Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59 results about "Spin magnetic moment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In physics, mainly quantum mechanics and particle physics, a spin magnetic moment is the magnetic moment caused by the spin of elementary particles. For example, the electron is an elementary spin-1/2 fermion. Quantum electrodynamics gives the most accurate prediction of the anomalous magnetic moment of the electron.

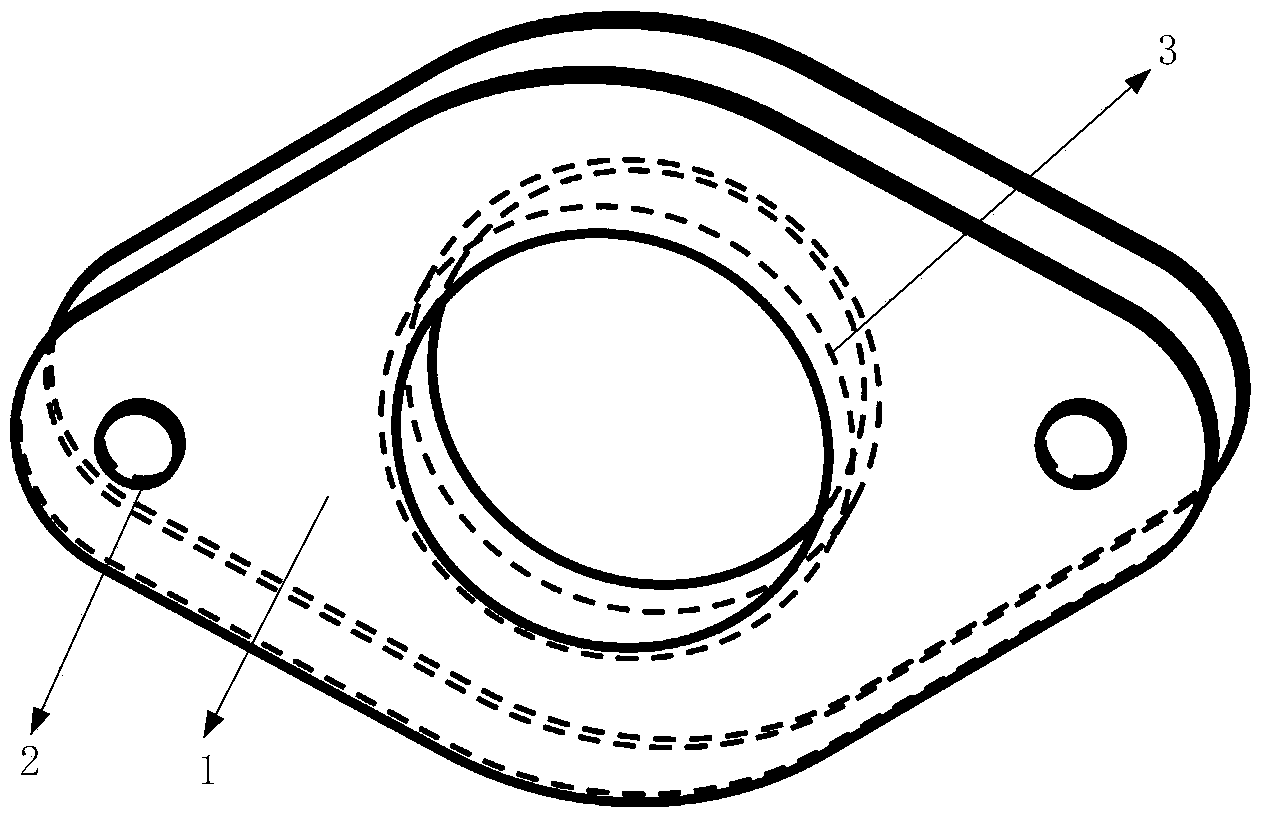

Magnetic resistance sensor for measuring magnetic field

ActiveCN102565727AHigh sensitivityImprove linearityMagnetic measurementsElectrical measurementsElectrical resistance and conductanceSpin magnetic moment

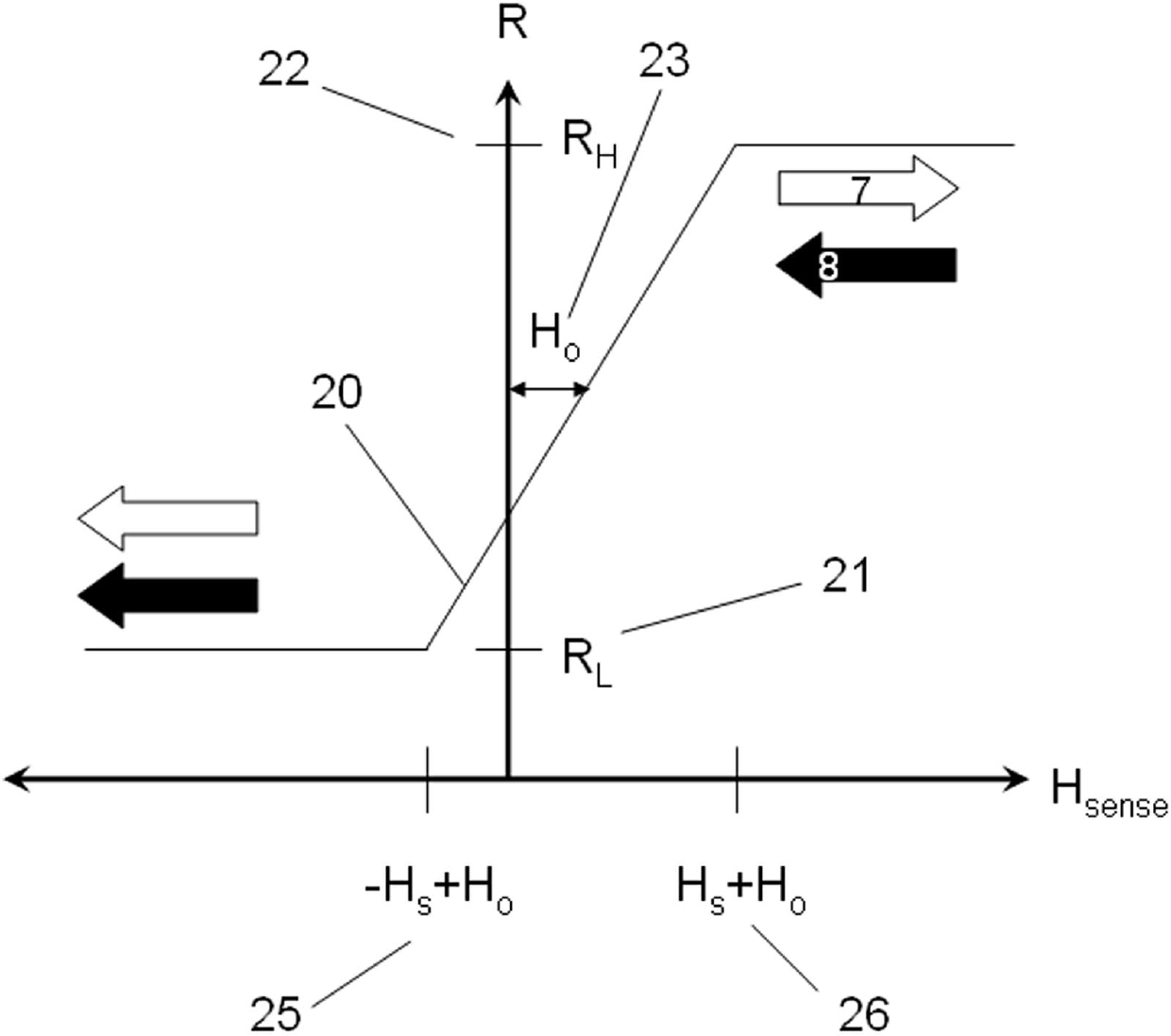

The invention provides a magnetic resistance sensor for measuring a magnetic field. By the sensor, the sensitivity of a magnetic resistance sensing element can be calculated, and is related to shape anisotropy and an outer field. A long shaft of a magnetic resistance element is parallel to a sensitive direction, and the magnetic moment of the magnetic resistance element can be further saturated by the component Hcross of the outer field in the vertical sensitive direction at the same time. A monolithic permanent magnet has the effect of generating an Hcross field with an angle and offsetting a non-ideal field along an easy magnetization axis at the same time. The magnetic resistance element with high sensitivity can be widely applied in the field of electrics. Six electrical bridges formed by the magnetic resistance sensor can be presented in the magnetic resistance sensor.

