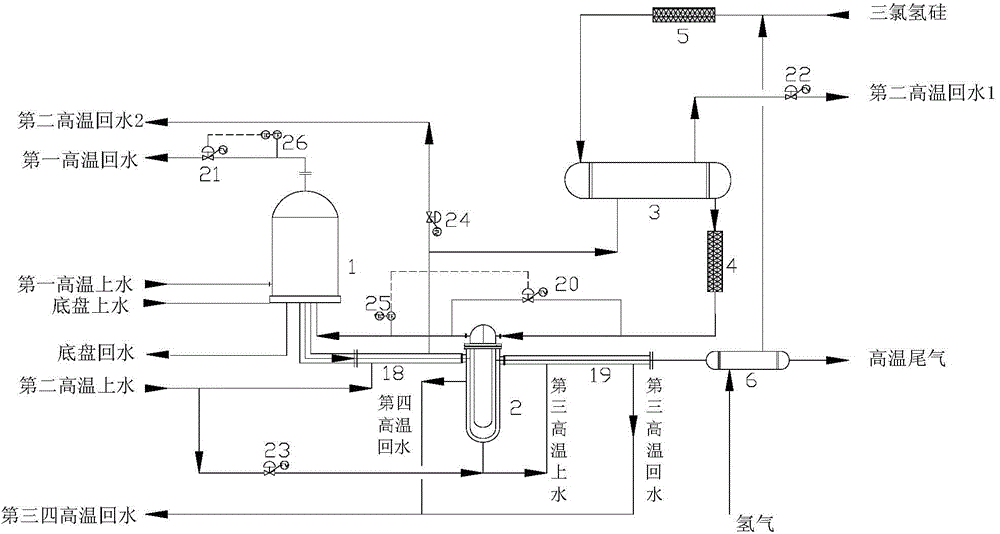

Heat energy utilization method and heat energy utilization system in polycrystalline silicon production

ActiveCN104787766AImprove feed processFeed process optimizationSiliconChemical industryMetallurgyHeat energy

The present invention discloses a heat energy utilization method and a heat energy utilization system during polycrystalline silicon production. According to the method, high temperature backwater from a reduction furnace system in polycrystalline silicon production is conveyed into a flash evaporation system and is subjected to flash evaporation in the flash evaporation system, wherein the temperature of the high temperature backwater entering the flash evaporation system is 145-160 DEG C, and the pressure is 0.5-0.6 MPa; the low pressure steam with the pressure of 0.175-0.25 MPa is flash-evaporated from the flash evaporation system, and the remaining high temperature water with the temperature of 128-133 DEG C after the flash evaporation is pressurized, then returns to the reduction furnace, and forms the high temperature feeding water of the reduction furnace system; and the flash-evaporated low pressure steam is conveyed to other equipment requiring the steam in the polycrystalline silicon production, and the condensate obtained through heat exchange with other equipment returns to the flash evaporation system. With the method of the present invention, a lot of the heat energy produced in the polycrystalline silicon production can be completely utilized so as to improve the heat energy recovery and utilization rate.

