Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87 results about "Surface dynamics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

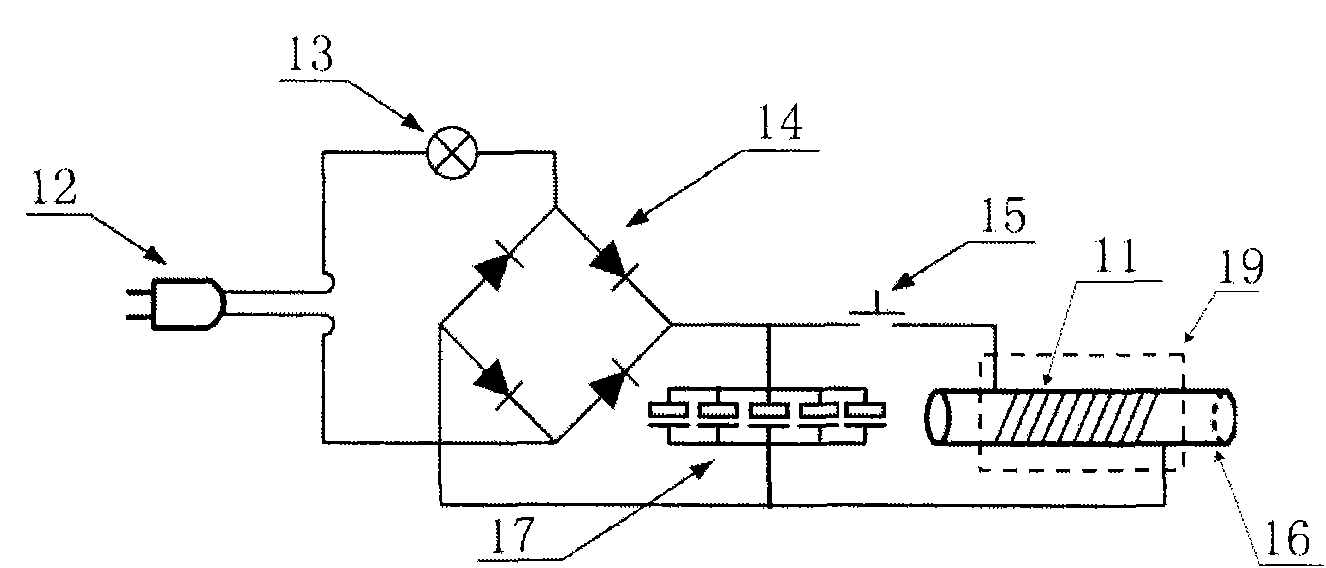

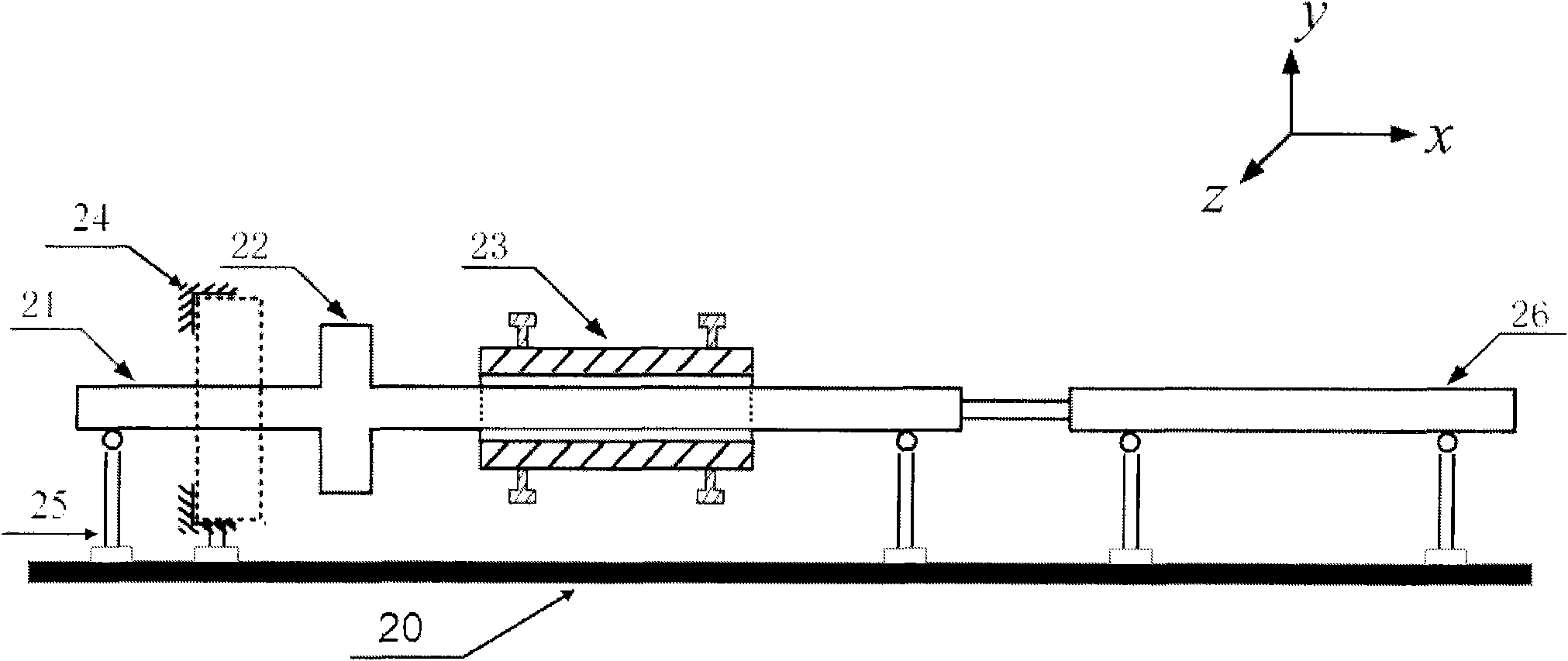

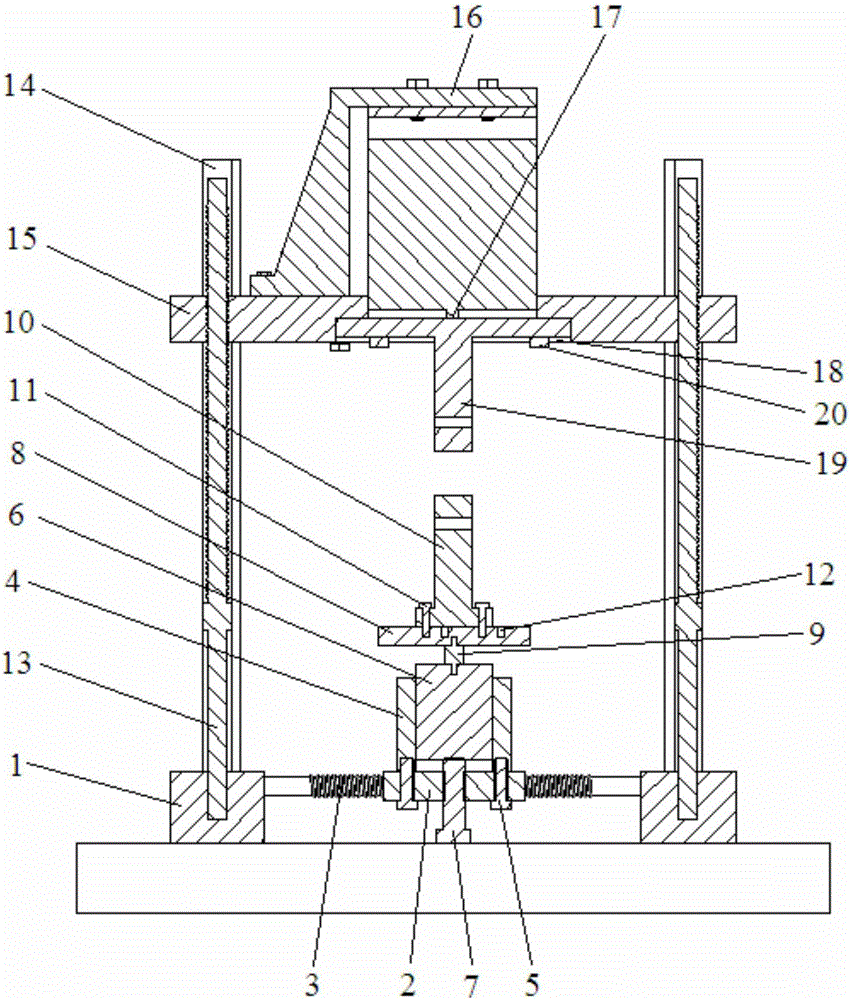

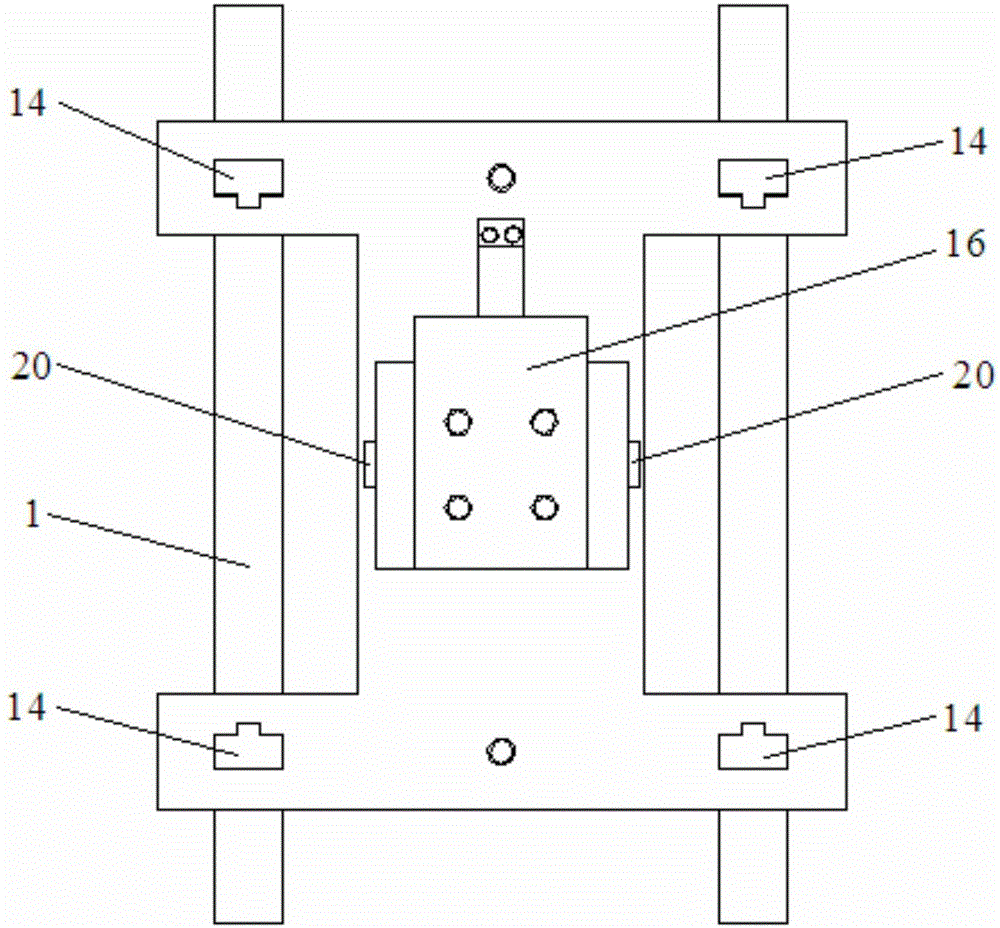

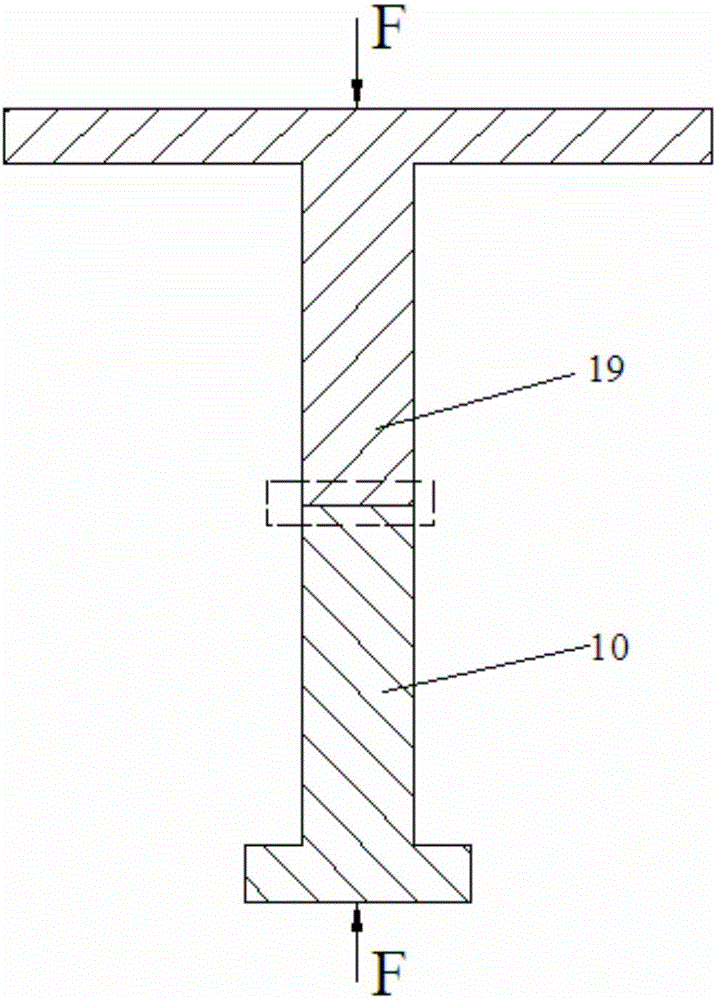

System and method for performing impact loading on micro test piece and measuring dynamic mechanical property

InactiveCN102135480ASolve the study of dynamic mechanical properties at high strain ratesLaunch fastStrength propertiesFerroelectric thin filmsStress–strain curve

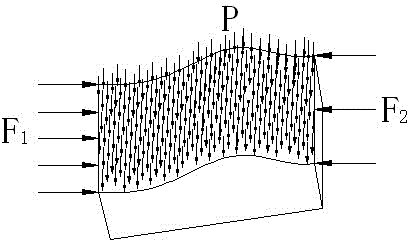

The invention relates to a system and a method for performing impact loading on a micro test piece and measuring dynamic mechanical property. The method comprises the following steps of: instantly accelerating a bullet by using an electromagnetic pulse launch technology and launching the bullet at high speed; transmitting a stretching stress wave generated by collision of the bullet to the micro test piece by using a separated Hopkinson bar technology so as to generate the impact loading on the micro test piece; recording strain data of an input bar and an output bar, and acquiring an enlarged surface dynamic deformation image of the micro test piece; analyzing and obtaining a stress strain curve of the micro test piece subjected to the impact loading having different strain rates; and analyzing the surface dynamic deformation image of the micro test piece and obtaining a distribution of a bidimensional displacement field and a strain field during dynamic impact loading of the micro test piece. By the system and the method, the problem of research on the dynamic mechanical property of a micro electro mechanical system (MEMS), and membrane materials such as piezoelectric thin films, ferroelectric thin films and the like is solved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

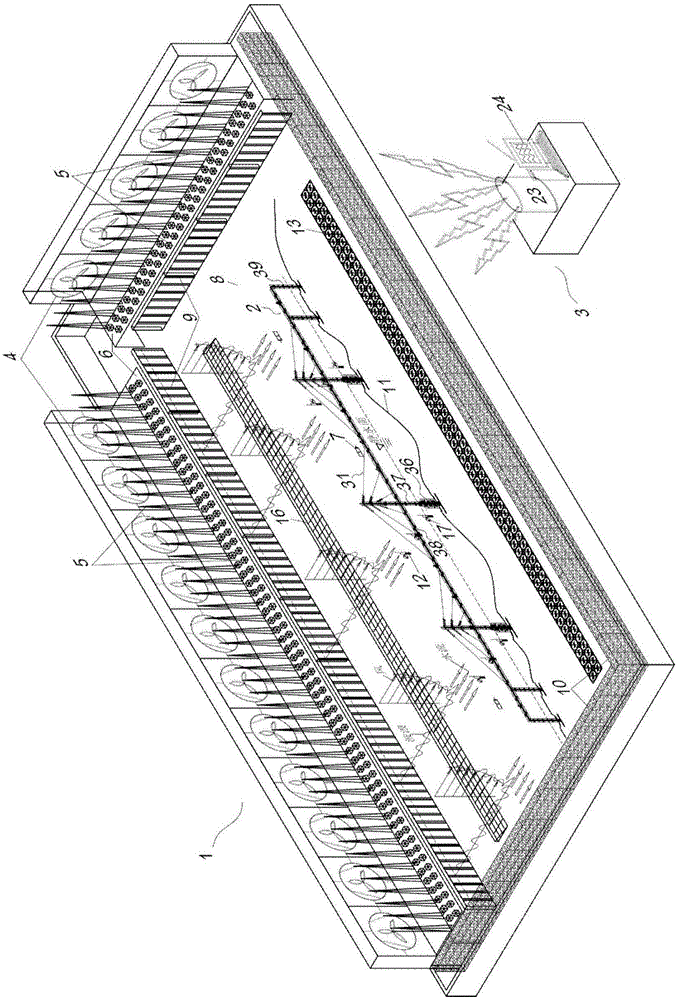

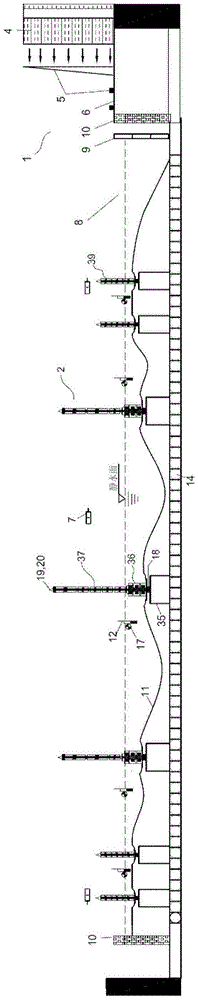

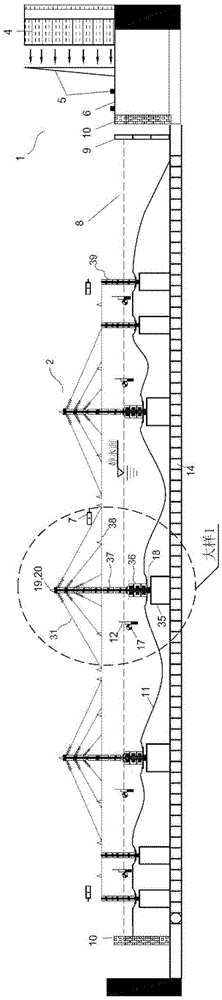

Test system for dynamic response of bridge full-bridge elastic model to wind, wave and current coupling

ActiveCN105115697AHigh similarityRealistic simulation of air/water bomb effectsHydrodynamic testingPilot systemFull bridge

The invention discloses a test system for dynamic response of bridge full-bridge elastic model to wind, wave and current coupling. The test system comprises: a wind, wave and current coupling field simulating system used for generating a target wind, wave and current coupling field through a simulation-feedback-control mechanism; a bridge full-bridge elastic model which is arranged in the wind, wave and current coupling field simulating system and is used for simulating the appearance, the rigidity, the quality and the damping characteristics of an elastic structure of the full bridge in construction and completion states of the bridge; and a test analyzing system used for acquiring and analyzing wind, wave and current coupling field parameters, and dynamic responses, such as displacement, acceleration speed, underwater foundation surface dynamic water pressure distribution, and foundation six component forces, of the bridge full-bridge elastic model under the action of the wind, wave and current coupling field. According to the invention, the test system can realize simulation of the wind, wave and current coupling field with space correlation and time continuity and synchronization, simulation of the full-bridge elastic model in construction and completion states of the bridge, and real-time test and analysis of the wind, wave and current coupling field parameters and dynamic responses of the bridge full-bridge elastic model. Beyond that, the test system is convenient to implement, achieves high precision and strong reliability.

Owner:CCCC HIGHWAY BRIDNAT ENG RES CENT

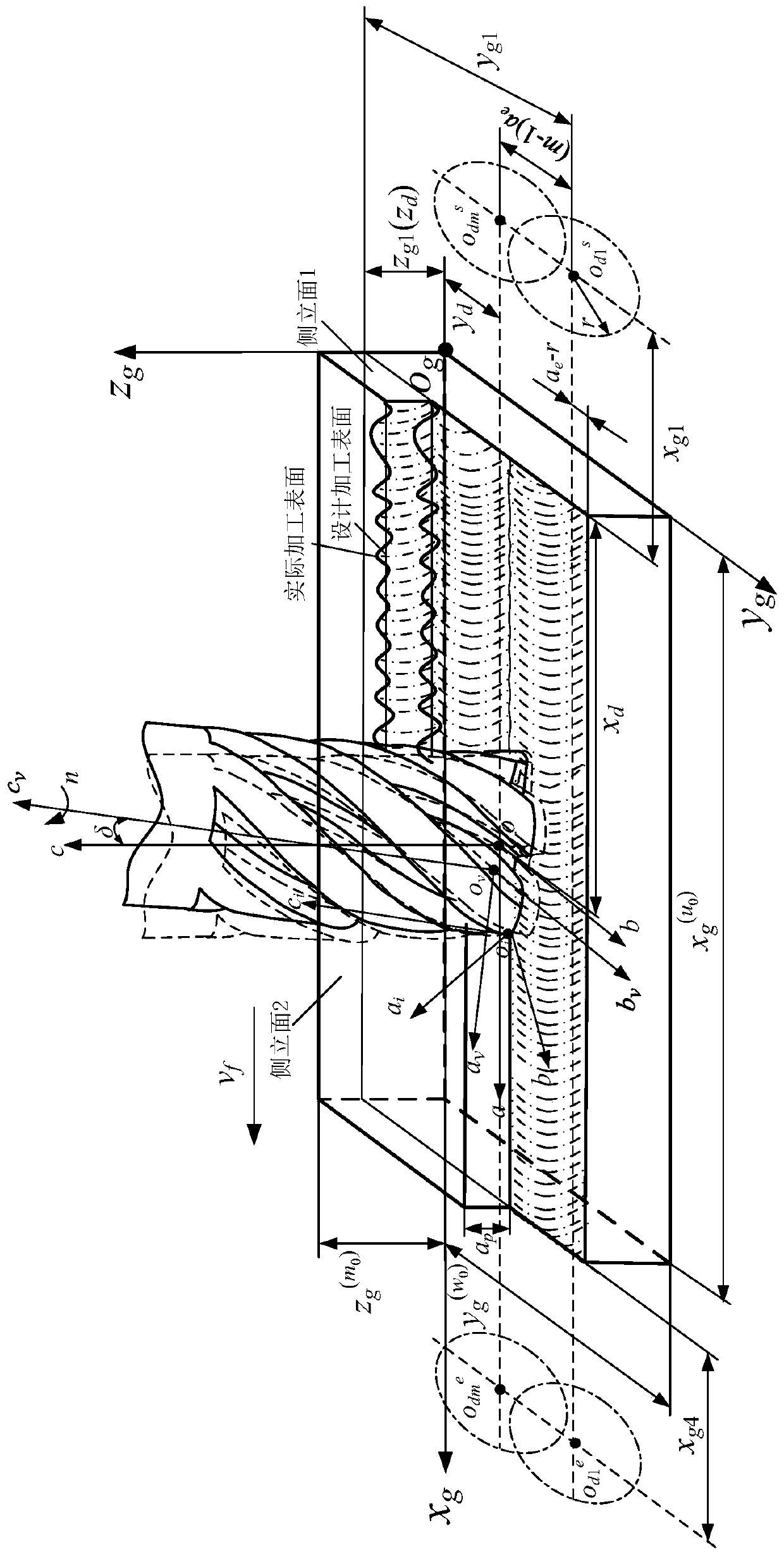

Modeling method for dynamic machining features of complex curved surface

ActiveCN104281098AGuaranteed flexibilityGood effectProgramme controlComputer controlModel methodAdaptive optimization

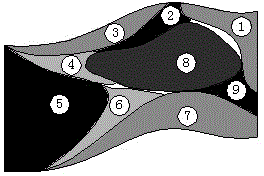

The invention provides a modeling method for dynamic machining features of a complex curved surface and belongs to the technical field of CAD / CAM. The modeling method for the dynamic machining features of the complex curved surface comprises the steps that firstly, according to a selected machining scheme, machining intermediate state features corresponding to all machining stages in the curved surface machining scheme are defined; secondly, curved surface machining area division is conducted on each intermediate stage feature according to selected machining devices, cutting parameters and machining optimization objects of different machining stages, so that curved surface machining sub-features are obtained. According to the modeling method for the dynamic machining features of the complex curved surface, FunctionBlock is used as an information carrier of the curved surface dynamic machining features, when manufacturing resources are changed, an event triggering-responding mechanism of the FunctionBlock is utilized, a defined curved surface feature modeling method in the FunctionBlock is automatically called, and the intermediate state features of curved surface machining and curved surface machining sub-features contained by the intermediate state features are updated in real time. By the adoption of the modeling method for dynamic machining features of the complex curved surface, the curved surface machining features can be dynamically updated according to the change of the manufacturing resources, and the modeling method is the key technology for achieving complex curved surface self-adaption optimized machining.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