Owner:MULTIDIMENSION TECH CO LTD

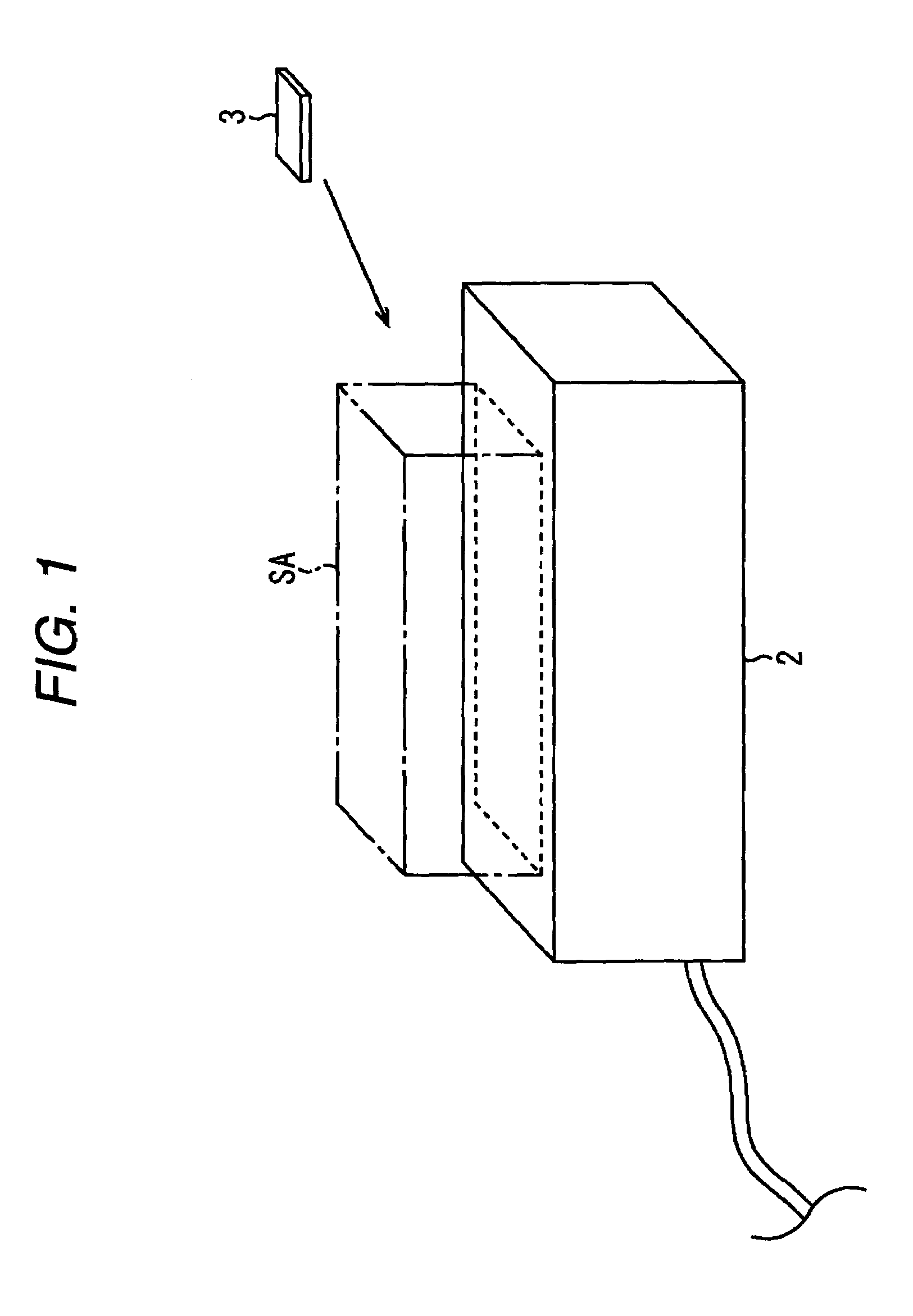

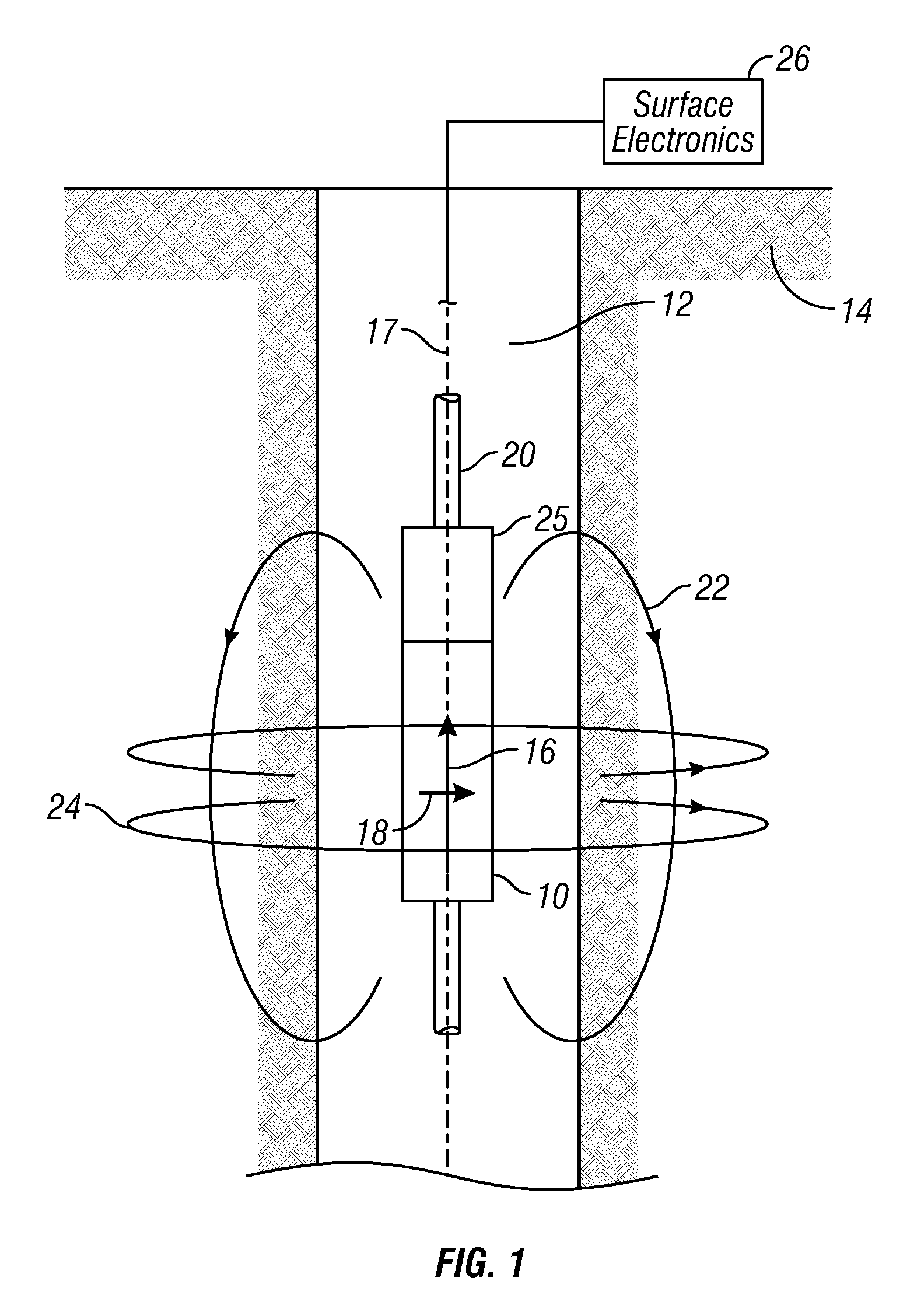

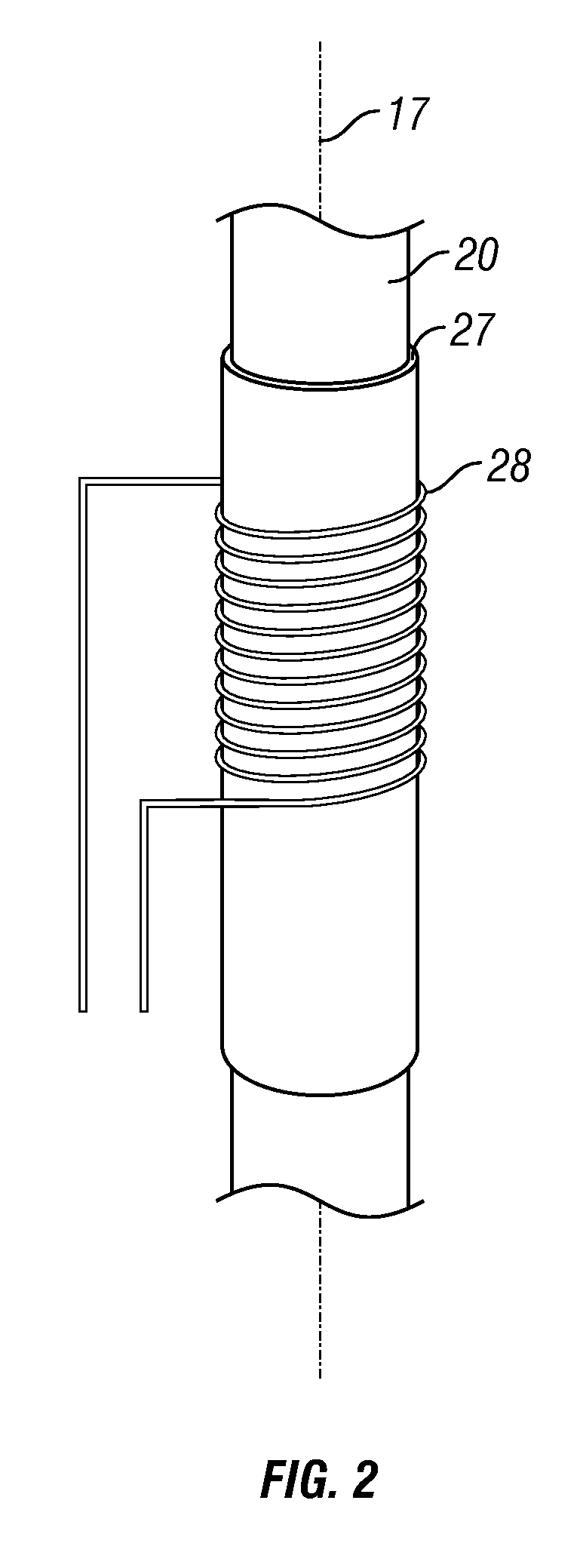

Nuclear magnetic resonance tool using switchable source of static magnetic field

ActiveUS20060255799A1Effective permeability of magneticElectric/magnetic detection for well-loggingMaterial analysis by using resonanceSolid-state nuclear magnetic resonanceSpin magnetic moment

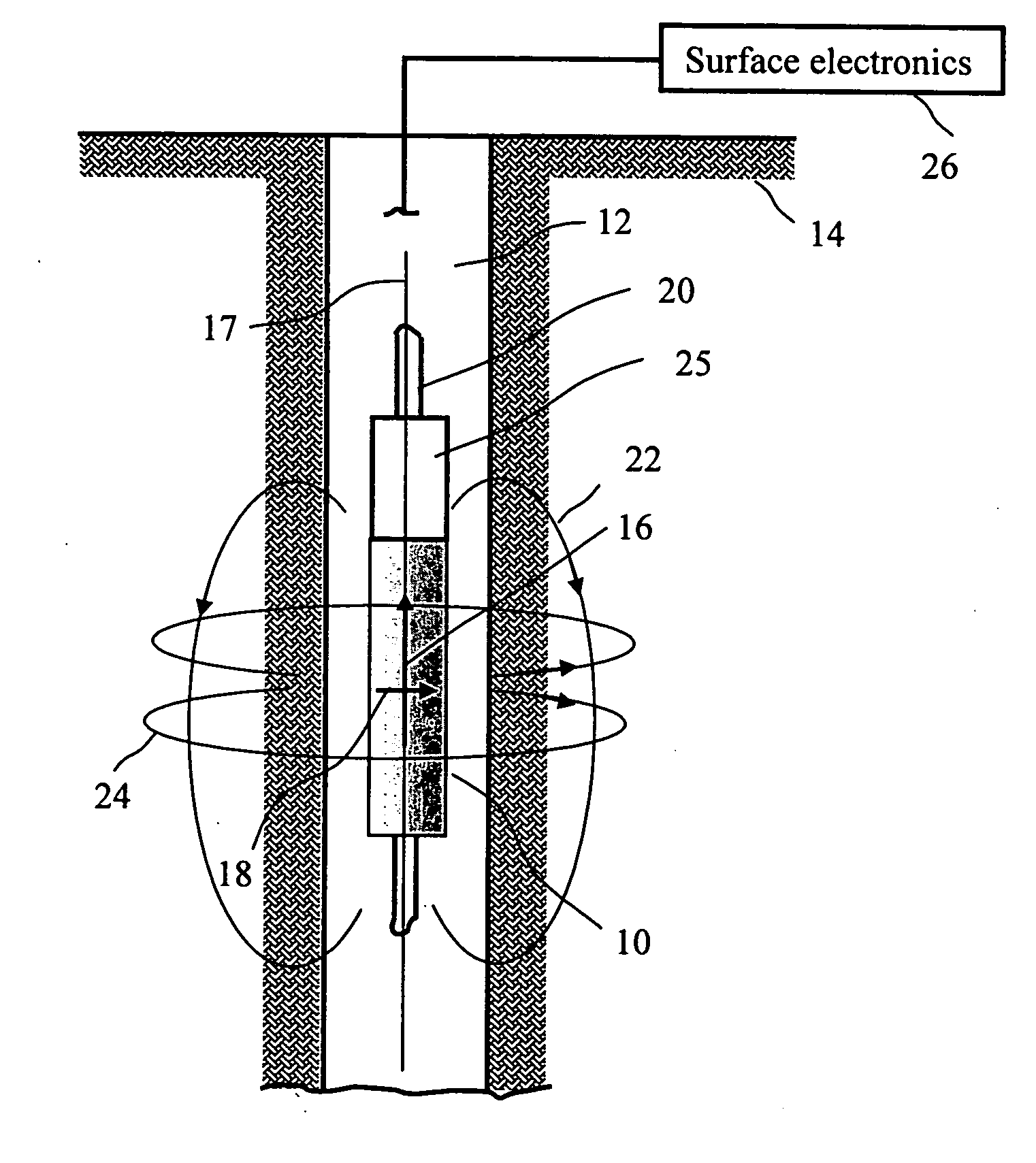

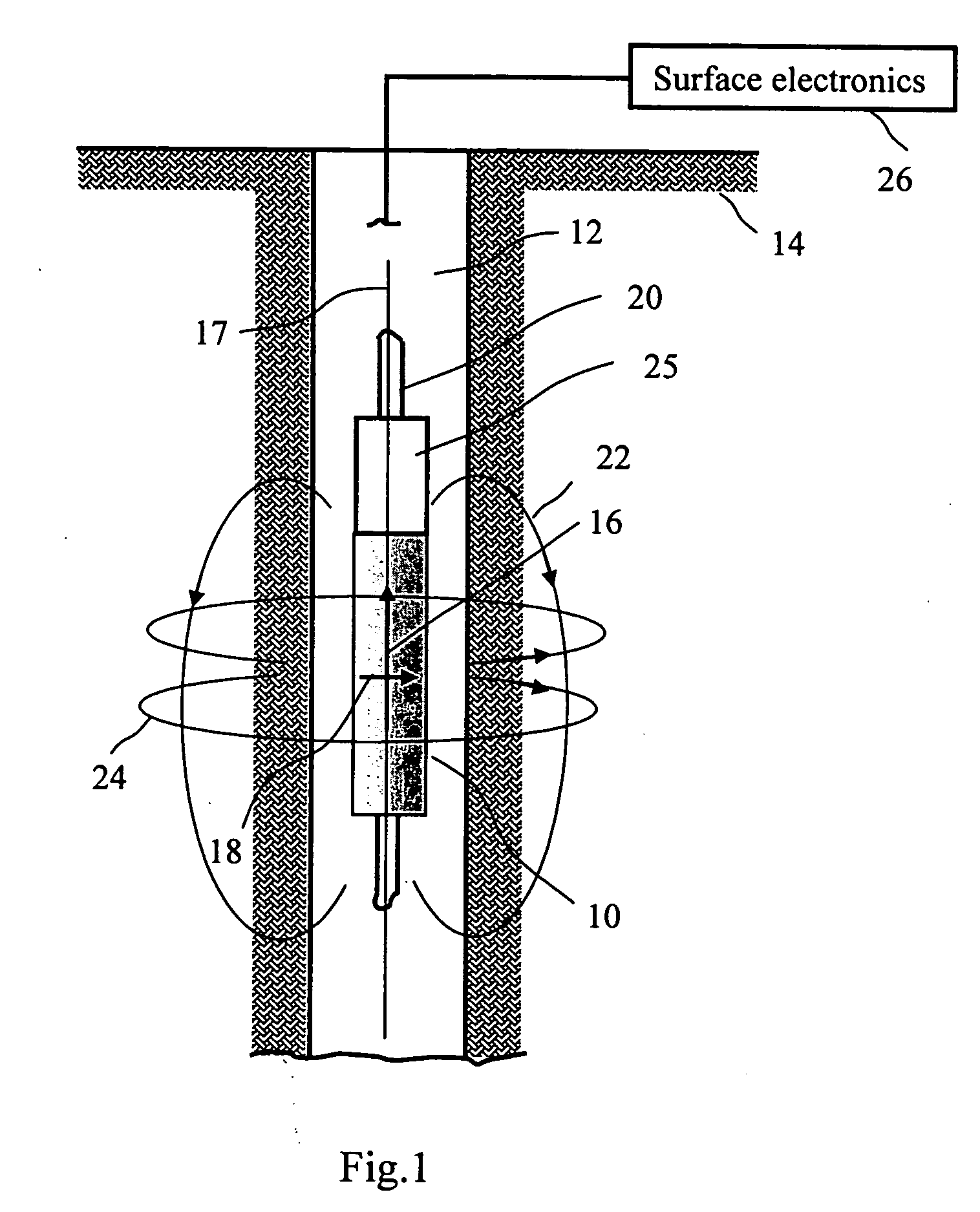

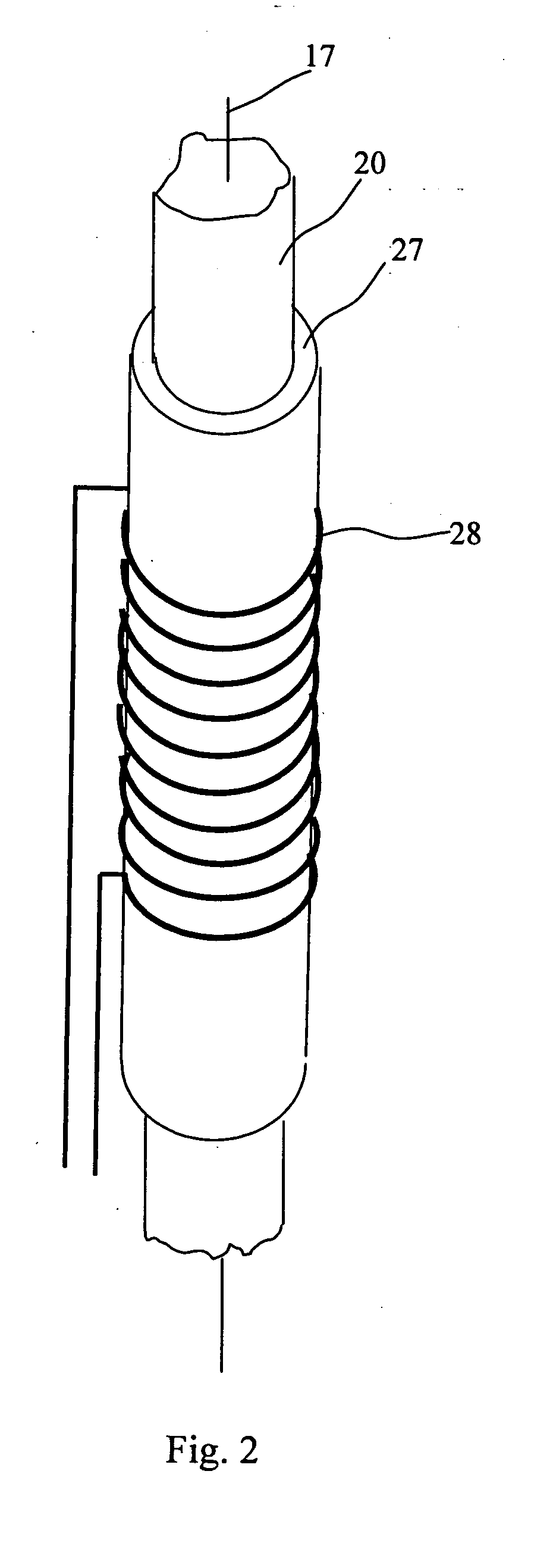

A nuclear magnetic resonance sensing apparatus and method for operating in an earth borehole comprises a source of switchable magnetic field to polarize nuclei in the region of interest, said source comprising a coil wound on a magnetic core having controllable residual magnetization. Maintaining the magnetization of the core during a polarization interval does not require steady current in the coil. Switching intensity and polarity of magnetization of the core causes precession of spin magnetic moments of the nuclei; the precession induces a signal indicative of nuclear magnetic resonance properties of earth formations.