Owner:XINTE ENERGY

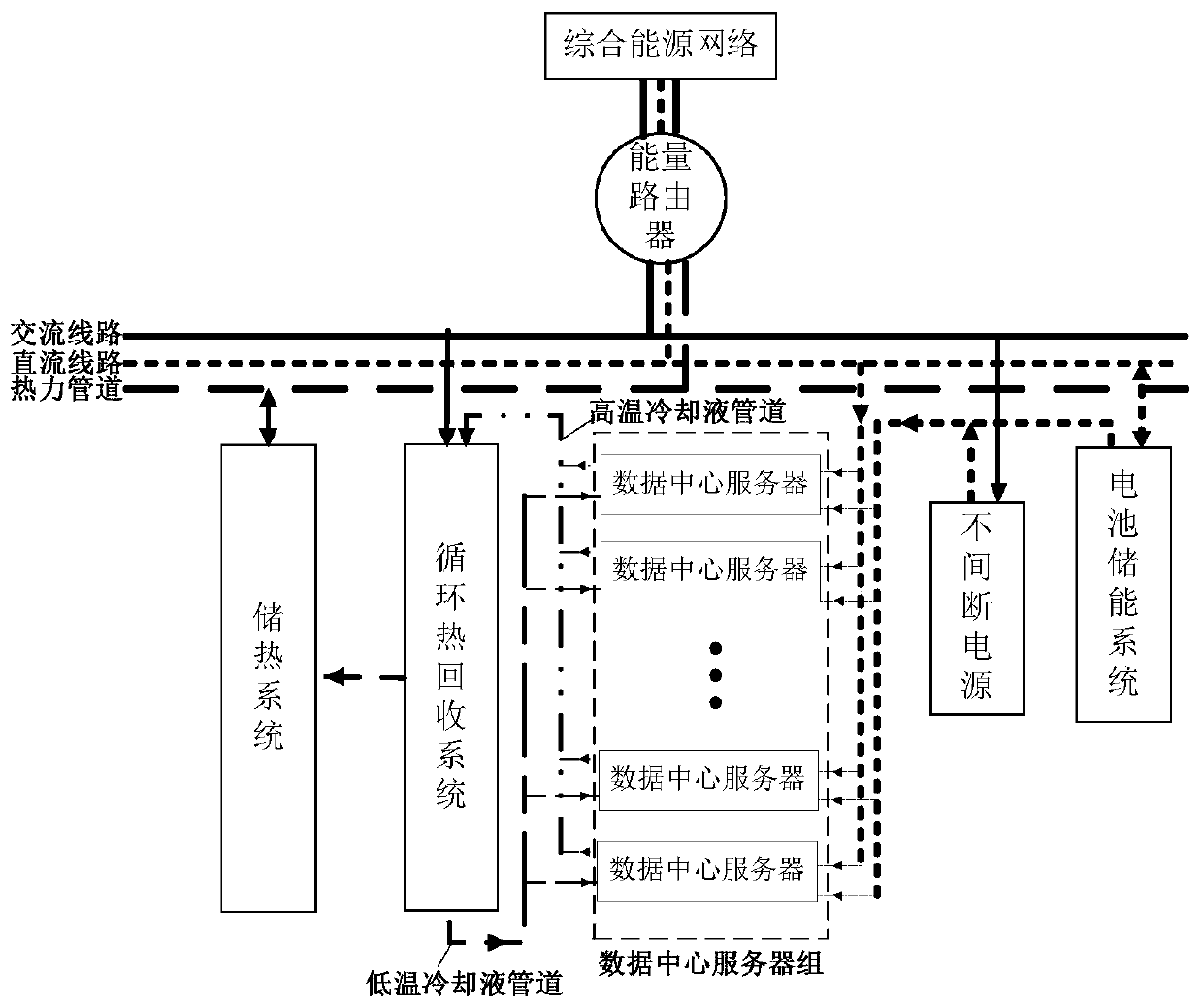

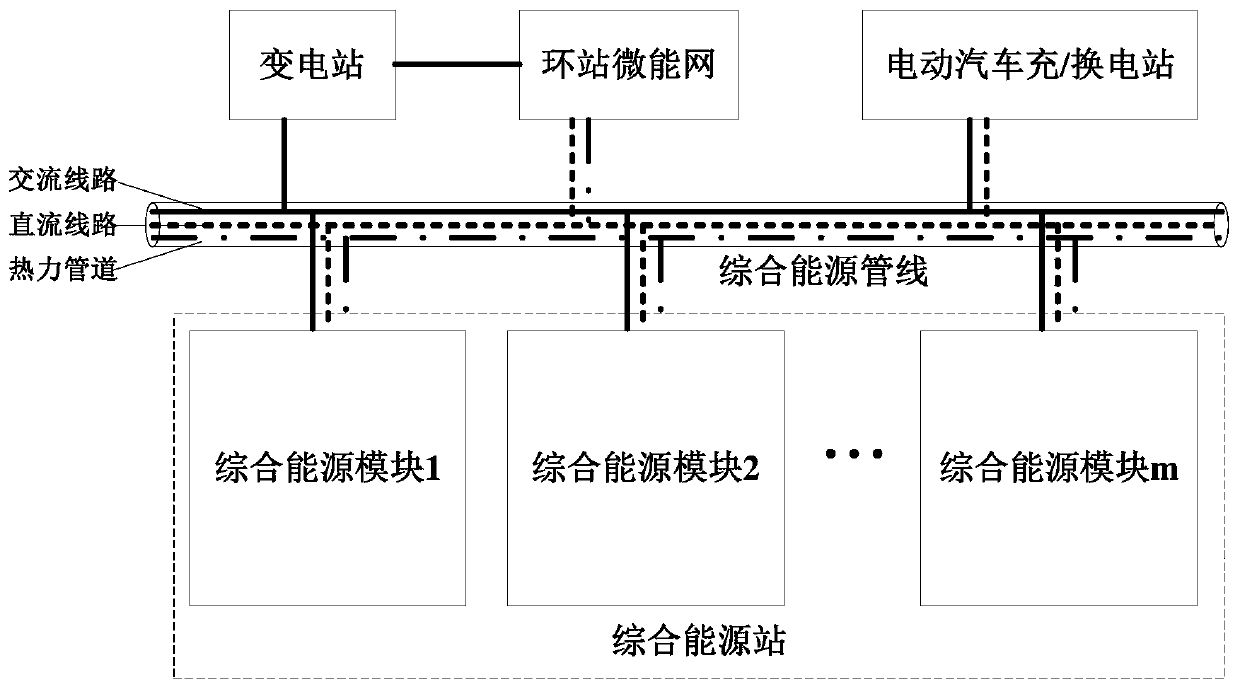

Comprehensive energy station

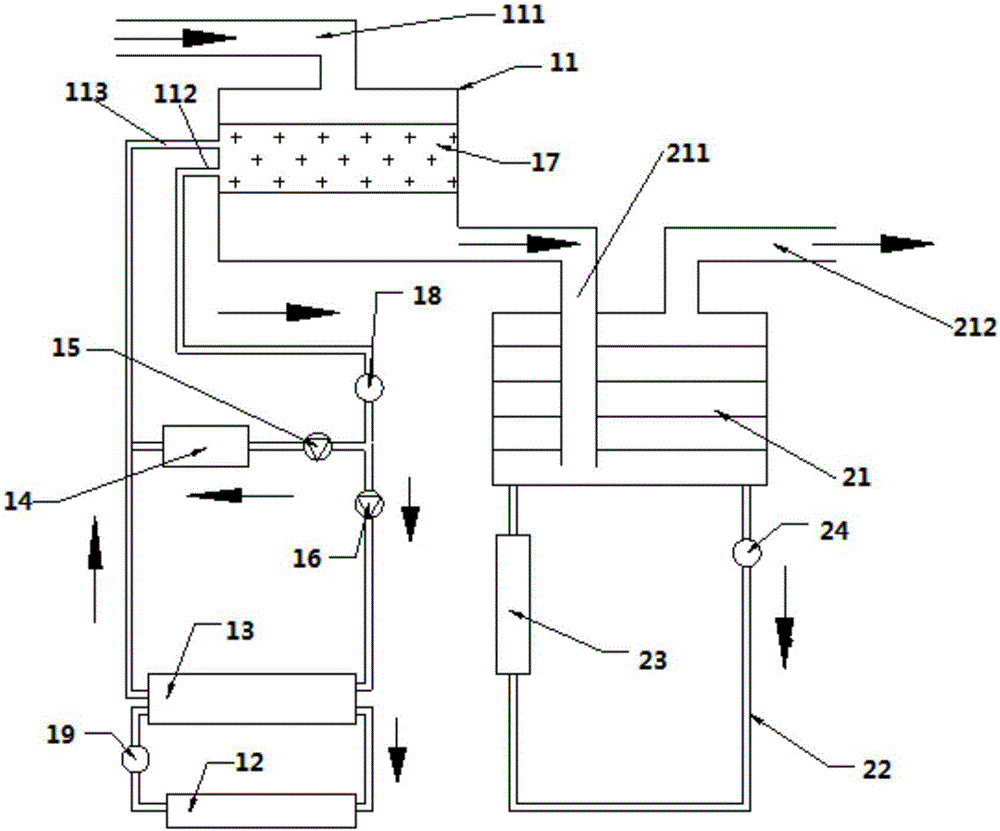

PendingCN110797860AAddress reliabilitySolve the problem of heat recoveryFlexible AC transmissionData processing applicationsData streamThermal energy storage system

The invention provides a comprehensive energy station, which comprises a plurality of comprehensive energy modules, wherein the comprehensive energy modules are connected through comprehensive energypipelines. The comprehensive energy module comprises an energy router, a data center server group, a battery energy storage system, a circulating heat recovery system, a heat storage system and an uninterruptible power supply, wherein the data center and the energy storage system are deeply integrated, heat energy recovery, storage and reutilization of the data center are considered, and comprehensive energy supply and services can be provided for users at the same time. According to the technical scheme provided by the invention, functional complementation and multi-value integration of the battery energy storage system and the data center server group are facilitated; the problems of highly reliable power supply and heat recovery of the data center server are solved while energy servicesare provided, and value improvement and sharing are achieved; and meanwhile, a solid foundation can be provided for three-in-one of an energy flow, a service flow and a data flow of the energy internet.

Owner:CHINA ELECTRIC POWER RES INST +1

Engine thermal energy recovery generating set

InactiveCN106337715AAchieve recyclingSimple structureInternal combustion piston enginesExhaust apparatusExternal combustion engineEngineering

The invention relates to a thermal energy recovery power generation device of an internal combustion engine, which comprises a heat energy recovery box, a cold end heat sink and a temperature difference power generation device, among which the heat energy recovery box is connected with an exhaust port of an internal combustion engine, a cooling liquid outlet of the internal combustion engine is connected to a hot end inlet port of the thermoelectric generator through a first pipe, a coolant inlet of the heat