Laser marking device and marking method

A laser marking and laser marking machine technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of low coding efficiency, and achieve the effect of ensuring the reading rate, ensuring stability, and good positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

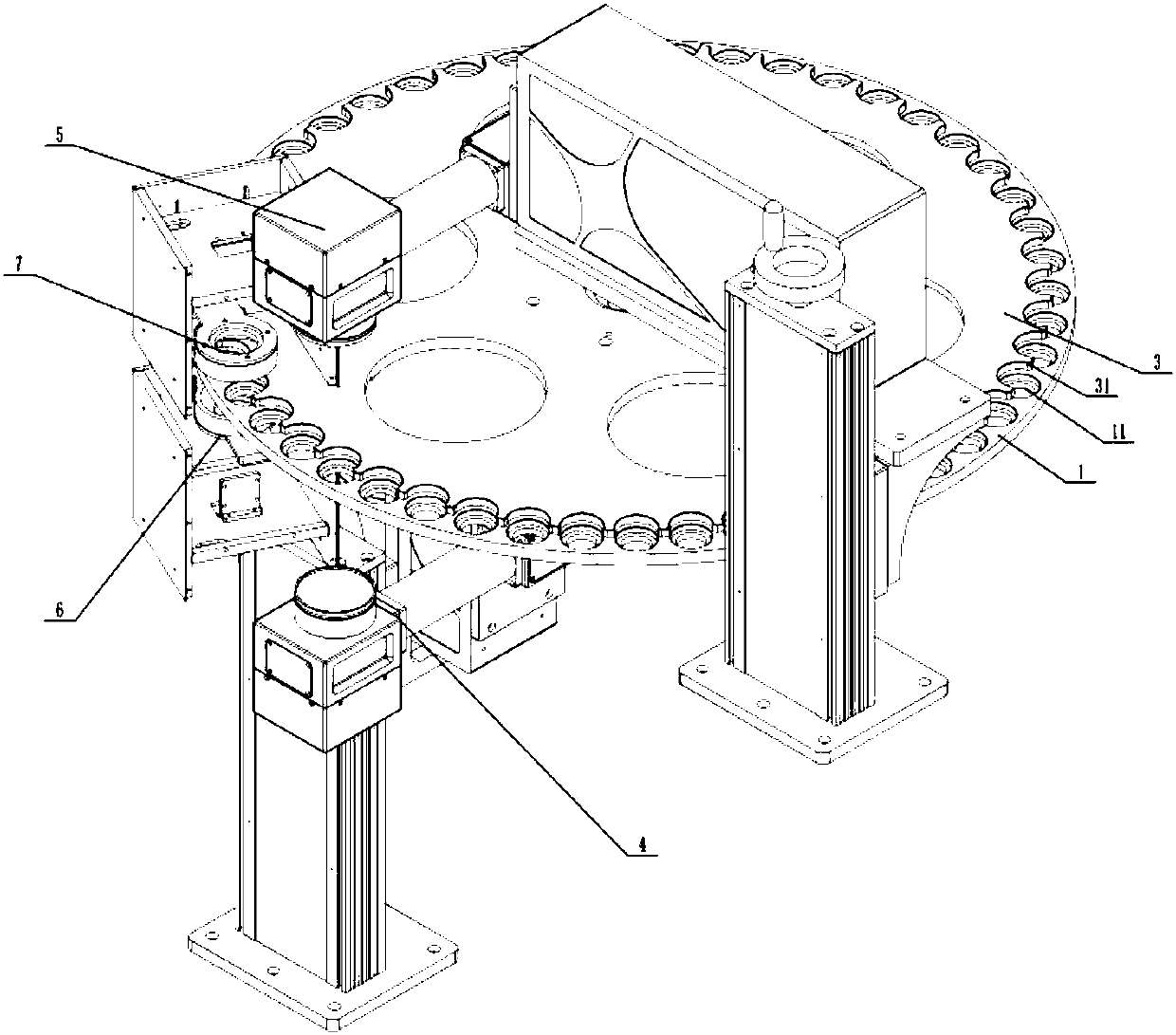

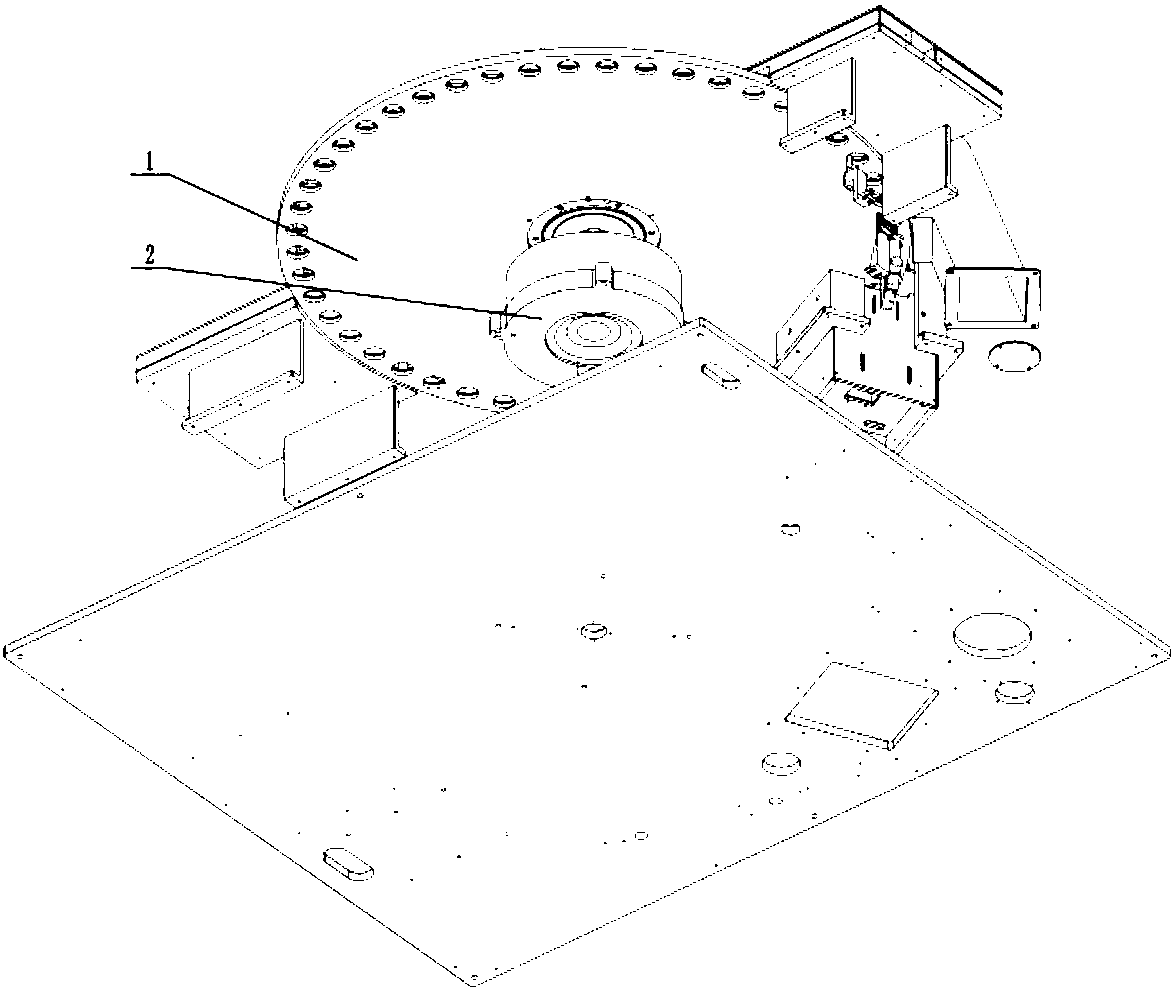

[0043] Such as Figure 1-2 As shown, the laser marking equipment provided by the present invention includes:

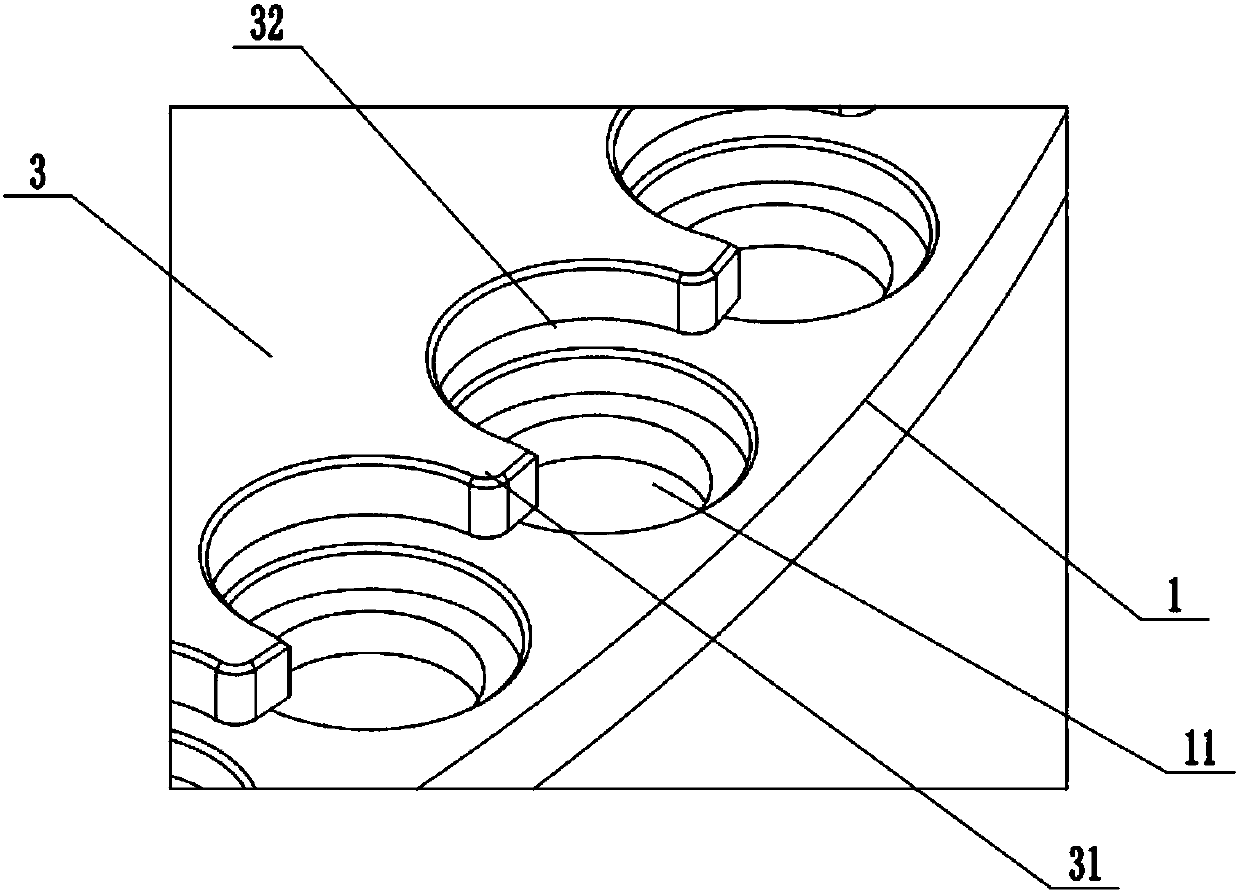

[0044] Circular turntable 1, and a plurality of positioning holes 11 for fixing products are radially arranged on the circular turntable 1; each positioning hole 11 can correspond to fix a product, such as bottle caps, etc.;

[0045] The drive assembly 2 is used to drive the circular turntable 1 to rotate at a constant speed; in this embodiment, the drive assembly 2 can be a DD motor, and at the same time, because the circular turntable 1 will continue to rotate during the marking process, it will generate The inertia of the laser will affect the trajectory of the laser marking, for example, it will cause the lines of the last printed two-dimensional code to bend. In the present invention, it has been proved by a lot of creative work that when the radius of the circular turntable 1 is R≧460mm (preferably 500mm), And when the rotational angular velocity ω≦22.5° / s (pre...

Embodiment 2

[0060] This embodiment provides a laser marking method, which includes the following steps:

[0061] S1. Set the marking parameters of the outer code and the inner code, and send them to the outer code laser marking machine and the inner code laser marking machine;

[0062] S2. Fixing the product into the positioning hole of the circular turntable, and the drive assembly drives the circular turntable to rotate at a constant speed;

[0063] S3. The outer code laser marking machine and the inner code laser marking machine simultaneously complete the code assignment on the outer surface and the inner surface of the product according to the marking parameters;

[0064] And S4, using the outer code reading unit and the inner code reading unit to simultaneously complete the decoding of the outer code and the inner code.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com