Owner:BAKER HUGHES INC

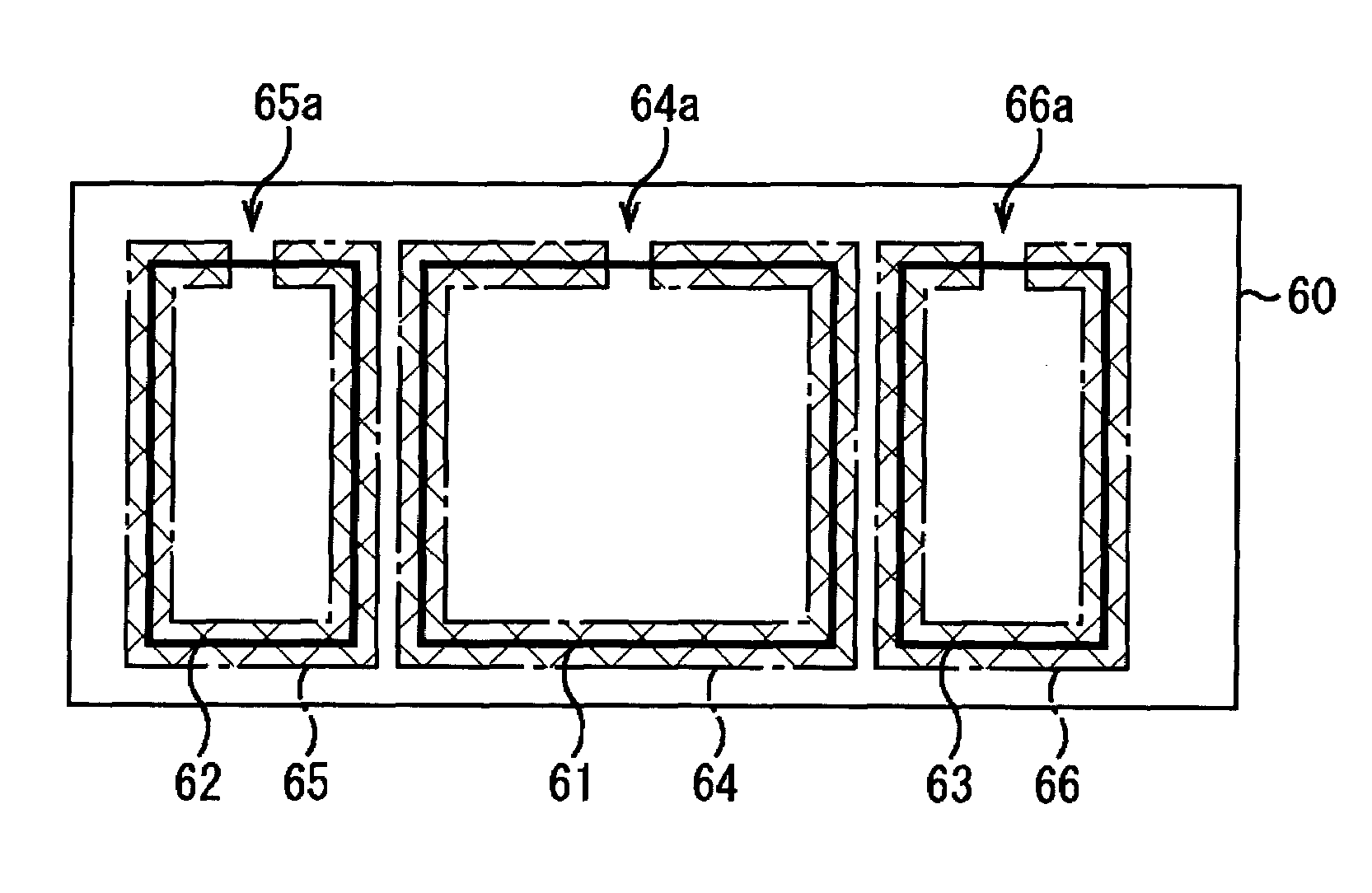

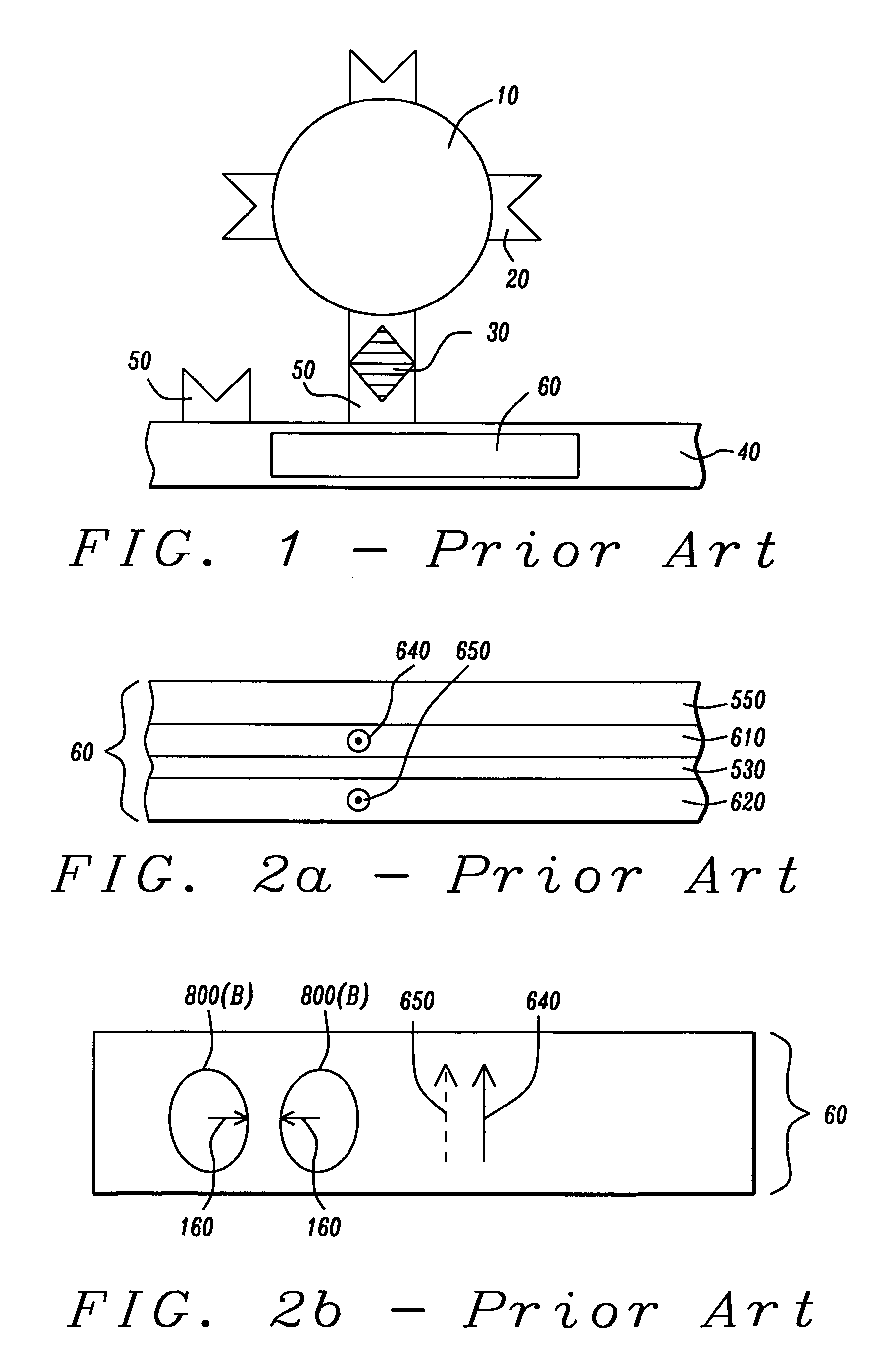

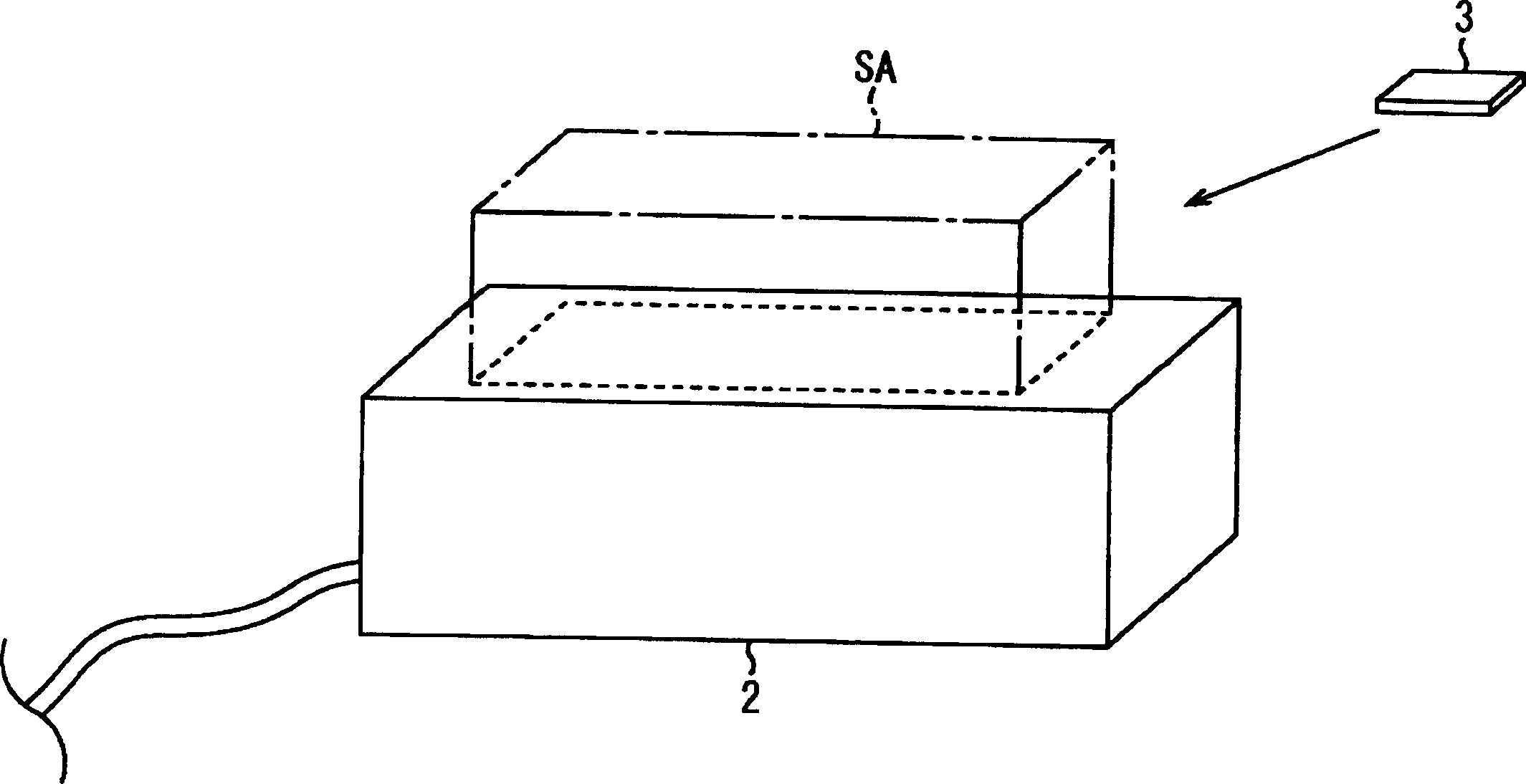

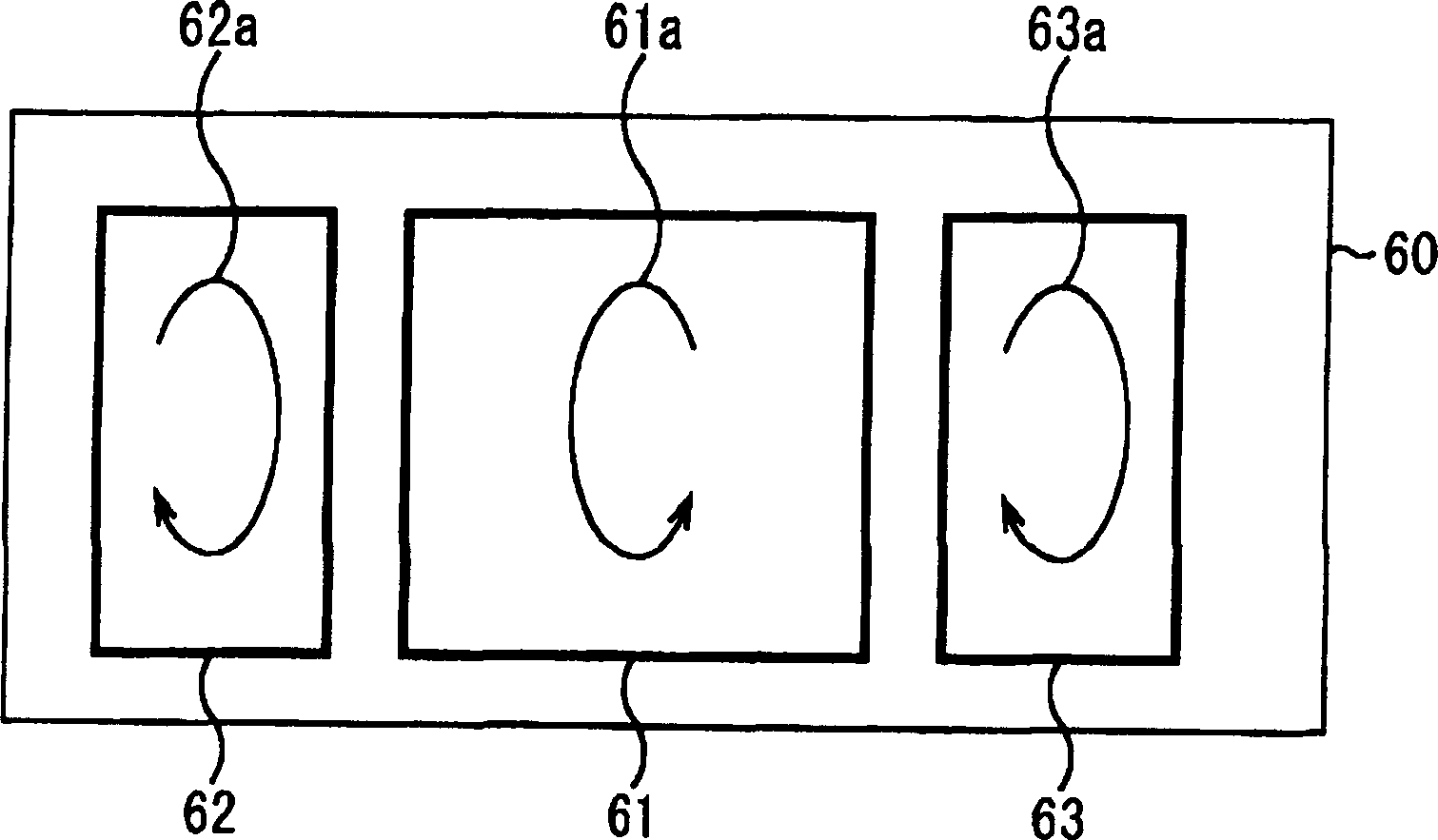

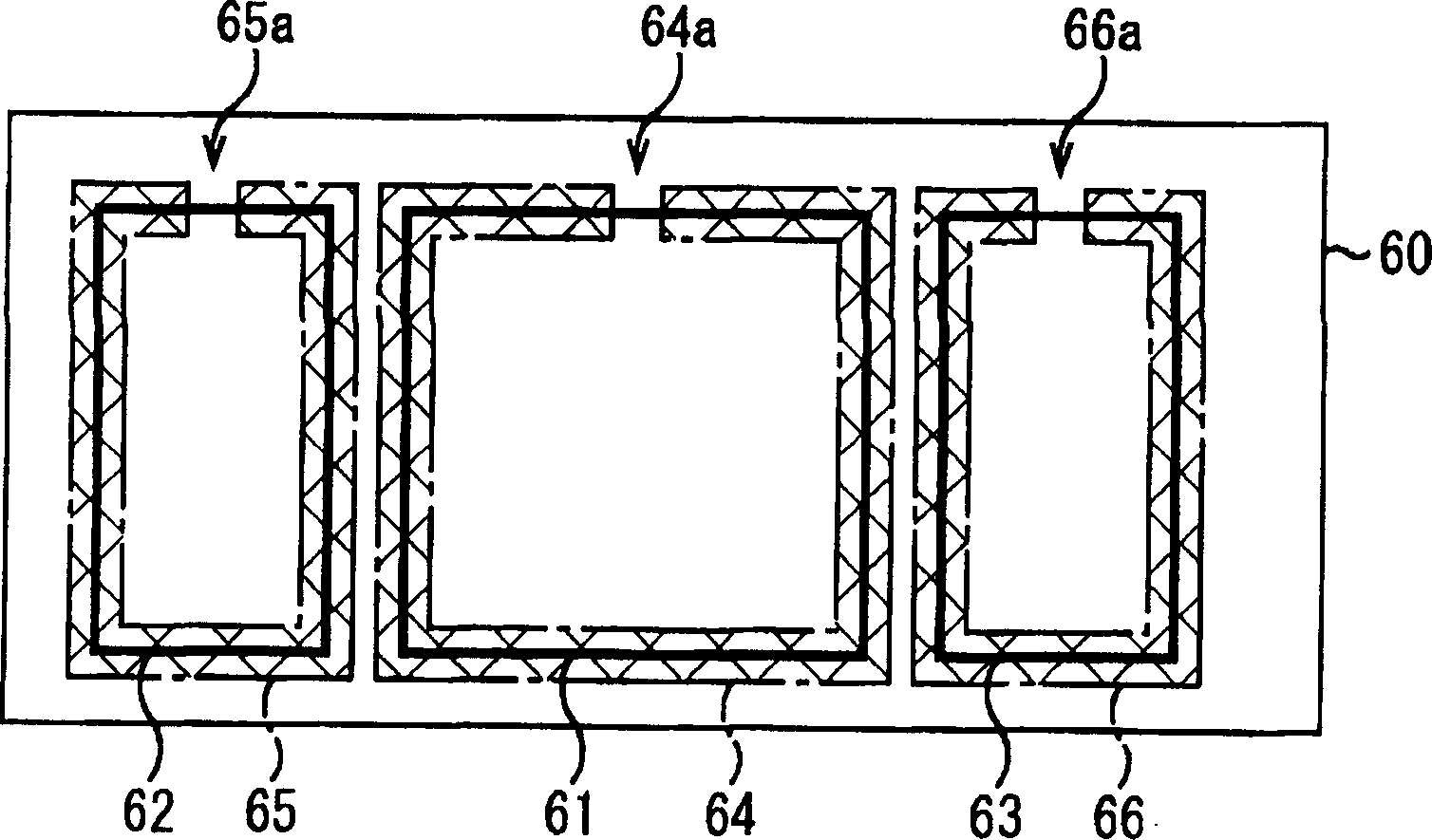

Loop antenna device

InactiveUS7142163B2Inhibition formationResonant long antennasAntenna arraysElectrical conductorSpin magnetic moment

A plurality of small loop antenna cells 61, 62 and 63 are magnetically coupled to an antenna coil 8 of a non-contact type data carrier 3. In the plurality of small loop antenna cells, the directions of the magnetic moments of the signals transmitted to the non-contact type data carrier 3 are opposite to each other, the sum of the magnetic moments generated from all the small loop antenna cells 61 to 63 is zero and a conductor forming a short ring pattern 67 is provided collectively for the plurality of small loop antenna cells. Thus, imbalance caused between the small loop antenna cells 61 to 63 can be compensated for by the short ring pattern 67.

Owner:SEIKO EPSON CORP +1

MRAM storage unit

ActiveCN110660420AReduce read error rateLess prone to read errorsMagnetic-field-controlled resistorsSolid-state devicesSpin magnetic momentSoftware engineering

The invention provides an MRAM storage unit. The unit comprises two magnetic tunnel junctions and a spin orbital moment providing line, the two magnetic tunnel junctions are located on the surface ofthe same side of the spin orbital moment providing line, wherein the free layer of each magnetic tunnel junction is close to the spin orbital moment providing line, the magnetization directions of thereference layers of the two magnetic tunnel junctions are the same, and the spin orbital moment providing line is used for applying spin magnetic moments in opposite directions to the two magnetic tunnel junctions, so that the free layers of the two magnetic tunnel junctions have opposite magnetization directions. According to the MRAM storage unit, complementary resistance states can be stored,differential signals are formed during state reading, the reading error rate is reduced, and the data reading speed can be remarkably increased.

Owner:CETHIK GRP +1

Spin torque oscillator with low magnetic moment and high perpendicular magnetic anisotropy material