energy recovery tank is connected to a hot end outlet port of the thermoelectric generator through a second pipe; the heat energy recovery box is used for absorbing heat of the tail gas discharged from the internal combustion engine to heat the cooling liquid in the heat energy recovery tank; and a water inlet of the cold end radiator is connected to a cold end outlet port of the thermoelectric generator, and a water outlet of the cold end radiator is connected to a cold end inlet port of the thermoelectric generator. By the technical solution of the present invention, recovery and utilization of the engine exhaust gas can be realized.

Owner:温后东

Low temperature organic malodorous gas treating system

ActiveCN103623680AStay hydratedReduce adverse effectsDispersed particle separationAir quality improvementBiological filterEnvironmental engineering

The invention discloses a low temperature organic malodorous gas treating system, comprising a malodorous gas collection system, an ozone generation system, an ozonation pre-reaction zone, a biological deodorizing tower, a heat energy recovery system and a spraying and watering device. During operation of the treating system, organic malodorous gas having passed through a deodorizing fan is mixed with ozone from an ozone generator in a conveying pipeline, a gas mixture enters into the ozonation pre-reaction zone, gas obtained after completion of a reaction enters into the biological deodorizing tower through the bottom of the biological deodorizing tower, and the heat energy recovery system is arranged at the bottom of the biological deodorizing tower. In the biological deodorizing tower, pollutants in malodorous gas is decomposed by microbes in a carbonaceous biological filter pack and then discharged from an air outlet at the upper part of the biological deodorizing tower after reaching standards, and the spraying and watering device is arranged above the filter pack. The low temperature organic malodorous gas treating system provided by the invention is especially applicable to treatment of organic malodorous gas at a temperature of less than 5 DEG C and has the advantages of a simple structure, basically no generation of secondary pollution, low operation cost and simple operation and management.

