Framed sleeper unit

A frame type and sleeper technology, applied in the field of track structure, can solve problems such as high maintenance and repair costs, maintenance and repair, and poor rail surface, and achieve the effects of maintaining dynamic smoothness, reducing maintenance costs, and reducing natural vibration frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

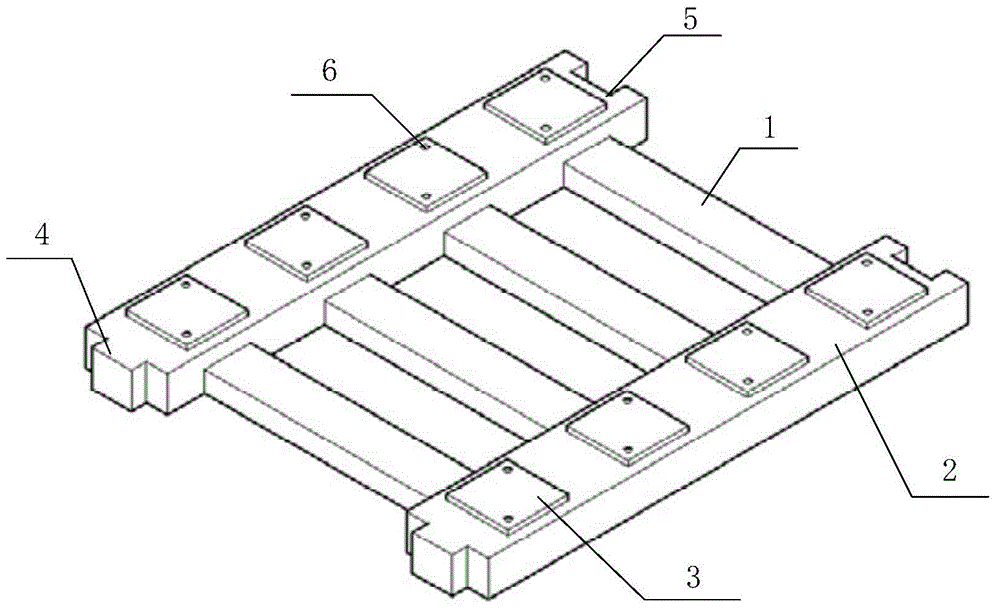

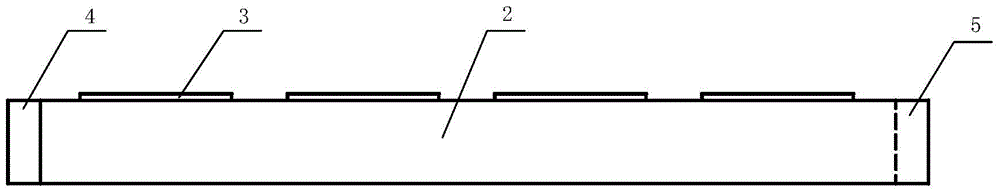

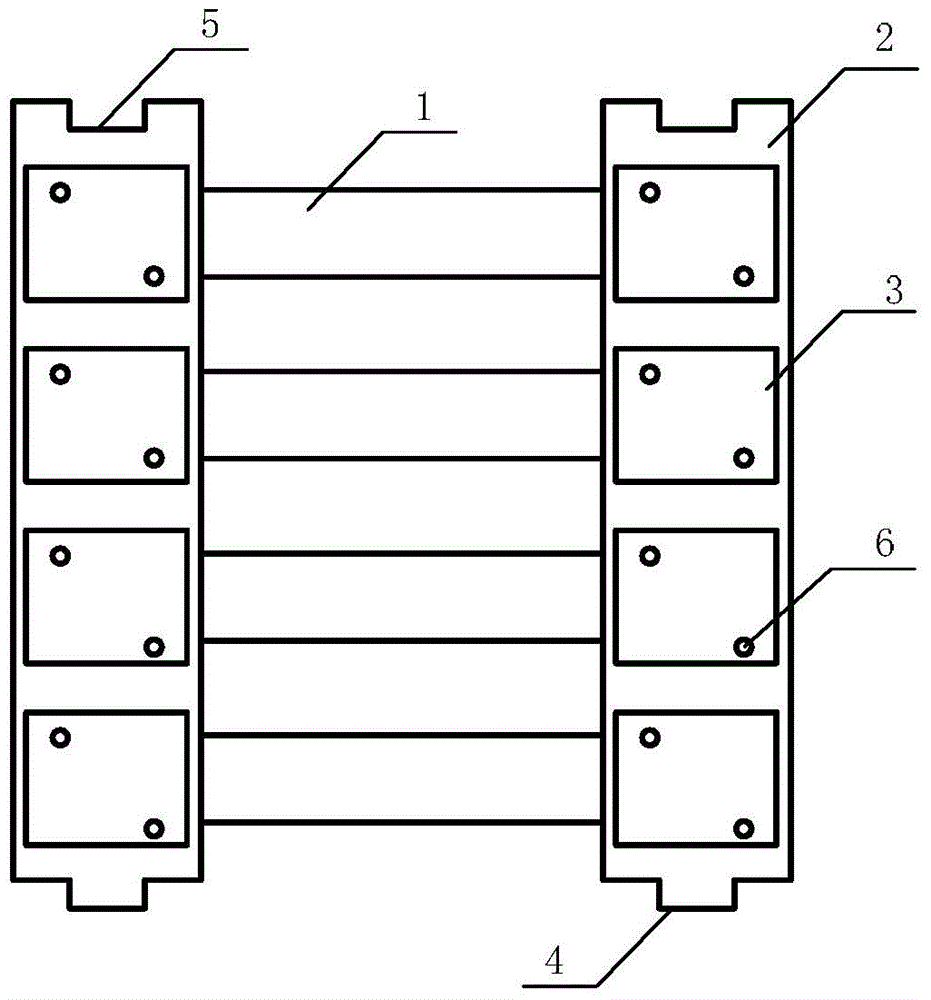

[0027] The present invention will be further described below in conjunction with the embodiments shown in the drawings.

[0028] See Figure 1-7 , The present invention includes: a railroad track crisscross frame type sleeper, including two longitudinal sleepers 2 and 4 transverse sleepers 1, each of the longitudinal sleepers is provided with 4 rail platforms 3 on the upper part, the rail platform There are two threaded holes 6; the two ends of the longitudinal sleeper are provided with a coupling structure, such as a convex head 4 at one end and a groove 5 at the other end, so that two adjacent frame-type sleepers can pass through their respective convex heads and grooves Interlocking.

[0029] The longitudinal sleepers 2 are placed along the direction of the railway line, and the horizontal sleepers 1 are designed perpendicular to the longitudinal sleepers and are arranged at intervals in parallel along the direction of the railway line. Preferably, the intervals between the hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com