Embodiments disclosed herein generally relate to a magnetic disk device employing a MAMR head. The MAMR head includes an STO. The STO comprises an underlayer, an SPL, an interlayer, an FGL, and a capping layer. The SPL is comprised of a high perpendicular magnetic anisotropy material. The SPL has a large effective perpendicular magnetic anisotropy field, and the SPL has a lower magnetic moment than the FGL. An applied current is adapted to flow in a direction from the FGL to the SPL resulting in the magnetization direction of the SPL being almost perpendicular to the FGL and anti-parallel to a head-gap magnetic field due to a relation between a first spin torque directed from the SPL to the FGL and a second spin torque directed from the FGL to the SPL.

Owner:WESTERN DIGITAL TECH INC

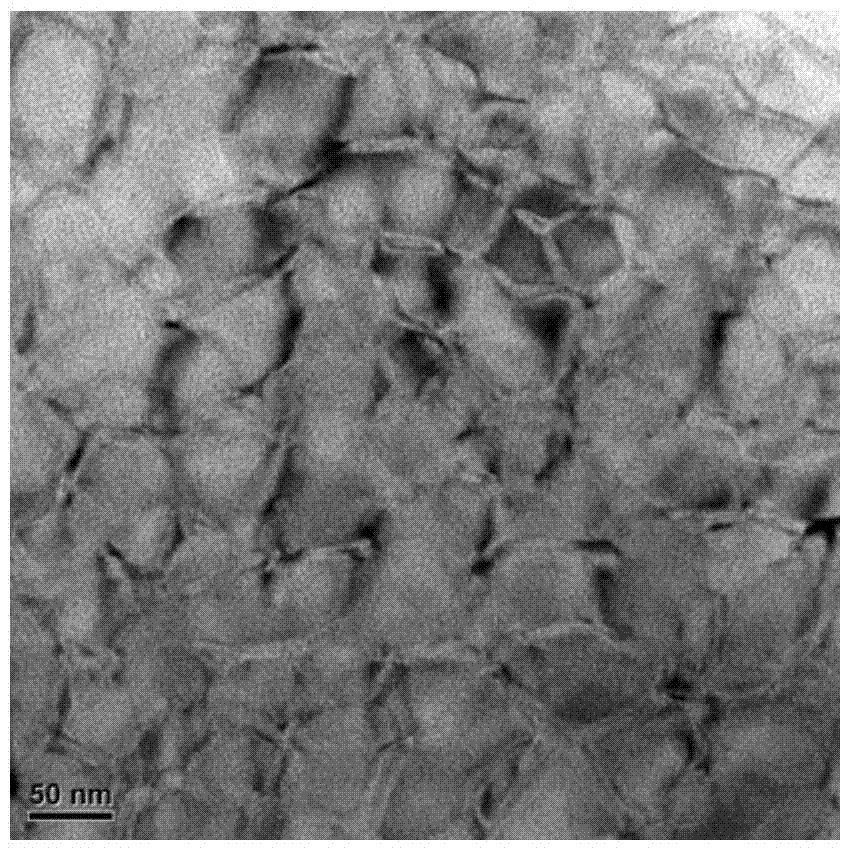

Microwave aging treatment method for cobalt-based rare earth permanent magnetic materials

ActiveCN104233138AGood mechanical propertiesHigh magnetic performanceMagnetic materialsBond energyElectromagnetic field

The invention provides a microwave aging treatment method for cobalt-based rare earth permanent magnetic materials. Cobalt-based rare earth permanent magnetic material sintered blanks prepared by a powder metallurgy method are treated in a second-stage artificial aging or multi-stage artificial aging manner after the heating and the heat preservation in a microwave manner; by utilizing the high-frequency electromagnetic field of microwaves, on one hand, the electron spin magnetic moment orientation of 3d casing layers of transition metals in alloys is affected, the bonding energy between the transition metals and rare earth metals is weakened, the nucleation potential barriers of new Sm2Co17R phrases and SmCo5 phrases are reduced, nanocrystalline particles containing the Sm2Co17R phrases and the SmCo5 phrases are beneficial to form, and high saturation magnetization intensity and high mechanical property can be obtained; on the other hand, the microwaves can be converted into the diffused energy of atoms, the diffused speed of the atoms is increased, the sintering progress is accelerated, and the cell-shaped structures are refined. For the rare earth permanent magnetic materials treated by the method, the cell-shaped structures can be small and uniform. The method can be applied to prepare rare earth permanent magnetic materials which contain Sm (samarium), Co (cobalt), Fe (ferrum), Cu (copper), Zr (zirconium) or Ti (titanium) and have good mechanical property and high mechanical property, so that the method is suitable for industrialized application.