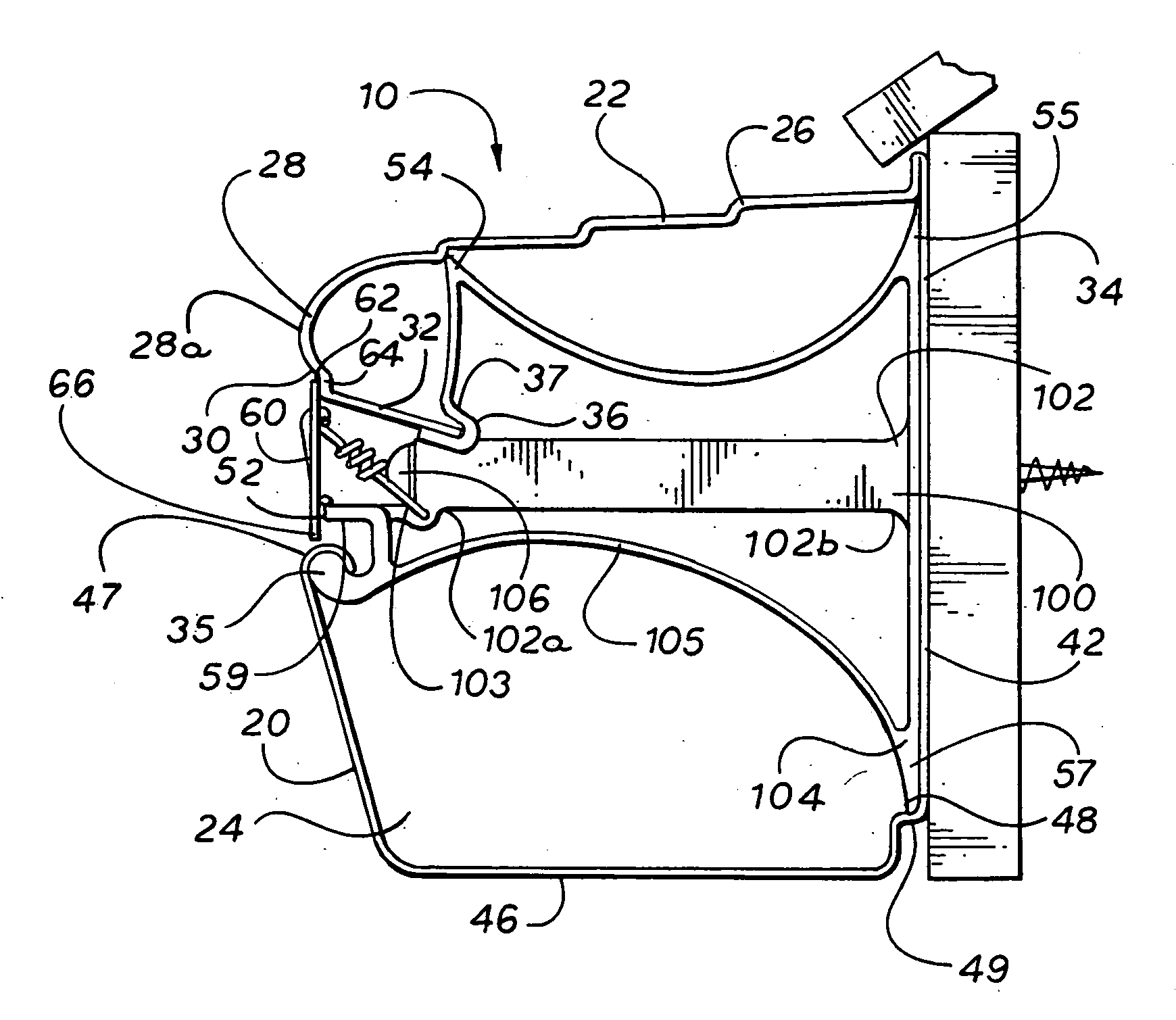

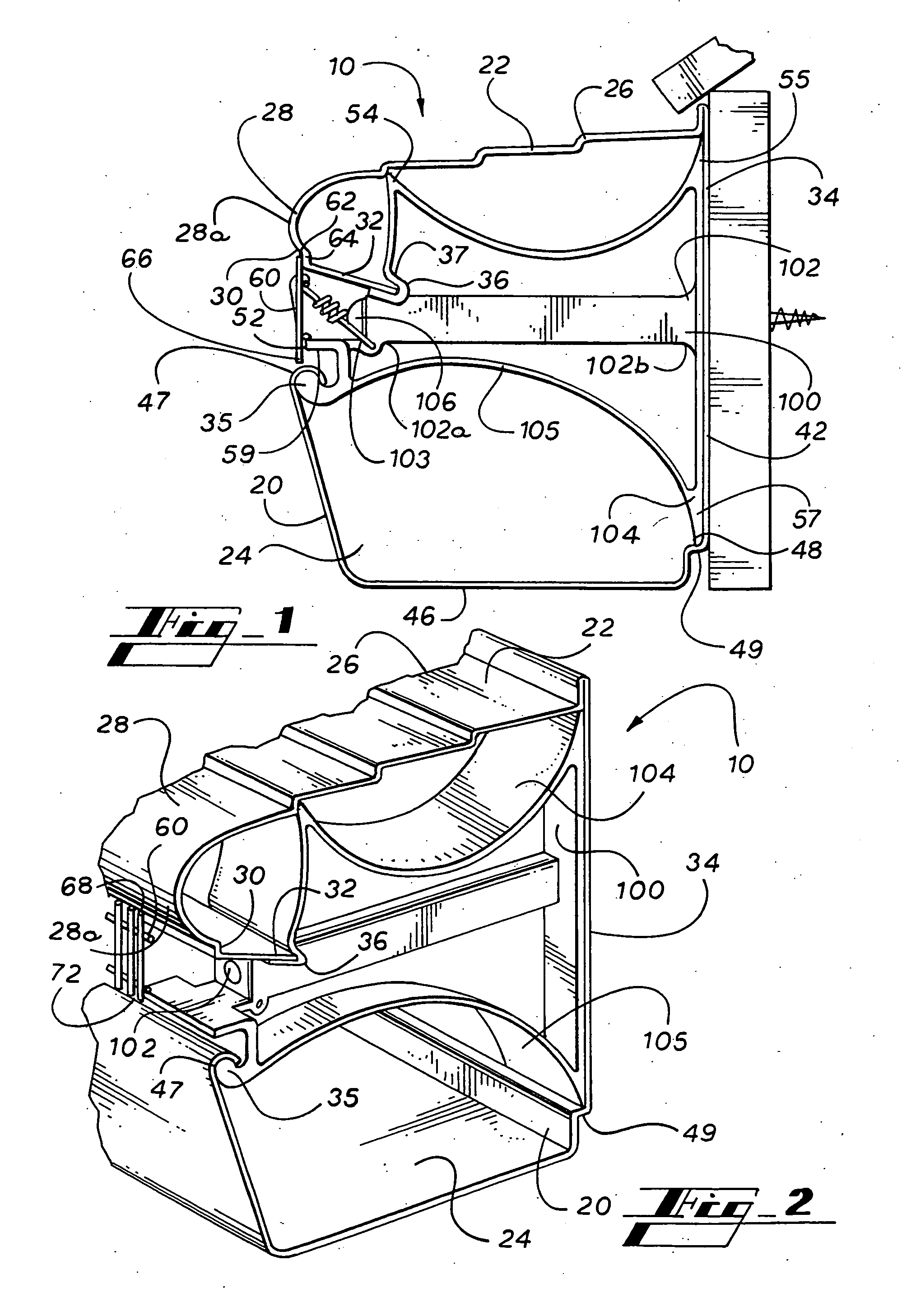

Covered rain gutter system

A covered, multi-compartment rain gutter that mounts to facia to collect water upon exit from the peripheral edge of a roof structure, wherein surface dynamics facilitate the collection of rainwater and minimize the passage of undesirable debris, and wherein a straining member further limits the passage of debris into the gutter collection compartment.

Owner:PIJANOWSKI WALTER

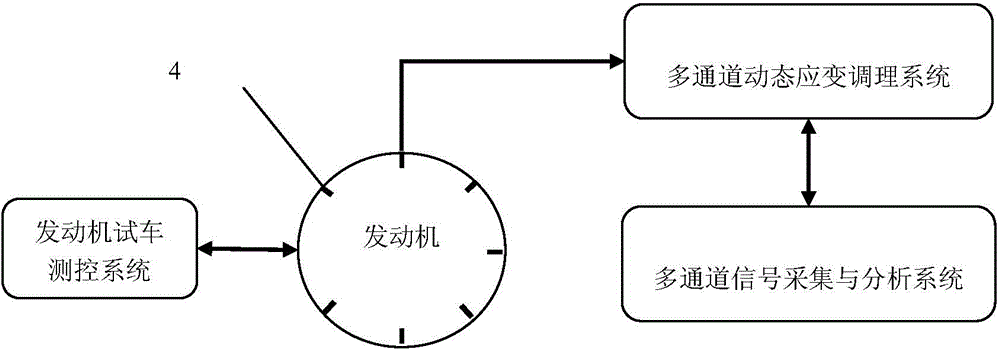

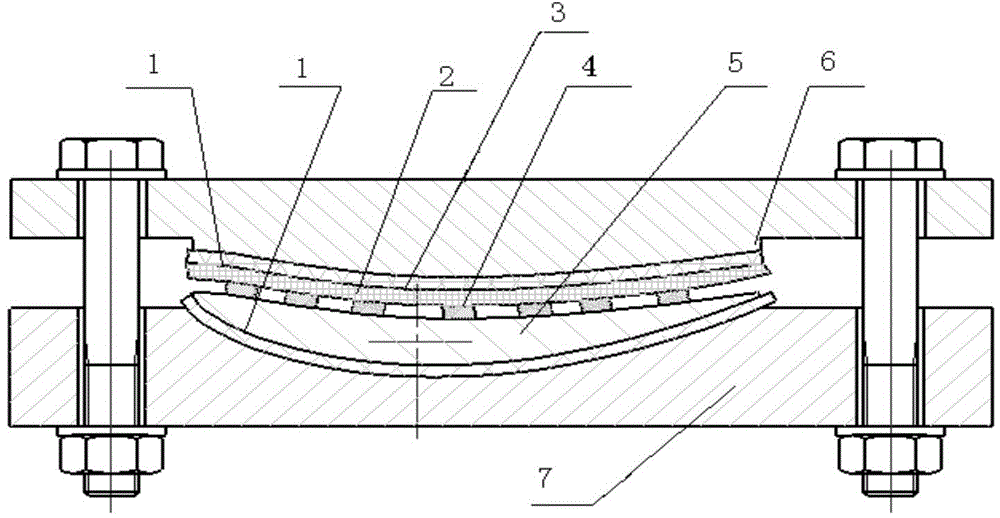

Dynamic stress testing method for stator vane under operating state of gas turbine engine

The invention belongs to the technology for testing aircraft engines and relates to an engine vane surface dynamic stress testing method. A dynamic stress testing method for a stator vane under the operating state of a gas turbine engine allows a dynamic stress test to be conducted on a guide vane and the stator vane of the engine under the operating state of the engine. Due to the fact that strain gages are directly stuck to the vanes of the engine to conduct dynamic testing, test data are real and accurate, information is complete, quantitative analysis is easy, and bases can be provided for analysis of faults such as vane cracking and chip off-falling, and meanwhile reliable data are provided for the further mastering of the distribution of charges on the surfaces of the engine vanes.

Owner:AECC AVIATION POWER CO LTD

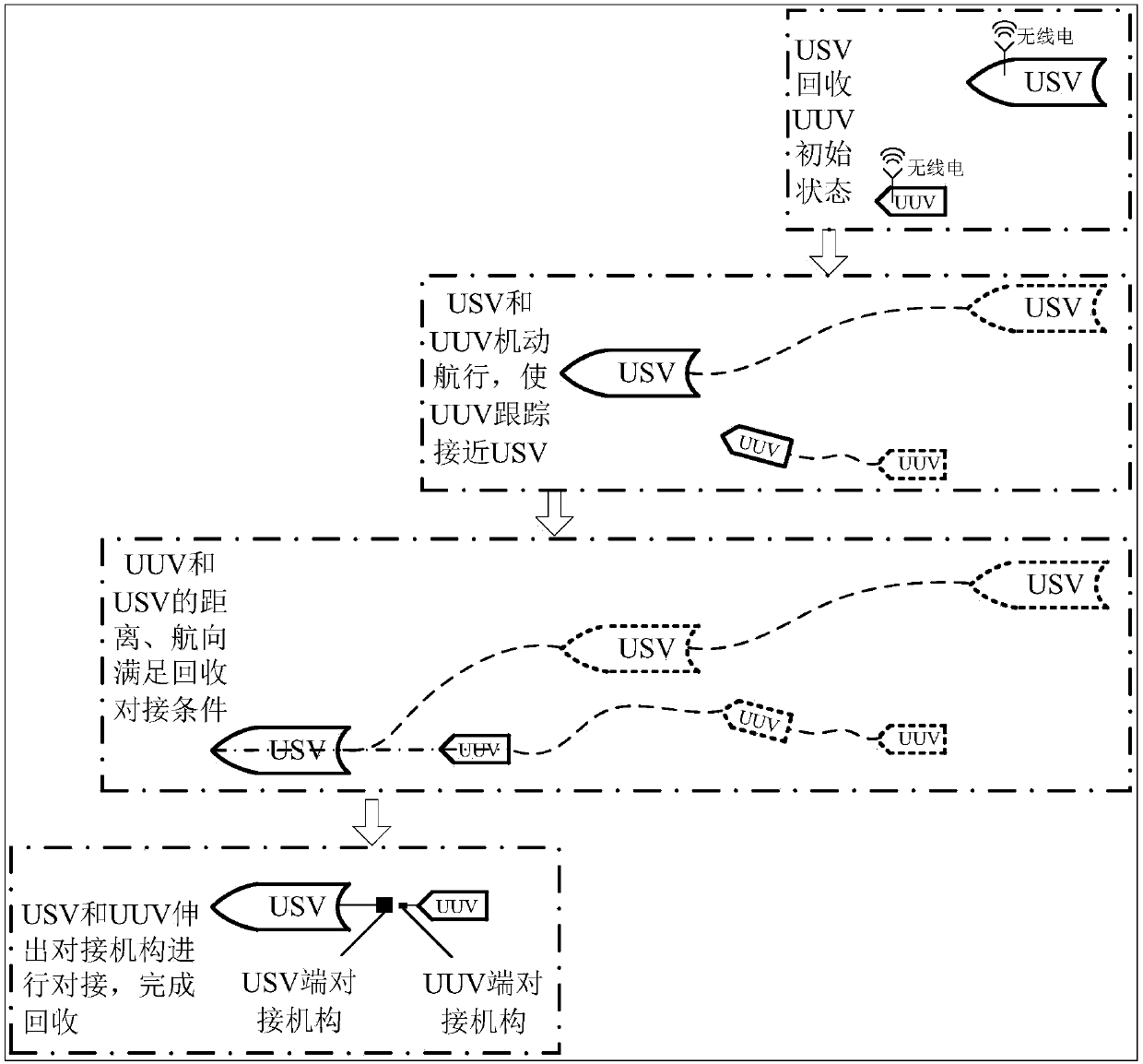

USV water surface dynamic autonomous recovery UUV method

ActiveCN107065882ASafe and reliable self-recyclingSmooth sailingPosition/course control in two dimensionsClassical mechanicsBiological activation

The invention discloses an USV (Unmanned Surface Vehicle) water surface dynamic autonomous recovery UUV (Unmanned Underwater Vehicle) method, and the method comprises the steps: an USV sails to an UUV in a fixed speed, and the UUV keeps to standby in site; the USV calculates an initial position point of a virtual USV which is needed to be tracked by the USV according to quadrant of a recovery circle accessed by the USV; movement calculation of the virtual USV is performed, and the USV tracks the virtual USV; the UUV keeps to standby in site; when the USV access an activation circle, the USV keeps to sail in current course and speed and transmits an activation instruction to the UUV through radio; the UUV receives the activation instruction, performs movement calculation of the virtual UUV and starts to track the virtual UUV; the UUV access a connection circle, a connection structure is released, and the USV is noticed to release the connection structure through the radio; the UUV is connected with the USV through the connection structure, and the recovery is completed. According to the invention, recovery maneuvering strategies are autonomously adopted according to in-site conditions, and the autonomous recovery of the UUV is realized.

Owner:HARBIN ENG UNIV

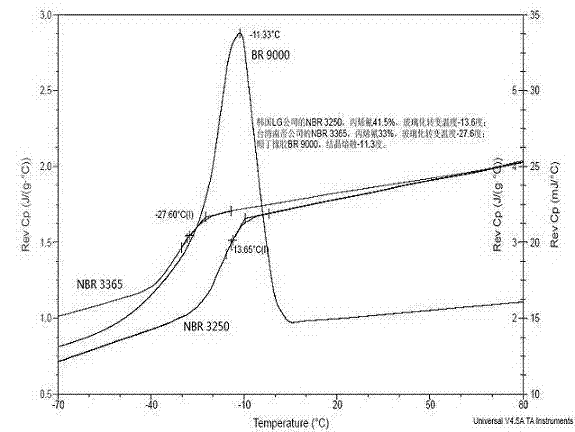

Ice-surface dynamic anti-slip rubber sole and production method thereof

The invention relates to a sole, and provides an ice-surface dynamic anti-slip rubber sole and a production method thereof. The ice-surface dynamic anti-slip rubber sole comprises the following compositions: natural rubber, chloroprene rubber, brominated butyl rubber, nanometer silica, a plasticizer, an anti-ageing agent, a silica activator, a silane coupling agent, hemp fiber, polyethylene wax, zinc oxide, sulfur and a sulfuration promoter. By selecting reasonably-optimized main rubber composition and compounding agents, operation is simple and practicable, and industrialized production is facilitated. The prepared ice-surface dynamic anti-slip rubber sole has extremely anti-slip effect on road interfaces of snowfield, frosted ice surface, dry ice surface and wet ice surface, is stable in comprehensive performances, guarantees a wear to not slip down because of a wet and slippery ice surface, and has extremely good market prospect.

Owner:茂泰(福建)新材料科技有限公司

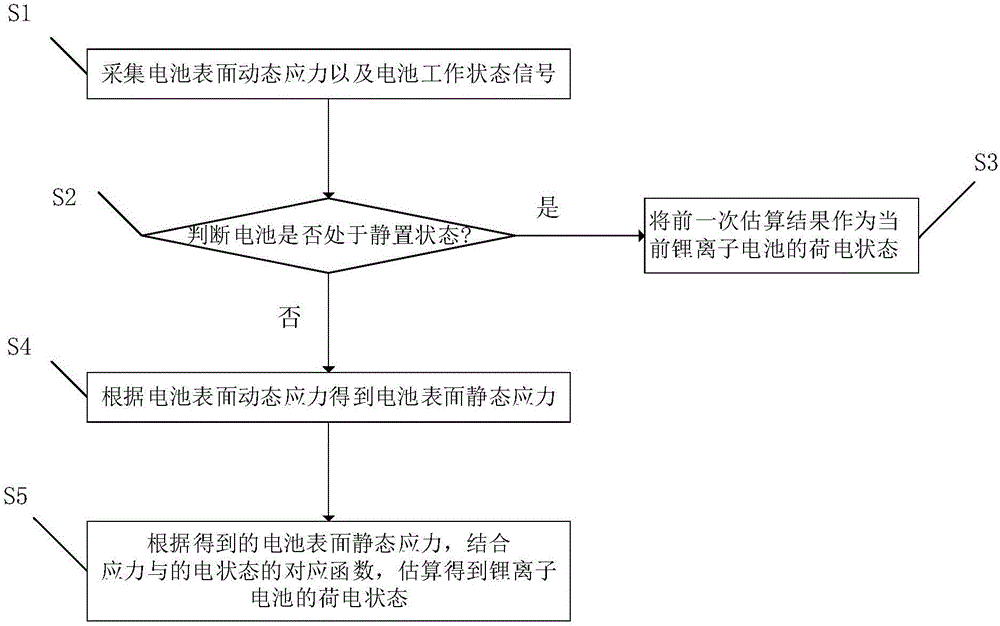

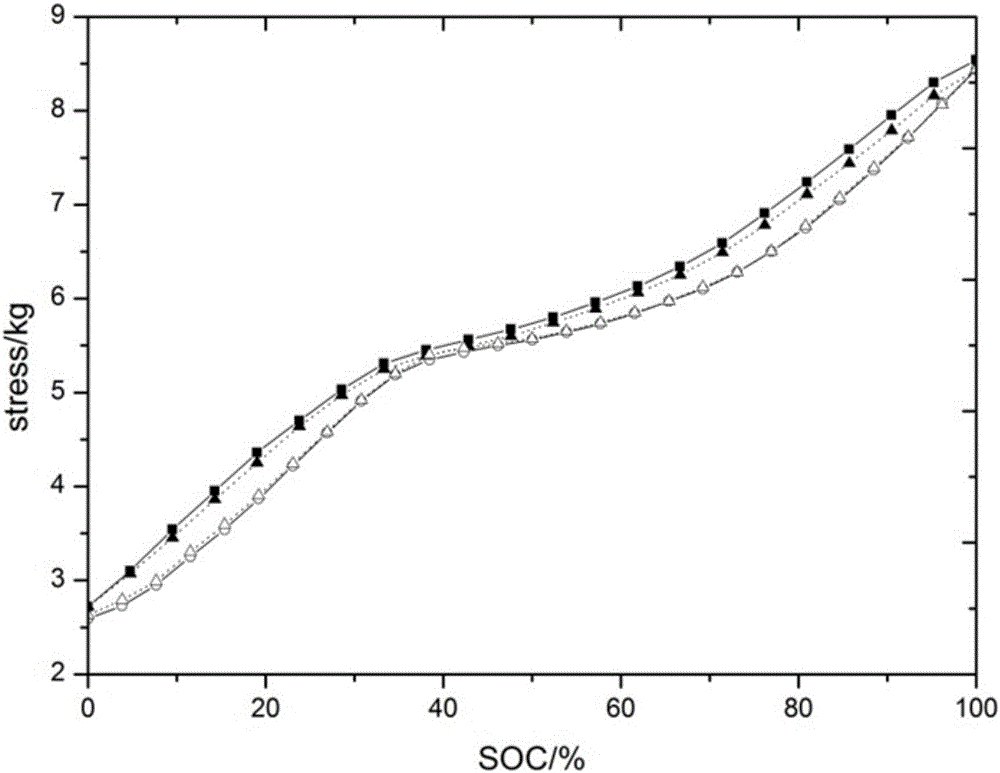

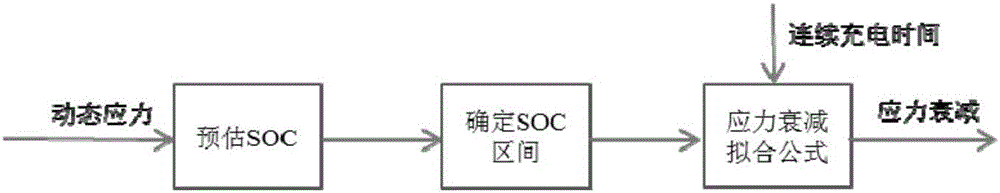

Method for estimating state of charge of soft package lithium-ion battery

ActiveCN105759216AImprove accuracyReduce complexityElectrical testingStress measurementElectrical battery

The invention relates to a method for estimating the state of charge of a soft package lithium-ion battery. The method comprises a step S1 of acquiring battery surface dynamic stress and a battery working state signal that includes first data for indicating that a battery is in a charging, standing or discharged state; a step S2 of determining whether the battery is in a standing state, if so, executing a step S3, and otherwise, executing a step S4; the step S3 of taking the previous estimation result as the current state of charge of the lithium-ion battery; the step S4 of obtaining battery surface static stress according to the battery surface dynamic stress, and executing a step S5; and the step S5 of estimating the state of charge of the lithium-ion battery by combining a corresponding function of the static stress and the state of charge according to the obtained battery surface static stress. Compared with the prior art, the invention achieves the estimation of the charge of charge of the lithium-ion battery by using a method based on stress measurement, and reduces the system complexity while improving the system accuracy.