Owner:NISHIHARA ENVIRONMENT ENG SHANGHAI CO LTD

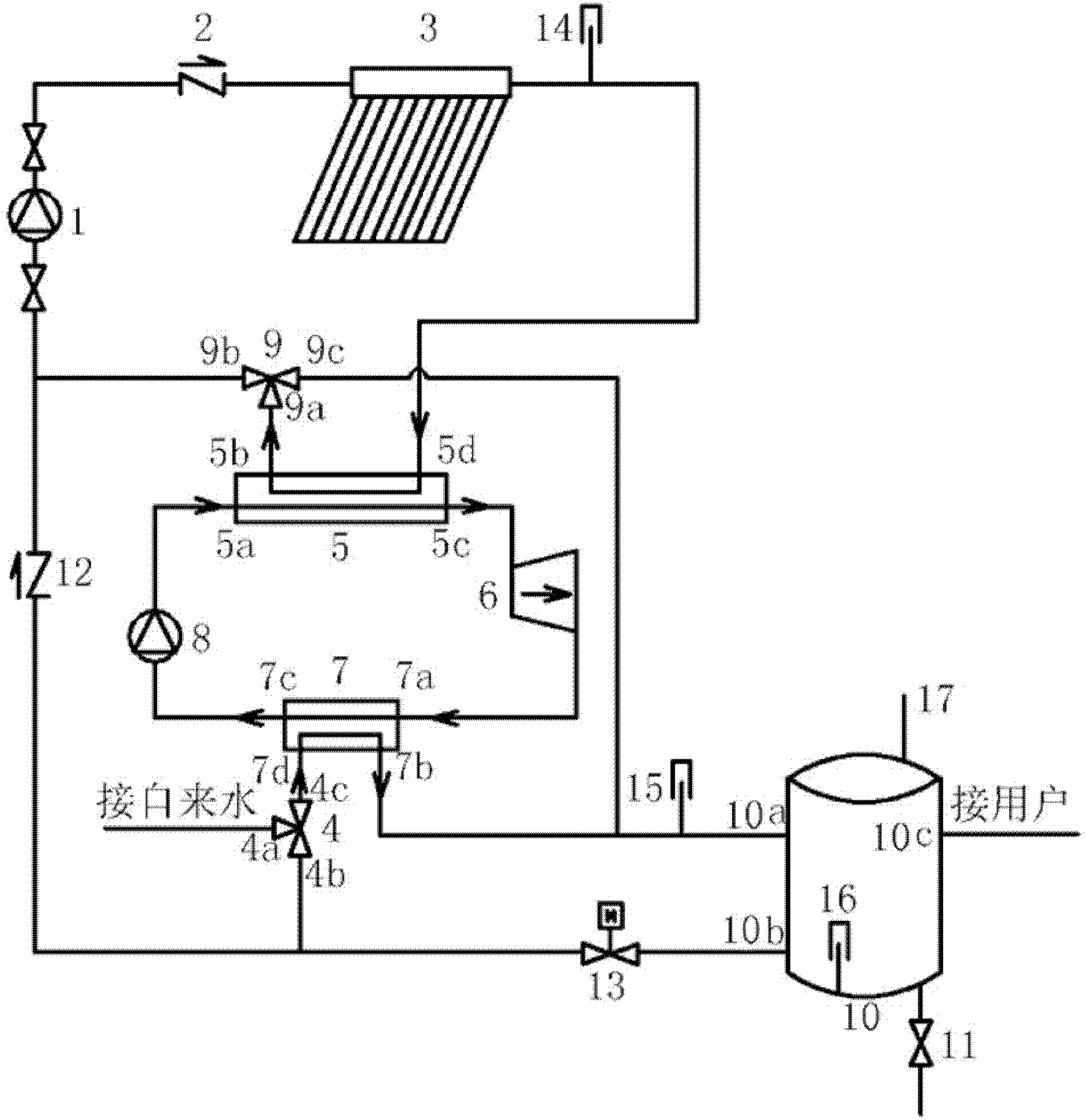

Thermal energy comprehensive utilization device for supplying hot water and generating power through solar energy

ActiveCN102418954AIncrease profitShorten heating timeFrom solar energyLighting and heating apparatusWater sourceSolar water heating system

The invention discloses a thermal energy comprehensive utilization device for supplying comfortable hot water and generating power through solar energy. The device mainly comprises two parts, namely a solar hot water system and a Rankine cycle system. The device can be adjusted according to a water supply temperature set by a user, water is heated by a solar thermal collector, and effluent of thethermal collector is subjected to thermal energy recovery or cyclic heating. If the temperature of the effluent of the thermal collector is higher than the set water supply temperature, the Rankine cycle system is started to convert high-temperature thermal energy into electric energy; and if a water supply temperature of a water tank on a user side is lower than the set temperature, the water tank of the user is heated through the solar thermal collector, so that the condition that the water tank of the user provides comfortable hot water all the time is ensured. By the device, utilization amount and utilization efficiency of solar energy can be improved, the comfort level of domestic hot water is improved, the solar energy can be comprehensively used for supplying the domestic hot waterand generating the power, and evaporation waste of a water source caused by excessive heat energy is prevented; and the device is suitable for technical upgrade and technical transformation of civil and industrial solar thermal collectors.