Owner:CENT SOUTH UNIV

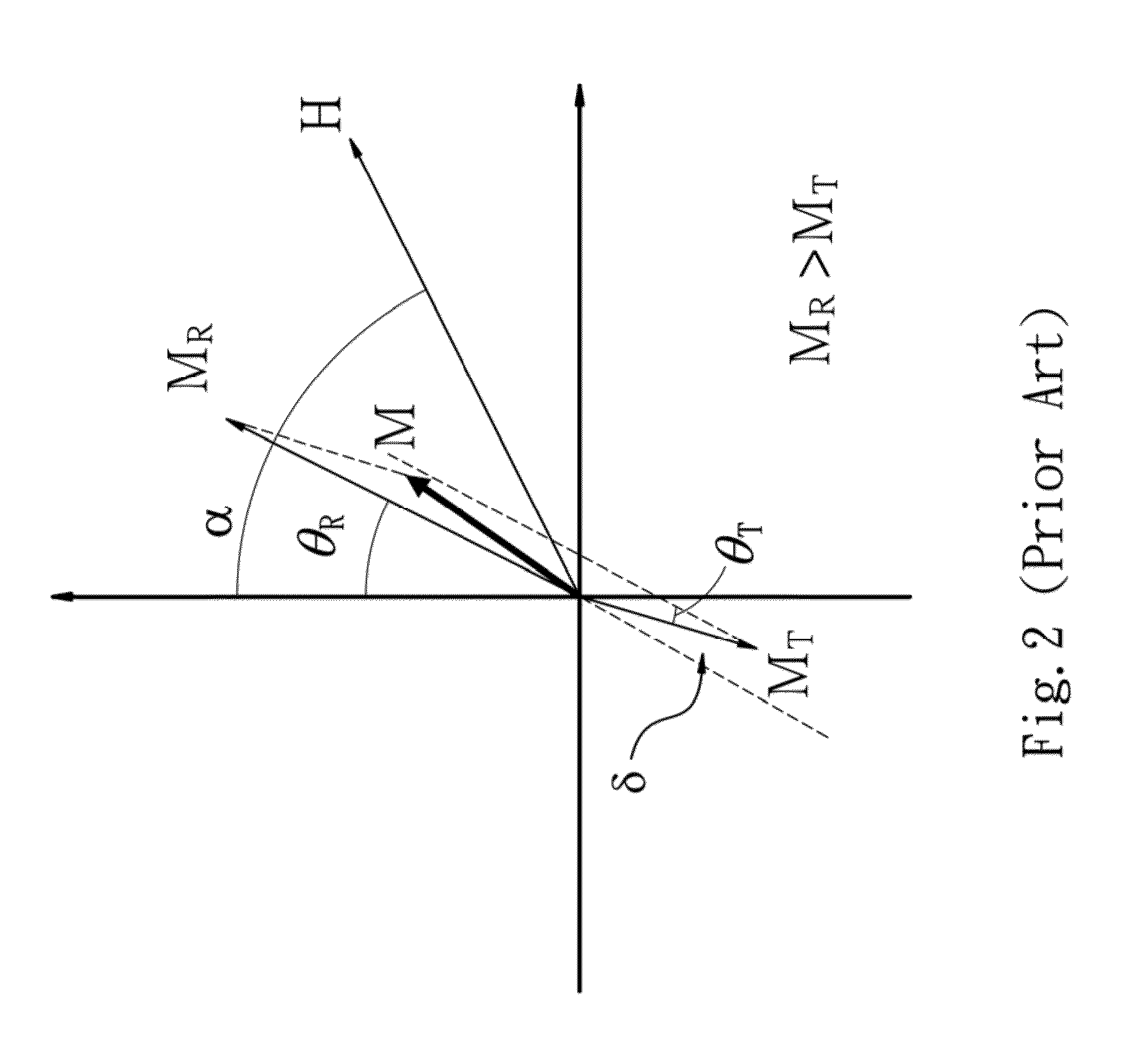

Method of measuring dimensionless coupling constant of magnetic structure

In A method for measuring a dimensionless coupling constant of a magnetic structure includes the following steps. A step of applying an external vertical magnetic field is performed for enabling magnetic moments of a RE-TM (Rare Earth-Transition metal) alloy magnetic layer of the magnetic structure to be vertical and saturated. A step of measuring a compensation temperature is performed when the sum of the magnetization of the RE-TM alloy magnetic layer is zero. A step of applying an external parallel magnetic field to the RE-TM alloy magnetic layer is performed. A step of adjusting the temperature of the magnetic structure to the compensation temperature and measuring a hysteresis loop of the magnetic structure under the external parallel magnetic field is performed, wherein the inverse of the slope of hysteresis loop is a dimensionless coupling constant.

Owner:NATIONAL YUNLIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

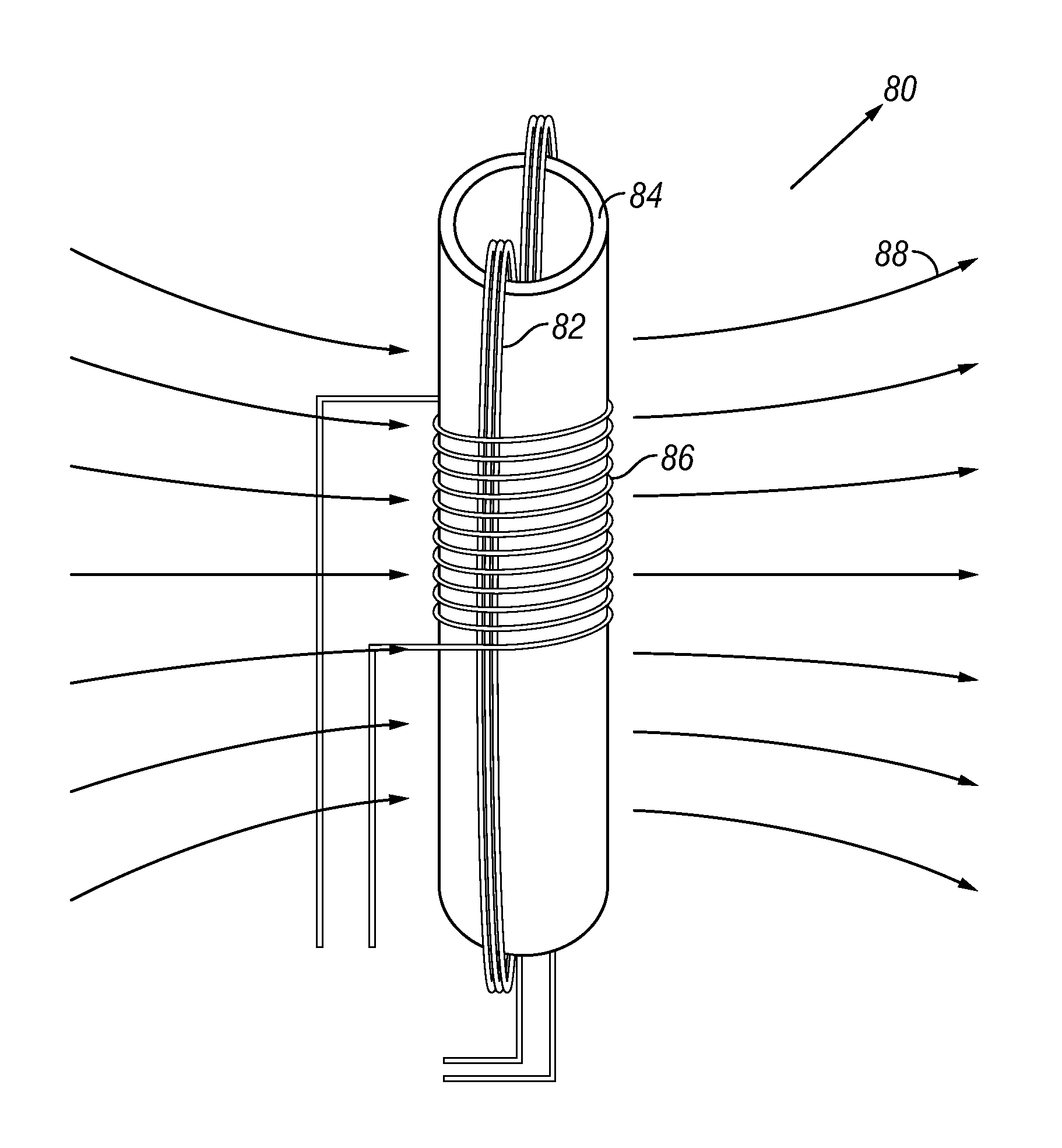

Nuclear magnetic resonance tool using switchable source of static magnetic field

ActiveUS7859260B2Electric/magnetic detection for well-loggingMaterial analysis by using resonanceSolid-state nuclear magnetic resonanceSpin magnetic moment

A nuclear magnetic resonance sensing apparatus and method for operating in an earth borehole comprises a source of switchable magnetic field to polarize nuclei in the region of interest, said source comprising a coil wound on a magnetic core having controllable residual magnetization. Maintaining the magnetization of the core during a polarization interval does not require steady current in the coil. Switching intensity and polarity of magnetization of the core causes precession of spin magnetic moments of the nuclei; the precession induces a signal indicative of nuclear magnetic resonance properties of earth formations.

Owner:BAKER HUGHES INC

Magnetic microstructures for magnetic resonance imaging

The present invention relates to a magnetic resonance structure with a cavity or a reserved space that provides contrast and the additional ability to frequency-shift the spectral signature of the NMR-susceptible nuclei such as water protons by a discrete and controllable characteristic frequency shift that is unique to each MRS design. The invention also relates to nearly uniform solid magnetic resonance T2* contrast agents that have a significantly higher magnetic moment compared to similarly-sized existing MRI contrast agents.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE COMMERCE +1

Distributed magnetic target identification method of magnetic detection

ActiveCN108072906AEasy to detectImprove efficiencyElectric/magnetic detectionAcoustic wave reradiationSpin magnetic momentAtomic physics

The invention discloses a distributed magnetic target identification method of magnetic detection, and belongs to magnetic detection technologies. N unmanned aerial vehicles (UAVs) with atom magnetometers are used to measure the local magnetic field intensity, magnetic anomaly signals are determined after carrying out magnetic compensation on measuring values, and a magnetic field intensity calculating model is established to resolve a magnetic moment of a magnetic anomaly target and position distribution condition of the magnetic anomaly target relative to the UAVs. A traditional single-UAV detection manner in which an optical pump magnetometer serves as a sensitive unit is improved into a detection manner in which the atom magnetometer serves as the sensitive unit and the multiple UAVs for the network, a detection system can detect weak signals more effectively, and the magnetic anomaly can be detected more efficiently and positioned more precisely by forming the network by the UAVs.

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

Method for quick measurement of remnant magnetic moment and inductive magnetic moment of tested object in terrestrial magnetic field

InactiveCN104375102AAccurate measurementShort measuring cycleMagnetic property measurementsData processing systemSpin magnetic moment

The invention discloses a system for quick measurement of the magnetic moment of a spacecraft in a terrestrial magnetic field. According to the system, the magnetic moment of the spacecraft is measured through the combination of the magnetic flux method and the terrestrial magnetic orientation method. The system comprises a lengthwise guide rail and a rotary table capable of achieving autogiration and arranged on the guide rail in a sliding mode, wherein the rotary table is used for supporting the spacecraft and enabling the spacecraft to rotate around the rotary table for measurement of the magnetic moment of the spacecraft, five vertical magnetic flux induction coils are arranged in the middle of the guide rail in parallel and are supported by a supporting device, the guide rail penetrates through the five magnetic flux induction coils to enable the rotary table to penetrate through the centre of the magnetic flux induction coils in a sliding mode, and the five magnetic flux induction coils are electrically connected with a fluxmeter through wires respectively to transmit a measured magnetic flux signal to a data processing system through the fluxmeter. The invention further discloses a method for quick measurement of the magnetic moment by means of the system. When the magnetic moment of the spacecraft is measured through the combination of the magnetic flux method and the terrestrial magnetic orientation method, the spacecraft magnetic moment measurement period is shortened, real magnetic moment in two directions can be measured, and testing precision is improved.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

Controllable magnetic systems

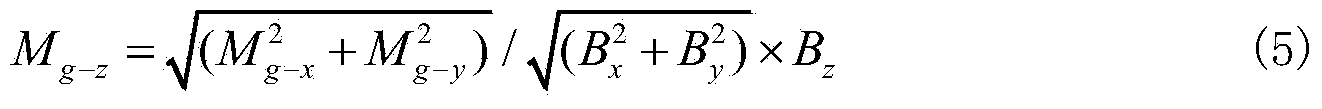

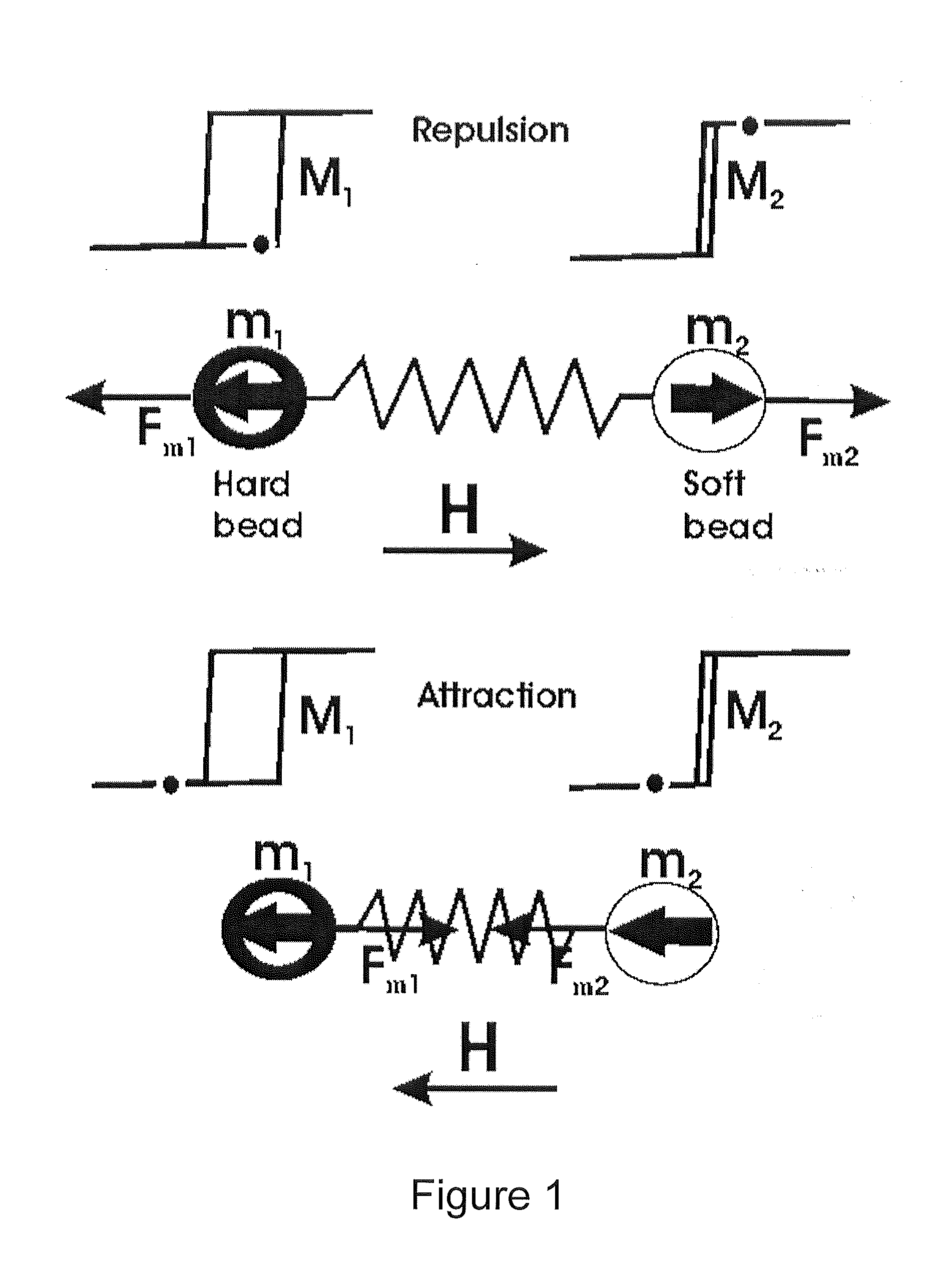

ActiveUS20110052393A1Different resistanceGreat viscous resistancePropellersEndoscopesSpin magnetic momentCoupling

This invention relates to methods and devices for propulsion through a fluid, in particular at low Reynolds number. We describe a method of propelling one of a magnetic device and a fluid relative to the other, the magnetic device comprising a pair of magnetic moments linked by an elastic coupling element, one of said moments having a greater resistance to a change in orientation due to an external applied magnetic field than the other, the method comprising applying an elliptical or ellipsoidal rotating magnetic field to the device to cause a change in mutual attraction or repulsion between said magnetic moments to thereby change a physical configuration of said device, propelling said device relative to said fluid.