Owner:TONGJI UNIV

Electric-field enhanced performance in catalysis and solid-state devices involving gases

ActiveUS20100323258A1Improved catalytic converterLow costCellsMachining electric circuitsFuel cellsDesorption

Owner:UNIV OF FLORIDA RES FOUNDATION INC

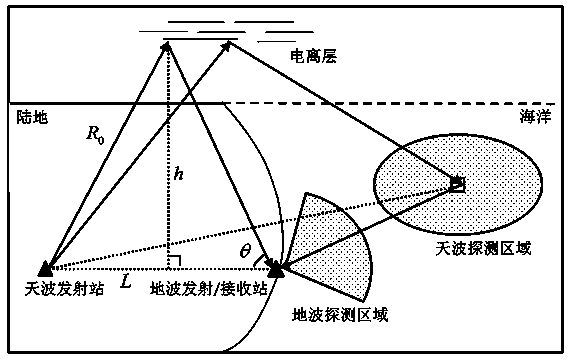

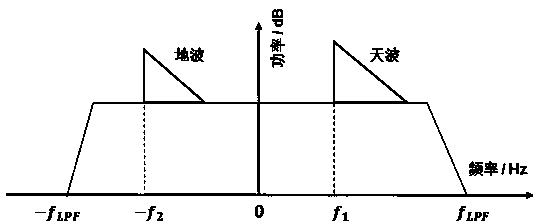

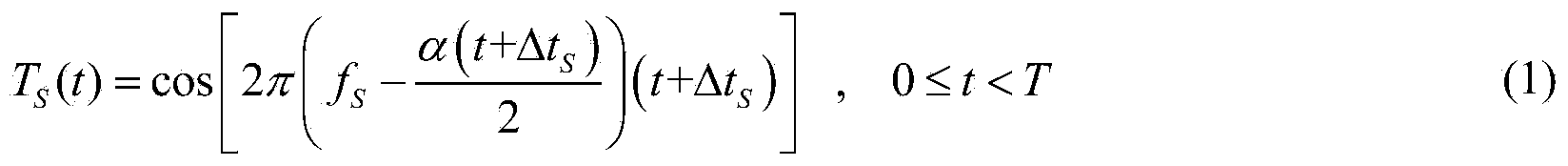

Method for simultaneously receiving sky wave and ground wave BVR radar signals

ActiveCN103869293AAchieve separationSimple methodRadio wave reradiation/reflectionRadar systemsFrequency spectrum

The invention discloses a method for simultaneously receiving sky wave and ground wave BVR radar signals. A distance offset method is used for transmitted signals on a sky wave transmitting station and a ground wave transmitting station so that a ground wave radar station on a shore base can simultaneously receive echo signals obtained by signals transmitted by a sky wave radar and a ground wave radar and scattered by a sea surface or a ship or a low altitude flight object. The method is simple and convenient to achieve, distance offset only needs to be conducted on sky wave transmitting signals and ground wave transmitting signals, it is guaranteed that the ocean of the sky wave radar and the ground wave radar or an object echo wave spectrum is within the bandwidth of a receiver filter, and aliasing of the distances and spectrum can not happen. An existing ground wave radar receiving system is used so that the purpose that the two BVR methods of sky wave transmitting and ground wave transmitting can be simultaneously used for detecting the ocean or target can be achieved. The combined detection mode can improve the detection accuracy of ocean surface dynamic parameters such as wind, waves and currents, the detection distance of a high-frequency BVR radar system is increased, and close distance fine detection and long distance ocean surface dynamic element detection are achieved.

Owner:WUHAN UNIV

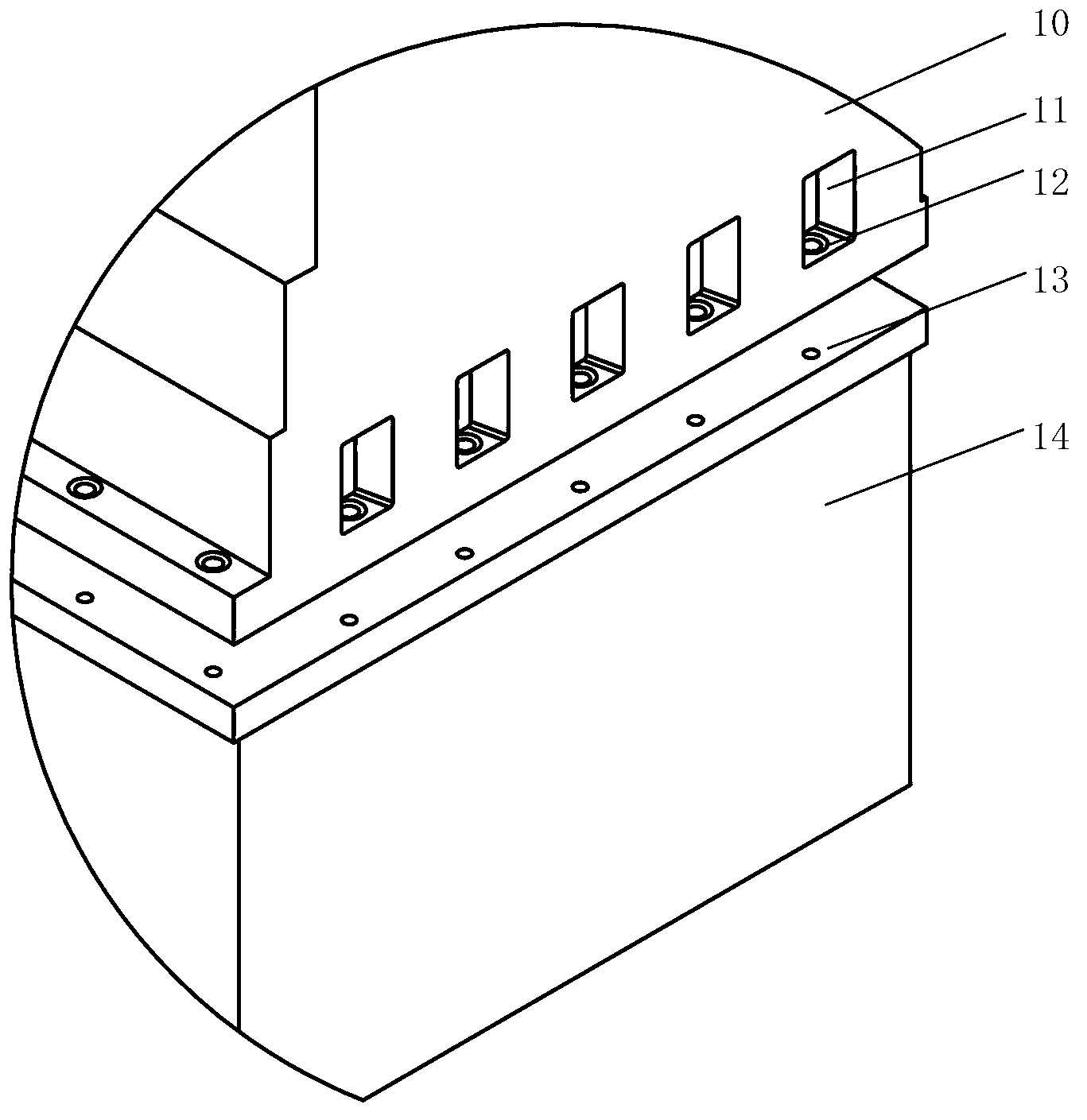

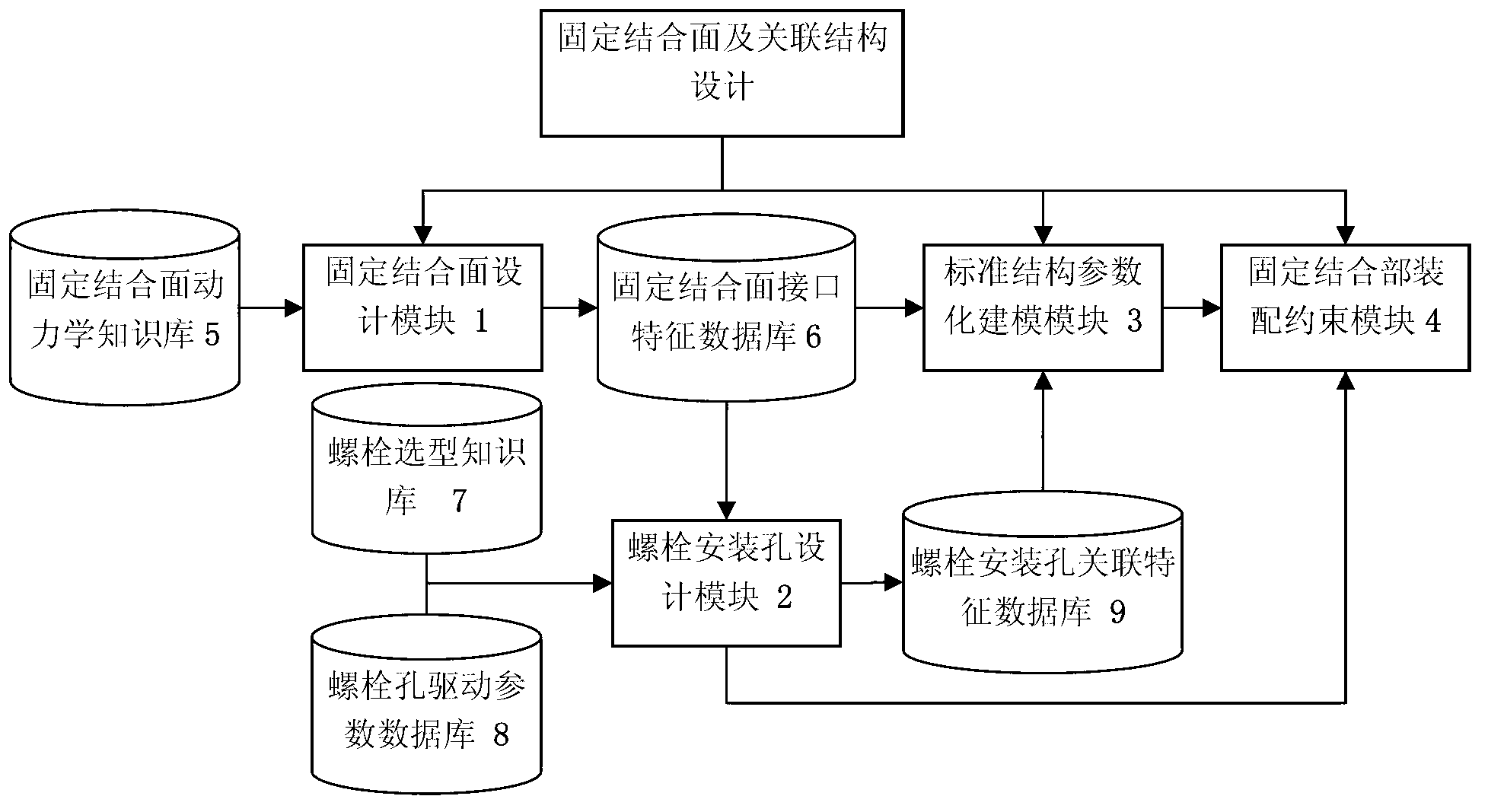

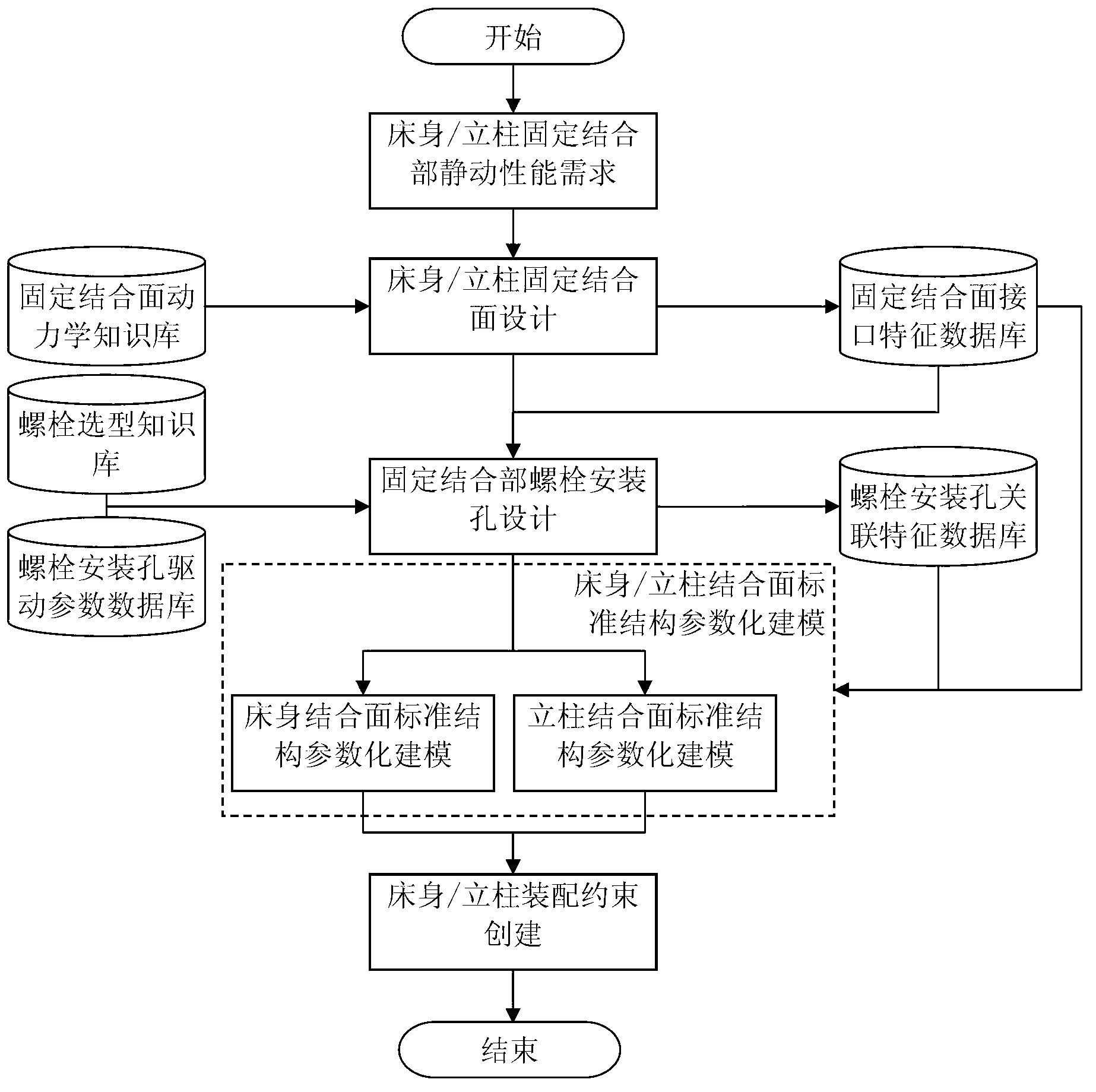

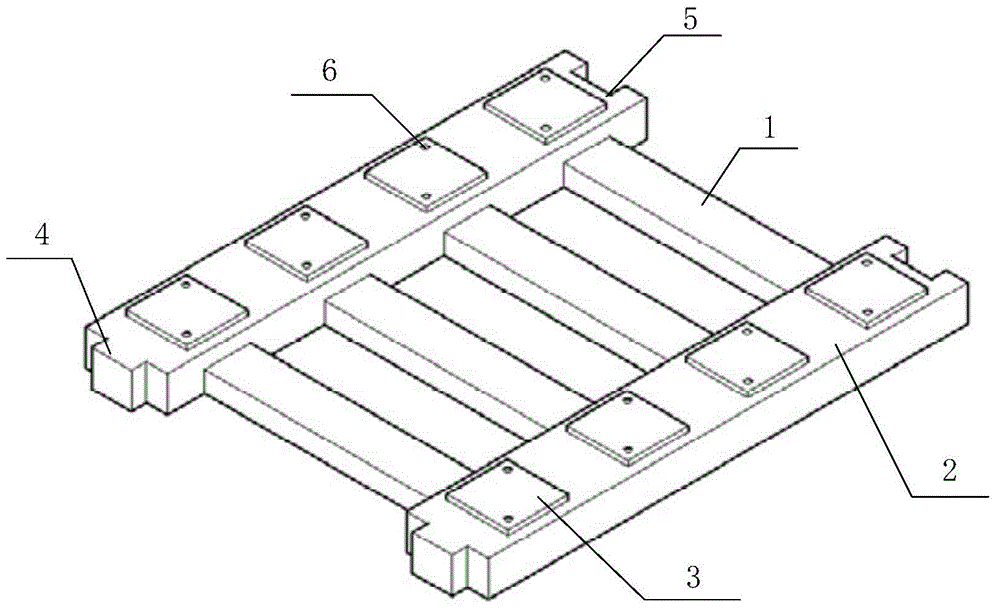

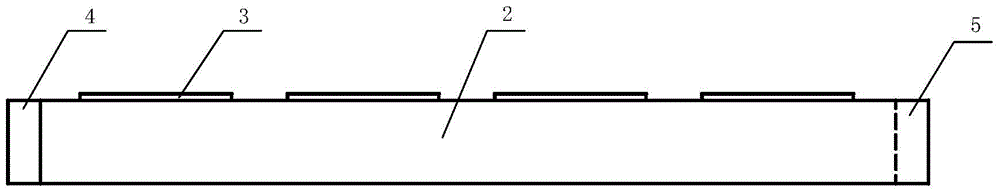

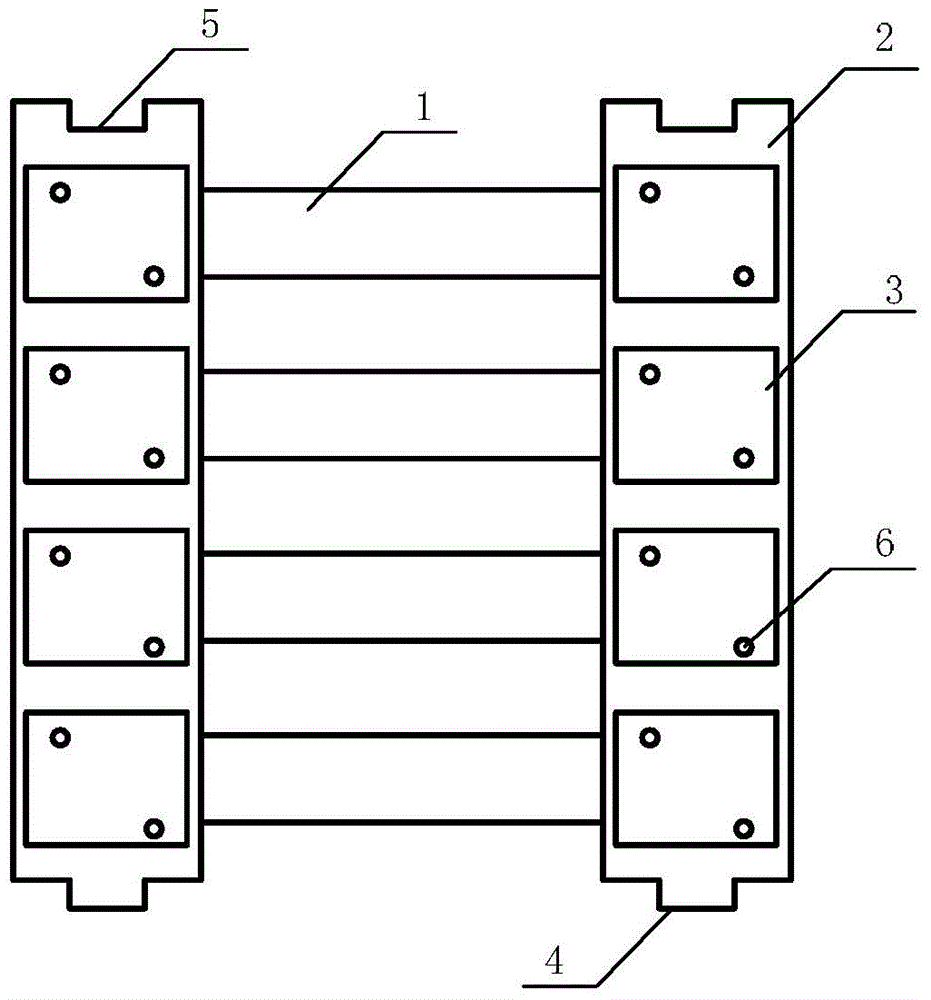

Quick-tool-design-oriented fixed joint surface database and creating method thereof

ActiveCN103294810AAutomate creationImplement parametric modelingSpecial data processing applicationsModel selectionLarge size

The invention discloses a quick-tool-design-oriented fixed joint surface database and a creating method thereof. The database comprises a fixed-joint-surface dynamics knowledge base, a fixed-joint-surface design module, a fixed-joint-surface interface characteristic database, a bolt model-selection knowledge base, a bolt-hole driving parameter database, a fixed-joint-surface bolt-mounting-hole design module, a bolt-mounting-hole correlative characteristic database, a standard structure parameterized modeling module and an assembly constraint creating module. The creating method includes designing a joint surface according to dynamics needs of tool fixed joint surfaces, performing automated design of a bolt mounting hole structure according to a joint surface structure, completing parameterized modeling of a large-size joint-part standard structure of a tool according to the joint surface and the mounting hole structure, and automatically creating an assembly constrained relationship of the joint surface. Automated creation of the fixed joint surface during designing of the tool, the parameterized modeling and automated assembly of correlative characteristics of a tool structure member can be realized, technical support is provided to quick design and assembly of the tool.

Owner:TIANJIN UNIV

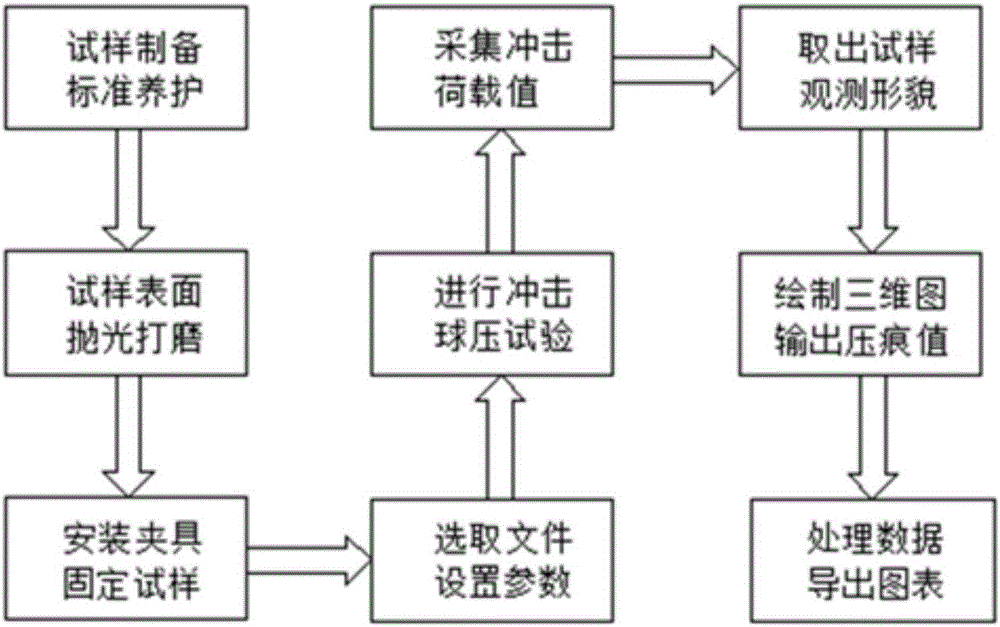

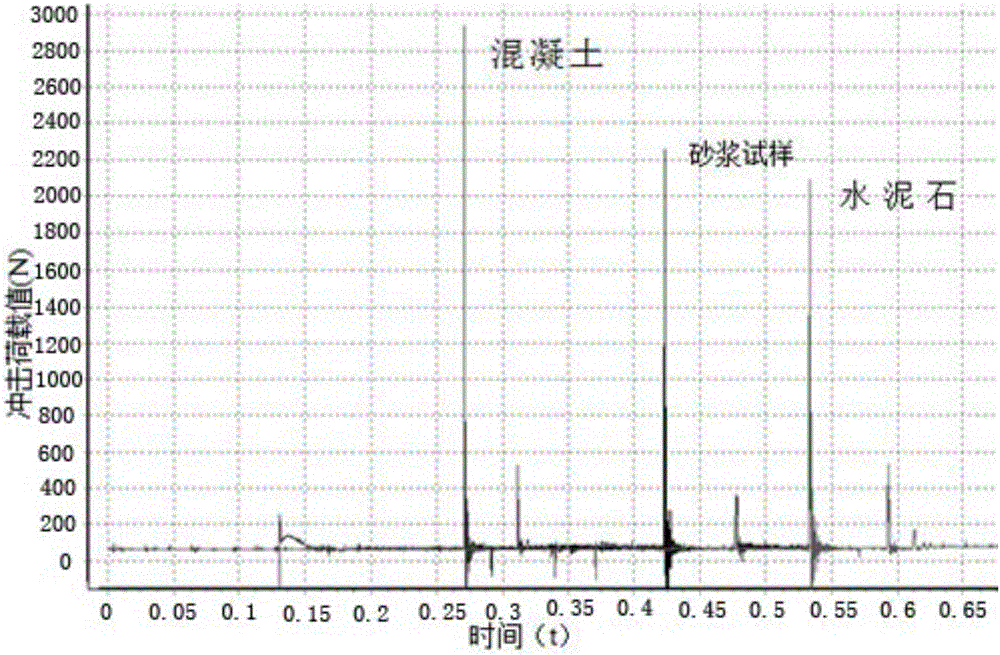

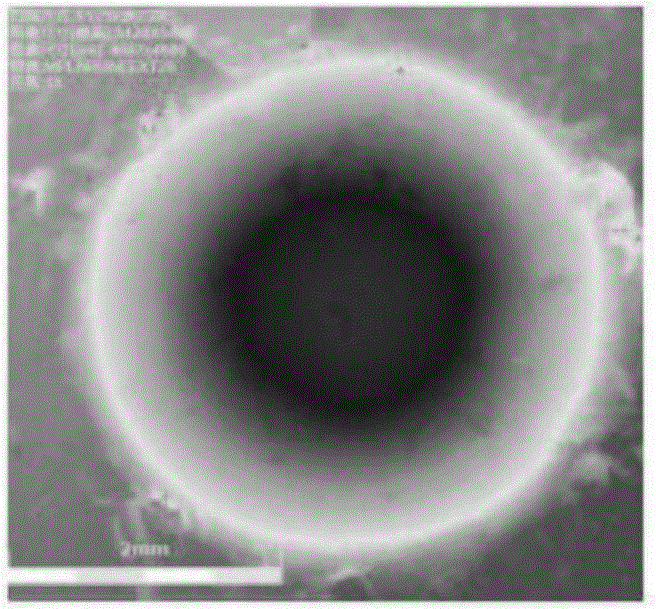

Impacting ball-pressure testing and evaluation method of engineering material

The invention belongs to the technical field of engineering material detection and in particular relates to an impacting ball-pressure testing and evaluation method of an engineering material. An impact load and an impact indentation radius are obtained through an impacting ball-pressure test, so that the plasticity resistance, deformation capability, elasticity recovery capability, surface dynamic elastic modulus and shear modulus of the engineering material are analyzed; the impacting ball-pressure testing and evaluation method comprises four parts including test sample treatment, impacting testing, three-dimensional shape inspection and data processing. Compared with the prior art, the impacting ball-pressure testing method provided by the invention can realize polishing on a test sample needing surface treatment; a self-researched automatic ball-pressure tester can be used for carrying out a small-energy impacting ball-pressure test, and shape changes of the test sample are analyzed by measuring a 3D (Three Dimensional) shape of a surface damaged region of the test sample through utilizing a laser confocal technology; finally, test sample surface mechanical properties including the plasticity resistance, deformation capability, elasticity recovery capability, surface dynamic elastic modulus and shear modulus and the like of the surface of the test sample are analyzed through corresponding software; finally, one set of complete impacting ball-pressure testing method of the engineering material is obtained.