Owner:宝莲华新能源技术(上海)股份有限公司 +1

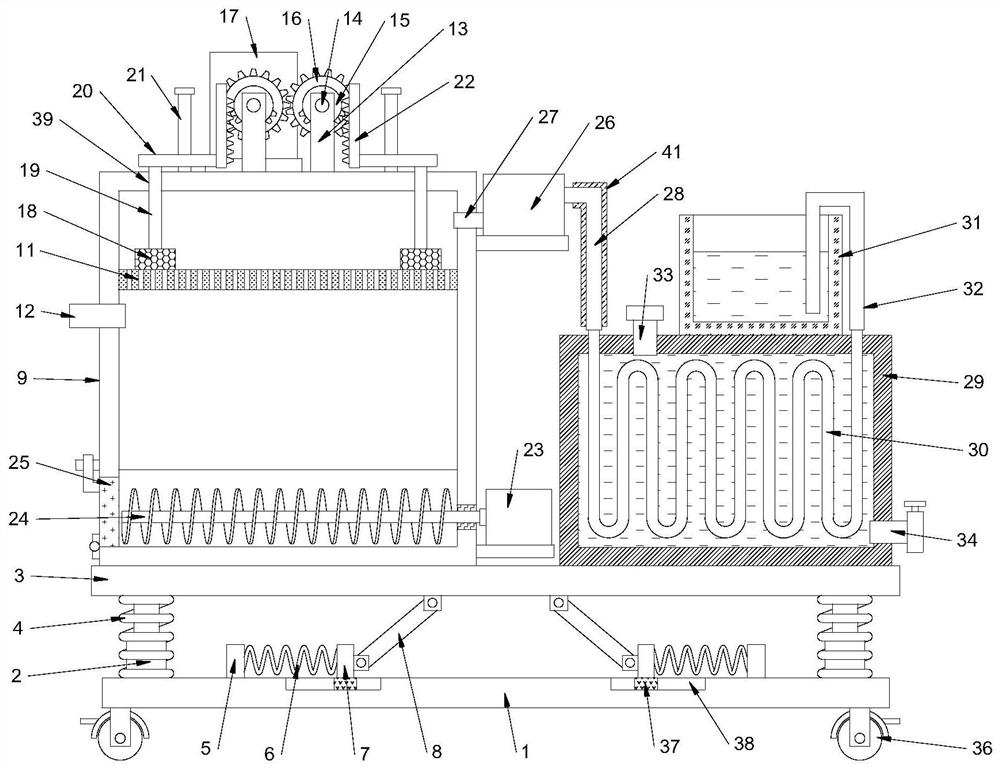

Flue gas deep dedusting and filtering device for coal boiler

InactiveCN111617599AImprove shock absorption and cushioning effectPlay the effect of dredging the meshGas treatmentDispersed particle filtrationThermodynamicsFlue gas

The invention discloses a flue gas deep dedusting and filtering device for a coal boiler, and belongs to the field of dedusting and filtering equipment. The flue gas deep dedusting and filtering device for a coal boiler includes a base, and telescopic sleeves are fixed to the four corners of the top of the base correspondingly. A supporting plate is arranged above the base. The tops of the telescopic sleeves are fixedly connected with the bottom of the supporting plate. The outer side of each telescopic sleeve is sleeved with a first spring, and the two ends of each first spring are fixedly connected with the top of the base and the bottom of the supporting plate correspondingly. Fixing plates are symmetrically fixed to the top of the base, second springs are symmetrically fixed to one side walls of the fixing plates, and sliding plates are symmetrically connected to the top of the base in a sliding mode. The device is good in damping effect, so that a good protection effect can be achieved in the transportation process. When a stainless steel filter screen plate is blocked, dredging can be conducted conveniently and rapidly. A heat energy recovery function is achieved.