Owner:UNIV OF EXETER

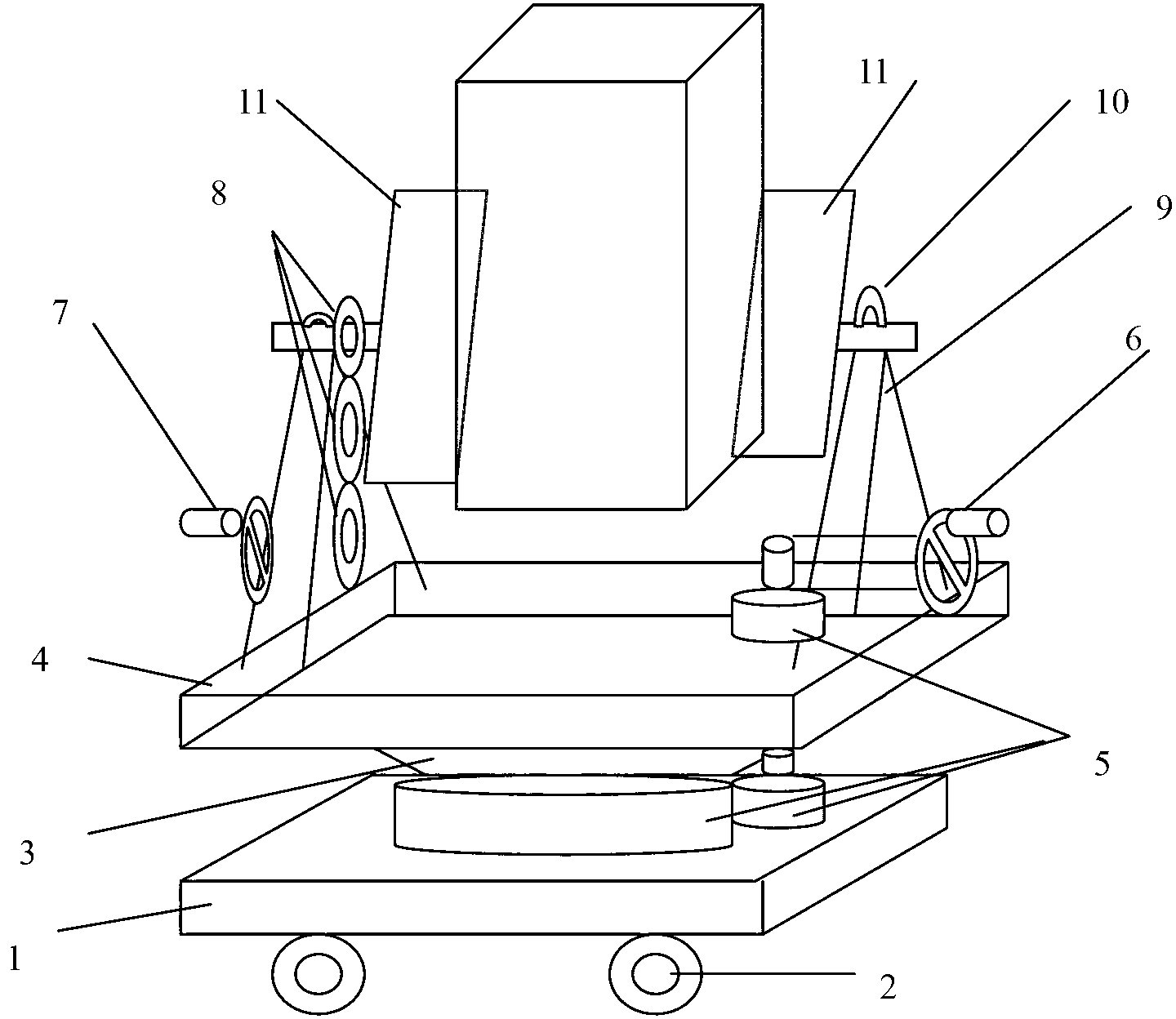

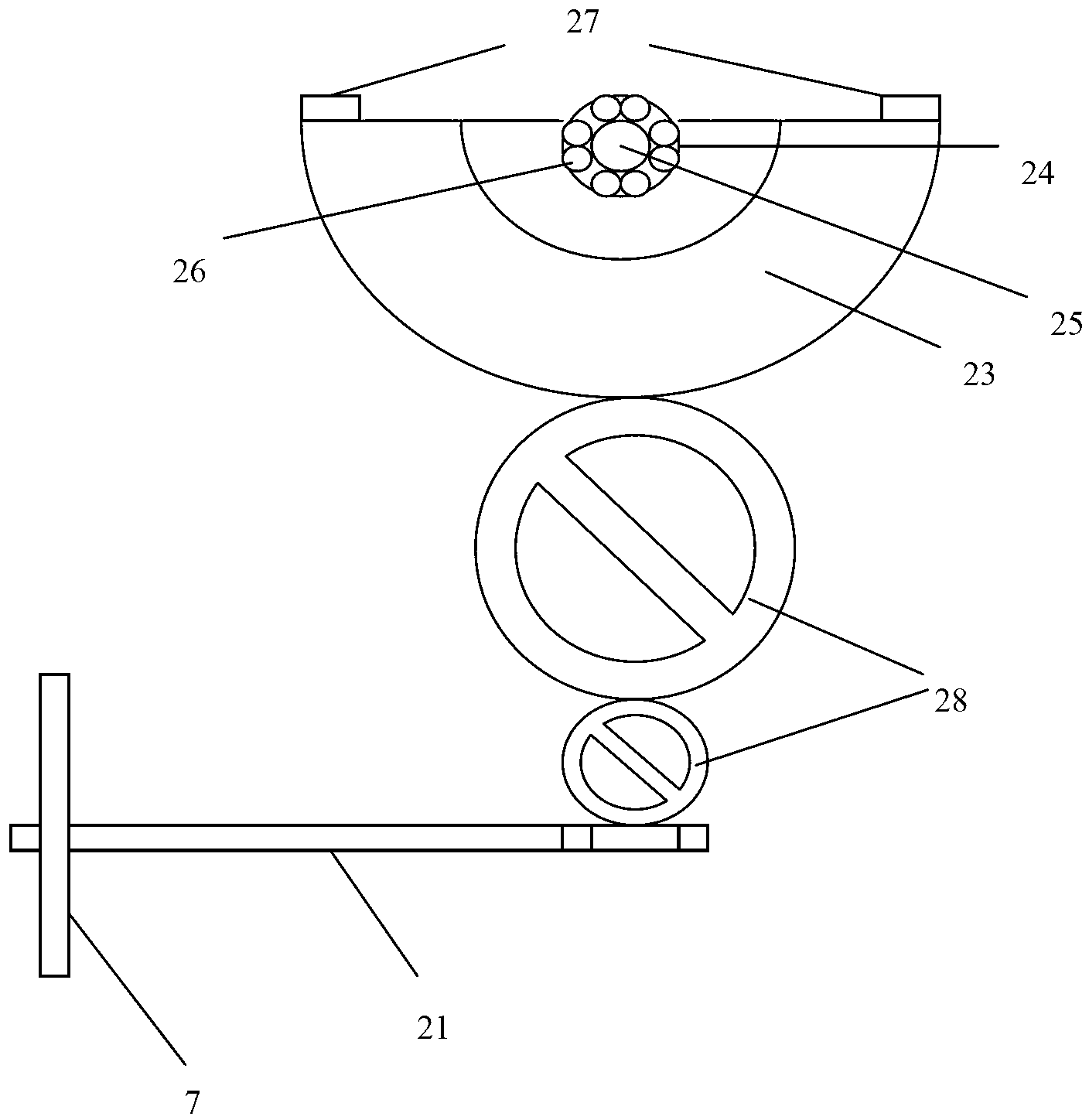

Non-magnetic rotary table used for measuring magnetic moment of satellite

ActiveCN103323797AReduce thrustEnsure safetyMagnetic property measurementsSpin magnetic momentMeasurement point

The invention relates to a non-magnetic rotary table used for measuring the magnetic moment of a satellite in a low-magnetic environment magnetic field. The non-magnetic rotary table comprises a trolley used for moving equipment, universal wheels mounted on the bottom face of the trolley, a sitting type rolling bearing arranged at the center of the upper surface of the trolley, a revolving platform arranged above the sitting type rolling bearing and a support mounted on the upper surface of the revolving platform. A bevel gear is arranged between the sitting type rolling bearing and the revolving platform and connected to a rotation measurement transmission mechanism. A transposition transmission mechanism used for transposition transmission is arranged on the support. The transposition transmission mechanism is connected to a transposition hand wheel. A fixture used for fixing and tightly clamping the satellite is arranged on the support. The non-magnetic rotary table used for measuring the magnetic moment of the satellite is reasonable in technology, convenient to operate and low in manufacturing cost; the sitting type rolling bearing and a limiting device are used, so that the non-magnetic rotary table is high in design stability coefficient and ensures the safety of the satellite at the time of horizontal movement, transposition and rotation; a positioning device is used for guaranteeing the accuracy of the position of measuring points, and the non-magnetic rotary table can be applied to magnetic moment measurement for various satellites.

Owner:SHANGHAI INST OF SATELLITE EQUIP

Magnetic moment real-time test system and test method thereof

InactiveCN104391259AHigh precisionImprove anti-interference abilityMagnetic property measurementsMagnetic tension forceEngineering

The invention discloses a magnetic moment real-time test system of which a magnetic moment device is arranged in the ground environment testing process. The magnetic moment real-time test system comprises a magnetic flux test unit, a resistance test unit, a temperature test unit, a constant current drive unit and a measurement and control unit. The magnetic moment device is arranged in a high and low temperature testing container. The middle part of the magnetic moment device is provided with a temperature sensor. A test coil is fixed on the fixed position of one side of the magnetic moment device and measures magnetic moment of the magnetic moment device in real time via a flux-meter. A controller electrically communicates with the flux-meter, a temperature transmitter, a voltage measuring module, a current measuring module and an H-bridge commutation circuit respectively. Working current is loaded on the magnetic moment device by utilizing the constant current drive unit, and the measured value signals of magnetic moment, temperature, voltage and current are received and displayed in real time in a display system. Besides, the invention also discloses a magnetic moment real-time measuring method utilizing the system.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

GMR biosensor with enhanced sensitivity

ActiveUS8133439B2High sensitivityFree layer bias pointNanomagnetismFlow propertiesHysteresisSensor array

A sensor array comprising a series connection of parallel GMR sensor stripes provides a sensitive mechanism for detecting the presence of magnetized particles bonded to biological molecules that are affixed to a substrate. The adverse effect of hysteresis on the maintenance of a stable bias point for the magnetic moment of the sensor free layer is eliminated by a combination of biasing the sensor along its longitudinal direction rather than the usual transverse direction and by using the overcoat stress and magnetostriction of magnetic layers to create a compensatory transverse magnetic anisotropy. By making the spaces between the stripes narrower than the dimension of the magnetized particle and by making the width of the stripes equal to the dimension of the particle, the sensitivity of the sensor array is enhanced.

Owner:APPLIED SPINTRONICS +1

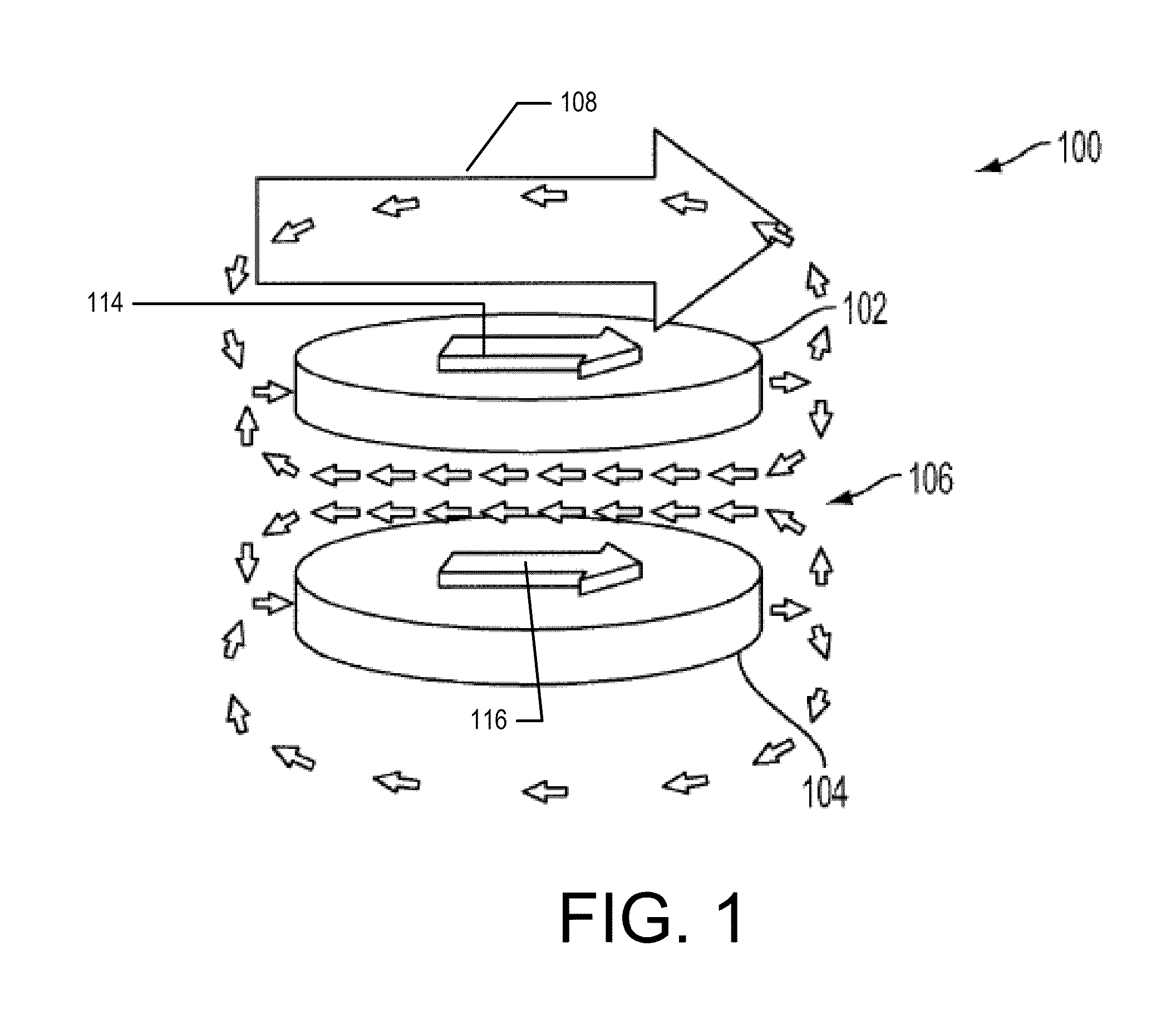

Method and system for mapping a geological structure of a formation on one side of a surface using magnetic moments of different values

ActiveUS9405031B2Strengthen restrictionsEffectively and coarsely scanDetection using electromagnetic wavesElectric/magnetic detection for transportSpin magnetic momentGeological structure

A method for mapping geological structures of a formation on a side of a surface, includes: generating a magnetic moment using at least one magnetic moment generator to build up a magnetic field in the formation in an on-period, wherein the magnetic moment has a moment strength, and wherein the magnetic moment is positioned on another side of the surface; changing the magnetic moment to change the magnetic field; and making at least one record in a recording device at a recording time trecord in an off-period, wherein the record includes at least a representation of the change in the magnetic field and / or a representation of the magnetic field obtained by a B / E-measuring unit; wherein the on-period is separated from the off-period by the act of changing the magnetic moment.