Owner:INNER MONGOLIA UNIV OF TECH

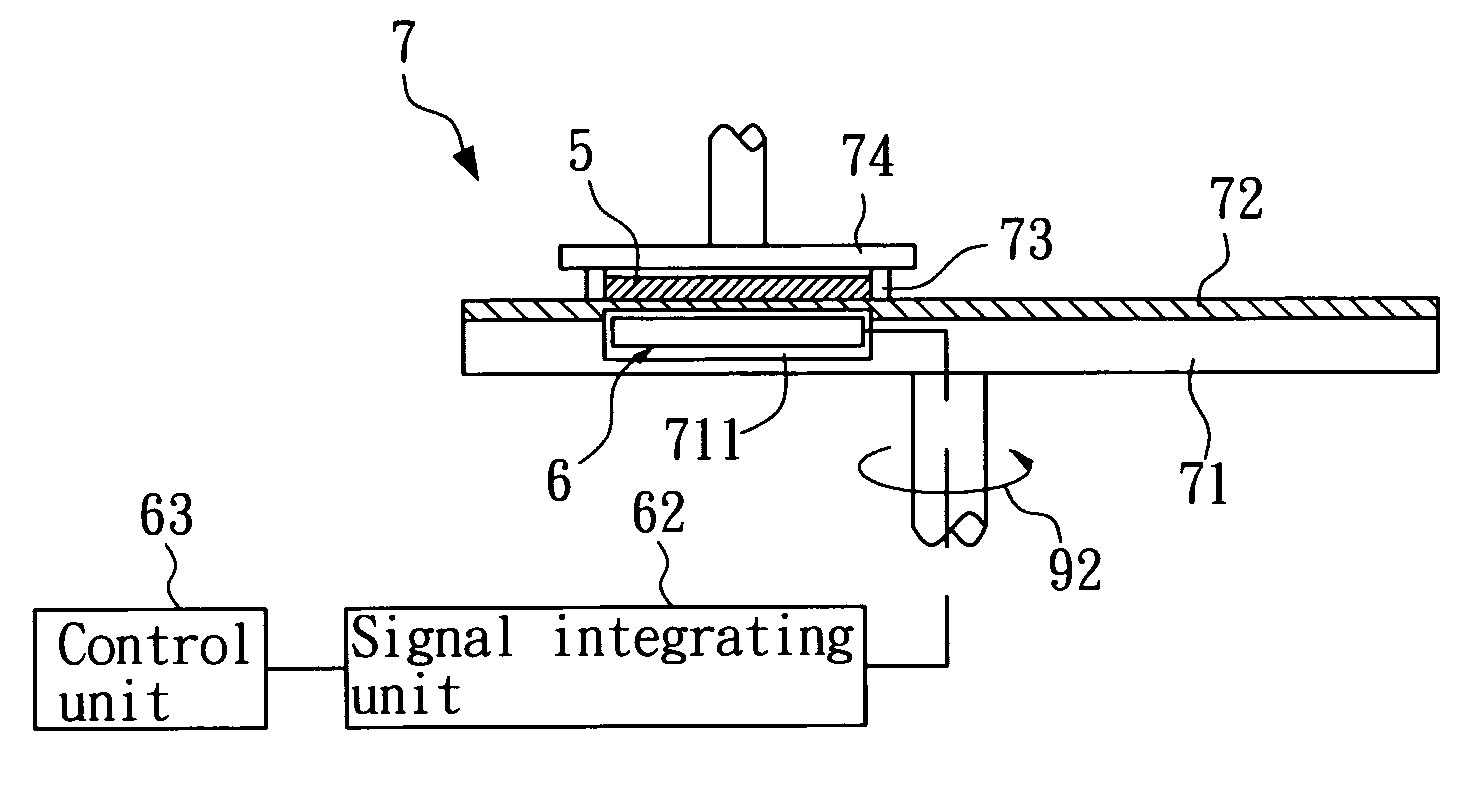

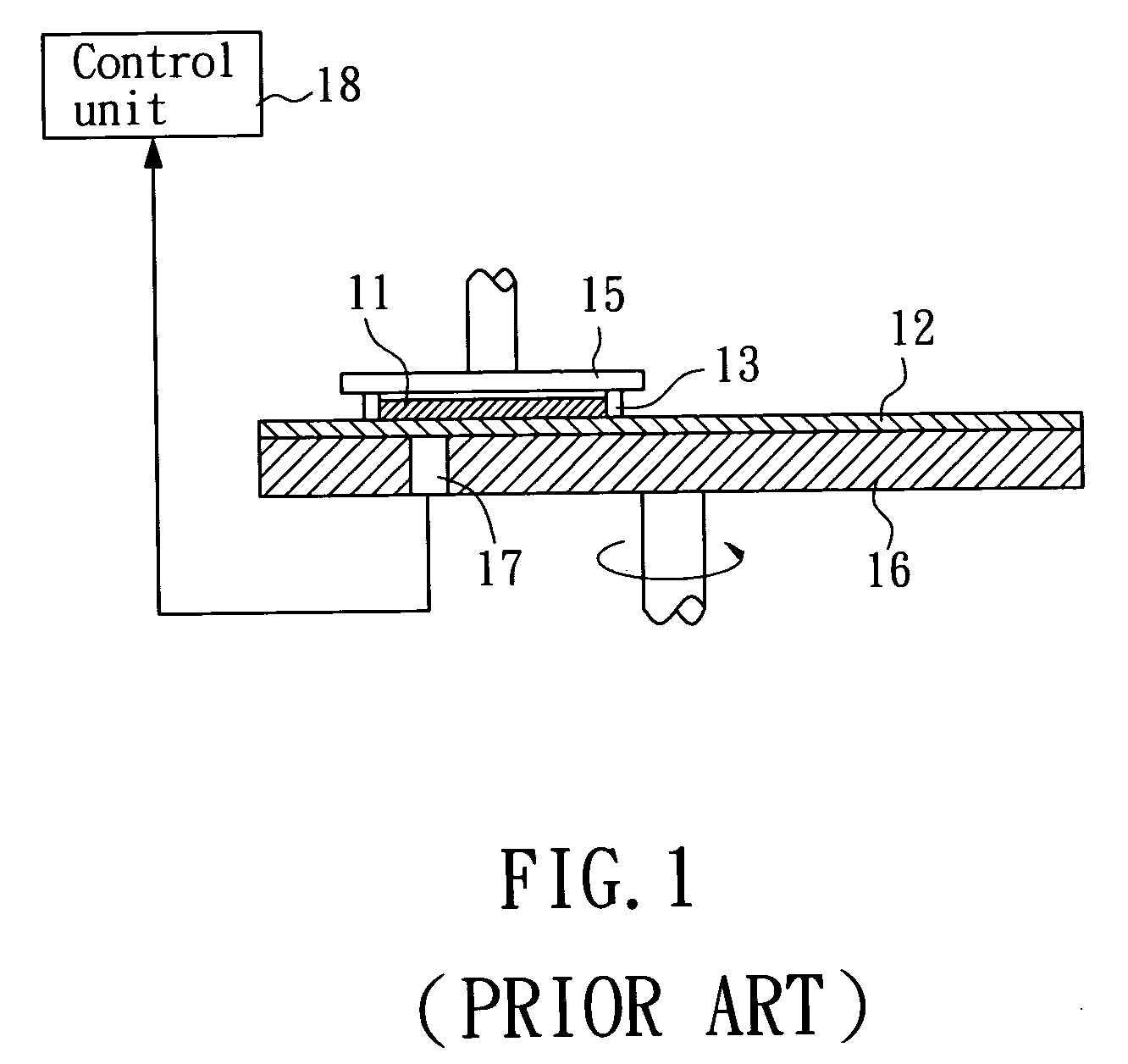

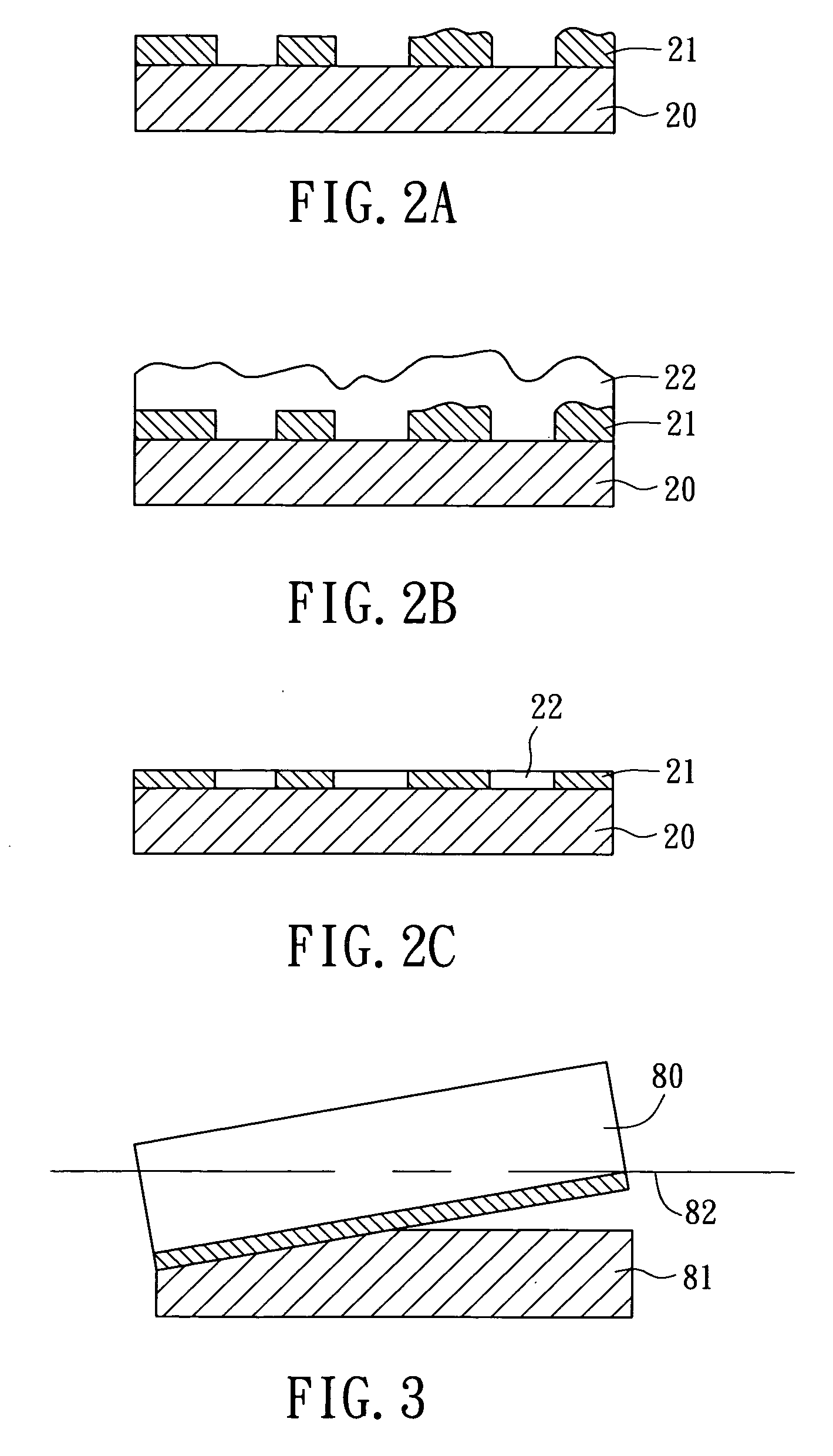

Apparatus for endpoint detection during polishing

InactiveUS20070082582A1Improve detection accuracyLapping machinesGrinding feed controlLinear motionEngineering

An apparatus for endpoint detection during polish, being used to monitor the surface polishing status of a polishing surface of a workpiece, is disclosed, which comprises: a probe, being positioned above the workpiece by a height; and at least a sensing element, being disposed on the probe at a position corresponding to the polishing surface, capable of sensing the thickness variation of the workpiece during a polishing process as it is performing a surface dynamic scan upon the workpiece in rotating while it is being driven to proceed a linear motion of displacement. Preferably, the sensing element can be a device selected from the group consisting of an optical sensor, an eddy current sensor and the combination of the two for carrying out optical detection and magnetic flux detection. It is noted that the apparatus for endpoint detection of the invention not only is advantaged in its all-zone detection ability, but also it has enhanced detection accuracy with respect to different metal layer of different thickness.

Owner:IND TECH RES INST

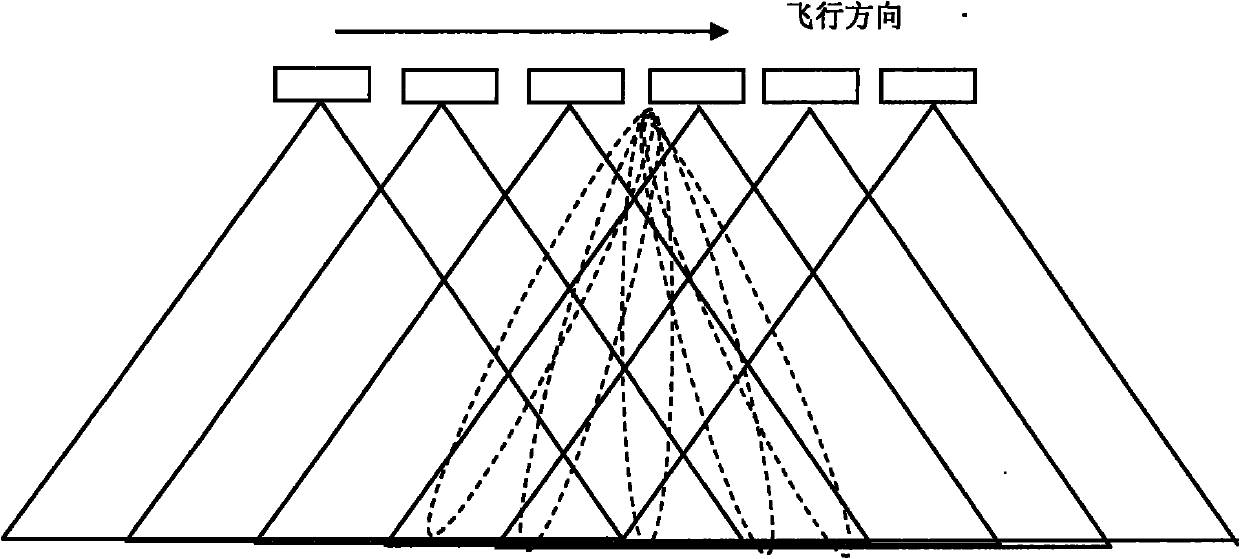

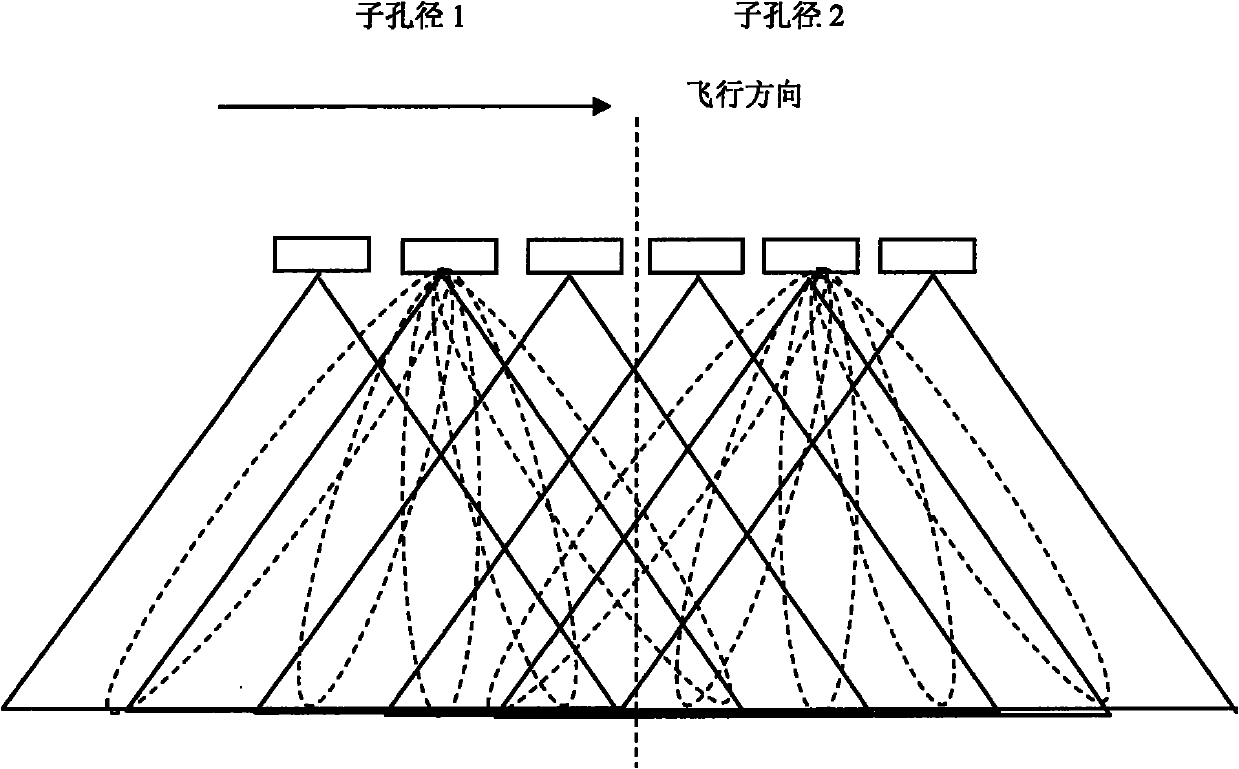

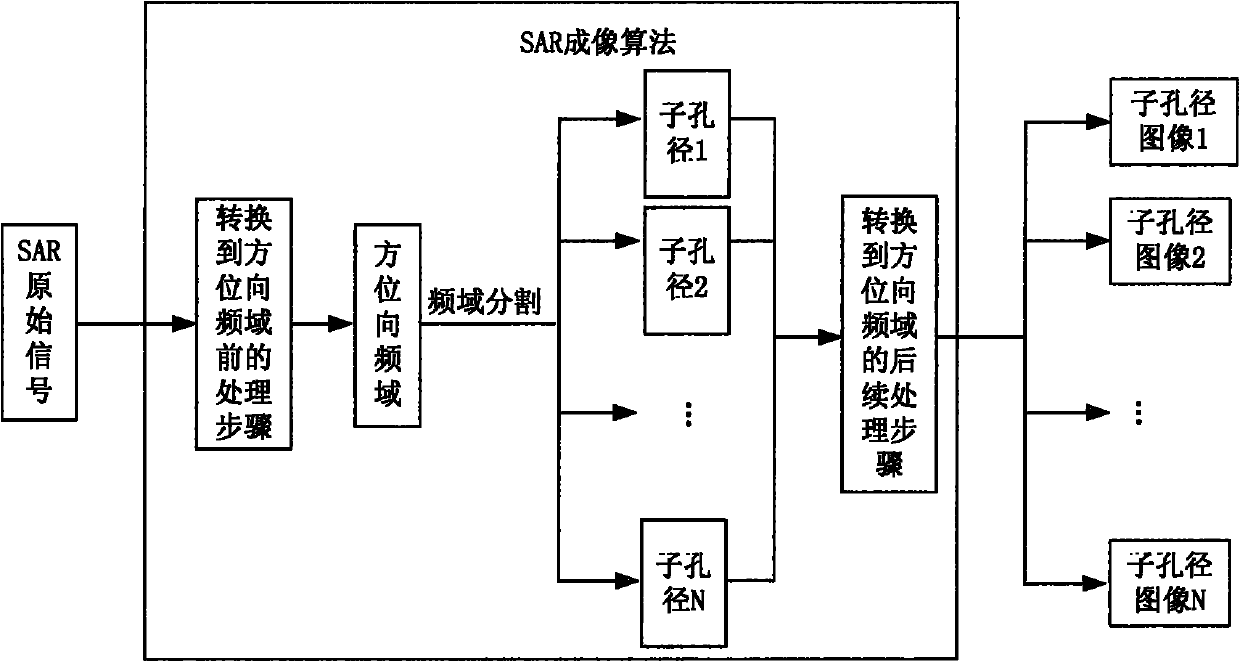

Marine dynamic information extraction method on basis of SAR (Synthetic Aperture Radar) sub-aperture sequence images

InactiveCN102565772AAccurate extractionRadio wave reradiation/reflectionImaging processingSynthetic aperture sonar

The invention discloses a marine dynamic information extraction method on the basis of SAR (Synthetic Aperture Radar) sub-aperture sequence images and relates to a SAR technology. The marine dynamic information extraction method on the basis of the SAR sub-aperture sequence image comprises the following steps of: (A) carrying out sub-aperture imaging processing on SAR echo data to obtain the sub-aperture sequence images; (B) after carrying out characteristic extraction and meshing on each sub-aperture sequence image, carrying out sea surface dynamic information extraction for once on each twoadjacent sub-aperture sequence images to obtain characteristic movement speeds Vx (S, T) and Vy (S, T) of each grid; and (C) averaging results obtained by repeatedly extracting and reducing the errorand the noise to obtain marine dynamic information. The method disclosed by the invention is simple, is easy to operate, has wide application range and can be used for accurately extracting the dynamic information of the sea surface.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