Owner:尚俊

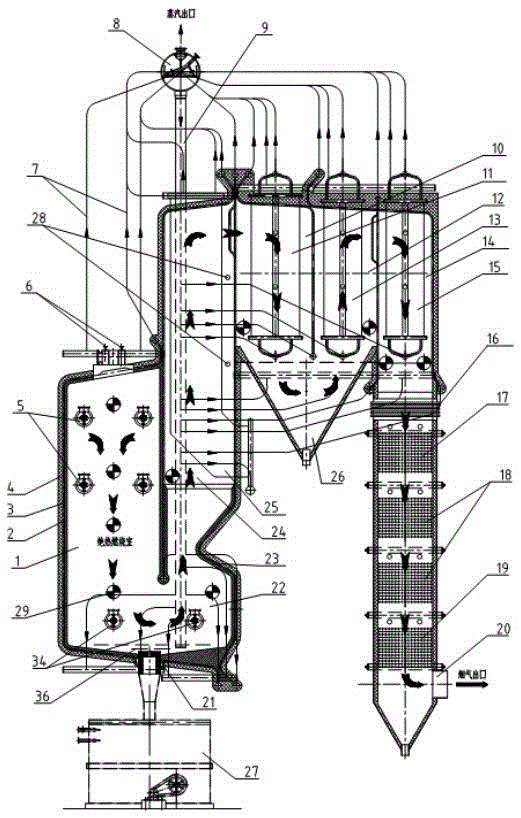

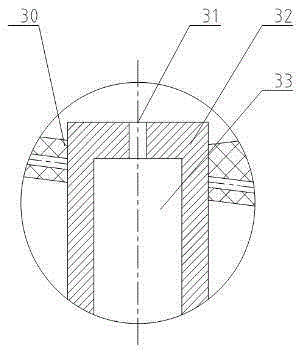

Incineration boiler for high-concentration salty organic waste liquid

ActiveCN105240861AReduce incineration costsSimple preparation processChemical industryIncinerator apparatusCombustion chamberThermal insulation

The invention discloses an incineration boiler for high-concentration salty organic waste liquid. The environment-friendly and energy-saving requirements for harmlessness, reduction and resourcezation of high-concentration salty organic waste liquid are met through high-temperature incineration and waste heat recovery. The incineration boiler structurally and mainly comprises auxiliary combustors, waste liquid spray guns, a thermal insulation hearth combustion chamber, a steering chamber, a radiation cooling chamber, a radiation water-cooling pipe panel, convection current evaporation pipe panels, a steam pocket, a high-temperature economizer, a low-temperature economizer, an ash falling bucket, a flue connection expansion joint and a furnace wall. The thermal insulation hearth combustion chamber is formed by a hearth wall-covering film type water-cooling wall in a defined manner, salty waste liquid is combusted, and recycling is conducted in a salt dissolving tank. High-temperature smoke generated in combustion sequentially enters the thermal insulation combustion steering chamber, a quenching chamber, the multiple stages of convection current evaporation cooling chambers and the economizers to be subjected to heat energy recovery. The incineration boiler has the beneficial effects of being simple in manufacturing process, convenient to maintain, safe and stable in running, and suitable for being used and popularized in high-concentration salty organic waste liquid processing in the industries of chemical engineering, oil refining, papermaking and the like.