Owner:SKYTEM SURVEYS APS

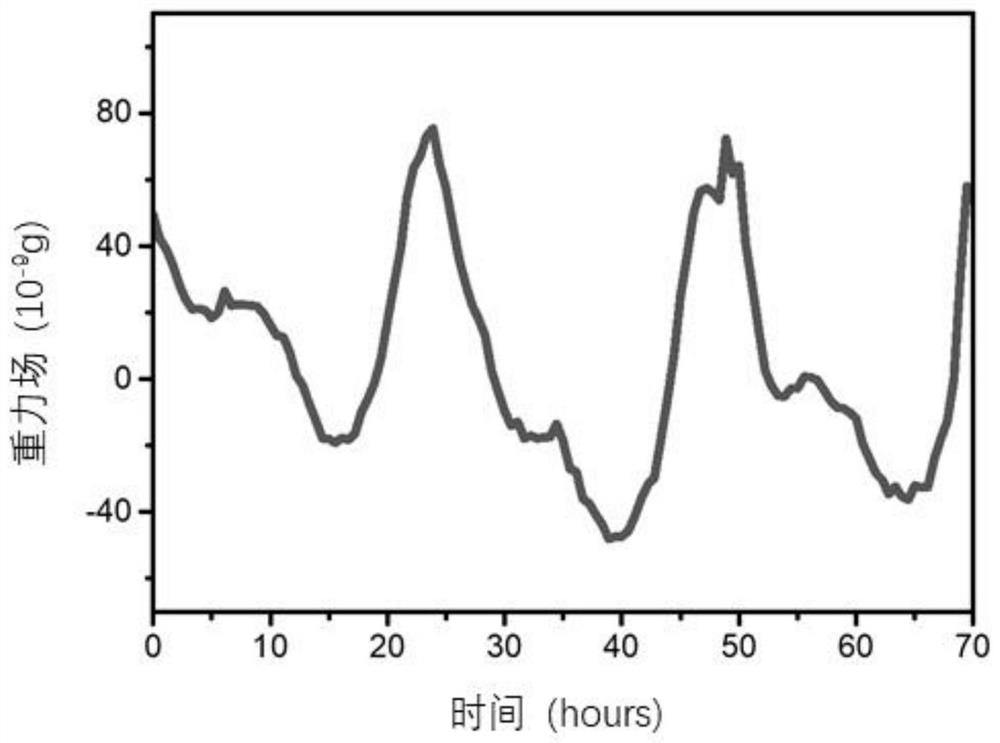

High-precision magnetic suspension relative gravimeter, control method and application

PendingCN113917552AAvoid dependenceImprove parameter stabilityGravitational wave measurementSpin magnetic momentEngineering

The invention belongs to the technical field of gravimeters, and discloses a high-precision magnetic suspension relative gravimeter, a control method and application, a magnetic-gravity potential well adopted by the control method of the high-precision magnetic suspension relative gravimeter is realized based on a permanent magnet combination mode, and an anti-magnetic suspension mechanical system is used as a gravity sensitive device, the anti-magnetic suspension is to realize the suspension of the mass body by utilizing the anti-magnetic interaction generated by the spinning magnetic moment in the anti-magnetic material. The gravimeter based on the anti-magnetic suspension system is different from an existing method in the physical principle and is a complete principle innovation. Most importantly, compared with the prior art, the method has the advantages of being capable of working at room temperature, small in size, high in precision and high in stability, other gravimeters cannot have the advantages at the same time at present, and therefore the method has clear advantages in gravity measurement scenes with high requirements for the indexes in the future. The anti-magnetic suspension is completely passive suspension, has very high parameter stability in principle, and realizes low drift.

Owner:南京蓝色引力科技有限公司

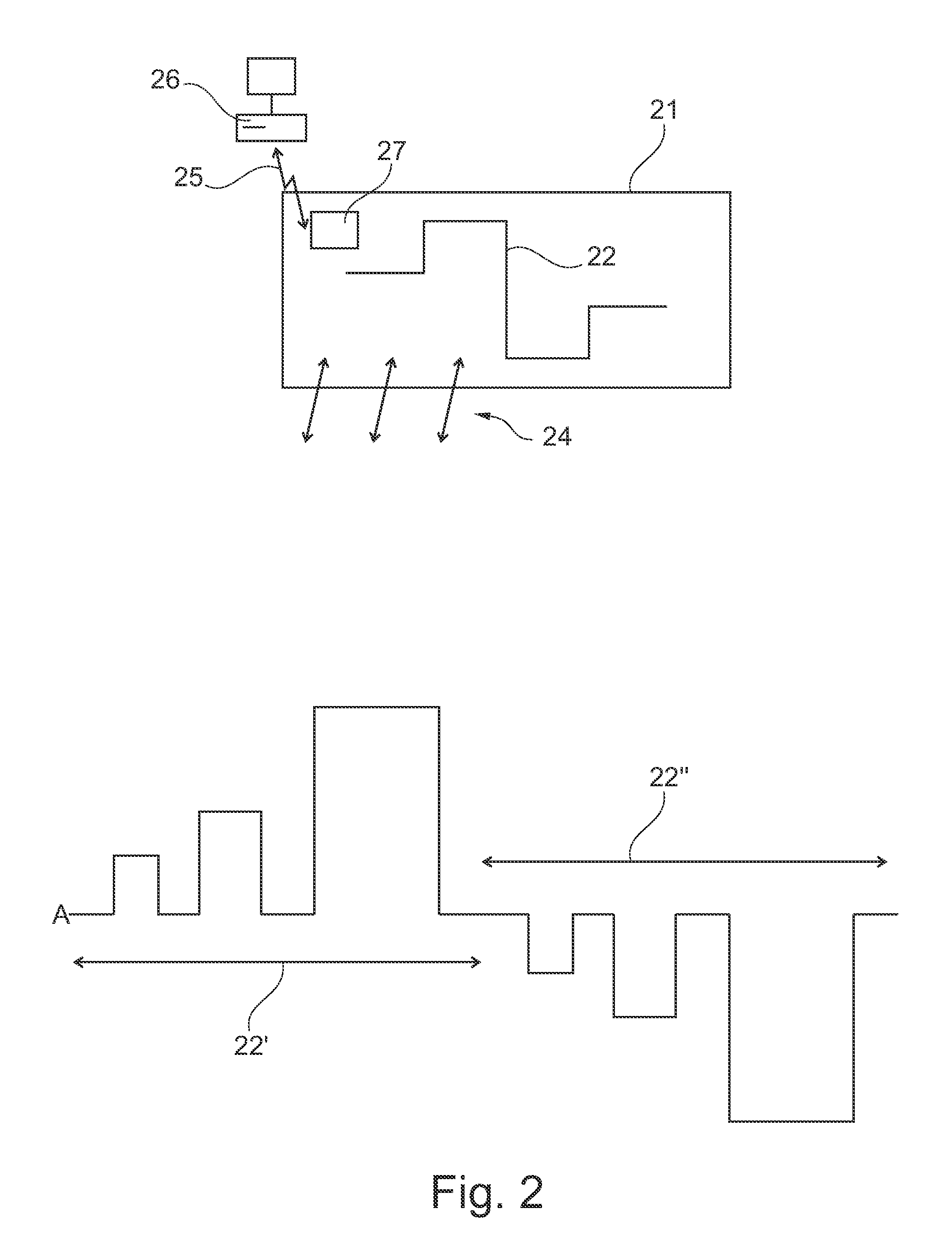

Method and system for mapping a geological structure of a formation on one side of a surface using magnetic moments of different values

ActiveUS20140218038A1Reduce the impactStrengthen restrictionsElectric/magnetic detectionAcoustic wave reradiationSpin magnetic momentGeological structure

A method for mapping geological structures of a formation on a side of a surface, includes: generating a magnetic moment using at least one magnetic moment generator to build up a magnetic field in the formation in an on-period, wherein the magnetic moment has a moment strength, and wherein the magnetic moment is positioned on another side of the surface; changing the magnetic moment to change the magnetic field; and making at least one record in a recording device at a recording time trecord in an off-period, wherein the record includes at least a representation of the change in the magnetic field and / or a representation of the magnetic field obtained by a B / E-measuring unit; wherein the on-period is separated from the off-period by the act of changing the magnetic moment.

Owner:SKYTEM SURVEYS APS

Loop antenna device

A plurality of small loop antenna cells 61, 62 and 63 are magnetically coupled to an antenna coil 8 of a non-contact type data carrier 3. In the plurality of small loop antenna cells, the directions of the magnetic moments of the signals transmitted to the non-contact type data carrier 3 are opposite to each other, the sum of the magnetic moments generated from all the small loop antenna cells 61 to 63 is zero and a conductor forming a short ring pattern 67 is provided collectively for the plurality of small loop antenna cells. Thus, imbalance caused between the small loop antenna cells 61 to 63 can be compensated for by the short ring pattern 67.

Owner:SEIKO EPSON CORP +1

Electromagnetic force-based cluster spacecraft magnetic moment optimal allocation method

ActiveCN108363840AOptimize allocationEfficient allocationGeometric CADConstraint-based CADSpin magnetic momentDistribution method

The invention provides an electromagnetic force-based cluster spacecraft magnetic moment optimal allocation method. A magnetic moment allocation problem is converted into an optimization problem; by establishing an objective function, calculating interference moments and analyzing constraint conditions, currents in axial coils of two spacecrafts are calculated by adopting a simulated annealing algorithm; optimal allocation of magnetic moments is realized; and the speed is higher. The proposed magnetic moment optimal allocation method enables a total interference moment of an interference moment of a geomagnetic field and an interference moment between the spacecrafts to be minimal; and through simulation analysis of magnetic moment allocation of two situations that the magnetic moments ofthe two spacecrafts are not restrained and assumed to be same, a conclusion is obtained that enabling the magnetic moments of the two spacecrafts to be same is more favorable for realizing better allocation, and the energy consumption is balanced.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

Method for switching magnetic moment in magnetoresistive random access memory with low current

Owner:IND TECH RES INST

Competitive spin current control-based magnetic random access memory and preparation method thereof

InactiveCN110635024AImprove stabilityReduce power consumptionMagnetic-field-controlled resistorsDigital storageStatic random-access memoryTunnel junction

The invention provides a competitive spin current control-based magnetic random access memory and a preparation method thereof. By applying pulse voltage to a spin orbit coupling layer, the spin orbitmoment effect produced by competitive spin current controls generation of 180-DEG turnover of a magnetic moment of a magnetic free layer in a magnetic tunnel junction, and writing of information is realized. By measuring the change of voltages at two ends of a magnetic tunnel junction, change of tunneling resistance is obtained, and reading of information is achieved.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Method of manipulating a quantum system comprising a magnetic moment

A method for manipulating a quantum system comprises at least one mobile charge carrier with a magnetic moment. The method comprises the steps or acts of applying magnetic field to the charge carrier. The magnetic is spatially non-homogeneous. The method also comprises bringing the charge carrier into an oscillatory movement along a path. The magnetic field depends on the position of the charge carrier on said path. The oscillatory movement may be caused by electrostatic interaction with gate electrodes. Due to this approach, thus, in a magnetic moment resonance process the conventional oscillating magnetic field is replaced by an oscillating electric field which is locally transformed into a magnetic field by the Coulomb interaction that displaces the charge carrier wave function within an inhomogeneous magnetic field or in and out of a magnetic field.

Owner:IBM CORP

Method and system for mapping a geological structure of a formation on one side of a surface using magnetic moments of different values

ActiveUS20150234073A1Reduce the impactStrengthen restrictionsAcoustic wave reradiationElectric/magnetic detection for transportSpin magnetic momentEarth surface

A method for mapping geological structures of a formation on a side of a surface, includes: generating a magnetic moment using at least one magnetic moment generator to build up a magnetic field in the formation in an on-period, wherein the magnetic moment has a moment strength, and wherein the magnetic moment is positioned on another side of the surface; changing the magnetic moment to change the magnetic field; and making at least one record in a recording device at a recording time trecord in an off-period, wherein the record includes at least a representation of the change in the magnetic field and / or a representation of the magnetic field obtained by a B / E-measuring unit; wherein the on-period is separated from the off-period by the act of changing the magnetic moment.