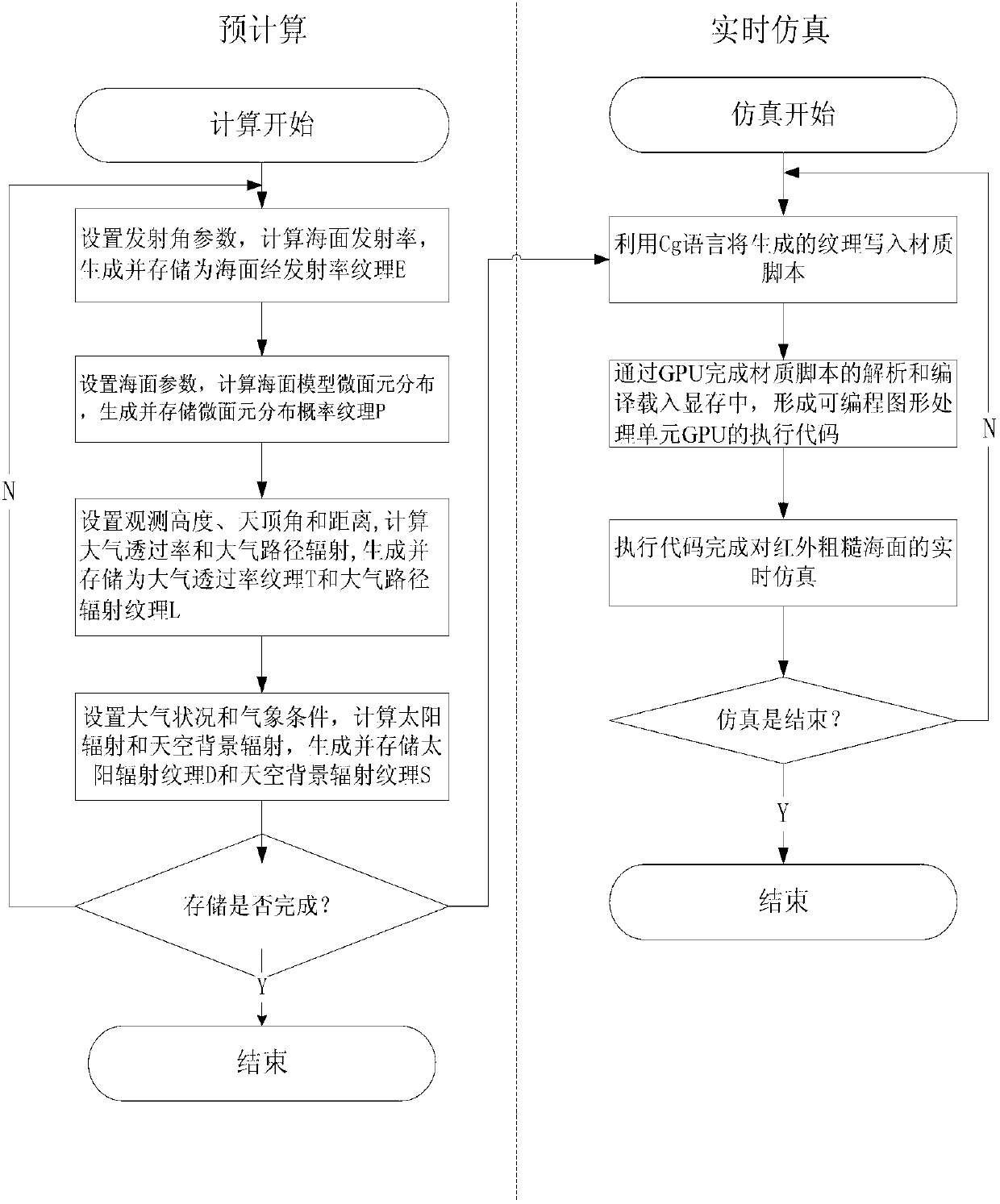

Infrared rough sea surface dynamic simulation method based on texture

InactiveCN103123670AMeet the Reality Requirements for SimulationRun fastSpecial data processing applicationsVideo memoryGraphics processing unit

The invention discloses an infrared rough sea surface dynamic simulation method based on texture, and mainly solves the problems that in the prior art, the truthfulness and the real-time performance of infrared rough sea surface simulation are low. The implementation procedures of the infrared rough sea surface dynamic simulation method based on the texture include that a Torrance-Sparrow illumination model is used for establishing a sea surface infrared radiation brightness formula; atmosphere circulation software, namely Atmosphere, is used for calculating the emissivity of a sea surface, the micro surface element distribution probability, the sun radiation brightness, the sky radiation brightness, the atmospheric path radiation brightness and the atmospheric transmissivity; calculated results are stored as a digital dynamics simulator (DDS) texture map, and the Cg programming language is used for writing the DDS texture map into a material script; and a graphic processing unit (GPU) is used for finishing the parsing and the compiling of the material script, and a video memory is loaded so that execution codes are formed; and the execution codes are used for finishing real-time simulation of the infrared rough sea surface. The infrared rough sea surface dynamic simulation method based on the texture has the advantages of high physical truthfulness and real-time performance and the like, can be applied to full-view simulation of the background of the sea surface, and provides an infrared radiation main background for infrared feature recognition of targets on the sea surface.

Owner:XIDIAN UNIV

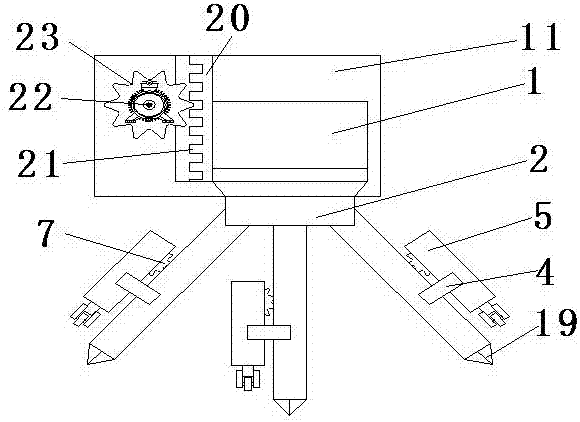

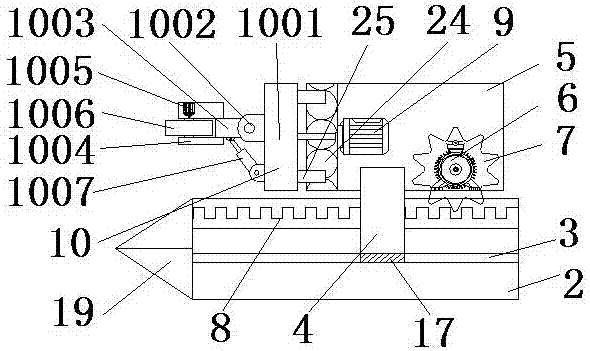

Surveying and mapping method based on municipal engineering

InactiveCN107966139AEasy to adjust the positionEasy to cleanSurveying instrumentsCleaning using toolsMorphologic changeEngineering

The invention discloses a surveying and mapping method based on municipal engineering, which includes the steps of: 1) installation; 2) fine tuning: selecting different positions, and performing observation by moving a leveling instrument, by means of a traveling device, to a predetermined position, and performing fine tuning to the leveling instrument through the observation results at differentpositions to level the leveling instrument; 3) ground surface static surveying and mapping: pre-setting a plurality of different points in a surveying zone, and moving the leveling instrument to the preset points to collect signals of surrounding environment, and mapping figures of measurement results of the leveling instrument at the preset points, and performing overall analysis to the figures with combination of coordinate reference of the preset points, thereby acquiring geometric position information of buildings and ground surface morphologic change in the surveying zone; 4) ground surface dynamic surveying. The invention relates to the technical field of surveying and mapping methods. According to the surveying and mapping method, position of a surveying and mapping device can be adjusted conveniently, and accumulated dust on the leveling instrument can be removed effectively and dust on connection positions can be removed completely, so that the apparatus can slide smoothly.

Owner:RUIAN DONGNAN MUNICIPAL ENG CONSTR CO LTD

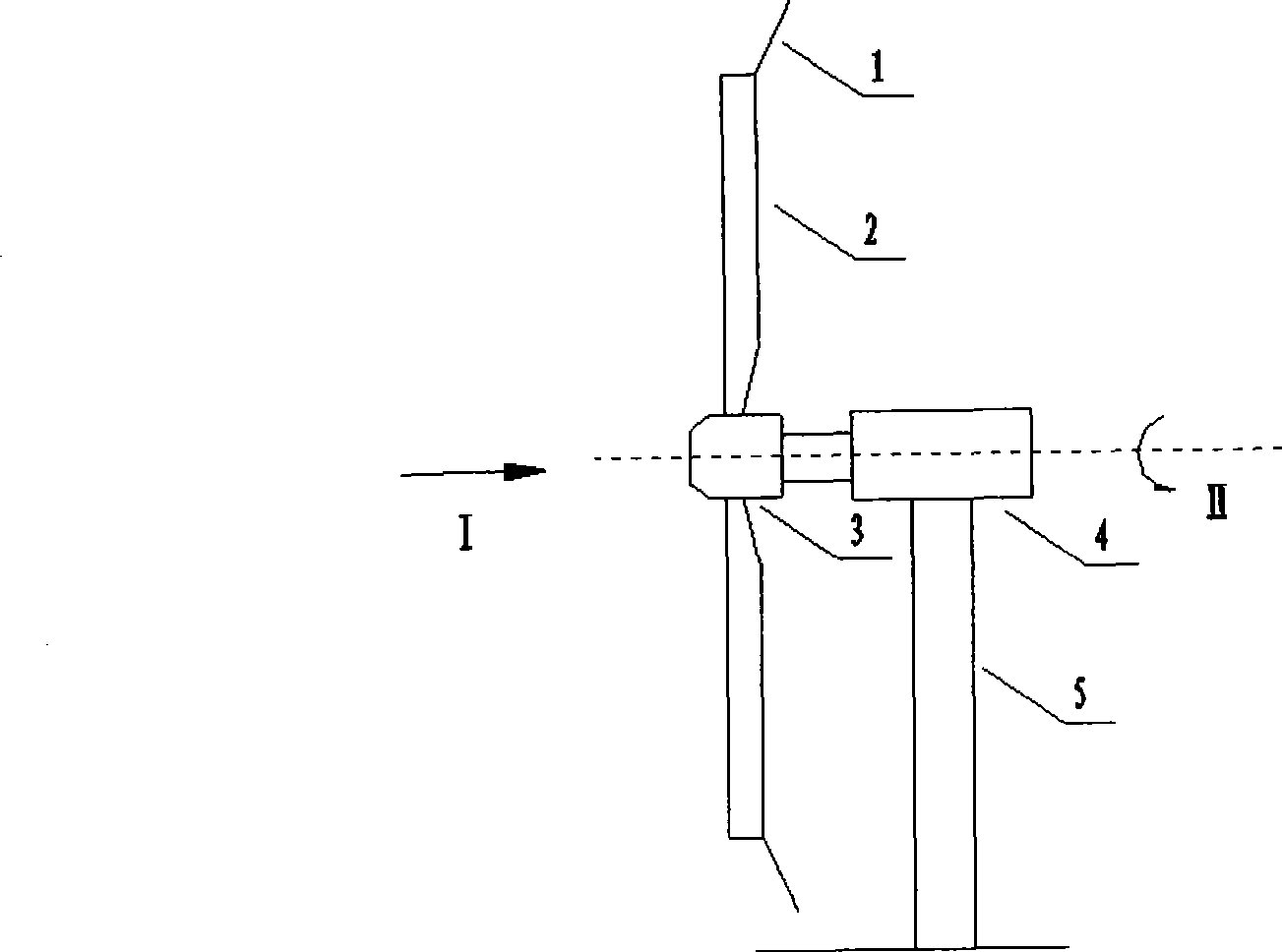

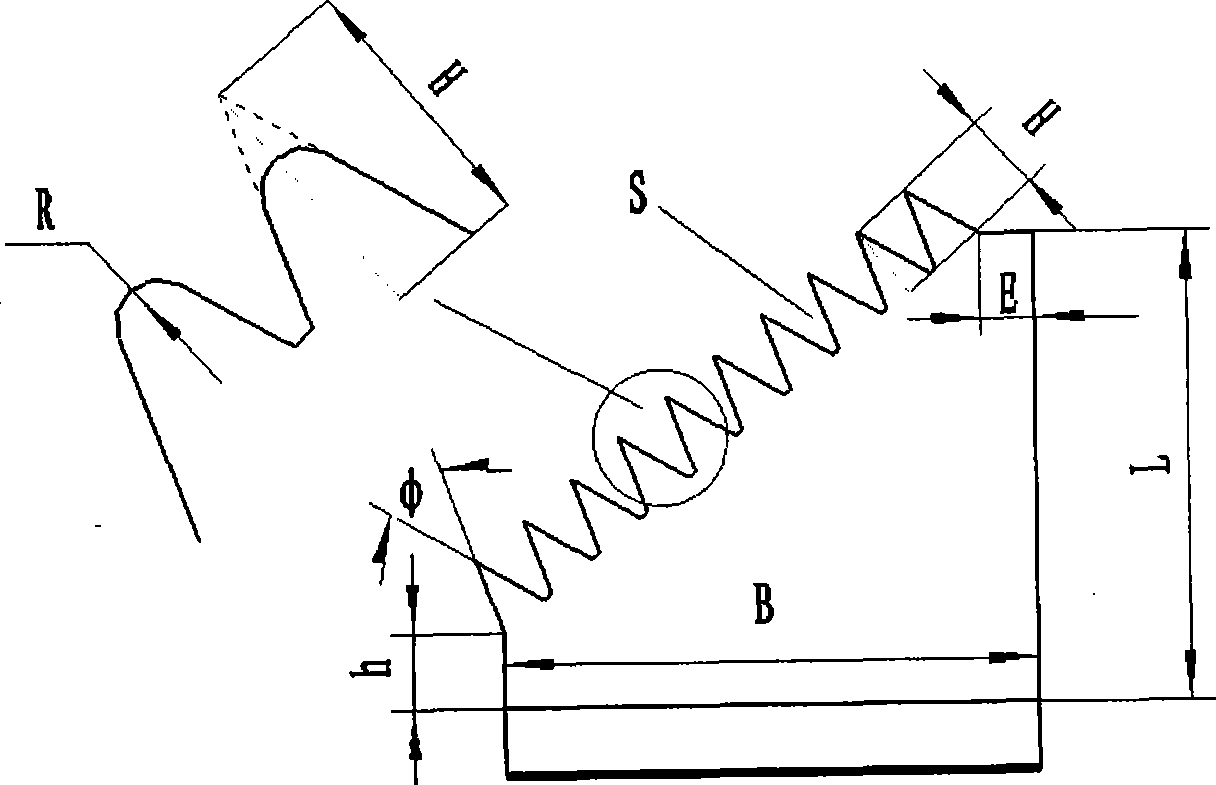

Horizontal axle wind mill with blade tip winglet

InactiveCN101498276AImprove performanceWith automatic stall adjustment functionFinal product manufactureMachines/enginesWinding machineStructural dynamics

The invention relates to a wind power generating device, in particular to a horizontal-shaft wind machine with a blade tip winglet, more particular to a horizontal-shaft wind machine blade tip tooth-shaped winglet device which has an automatic speed-reduction regulatory function, can improve the wind wheel aerodynamic characteristic, the structural dynamic characteristic, the blade surface dynamic load distribution and the blade tip vortex shedding frequency of the wind machine and can reduce the radiation noise of a wind wheel. The horizontal-shaft wind machine blade tip tooth-shaped winglet device comprises a blade (2), a hub (3), an engine room (4) and a tower base (5), wherein the blade tip of the blade of the wind wheel is provided with a winglet (1) which is in a flat plate shape and is also in a similar triangle shape, and the sloping edge (S) of the blade tip winglet (1) is in a comb shape. The invention improves the combination property of the wind machine by simply installing a winglet in a flat plate shape on the blade tip of the wind machine under the premise of no alteration of the structural parameters of an original wind machine; the blade tip winglet adopts a flat plate type structure; and the invention has the advantages of simple structure, short process flow, less working procedure, low manufacturing cost and simple installation.

Owner:INNER MONGOLIA UNIV OF TECH

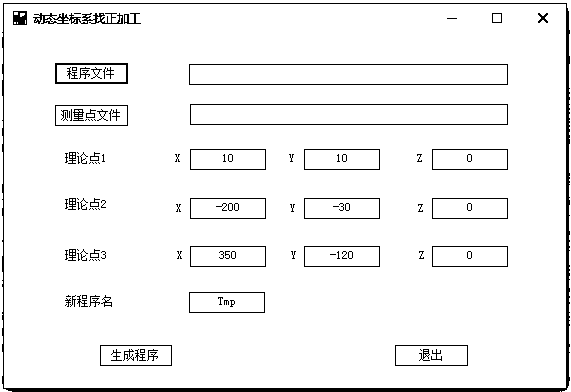

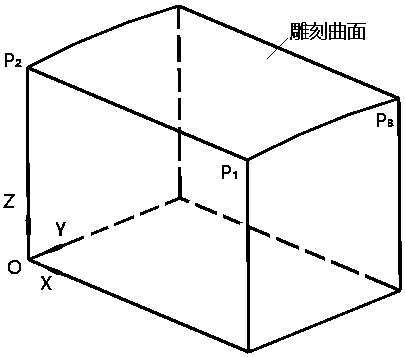

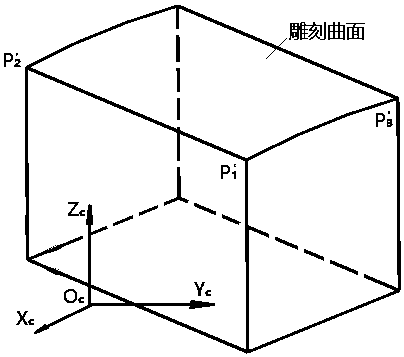

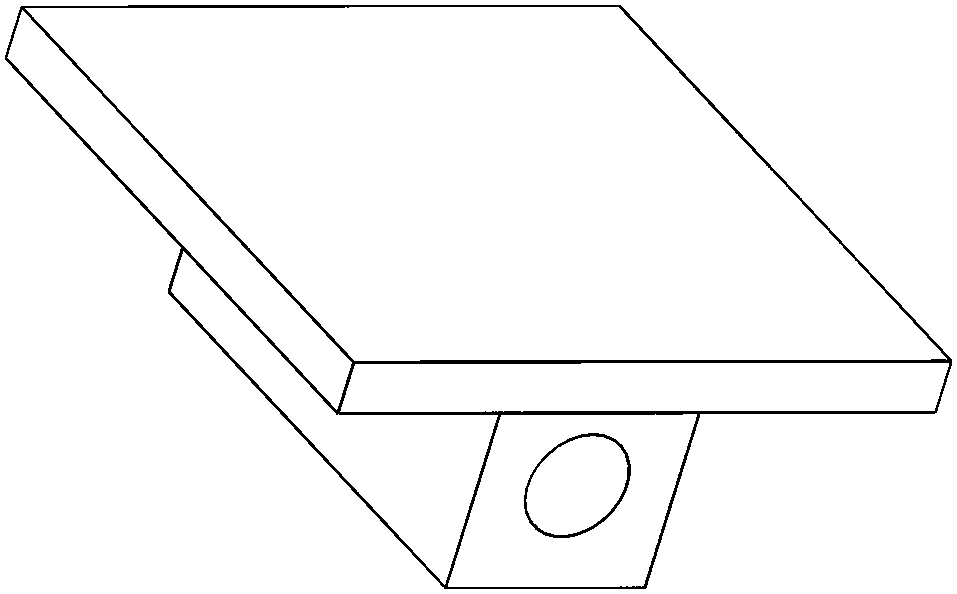

Surface dynamic compensation carving path generation method

The present invention discloses a complex surface numerical control milling carving processing automation intelligent compensation programming method in machine manufacturing. The method comprises thesteps of: 1) construction and initialization of a measurement compensation processing initial programming system; 2) establishment of a dynamic programming coordinate system; 3) surface measurement,and construction of a real carving surface; 4) according to the dynamic programming coordinate system, transformation of coordinates of a theoretical surface carving program, and calculation of coordinates of processing tool track element points; and 5) program transformation, and obtaining of an actually processing NC program. According to the numerical control milling carving processing automation intelligent compensation programming, a measurement head dynamically measures and constructs the processing coordinate system and performs program compensation transformation for the shape and thelocation condition of each part to rapidly perform compensation carving processing so as to improve the surface carving processing precision and programming efficiency of the numerical control program.

Owner:SHENYANG INST OF ENG

Material surface dynamic ice formation adhesion determination method and device thereof

InactiveCN108181233AGood for measuring dynamic icing adhesion strengthOptimizationUsing mechanical meansMaterial analysisMeasurement deviceDisplay device