Owner:大连科林能源工程技术开发有限公司

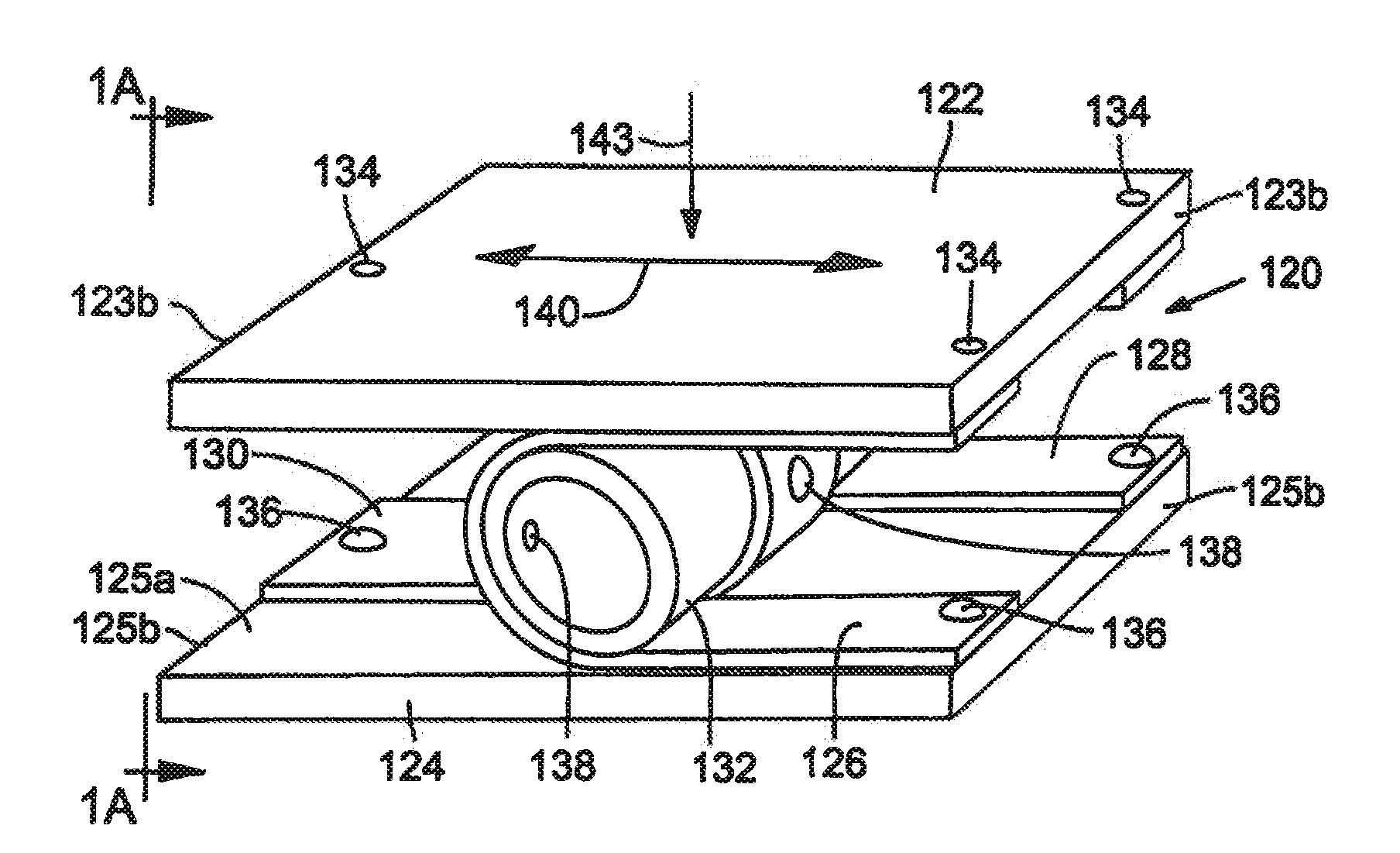

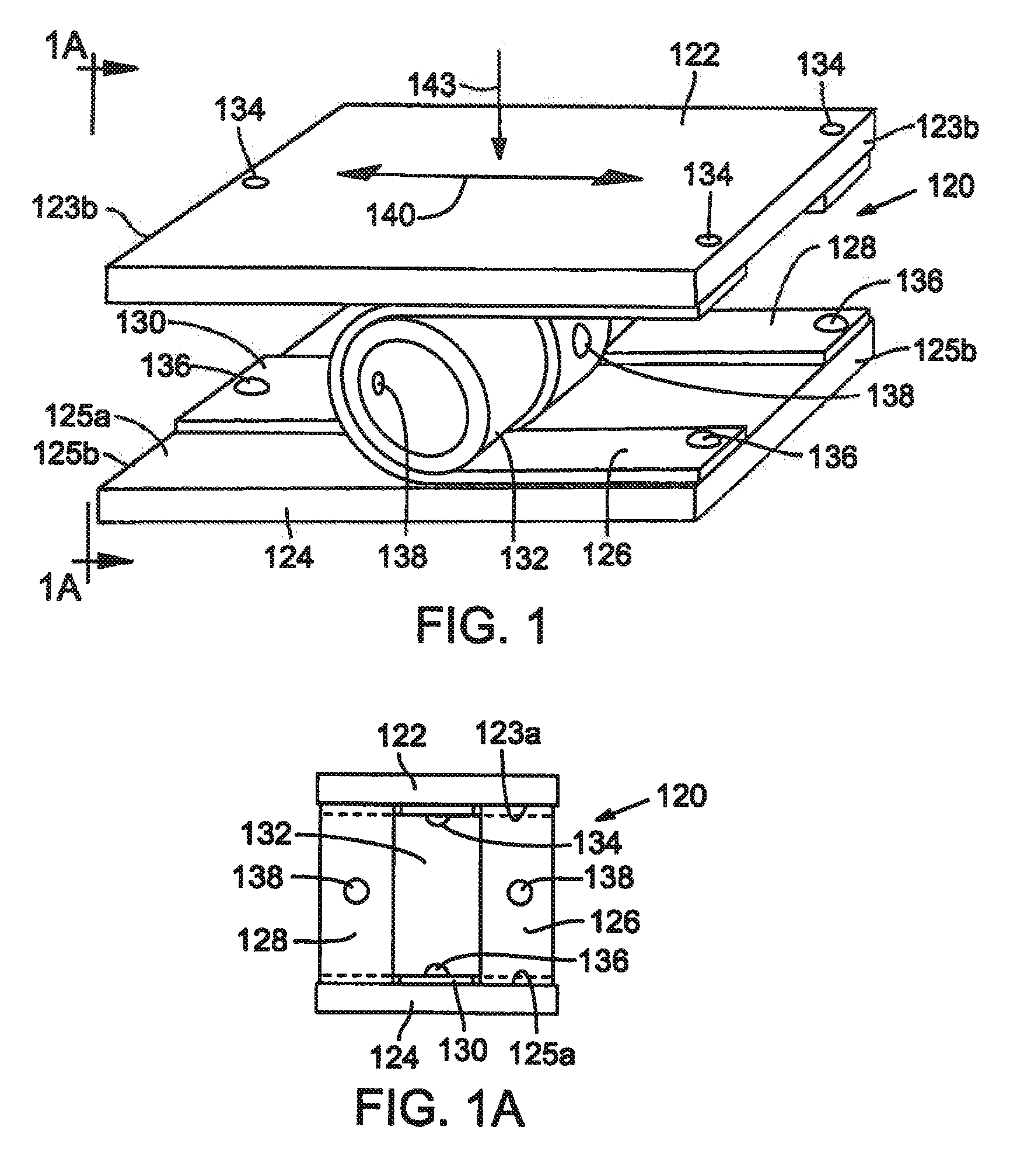

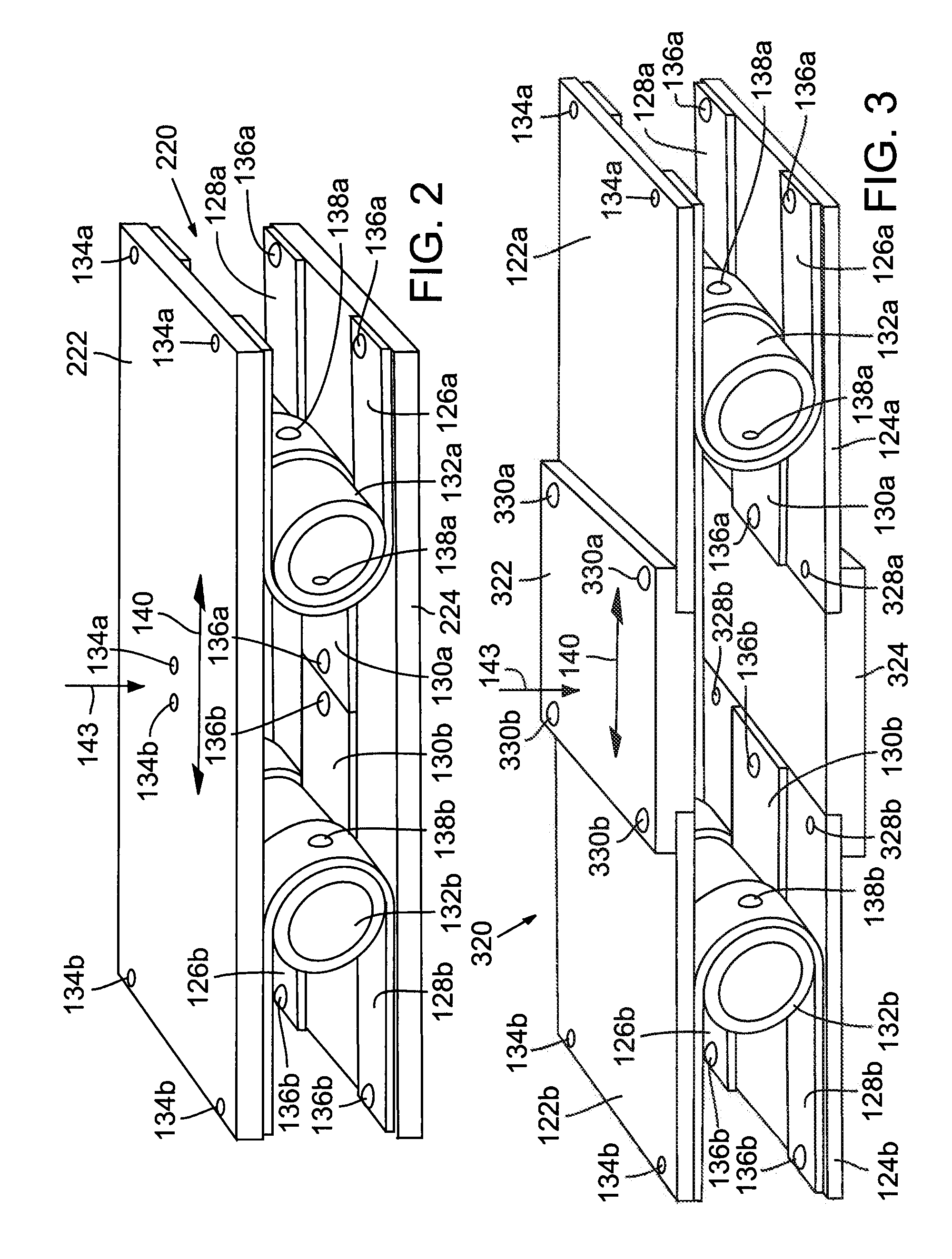

Linear roller bearing assembly and sub-assembly and reciprocating machinery incorporating the same

ActiveUS20100281861A1High thermodynamic engine efficiencyImprove power densityRolling contact bearingsLinear bearingsLinear motionEngineering

Linear roller bearing assemblies can include a hub, a collar around the hub and roller bearing sub-assemblies disposed in a radial pattern around the hub. The roller bearing sub-assemblies can guide linear movement of the hub relative to the collar along a selected direction. Each roller bearing sub-assembly can include a roller and straps wrapped partially around the roller. Each strap is connected to at least one of the hub and the collar. And at least one of the straps can be connected to the roller while at least one of the straps can be circumferentially free of the roller. The hub and collar are moveable relative to each other along the selected direction for a distance that is approximately half of a circumference of the roller. Methods of forming linear roller bearing assemblies are also disclosed, as are multi-cylinder Stirling engines and a thermal energy recovery system.

Owner:STIRLING INNOVATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com