Owner:SKYTEM SURVEYS APS

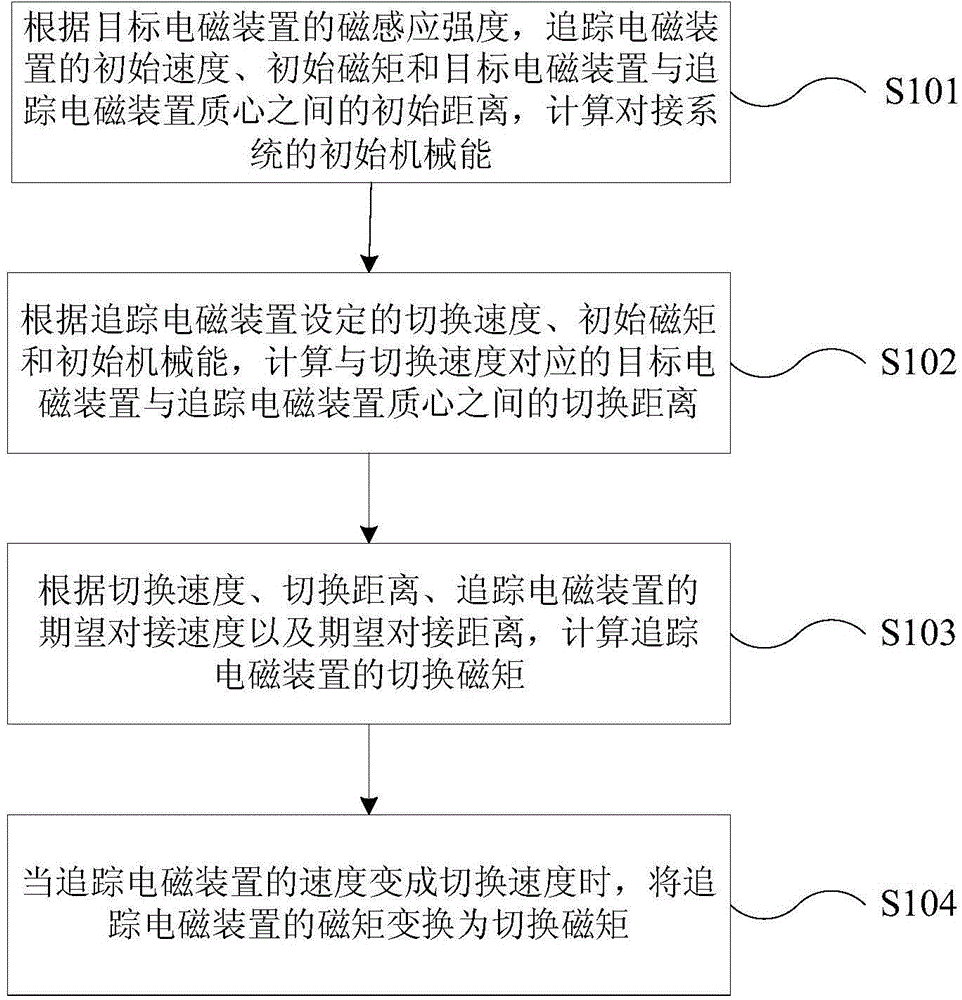

Electromagnetic docking control method and device

InactiveCN104679961ASimple design methodLess design parametersSpecial data processing applicationsSpin magnetic momentClassical mechanics

The invention discloses an electromagnetic docking control method and a device, which adopt an anomalous magnetic moment control plus one-time magnetic moment switching mode, wherein the electromagnetic docking control method includes the following steps: according to the magnetic induction intensity of a target electromagnetic device, the initial speed and initial magnetic moment of a tracking electromagnetic device and the initial distance between the barycenters of the target electromagnetic device and the tracking electromagnetic device, the initial mechanical energy of a docking system is calculated; according to the set switching speed and initial magnetic moment of the tracking electromagnetic device and the initial mechanical energy of the docking system, the switching distance, which corresponds to the switching speed, between the barycenters of the target electromagnetic device and the tracking electromagnetic device is calculated; according to the switching speed, the switching distance and the expected docking speed and expected docking distance of the tracking electromagnetic device, the switching magnetic moment of the tracking electromagnetic device is calculated; when the speed of the tracking electromagnetic device is changed into the switching speed, the electromagnetic moment of the tracking electromagnetic device is transformed into the switching magnetic moment. The invention solves the technical problem that the design of the conventional method is complex and the requirement for control design robustness is high.

Owner:NAT UNIV OF DEFENSE TECH

Shimming assistance unit, shimming assistance method, MRI apparatus and magnet apparatus

ActiveUS20160146912A1Easy to operateMagnetic measurementsMagnetsSingular value decompositionSpin magnetic moment

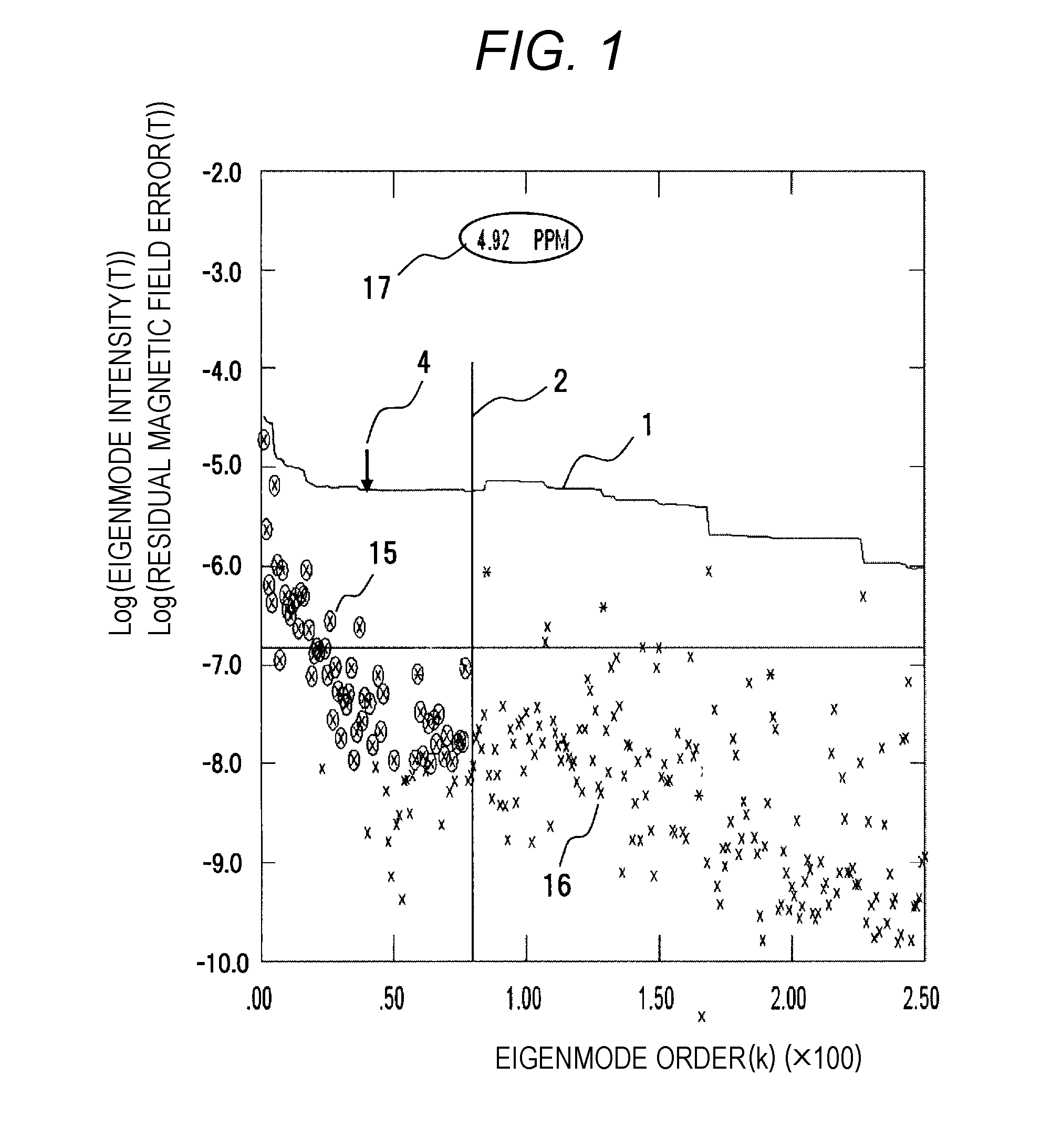

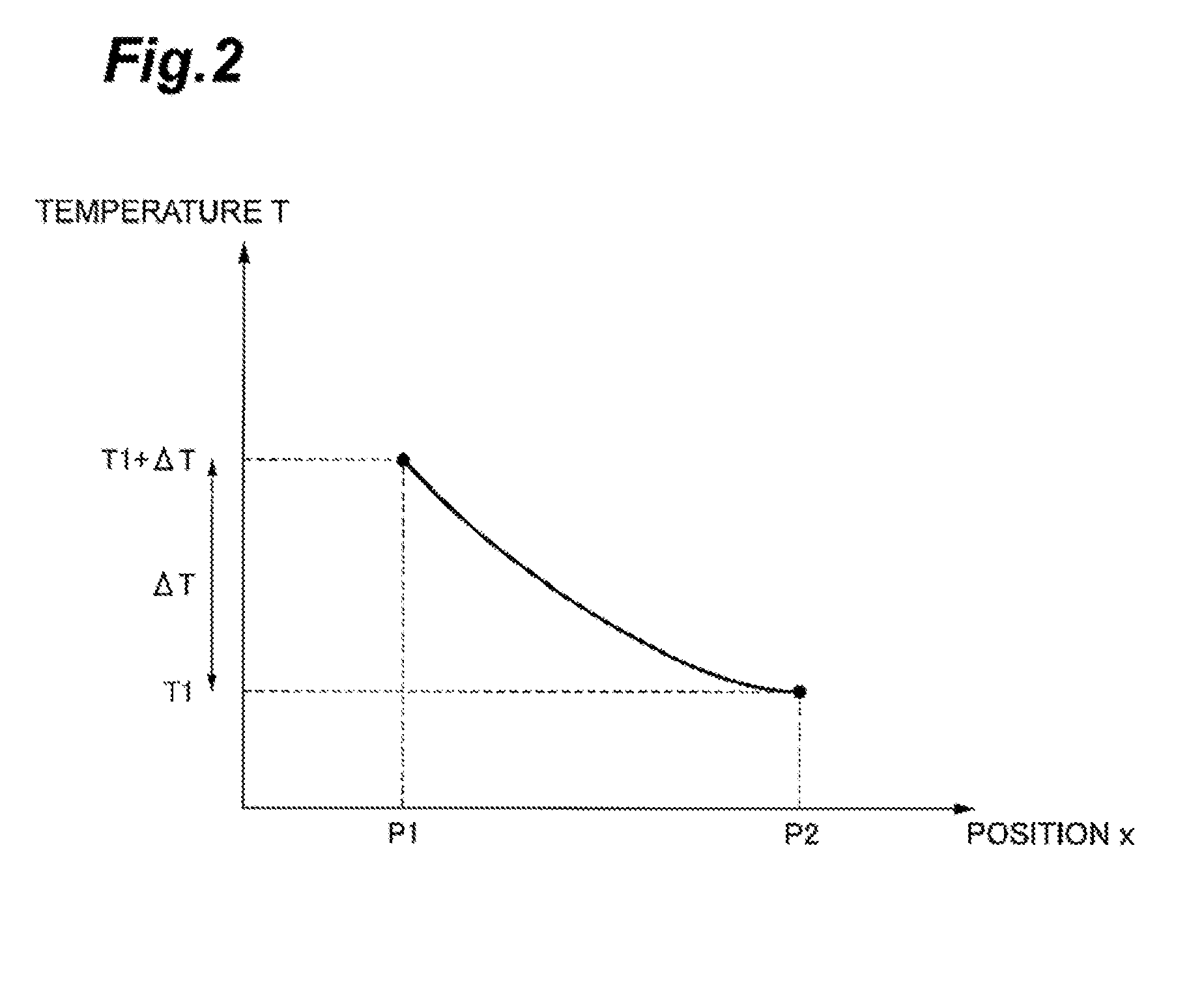

The shimming work assistance unit performs singular value decomposition of a response matrix, which represents the relationship between an error magnetic field distribution and an adjusted magnetic moment placement distribution. From the multiple eigenmodes obtained, the eigenmodes are selected and added one by one in order from the eigenmode with the highest singular value, and the residual magnetic field error, which represents the fluctuation range of the difference between the magnetic field distribution, generated by the placement of the shimming magnetic moments corresponding to said eigenmode, and the error magnetic field distribution, is displayed on a display unit as a function graph of eigenmode order (line graph (1)).

Owner:FUJIFILM HEALTHCARE CORP

Spin control mechanism and spin device

InactiveUS20160268497A1Piezoelectric/electrostriction/magnetostriction machinesSemiconductor/solid-state device detailsSpin magnetic momentSpins

A spin control mechanism includes a spin portion and a first channel portion. The spin portion has a magnetic moment that can be reversed and rotated. The first channel portion is provided in contact with the spin portion, and is configured from ferromagnetic insulator. Then, the spin control mechanism controls a direction of the magnetic moment of the spin portion using a spin current generated by a temperature gradient provided to the first channel portion.

Owner:JAPAN SCI & TECH CORP +1

Optical excitation method for generating spin-polarized electrons and spin current

InactiveCN102983158ASpectral range is unlimitedImprove efficiencySemiconductor devicesEffective surfaceElectron

The invention discloses an optical excitation method for generating spin-polarized electrons and spin current. Through interaction between an evanescent wave generated by optical total reflection on an interface and a structure which is included by a functional layer generating the spin-polarized electrons and the spin current on the interface, is made of a surface plasmon metal material and has a nanometer characteristic size, a surface plasmon is excited, so that surface free electrons in resonance transition generate spin precession in an effective surface magnetic field of the structure made of the surface plasmon metal material to form a common spin magnetic moment component so as to generate the spin-polarized electrons in the functional layer generating the spin-polarized electrons and thus form the spin current along with spreading of the surface Plasmon on the surface (or interface).

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

An imaging method for MRI contrast enhancement

ActiveCN104161517BSolve the scan time is too longReduce usageDiagnostic recording/measuringSensorsInversion recoveryReconstruction method

The invention discloses an imaging method for MRI contrast enhancement, which uses an optimized inversion pulse to replace the inversion pulse and its recovery delay time of the conventional inversion recovery sequence in magnetic resonance imaging. Under the precise control of the optimized pulse, different The spin of the tissue will evolve towards the trend of maximizing the longitudinal magnetic moment difference, and the maximum longitudinal magnetic moment difference will be obtained at the end of the pulse; on this basis, applying a 90° excitation readout pulse will maximize the magnetic moment difference between tissues Turn over to the transverse plane, collect gradient echo signals to form k-space data, and use the improved phase-sensitive image reconstruction method to finally achieve the purpose of enhancing the contrast between tissues. The invention solves the problem that the scanning time of the conventional inversion recovery sequence is too long, fully utilizes the advantages of the flexibility of the optimized pulse waveform and the flexibility of the phase-sensitive image reconstruction method, avoids the use of expensive magnetic resonance contrast agents, and has excellent performance and cost. Outperforms current MRI contrast enhancement methods.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

Magnetic microstructures for magnetic resonance imaging

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE COMMERCE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com