Owner:SICHUAN UNIV +1

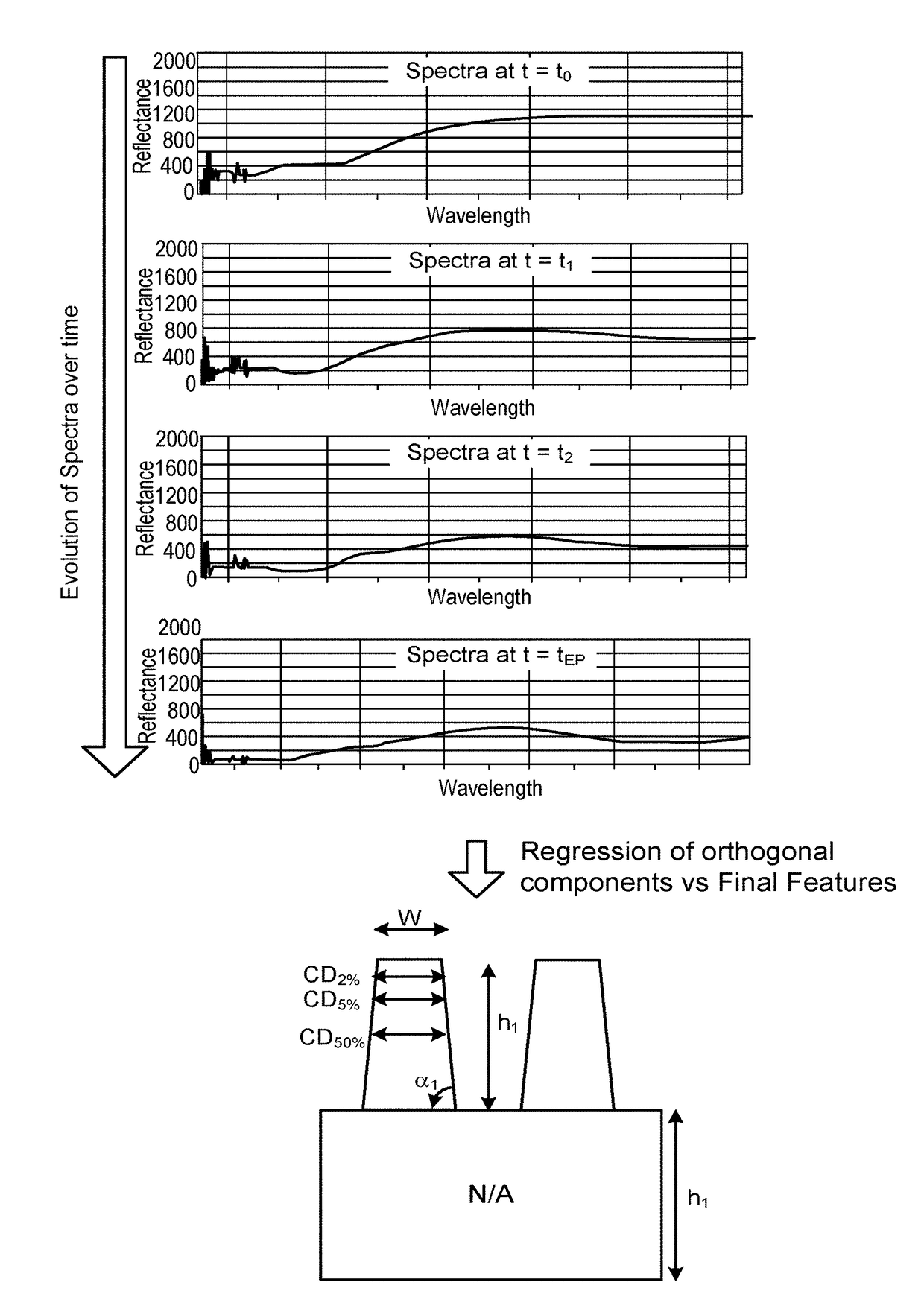

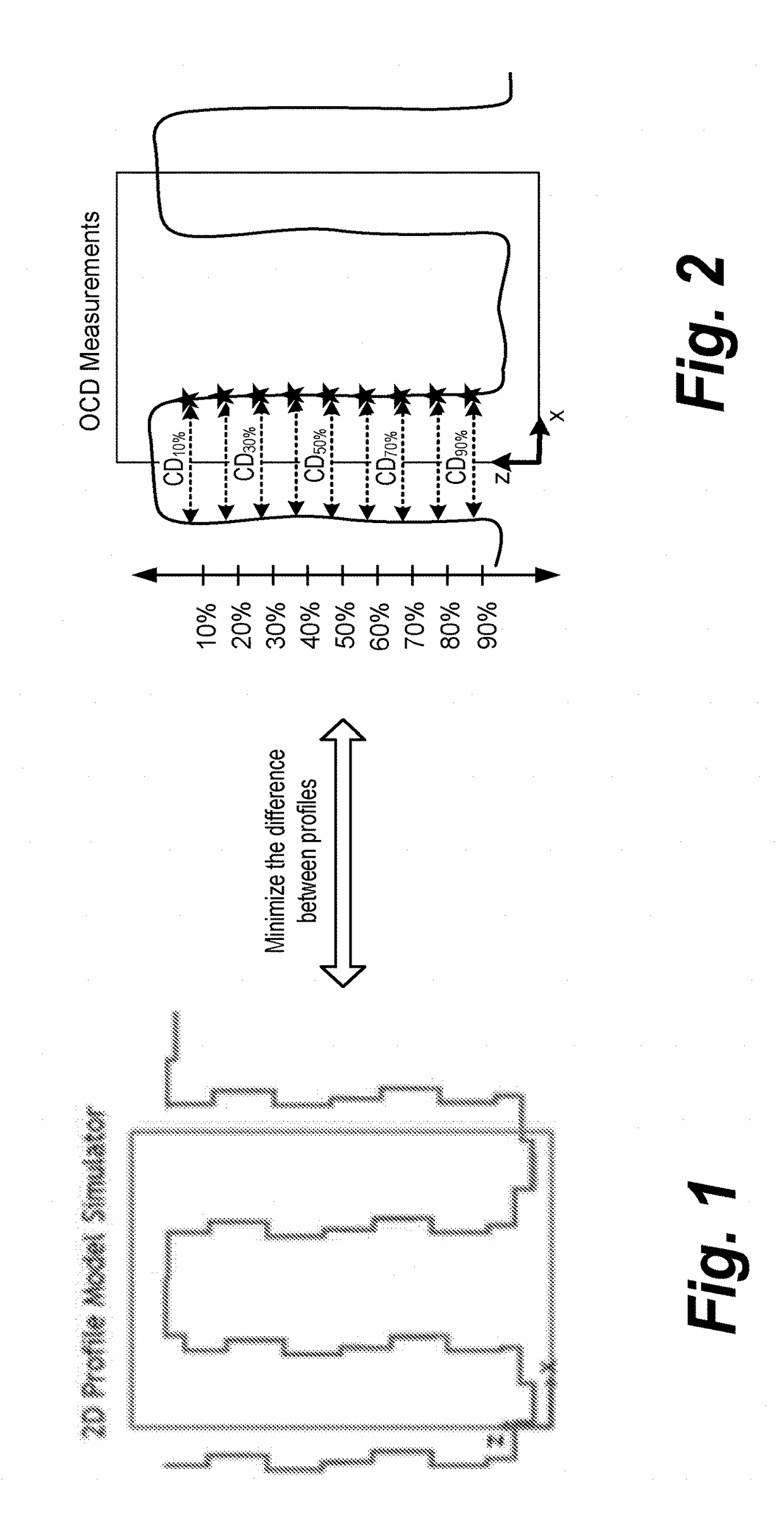

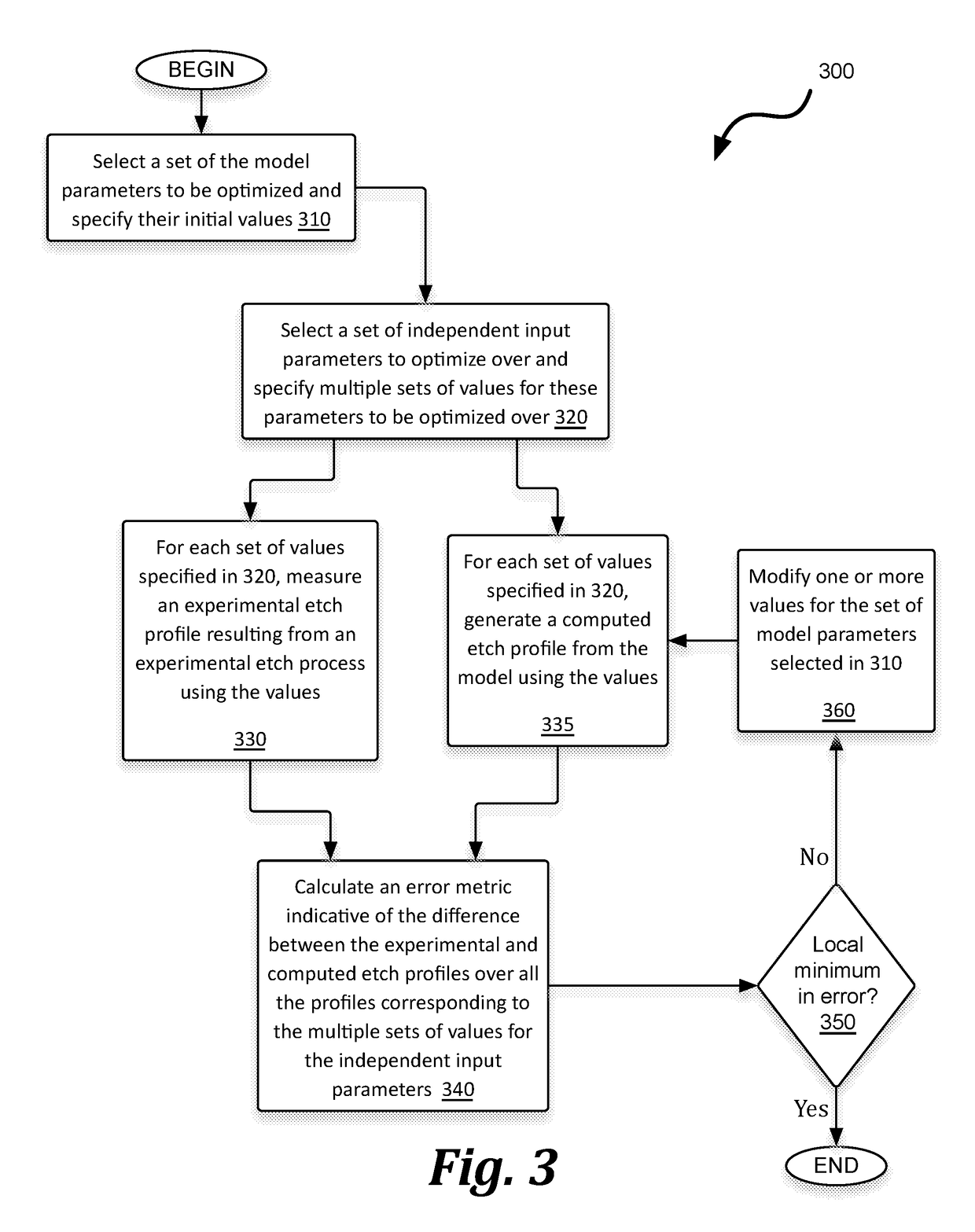

Methods and apparatuses for etch profile optimization by reflectance spectra matching and surface kinetic model optimization

ActiveUS20180260509A1Photomechanical apparatusScattering properties measurementsReflectance spectroscopyModel parameters

Disclosed are methods of optimizing a computer model which relates the etch profile of a feature on a semiconductor substrate to a set of independent input parameters (A), via the use of a plurality of model parameters (B). In some embodiments, the methods may include modifying one or more values of B so as to reduce a metric indicative of the differences between computed reflectance spectra generated from the model and corresponding experimental reflectance spectra with respect to one or more sets of values of A. In some embodiments, calculating the metric may include an operation of projecting the computed and corresponding experimental reflectance spectra onto a reduced-dimensional subspace and calculating the difference between the reflectance spectra as projected onto the subspace. Also disclosed are etch systems implementing such optimized computer models.

Owner:LAM RES CORP

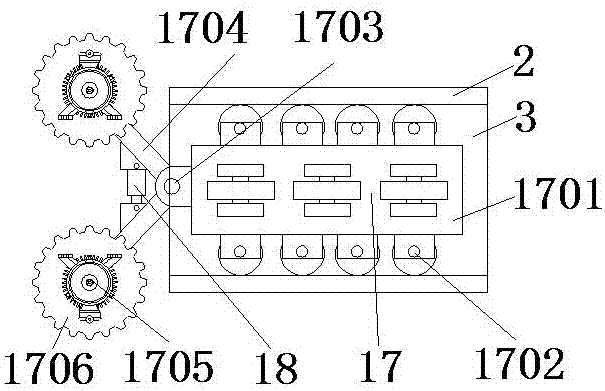

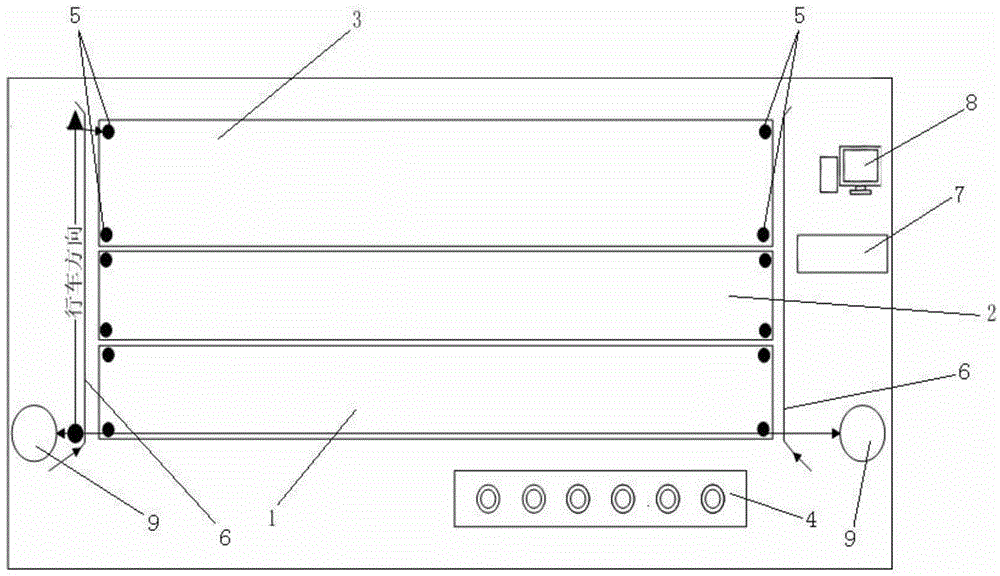

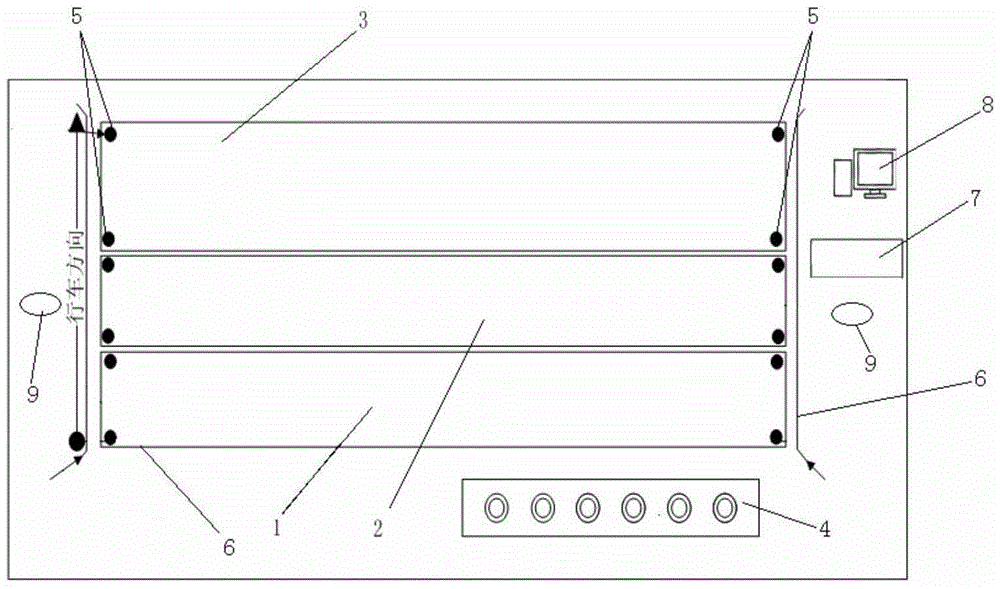

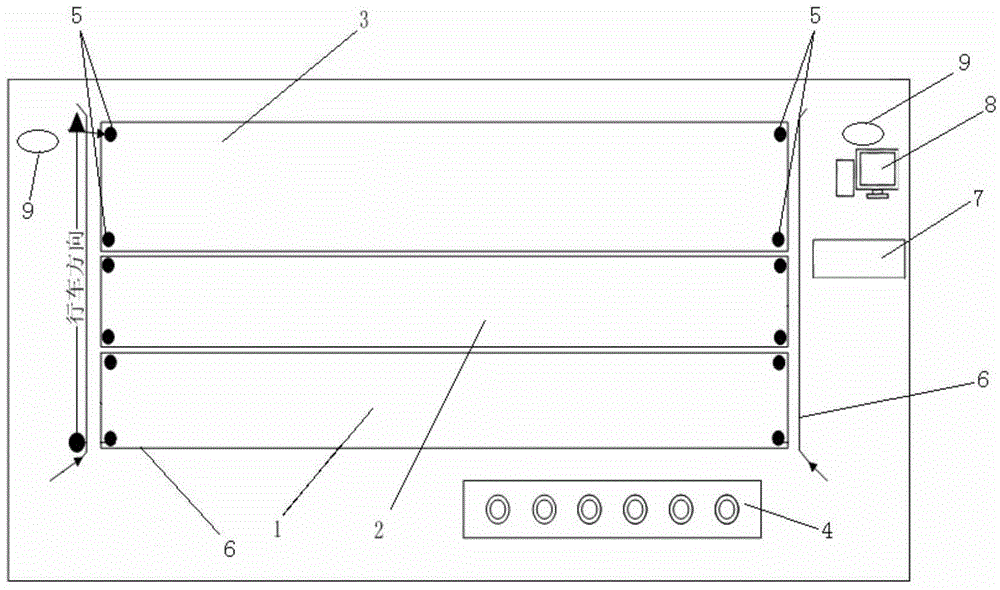

Novel multi-platform-surface dynamic weighing system

InactiveCN104359540AGuaranteed measurementIncrease widthSpecial purpose weighing apparatusMulti platformHigh velocity

The invention discloses a novel multi-platform-surface dynamic weighing system. The novel multi-platform-surface dynamic weighing system comprises a vehicle separator, a tire identifier, a scale body, signal acquisition equipment, signal processing equipment, a first scale platform, a second scale platform and a third scale platform, wherein the first scale platform, the second scale platform and the third scale platform are sequentially arranged abreast along the driving direction; the vehicle separator is used for separating vehicles; the tire identifier is arranged in front of the first scale platform or behind the third scale platform, and the vehicles pass through the tire identifier and the vehicle separator. Due to the adoption of the structure in which the three scale platforms are arranged abreast, the length of the three-scale-platform weighing system is increased compared with a single-scale-platform weighing system and a double-scale-platform weighing system, the staying time of the vehicles on the scale platforms is prolonged, and the influence on weighing errors caused by non-standard vehicle passing behaviors such as S-type passing of the vehicles, jumping of the vehicles over the scale platforms and high-speed passing of the vehicles through the scale platforms can be eliminated.

Owner:重庆市华驰交通科技有限公司

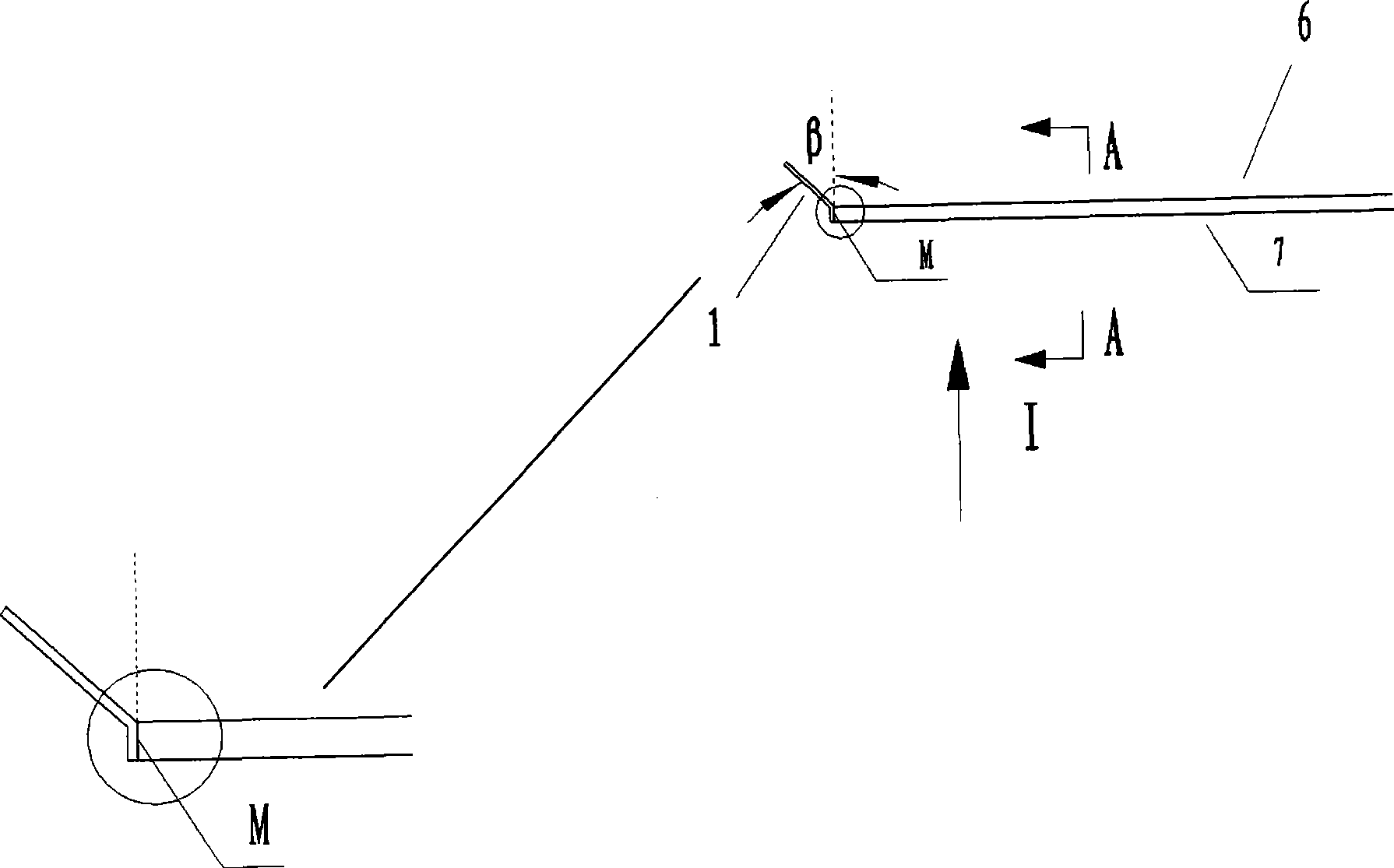

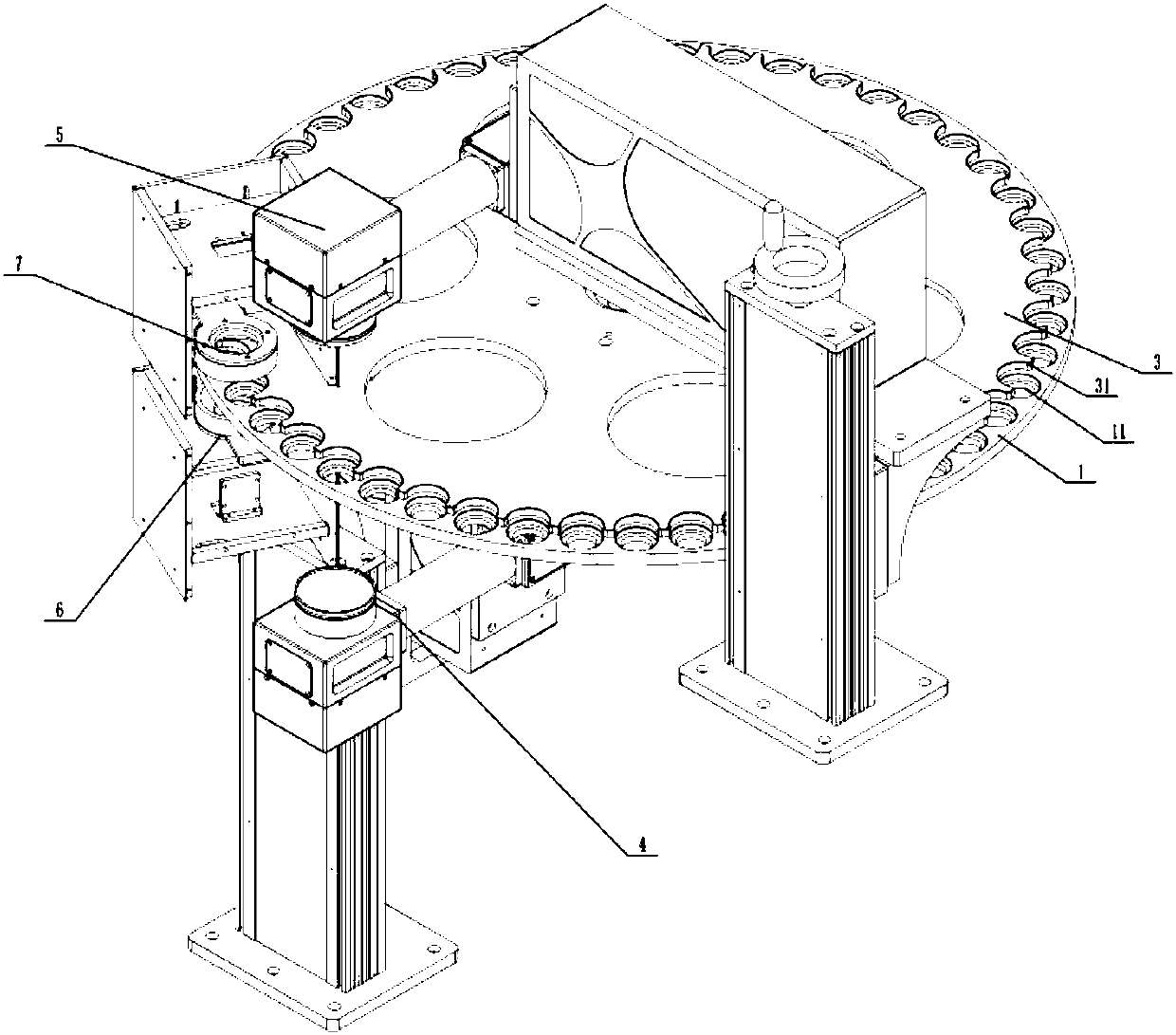

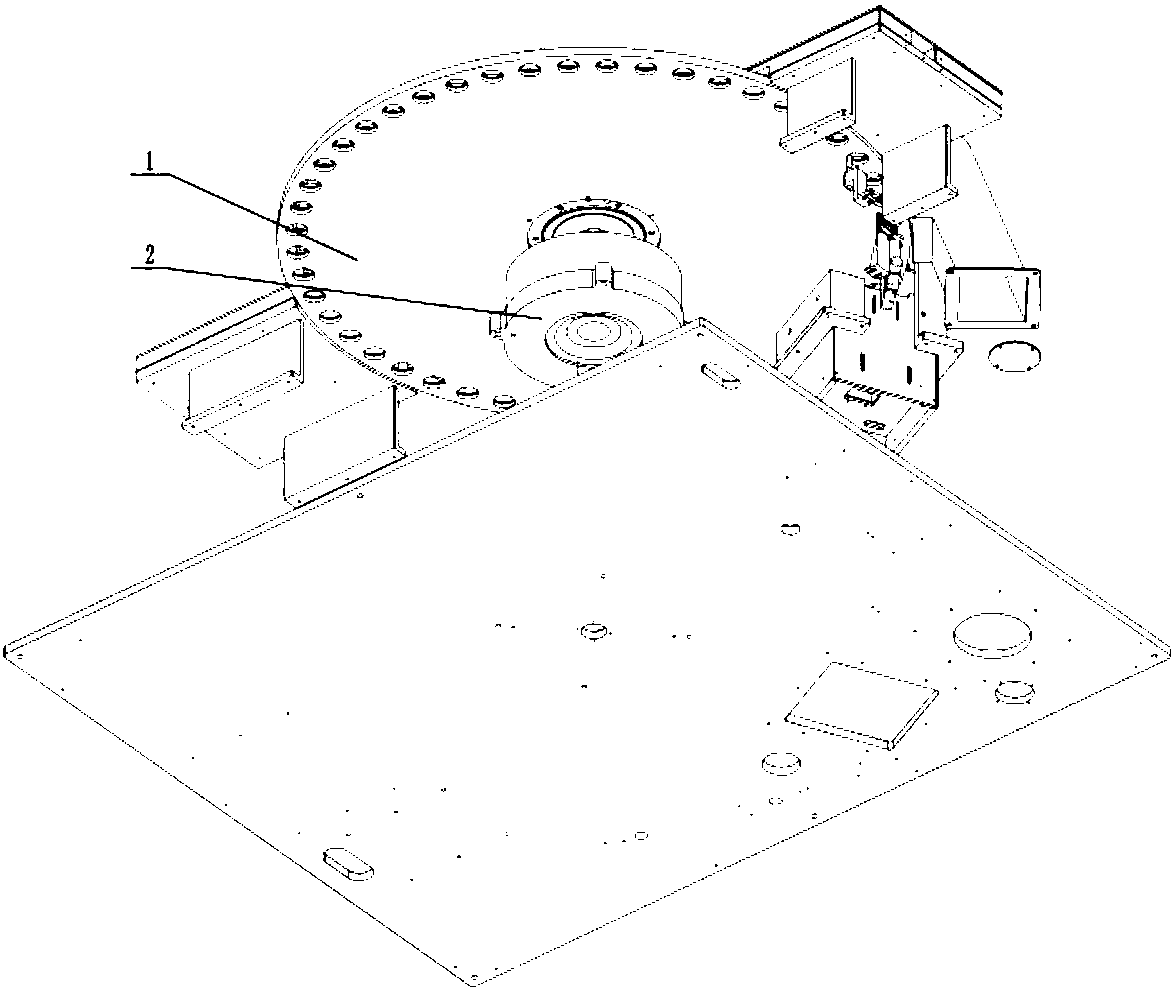

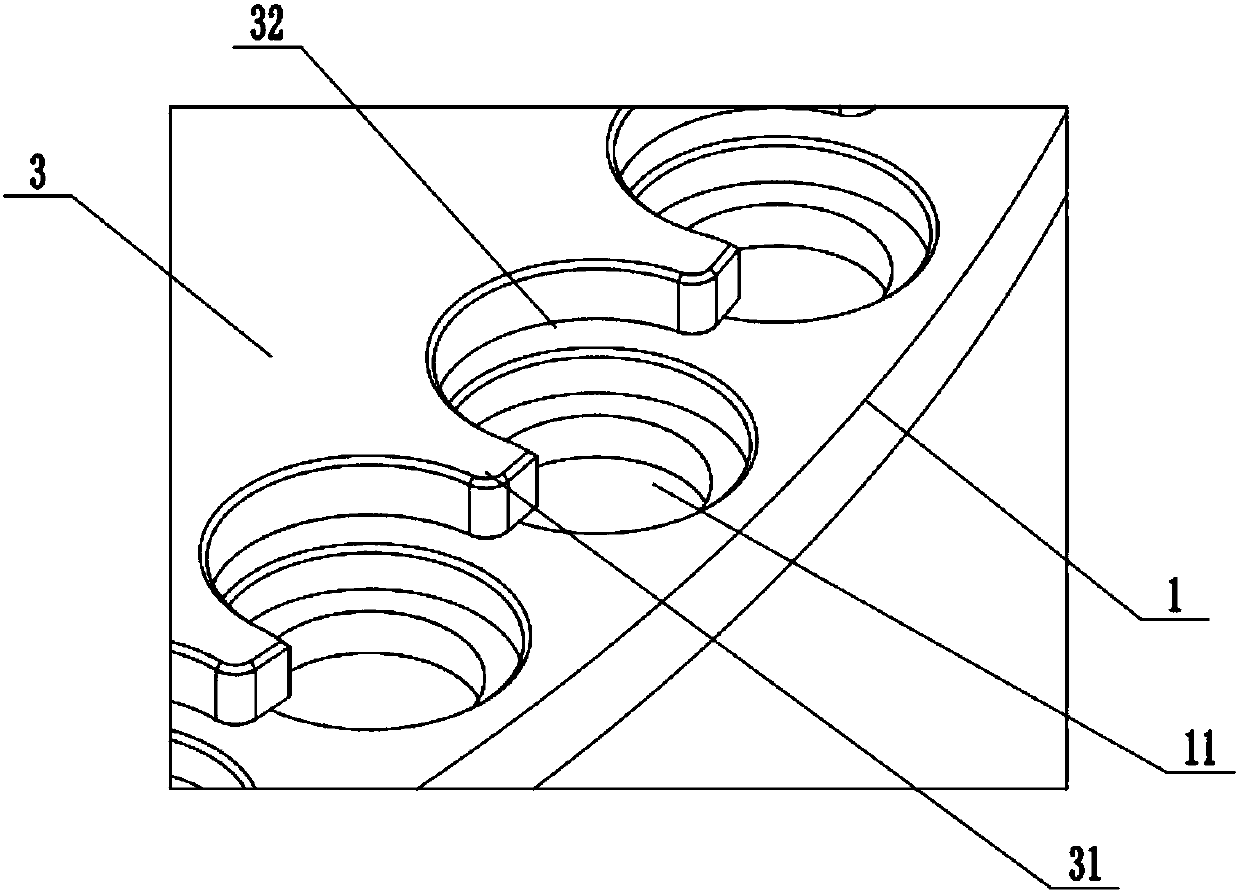

Laser marking device and marking method

ActiveCN107755886AGuaranteed literacy rateGuaranteed laser coding efficiencyAblative recordingMetal working apparatusEngineeringBottle cap

The invention discloses a laser marking device. The laser marking device comprises a circular rotary disc, a driving assembly, an outer code laser marking machine and an inner code laser marking machine, wherein a plurality of locating holes used for fixing products are formed in the circular rotary disc in the radial direction; the driving assembly is used for driving the circular rotary disc torotate at a constant speed; the outer code laser marking machine is arranged below the circular rotary disc, and is used for tagging the outer surfaces of the products to form outer codes; the inner code laser marking machine is arranged above the circular rotary disc, and is used for tagging the inner surfaces of the products to form inner codes; and the outer codes and the inner codes are formedat the same time. According to the laser marking device, dynamic tagging is achieved through a rotating workbench, stability of the bottle cap products during double-surface dynamic tagging can be guaranteed, time for waiting the products to be transported in place can be shorted, and production efficiency can be guaranteed to the greatest extent.

Owner:HANS LASER TECH IND GRP CO LTD

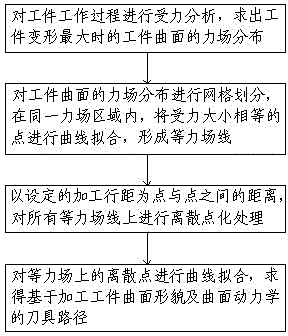

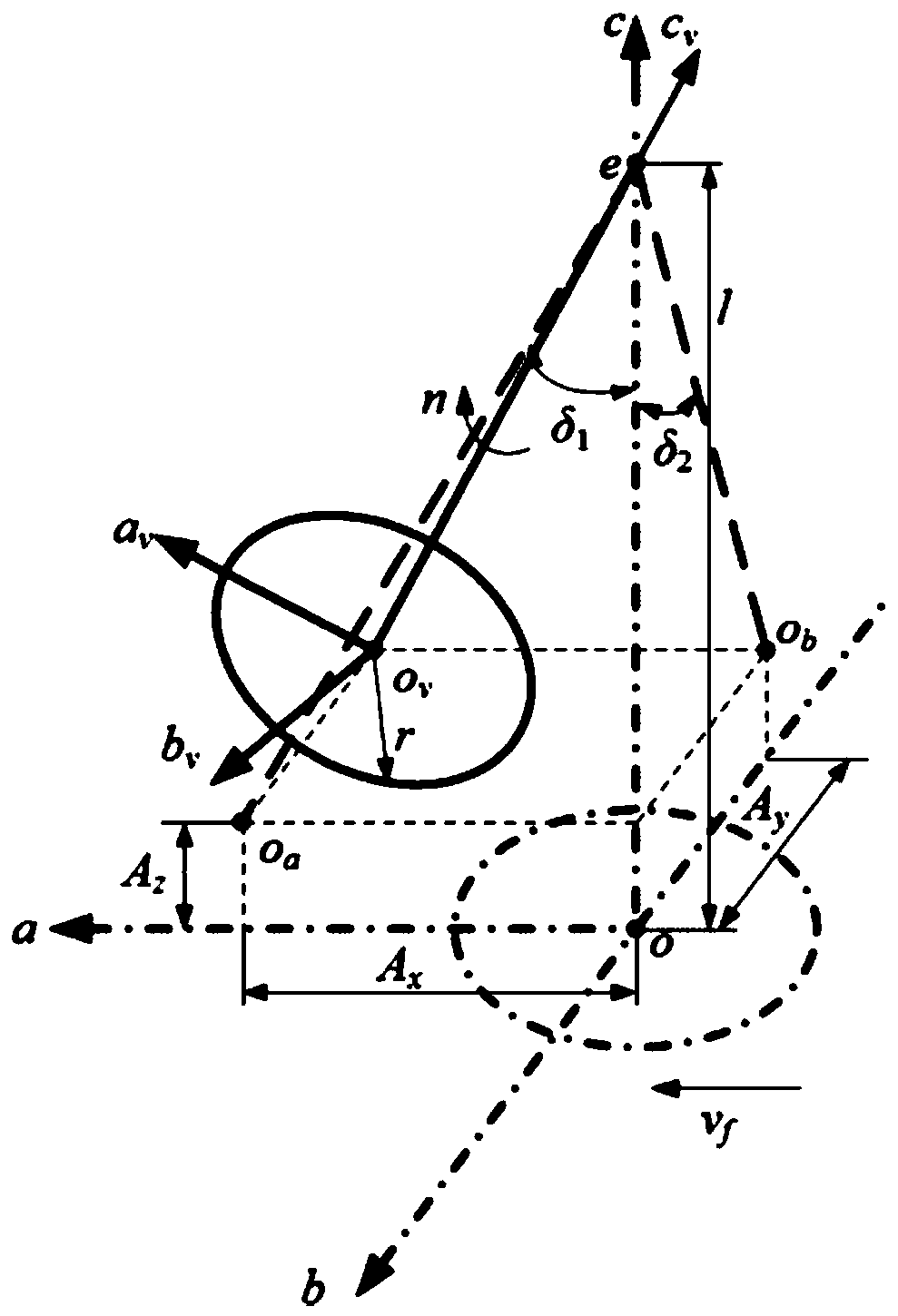

Tool path forming method based on curved surface morphology and curved surface dynamics of machined workpiece

InactiveCN103558807AAvoid crack phenomenonExtended service lifeProgramme controlComputer controlCurve fittingForce analysis

The invention provides a tool path forming method based on curved surface morphology and curved surface dynamics of a machined workpiece. The method includes the first step of carrying out force analysis on the working process of the workpiece to figure out the force field distribution of the curved surface of the workpiece when deformation of the workpiece is maximum, the second step of carrying out grid division on the force field distribution of the curved surface of the workpiece and carrying out curve fitting on points with the same applied force in the same force field region to form an equal force field line, the third step of carrying out discrete pointillized processing on all the equal force field lines with a set machining line spacing as the distance between the points, and the fourth step of carrying out curve fitting on discrete points in equal force fields to obtain a tool path based on the curved surface morphology and the curved surface dynamics of the machined workpiece. Through the method, the tool path is determined according to force analysis conditions so as to enable the direction of the tool path to be parallel to the forced direction of the curved surface, and consequently the phenomenon that the curved surface of the workpiece cracks due to tooling is prevented to the maximum extent. Furthermore, the damage of plunge milling tool marks to the textiles of the curved surface of the workpiece is prevented, and the service life of the workpiece is prolonged.

Owner:UNIV OF JINAN

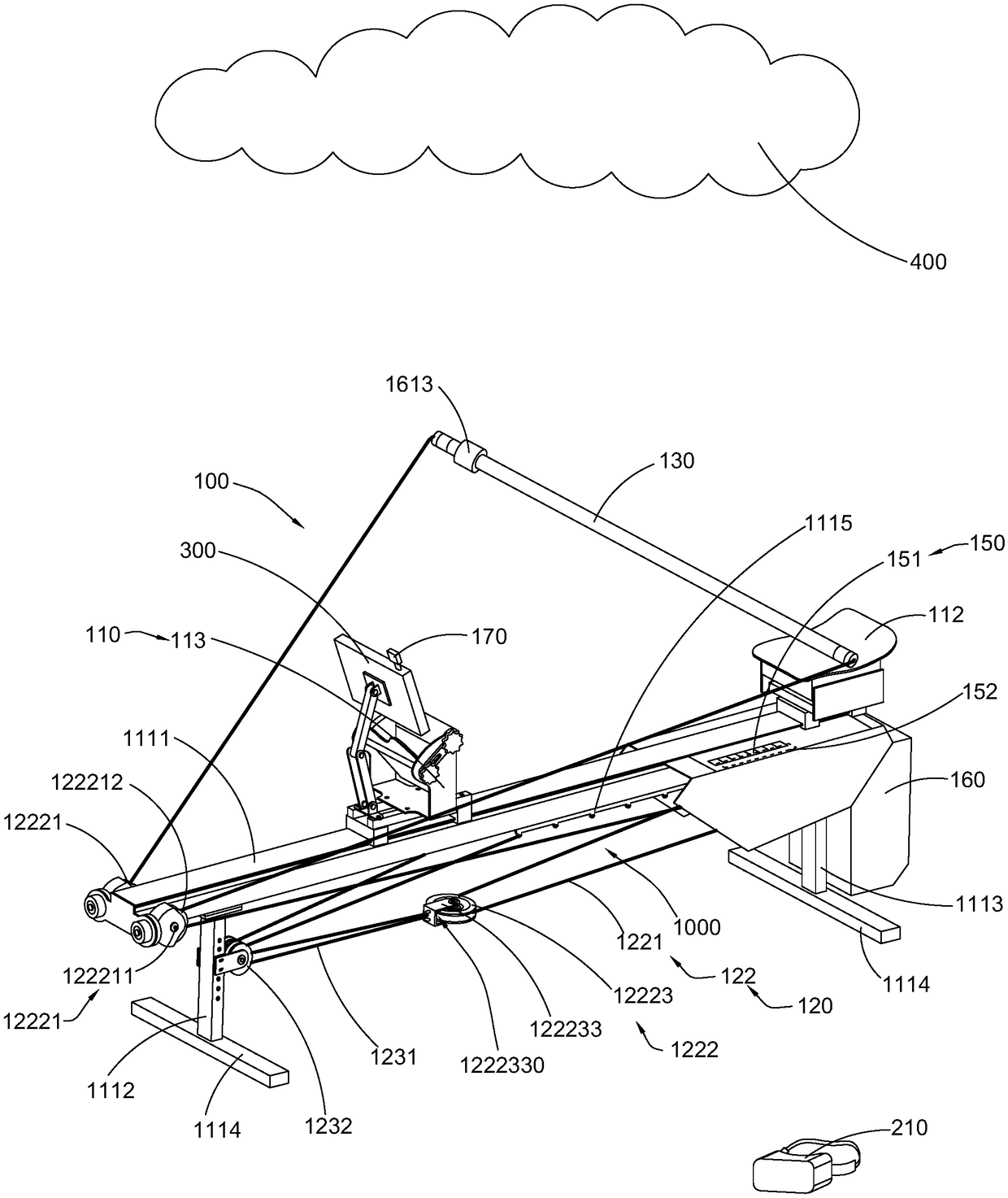

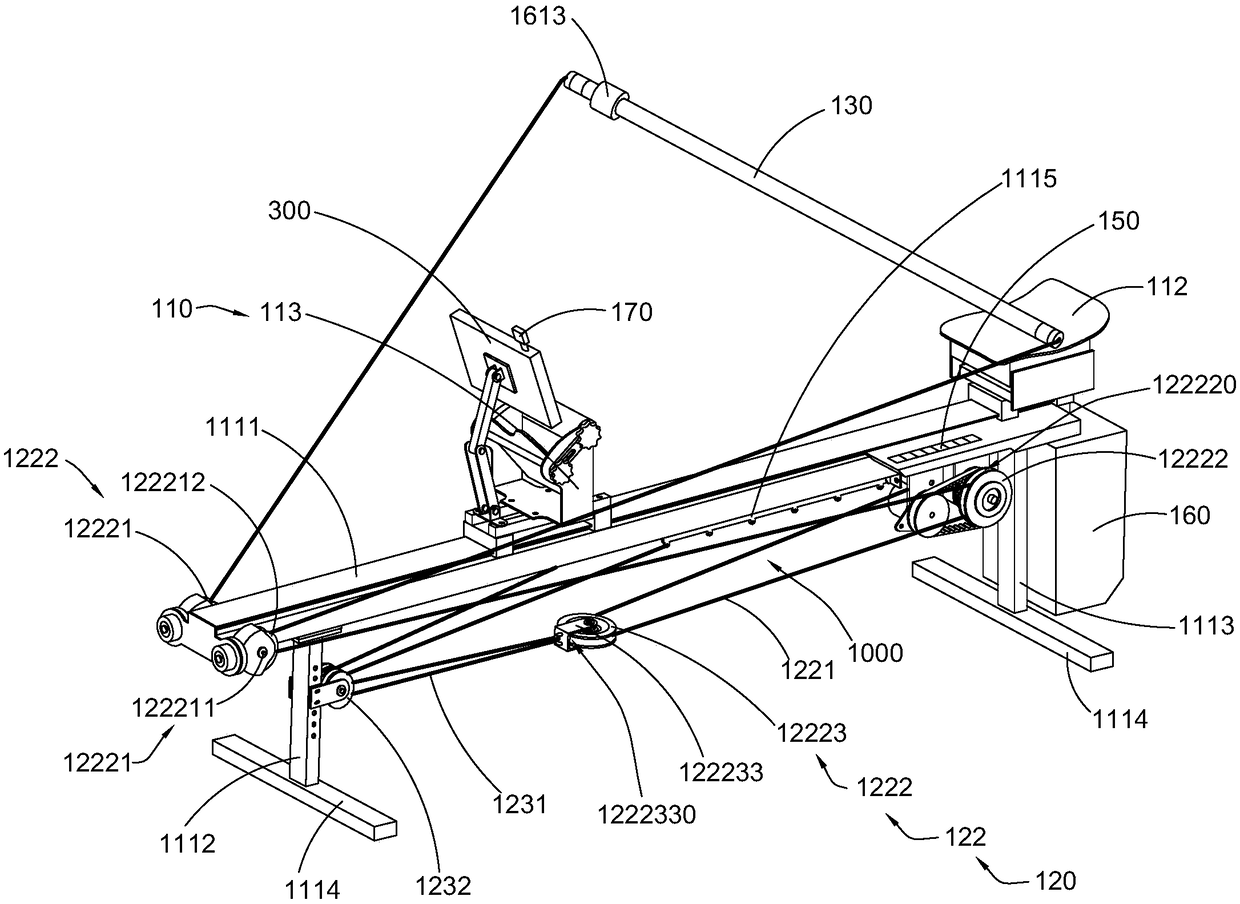

Virtual water sport land-based training system and training method thereof

Disclosed is a virtual water sport land-based training system. The system comprises a cloud end device, water sport land-based equipment, display equipment and a pair of virtual glasses. The water sport land-based equipment is wirelessly connected with the cloud end device; the display equipment is connected with the water sport land-based equipment; the virtual glasses are wirelessly connected with the display equipment, so that various kinds of water surface dynamic environments are displayed through the virtue glasses and the display equipment, meanwhile water sport operation is performed through the water sport land-based equipment to perform actual operation training under various kinds of simulated scenarios, various kinds of data are transmitted to the cloud end device, and networkon-line competitions can be performed through the cloud end device.

Owner:桐乡创智体育科技有限公司

Construction method of dynamic spatial space index for supporting STL data source

InactiveCN104866687AImprove removal efficiencyGuarantee opennessSpecial data processing applicationsEdge structureNear neighbor

The invention provides a construction method of a gridding curved surface dynamic spatial index for supporting a STL data source, and belongs to the field of digital design and manufacturing. The method is characterized by comprising the following steps: constructing a KD tree index of a gridding curved surface vertex for a digital model in a STL file format, gradually eliminating vertex redundant data in the gridding curved surface in the construction process; fast querying vertex information in the STL data source through the nearest neighbor query algorithm of a KD tree, and improving vertex data duplicate elimination efficiency; integrating into a half-edge data structure based on the openness of KD tree leaf node layer data storage; connecting an adjacent triangular patch through the half-edge ring order and dual half-edge information in the half-edge structure to realize the fast reconstruction of a complete curved surface topological structure. Through the adoption of the integrated dynamic index of the KD tree and the half-edge structure, the removing time and the topological reconstruction time of the redundant vertex are greatly reduced, and the fast query of the gridding curved surface topological neighborhood information is effectively supported.

Owner:SHANDONG UNIV OF TECH

Framed sleeper unit

A framed sleeper unit comprises two longitudinal sleepers and a plurality of horizontal sleepers. The horizontal sleepers are arranged between the longitudinal sleepers to form the frame sleeper unit. Two ends of each longitudinal sleeper are provided with joint structures to link two adjacent framed sleeper units. The frame sleeper units are laid on a granular-mixture ballast bed or a concrete ballast bed along a railway track direction, and rails are placed on a rail bed and connected with the sleepers through a fastening system. The framed sleeper unit has the advantages that under wheel load action, crushing never occurs to the rail seat; contact areas of the sleepers and the ballast bed are expanded, pressure applied to the top face of the ballast bed is reduced, and stability of the rail structure is improved; influence of wheel rail impact load to the ballast bed is reduced; rail support uniformity is enhanced, and rail surface dynamic harshness is maintained; maintenance of the ballast track of a high-speed railway is facilitated, and maintenance cost is lowered.

Owner:TONGJI UNIV

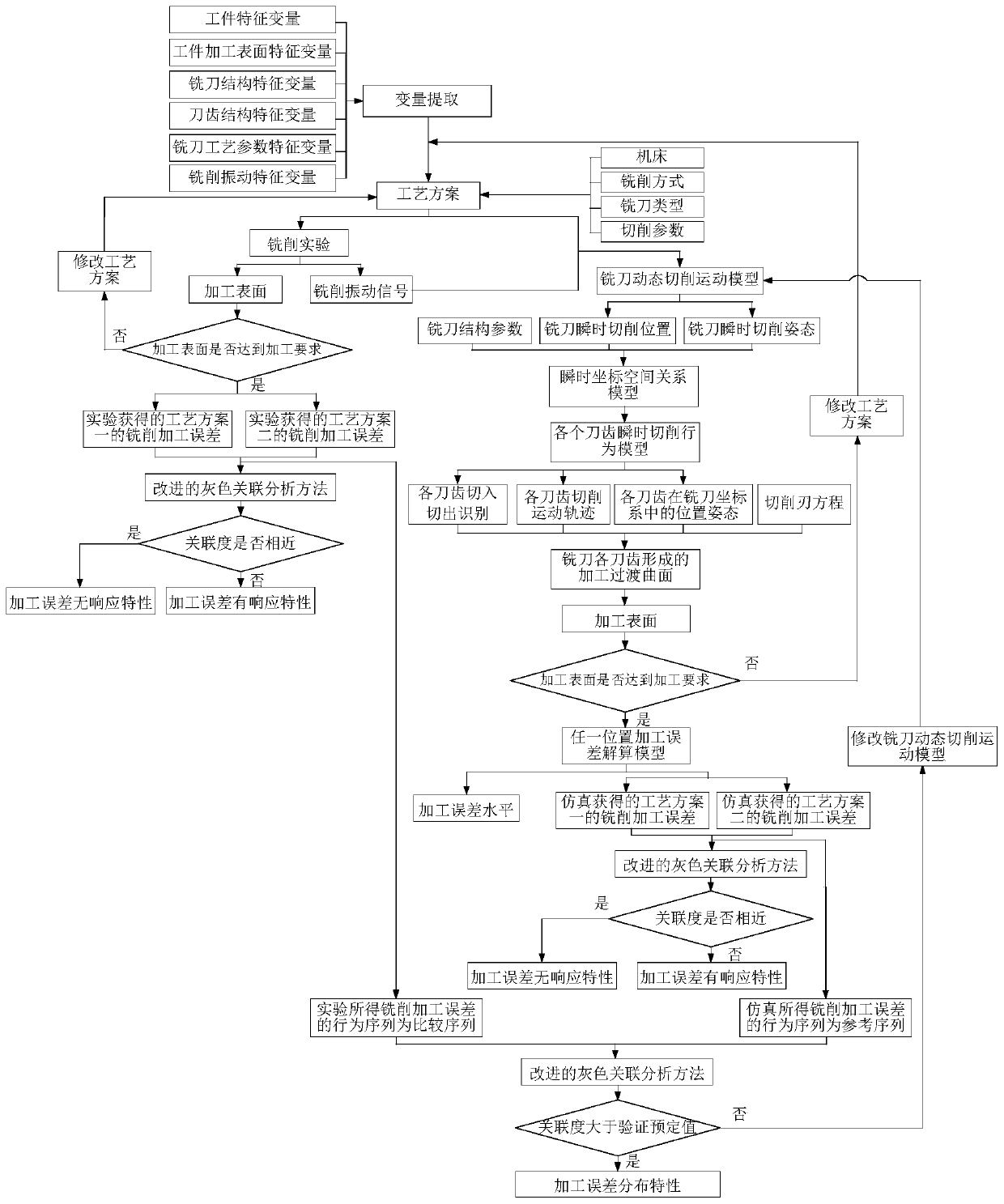

Simulation model and verification method for milling cutter cutting machining error forming process

The invention discloses a simulation model and verification method for a milling cutter cutting machining error forming process and belongs to the technical field of a milling cutter. In order to disclose a milling machining error forming process, the invention provides a method for describing a cutter tooth machining transition surface dynamic forming process. A milling machining error forming process calculation model is established; dynamic characteristics and control variables of the machining error forming process are illuminated; through combination of a simulation example and an experiment result, effectiveness of the model is verified; and the end milling cutter cutting machining error forming process is described accurately. According to the method, machining error formation undermilling vibration, milling cutter track and pose, and cutter tooth track and pose continuous change condition can be reflected. According to the verification method for the end milling cutter millingmachining error calculation model, an end milling cutter dynamic cutting movement model and a cutter tooth cut-in / cut-out calculation model in the method are verified, and the effectiveness and feasibility of the models are determined.

Owner:HARBIN UNIV OF SCI & TECH

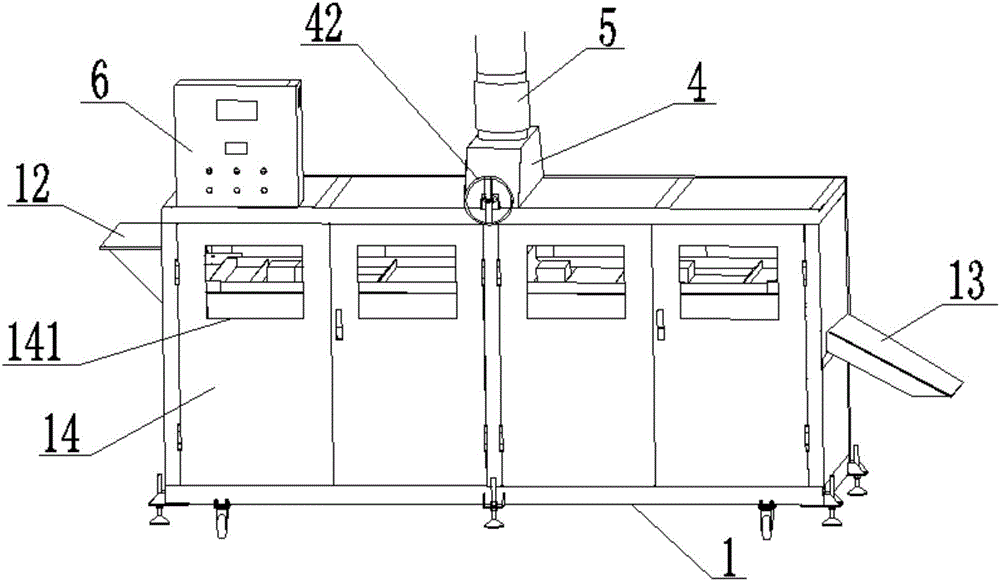

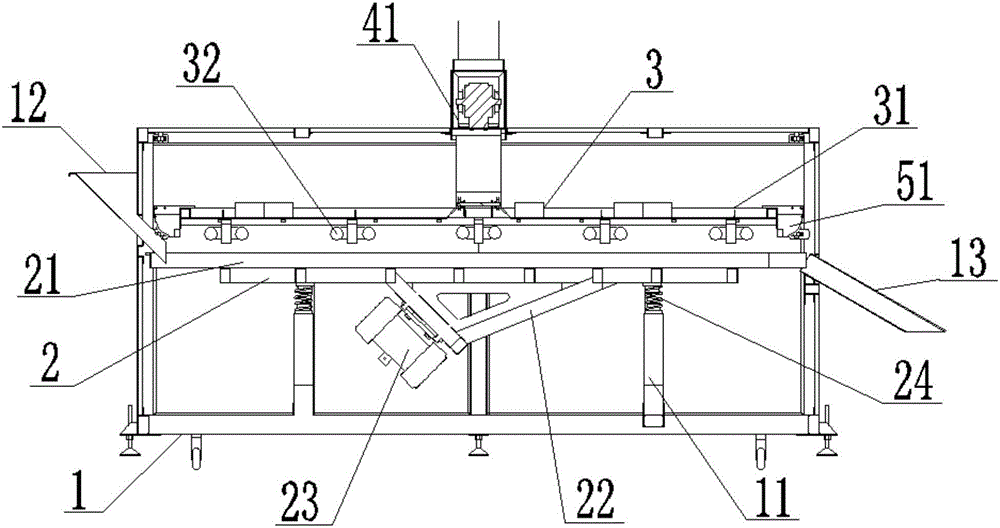

High-ultraviolet ray sterilizing machine

InactiveCN107518244AFast shippingImprove the bactericidal effectFood preservationRadiationUltravioletEngineering

The invention relates to a sterilizing device, in particular to a strong ultraviolet ray sterilizing machine. It includes a frame, a vibrating component, an ultraviolet sterilizing device, a lifting drive mechanism, a cooling and ventilation system and a power distribution box. The inside of the frame is equipped with an installation column, and the left and right sides of the frame are respectively equipped with a feed hopper and a discharge box. The vibration assembly is installed above the installation column, the lifting drive mechanism is fixedly installed on the upper part of the frame, the ultraviolet sterilizing device is installed at the lower end of the lifting drive mechanism, and the ultraviolet sterilizing device can be integrated through the lifting drive mechanism. Moving up and down. The advantage of the present invention is that by setting the vibrating component, the food on the vibrating pallet can obtain the full-surface dynamic sterilization process of the upper ultraviolet germicidal lamp, and by setting the eccentric vibrating device with a certain vibration angle, the vibration of the material in the trough is realized. Continuous jumping and full circumferential turning motion for single layer evenly paving.

Owner:伍晓政

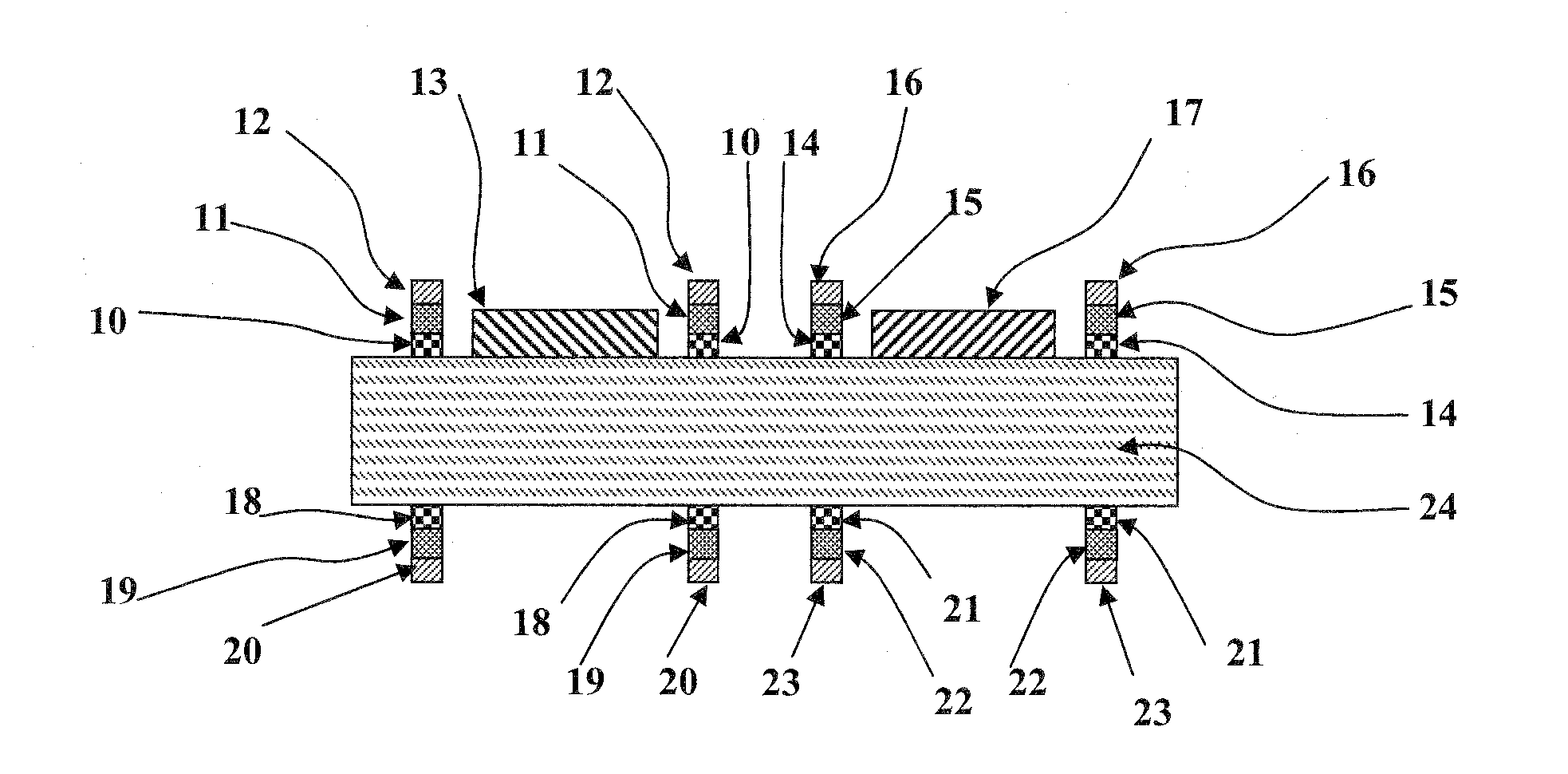

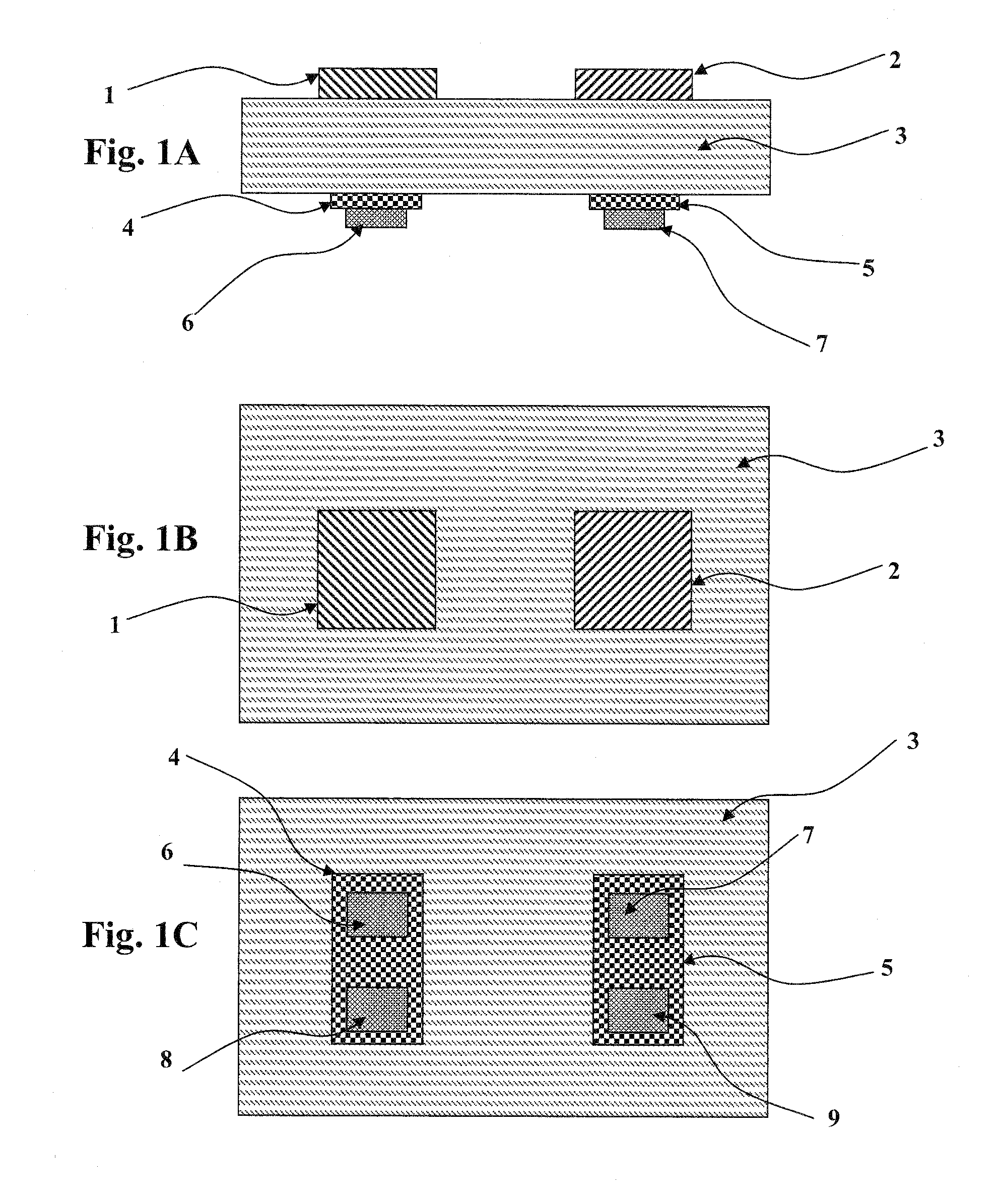

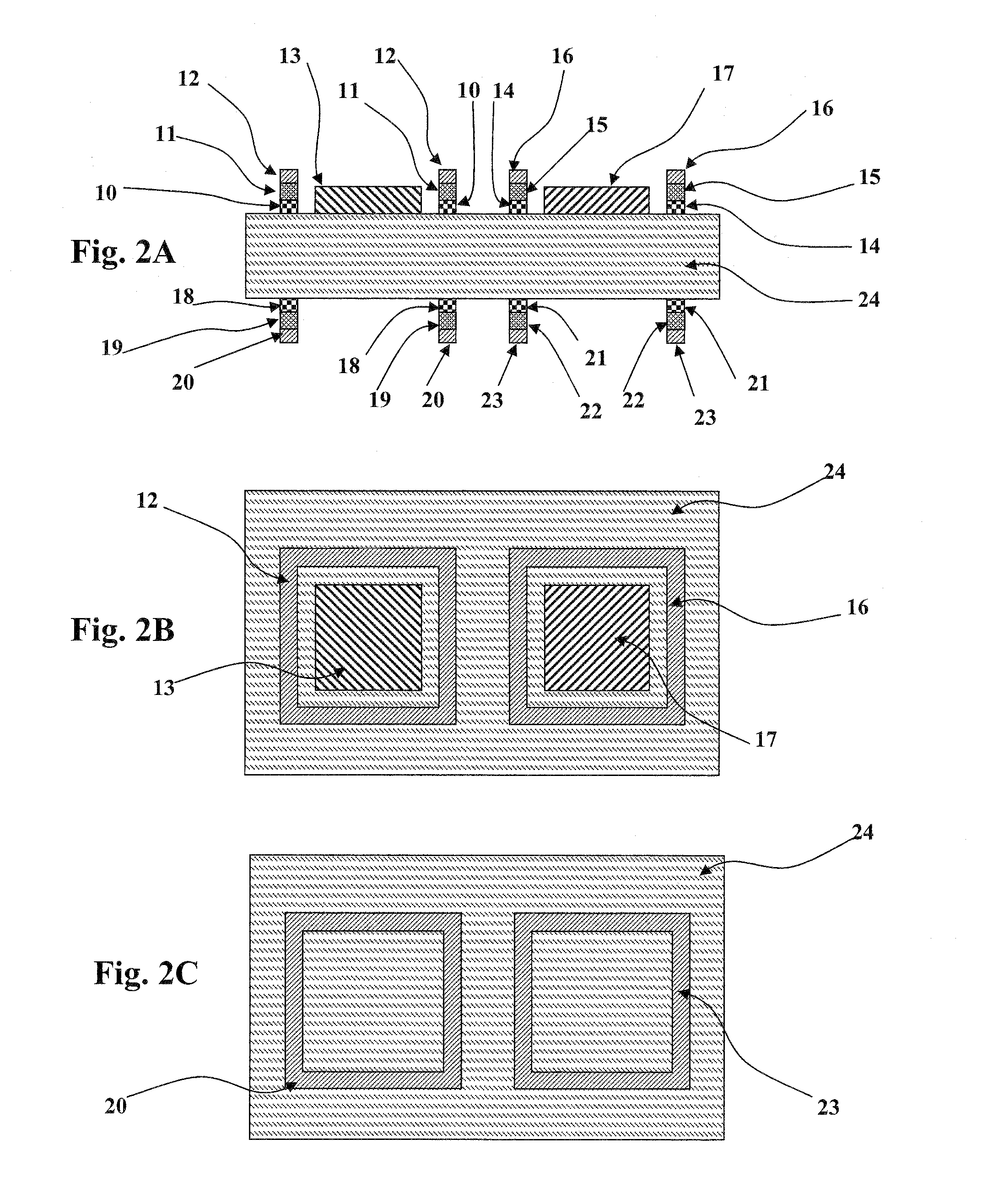

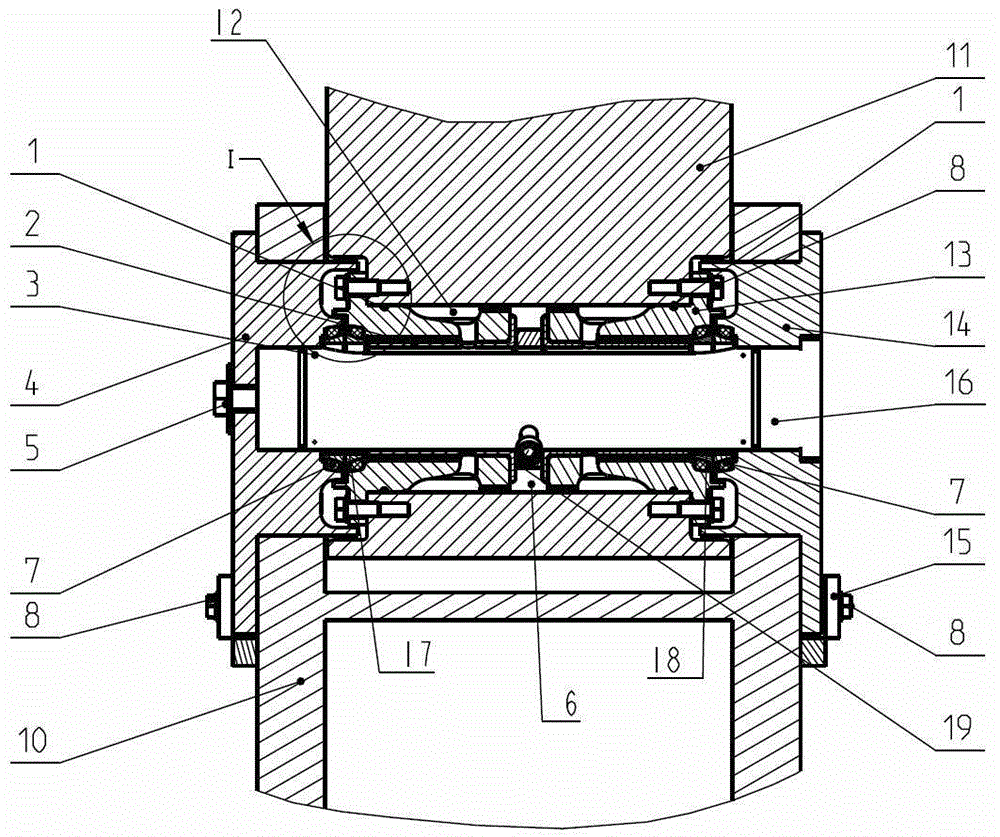

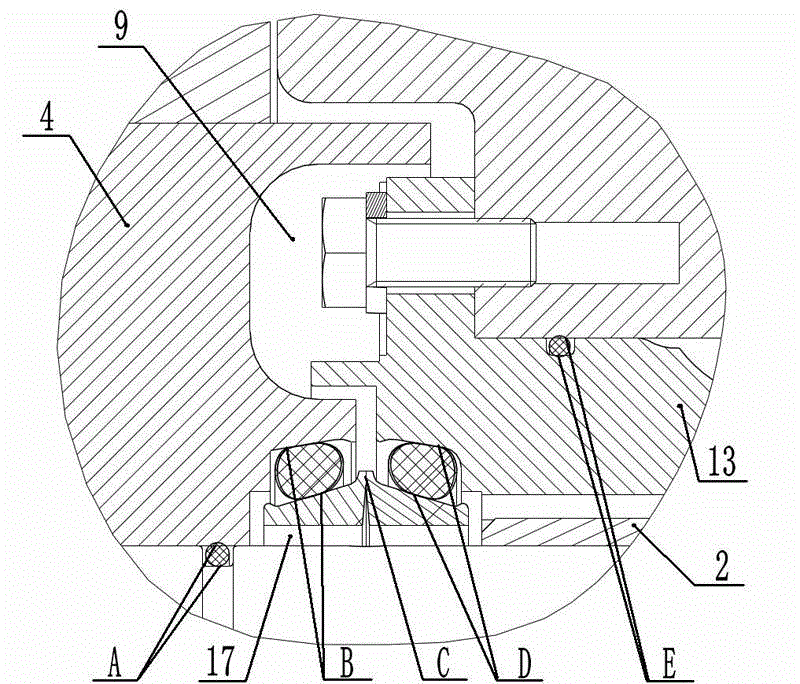

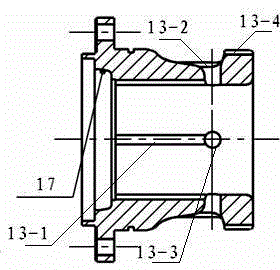

Measuring device and method for mechanical junction surface dynamic contact parameters based on surface texture

ActiveCN106018264AChange dynamic characteristicsSimple structureUsing mechanical meansMaterial analysisMeasurement deviceSingle degree of freedom

Provided is a measuring device and method for mechanical junction surface dynamic contact parameters based on a surface texture. The measuring device comprises bases and a base plate, the base plate is connected with the bases through first lead screws, a fixing sleeve is fixed on the base plate, a guiding shaft is arranged in the fixing sleeve, a normal force application bolt abuts against the guiding shaft upwards, a cushion block is arranged above the guiding shaft, a pressure sensor is arranged between the cushion block and the guiding shaft, a first test specimen is fixed on the cushion block, the bases on the two sides are connected to a crown plate through second lead screws respectively, an exciter and a second test specimen are arranged on the crown plate, the exciter downwards abuts against the second test specimen, acceleration sensors are arranged on the two sides of the second test specimen, and by adjusting a first lead screw and / or a second lead screw, normal contact or tangential contact between the second test specimen and the first test specimen is controlled; the measuring device is simplified into a single-degree-of-freedom system, measuring of rigidity of normal contact and tangential contact of the two test specimens can be conducted by means of one device, the structure is simple, and the complexity degree of testing is reduced.

Owner:河北冀泰机械科技有限公司

Working device articulating mechanism

ActiveCN104454957AEasy accessReduce Adhesive WearBearing componentsPivotal connectionsParticulatesMechanical engineering

The invention provides a working device articulating mechanism, and relates to the technical field of construction machinery. The articulating mechanism comprises a bearing bush, a shaft arranged in the bearing bush in a penetrating way, and a dustproof ring, wherein a lining sleeves the bearing bush, and the two ends of the shaft respectively sleeve left and right floating seal seats; a first floating oil seal cavity is arranged on a surface, in contact with the left floating seal seat, of the lining, and a second floating oil seal cavity is arranged on a surface, in contact with the right floating seal seat, of the lining; the first and second floating oil seal cavities are communicated with the shaft, and a floating oil seal is arranged in each floating oil seal cavity. Compared with the prior art, the floating oil seals are respectively arranged on the inner end surfaces of the floating seal seats and in the floating oil seal cavities on the lining, so that a static seal is formed; when the floating oil seals contact with each other and rotate, an end surface dynamic seal is formed, and thus small particulate matters can not enter a part between the shaft and a shaft sleeve easily, and the dustproof effect is very good, and therefore, the adhesive wear and the abrasive wear of bearings can be reduced, and the reliability of a sliding bearing mechanism in work is improved.

Owner:LIUGONG CHANGZHOU MACHINERY +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com